High-strength and high-elasticity-modulus casting Mg alloy and preparation method thereof

A high-elastic casting magnesium alloy technology, applied in the field of magnesium alloy processing, can solve the problems of poor elastic deformation resistance, low elastic modulus, etc., and achieve long-lasting thinning effect, long-lasting effect, and good decay resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

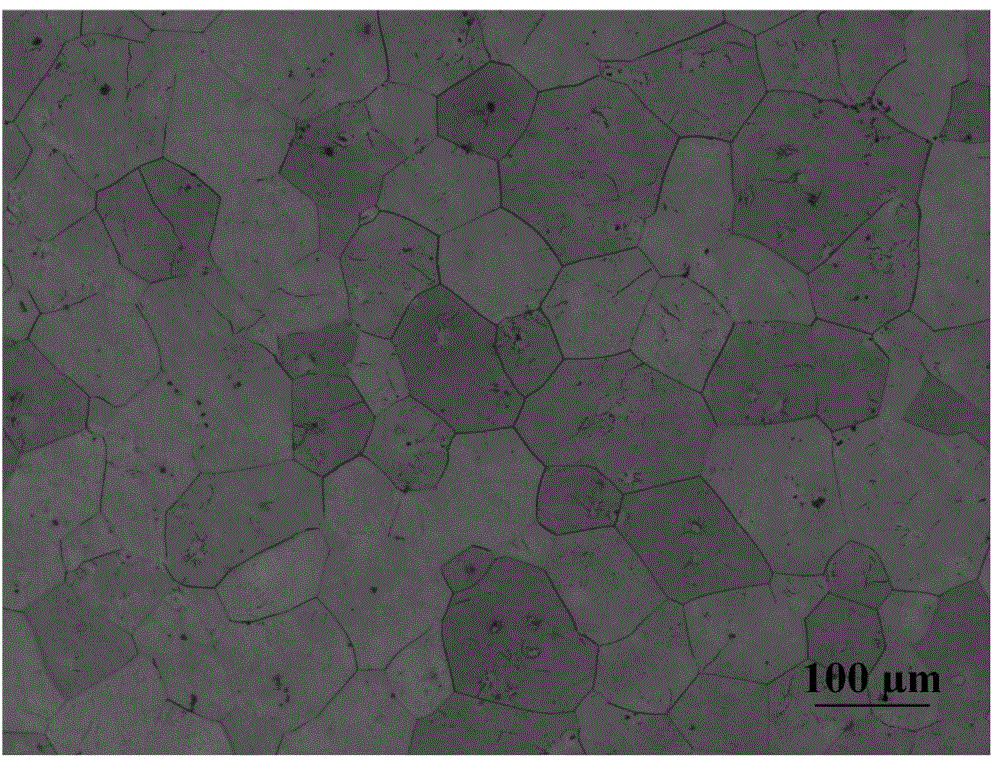

Embodiment 1

[0041] The components and mass percentages of the high-strength and high-elastic-modulus cast magnesium alloy involved in this embodiment are: 6wt% Gd, 5wt% Y, 5wt% Li, 6wt% Al, and the content of impurity elements Si, Fe, Cu and Ni Less than 0.03wt%, and the balance is Mg (wt% refers to the percentage of components in the total mass of the prepared magnesium alloy, and the total mass is the sum of the mass of Mg, Al, Li and various master alloys).

[0042] The preparation method of the magnesium alloy includes two process steps of vacuum smelting and subsequent heat treatment.

[0043] Among them, the previous vacuum smelting process steps are as follows:

[0044] (1) Baking material: Preheat pure Mg, pure Al, intermediate alloys Mg–Gd and Mg–Y at 170°C for more than 3 hours, while pure Li does not need to be preheated;

[0045] (2) Melting Mg, Gd, Y and Al: Preheat the crucible in the vacuum induction melting furnace to 400°C, and put it in the middle of dried pure Mg, pure...

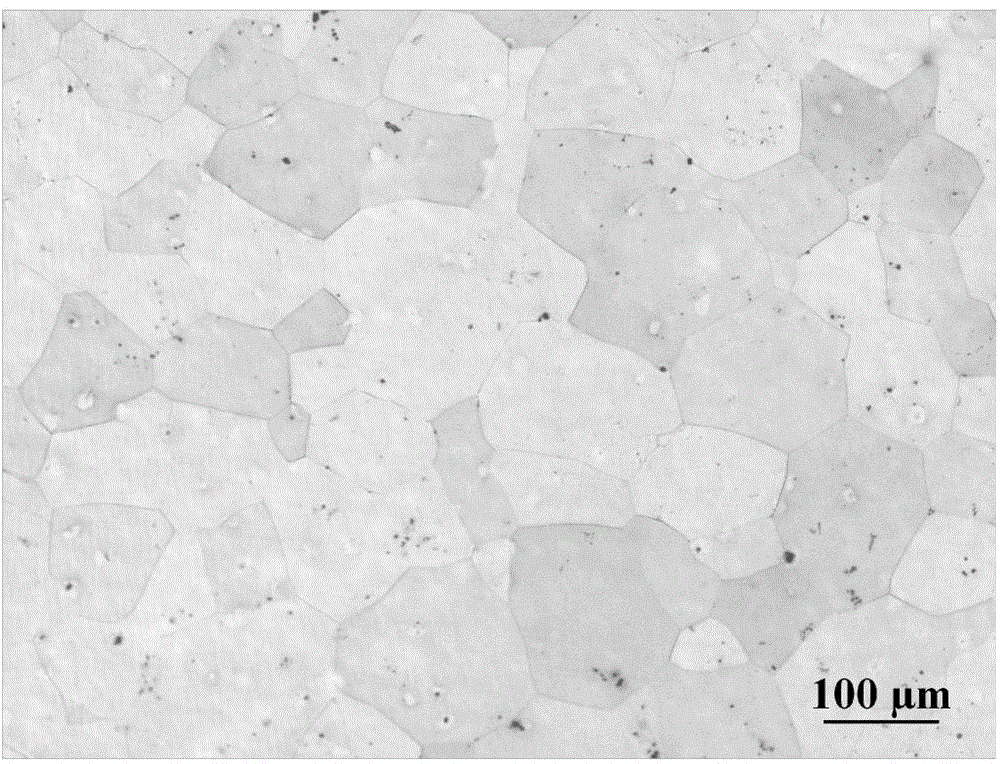

Embodiment 2

[0053] The components and mass percentages of the high-strength and high-elastic-modulus cast magnesium alloy involved in this embodiment are: 12wt% Gd, 1wt% Y, 1wt% Li, 2wt% Al, and the content of impurity elements Si, Fe, Cu and Ni Less than 0.03wt%, the balance is Mg.

[0054] The preparation method of the magnesium alloy includes two process steps of vacuum smelting and subsequent heat treatment.

[0055] Among them, the previous vacuum smelting process steps are as follows:

[0056] (1) Baking material: Preheat pure Mg, pure Al, intermediate alloys Mg–Gd and Mg–Y at 230°C for more than 3 hours, while pure Li does not need to be preheated;

[0057] (2) Melting Mg, Gd, Y and Al: Preheat the crucible in the vacuum induction melting furnace to 500°C, and put it in the middle of dried pure Mg, pure Al, Mg-Gd and Mg-Y, Mg-Gd The alloy is Mg-50wt%Gd, that is, Gd accounts for 50wt% in the master alloy Mg-Gd, and the addition is determined according to the mass percentage (i.e. ...

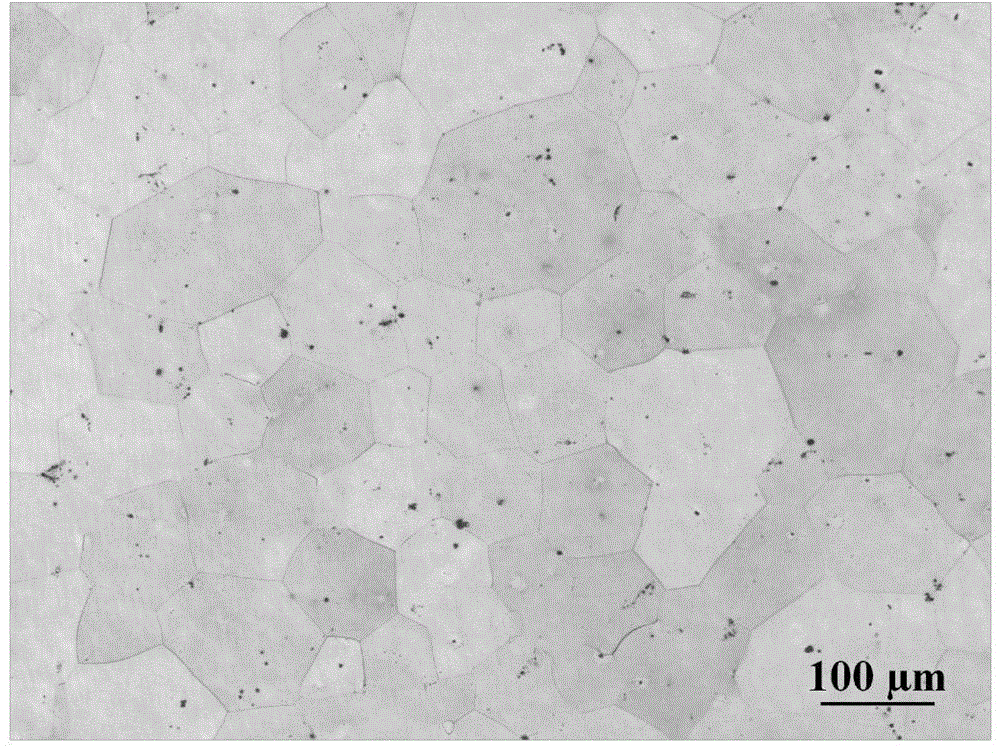

Embodiment 3

[0065] The components and mass percentages of the high-strength and high-elastic-modulus cast magnesium alloy involved in this embodiment are: 9wt% Gd, 3wt% Y, 3wt% Li, 4wt% Al, and the content of impurity elements Si, Fe, Cu and Ni Less than 0.03wt%, the balance is Mg.

[0066] The preparation method of the magnesium alloy includes two process steps of vacuum smelting and subsequent heat treatment.

[0067] Among them, the previous vacuum smelting process steps are as follows:

[0068] (1) Baking material: Preheat pure Mg, pure Al, intermediate alloys Mg–Gd and Mg–Y at 200°C for more than 3 hours, while pure Li does not need to be preheated;

[0069] (2) Melting Mg, Gd, Y and Al: Preheat the crucible in the vacuum induction melting furnace to 450°C, and put it in the middle of dried pure Mg, pure Al, Mg–Gd, Mg–Y, Mg–Gd The alloy is Mg-35wt%Gd, that is, Gd accounts for 35wt% in the master alloy Mg-Gd, and the addition amount is determined according to the mass percentage (ie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com