A W-type flame decoupling combustion furnace and decoupling combustion method

A combustion method and combustion furnace technology, which are applied in the combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of reduced boiler efficiency and safety, and increased carbon content in fly ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

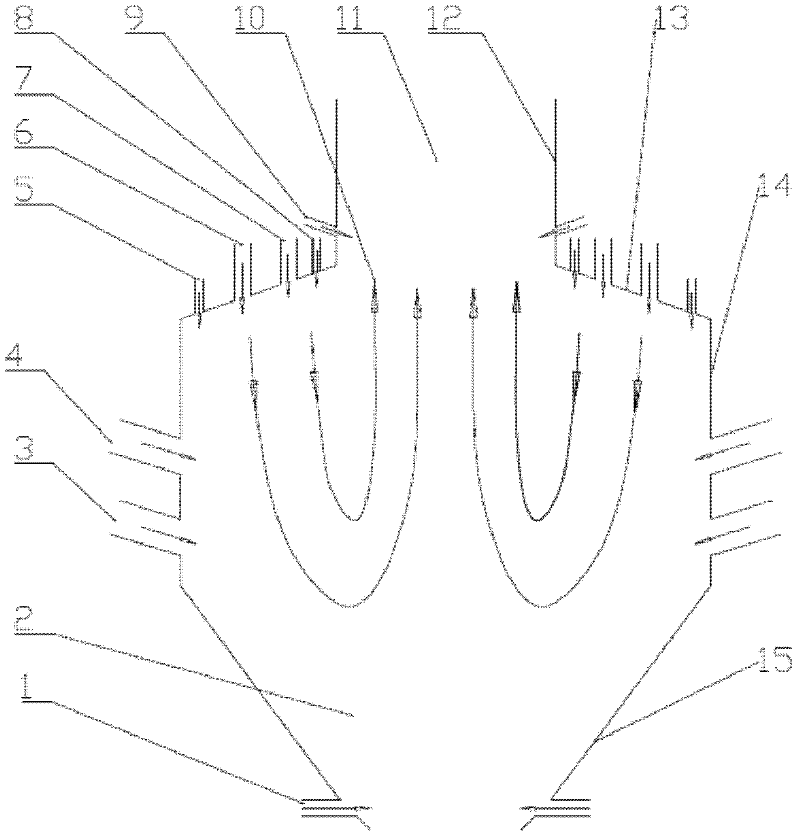

[0058] The W-type flame decoupling combustion furnace and the decoupling combustion method of the present invention will be further described below in conjunction with the accompanying drawings.

[0059] Such as Figure 1~2 As shown, the W-type flame decoupling combustion furnace of the present invention includes a bottom boundary air nozzle 1, a lower furnace 2, a secondary air nozzle 3 under the side wall, a secondary air nozzle 4 on the side wall, and a secondary air nozzle 5 attached to the wall. Light primary air nozzle 6, thick primary air nozzle 7, super concentrated primary air nozzle 8, upper furnace burnout air nozzle 9, flue gas flow 10, upper furnace 11, upper furnace side wall 12, lower furnace arch 13, lower furnace side Wall 14, lower furnace cold ash hopper wall 15 and boiler side wall 16.

[0060] The structure of the W-type flame furnace of the present invention and the air distribution mode are as figure 1 shown.

[0061] The multi-channel pulverized coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com