Enriched multiple straight-through powder coal burners

A pulverized coal burner and enrichment technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of difficult layout of large-capacity boilers, affecting the service life of nozzles, and large nozzle areas, etc., to achieve Easy maintenance and operation, eliminate slagging and high temperature corrosion, reduce the effect of reducing atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Concrete structure and working principle of the present invention are described in detail below in conjunction with accompanying drawing:

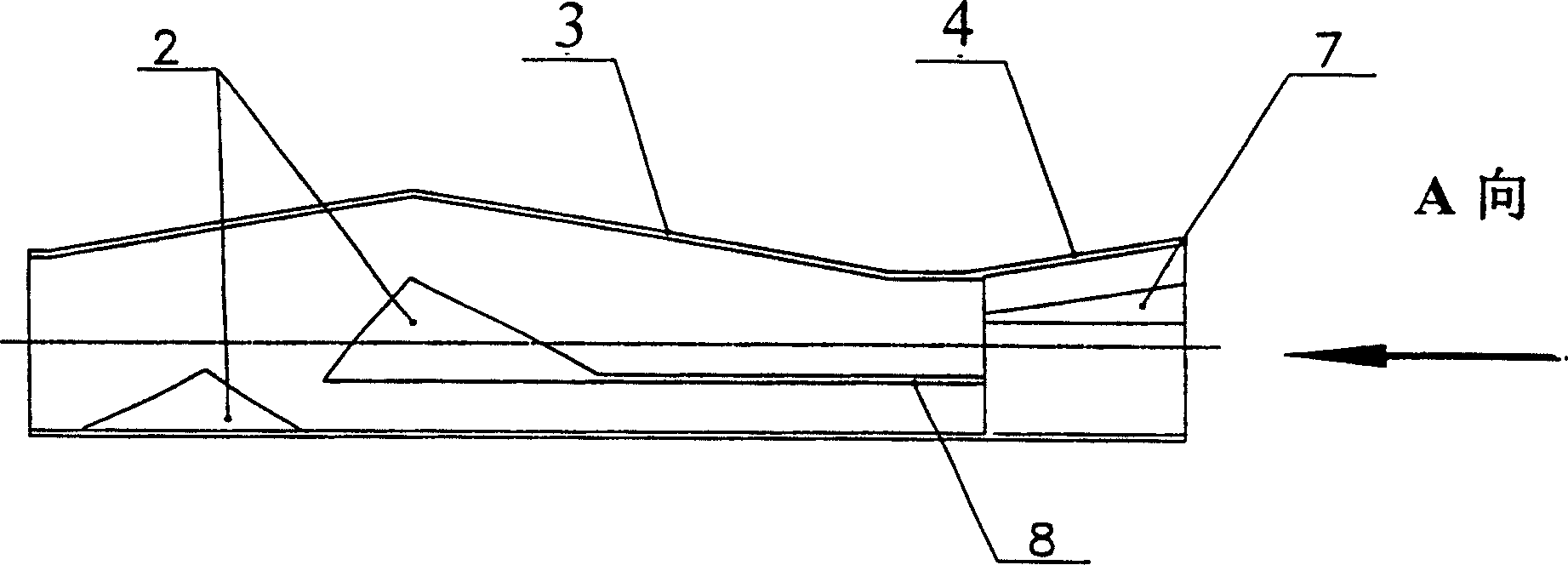

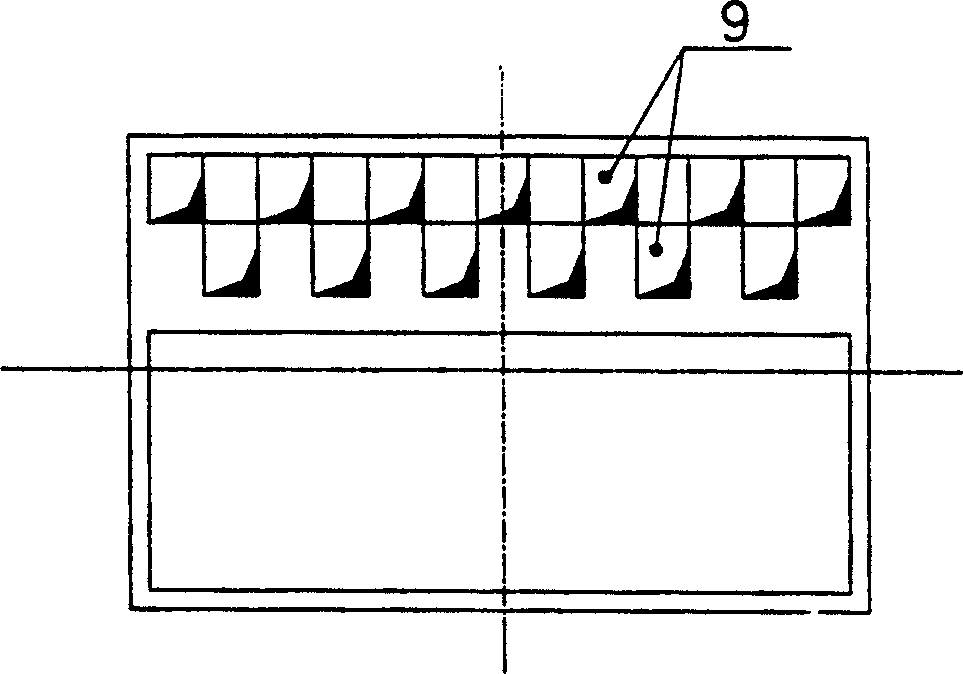

[0012] Figure 1 is a schematic diagram of the layout of the burner in the four corners of the boiler furnace. The hypotenuse side of the nozzle 4 is arranged on the fire side 5, the straight side of the nozzle is on the back fire side 6, and the distance between the center line of the burner and the center of the furnace The installation deflection angle is determined by the imaginary cutting circle. The square garden joint head 1 connects the burner square channel and the primary air duct. figure 2 A schematic diagram of the burner structure. It includes a primary air square passage 3, a separation block 2 and a partition 8 arranged in the square passage, a burner nozzle 4, a wedge-shaped baffle 7 arranged in the nozzle and a zigzag multi-strand small nozzle 9 at the outlet of the nozzle ( As shown in Figure 3). General separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com