Combined magnetizing type permanent magnet built-in rotor of axial magnetic field permanent magnet motor

A permanent magnet motor, axial magnetic field technology, applied in electromechanical devices, electric components, magnetic circuit rotating parts, etc., can solve the difficulty of increasing the processing and installation of permanent magnets, the serious eddy current loss on the surface of permanent magnets, and the installation of permanent magnets. , protection difficulties, etc., to achieve the effect of obvious salient pole effect, high rotor structure strength, and good magnetic concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

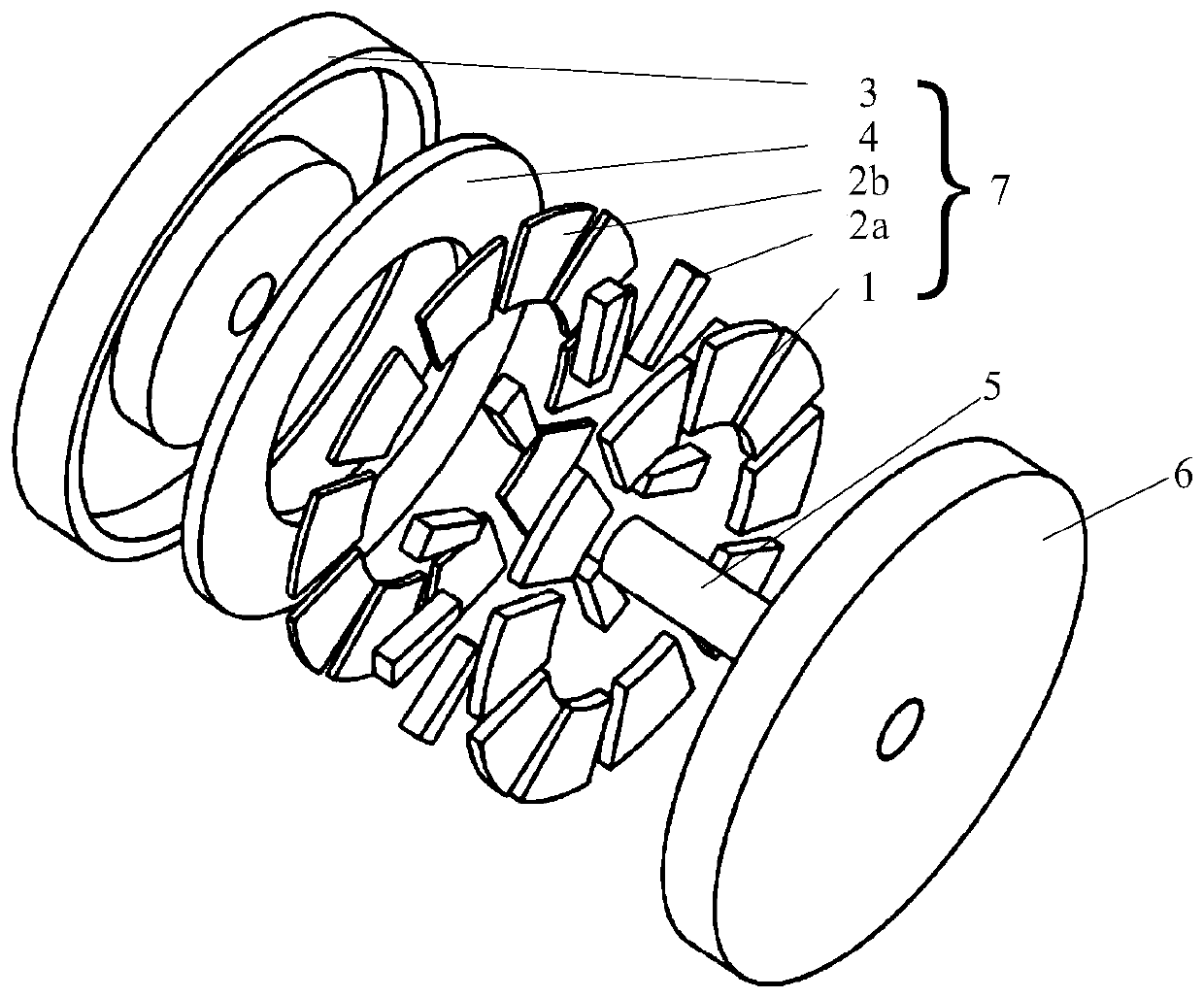

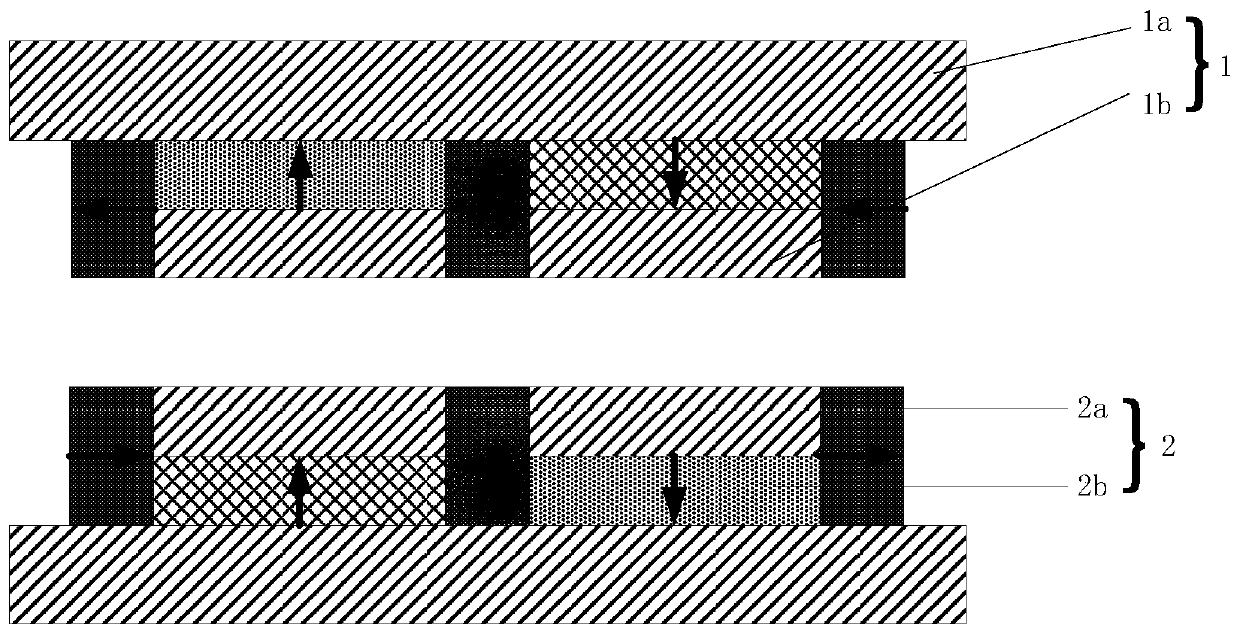

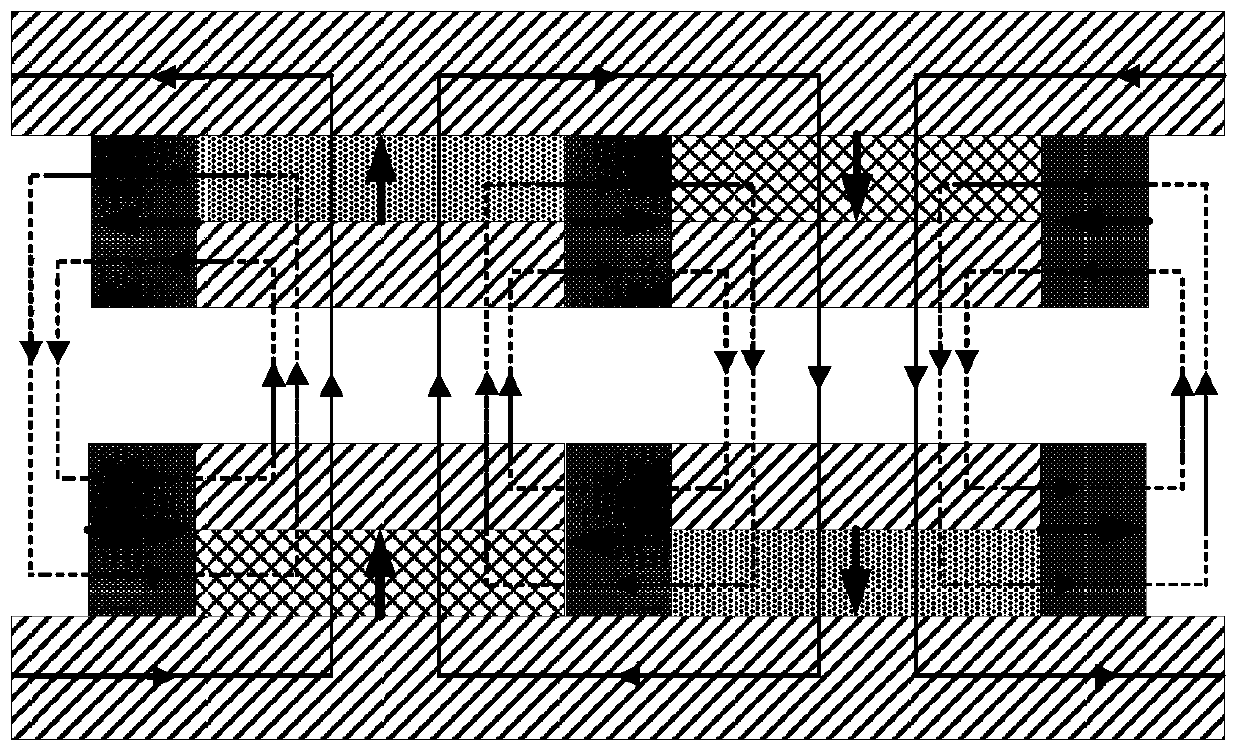

[0038] The present invention provides an axial field permanent magnet motor combined magnetization type permanent magnet built-in rotor structure, which has two permanent magnet rotor disks, and the two rotors are installed on the rotating shaft 5 in such a way that the permanent magnets face each other. The rotor structure mainly includes: rotor outer core 1a and rotor inner core 1b, permanent magnet 2a and permanent magnet 2b, rotor supporting shell 3, rotor back yoke 4, rotating shaft 5, first rotor disc 6, second rotor disc 7.

[0039] The rotor back yoke 4 is installed on the rotor support shell 3, and the bonding strength is enhanced by structural glue. The rotor support shell 3 can enhance the structural strength of the rotor, and is used to protect the iron core 1 and the permanent magnet 2, and reduce the speed of the rotor running at high speed. When the centrifugal force affects the rotor structure, the permanent magnets 2 are alternately and evenly arranged on the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com