Amorphous alloy roll-core and its production method

An amorphous alloy, coiled iron core technology, applied in the field of transformer manufacturing, can solve problems such as unfavorable promotion, increase in no-load loss, and decline in core performance, saving amorphous alloy materials, reducing the possibility of failure, and reducing load. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

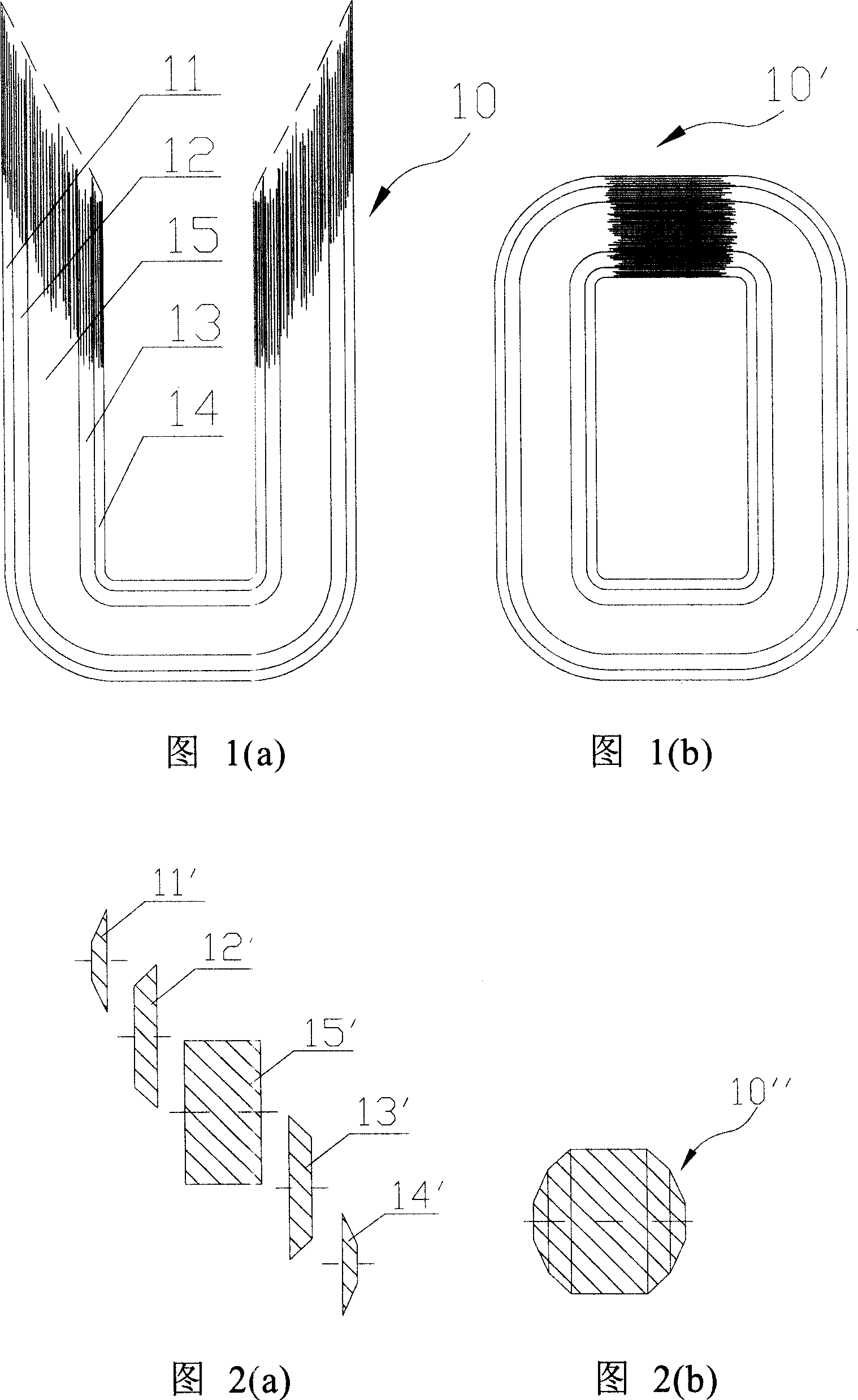

[0055] 1. Embodiment 1: Single-phase open coil core

[0056] As shown in FIG. 1( a ), the amorphous alloy single-phase open coiled iron core 10 according to the present invention, as shown in FIG. 1( b ), forms a closed coiled iron core 10 ′ after the opening part is closed.

[0057] The iron core is composed of five U-shaped single frames 11, 12, 13, 14 and 15 with different cross-sectional shapes. Wherein the U-shaped single frame 15 with the largest cross-sectional area is the main frame, and the main frame is made of amorphous alloy material, and all the other single frames 11, 12, 13, 14 are made of silicon steel strip material. The cross-sectional shape of each single frame is shown in Figure 2(a). The cross-section 15' of the main frame and the cross-sections 11', 12', 13', and 14' of the other single frames are combined to form a U-shaped single-phase open coil core. The cross-section 10 ", the shape is shown in Fig. 2(b).

[0058] When the U-shaped single frames are...

Embodiment 3

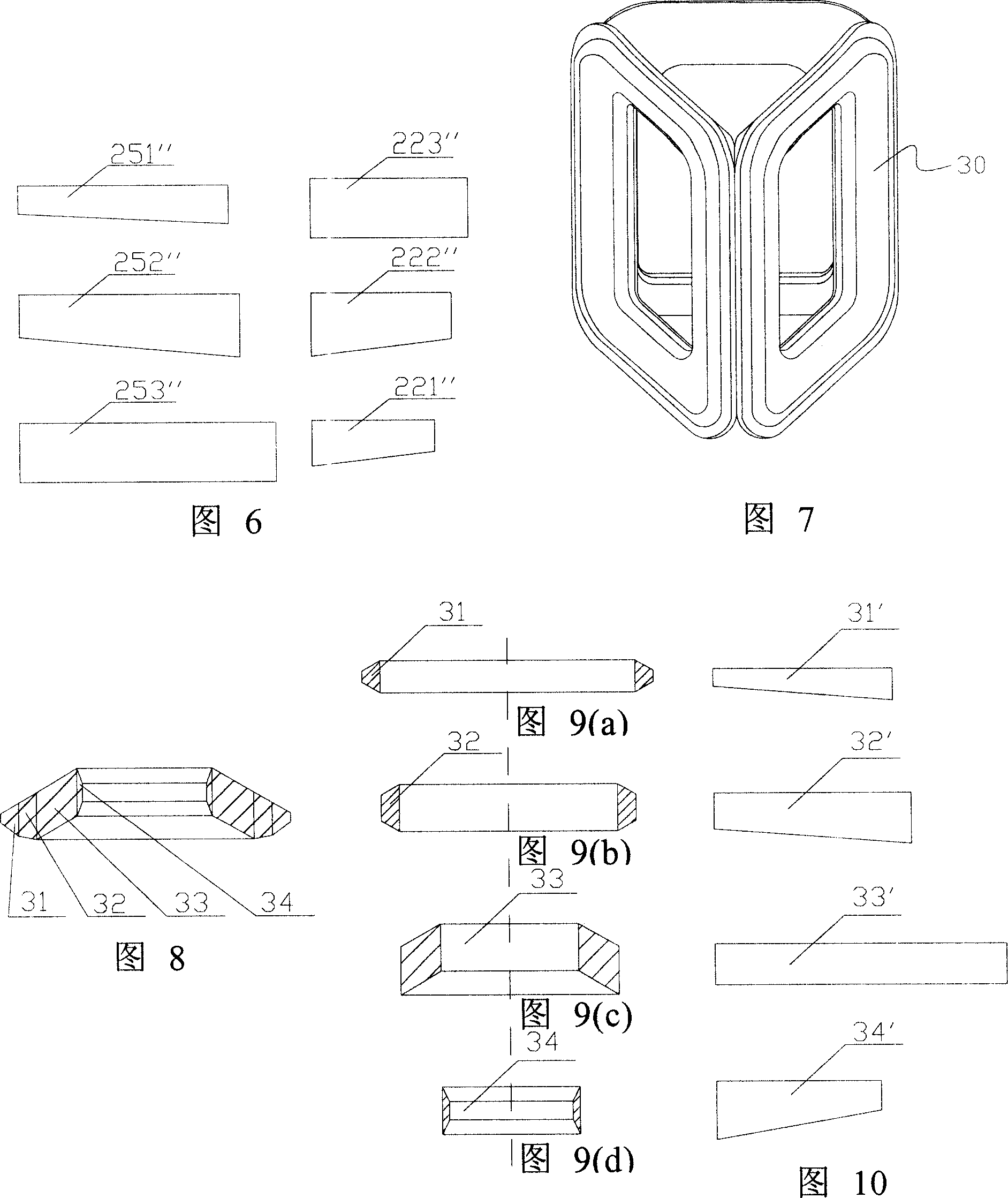

[0073] Embodiment 3: Three-phase three-column three-dimensional closed coil core

[0074] As shown in Fig. 7, the three-phase three-column three-dimensional closed coil core of the present invention is composed of three closed unit frames 30 with the same or substantially the same shape, and the cross-section of each unit frame 30 As shown in Figure 8, each unit frame is composed of four single frames 31, 32, 33, 34, the single frame 33 with the largest cross-sectional area among the four single frames is the main frame, and the main frame 33 is composed of non- The crystal alloy material is formed after winding and annealing, and the other single frames 31, 32, 34 are formed by winding and annealing silicon steel strips. The cross-sectional shape of each single frame is as shown in Figure 9, and the shape of each material strip forming each single frame is as shown in Figure 10. The strips are respectively 31', 32', 34'.

[0075] Manufacturing method of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com