Combined process for delayed coking and hydrotreating

A hydrotreating and delayed coking technology, applied in the combined process field, can solve the problems of heavy distillation range of coking wax oil, complex fractionation tower process, high aromatics content, etc., achieve process optimization, ensure long-term operation, reduce coke yield and The effect of gas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

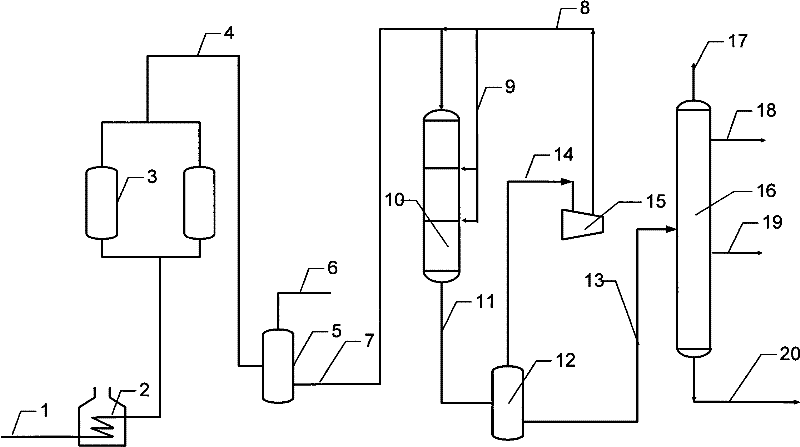

Image

Examples

Embodiment 1

[0032] The raw material oil used in Example 1 is high-sulfur residue reduction, and its properties are listed in Table 1.

[0033] The reaction conditions of delayed coking are that the temperature at the outlet of the heating furnace is 500°C, the coke tower top pressure is 0.17MPa, and the circulation ratio is 0. The coke tower top oil gas is separated into gas components and liquid components after heat exchange and cooling. Coking whole distillate liquid components (including naphtha, diesel oil and wax oil fractions) are pressurized and carried out with hydrogen in a reactor under hydrotreating conditions, and the reactor is filled with a hydrotreating agent and a hydrotreating catalyst , the ratio of the two is 15:85, and the specific reaction conditions, product distribution and product properties are listed in Table 2-Table 4 respectively.

[0034] As can be seen from Table 2, the coking liquid product yield is 63.7% by weight, and as can be seen from Table 4, the sulf...

Embodiment 2

[0036] The feedstock oil used in Example 2 is acid-containing naphthenic residue, and its properties are listed in Table 5.

[0037] The reaction conditions of delayed coking are that the temperature at the outlet of the heating furnace is 500°C, the coke tower top pressure is 0.17MPa, and the circulation ratio is 0. The coke tower top oil gas is separated into gas components and liquid components after heat exchange and cooling. Coking whole distillate liquid components (including naphtha, diesel oil and wax oil fractions) are pressurized and carried out with hydrogen in a reactor under hydrotreating conditions, and the reactor is filled with a hydrotreating agent and a hydrotreating catalyst , the filling ratio is 15:85, and the specific reaction conditions, product distribution and product properties are listed in Table 6-Table 8 respectively.

[0038] As can be seen from Table 6, the coking liquid product yield is 71.23% by weight, and as can be seen from Table 8, the sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com