Method for preparing dihydric alcohol from lignocellulosic biomass

A technology for wood fiber and biomass, which is applied in the chemical industry, can solve the problems of difficulty in industrialization, high energy consumption for separation, high price, etc., and achieves the effects of improving stability, good selectivity and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

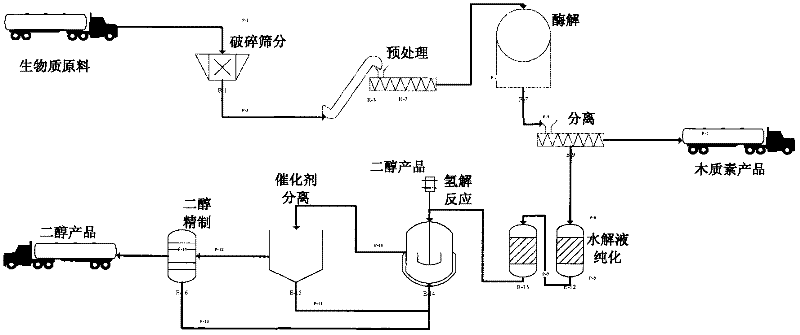

[0035] The present invention uses lignocellulosic biomass as the preparation method of the mixed glycol of raw material, comprises the following steps:

[0036](1) Lignocellulosic biomass pretreatment-enzymatic saccharification: The lignocellulosic biomass here includes agricultural and forestry residues or wastes such as agricultural straw, wood chips, and wood chips. Lignocellulosic biomass is preliminarily crushed to less than 5 cm, mixed with 0.5-10% alkali solution or 0-10% acid solution or other suitable pretreatment chemical reagents, and pretreated at 50-300 ° C for 0.5 -20 hours, destroy the crystalline structure in the lignocellulosic biomass, then wash the pretreated raw material and transfer it to an enzymatic hydrolysis tank, and then separate the solid and liquid after being hydrolyzed by cellulase to obtain a soluble carbohydrate solution, which mainly contains Glucose, xylose, arabinose and other monosaccharides, soluble oligosaccharides, and a very small amoun...

Embodiment 1

[0048] Crush 100kg of straw (raw material from Jiaonan, Qingdao) to less than 5cm, add 1% NaOH solution, solid-to-liquid ratio 1:2, and treat at 105°C for 3 hours. Depending on the enzymatic hydrolysis conditions, the components of the crude sugar solution mainly contain glucose, xylose, arabinose, xylan, cellobiose, trisaccharide and other soluble oligosaccharides and sugar degradation products, such as furfural and 5-hydroxymethylfurfural Wait. The enzymatic hydrolysis mixed sugar solution is decolorized by activated carbon, and then concentrated after ion exchange, so that the sugar concentration in the solution reaches 10-50 wt%, that is, the hydrogenolysis raw material solution for preparing diol is obtained. The evaluation of the hydrogenolysis reaction of the sugar solution was carried out in a batch type autoclave. Transfer 5L of 20wt% mixed sugar solution into a 10L stainless steel autoclave, adjust the pH of the solution to 13-14 with NaOH, and add 10% of the substra...

Embodiment 2

[0055] The specific implementation process is the same as in Example 1, except that the alkali concentration in the pretreatment stage is 2%, the temperature in the pretreatment section is 100°C, and the enzymatic hydrolysis yields of glucose, xylose, and arabinose can reach 84.8%, 85.6%, and 63.2% %; In the stage of hydrogenolysis of mixed sugar liquid, the catalyst used is 5% Ru / C, and the reaction is 30 minutes, the yield of 1,2-propanediol reaches 25.6%, the yield of ethylene glycol reaches 13.8%, 1,2-butanediol The yield of alcohol reaches 2.7%, the yield of 1,2-hexanediol reaches 0.1%, and the yield of glycerin reaches 20.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com