Solid catalyst for petroleum liquid component sweetening and preparation method

A technology of solid catalysts and liquid components, applied in chemical instruments and methods, physical/chemical process catalysts, petroleum industry, etc., can solve problems such as short life, reduced catalyst activity, difficult catalyst regeneration, etc., to increase alkalinity, sulfur Effects of Alcohol Oxidation Activity and Stability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 This example provides the preparation of the catalyst of the present invention

[0025] The first step of impregnation: take 15.0g γ-Al 2 o 3 Store in a sealed container after vacuum drying for 24 hours. 30.0g Mg(NO 3 ) 2 ·6H 2 O and cocatalyst 6.0g Ni(NO 3 ) 2 ·6H 2 O is dissolved in 30.0g of distilled water to make the impregnation solution for the first step of impregnation; the dried carrier γ-Al 2 o 3 Immerse in the above impregnating solution. Ultrasonic vibration is used during the impregnation process. The frequency of the ultrasonic wave is 40KHz, the impregnation temperature is 30°C, and the impregnation time is 24 hours; The time is 5 hours, and the basic catalyst support after calcination and activation is obtained;

[0026] The second step of impregnation: take 0.5g sulfonated cobalt phthalocyanine and 0.1g C 12 h 28 Dissolve BrN in a mixed solution of ethanol and water at a ratio of 5:1 by volume to make an impregnation solution for t...

Embodiment 2

[0027] Example 2 This example illustrates the experimental method of catalyst desulfurization activity

[0028] 1), static test

[0029] Add 25ml of mercaptan-containing gasoline liquid into a closed reactor equipped with 1.0g of catalyst, place it statically, and measure the concentration of mercaptan.

[0030] 2), simulated dynamic test

[0031] Add 25ml of mercaptan-containing gasoline liquid into a closed reactor equipped with 1.0g of catalyst, shake and stir, and measure the concentration of mercaptan.

[0032] Mercaptan concentrations were analyzed using a gas chromatograph with a flame photometric detector. The chromatographic column is a capillary column, and the analysis conditions are as follows: column oven: 50°C; injector at 200°C; detector at 220°C; carrier gas (N 2 ): 25ml / min; H 2 : 30ml / min; air: 300ml / min; injection volume: 0.5μL. In the following examples, the concentration of trace mercaptans has been analyzed and measured by this method.

Embodiment 3

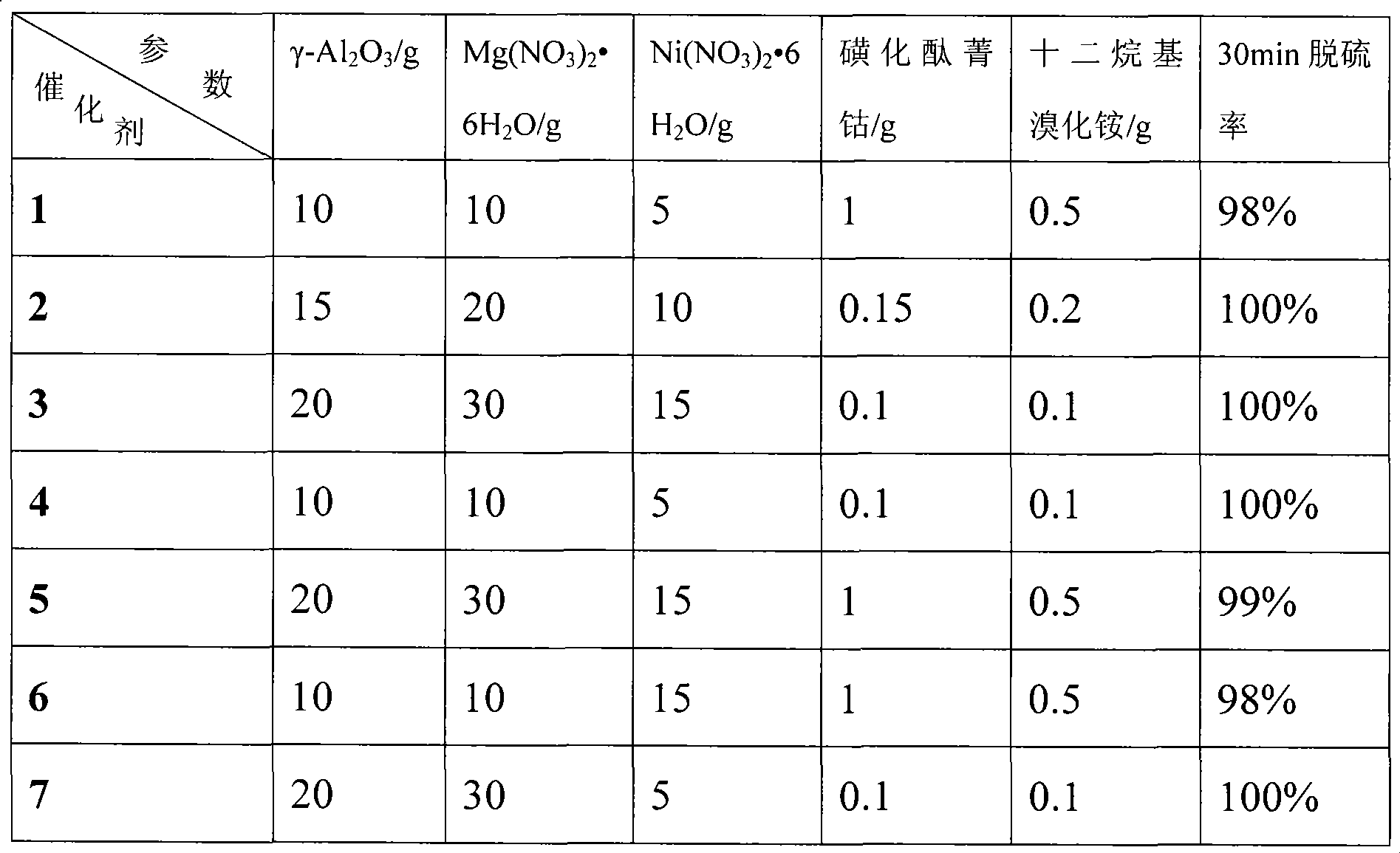

[0033] Example 3 This example illustrates the impact of catalyst formulation parameters on the catalyst

[0034] During the preparation of the catalyst of this example, other preparation process conditions and parameters were consistent with Example 1 except the formulation parameters shown in the table. The sweetening activity analysis data are shown in the table:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com