Deep desulfurization technology of refinery liquefied petroleum gas

A liquefied petroleum gas, deep desulfurization technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of unfavorable deep processing, etc., and achieve the effect of improving quality, increasing processing depth, and maximizing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

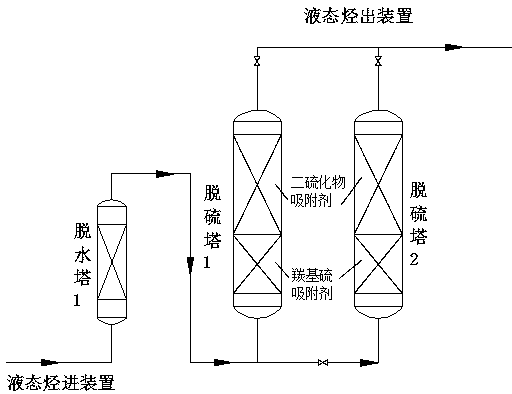

Embodiment 1

[0037] Collected from catalytic cracking liquid hydrocarbons in a refinery, after dehydration by 3A molecular sieve, the total sulfur is 75mg / m3, including disulfide 53mg / m3, COS 21mg / m3, and other sulfide 1mg / m3. A single-column desulfurization simulation experiment was carried out with mixed packing of carbonyl sulfide and disulfide removal adsorbents. The decarbonyl sulfide adsorbent is packed in the lower layer of the desulfurization column with a loading volume of 50mL; the disulfide removal adsorbent is packed in the upper layer of the desulfurization column with a loading volume of 150mL, the liquid hydrocarbon flow rate is 100mL / h, the test temperature is 40°C, and the test pressure is 1.4MPa. 400 hours before the test run, no sulfide was detected at the outlet; after 500 hours of operation, the total outlet sulfur was 2mg / m3, of which disulfide was 1.3mg / m3, COS was 0.5mg / m3, and other sulfides were 0.2mg / m3; after 800 hours of operation, the total outlet Sulfur 3.5mg...

Embodiment 2

[0040] Collected from the carbon four components of a refinery gas separation unit, after dehydration by 3A molecular sieve, the total sulfur is 35mg / m3, of which disulfide is 22mg / m3, COS is 10.8mg / m3, and other sulfide is 1.2mg / m3. A single-column desulfurization simulation experiment was carried out with mixed packing of carbonyl sulfide and disulfide removal adsorbents. The decarbonylsulfide adsorbent is packed in the lower layer of the desulfurization column, with a loading volume of 40mL; the disulfide removal adsorbent is loaded in the upper layer of the desulfurization column, with a loading volume of 120mL, the liquid hydrocarbon flow rate is 80mL / h, the test temperature is 30°C, and the test pressure is 1.2MPa. 500 hours before the test operation, no sulfide was detected at the outlet; after 600 hours of operation, the total sulfur at the outlet was 1.5mg / m3, of which disulfide was 1.1mg / m3, COS was 0.1mg / m3, and other sulfides were 0.3mg / m3; after 900 hours of operat...

Embodiment 3

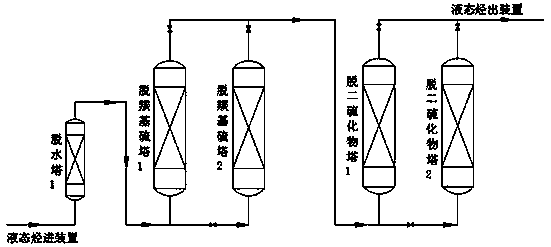

[0042] On-site sideline test in a coking workshop of a refinery, the total sulfur of liquid hydrocarbons is 150~450mg / m3, and a 3A molecular sieve dehydration tank is added before the liquid hydrocarbons enter the desulfurization tank. The sulfide tank and the disulfide removal tank are operated in series with two tanks, the carbonyl sulfide adsorbent is filled with 20L, the disulfide adsorbent is filled with 25L / tank, the test temperature is 25°C, the test pressure is 1.3MPa, and the on-site liquid hydrocarbon flow rate is 12L / h . After analysis and testing, the sulfides in the liquid hydrocarbons are mainly disulfides and COS, of which disulfides account for 70-84.5%, COS accounts for 15-29.5%, and other sulfides account for 0.5%. The running time of the test is 600 hours, the adsorption capacity of the adsorbent is 2.6%, the average removal rate is over 90%, the removal effect of disulfide and COS is obvious, and the removal results of total sulfur are shown in Table 1. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com