Loading type Pd base metal nanometer cluster catalyst, preparing method and applications thereof

A metal nanoparticle and base metal technology, which is applied to a supported Pd-based metal nanocluster catalyst and the field of preparation and application thereof, can solve the problems of decreased catalyst activity, difficult hydrogenation of intermediate products, and difficulty in product separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

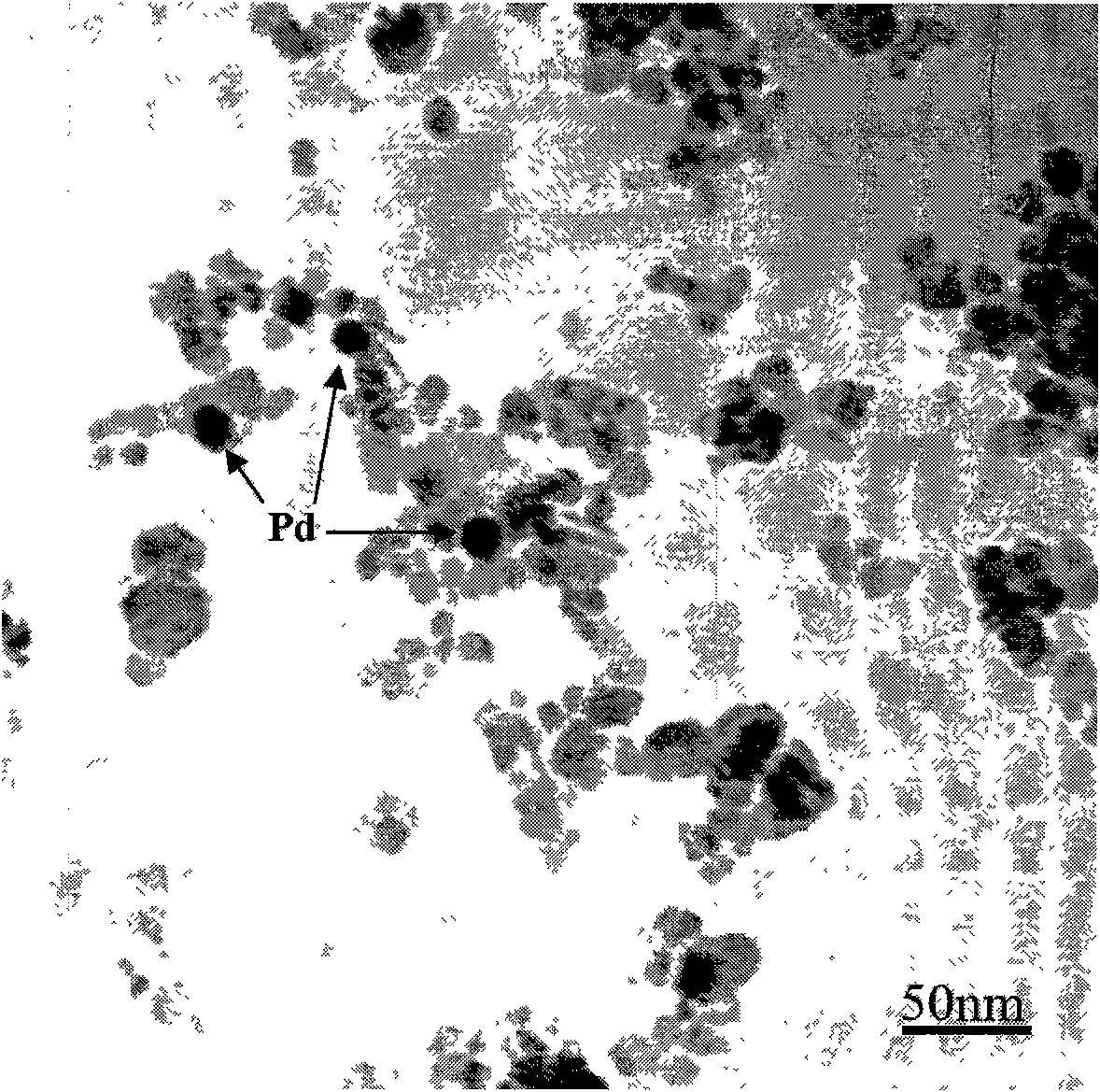

[0066] Example 1: Preparation of γ-Fe by Pd nanoclusters and in a partially reduced state 2 o 3 Constituted catalyst (Pd: 3wt.%) and its catalytic performance test. (wt.% is mass percentage, the same below)

[0067] 1. Catalyst preparation

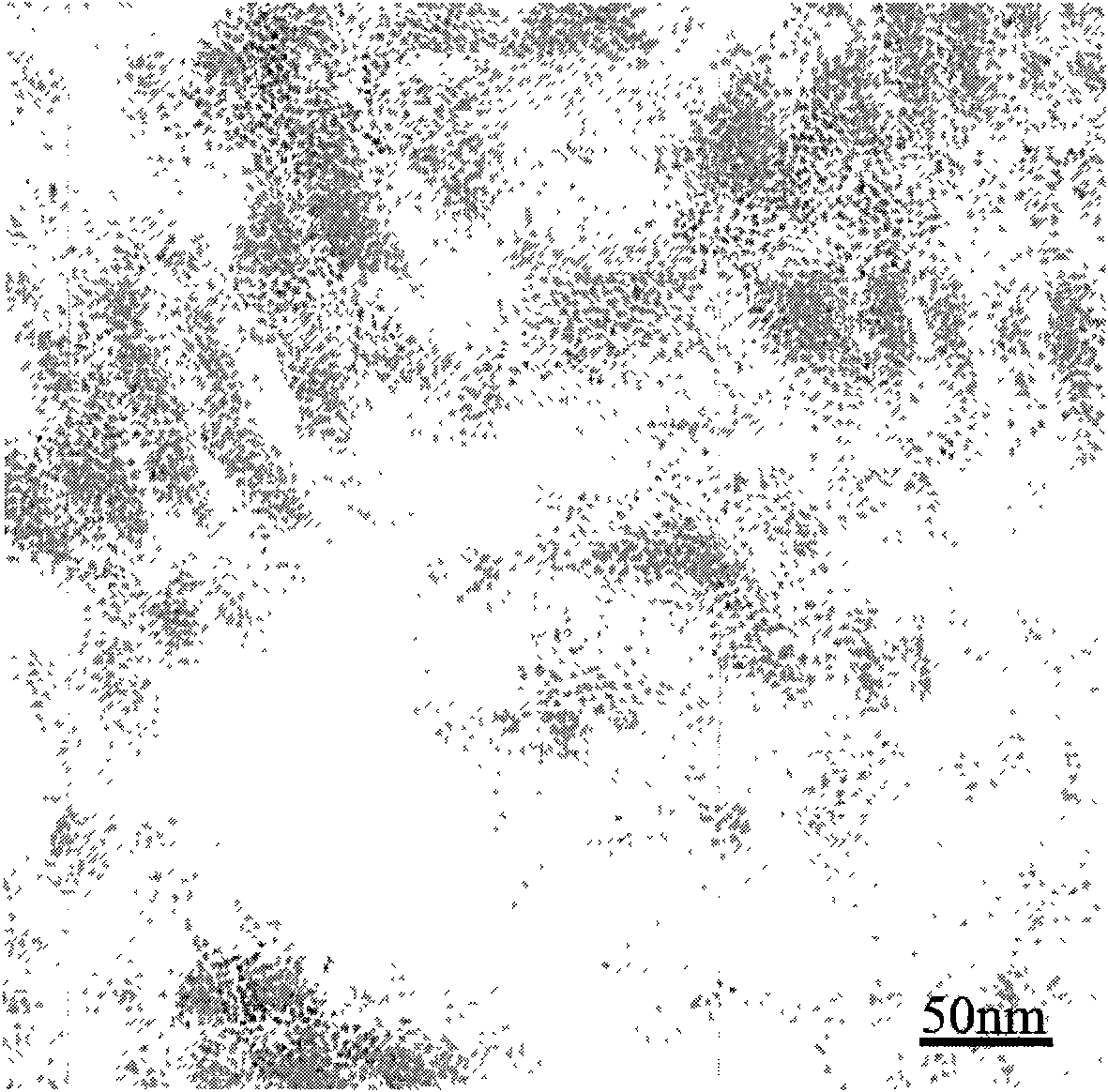

[0068] Get 10ml concentration and be that the sodium hydroxide aqueous solution of 0.20mol / L joins in the palladium chloride aqueous solution of 20ml (2.82 * 10 -2 mol / L), stirred at room temperature for 1min to obtain a palladium metal compound colloid, and the content of Pd in the colloid was 2.00g / L. The electron micrograph of the palladium metal compound nanoparticle in the palladium metal compound colloid is as figure 1 shown. Transmission electron microscope (TEM) analysis shows that the average particle size of the palladium metal compound nanoparticles is 2nm, and the particle size distribution is 1-3nm.

[0069] 10% ammonia water and 4% ferric chloride (0.25mol / L) aqueous solutions were prepared respectively, and an approp...

Embodiment 2

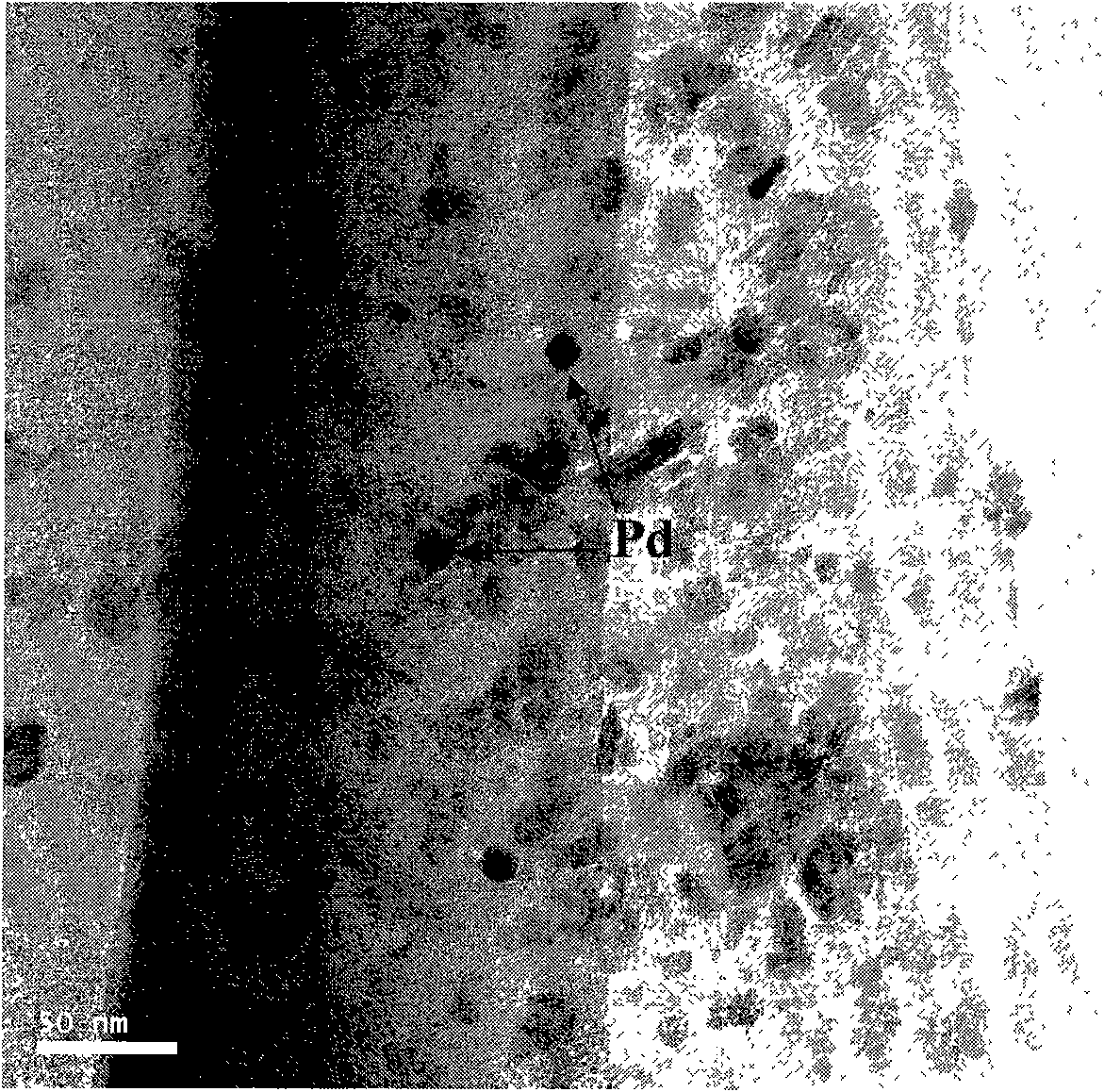

[0087] Embodiment 2: Preparation is made of Pd nano-clusters and Fe in a partially reduced state 3 o 4 The constituted catalyst (Pd: 0.25wt.%) and its catalytic performance test.

[0088] 1. Catalyst preparation

[0089] Disperse 1g of palladium chloride in 300ml of ethylene glycol, add 1ml of hydrochloric acid (30wt.%), and prepare the ethylene glycol solution of palladium chloric acid (1.88×10 -2 mol / L). Cool the freshly prepared palladium chloride ethylene glycol solution and NaOH aqueous solution (0.25mol / L) to 263K. Take 4.5ml of fully cooled NaOH aqueous solution and add it to 12ml of palladium chloride in ethylene glycol solution under stirring, and continue to stir for 120min at a temperature of 273K to obtain a palladium metal compound colloid. The content of Pd in the colloid is 1.45g / L.

[0090] Fe 3 o 4 The nanostructure material is prepared as follows: 10g of ferric chloride hexahydrate and 10g of urea are dissolved in 60ml of ethylene glycol, heated to 46...

Embodiment 3

[0103] Example 3: Preparation of γ-Fe by Pd nanoclusters and in a partially reduced state 2 o 3 Constituted catalyst (Pd: 15wt.%)

[0104] Prepare palladium metal compound colloid according to the method of step one in Example 1.

[0105] Prepare 2% (mass percentage) KOH aqueous solution and 0.17mol / L ferric nitrate aqueous solution respectively, take an appropriate amount of KOH aqueous solution and slowly add it dropwise to 150ml ferric nitrate solution under stirring, finally control the pH at about 4, and age for 10 minutes. Filtrate and wash the precipitated ferric hydroxide, beat the filter cake in 30ml of 1% dilute hydrochloric acid and slightly heat the slurry at 333K to obtain ferric hydroxide colloid, cool to room temperature for later use.

[0106] Add 176.6ml of the above-mentioned newly prepared palladium metal compound colloid dropwise to the above-mentioned ferric hydroxide colloid, then inject a mixed solution of 100ml of ethylene glycol and glycerol (ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com