Permanent magnet synchronous motor rotor and permanent magnet synchronous motor

A technology for permanent magnet synchronous motors and rotors, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc. Vibration and noise, low utilization rate of permanent magnets and other problems, to achieve the effect of improving anti-demagnetization performance, reducing magnetic flux leakage, and less magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

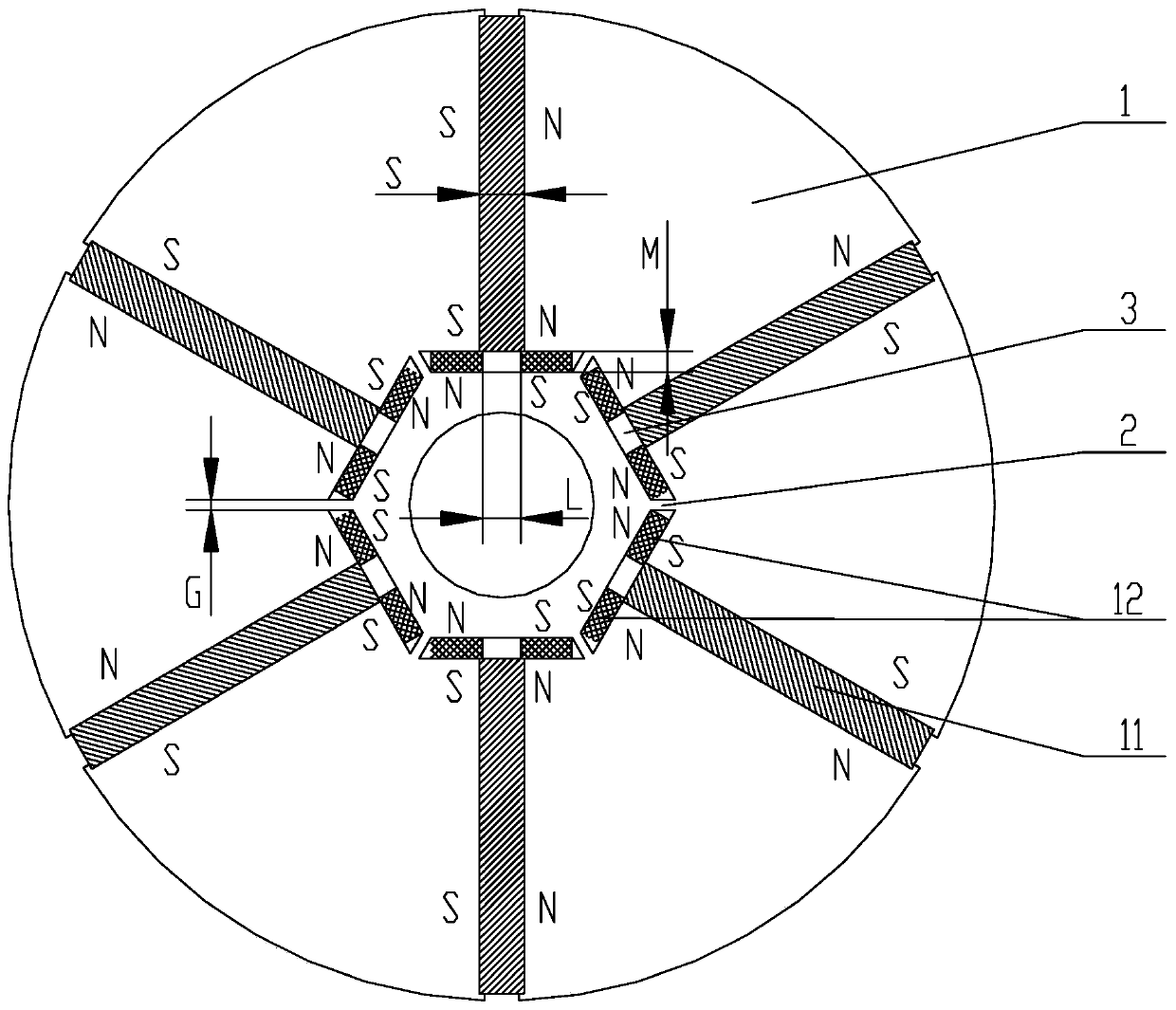

[0039] The present invention provides a permanent magnet synchronous motor rotor, the structure of the permanent magnet synchronous motor rotor is as follows figure 1 , Figure 7 and Figure 8 As shown, it includes a rotor core 1, on which six tangential permanent magnets 11 are evenly distributed in the radial direction, and the same polarity of two adjacent tangential permanent magnets 11 is opposite, that is to say, one tangential One side of the permanent magnet 11 is an N pole (or S pole), and the other tangential permanent magnet 11 side close to this side and opposite to it is also an N pole (or S pole). A radial permanent magnet 12 is arranged symmetrically on both sides of one end of each tangential permanent magnet 11 near the inner side of the rotor core 1 . The two radial permanent magnets 12 sandwiched between two adjacent tangential permanent magnets 11 have the same polarity facing the stator direction, which is the same as the polarity of the adjacent side of...

Embodiment 2

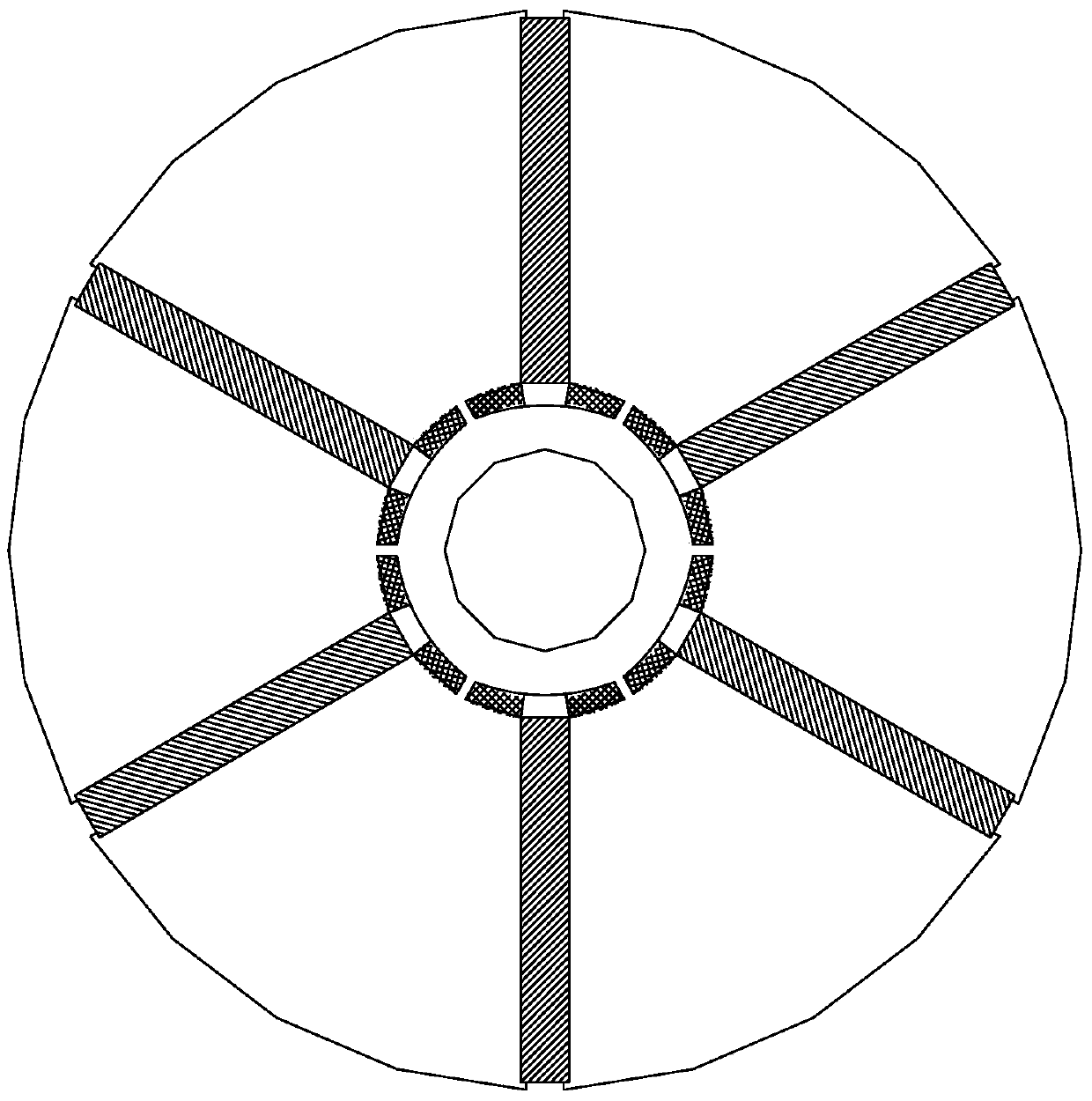

[0046] This embodiment provides a permanent magnet synchronous motor rotor, the structure of which is basically the same as that of the rotor described in Embodiment 1, and will not be repeated here.

[0047] The difference is that: if figure 2 As shown, the cross-sectional shape of each radial permanent magnet is arc-shaped, and further, the arc-shaped is an arc-shaped straight bar, and the arc-shaped straight bar has two arc-shaped sides and oppositely arranged The two straight sides, and the two arc-shaped sides are arranged along the circumference of the rotor, and the two straight sides are arranged along the radial direction of the rotor.

Embodiment 3

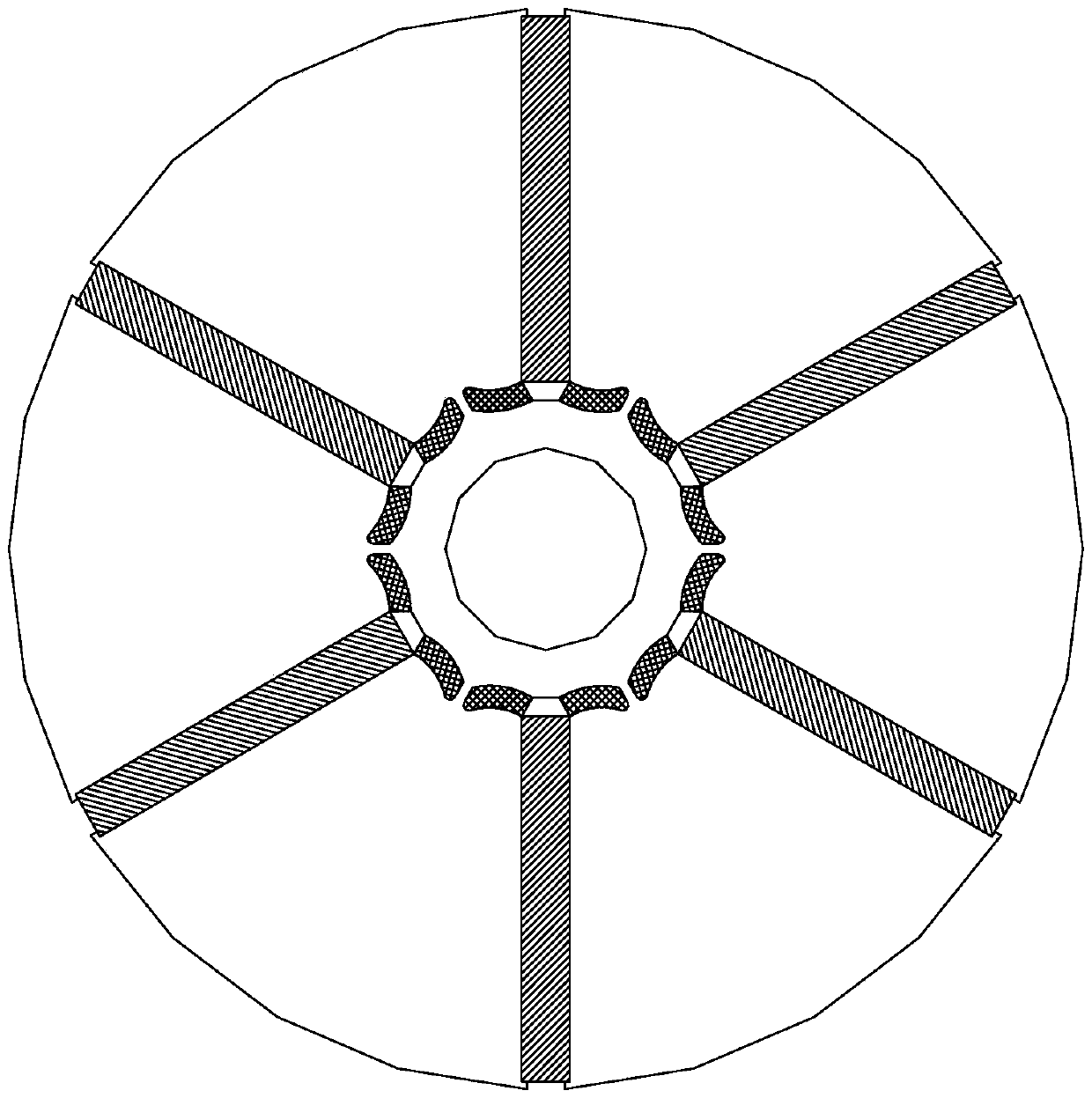

[0049] This embodiment provides a permanent magnet synchronous motor rotor, the structure of which is basically the same as that of the rotor described in Embodiment 1, and will not be repeated here.

[0050] The difference is that: if image 3 As shown, the cross-sectional shape of each radial permanent magnet is a curved arc, further, the curved arc is an arc-shaped curved bar, and the arc-shaped curved bar has two sets of curved arc-shaped sides, one of which is set opposite and two curved sides arranged along the rotor circumference, and the other group is two curved sides arranged opposite and arranged radially along the rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com