Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

224results about How to "Improve the magnetic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transcranial magnetic stimulation by enhanced magnetic field perturbations

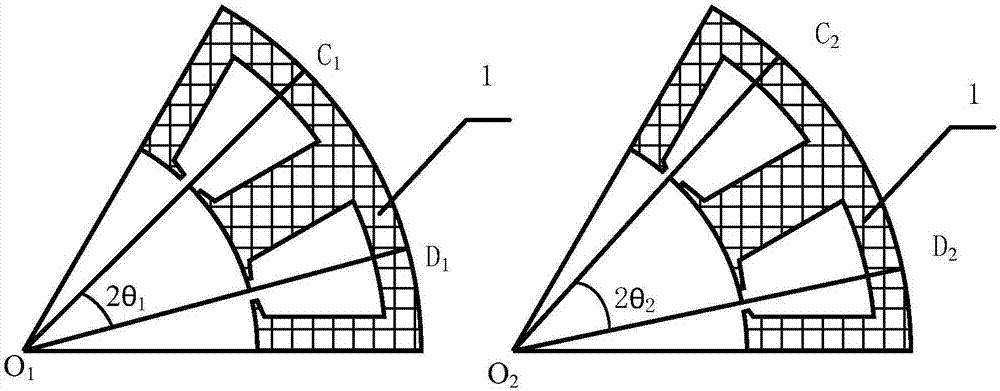

InactiveUS20110105826A1Facilitate local stimulationIncrease changeElectrotherapySurgeryMagnetic perturbationMagnetic field perturbation

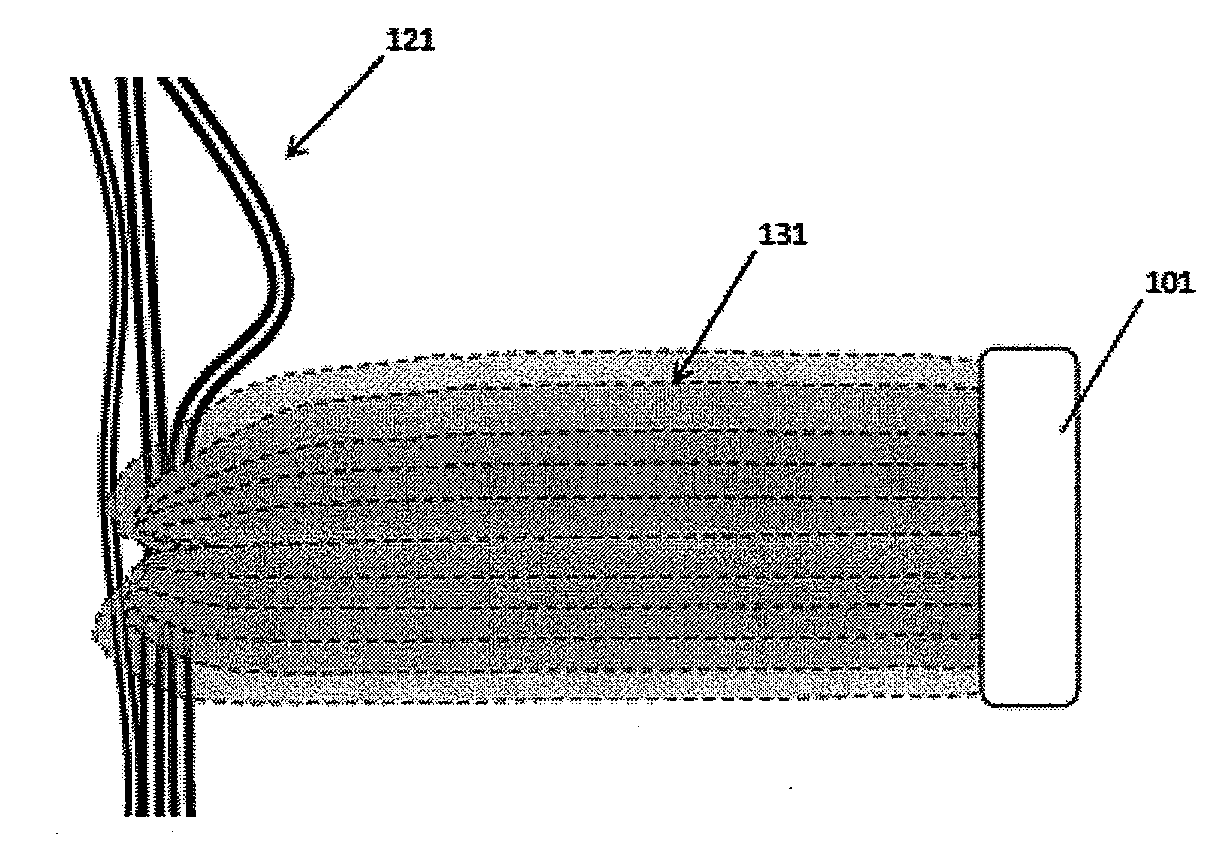

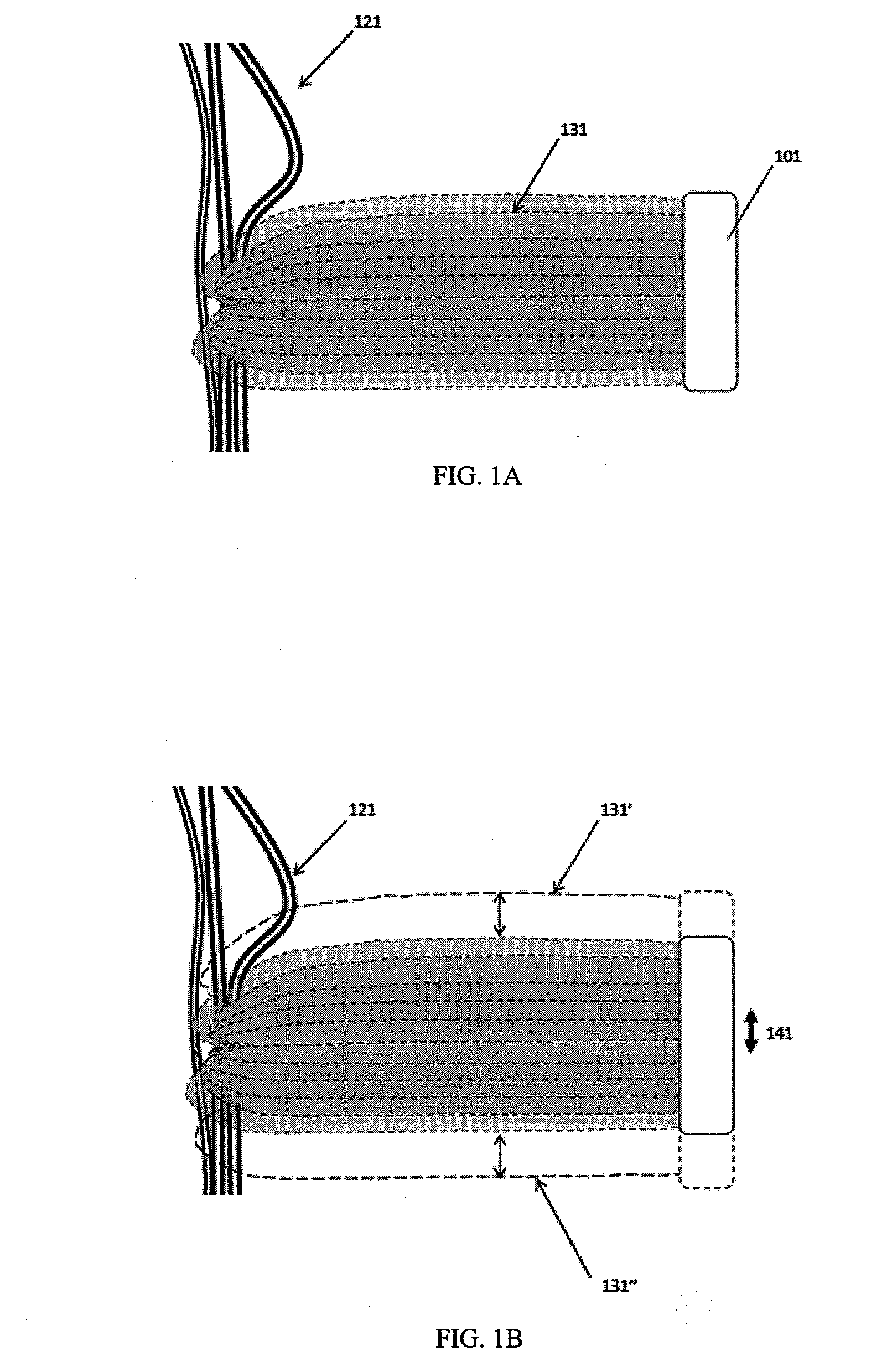

Described herein are devices, systems and methods to enhance the magnetic perturbation of a neuronal (e.g., brain) target during Transcranial Magnetic Stimulation (TMS), thereby enhancing the induced current in the target. In general, these devices, systems and methods enhance the magnetic perturbation (dB / dt) of the target by mechanically moving a TMS electromagnet (e.g. coil) at a frequency of greater than 1 kHz.

Owner:CERVEL NEUROTECH

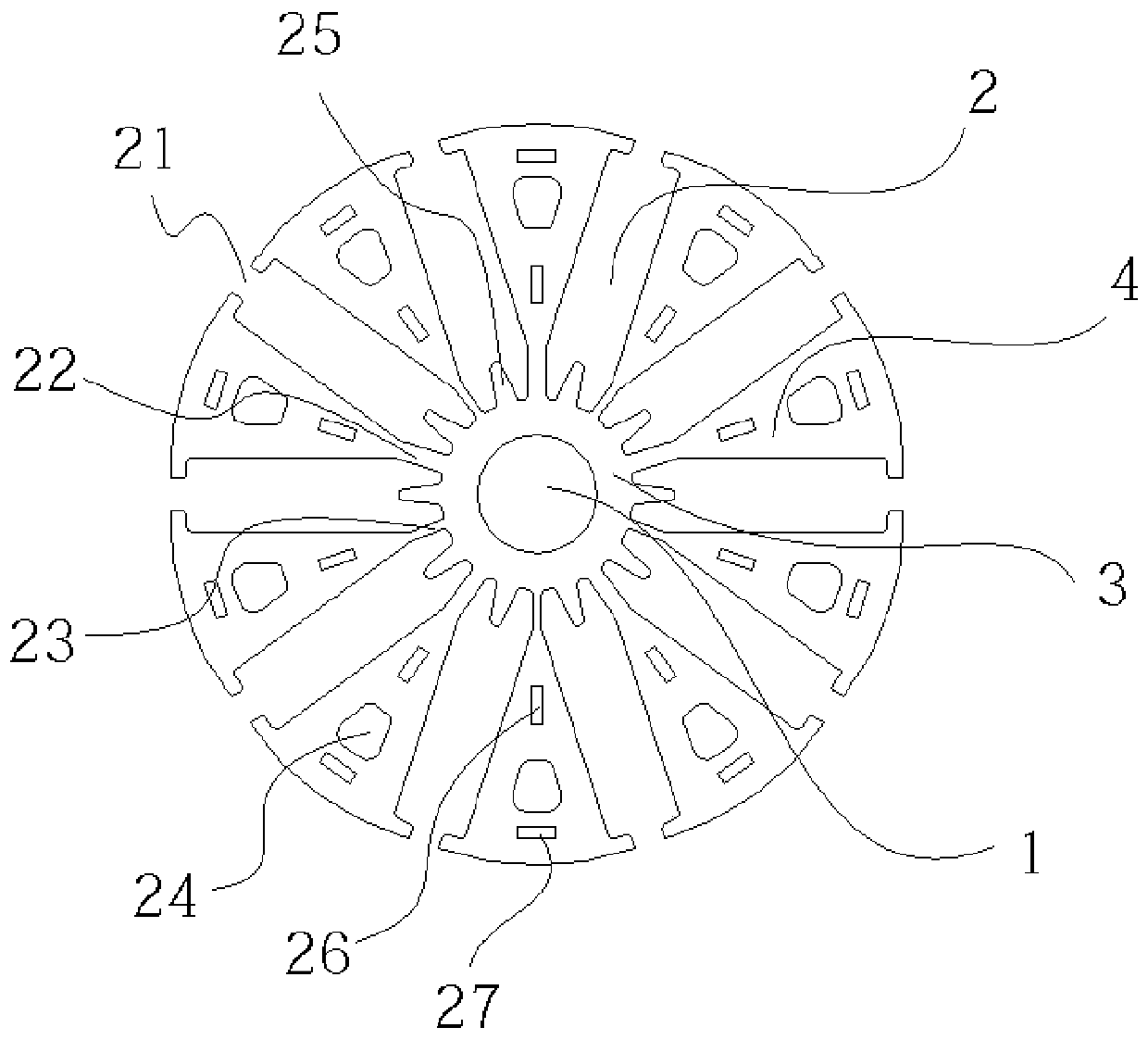

Mixed excitation permanent magnet flux switching motor

InactiveCN101820192AImprove tuning performanceReduced ampere-turnsMagnetic circuit rotating partsMagnetic circuit stationary partsTooth numberConductor Coil

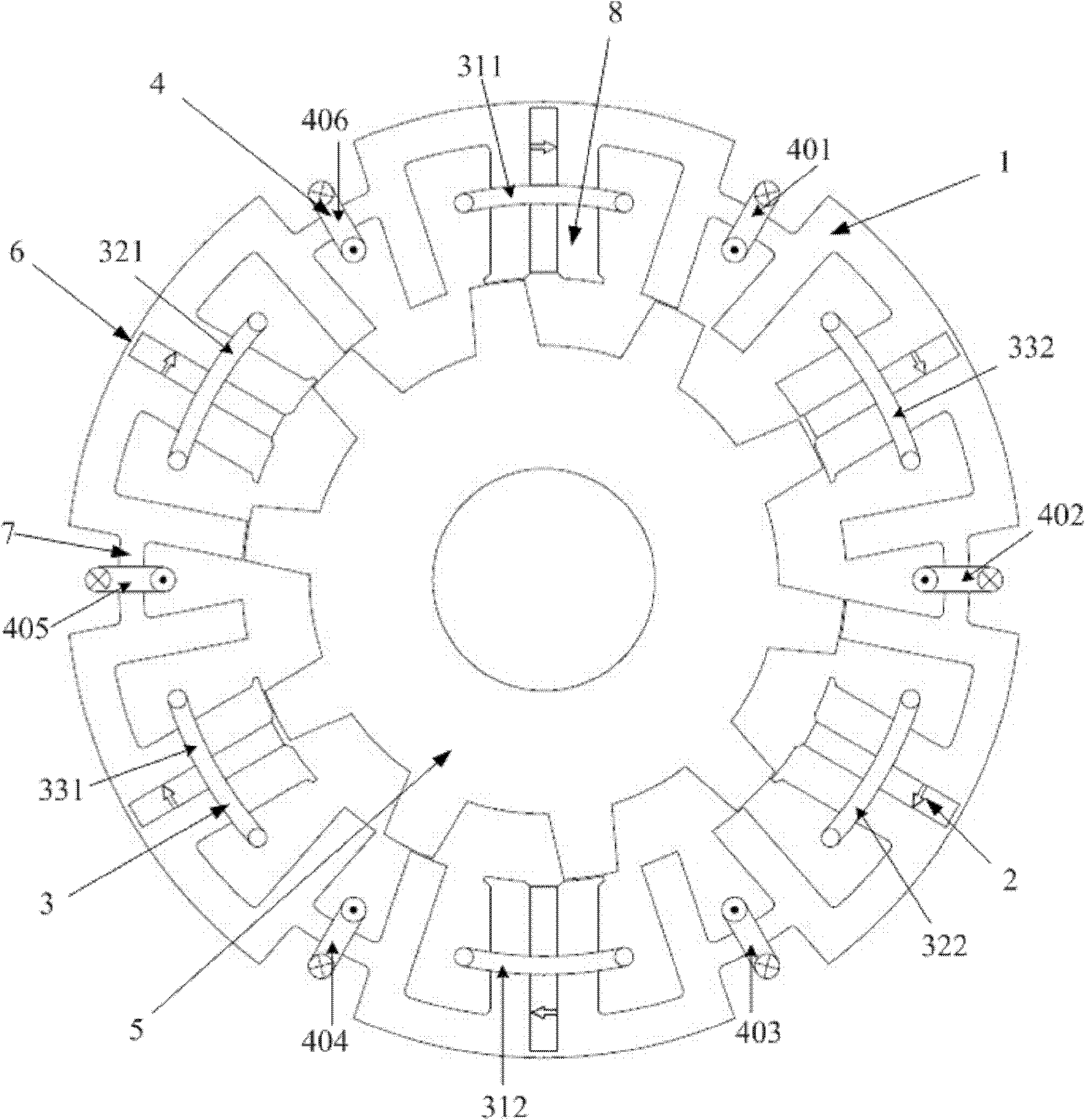

The invention discloses a mixed excitation permanent magnet flux switching motor which comprises permanent magnets, three-phase armature windings and single-phase excitation windings, wherein the single-phase excitation windings are arranged on a stator, the tooth number of the stator is 4 times number of permanent magnets; and a rotor is in a salient pole structure and has no windings or permanent magnets, thereby having high mechanical strength and being suitable for high-speed operation. An air-gap field comprises an electric excitation magnetic field generated by the excitation windings and a magnetic field generated by the permanent magnets, and is flexibly adjusted by changing an excitation current. An electric excitation magnetic line of force is closed by using an iron core connecting magnetic bridge, which is beneficial to reducing the electric field ampere-turns and lowering the electric excitation copper loss. The armature windings and the excitation windings are distributed in different stator grooves at intervals, which is beneficial to increasing the self-inductance of the armature windings and the mutual inductance of the windings and effectively inhibiting the short circuit current of a motor.

Owner:CHANGZHOU INST OF TECH

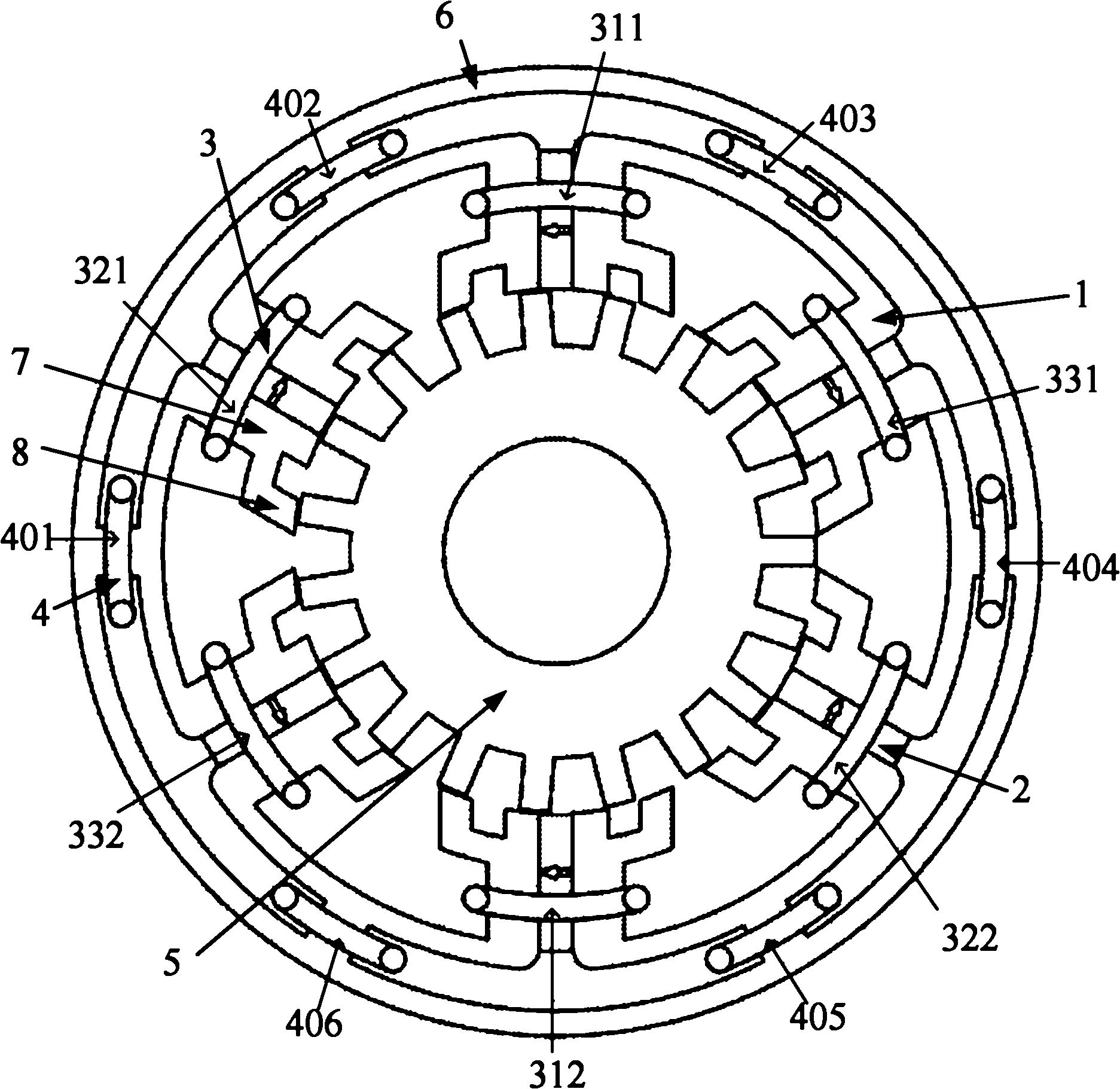

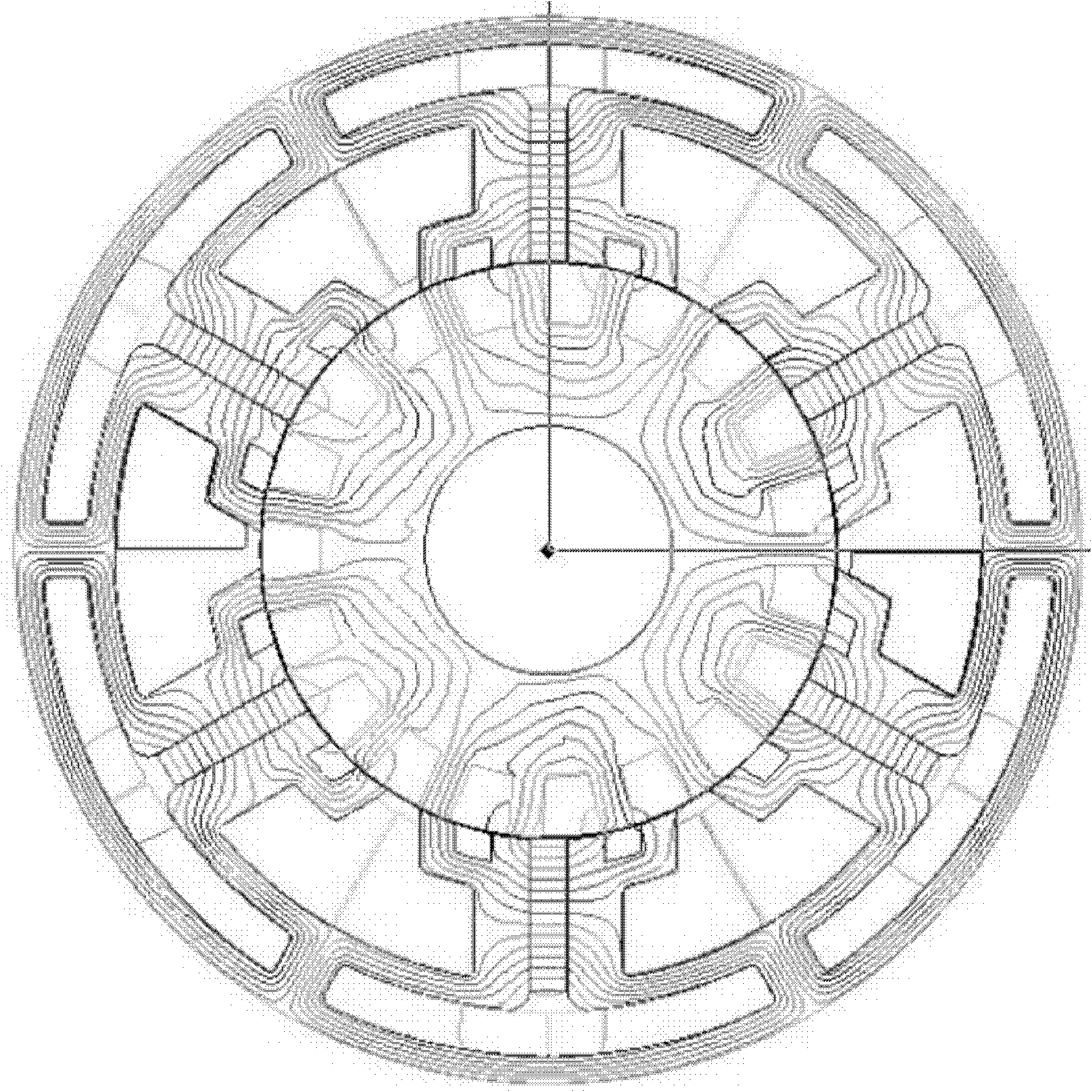

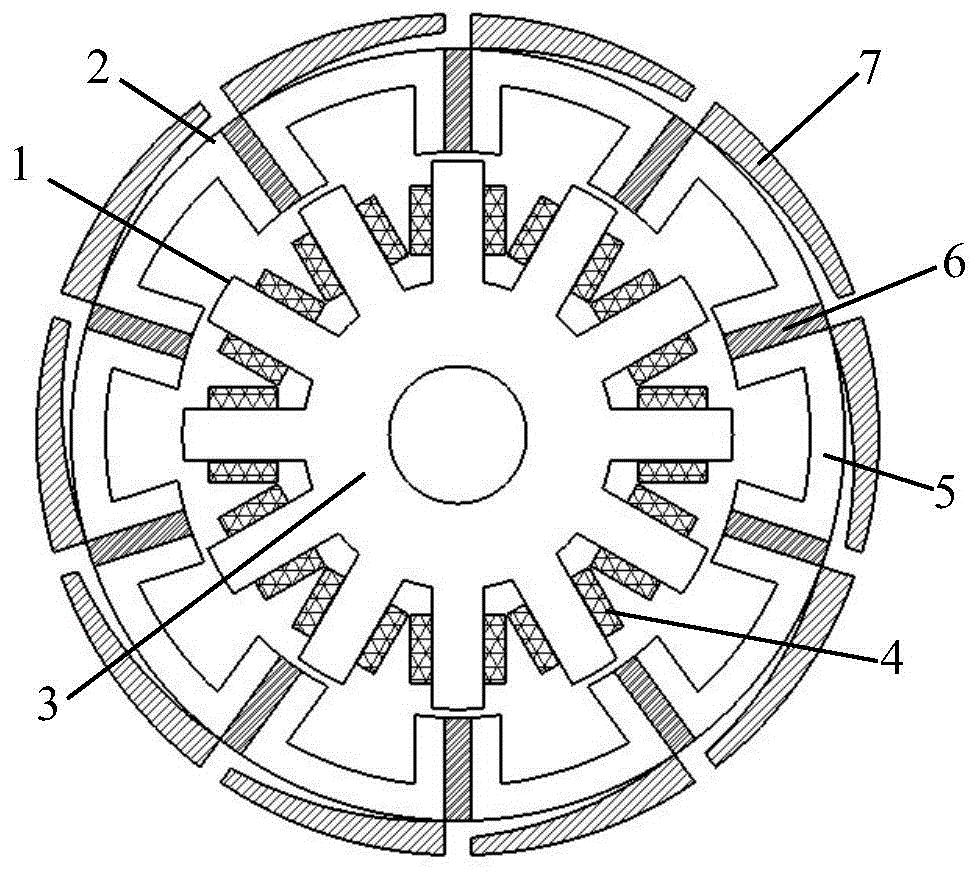

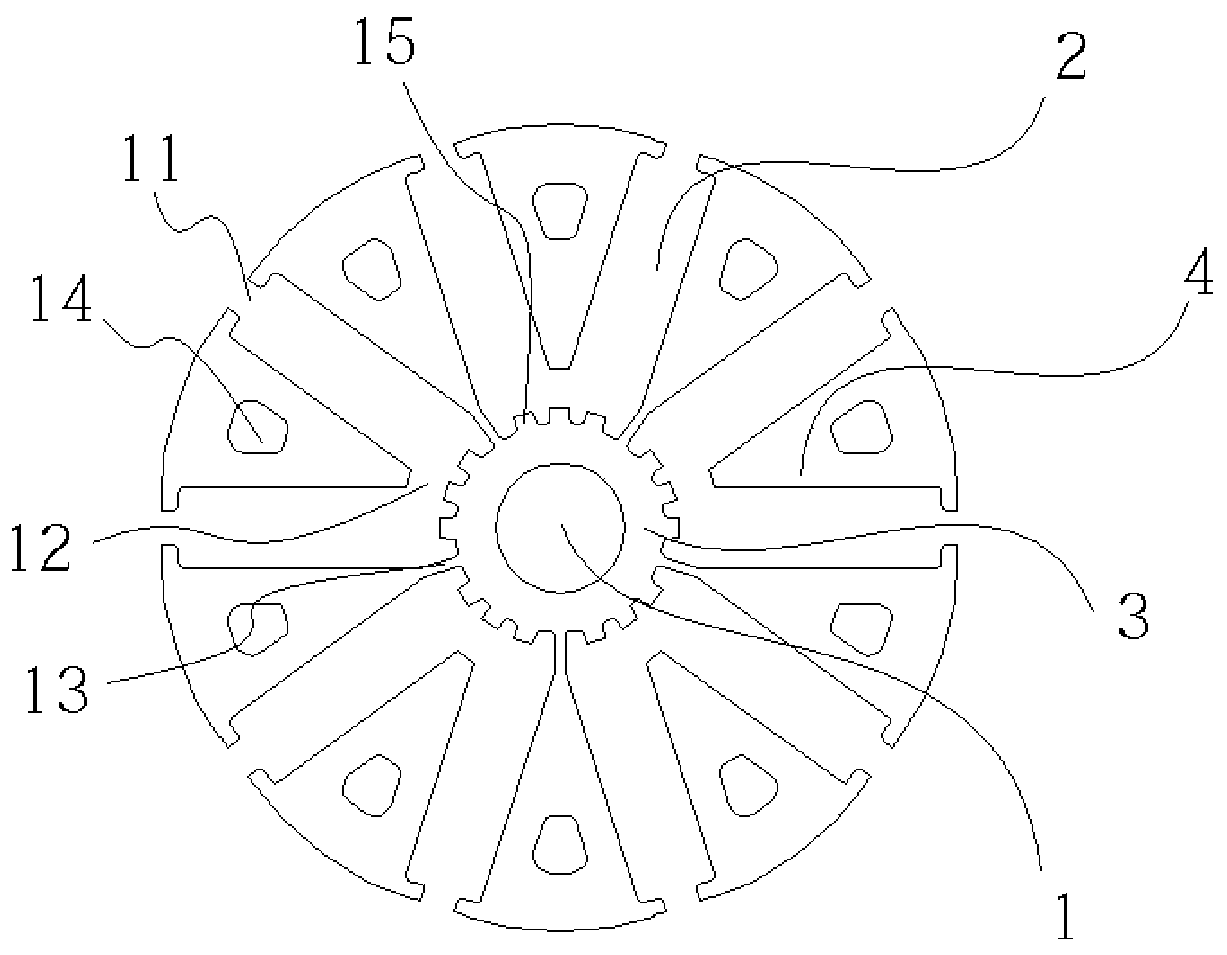

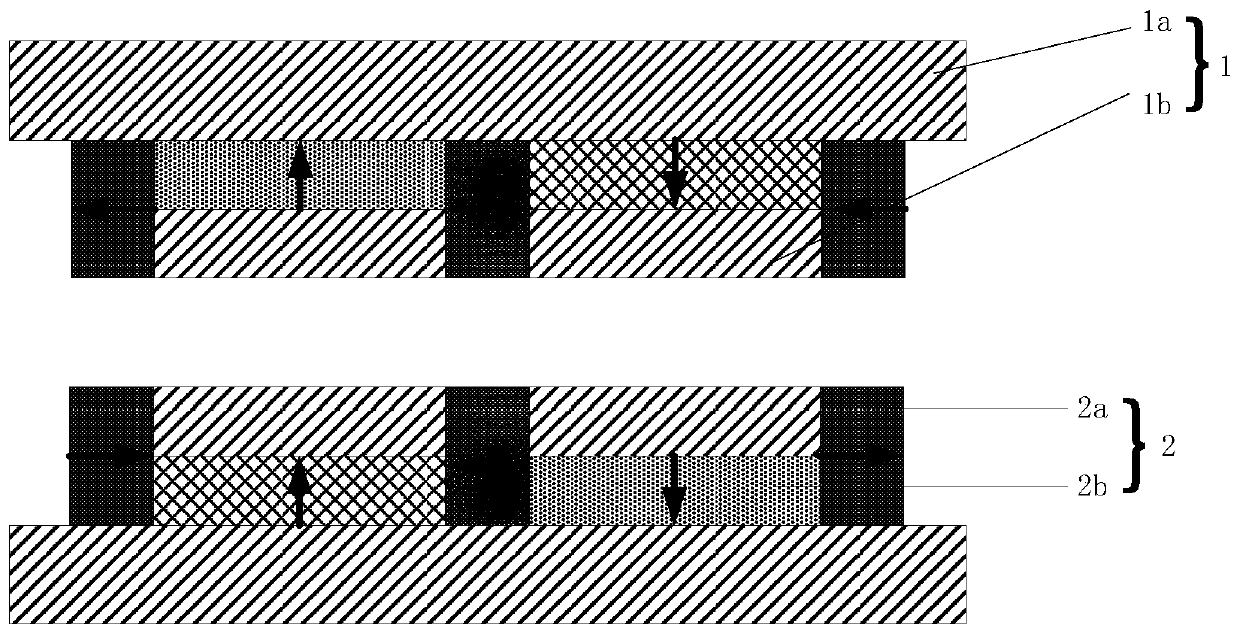

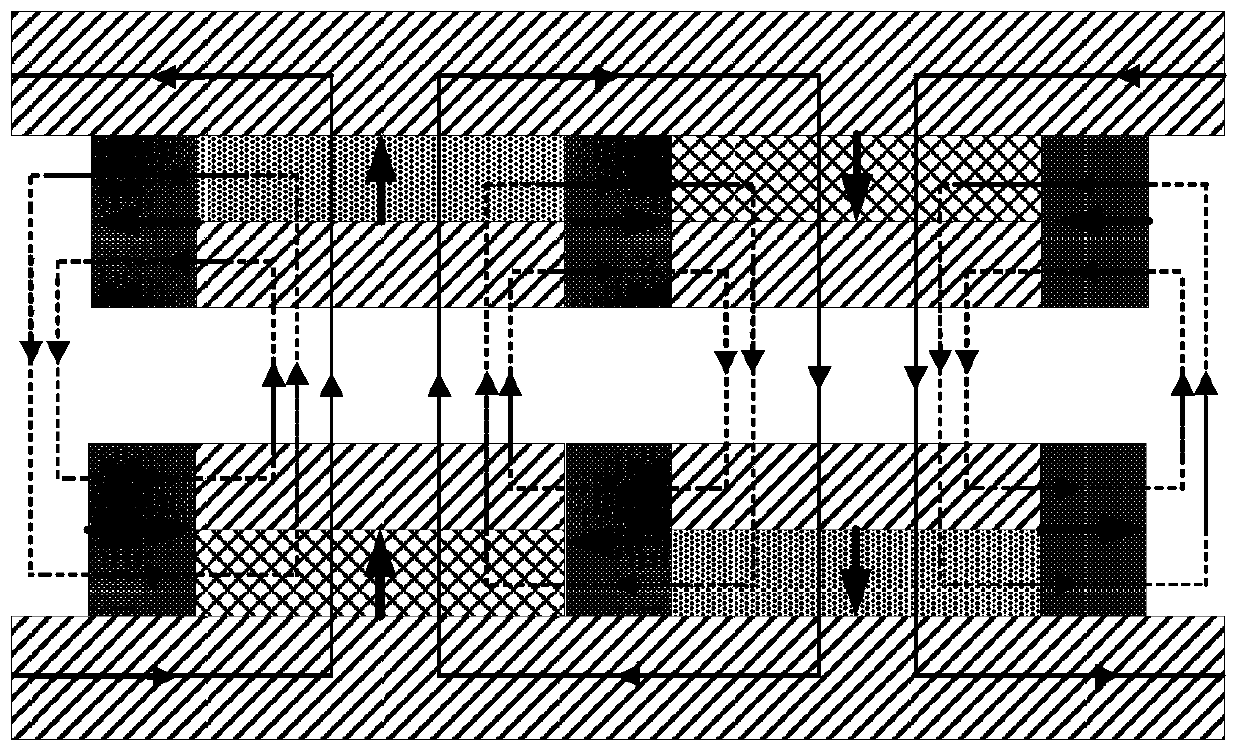

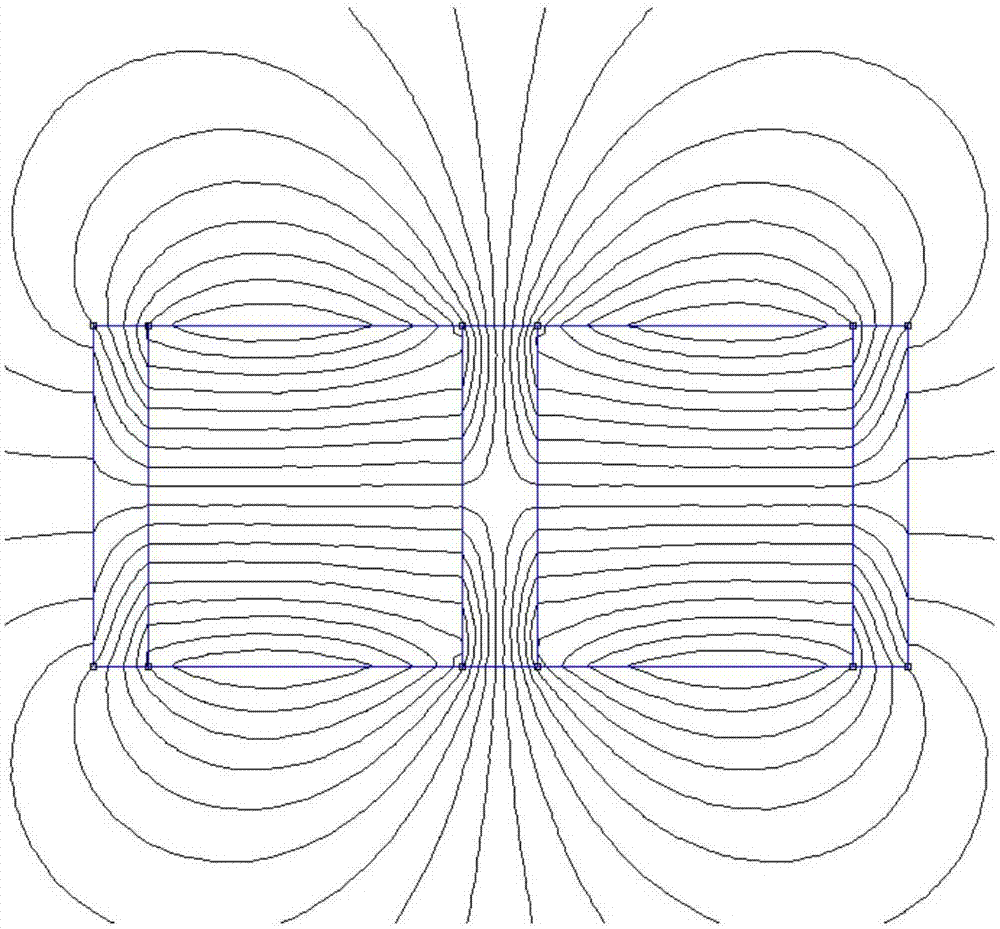

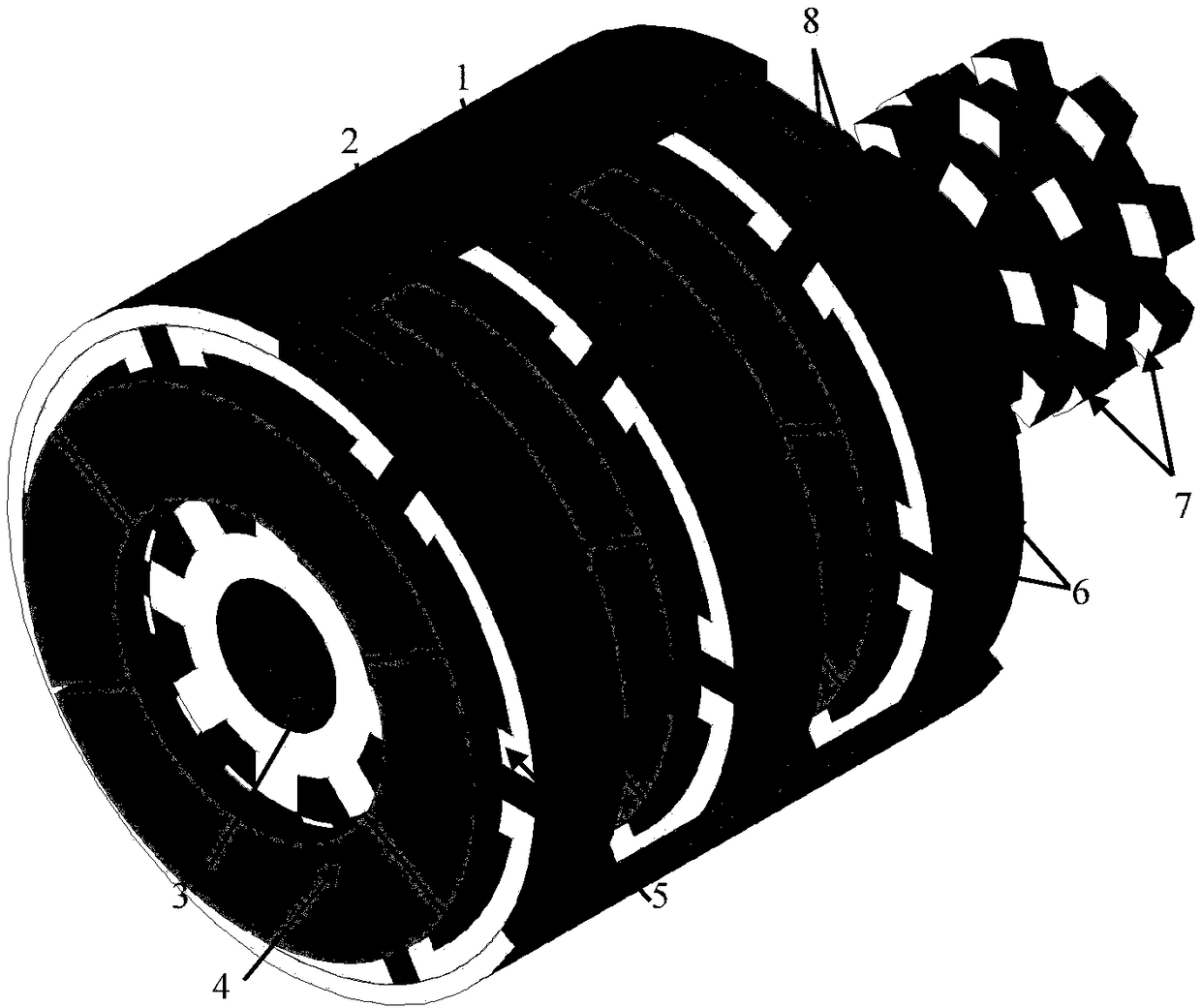

Multitooth magnetic bridge type hybrid excitation magnetic flux switching motor

InactiveCN101834474AReduced risk of irreversible demagnetizationReduce lossMagnetic circuit stationary partsLow speedTooth number

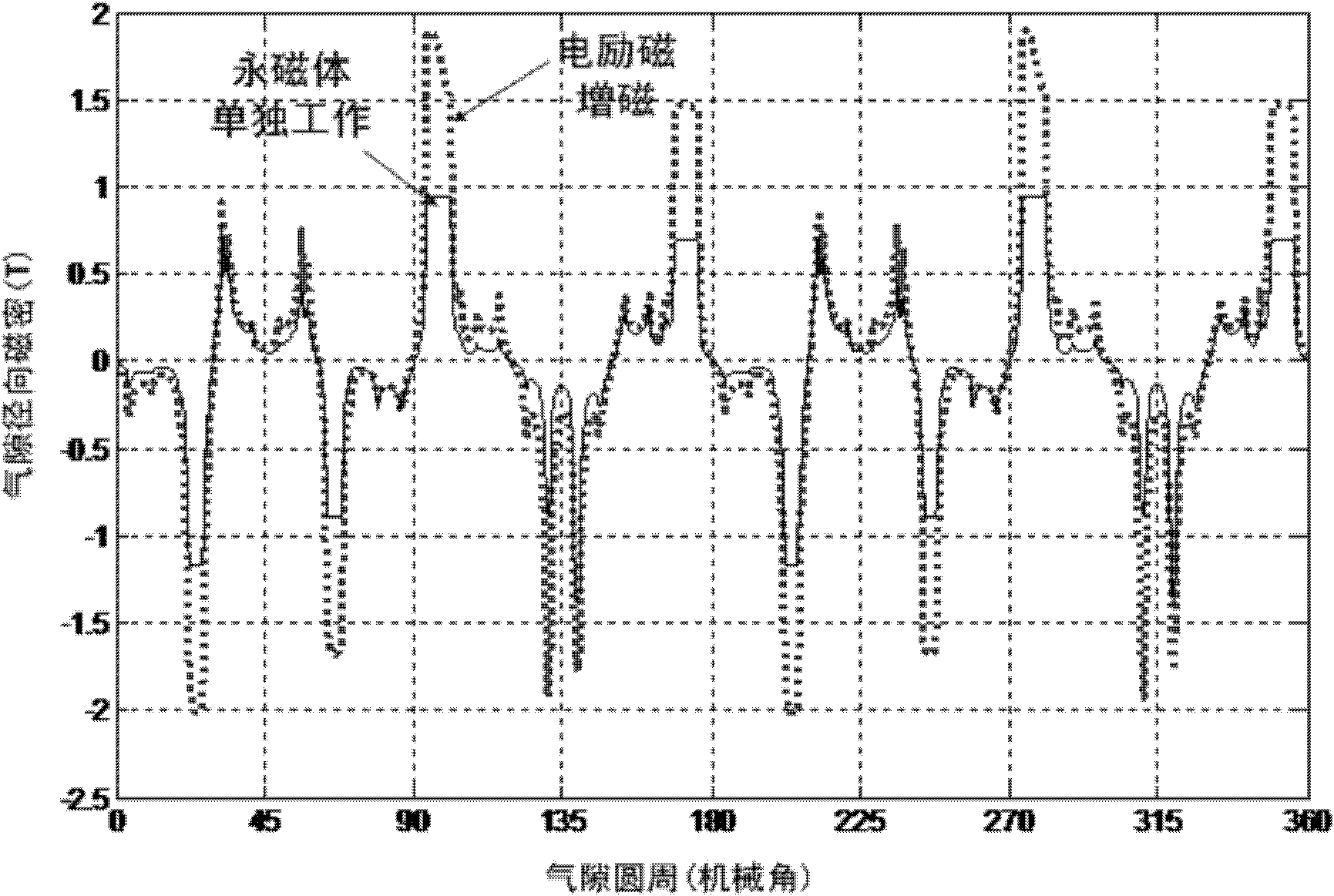

The invention discloses a multitooth magnetic bridge type hybrid excitation magnetic flux switching motor. Permanent magnets, an armature winding and a single-phase excitation winding are installed on a stator; the tooth number of the stator is four times of the number of the permanent magnets; and part of a rotor part is a salient pole, and a rotor has no winding or permanent magnets and has simple and firm structure. An air gap magnetic field comprises an electric excitation magnetic field generated by the excitation winding and a magnetic field generated by the permanent magnets and is adjusted by changing the magnitude and the direction of excitation current, thereby improving the rotating speed operating range and the magnetic weakening capability of the motor. An electric excitation magnetic force line is connected with a magnetic bridge for closing after penetrating through an iron core at the top of the permanent magnets, which is beneficial to reducing the electric excitation ampere turns. The invention has parallel connecting structure of the excitation winding and the permanent magnet in space, bipolarity of phase magnetic flux, large magnetic chain change amplitude value and higher torque output capability and power density and is suitable for a low-speed straight application occasion.

Owner:CHANGZHOU INST OF TECH

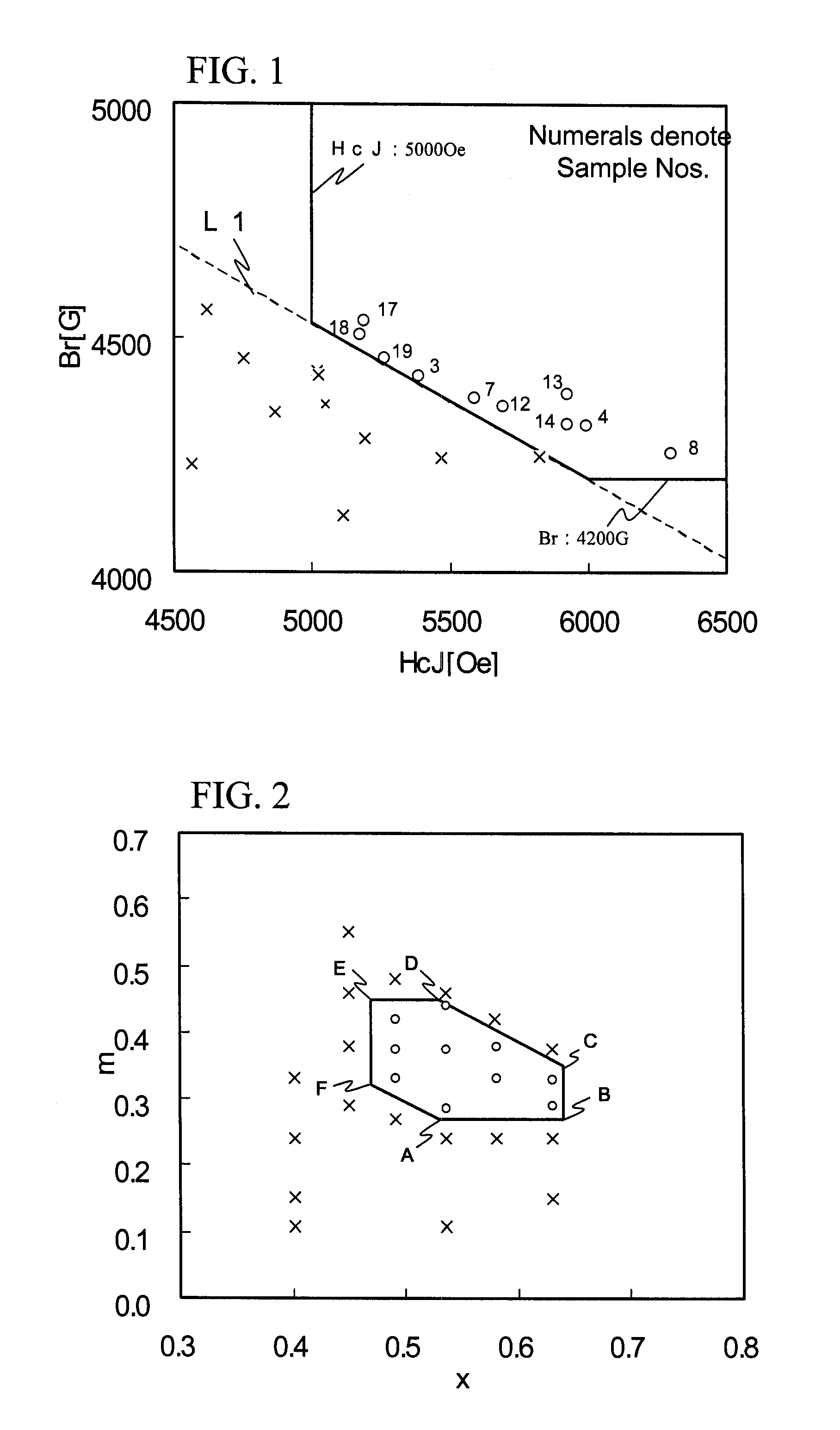

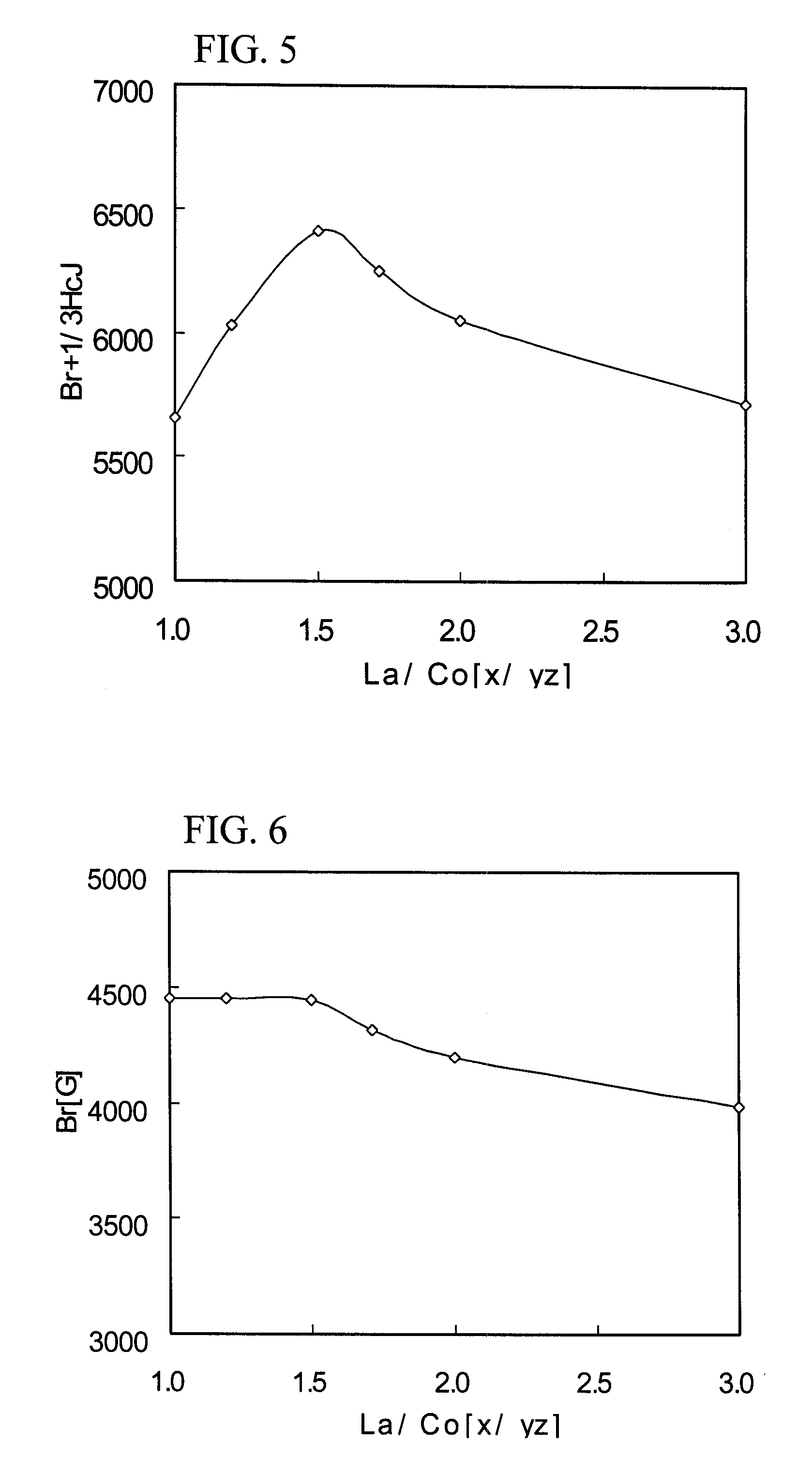

Ferrite magnetic material

ActiveUS20070138432A1Saturation magnetization become lowDegradation of magnetic propertyMagnetic materialsMetalMaterials science

The present invention provides a ferrite magnetic material capable of attaining such magnetic properties that Br+(⅓)HcJ is 6200 or more even by sintering at a temperature of 1150° C. or lower. The ferrite magnetic material includes as a main phase thereof a ferrite phase having a hexagonal structure, the main phase being represented by the following composition formula (1): LaxCamα1−x−m(Fe12−yCoy)z with α representing one or two of Ba and Sr; wherein the constituent ratios of the metal elements constituting the main phase satisfy the following conditions: x and m are the values in a region bounded by the points, A: (0.53, 0.27), B: (0.64, 0.27), C: (0.64, 0.35), D: (0.53, 0.45), E: (0.47, 0.45) and F: (0.47, 0.32) in the (x, m) coordinates shown in FIG. 2; 1.3≦x / yz≦1.8; and 9.5≦12z≦11.0.

Owner:TDK CORPARATION

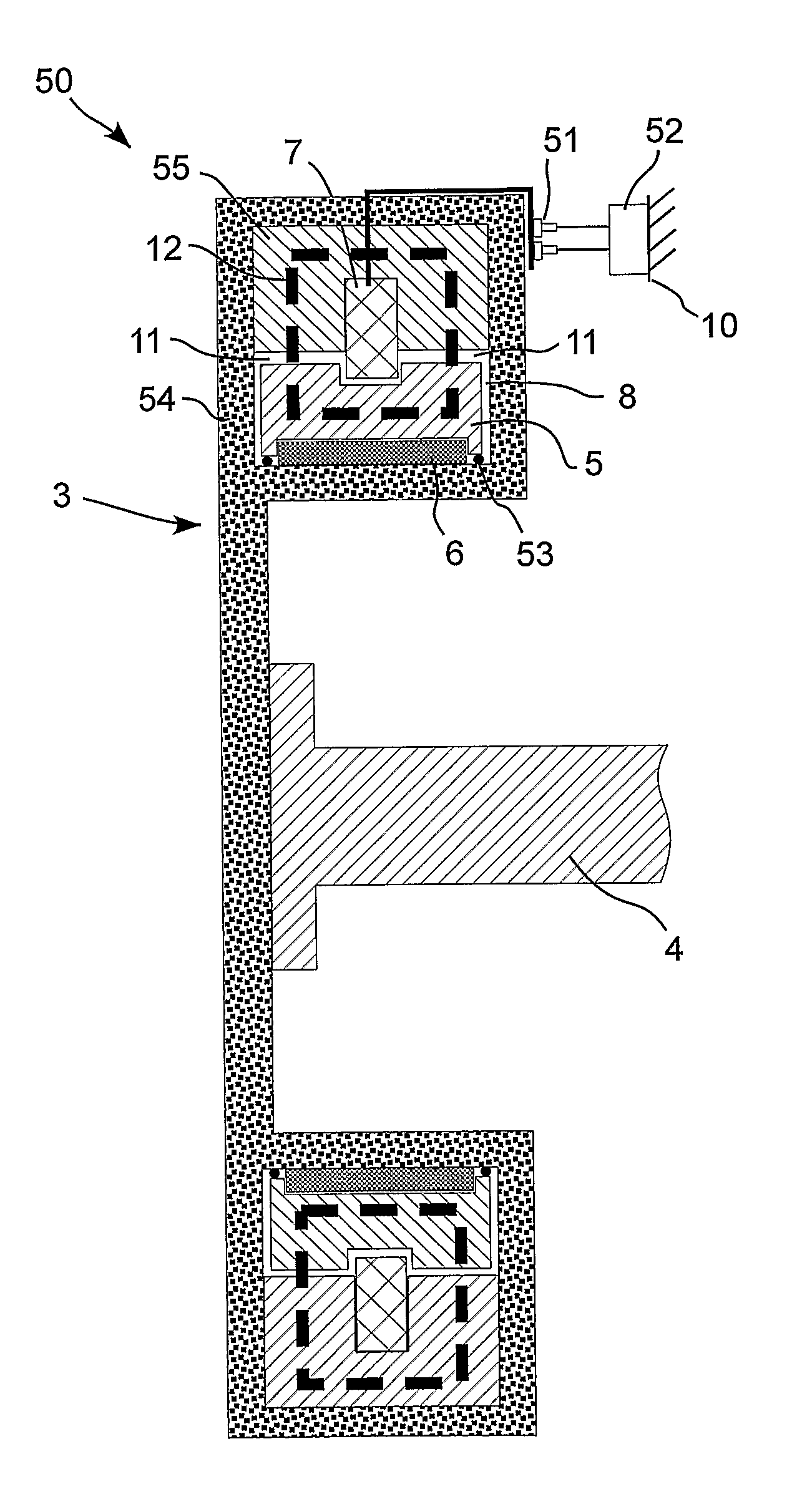

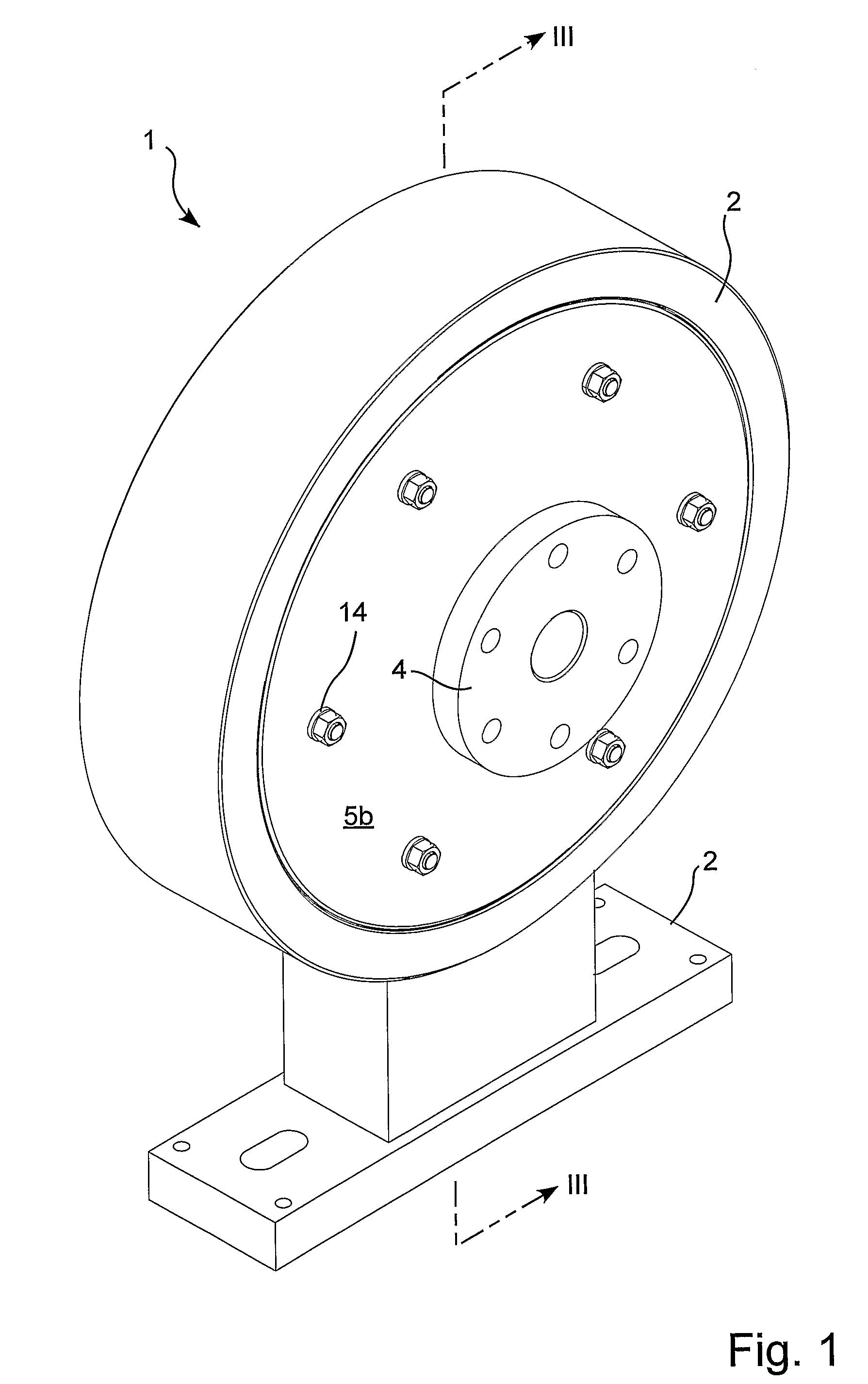

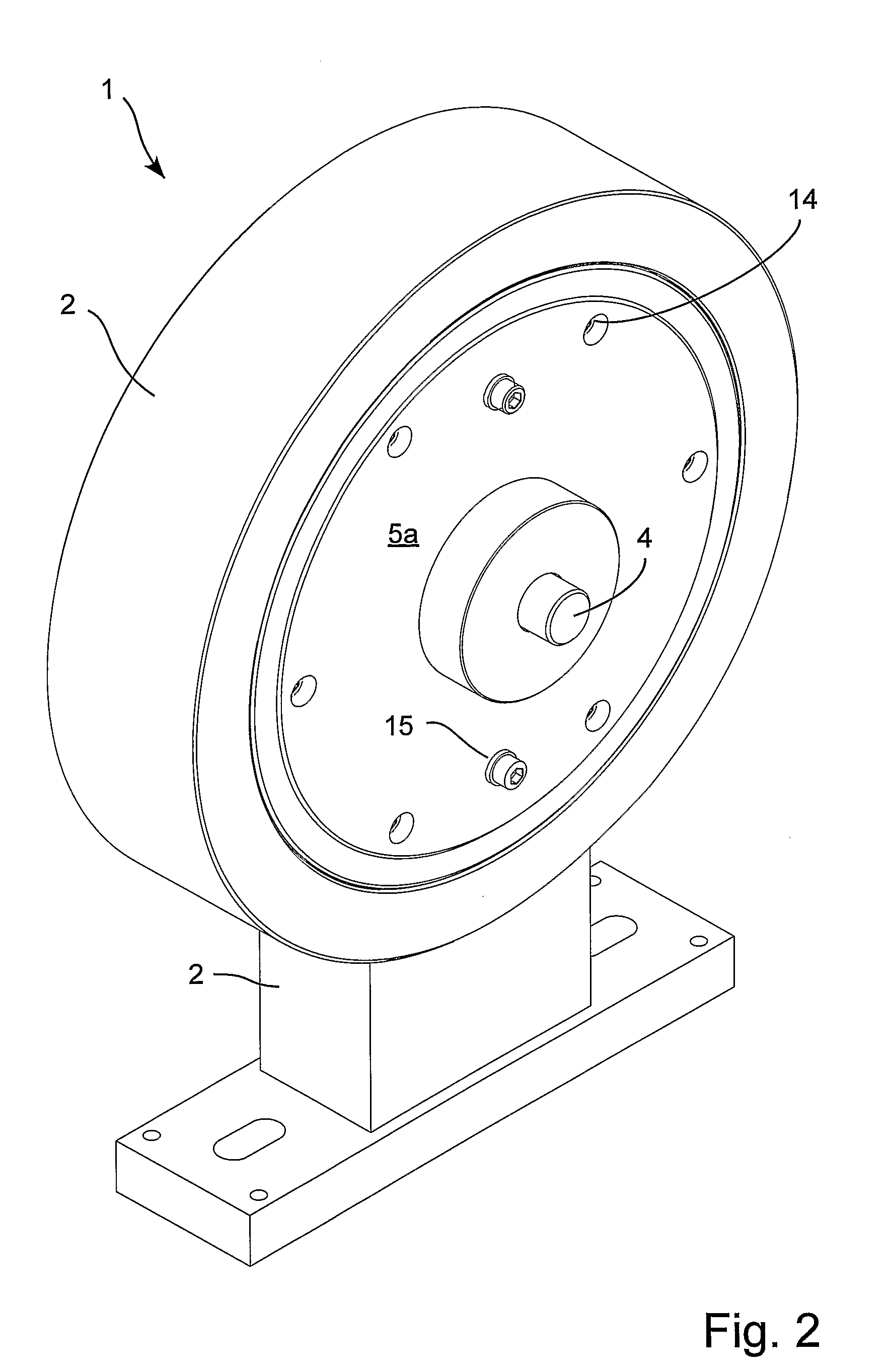

Torsional vibration damper

InactiveUS20090183959A1Improve the magnetic effectReduce power consumptionSpringsNon-rotating vibration suppressionMagnetorheological fluidEngineering

Torsional vibration damper which is suitable for dampening the motion of a rotatable element, said torsional vibration damper comprising an ‘actuation’ element which is connectable to the rotatable element, an ‘inertia’ element arranged co-axially and rotatably with said actuation element, an enclosed volume between said inertia element and said actuation element where a cross section through said enclosed volume taken on a plane which is parallel to the axis of the actuation element comprises at least one ‘axial’ portion which is arranged essentially parallel to the axis of the actuation element, an Electro-Rheological or a Magneto-Rheological fluid arranged at least in a part of said enclosed volume, and an electric or a magnetic field generator in the form of a coil which generates an electric or a magnetic field which passes through at least a portion of said enclosed volume. The field generator is integrated into the torsional vibration damper in such a way that a majority of the magnetic or electric field lines generated by the field generator pass through said ‘axial’ portion of said enclosed volume. In this way, an effective torsional vibration damper is provided.

Owner:DTU

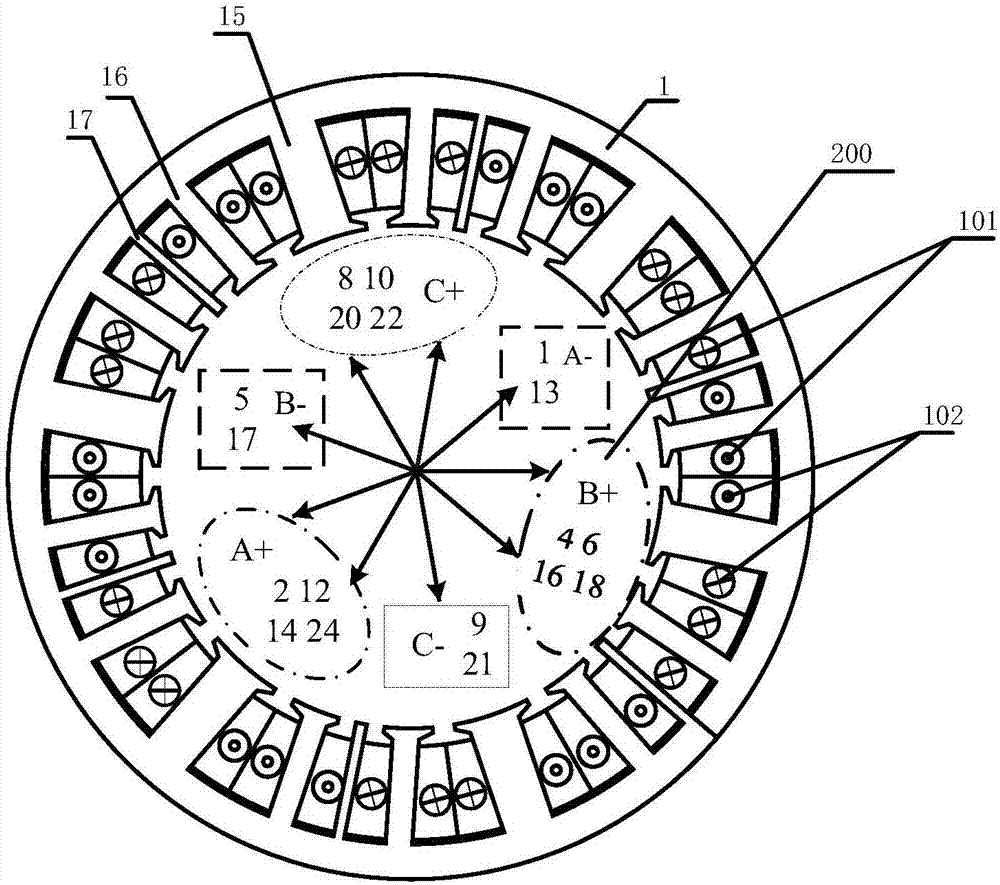

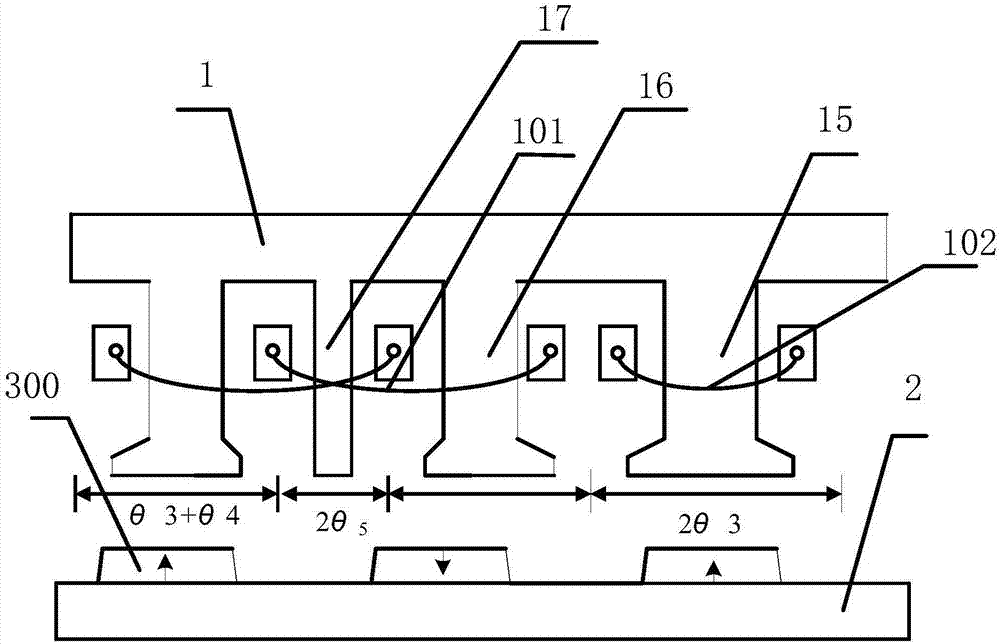

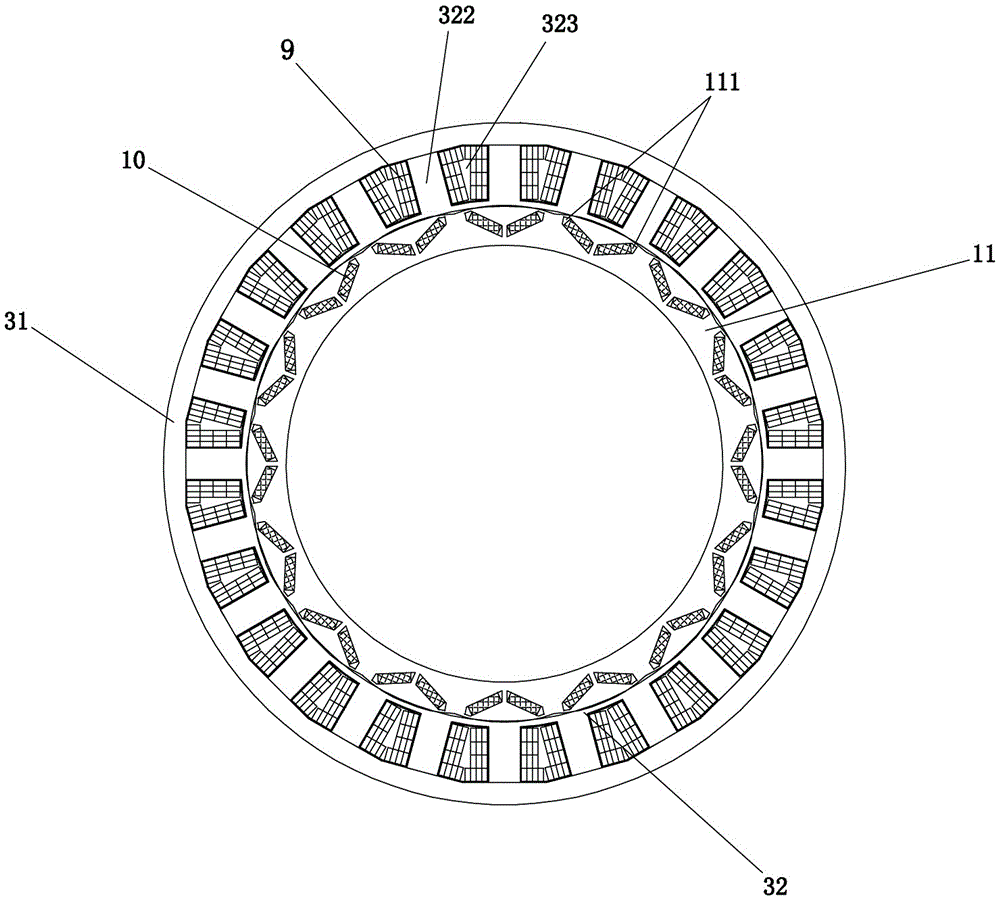

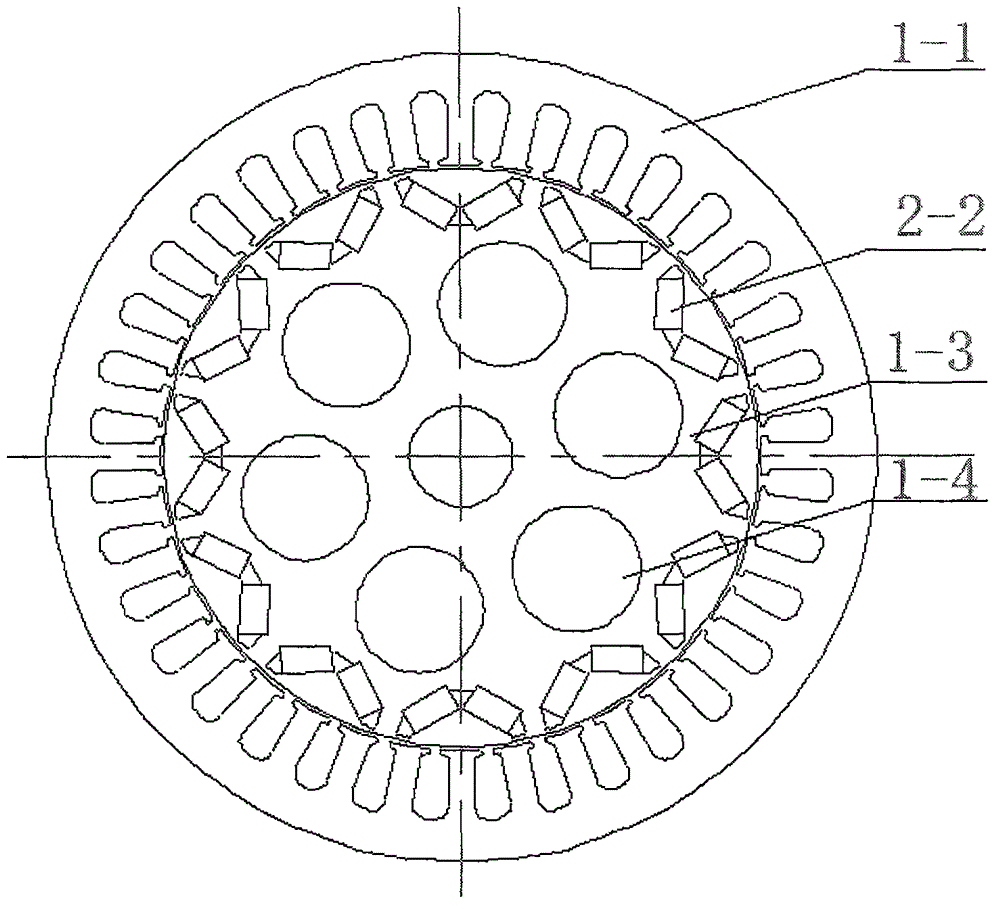

Low-vibration noise performance fractional slot concentrated winding permanent magnet motor and design method

ActiveCN107579606AReduce harmonic amplitudeReduce MMF tooth harmonicsMagnetic circuit stationary partsWindings conductor shape/form/constructionControl theoryConductor Coil

The invention discloses a low-vibration noise performance fractional slot concentrated winding permanent magnet motor and a design method, and belongs to the field of rotating motors. On the basis ofa motor matched with an existing notched pole, and some stator additional teeth are correspondingly added (the specific number of the teeth is determined according to the matched notched pole of the motor). For a three-phase 18 / 16 motor, six additional teeth are added, the position of each stator notch is calculated, and the winding structure adopts a concentrated winding structure corresponding to the three-phase 18 / 16 motor. The rotor structure adopts the common surface-mounted structure, and radial magnetizing is adopted; the motor has the advantages that the stator structure is changed, the content of tooth harmonic waves in the winding magnetomotive force in an air gap is lowered, therefore, the motor vibration and noise are lowered, and meanwhile the rotating torque of the motor is ensured. In addition, due to changes of the stator structure, the content of subharmonic waves of the magnetomotive force in the air gap is lowered, and then eddy-current losses generated in the permanent magnet are lowered. Accordingly, the motor has the great significance in motor body designing.

Owner:JIANGSU UNIV

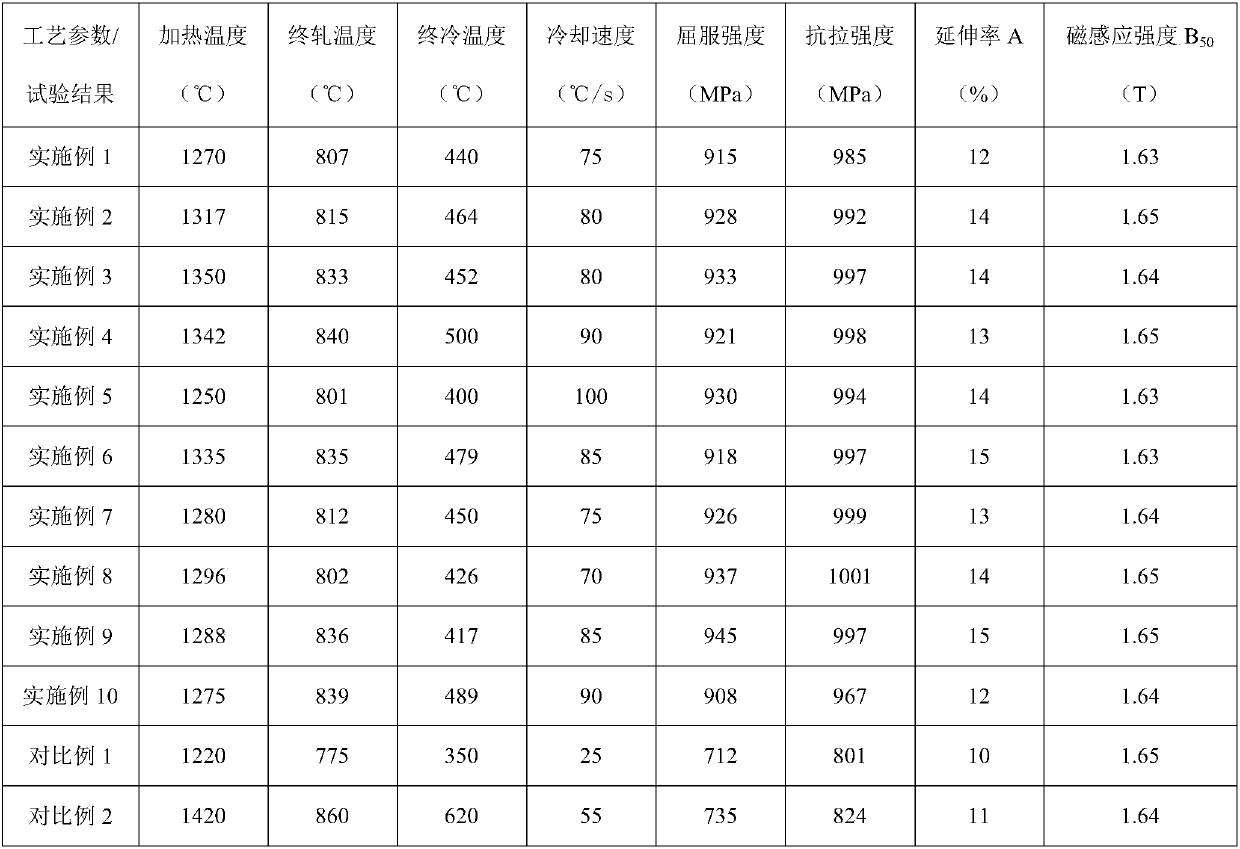

Super high strength magnet yoke steel and manufacturing method thereof

The invention discloses super high strength magnet yoke steel. The super high strength magnet yoke steel comprises, by weight percentage, 0.10-0.15% of C, smaller than or equal to 0.15% of Si, 1.85-2.00% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 0.20-0.30% of Ti, 0.05-0.07% of Nb, 0.35-0.55% of Mo, 0.001-0.003% of B, 0.02-0.10% of Als, smaller than or equalto 0.010% of N and the balance Fe and inevitable impurities. According to the super high strength magnet yoke steel, in order to further improve strength and effectively break through the extreme strength 700 MPa of steel of a ferritic structure, in a structure reinforcing manner, by adding a proper amount of bainite to form elements, in cooperation with a super fast cooling process, a bainite structure is obtained, and the super high strength magnet yoke steel is obtained.

Owner:武汉钢铁有限公司

Magnetic leakage type mechanical variable flux permanent magnet synchronous motor

InactiveCN104659996AEasy to adjustSimple manufacturing processSynchronous machine detailsMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention relates to a magnetic leakage type mechanical variable flux permanent magnet synchronous motor. The magnetic leakage type mechanical variable flux permanent magnet synchronous motor consists of a motor body and a mechanical magnetism regulation device. A mechanical transmission manner is adopted to achieve the purpose that the working magnetic field of the motor can be regulated, and the magnetic leakage type mechanical variable flux permanent magnet synchronous motor is a mechanical magnetism regulation permanent magnet synchronous motor which is applied to the driving fields of electric vehicles or hybrid electric vehicles.

Owner:JIANGXI UNIV OF SCI & TECH

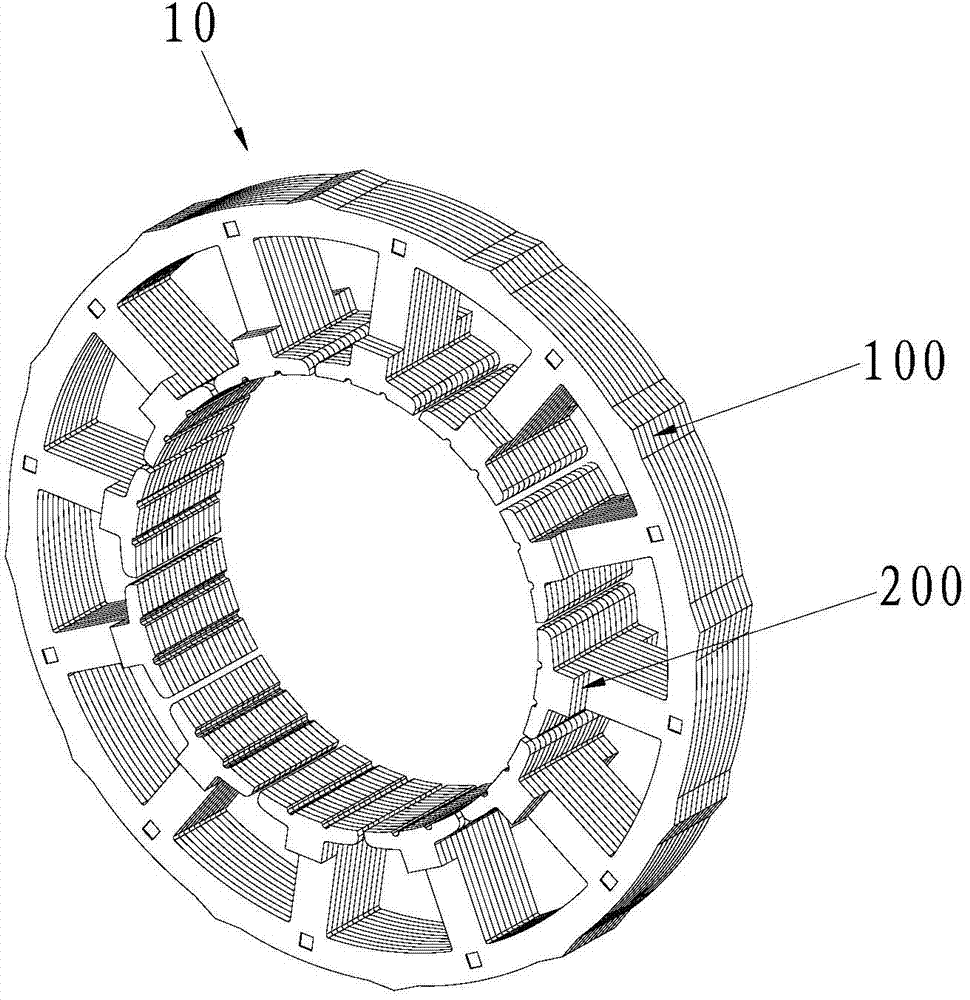

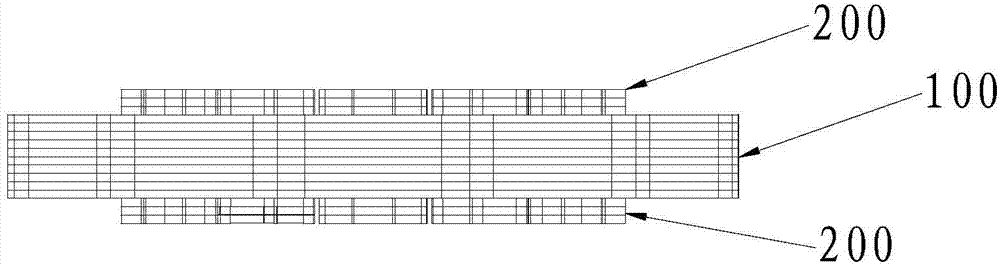

Motor stator iron core, motor stator, motor, and manufacturing method of motor stator

ActiveCN104734376AImprove performanceIncrease magnetic densityMagnetic circuit stationary partsManufacturing stator/rotor bodiesConductor CoilMagnet

The invention belongs to the technical field of motors and discloses a motor stator iron core, a motor stator, a motor and a manufacturing method of the motor stator. The motor stator comprises the motor stator iron core. The motor comprises the motor stator and the motor stator iron core. According to the motor stator iron core, one end or two ends of an iron core body are provided with tooth boot boss portions, the purpose of increasing the axial length of the motor stator iron core can be achieved, and the turn length of a winding is not increased; besides, the flux of a magnet on a rotor can be guided to stator teeth through the tooth boot boss portions, the magnetism gathering effect is better, the flux density of the stator iron core can be improved, the material utilization rate is higher, and the weight of the motor stator iron core is reduced. Meanwhile, the turn length of the winding of the motor stator is reduced, the weight of the winding is reduced, the length of the end of the motor is reduced, and the motor is high in performance and low in cost.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Preparation method of suspended packing bioreactor and application thereof

ActiveCN104609567AHigh speedImprove efficiencyWater contaminantsSustainable biological treatmentSlagUltraviolet

The invention provides a preparation method of a suspended packing bioreactor. The preparation method comprises the following steps: (1) uniformly mixing 0.2-0.6 part by weight of magnetic powder, 7-10 parts by weight of recycled rubber powder, 3-12 parts by weight of zeolite, 2-8 parts by weight of maleic anhydride, 0.2-0.8 part by weight of dicumyl peroxide, 0.5-2 parts by weight of chitin, 3-5 parts by weight of powdered coke and 1-2 parts by weight of slag powder, adding 70-75 parts by weight of high density polyethylene, and stirring at high speed; (2) adding the above mixed materials into a screw pelletizer and pelleting; (3) putting the pelleted particles into a screw extruder and carrying out extrusion molding, carrying out vacuum setting, cooling, carrying out mechanical holing, and carrying out cutting forming; and (4) finally irradiating the packing bioreactor by short wave ultraviolet. According to the invention, hydrophily of the suspended packing bioreactor is greatly enhanced, surface adsorbing capacity is increased, biofilm adsorption strength is raised, biofilm culturing period is shortened, and the biofilm is not easy to fall off. The suspended packing bioreactor is suitable for processing low concentration organic wastewater and phenolic wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

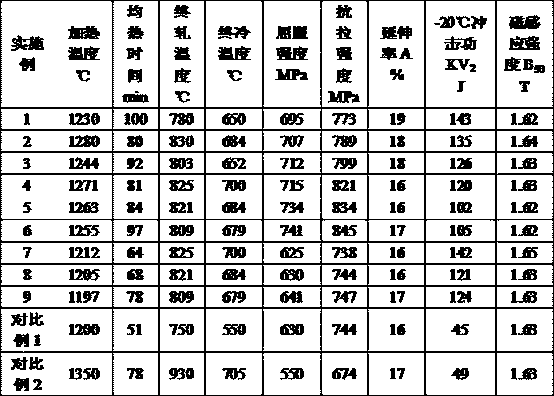

High-strength and high-toughness hot-rolled magnet yoke steel with yield strength greater than or equal to 650 MPa and production method

A high-strength and high-toughness hot-rolled magnet yoke steel with yield strength greater than or equal to 650 MPa comprises the following components in percentage by weight: 0.01-0.03% of C, less than or equal to 0.15% of Si, 1.45-1.75% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.04-0.08% of Ti, 0.01-0.02% of Nb, 0.02-0.10% of Als, and less than or equal to 0.010% of N. The production method comprises the following production steps: pouring after molten iron desulphurization, converter combined blowing and vacuum treatment; heating slabs; roughly rolling; precisely rolling; carrying out laminar cooling; and coiling. The yield strength of the magnet yoke steel is greater than or equal to 650 MPa, the tensile strength is greater than or equal to 750 MPa, the elongation is greater than or equal to 13%, the impact energy KV2 is greater than or equal to 80 J at the temperature of minus 20 DEG C, the magnetic induction performance B50 is greater than or equal to 1.50 T, and requirements of high-strength and high-magnetic-induction-performance steels for high-unit-capacity ultra-large hydro-generator rotor magnet yokes can be met.

Owner:武汉钢铁有限公司

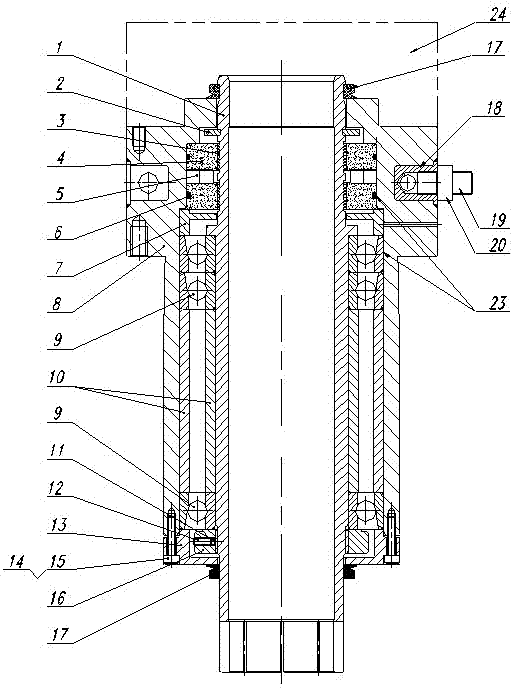

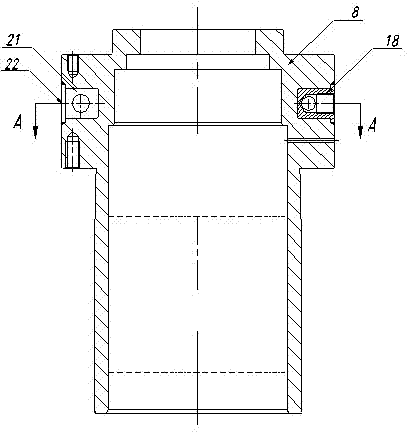

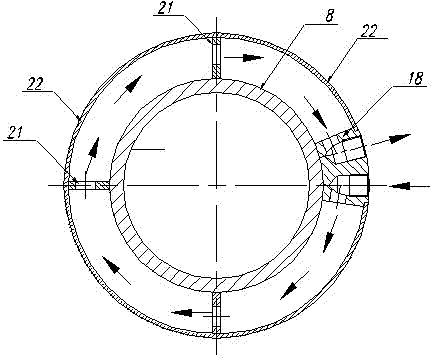

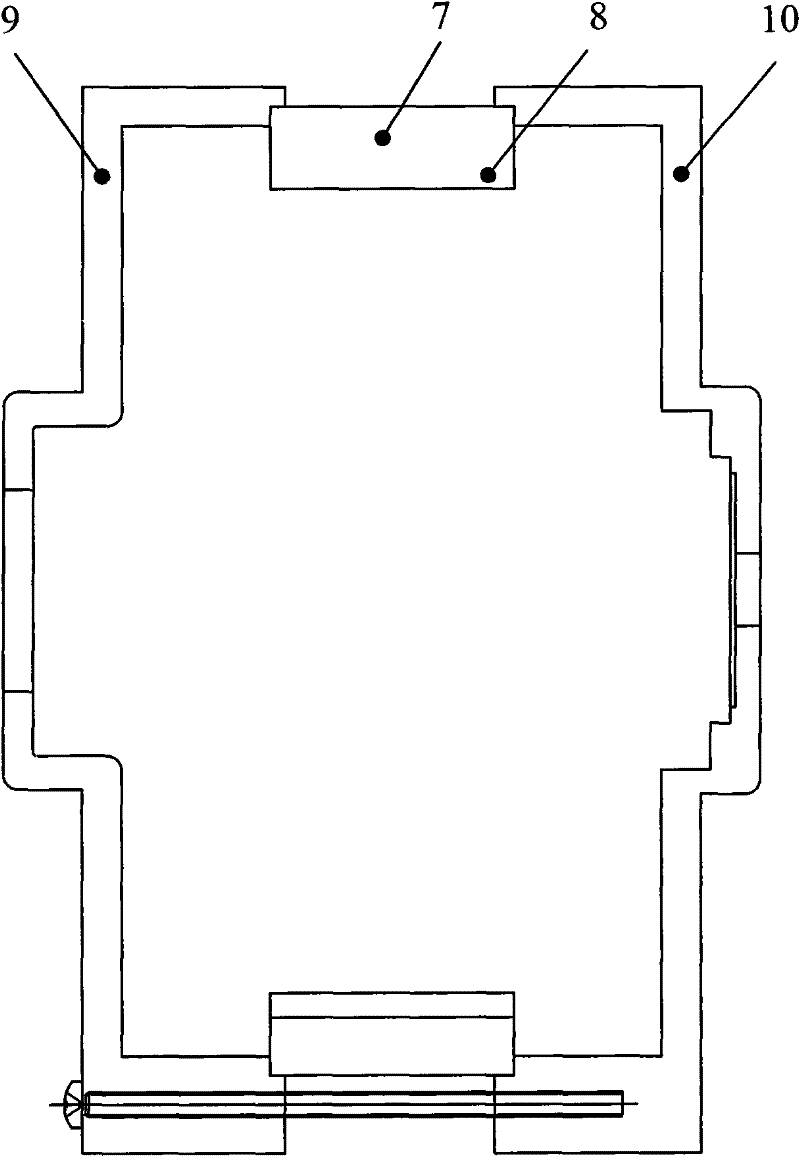

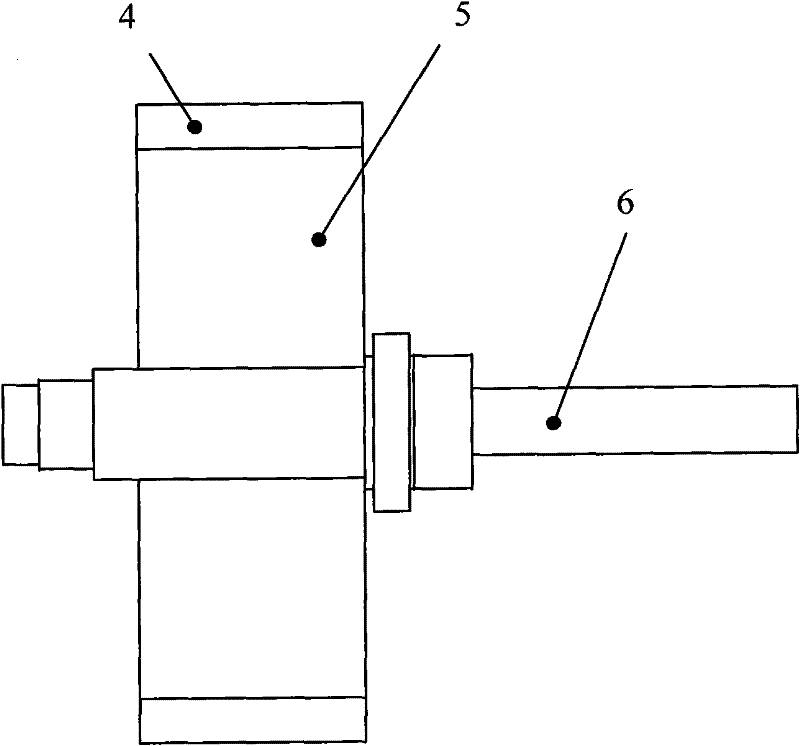

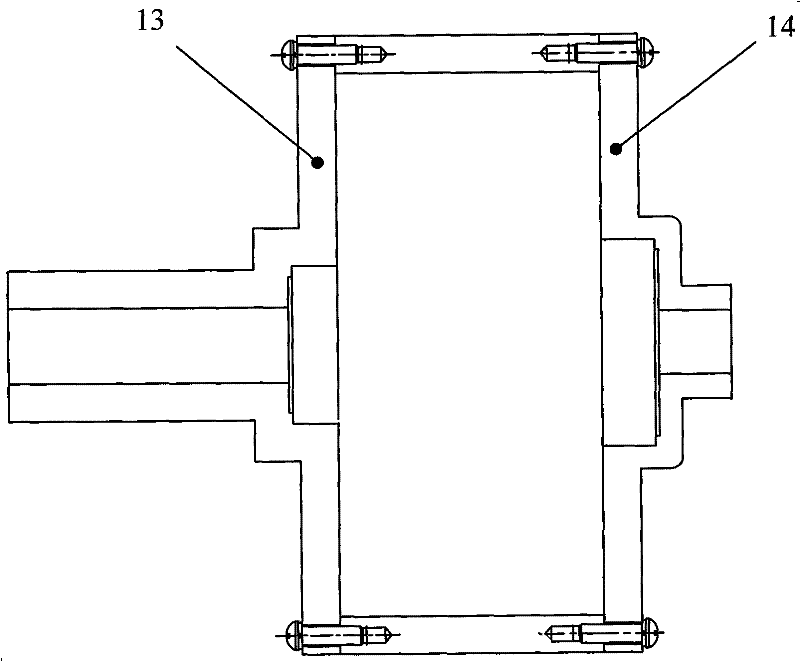

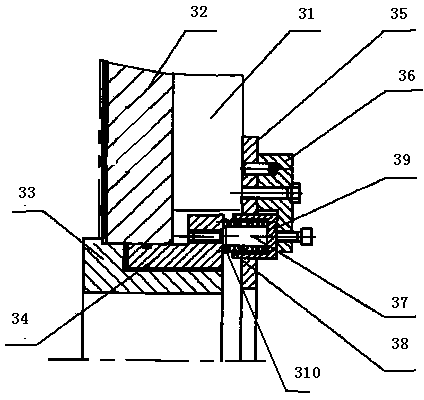

Sealing device for transmission input shafts in vacuum environment and using method of sealing device

InactiveCN102927283AReduce heat damageImprove the magnetic effectEngine sealsBall bearingMagnetic poles

The invention discloses a sealing device for transmission input shafts in a vacuum environment and a using method of the sealing device. The sealing device comprises a transmission input shaft, elastic shaft check rings, magnetic liquids, magnetic poles, magnets, O-shaped rings, special-made gaskets, outer casings, angular contact ball bearings, pairing ferrules, locking blocks, set screws with flat points, end caps, hexagon socket head cap screws, glue, lock nuts, V-shaped oil seals, a four-way connection block, a water outlet connector, a water inlet connector, a water delaying baffle block, outer water channel ferrule pieces and oil, wherein an oil seal limiting groove, check ring shaft grooves, magnetic liquid chambers, shaft shoulders, locking threads and equal division shaft kerfs are arranged on the transmission input shaft. According to the sealing device, novel magnetic fluid materials are applied for vacuum seal, a water cooling system is applied for cooling, by means of the sealing device, thermal damage is reduced in thermal field environments, magnetic effects of magnetism work pieces are improved, the vacuum sealing performance is good, and the sealing device can be used in vacuum sealing devices with higher vacuum requirements.

Owner:浙大新剑(上海)智能技术有限公司 +1

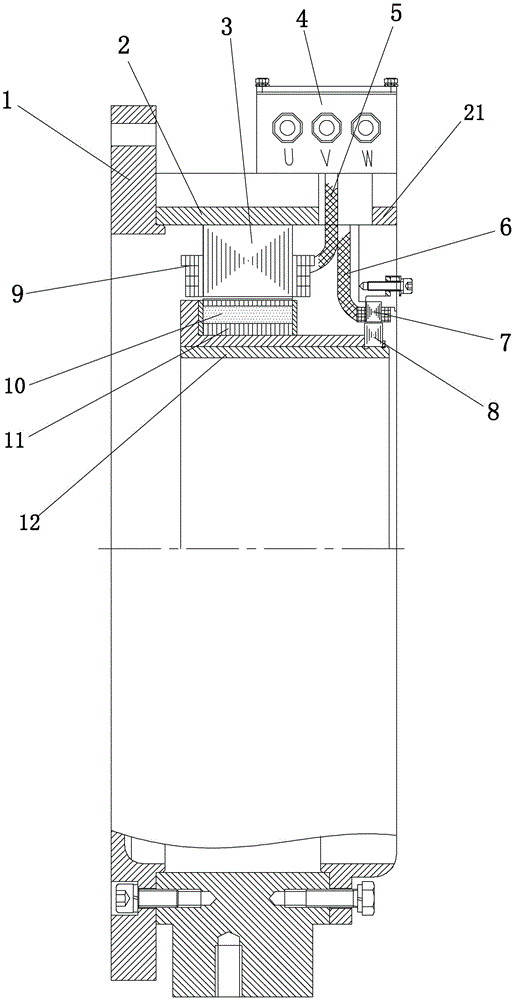

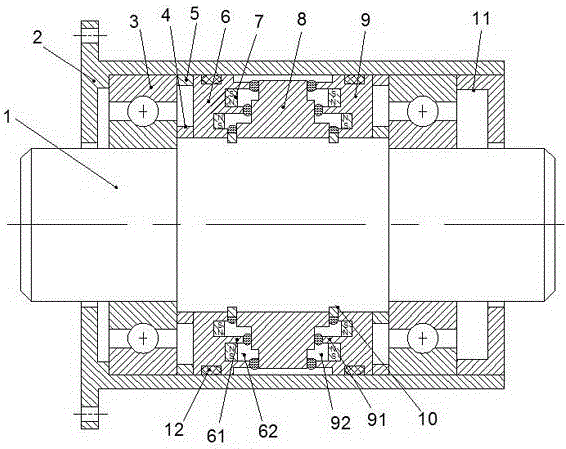

Built-in high-power-density permanent magnet motor integrated to 8AT transmission box

InactiveCN105634157AReduce torque rippleReduce harmonic lossMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingElectric machine

The invention discloses a built-in high-power-density permanent magnet motor integrated to an 8AT transmission box. The built-in high-power-density permanent magnet motor comprises a transmission box flange, a transmission box housing, a built-in permanent magnet motor stator, a rotor and a transmission box hub, wherein the transmission box flange is connected to the left end of the transmission box housing; a back end cover of the transmission box housing is arranged at the right end of the transmission box flange; the motor stator is arranged on the inner wall of the transmission box housing; a flat wire forming winding is arranged on the motor stator; the rotor is arranged on the transmission box hub; rotor magnetic steel is arranged in the rotor; the flat wire forming winding is connected with a wire outlet box; a rotary transformer rotor is arranged on the transmission box hub; a rotary transformer stator is arranged on the back end cover of the transmission box housing; the rotary transformer stator is connected with the wire outlet box; each stator punching sheet adopts a structure that a stator yoke and stator teeth are separated first and then combined; the stator punching sheet is a closed slot without teeth harmonics; and the rotor adopts a V-shaped insertion type magnetic steel structure and a cosine air gap design, so that the magnetism gathering is remarkable. The built-in high-power-density permanent magnet motor is novel in structure, can generate vibration and is small in noise, small in loss and high in efficiency.

Owner:FUJIAN YANAN ELECTRIC MACHINE

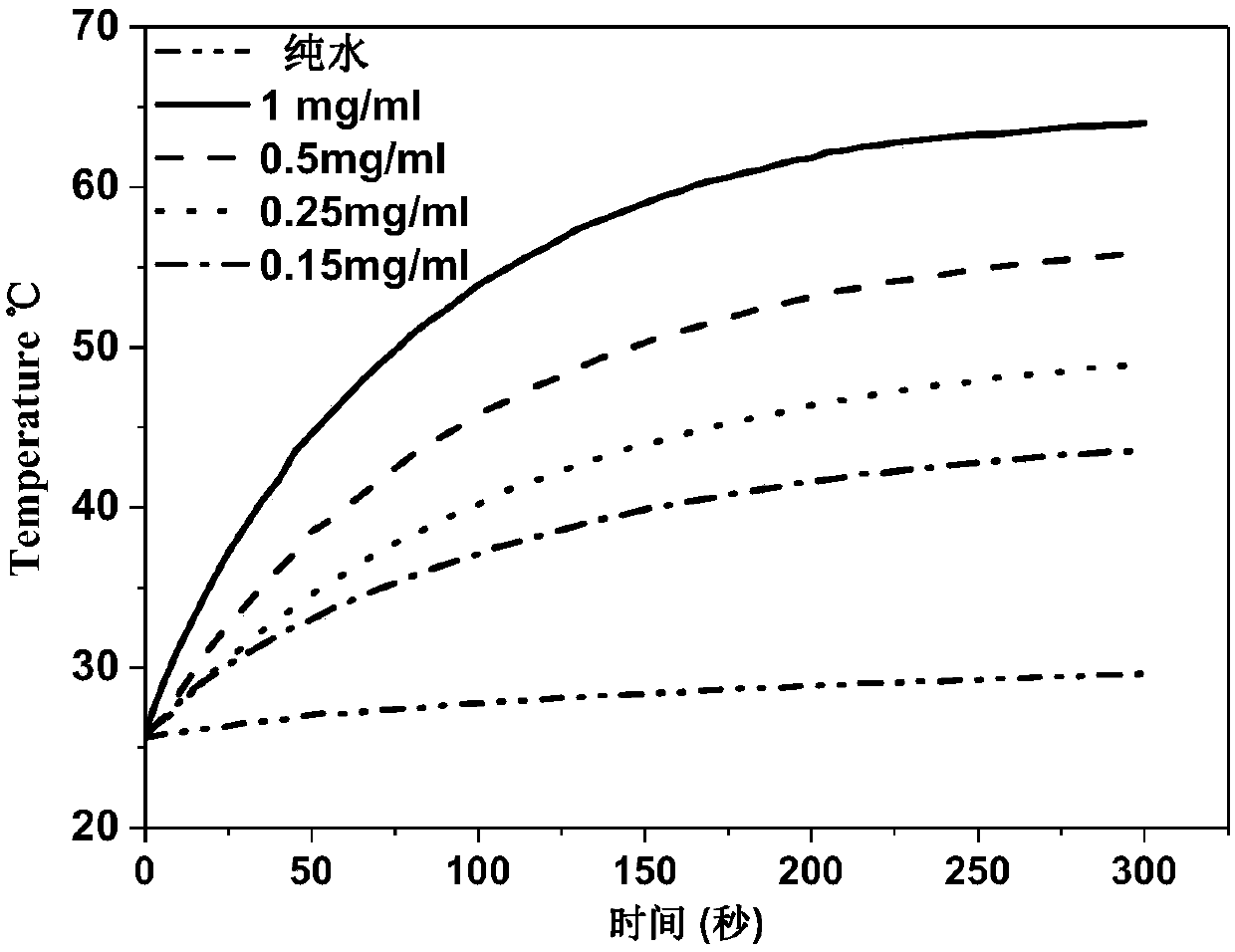

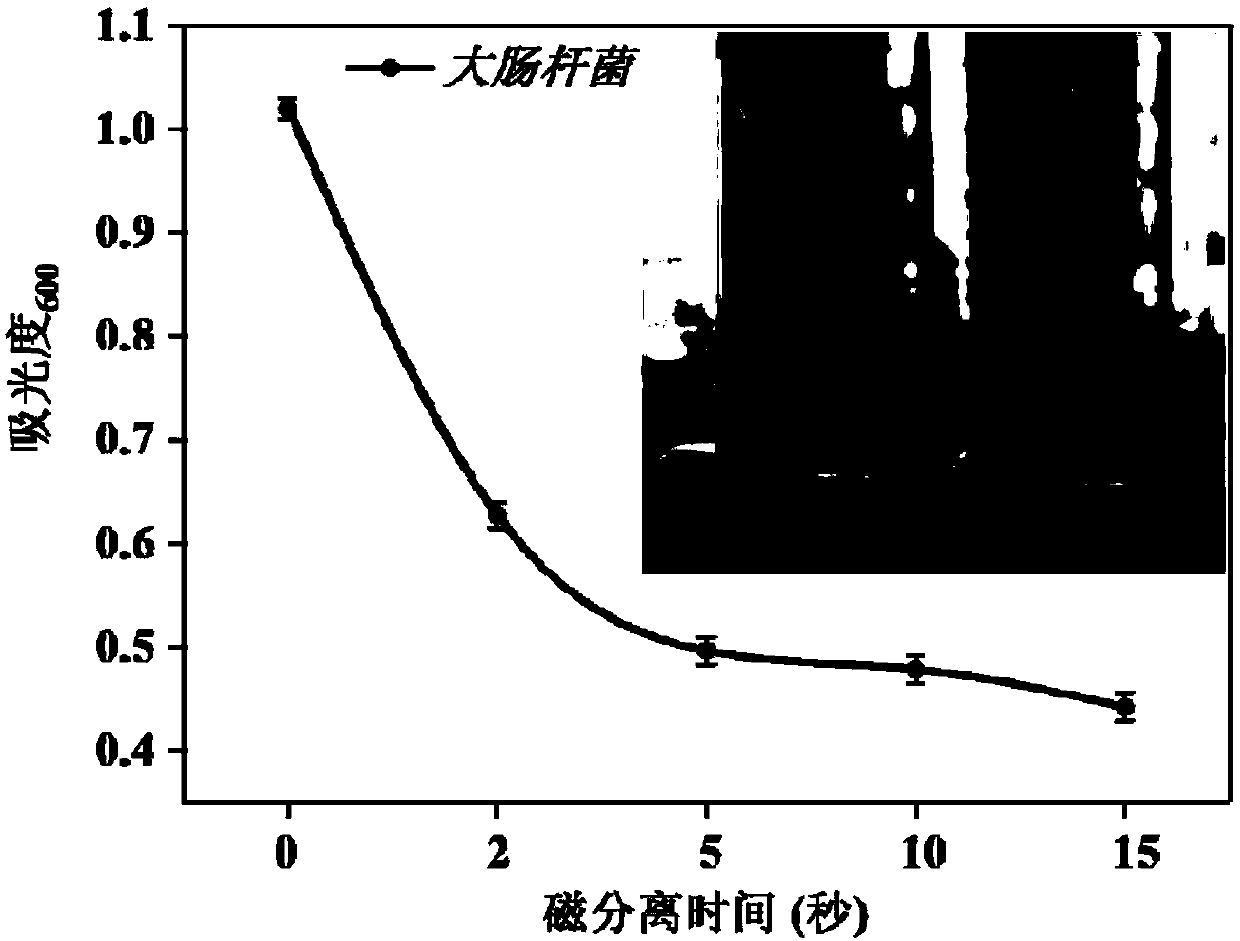

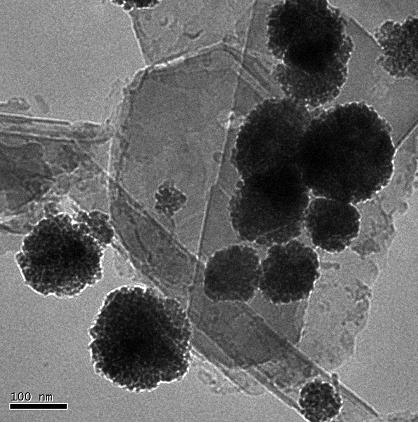

Magnetic material with nitric oxide/photo-thermal synergic antibacterial function as well as preparation method and application of magnetic material

ActiveCN107812188AQuick releaseEasy to separateAntibacterial agentsAntimycoticsMagnetic effectNitric oxide

The invention discloses a magnetic material with a nitric oxide / photo-thermal synergic antibacterial function as well as a preparation method and an application of the magnetic material. The preparation method comprises the following steps: firstly, synthesizing Fe3O4 granules which are uniform in particle size and remarkable in magnetic effect by using a hydrothermal method; modifying the surfaceof Fe3O4 by a layer of poly-dopamine PDA with a remarkable photo-thermal effect; and finally by taking a great amount of amino groups on the surface of the poly-dopamine as initial points, enabling methyl acrylate and ethidene diamine to react alternatively to prepare a structure with ferroferric oxide as a core, poly-dopamine as a middle part and twig-shaped polyamide-amino Fe3O4@PDA@PAMAM as anoutermost layer, and further loading nitric oxide, thereby obtaining the magnetic material with the nitric oxide / photo-thermal synergic antibacterial function. By adopting the magnetic material, sterilization can be achieved by heat generated through near-infrared radiation, and rapid NO (Nitric Oxide) release is promoted, photo-thermal synergic sterilization is achieved, and furthermore bacteriaare rapidly separated through magnetic iron oxide, so that the sterilization and purification effect is further improved.

Owner:JINAN UNIVERSITY

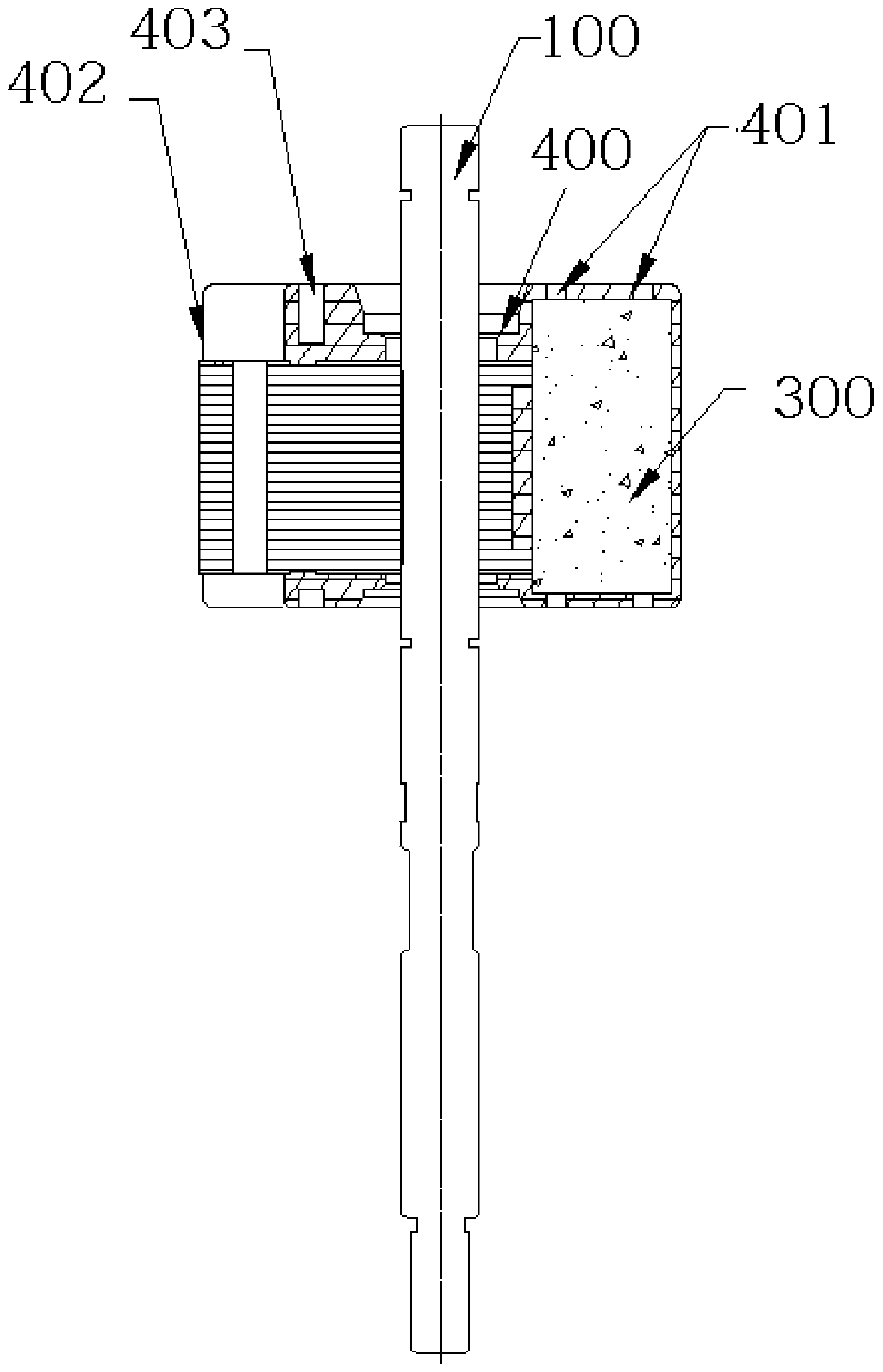

Rotor and motor

ActiveCN110277847AImprove the magnetic effectPrecise positioningMagnetic circuit rotating partsEngineeringMagnet

The invention relates to the electromechanical field, and discloses a rotor and a motor. The rotor comprises a rotating shaft (100), a magnet (300), a rotor core (200), a plastic-coated part (400) used for coating the rotor core (200), wherein at least part of the rotor core (200) is exposed from the plastic-coated part, thereby facilitating the improvement of the magnetism gathering ability of the rotor, being capable of reducing the plastic consumption of the plastic-coated part, and improving the performance of the plastic-packaged rotor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

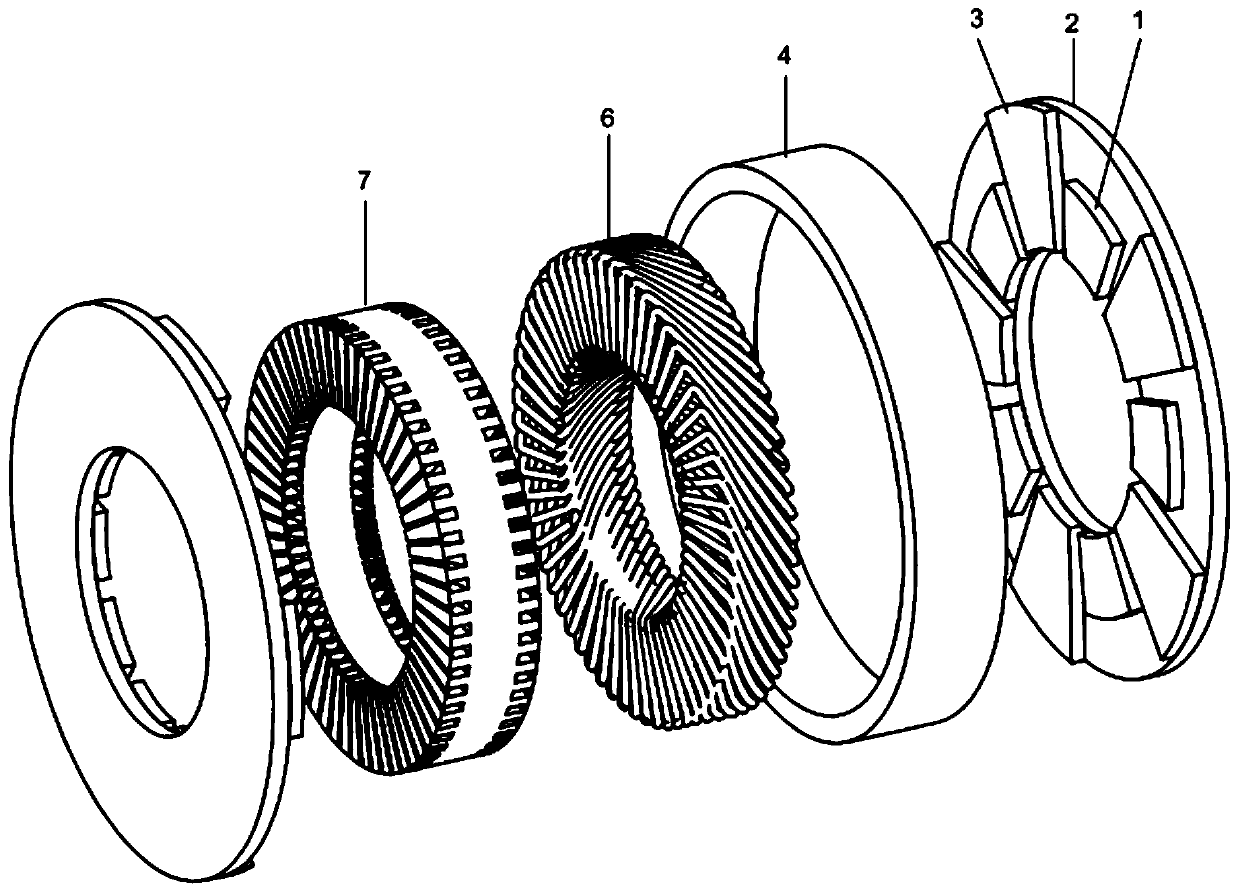

Combined magnetizing type permanent magnet built-in rotor of axial magnetic field permanent magnet motor

ActiveCN111541325AIncrease the main fluxReduce Flux LeakageMagnetic circuit rotating partsElectric machineryMagneto

The invention discloses combined magnetizing permanent magnet built-in rotor of an axial magnetic field permanent magnet motor. The rotor structurally comprises two rotor discs installed on a rotatingshaft, the first rotor disc comprises a rotor iron core, permanent magnets, a rotor supporting shell and a rotor back yoke, the permanent magnets comprise the first permanent magnet and the second permanent magnet, and the rotor iron core comprises a rotor outer iron core and a rotor inner iron core; the rotor back yoke is installed on the rotor supporting shell, and the first permanent magnets and the second permanent magnets are alternately and evenly arranged on the rotor back yoke in the circumferential direction. The rotor core is fixed to the second permanent magnets arranged on the rotor back yoke together so as to keep the permanent magnets fixed in the radial direction and the axial direction; the rotor iron core, the permanent magnets, the rotor supporting shell and the rotor back yoke are fixed together to form the first rotor disc which is installed on the rotating shaft, and then the first rotor disc is connected with the second rotor disc through the rotating shaft to fix the position of the second rotor disc in the axial direction to form a double-rotor structure. The permanent magnet rotor is good in magnetism gathering effect, high in air gap flux density and large in reluctance torque.

Owner:NANJING UNIV OF SCI & TECH

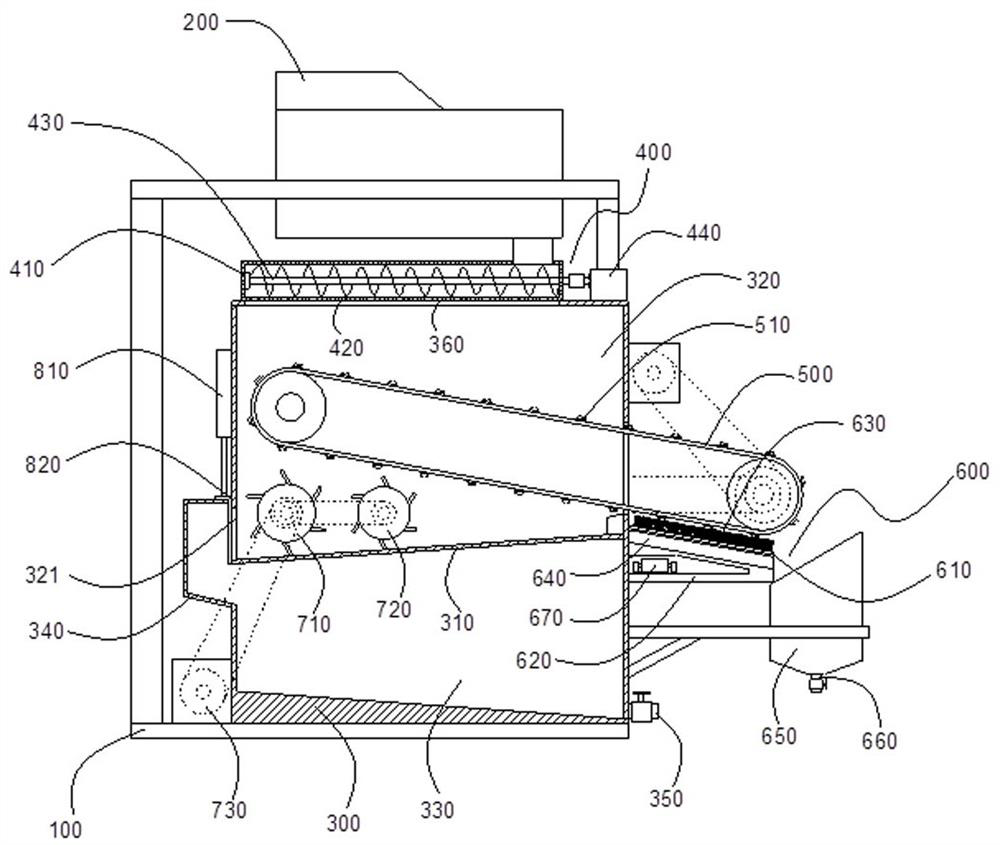

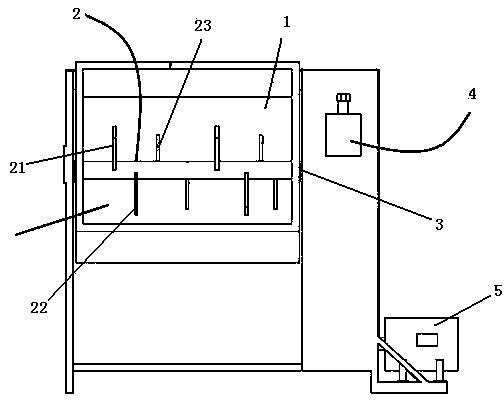

Rare metal powder preparation equipment

InactiveCN111701836ANovel structureImprove the magnetic effectSievingGas current separationIron removalEngineering

The invention provides rare metal powder preparation equipment which comprises a grinding machine and an iron removing device. The iron removing device comprises a box body, the inside of the box bodyis divided into an iron removing chamber and a storage chamber, a discharge opening is formed in one side with the lower inclination of the bottom of the iron removing chamber, an automatic gate is arranged on the outer side of the discharge opening, and a feeding hopper corresponding to the discharge opening is arranged in the storage chamber in a communicating mode. A spiral feeding machine isarranged outside a feeding port at the top of the iron removing chamber, and a feed inlet of the spiral feeding machine communicates with a discharging outlet of the grinding machine. A conveying beltis arranged at the position of the iron removing chamber in an inclined mode, one side of the end with the lower inclination of the conveying belt is located on the outer side of the box body, the conveying belt is of a mesh belt structure, a plurality of soft magnetic strips are arranged on the outer wall surface of the conveying belt, and a cleaning structure for cleaning and collecting scrap iron is arranged below the bottom of the end with the lower inclination of the conveying belt. By means of the equipment, metal powder can be subjected to scrap iron adsorption cleaning, scrap iron adhering to a cleaning piece is removed, and a good adsorption effect is maintained, so that continuous iron removal work is carried out, and the working efficiency is improved.

Owner:QINGYUAN JIAHE RARE METAL CO LTD

Immobilized enzyme for magnetic nanometer clay carrier and regenerating method thereof

InactiveCN102649954AImprove magnetic strengthVector regeneration method is simple and easyOn/in inorganic carrierTriethoxysilanePhysical chemistry

The invention relates to an immobilized enzyme for a magnetic nanometer clay carrier. The immobilized enzyme comprises a carrier with saccharifying enzyme and corresponding immobilized enzyme as immobilizing objects. The immobilized enzyme is prepared by taking a covalence coupling method as an immobilizing method and is characterized in that: the carrier is a magnetic nanometer Fe3O4@ clay compound material; the magnetic nanometer Fe3O4@ clay compound material is composed of magnetic Fe3O4 nanometer grains and a nanometer clay material; and the magnetic Fe3O4 nanometer grains are assembled on the nanometer clay in sequence. A superparamagnetic Fe3O4@ clay compound material is prepared by adopting a solvent heat method according to the invention; the surface of the Fe3O4@ clay compound material is modified by using gamma-aminopropyl triethoxy silane, and then glutaraldehyde is used as a coupling agent for covalently fixing the saccharifying enzyme on the surface of the carrier; two novel carrier regenerating strategies are designed; after the saccharifying enzyme is immobilized by the regenerated carrier, the excellent properties, such as original activity, thermal stability and reusability, of the immobilized enzyme are still maintained; and the immobilized enzyme is also suitable for the regeneration of the immobilized enzyme carrier according to the covalence coupling method.

Owner:LANZHOU UNIVERSITY

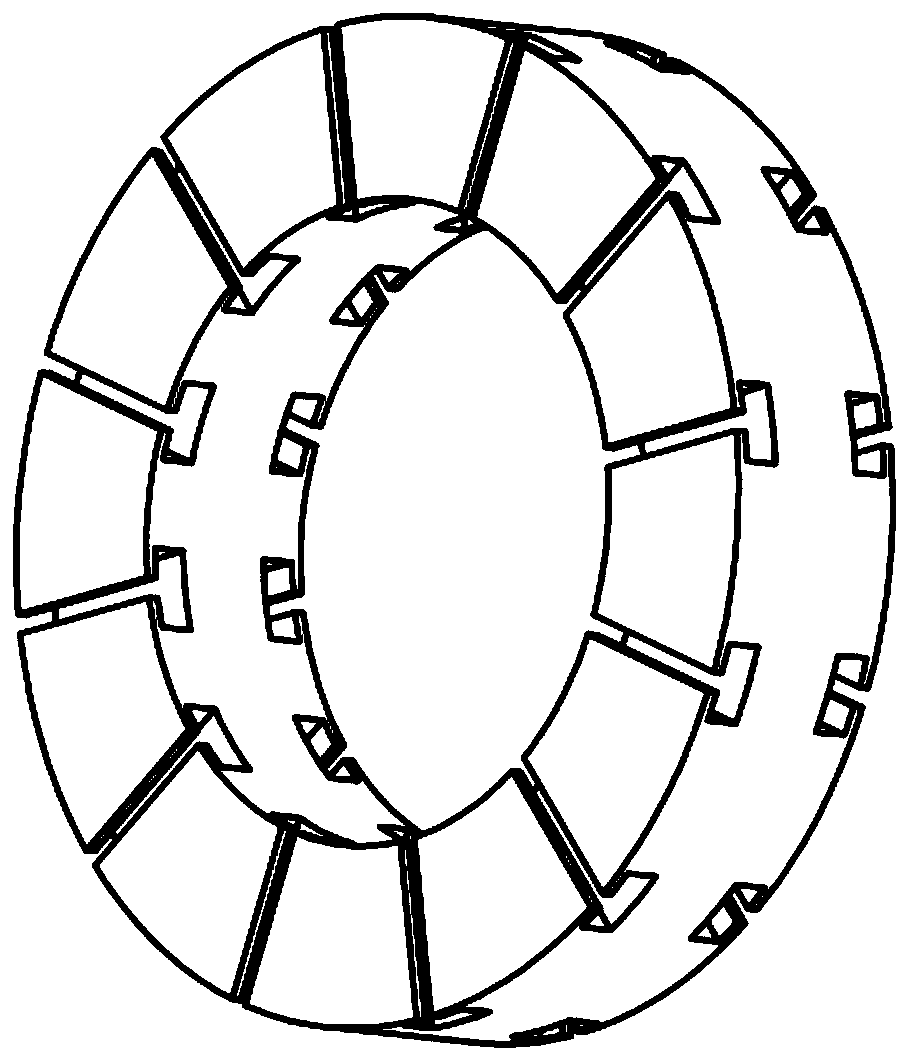

Magnetic field modulation type magnetic gear

ActiveCN102195442AAchieve torque transmissionHigh mechanical strengthDynamo-electric gearsNon magneticMagnetic loop

The invention discloses a magnetic field modulation type magnetic gear which is characterized by comprising an outer stator and an inner rotor, wherein an annular cavity is formed between the outer stator and the inner rotor, an adjustable magnet ring is arranged in the annular cavity, the outer stator consists of an outer stator iron core and 2N2 permanent magnets, and the polarities of the adjacent permanent magnets are opposite; the inner rotor consists of an inner rotor iron core and 2N1 permanent magnets, and the polarities of the adjacent permanent magnets are opposite; the inner rotor and the outer stator are connected through an output shaft; and the adjustable magnet ring is formed by arranging N1+N2 iron core blocks and N1+N2 non magnetic-conducting blocks into a ring shape in astaggered mode, and the adjustable magnet ring is connected with the output shaft of the adjustable magnet ring. Compared with the prior art, the magnetic gear provided by the invention has the following obvious protrude substantiality characteristic and outstanding advantages: the mechanical strength is increased, the volume is reduced, and the torque ripple is optimized.

Owner:NINGBO TIANAN MAGNETIC TRANSMISSION TECH CO LTD

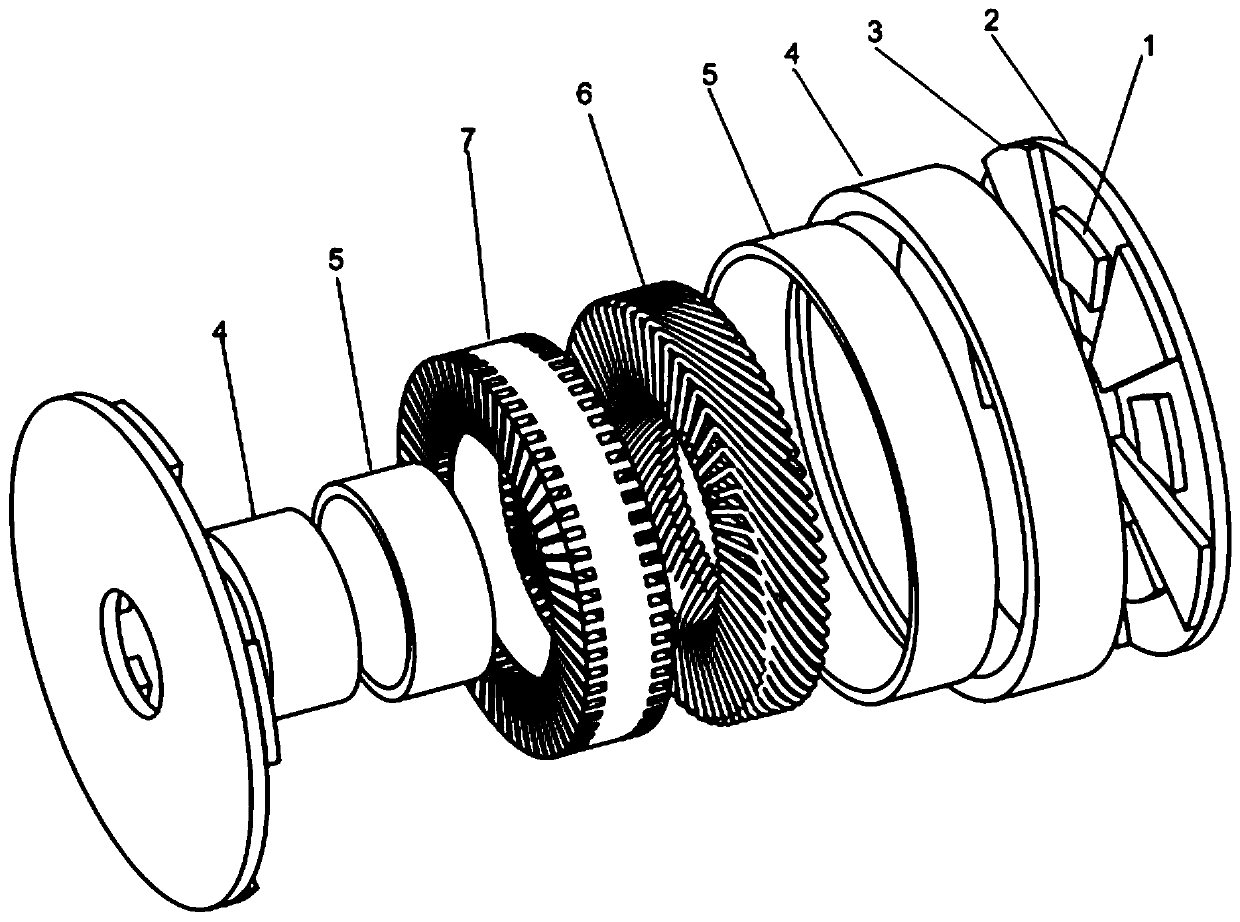

Axial magnetic flux concentrated winding type hybrid excitation motor

ActiveCN110460175AReduce electricity lossReduced risk of demagnetizationMagnetic circuit rotating partsSynchronous machine detailsElectric machineMagnetic poles

The invention diskloses an axial magnetic flux concentrated winding type hybrid excitation motor. The motor includes a stator disk and two rotor disks, wherein the stator disk includes a stator core,an armature winding, an exciting winding and a magnetic ring, the rotor disks respectively include a rotor back yoke, a magnetic pole block and a permanent magnet, left and right sides of the stator core of the stator disk are provided with stator slots, the armature winding is installed on a magnetic yoke of the stator core, two rotor disks are arranged on both sides of the stator disk, the number of rotor poles matches the number of the stator slots to form a concentrated winding motor structure, the permanent magnets and the magnetic pole blocks are alternately installed on the rotor disks,the two rotor disks are staggered and installed on both sides of the stator disk, the magnetic pole blocks extend outward in the radial direction and form an additional air gap of an excitation fieldin the axial direction with the magnetic ring on the stator core. The motor is advantaged in that the motor has high power density and wide magnetic field adjustment range, and has important application prospects in electric vehicle driving systems, hybrid power generation systems and aviation electric propulsion systems.

Owner:NANJING UNIV OF SCI & TECH

Anisotropic flexible magnetic stripe suitable for magnetism health

ActiveCN103745797AExcellent magnetic propertiesImprove flexibilityPermanent magnetsInorganic material magnetismMagnetic powderCorrosion

The invention relates to the field of magnetic materials, in particular to an anisotropic flexible magnetic stripe suitable for magnetism health. The anisotropic flexible magnetic stripe is prepared through the following steps in sequence: preparation of gyromagnetic ferrite powder: pre-sintering a gyromagnetic ferrite blank by using microwaves, and smashing to obtain the gyromagnetic ferrite powder; pre-magnetization and microwave pelletizing: uniformly mixing rare earth compound permanent magnetic powder and the gyromagnetic ferrite powder treated by using anti-rust oil together with 4-15 parts of bonding agent, 1-5 parts of heat stabilizer, 0.5-2 parts of coupling agent and 0.2-0.8 part of antioxidant solution, pre-magnetizing, and performing microwave vacuum drying to form agglomerated magnetic particle clusters; performing primary calendering; magnetic field orientation: cutting a primarily-calendered flexible magnet into magnetic stripes, heating, preserving heat, and performing heat tracing magnetic field orientation; secondary calendering: performing secondary calendering on the magnetic field-orientated magnetic stripes at 30-40 DEG C. The prepared magnetic stripe is excellent in performance and higher in ageing resistance and corrosion resistance.

Owner:HEYE HEALTH TECH CO LTD

Stepped end face type magnetic fluid sealing device

The invention relates to the field of mechanical engineering sealing, in particular to a stepped end face type magnetic fluid sealing device. The stepped end face type magnetic fluid sealing device comprises a housing, a left pole shoe, a middle pole shoe, a right pole shoe and permanent magnets, wherein the middle pole shoe is installed in the middle of a shaft, and step structures are symmetrically arranged on the left side and the right side of the middle pole shoe in the radial direction. The left pole shoe is installed on the left side of the middle pole shoe, the right pole shoe is installed on the right side of the middle pole shoe, pole teeth I and an annular groove I are arranged on the right end face of the left pole shoe, the pole teeth I correspond to the step side face of the left end of the middle pole shoe, and the annular groove I is formed among the pole teeth I. Pole teeth II and an annular groove II are arranged on the left end face of the right pole shoe, the pole teeth II correspond to the step side face of the right end of the middle pole shoe, and the annular groove II is formed among the pole teeth II. The permanent magnets are installed in the annular groove I and the annular groove II. The sealing device has good sealing properties and can meet the using requirements of working conditions including large gap, high speed, heavy load and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

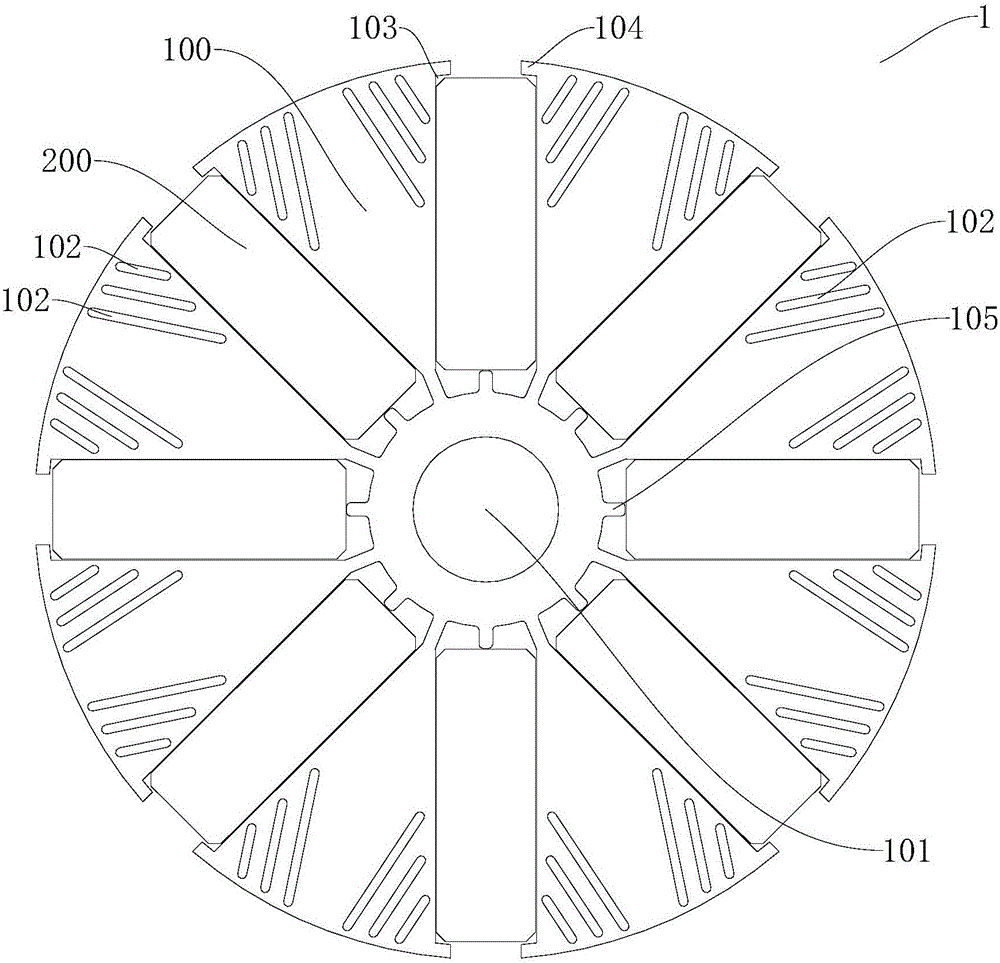

Rotor for motor and motor with rotor

ActiveCN106100177AImprove the magnetic effectExcellent air gap magnetic field distributionMagnetic circuit rotating partsMagnetMagnetic field

The invention discloses a rotor for a motor and the motor with the rotor. The rotor for the motor comprises a rotor core and a plurality of permanent magnets, wherein the rotor core comprises a rotating shaft hole; the rotor core is provided with a slit which runs through the rotor core along the axial direction of the rotor core and the slit and the peripheral surface of the rotor core are arranged at an interval; the permanent magnets are internally arranged in the rotor core; in the cross section of the rotor core, each permanent magnet extends along the radial direction of the rotor core; the plurality of permanent magnets are arranged along the circumferential direction of the rotor core; and the homopolarity of the adjacent permanent magnets in the circumferential direction of the rotor core is opposite. According to the rotor for the motor, the magnetic concentrating capability can be improved; the air-gap field is improved; and the placement space for the permanent magnets is not reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

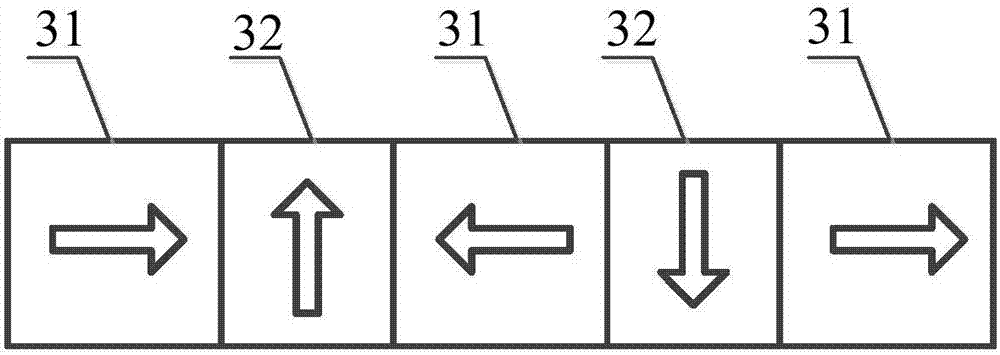

A permanent magnet rail

ActiveCN105803872BImprove the magnetic effectImprove riding performanceRailway tracksForce linesVehicle driving

The invention discloses a permanent magnet guide rail. The permanent magnet guide rail comprises: a horizontal magnetization magnet, a vertical magnetization magnet and carbon steel; the horizontal magnetization magnet and the vertical magnetization magnet are spaced apart and closely arranged; a piece of carbon steel is arranged above each vertical magnetization magnet, and The sum of the thickness of the vertical magnetization magnet and the thickness of the carbon steel is equal to the thickness of the horizontal magnetization magnet; Arranged in such a way that the density is the largest and the magnetic flux density under the guide rail is the smallest. By using the permanent magnet guide rail provided by the present invention, the magnetic concentration effect of the permanent magnet guide rail can be improved, so that most of the magnetic lines of force can be gathered to the working area above the guide rail, and the ride comfort and vehicle safety of the permanent magnet guide rail along the driving direction can be effectively improved. operational reliability.

Owner:SOUTHWEST JIAOTONG UNIV

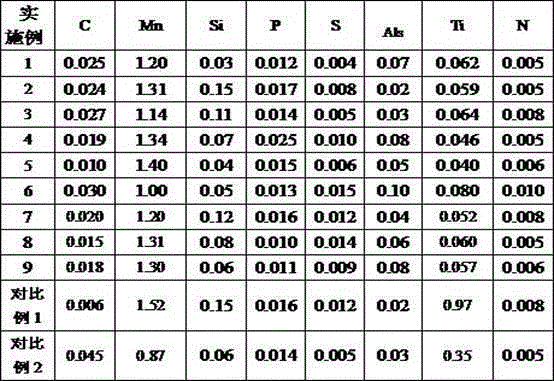

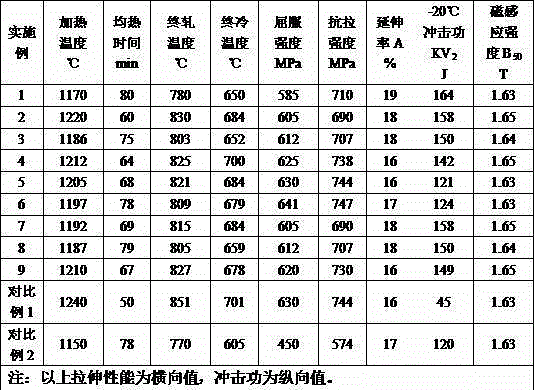

High-strength and high-toughness hot rolled magnetic yoke steel with yield strength to be 550MPa grade and production method

The invention discloses high-strength and high-toughness hot rolled magnetic yoke steel with the yield strength to be a 550MPa grade. The high-strength and high-toughness hot rolled magnetic yoke steel is prepared from the following components in percentage by weight: 0.01-0.03 percent of C, smaller than or equal to 0.15 percent of Si, 1.00-1.40 percent of Mn, smaller than or equal to 0.025 percent of P, smaller than or equal to 0.015 percent of S, 0.04-0.08 percent of Ti, 0.02-0.10 percent of Als and smaller than or equal to 0.010 percent of N. The high-strength and high-toughness hot rolled magnetic yoke steel is prepared through the following production steps: pouring after hot metal desulphurization, converter combined blowing and vacuum treatment; heating a slab; rough rolling; finish rolling; laminar cooling; and reeling. According to the high-strength and high-toughness hot rolled magnetic yoke steel disclosed by the invention, the yield strength is larger than or equal to 550MPa, the tensile strength is larger than or equal to 650MPa, the ductility A is larger than or equal to 15 percent, the impact energy KV2 at 20 DEG C below zero is larger than or equal to 100J, the magnetic induction performance B50 is larger than or equal to 1.50 T, and the demand of a large hydro-generator rotor magnetic yoke with high unit capacity for using the high-strength and high-toughness hot rolled magnetic yoke steel can be met.

Owner:武汉钢铁有限公司

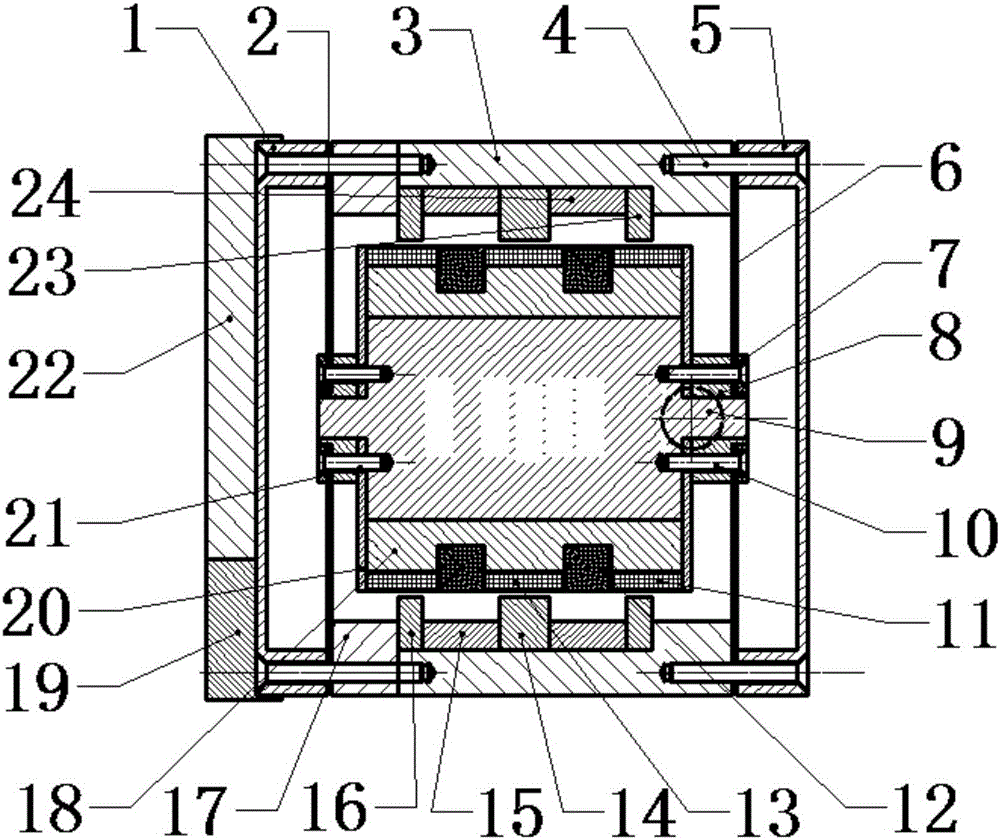

Low-frequency compensation inertia type actuator and detection method thereof

ActiveCN106224421ALower natural frequencyIncrease profitVibration dampersMagnetic springsInterference fitRubber ring

The invention discloses a low-frequency compensation inertia type actuator and an actuation method thereof. The low-frequency compensation inertia type actuator comprises a stator component, an oscillator component and a low-frequency compensation component attached to the stator component. The stator component comprises magnetic conductive plates, permanent magnets and a shell body. The magnetic conductive plates and the permanent magnets are arranged on the inner wall of the shell body at intervals. The oscillator component comprises a first spring piece, a second spring piece, an actuation rod, a magnetic conductive barrel, a baffle, rubber rings and coils. The low-frequency compensation component with the frequency response characteristic opposite to the frequency response characteristic of the inertia type actuator comprises a low-frequency compensator and a power amplifier. The ladder-like magnetic conductive barrel is connected with the actuation rod in an interference fit mode. The multiple sections of adjacent reversed coils are wound on the outer side of the protruding part of the magnetic conductive barrel. The two rubber rings are installed on the outer side of the downwards concave part of the magnetic conductive barrel. The rubber rings and the baffle jointly clamp the coils on the magnetic conductive barrel.

Owner:XI AN JIAOTONG UNIV +2

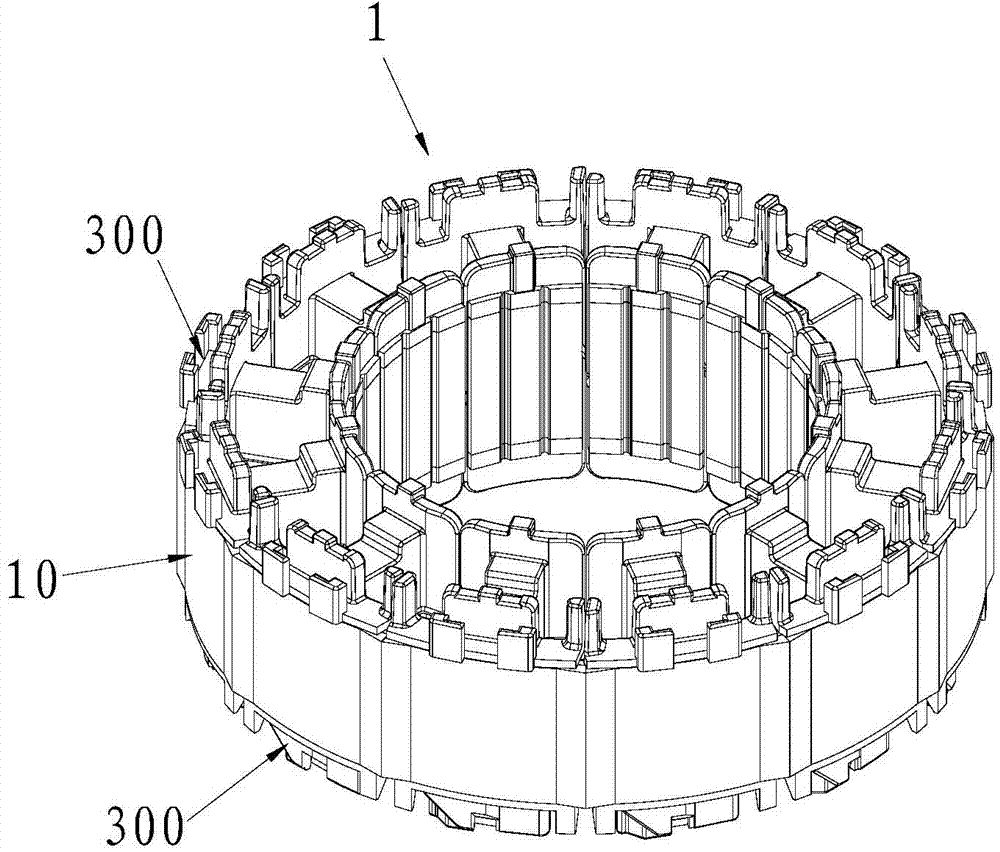

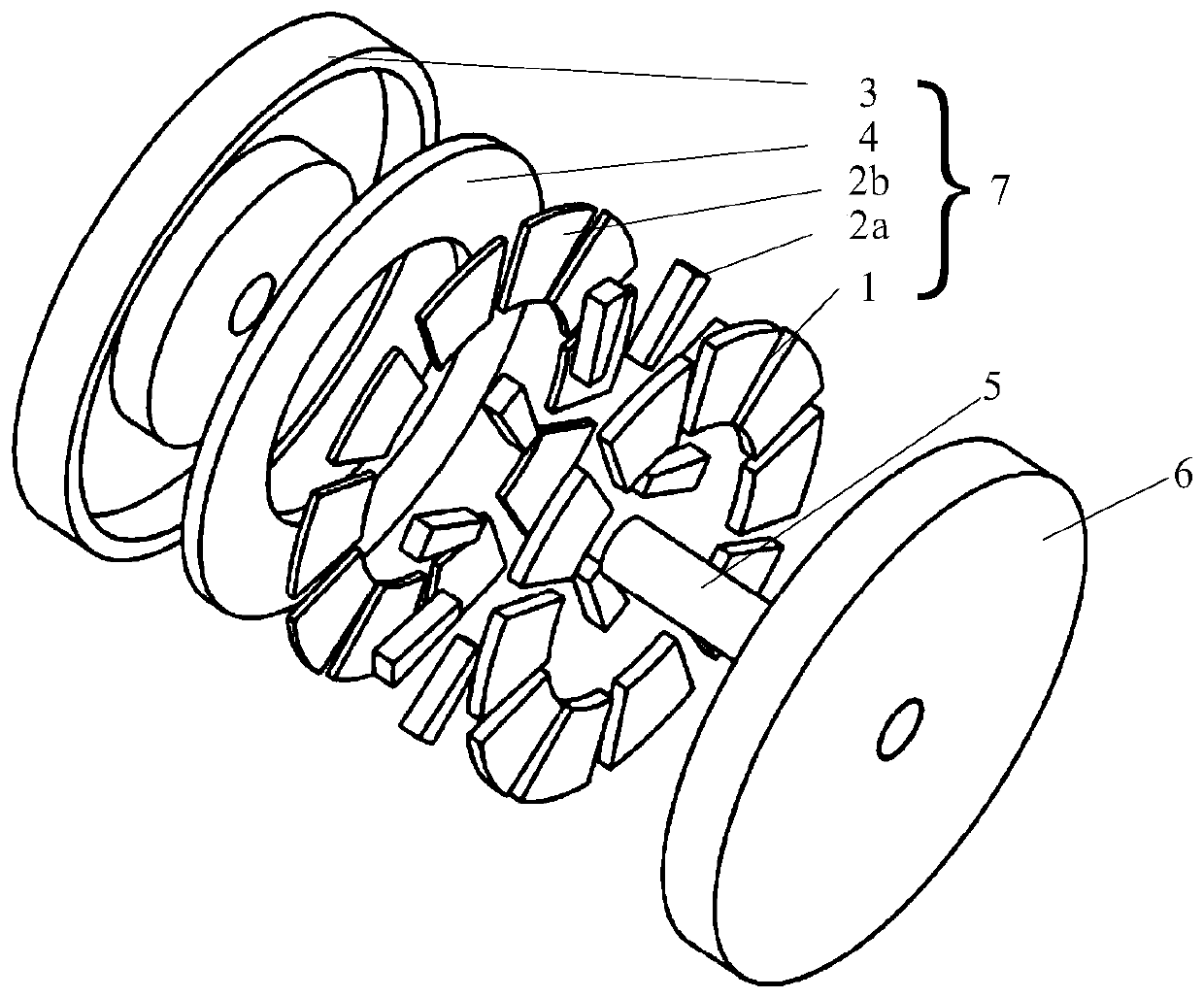

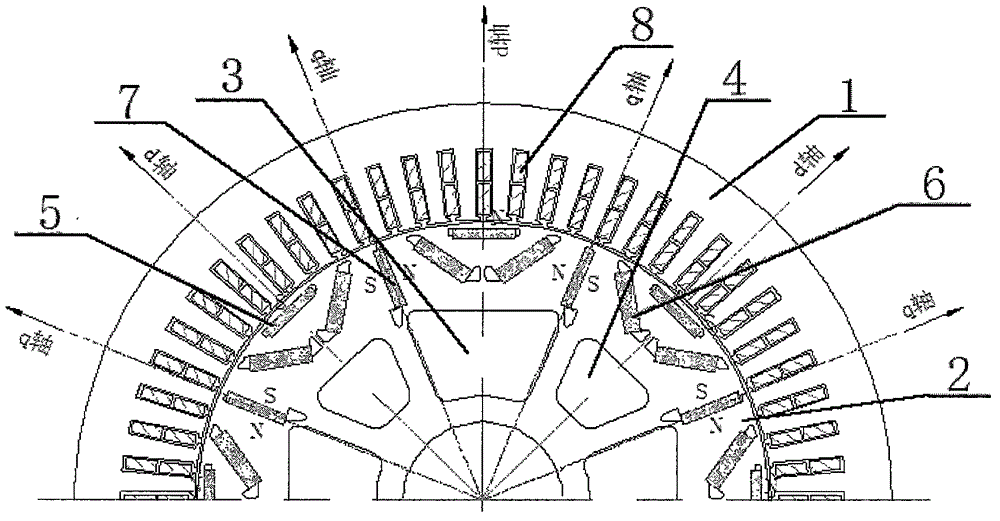

Permanent magnet synchronous motor with hybrid magnetic circuit arrangement

PendingCN105186818ASimple structureEasy to produceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

The present invention relates to a permanent magnet synchronous motor with hybrid magnetic circuit arrangement. The permanent magnet synchronous motor with the hybrid magnetic circuit arrangement comprises a stator iron core (1) and magnetic steels, the magnetic steels are arranged at the circumferential edge of a rotor iron core (2) unevenly, and comprise the tangential magnetic steels (7), the linear magnetic steels (5) and the V-shaped magnetic steels (6). Each V-shaped magnetic steel (6) is formed by arranging two magnetic steels, and the linear magnetic steels (5) are located at the inner side of a V-shaped magnetic steel set (6) and are close to the circumferential edge of the rotor iron core (2). The tangential magnetic steels (7) are arranged on a q-axis of the motor, and the number of the tangential magnetic steels (7) and the linear magnetic steels (5) is equal to the number of the V-shaped magnetic steels (6) and is equal to the series of the motor. The inner side of the rotor iron core (2) is equipped with the de-weight holes having the same number with the series of the motor, and the de-weight holes comprise the large de-weight holes (3) and the small de-weight holes (4). The permanent magnet synchronous motor with the hybrid magnetic circuit arrangement of the present invention solves the problems of the motor of high power density and cost, wide speed regulation range and electromagnetic noise.

Owner:CHANGZHOU PUSHI AUTOMOTIVE POWER SYST CO LTD

Novel double-moving-coil type loudspeaker

InactiveCN103945311AResolve distortionImprove sound qualityElectrical transducersEngineeringAtmospheric pressure

The invention provides a novel double-moving-coil type loudspeaker which comprises a support, a lower clamping plate is fixed in the support, a vibration diaphragm is fixed on the support located on the lower clamping plate, two grooves are formed in the lower clamping plate, magnets are arranged in the two grooves respectively, washers are arranged on the upper surfaces of the magnets, gaps are formed between the side walls of the grooves and the washers, a large voice coil and a small voice coil are arranged in the gaps respectively, the vibration diaphragm covers the washers, and the upper end of the large voice coil and the upper end of the small voice coil are fixedly connected with the vibration diaphragm. The novel double-moving-coil type loudspeaker is characterized in that magnetic circuits of the large voice coil and the small voice coil are double inter magnetic circuits or double outer magnetic circuits in the lower clamping plate, a first vent hole is formed in the lower clamping plate, a second vent hole is formed in the support, and the first vent hole is communicated with the second vent hole for air leakage to enable the air pressure in the vibration diaphragm and the air pressure of the outside to be consistent. The novel double-moving-coil type loudspeaker effectively solves the distortion problem caused by compression of space in and out of the diaphragm, the sound quality effect is improved, and product quality is improved.

Owner:ZHONGSHAN TIANJIAN ELECTROACOUSTIC

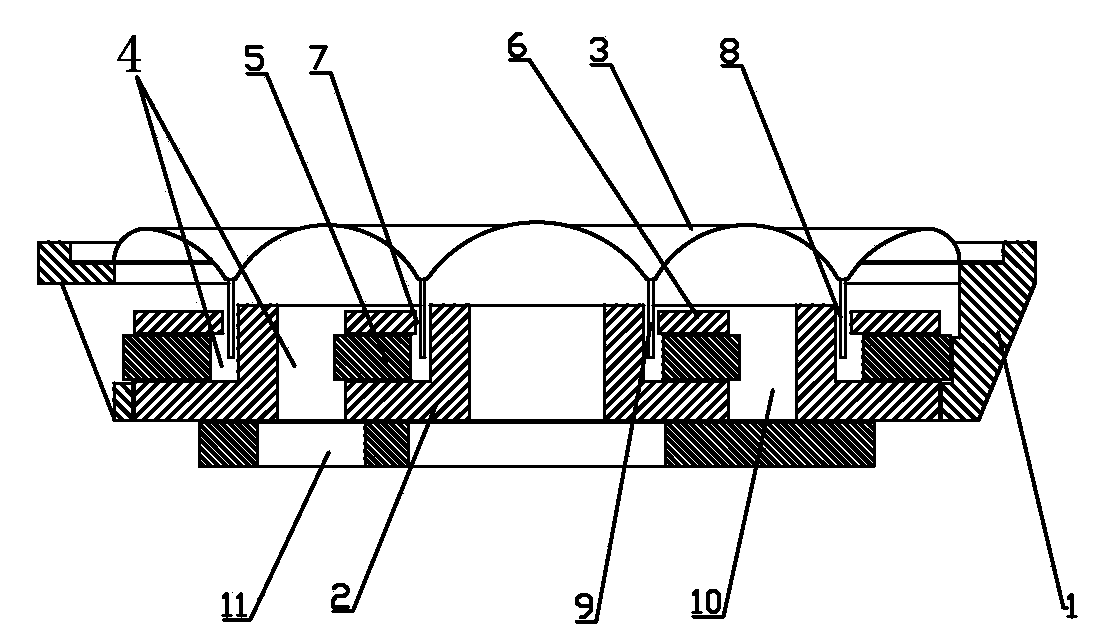

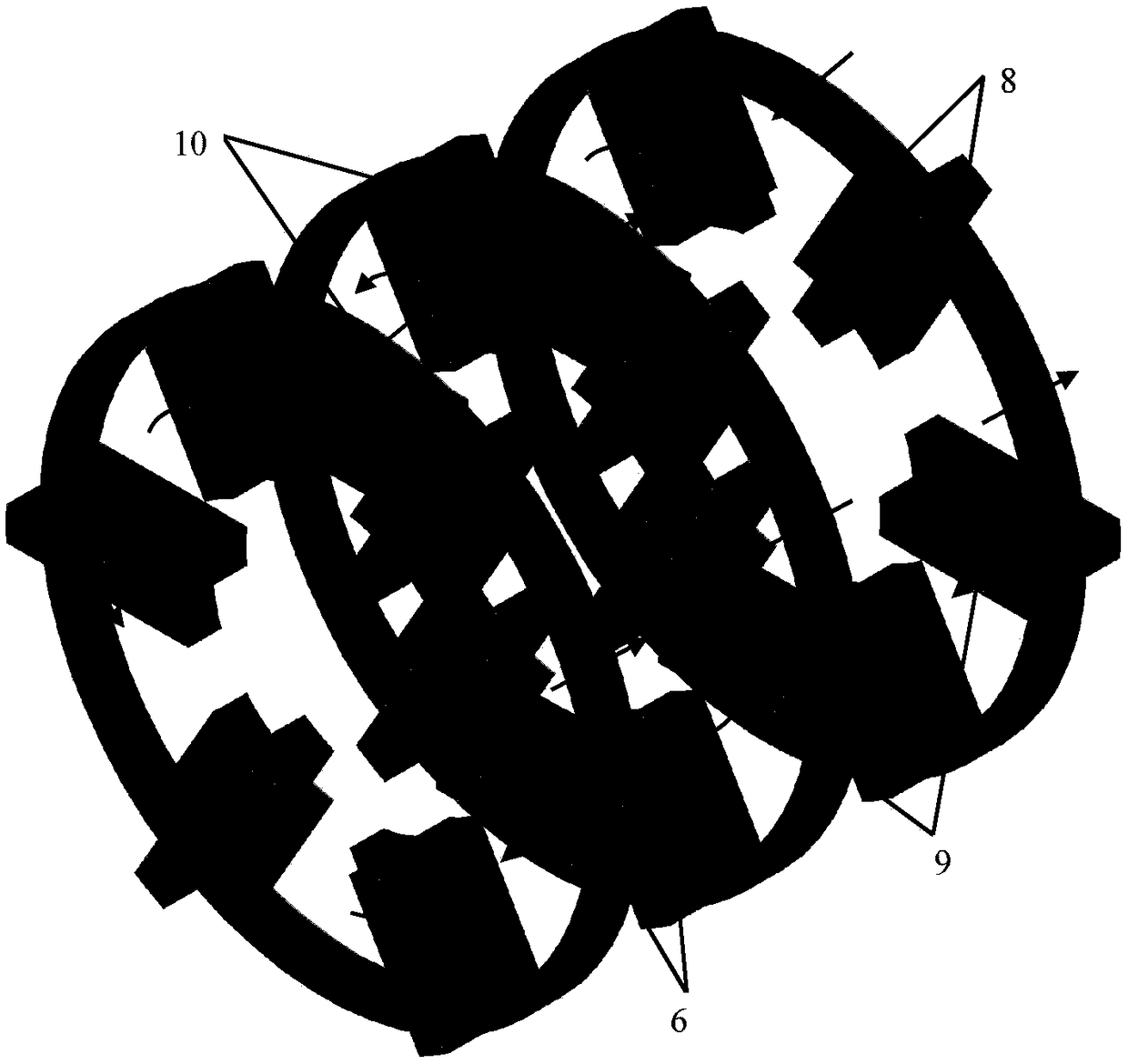

Flux switching type linear rotary permanent magnet actuator

InactiveCN109412370AImprove power factorLow priceMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetizationPermanent magnet motor

The invention provides a flux switching type linear rotary permanent magnet actuator. The actuator comprises a casing (1), stators, a mover, a winding and a mover shaft, wherein six stator poles are arranged in the circumferential direction of each stator; each stator comprises a stator yoke (2), the stator poles (5), tangentially-magnetized permanent magnets (6), U-shaped axially-magnetized permanent magnets (8) and concentrated windings (4); three same stators are arranged on the aluminum casing (1) in the axial direction; stator cores are connected by non-magnetic conductive materials; themover shaft is connected with the casing (1) through the sleeve connection of a linear bearing and a rotary bearing; the permanent magnets are embedded inside the stators; the mover comprises a movercore (3) and mover salient poles (7); and the mover salient poles are axially staggered by 22.5 degrees and forms a double-layer flux switching type structure together with the stator structure to improve the torque / thrust density. The actuator has the beneficial effects that the magnetization directions of the tangentially-magnetized permanent magnets and the axially-magnetized permanent magnetsare complemented to greatly increase the air gap flux density and further increase the torque / thrust density.

Owner:ANHUI UNIV OF SCI & TECH

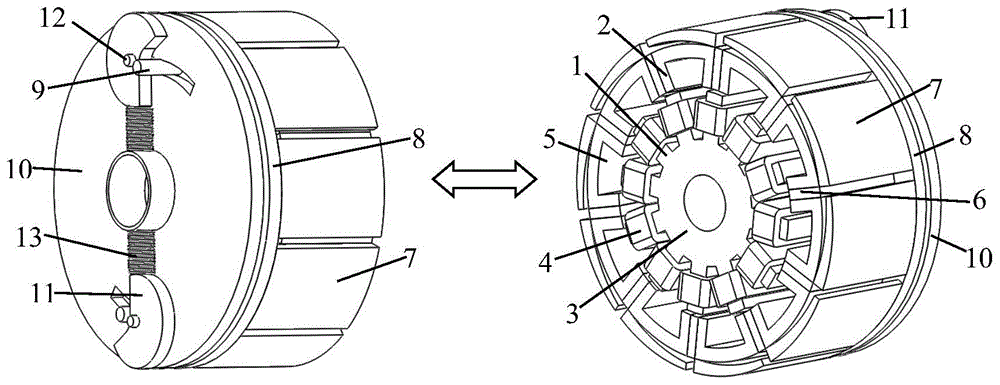

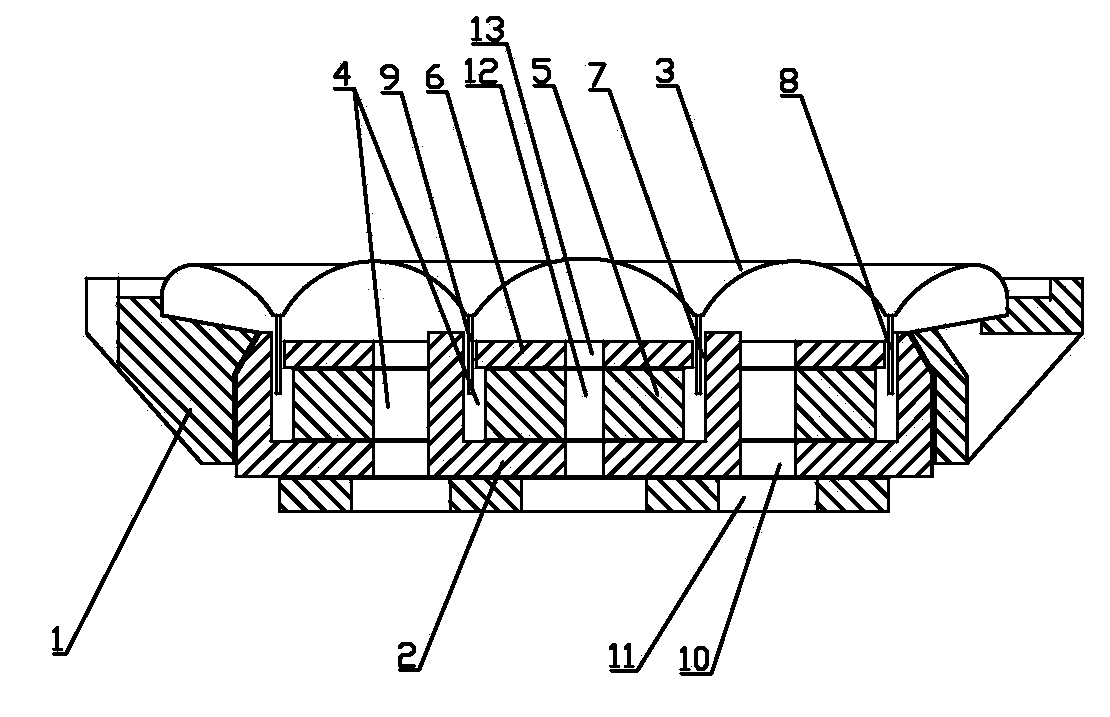

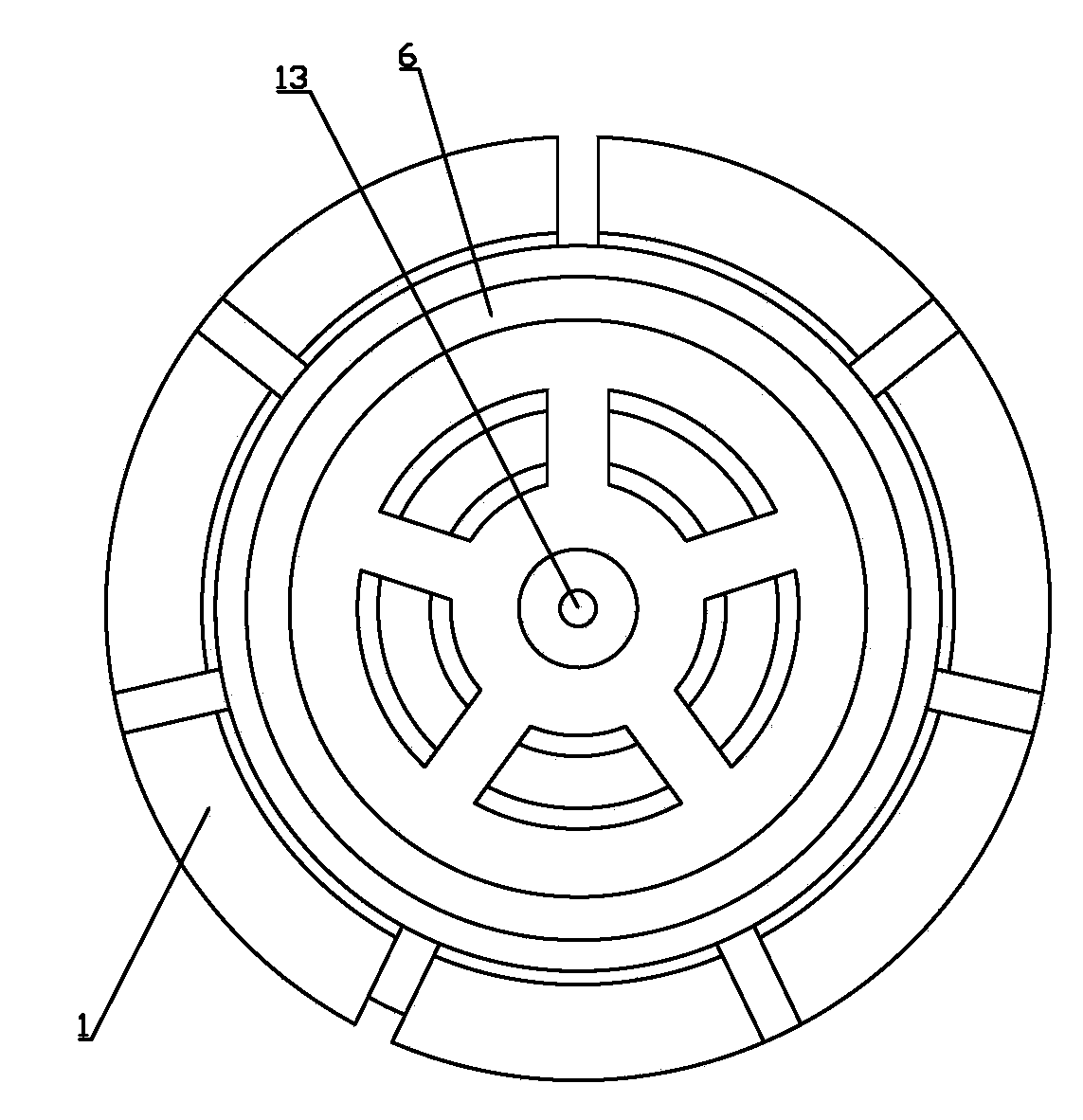

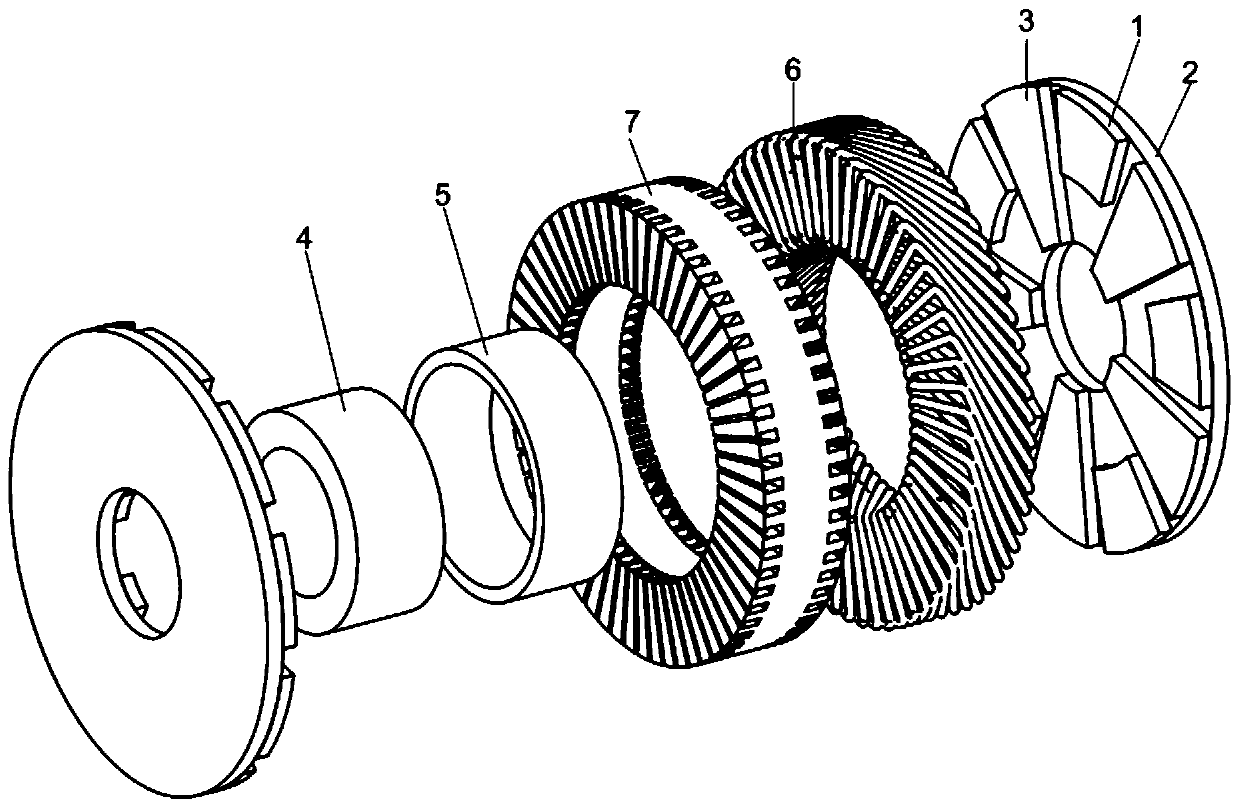

Drum-type distributed winding axial hybrid excitation motor

ActiveCN110611381AIncrease heightReduce lossMagnetic circuit rotating partsMagnetic circuit stationary partsHigh power densityConductor Coil

The invention discloses a drum-type distributed winding axial hybrid excitation motor. The motor comprises a stator disc and two rotor discs. The stator disc comprises a stator core, an armature winding, excitation windings and magnetic conductive rings. The rotor discs comprise rotor back yokes, magnetic conductive pole blocks and permanent magnets. Two axial end faces of the stator core are provided with a plurality of slots, and the number of the slots and slots positions on the two faces are at the same time. Two sides of a drum-type distributed armature winding coil are embedded and woundin two end face slots of the stator core, and a span is obtained by matching the number of pole slots. The excitation windings are installed on an inner ring or an outer ring of the armature windingor are installed on the inner ring and the outer ring simultaneously, and the magnetic conductive rings are correspondingly installed on inner rings or outer rings of the excitation windings. The rotor discs are arranged on two sides of the stator disc, and the number of rotor poles is matched with that of the stator slots. The permanent magnets and the magnetic conductive pole blocks are alternately installed on the rotor discs, and the two rotor discs are installed on a rotating shaft in a staggered mode by one pole. The drum-type distributed winding axial hybrid excitation motor has the advantages of high power density, wide magnetic field adjusting range and wide application prospect.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com