Lithium ion battery positive current collector high in safety performance, preparing method thereof and lithium ion battery

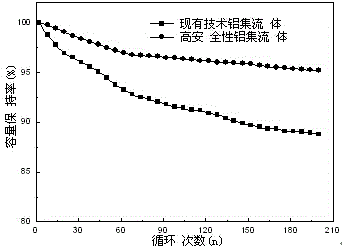

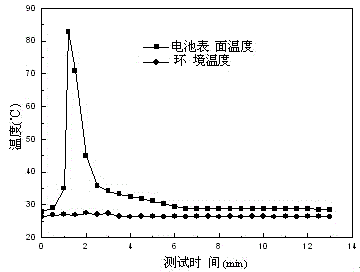

A technology for positive current collectors and lithium-ion batteries, applied in the direction of electrode carriers/collectors, battery electrodes, secondary batteries, etc., can solve the problems of small short-circuit resistance, fire and explosion, thermal runaway, etc., to reduce current value and increase resistance , Improve the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using aluminum foil with a thickness of 25 μm as the base material, the aluminum foil was ultrasonically oscillated in ethanol for 15 minutes to remove oil stains on the aluminum foil, and then left to stand in 0.5 mol / L sodium hydroxide solution for 2 minutes to remove the natural formation on the surface of the aluminum foil. The oxide layer was then rinsed with distilled water for 15 seconds to obtain a pretreated aluminum foil. With the pretreated aluminum foil as the anode and the graphite plate as the cathode, in 0.5 mol / L sulfuric acid aqueous solution, the voltage was 30 V, and the current density was 20 mA / cm 2 , oxidized for 25 minutes, then rinsed with distilled water for 15 seconds, and dried with hot air at 55 °C to obtain an aluminum foil coated with a porous alumina resistance layer. Pore structure (such as figure 1 shown), the pore size of the blind hole structure is 1–5 μm.

[0040] Preparation of lithium-ion batteries

[0041] The aluminum foil wi...

Embodiment 2

[0046]Using aluminum foil with a thickness of 35 μm as the base material, the aluminum foil was ultrasonically oscillated in acetone for 10 minutes to remove oil stains on the aluminum foil base material, and then left to stand in 0.25 mol / L potassium hydroxide solution for 1 minute to remove the natural formation on the surface of the aluminum foil The oxide layer was then rinsed with distilled water for 10 seconds to obtain a pretreated aluminum foil. With the pretreated aluminum foil as the anode and the graphite plate as the cathode, in a mixed aqueous solution of 0.1 mol / L sulfuric acid, 0.05 mol / L phosphoric acid and 0.02 mol / L 2-hydroxypropionic acid, the voltage was 20 V and the current density was 15 mA / cm 2 , oxidized for 20 minutes, then rinsed with distilled water for 15 seconds, and dried with hot air at 55°C to obtain an aluminum foil positive current collector with a porous resistive layer.

[0047] The thickness of the porous alumina resistance layer was detec...

Embodiment 3

[0051] Using aluminum foil with a thickness of 20 μm as the base material, the aluminum foil was ultrasonically oscillated in acetone for 10 minutes to remove the oil on the aluminum foil base material, and then mixed solution of 0.1 mol / L sodium hydroxide and 0.05 mol / L sodium bicarbonate Stand in the middle for 1 minute to remove the naturally formed oxide layer on the surface of the aluminum foil, and then rinse with distilled water for 10 seconds to obtain a pretreated aluminum foil. With the pretreated aluminum foil as the anode and the graphite plate as the cathode, in a mixed aqueous solution of 0.1 mol / L oxalic acid and 0.02 mol / L 2-hydroxypropionic acid, the voltage was 12 V and the current density was 15 mA / cm 2 , oxidized for 20 minutes, then rinsed with distilled water for 15 seconds, and dried with hot air at 55°C to obtain an aluminum foil positive current collector with a porous resistive layer.

[0052] The thickness of the porous alumina resistance layer was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com