Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Reduce demagnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

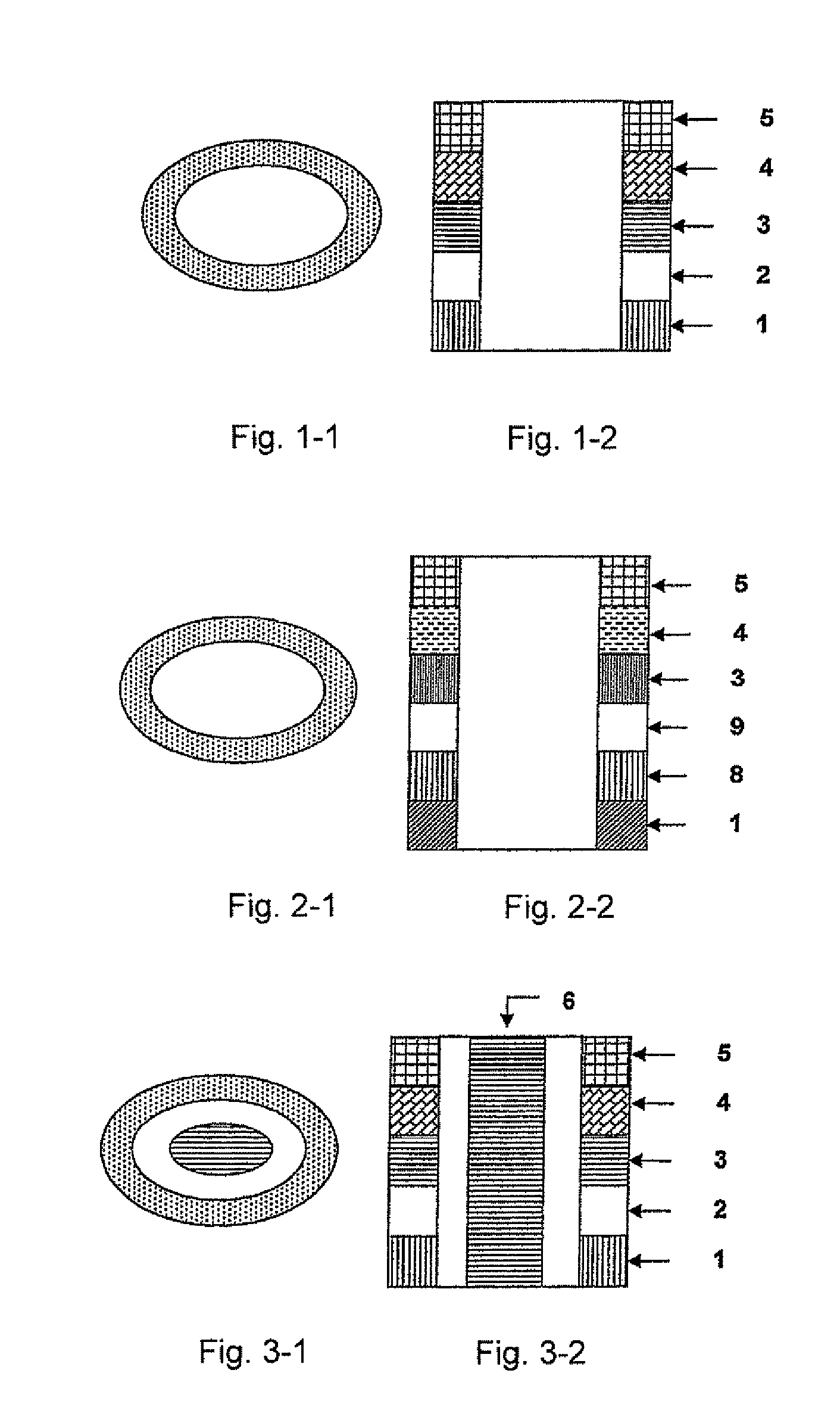

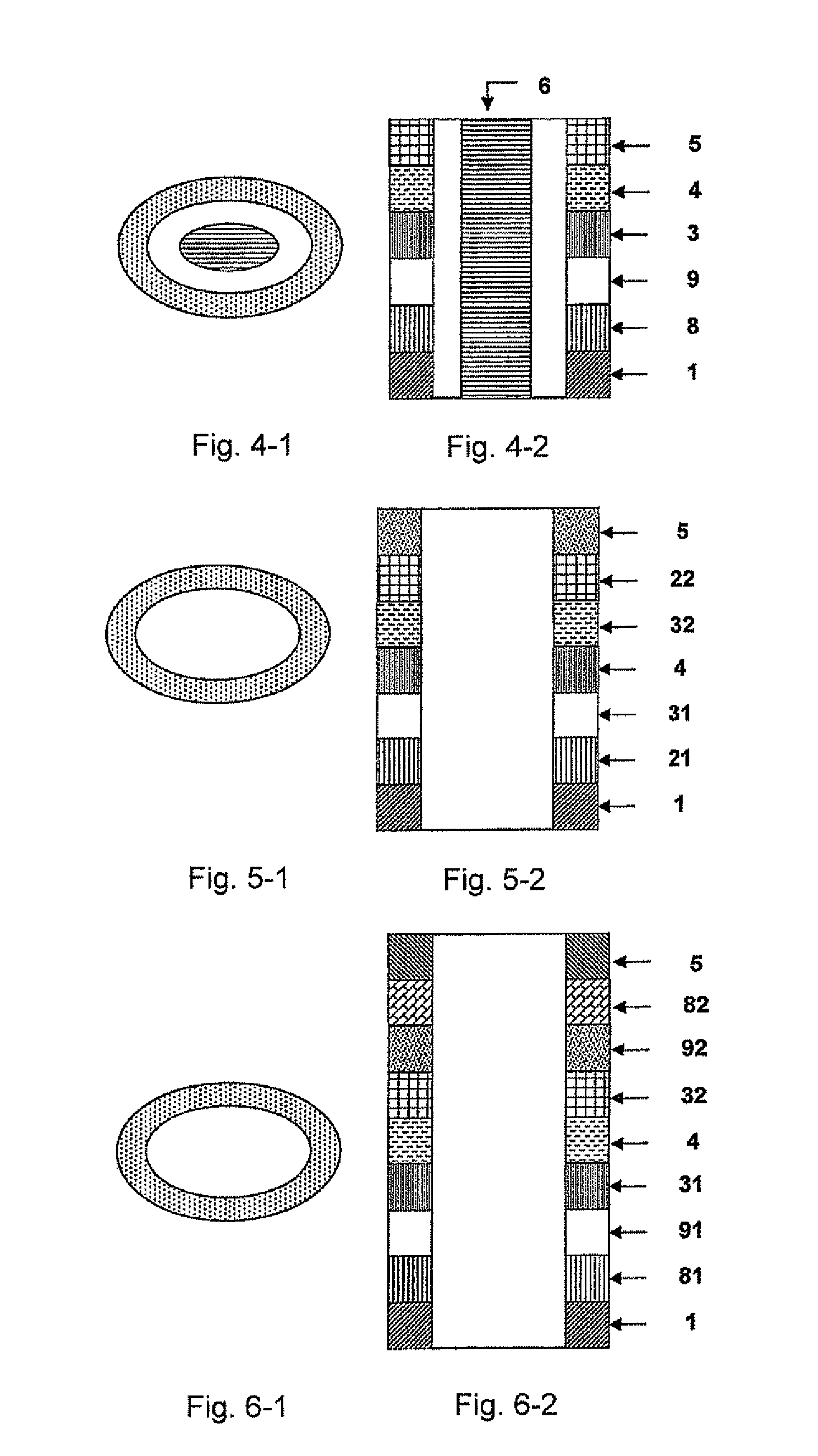

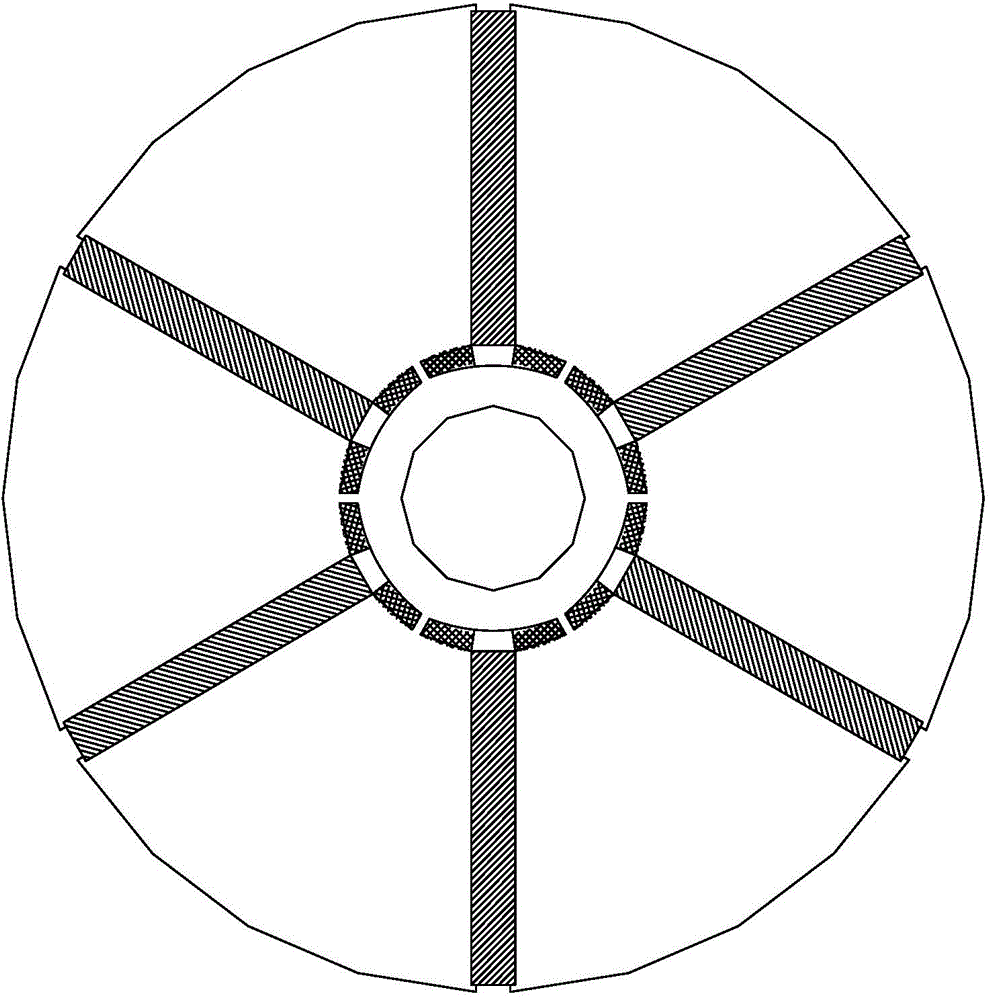

Close shaped magnetic multi-layer film comprising or not comprising a metal core and the manufacture method and the application of the same

InactiveUS7936595B2High densitySmall scaleNanomagnetismMagnetic measurementsMagnetic beadMagnetic logic

Each layer in the magnetic multilayer film is a closed ring or oval ring and the magnetic moment or flux of the ferromagnetic film in the magnetic unit is in close state either clockwise or counterclockwise. A metal core is put in the geometry center position in the close-shaped magnetic multilayer film. The cross section of the metal core is a corresponding circular or oval. A MRAM is made of the closed magnetic multilayer film with or without a metal core. The close-shaped magnetic multilayer film is formed by micro process method. The close-shaped magnetic multilayer film can be used broadly in a great variety of device that uses a magnetic multilayer film as the core, such as MRAM, magnetic bead in computer, magnetic sensitive sensor, magnetic logic device and spin transistor.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

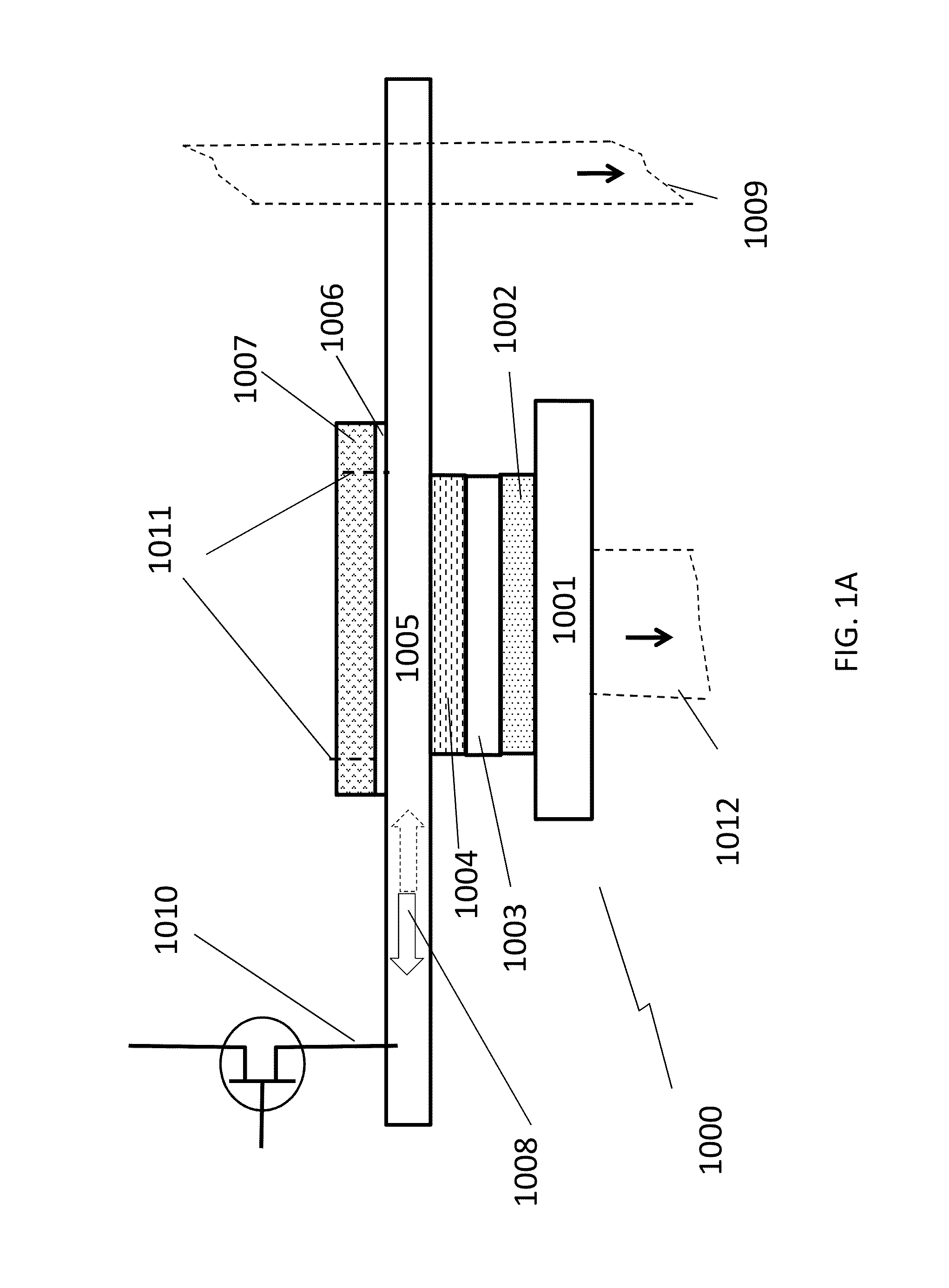

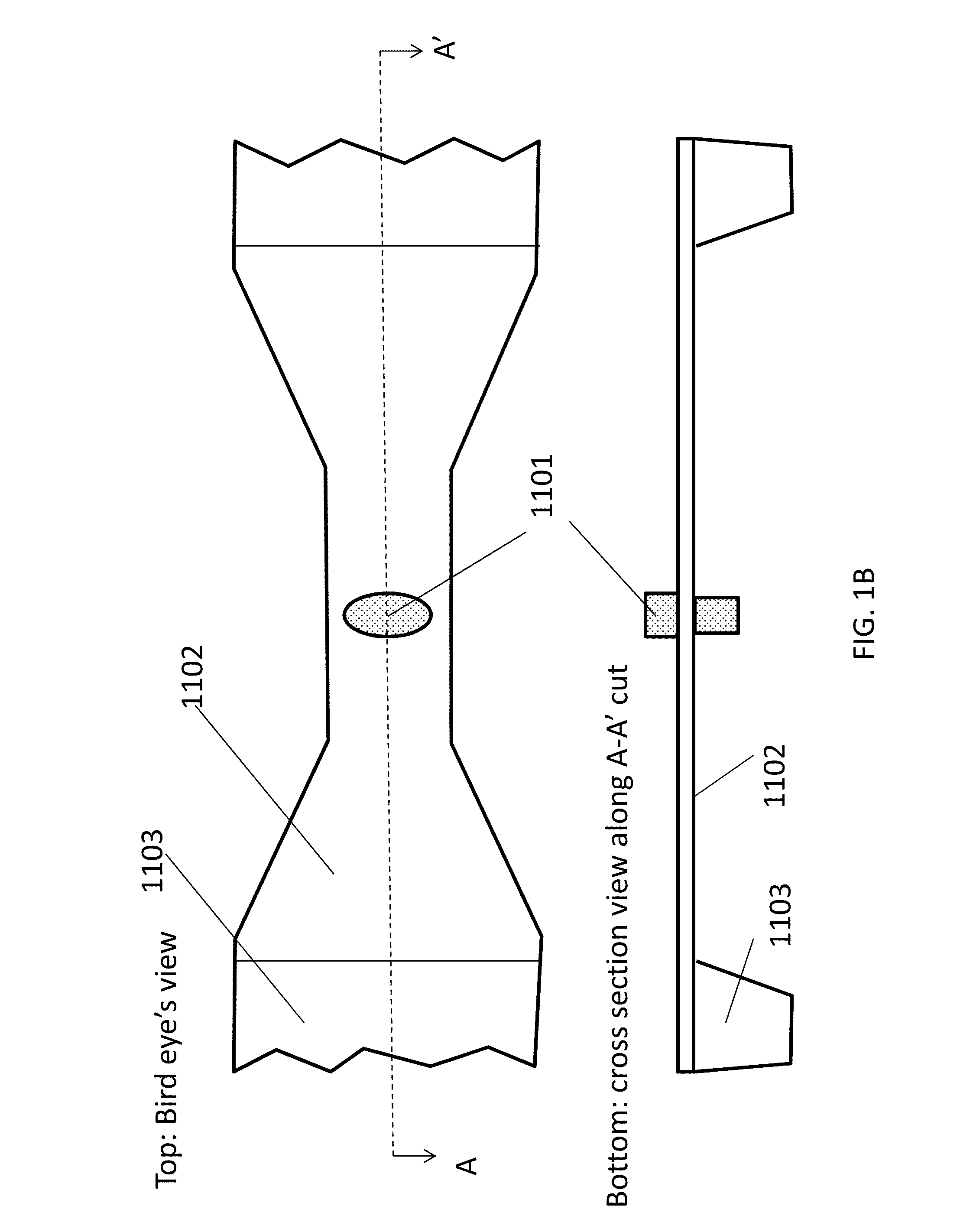

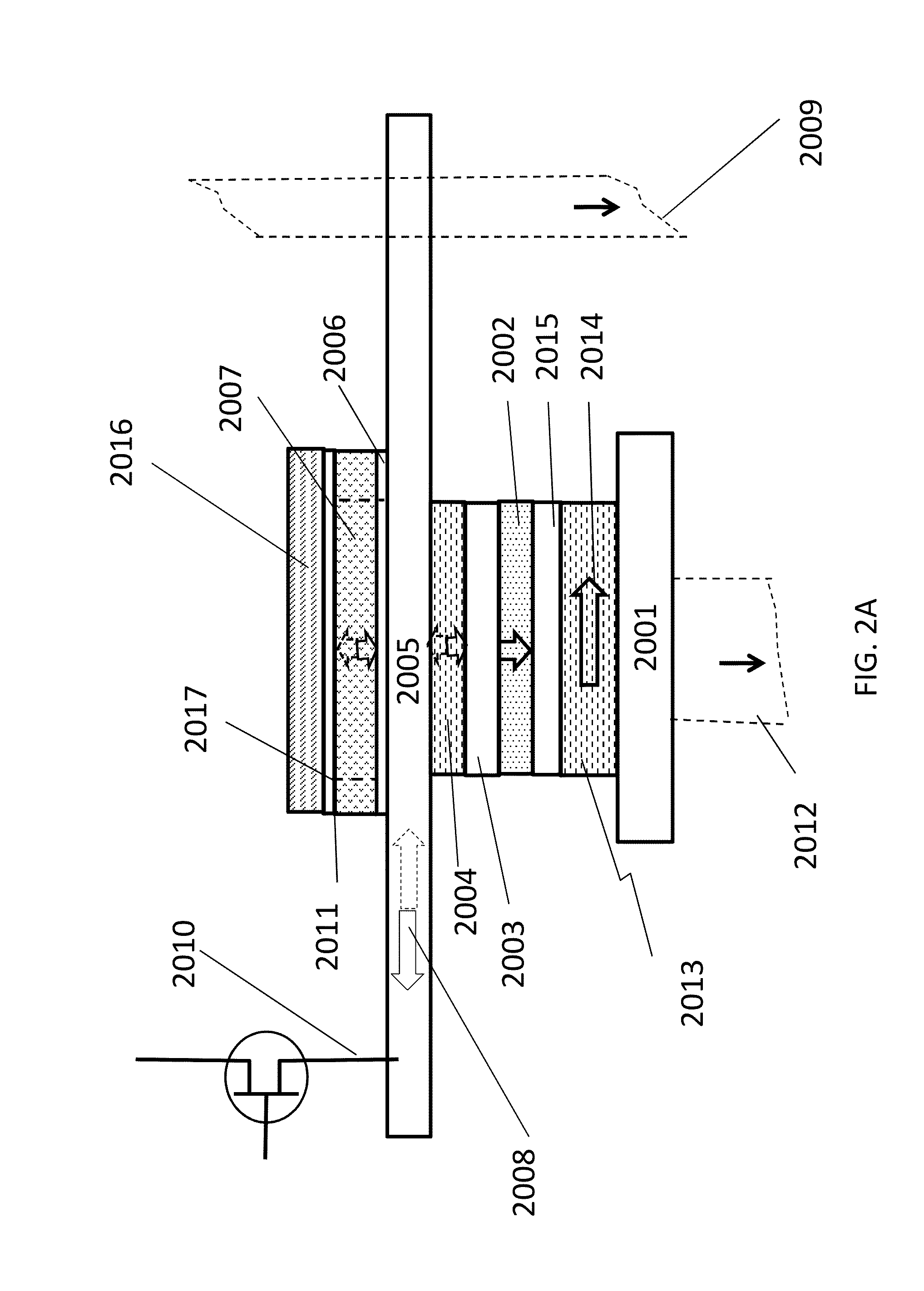

Magnetoresistive random access memory cell and 3D memory cell array

ActiveUS9218864B1Easy to implementImprove thermal stabilityDigital storageMagnetic stabilizationMagnetic reluctance

A novel three-terminal SOT-MRAM memory cell with a unique magnetic stabilization layer or structure is proposed. A complementary magnetic footprint of the data storage layer for the memory cell is able to be created within the magnetic stabilization layer or structure by the magnetic field from the storage layer to enhance the magnetic and thermal stability of the memory cell. Several designs for both perpendicular and in-plane SOT-MRAM memory cell have been invented. With proper wire connection and sensing arrangement, the proposed memory cell is capable of forming not only the 2D array but also 3D array.

Owner:GE YI +1

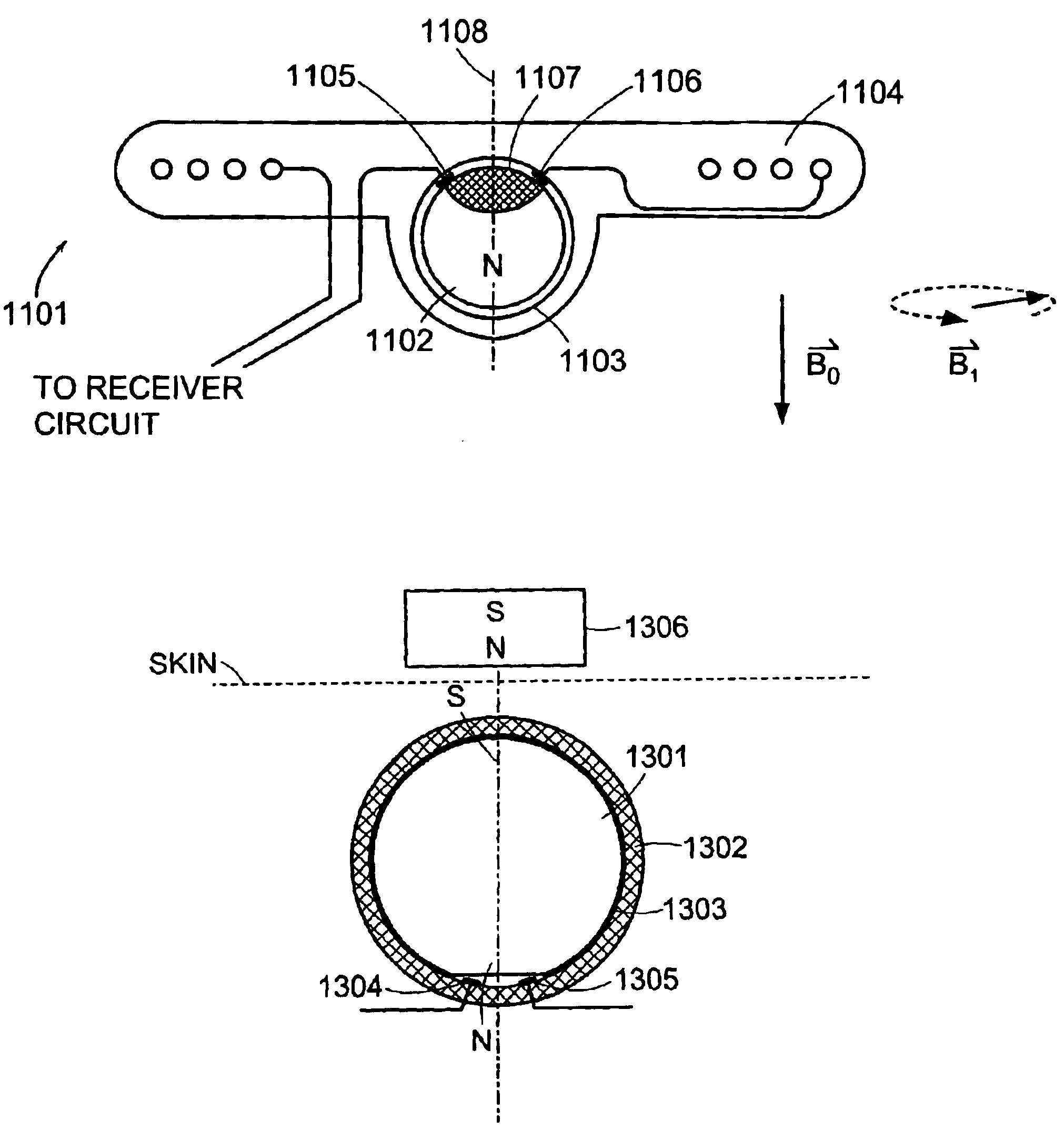

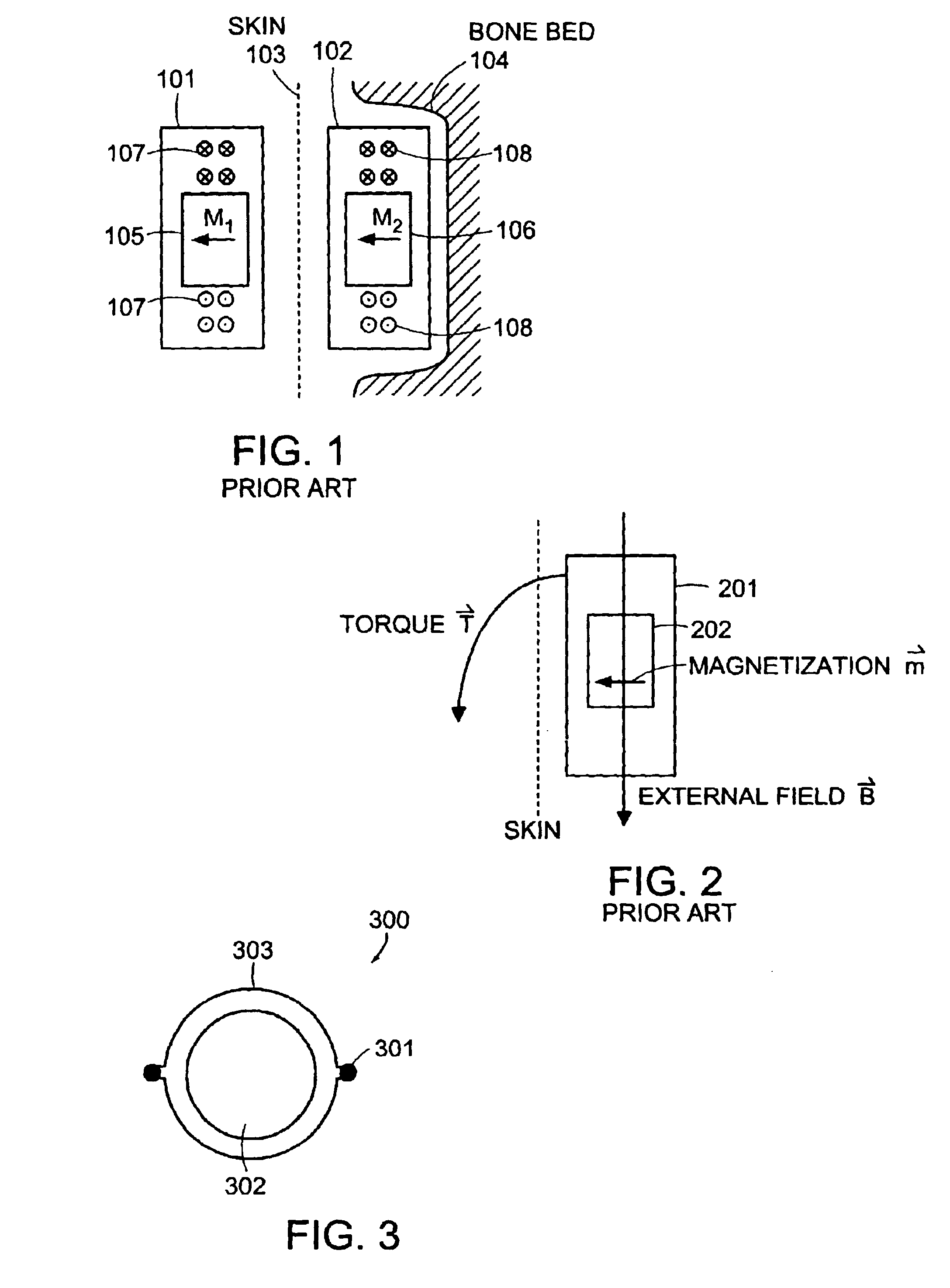

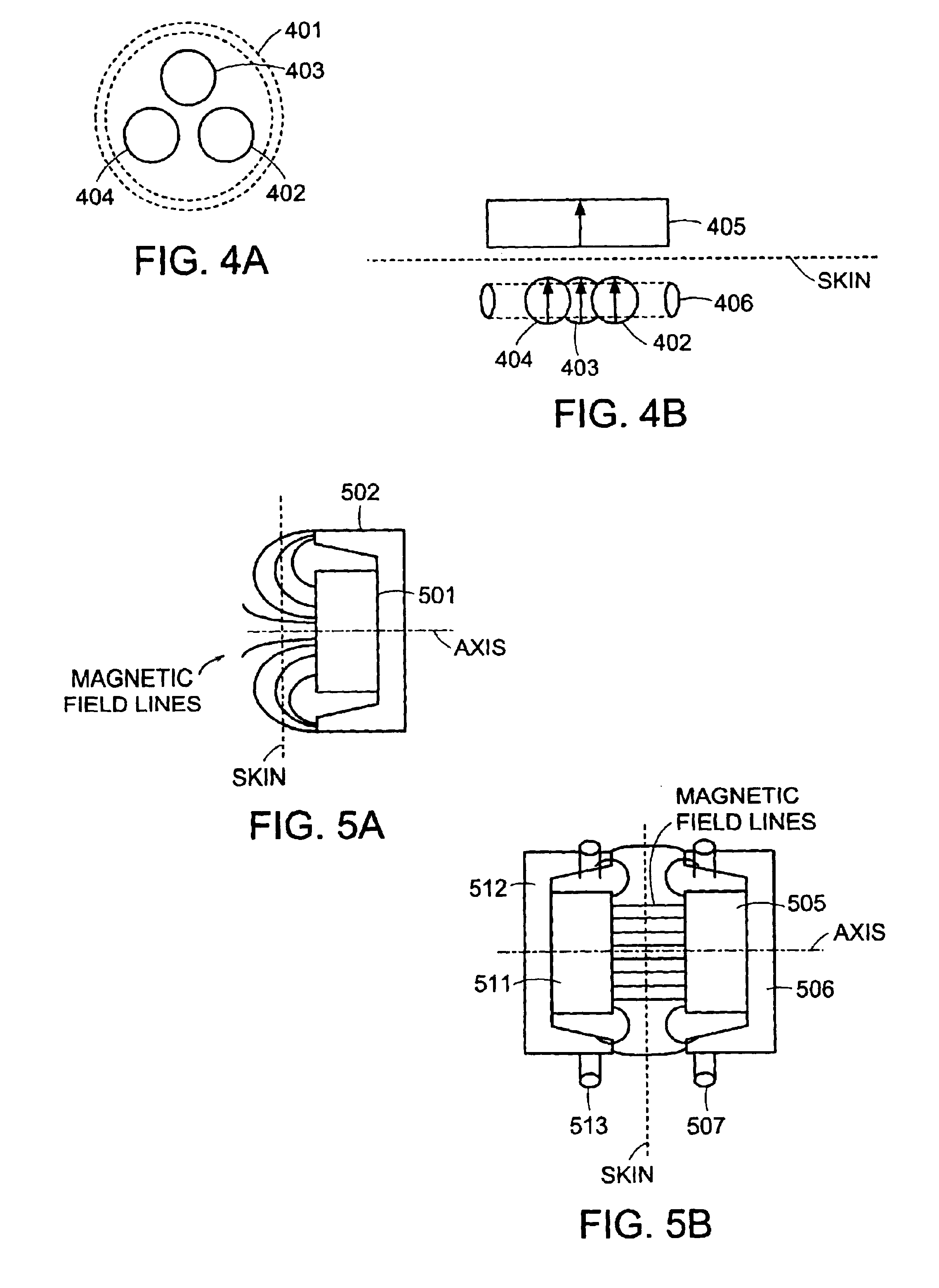

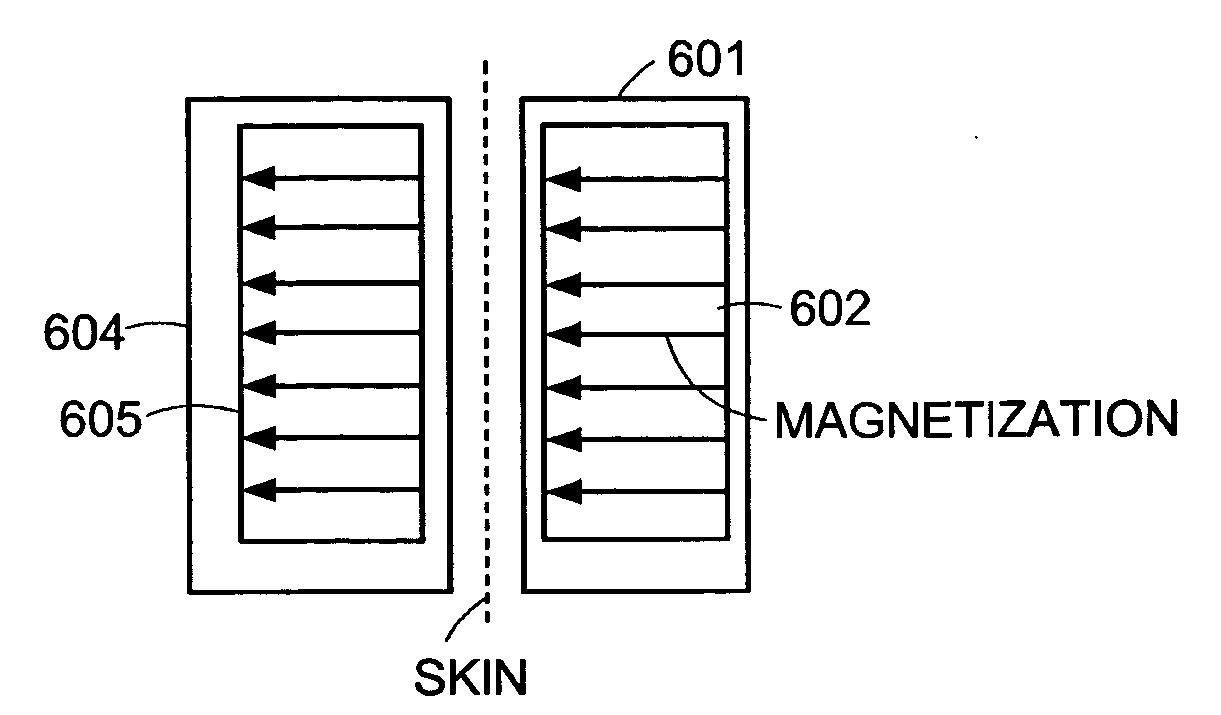

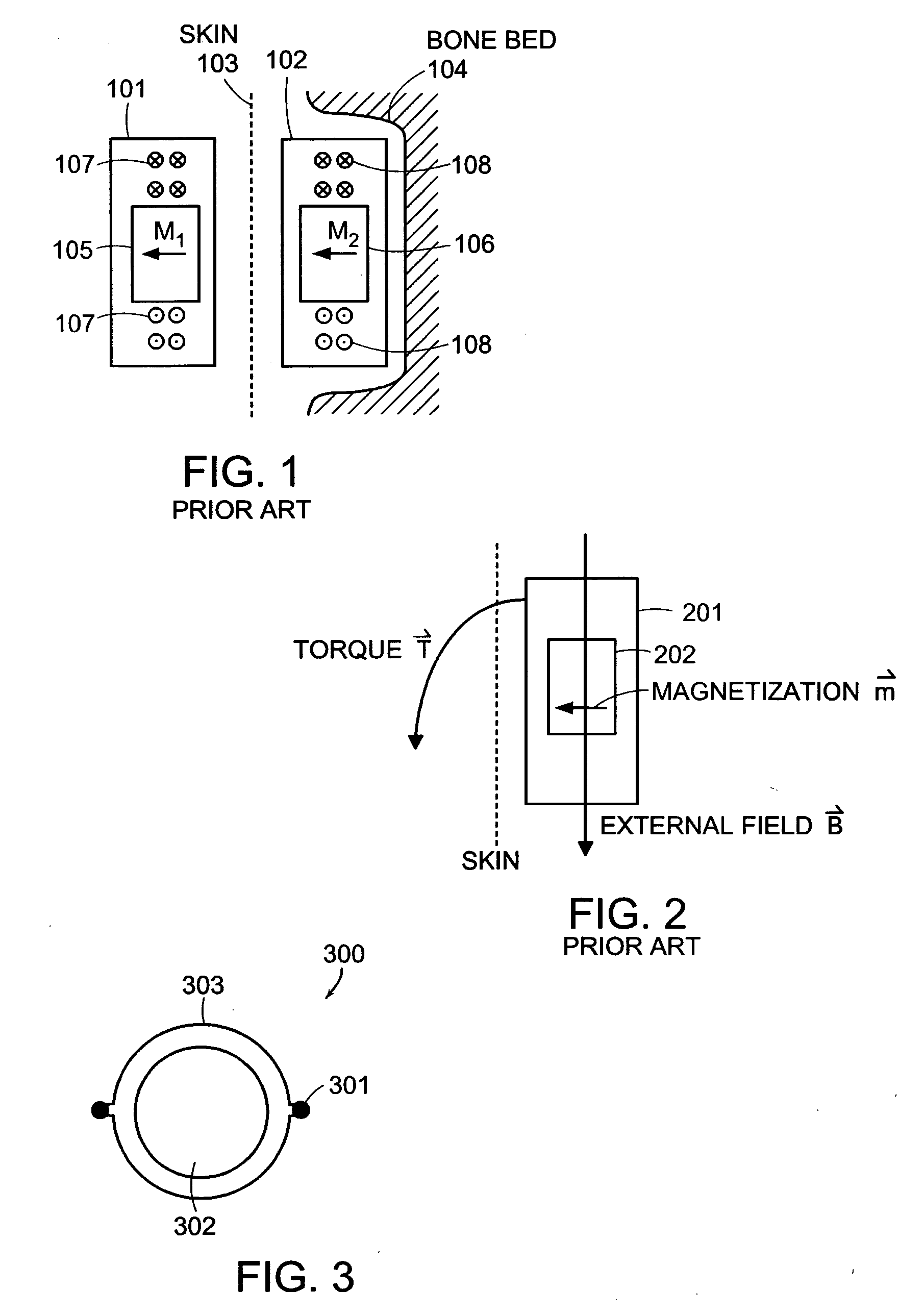

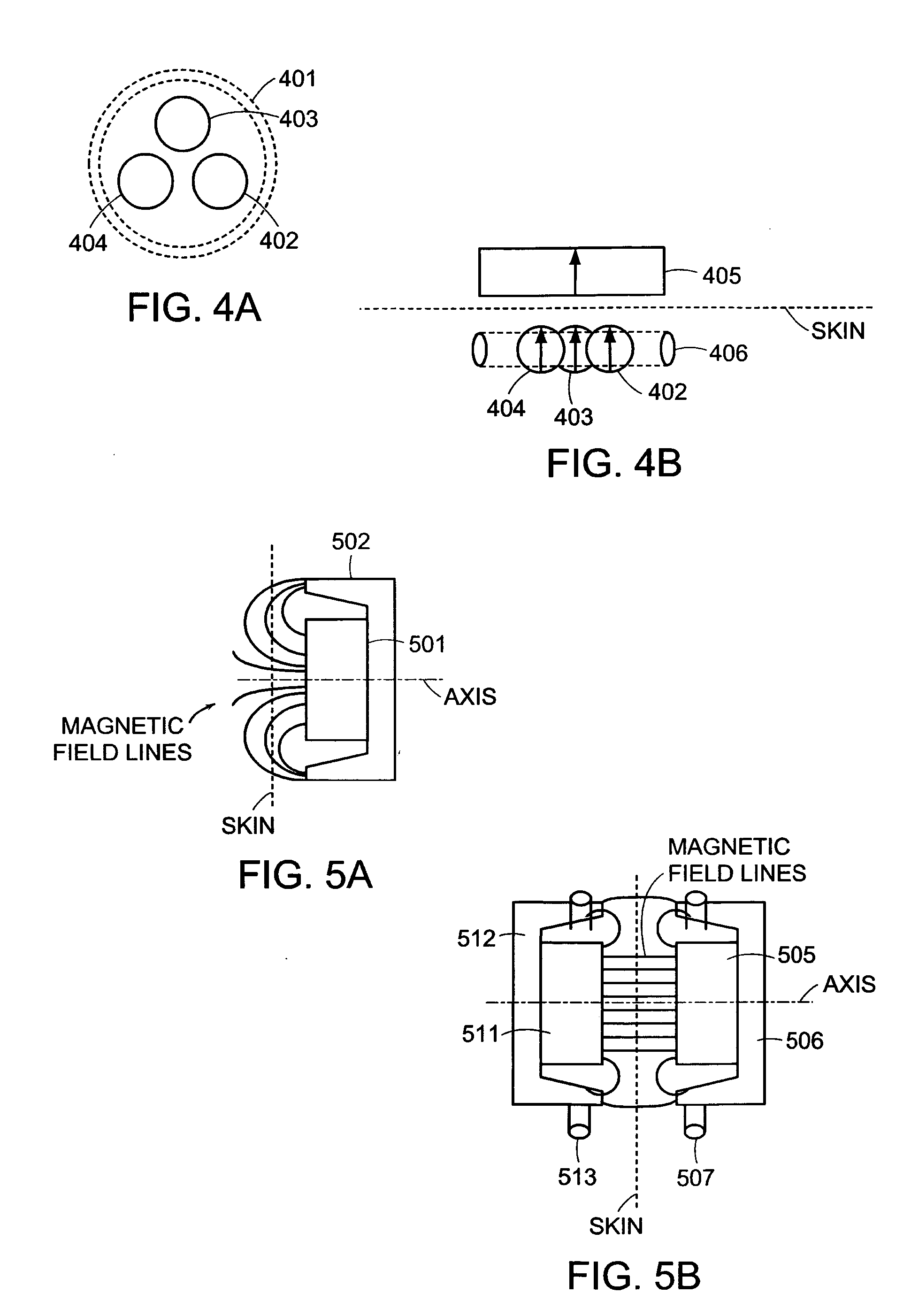

Reducing effects of magnetic and electromagnetic fields on an implant's magnet and/or electronics

InactiveUS6838963B2Provide protectionReduce torqueMagnetic movement switchesElectrotherapyMagnetic tension forceElectricity

An implantable magnet that can freely turn in response to an external magnetic field, thus avoiding torque and demagnetization on the implantable magnet. The implantable magnet can be combined with an electric switching function depending on the orientation of an external magnetic field, thus protecting an implanted coil and / or implant electronics against induction of over-voltage or performing an electric switching function for other various purposes. The magnetic switch may further include, for example, a first switching contact and a second switching contact. A magnetically soft body that includes an electrically conductive surface is shiftable between a first position where the body is in simultaneous contact with the first and second switching contacts, and a second position where the body is out of contact with at least one of the first and second switching contacts. The body and the implantable magnet are positioned such that the body is shifted to one of the first position and the second position as a function of the external magnetic field resulting in a magnetic force between the magnet and the magnetically soft body.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

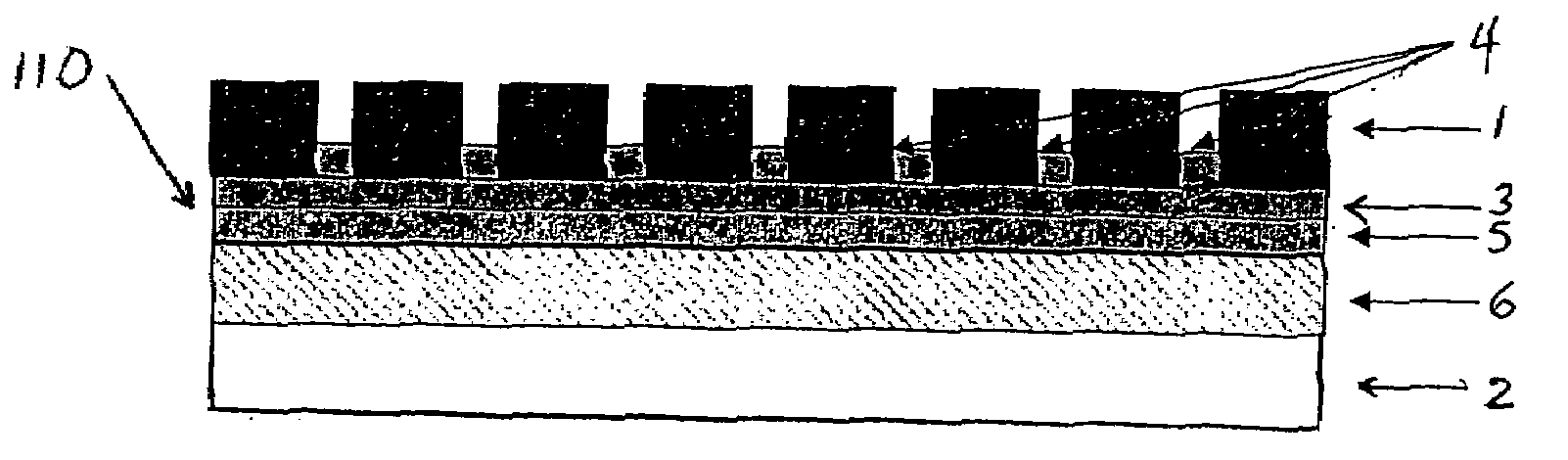

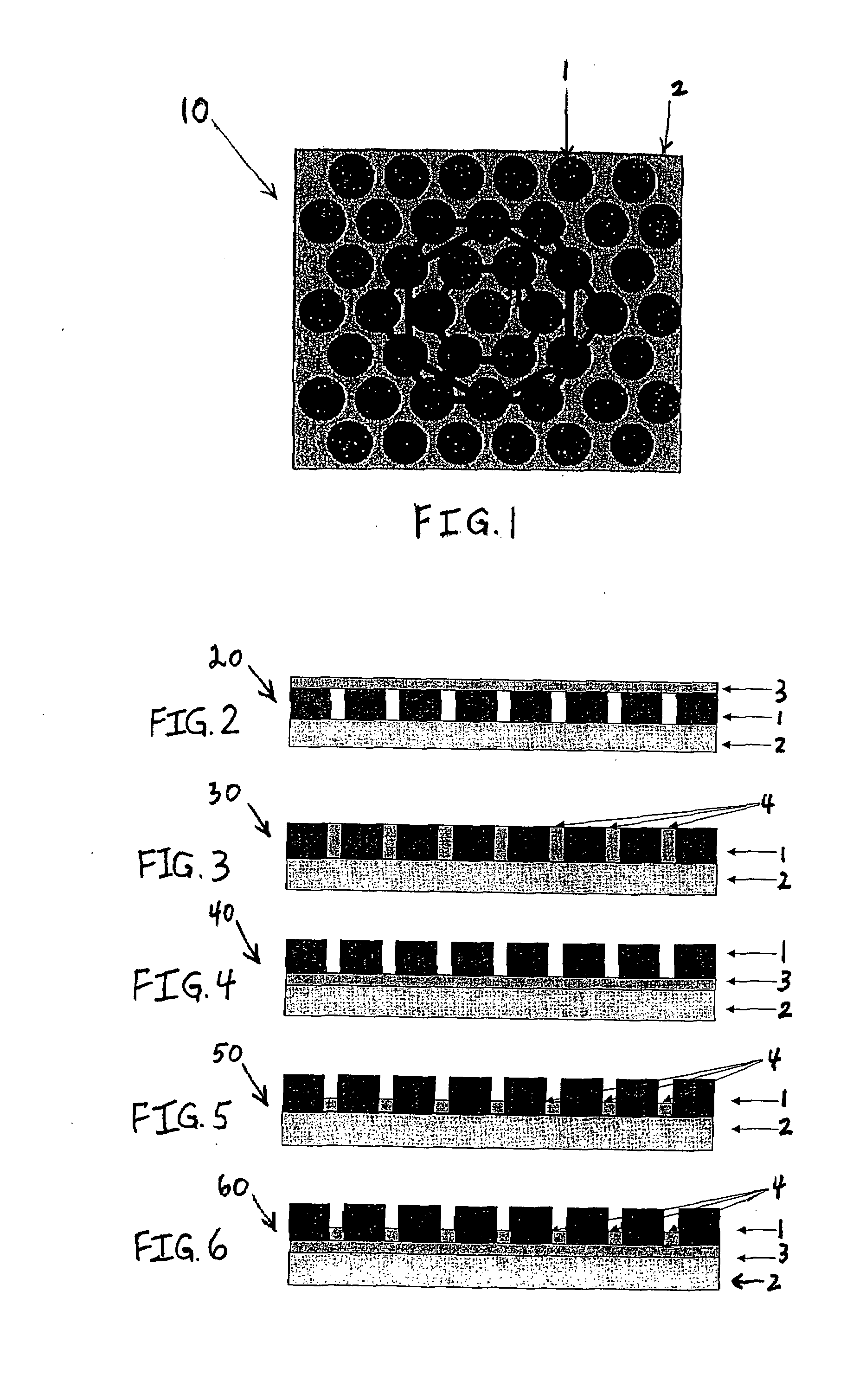

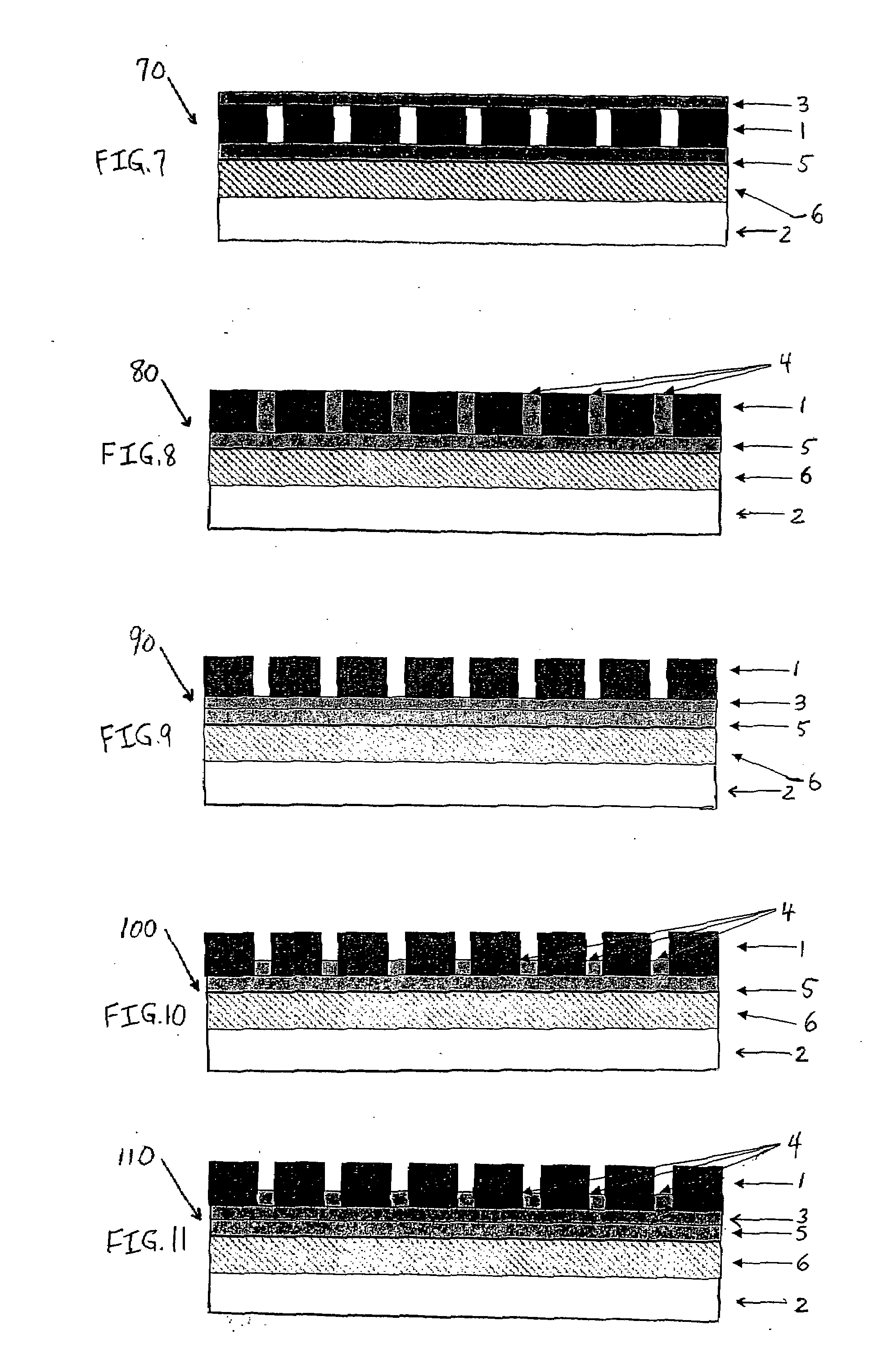

Close shaped magnetic multi-layer film comprising or not comprising a metal core and the manufacture method and the application of the same

InactiveUS20090168506A1High densitySmall scaleNanomagnetismMagnetic measurementsMagnetic beadMagnetic logic

Each layer in the magnetic multilayer film is a closed ring or oval ring and the magnetic moment or flux of the ferromagnetic film in the magnetic unit is in close state either clockwise or counterclockwise. A metal core is put in the geometry center position in the close-shaped magnetic multilayer film. The cross section of the metal core is a corresponding circular or oval. A MRAM is made of the closed magnetic multilayer film with or without a metal core. The close-shaped magnetic multilayer film is formed by micro process method. The close-shaped magnetic multilayer film can be used broadly in a great variety of device that uses a magnetic multilayer film as the core, such as MRAM, magnetic bead in computer, magnetic sensitive sensor, magnetic logic device and spin transistor.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Reducing effect of magnetic and electromagnetic fields on an implant's magnet and/or electronics

InactiveUS20050062567A1Reduce torqueReduce demagnetizationMagnetic movement switchesElectrotherapyMagnetic tension forceElectricity

An implantable magnet that can freely turn in response to an external magnetic field, thus avoiding torque and demagnetization on the implantable magnet. The implantable magnet can be combined with an electric switching function depending on the orientation of an external magnetic field, thus protecting an implanted coil and / or implant electronics against induction of over-voltage or performing an electric switching function for other various purposes. The magnetic switch may further include, for example, a first switching contact and a second switching contact. A magnetically soft body that includes an electrically conductive surface is shiftable between a first position where the body is in simultaneous contact with the first and second switching contacts, and a second position where the body is out of contact with at least one of the first and second switching contacts. The body and the implantable magnet are positioned such that the body is shifted to one of the first position and the second position as a function of the external magnetic field resulting in a magnetic force between the magnet and the magnetically soft body.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

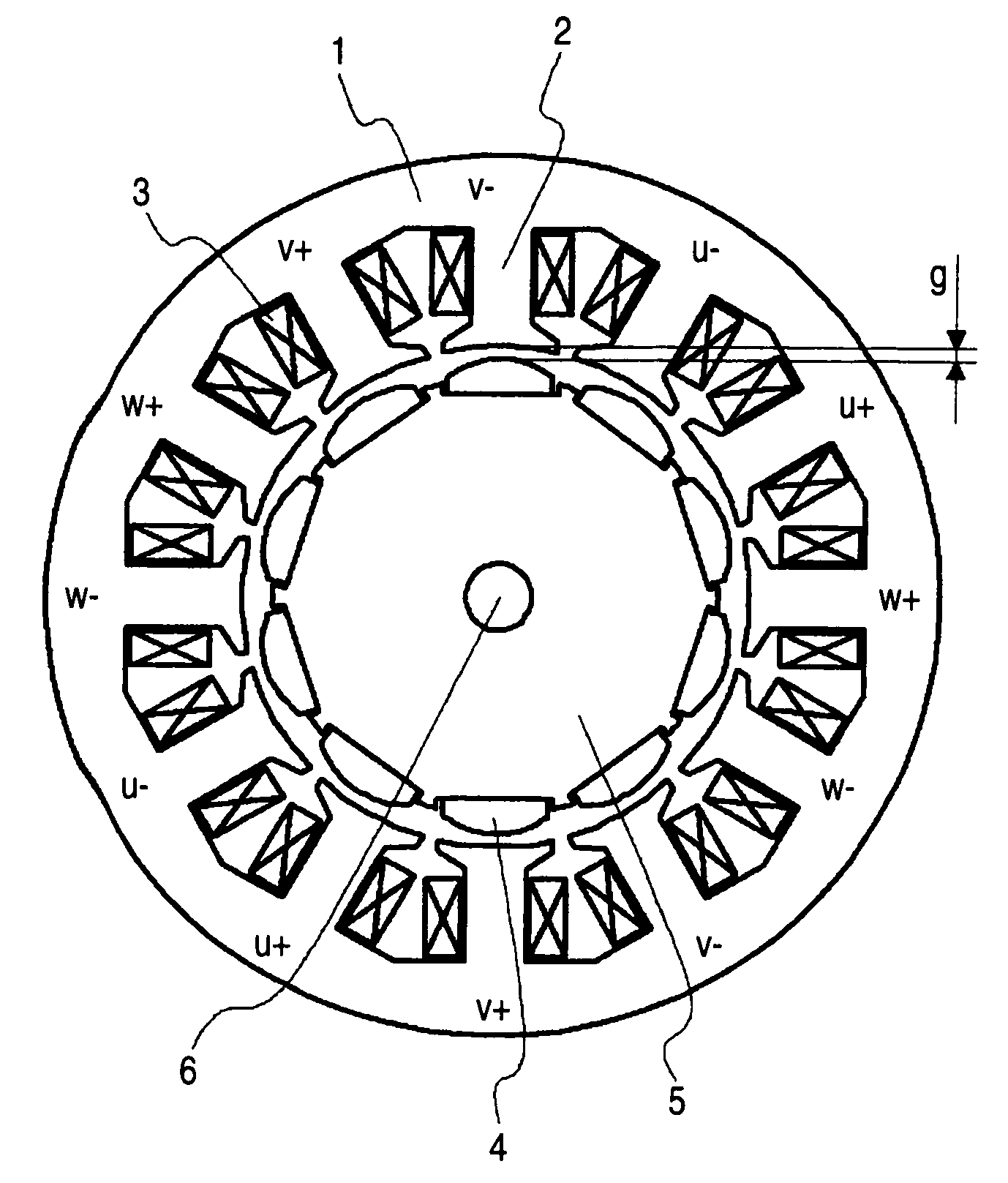

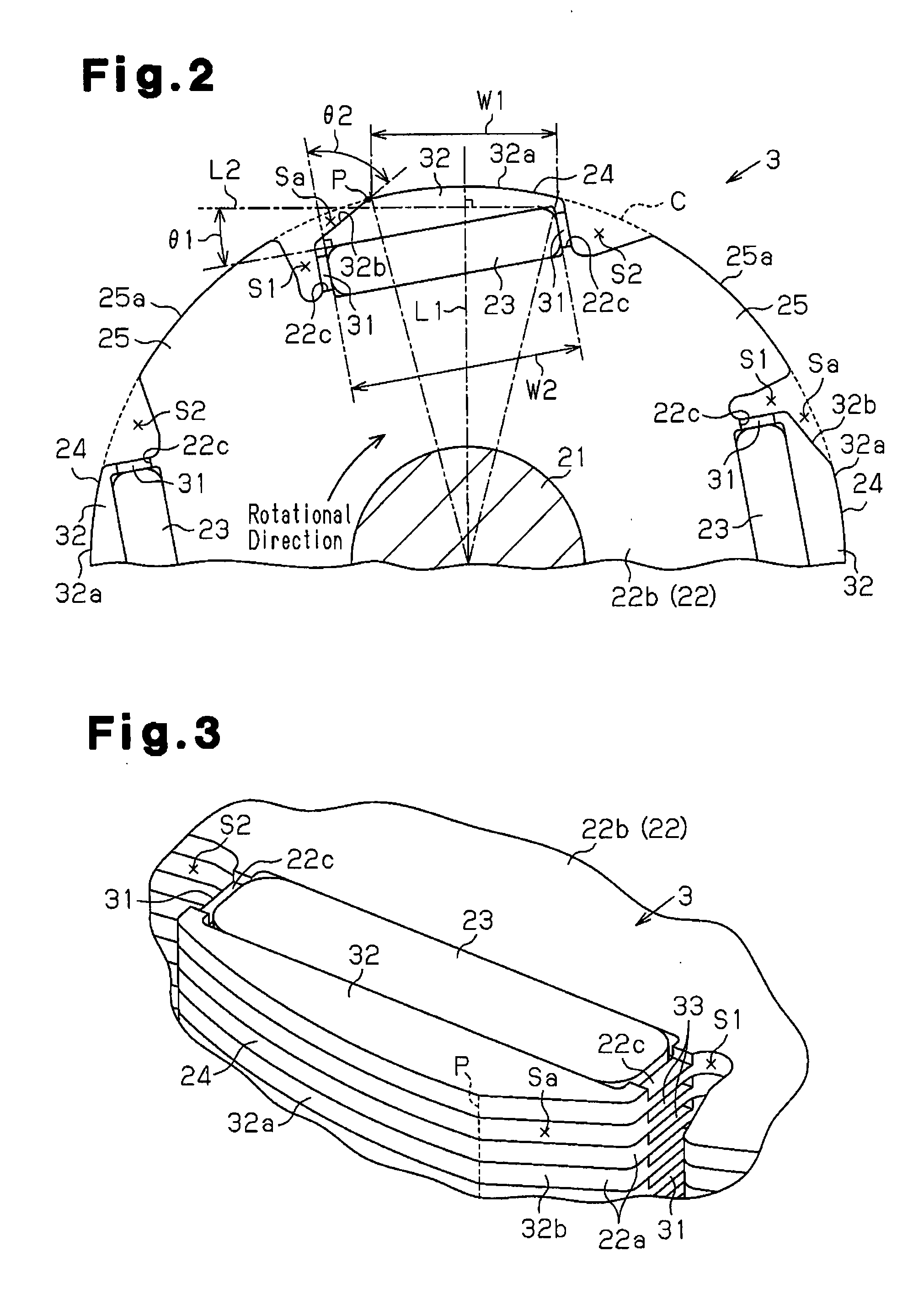

Permanent magnet rotating electric machine and electric power steering device using the same

ActiveUS20090251023A1Irreversible demagnetization can be decreasedCogging torque is decreasedMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsElectric power steeringElectric machine

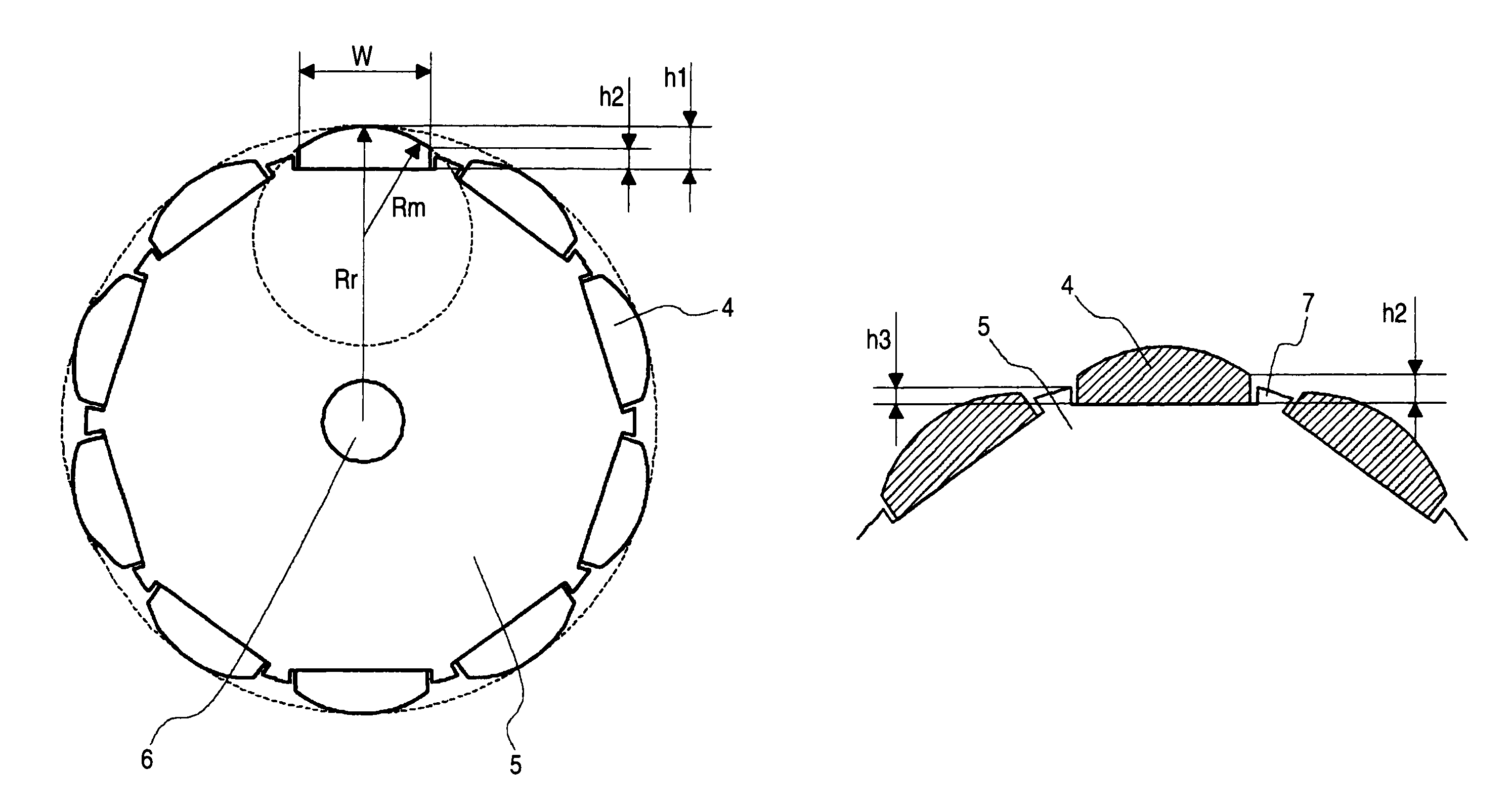

A permanent magnet rotating electric machine includes: a stator including: a stator core having teeth, and an armature winding wound around each of the teeth to configure the multiple phases; and a rotor including a rotor core, and permanent magnets provided in order around the rotor core. The rotor is arranged to be spaced apart from the stator with an air gap therebetween. Each of the permanent magnets has a curved surface opposed to the stator and is configured to satisfy the following relationship:0.65≤Rm×h1W(h1+g)≤1.37where Rm denotes a radius of curvature of the curved surface, h1 denotes a thickness of a central portion of the permanent magnet in the peripheral direction, W denotes a width of the permanent magnet in the peripheral direction, and g denotes an air gap length of the air gap.

Owner:MITSUBISHI ELECTRIC CORP

Brushless motor

InactiveUS20120091845A1Reduce demagnetizationIncrease torqueMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsPhysicsBrushless motors

A brushless motor includes a rotor and a stator. The rotor is provided with a rotor core including a plurality of magnet poles and a plurality of core poles. A void is formed at a boundary between each core pole and an adjacent magnet pole in the circumferential direction. Each magnet pole includes a peripheral core portion located closer to the stator than the magnet in the radial direction of the rotor. The void formed in at least one of two circumferential sides of each magnet pole includes an extended void region that extends into the peripheral core portion toward a middle point of the magnet pole in the circumferential direction.

Owner:ASMO CO LTD

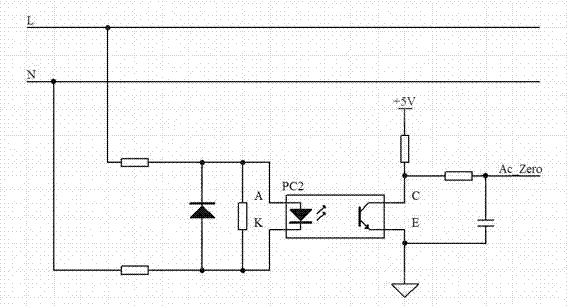

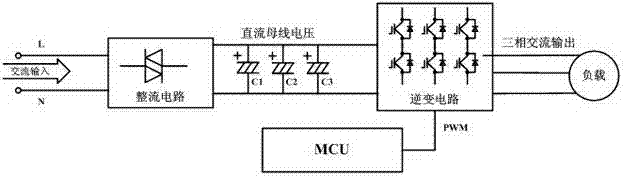

Poweroff detection method of alternating current power supply and poweroff protection method of direct current inverter compressor

ActiveCN102901936AReduce demagnetizationImprove reliabilityEmergency protective circuit arrangementsPower supply testingHolding timeEngineering

The invention discloses a poweroff detection method of an alternating current power supply and a poweroff protection method of a direct current inverter compressor. A wave form of alternating voltage of the alternating current power supply is detected, and when an absolute value of an amplitude value of the alternating voltage is less than a protection threshold Vp and the duration exceeds the set hold time T, the alternating current power supply is determined to be powered off, wherein when the hold time T is normally greater than the alternating voltage, the experienced dead time from -Vp to +Vp or from +Vp to -Vp before and after zero is t0. The poweroff detection method of the alternating current power supply can be used for detecting the alternating current power supply in real time, detecting the instantaneous poweroff condition of the power supply within short time, quickly reacting to the control of a controlled object, and implementing quick protection. When the method is used for poweroff protection of the direct current inverter compressor, a power supply inverter and the direct current inverter compressor can be effectively protected, thereby improving the reliability of a product and prolonging the service life of the product.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

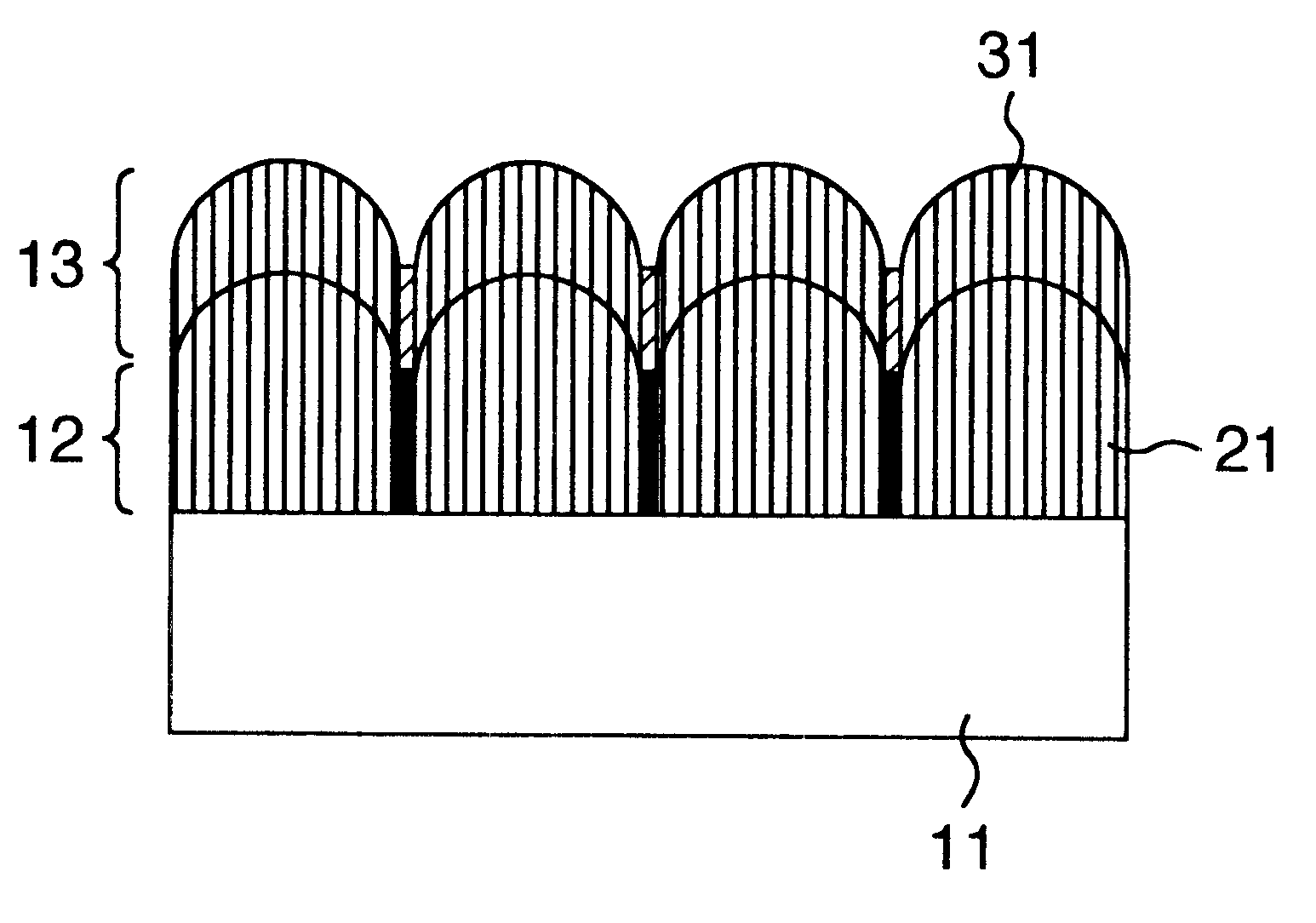

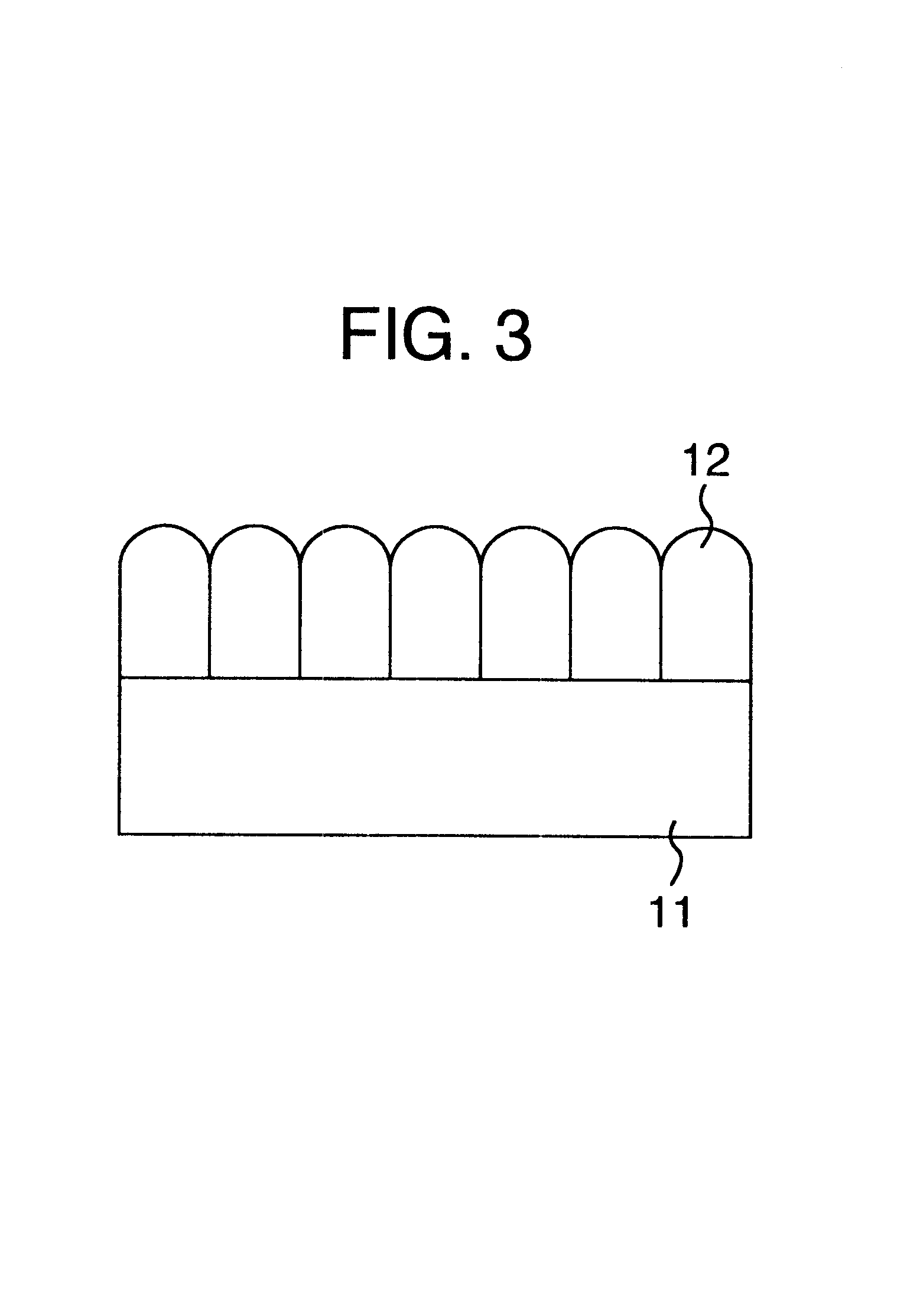

Magnetic recording disk

InactiveUS6472047B1Reduced magnetic interactionReduce demagnetizationBase layers for recording layersVacuum evaporation coatingSilicon oxideTitanium oxide

The magnetic recording medium includes an underlayer 12 formed of an inorganic compound layer, and a magnetic layer 13 formed over the underlayer 12. The inorganic compound layer as the underlayer 12 has crystal grains and at least one kind of oxide, the crystal grains having as main elements at least one of cobalt oxide, chromium oxide, iron oxide and nickel oxide, the at least one kind of oxide lying as a non-crystalline phase in grain boundaries between the crystal grains and selected from among silicon oxide, aluminum oxide, titanium oxide, tantalum oxide and zinc oxide.

Owner:HITACHT MAXELL LTD +1

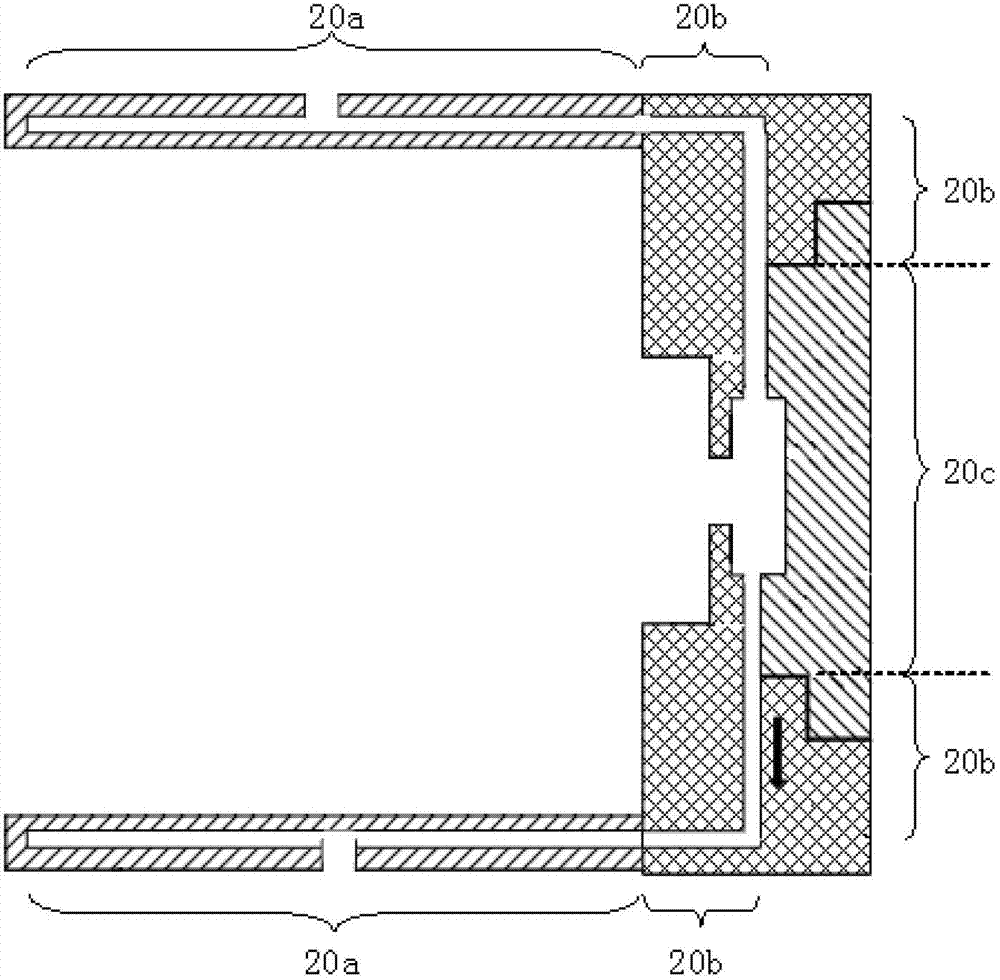

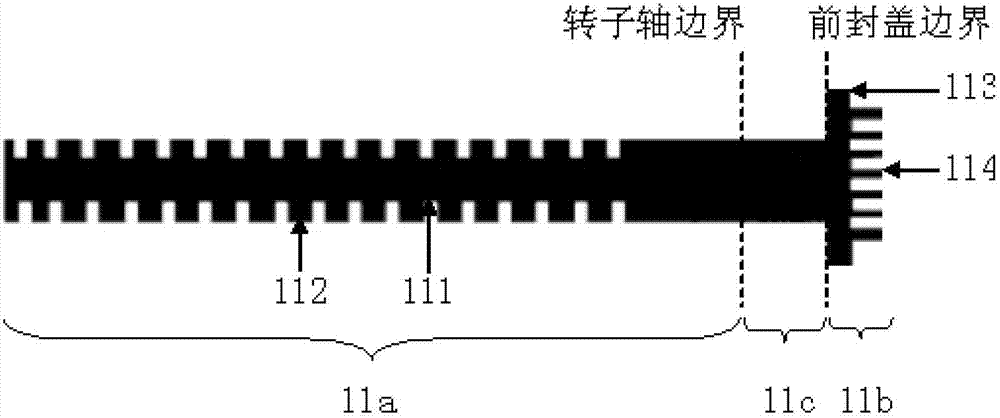

Cooling structure of inner rotor motor

ActiveCN102810943AElectrical performance impactImprove performanceMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringCooling medium

The invention discloses a cooling structure of an inner rotor motor. The inner rotor motor comprises a rotor shaft, a rotor section, a stator section, a front end cover and a seal cover. The cooling structure comprises a third cavity arranged between the front end cover and the seal cover, and the third cavity is used as one part of a cooling medium channel. The rotor shaft is internally provided with a heat conduction cavity, an opening of the heat conduction cavity is arranged at one side of the front end cover, and the inner part of the heat conduction cavity is provided with heat conduction media. The first end of a heat conduction rod is arranged in the heat conduction cavity and is contacted with the heat conduction media, the second end of the heat conduction rod is arranged in the third cavity and is contacted with cooling media, and the second end and the front end cover are sealed by adopting a static seal way. The rotor shaft and the heat conduction rod are sealed by adopting a dynamic seal way. The heat of the rotor section and the rotor shaft is transmitted from the first end of the heat conduction rod in the heat conduction cavity to the second end of the heat conduction rod and is dissipated through the cooling media in the third cavity. According to the cooling structure of an inner rotor motor, the good heat dissipating effects of the stator and the rotor are obtained, and meanwhile the strict requirements for insulation, seal and volume are satisfied.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

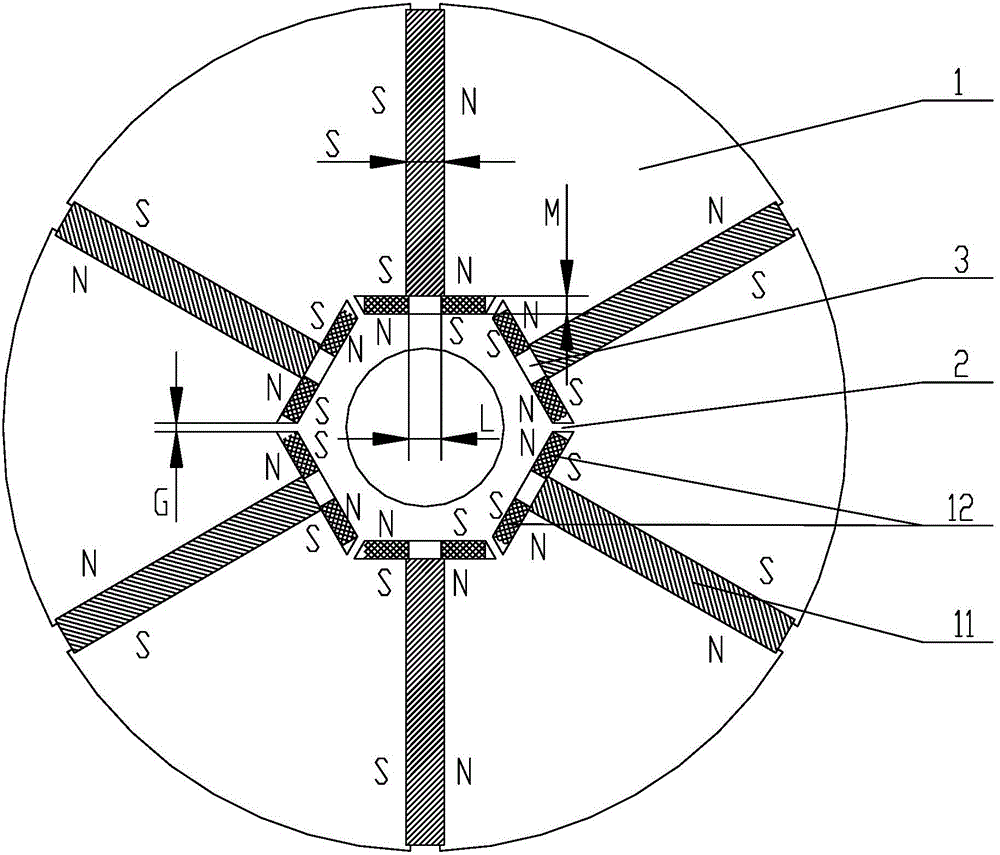

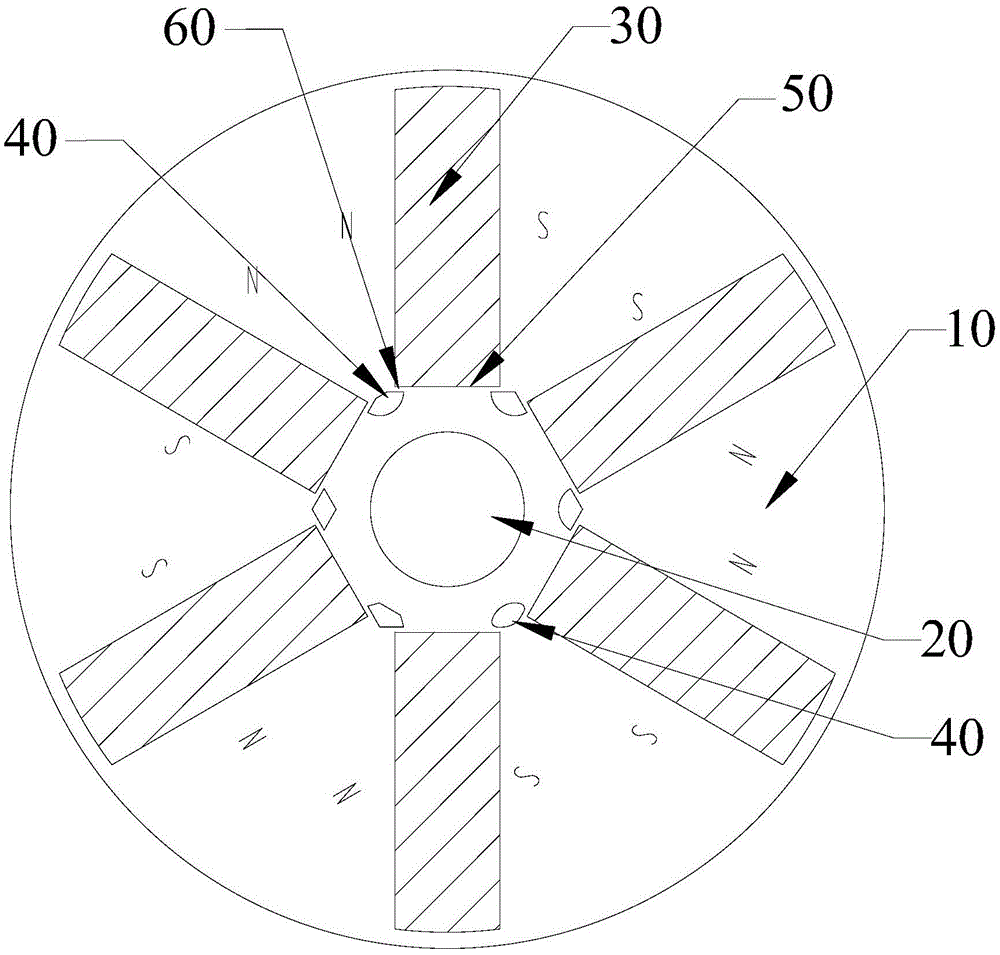

Rotor of permanent magnet synchronous motor and permanent magnet synchronous motor provided with same

ActiveCN104485762AHigh mechanical strengthReduce Flux LeakageSynchronous machine detailsMagnetic circuit rotating partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a rotor of a permanent magnet synchronous motor and the permanent magnet synchronous motor, which belong to the technical field of the permanent magnet synchronous motors, and are designed in order to solve the problems of high leakage flux, low permanent magnet utilization rate, influence on motor performance and efficiency and the like in existing rotor of the permanent magnet synchronous motor. The rotor of the permanent magnet synchronous motor comprises a rotor core, wherein an even number n of tangential permanent magnets are distributed evenly in radial direction on the rotor core, and the same polarities of two adjacent tangential permanent magnets are opposite; radial permanent magnets are arranged symmetrically on two sides of one end of each tangential permanent magnet close to the inner side of the rotor core respectively; every two radial permanent magnets sandwiched between two adjacent tangential permanent magnets have the same polarity in the direction facing to a stator, and a magnetic isolating bridge is arranged between every two radial permanent magnets. The invention further discloses a permanent magnet synchronous motor provided with the rotor. By utilizing the rotor, the leakage flux of the tangential permanent magnets on the inner side of the rotor is reduced, the utilization rate of the permanent magnets is improved, and the motor efficiency and the motor structural intensity are enhanced.

Owner:GREE ELECTRIC APPLIANCES INC +1

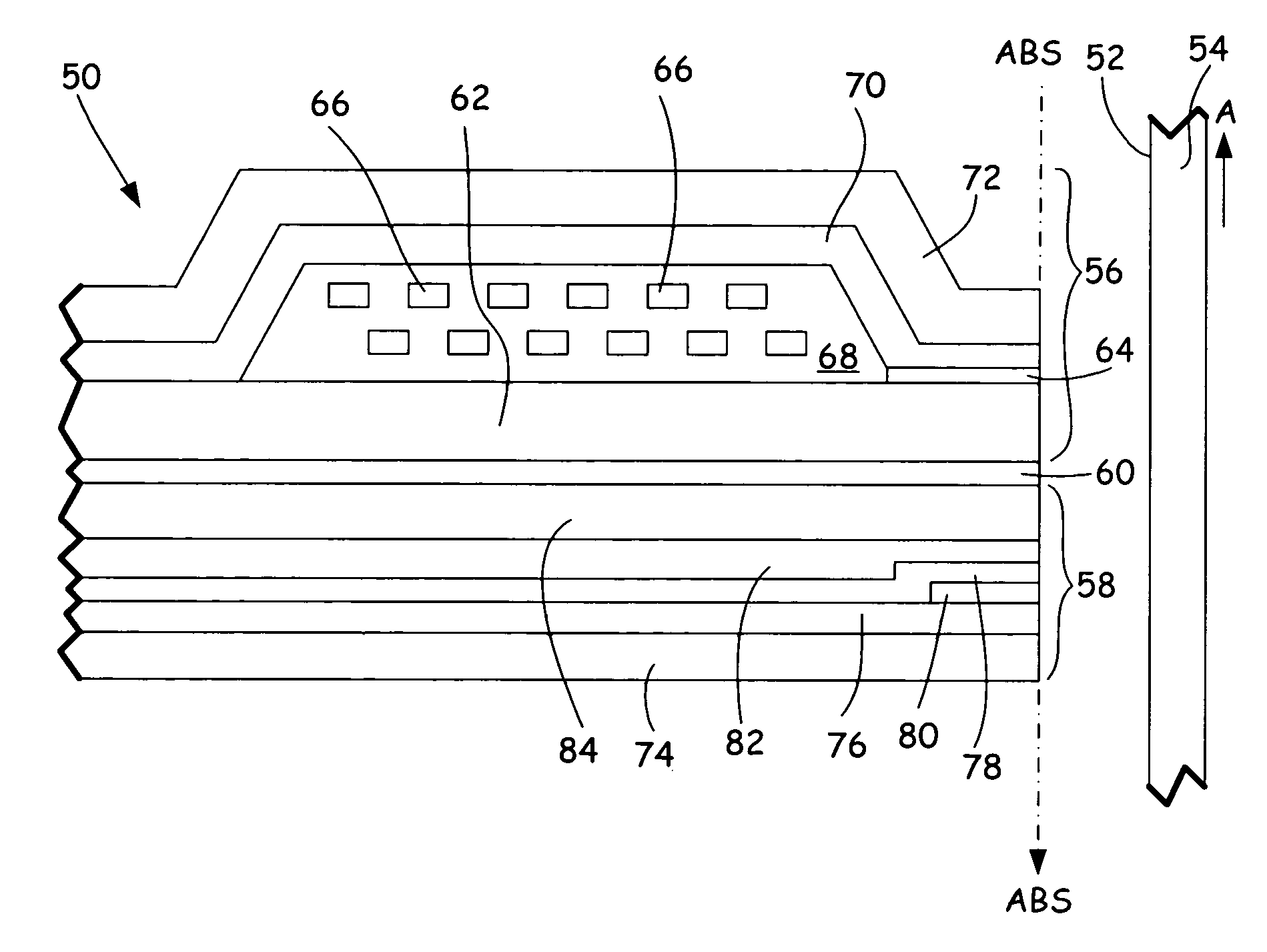

Domain wall free shields of MR sensors

InactiveUS7236333B2Reduce impactMaintaining couplingCarrier constructional parts dispositionRecord information storageMagnetic shieldNon magnetic

Owner:SEAGATE TECH LLC

Permanent magnet and permanent magnet rotating machine

ActiveUS20080055032A1Reduce torqueReduce demagnetizationMagnetic circuit rotating partsPermanent magnetsMagnetCentral region

Owner:SHIN ETSU CHEM IND CO LTD

Bit patterned magnetic media with exchange coupling between bits

InactiveUS20080085425A1Reduced coercivity distributionImprove stabilityPatterned record carriersNanoinformaticsMagnetic exchangeMagnetic media

A bit patterned magnetic recording medium, comprises a non-magnetic substrate having a surface; a plurality of spaced apart magnetic elements on the surface, each of the elements constituting a discrete magnetic domain or bit; and a layer of a ferromagnetic material for regulating magnetic exchange coupling between said magnetic elements. The layer has a saturation magnetization Ms ranging from about 1 to about 2,000 emu / cm3, preferably below about 400 emu / cm3, more preferably below about 200 emu / cm3, and may overlie, underlie, or at least partially fill spaces between adjacent magnetic elements.

Owner:SEAGATE TECH LLC

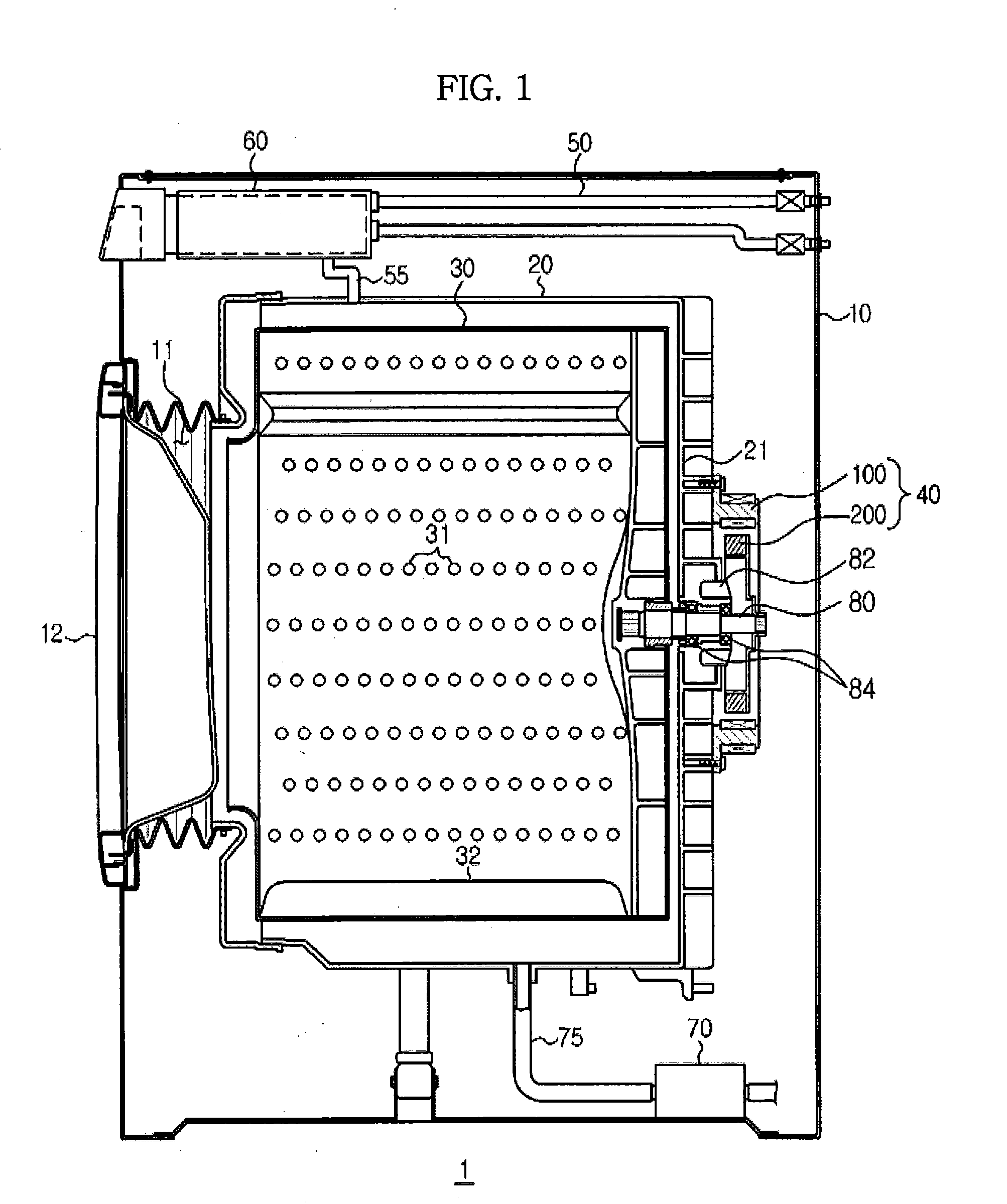

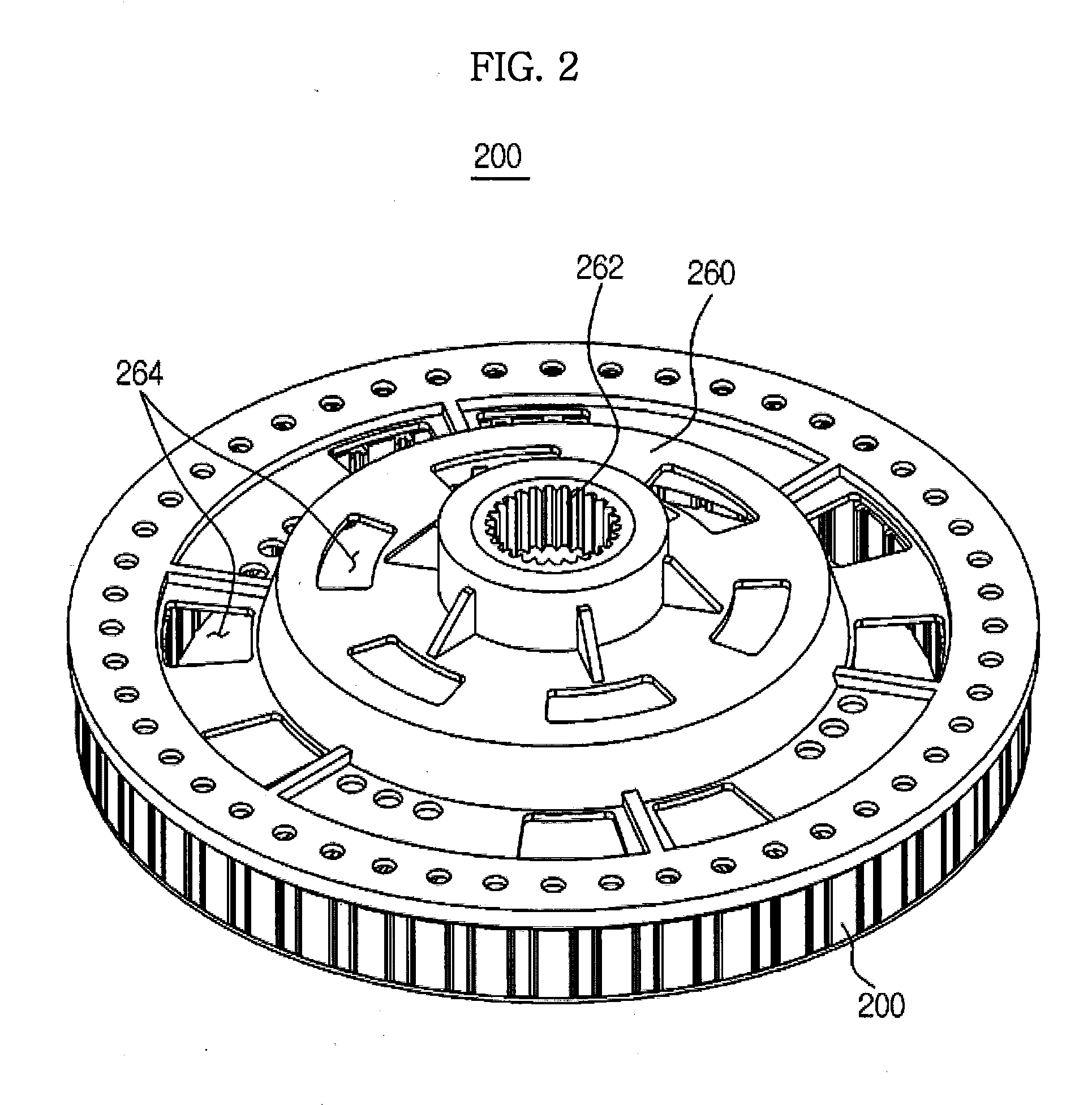

Motor and washing machine having the same

ActiveUS20130061641A1Reduce Flux LeakageReduce demagnetizationMagnetic circuit rotating partsMagnetic circuit characterised by insulating materialsEngineeringMotor shaft

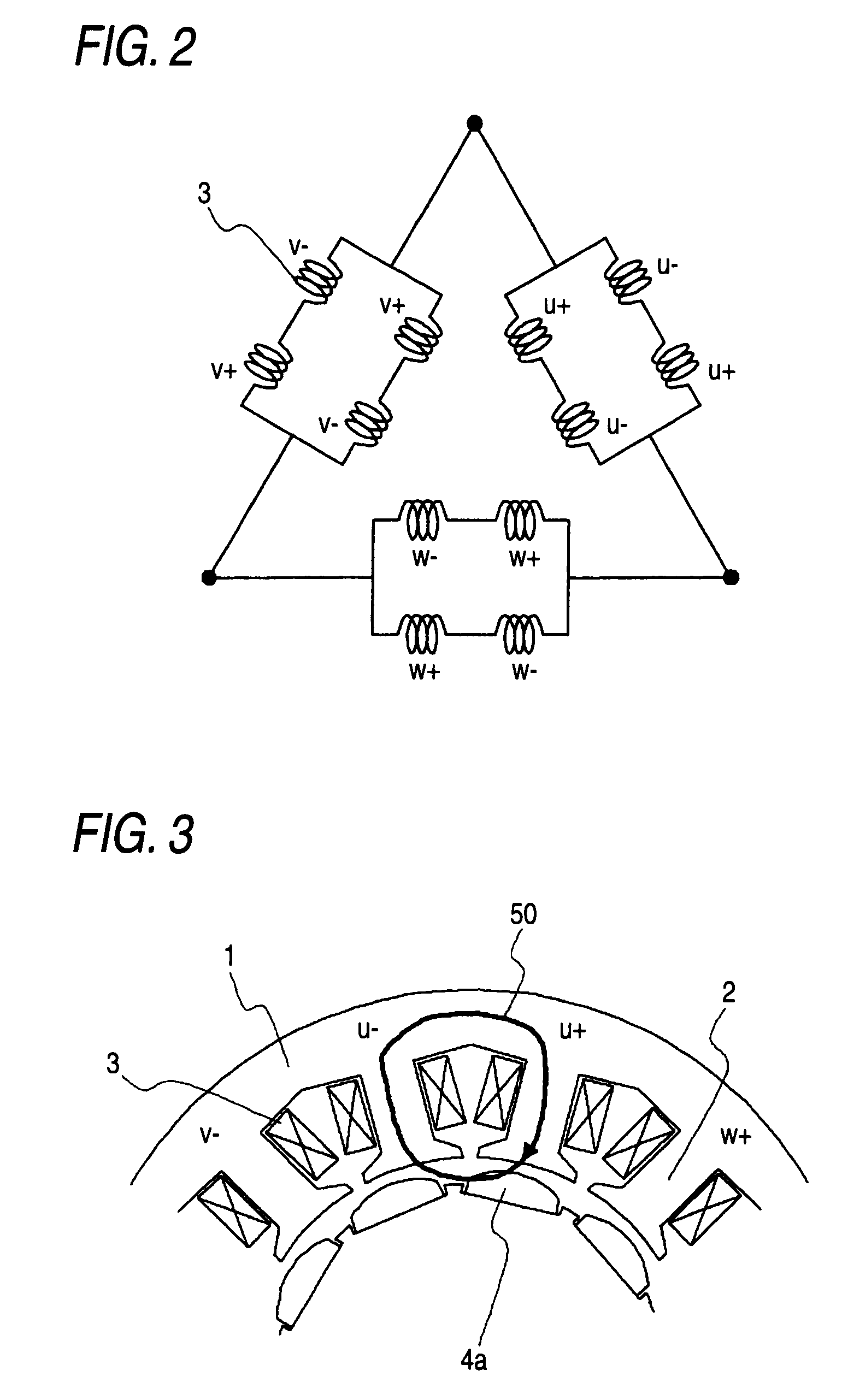

A motor having a structure capable of achieving a reduction in magnetic flux leakage occurring at a rotor and a washing machine, to which the motor is applied. The motor includes a stator including a plurality of stator cores arranged in a circumferential direction, and coils respectively wound around the stator cores, and a rotor rotatably arranged inside the stator. The rotor includes a plurality of rotor cores arranged in a circumferential direction of the rotor, a plurality of magnets each disposed between neighboring ones of the rotor cores such that the magnet extends in an axial direction of the rotor outwardly of upper and lower surfaces of the neighboring rotor cores, and a molded body to support the plurality of rotor cores and the plurality of magnets. The molding body includes a shaft hole, to which a motor shaft is coupled.

Owner:SAMSUNG ELECTRONICS CO LTD

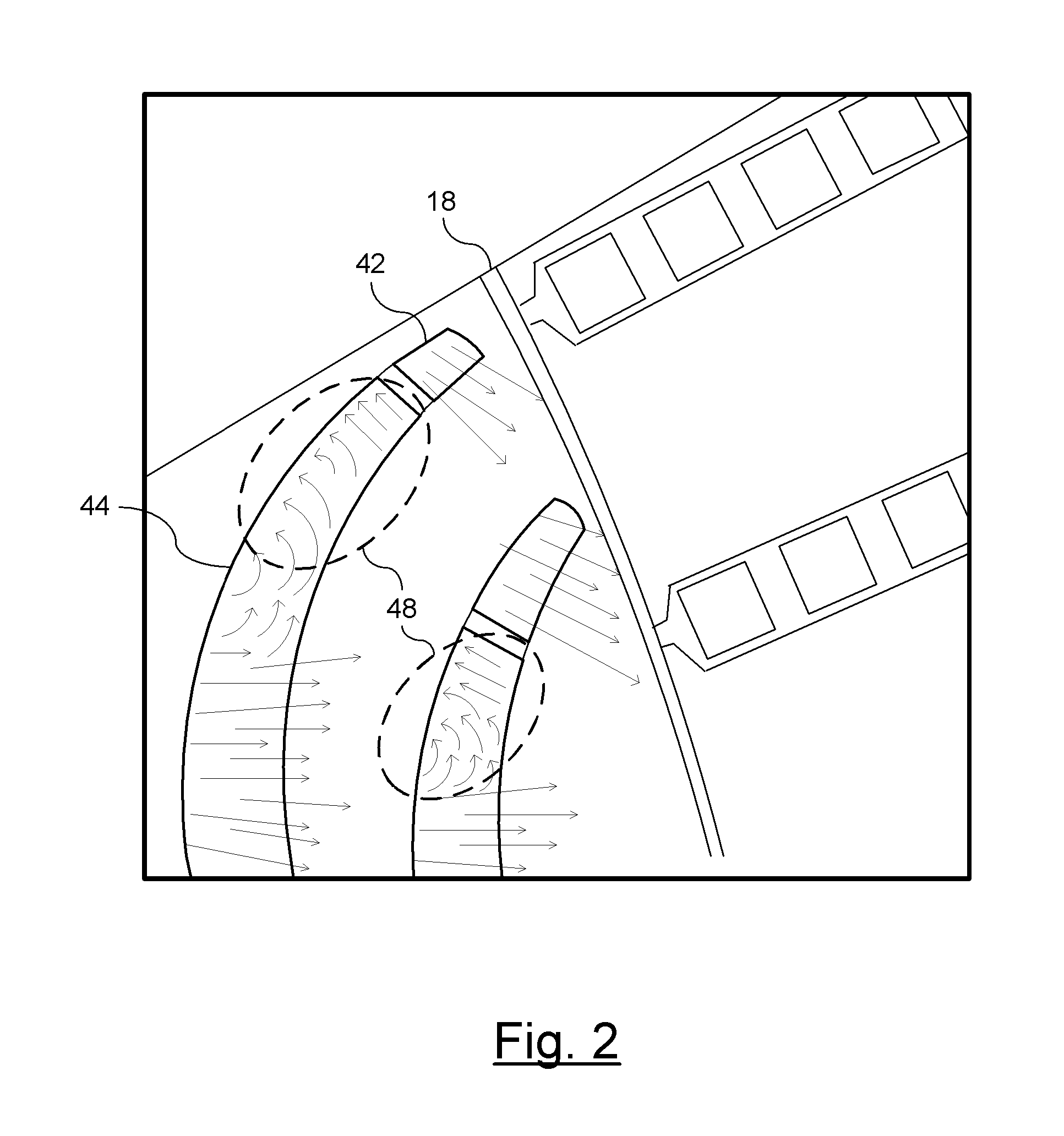

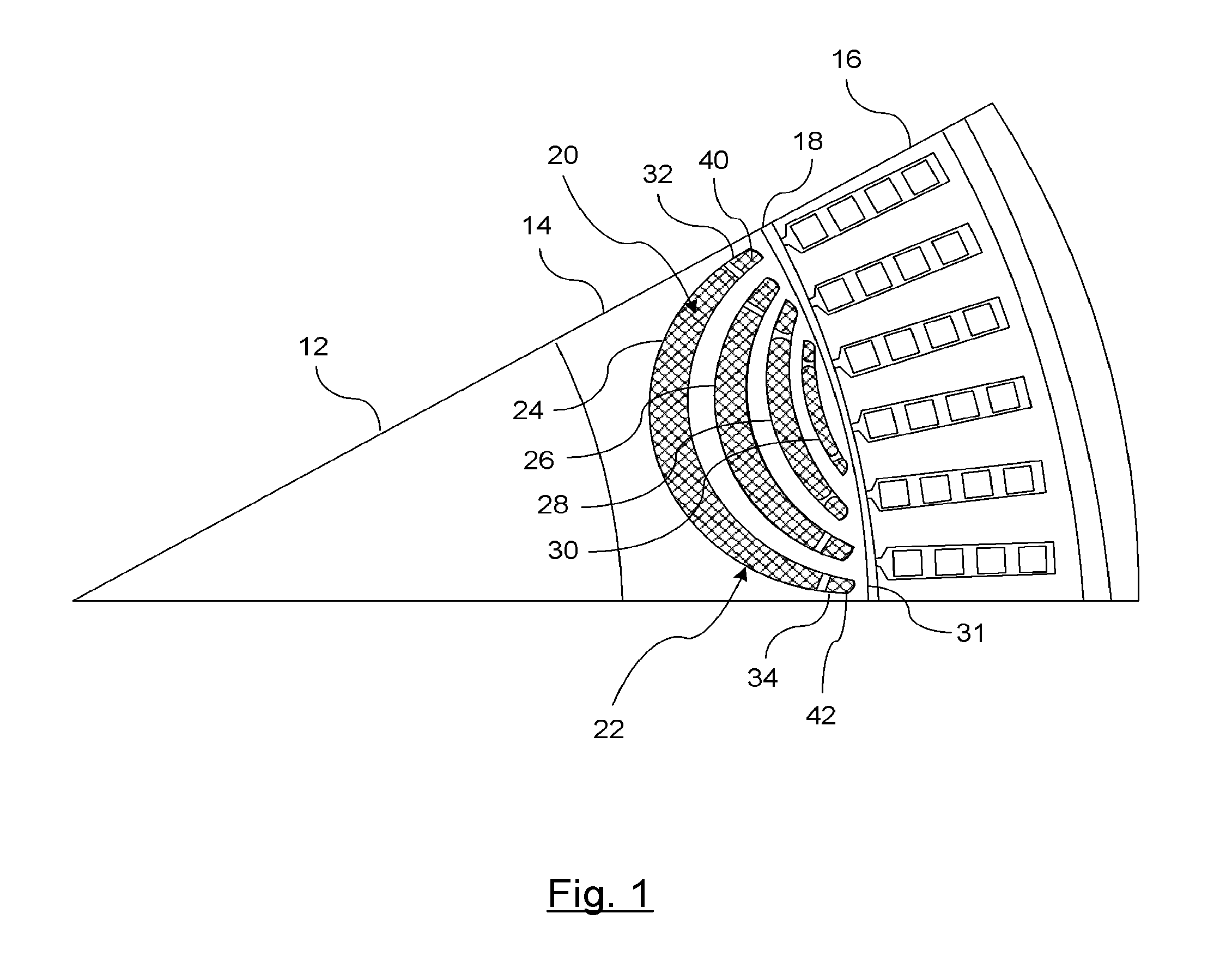

Bi-permanent magnets in synchronous machines

ActiveUS20130320796A1Low costReduce in quantityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsField strengthMagnet

A rotor for an interior permanent synchronous machine. A rotor core structure includes an outer cylindrical wall juxtaposed to an air gap. A plurality of arcuately-shaped cavities is formed within the rotor core structure. The plurality of arcuately-shaped cavities is substantially concentrically layered with respect to an outer cylindrical wall of the rotor core structure. Each arcuately-shaped cavity extending between first and second end sections is juxtaposed to the outer cylindrical surface wall of the rotor structure and includes an intervening center section. A plurality of permanent magnets is inserted within the plurality of arcuately-shaped cavities. Each first end section retains a respective first permanent magnet having a first magnet field strength. Each second end section retains a respective second permanent magnet having the first magnetic field strength. Each center section retains a respective third permanent magnet having a second magnet field strength less than the first magnetic field strength.

Owner:GM GLOBAL TECH OPERATIONS LLC

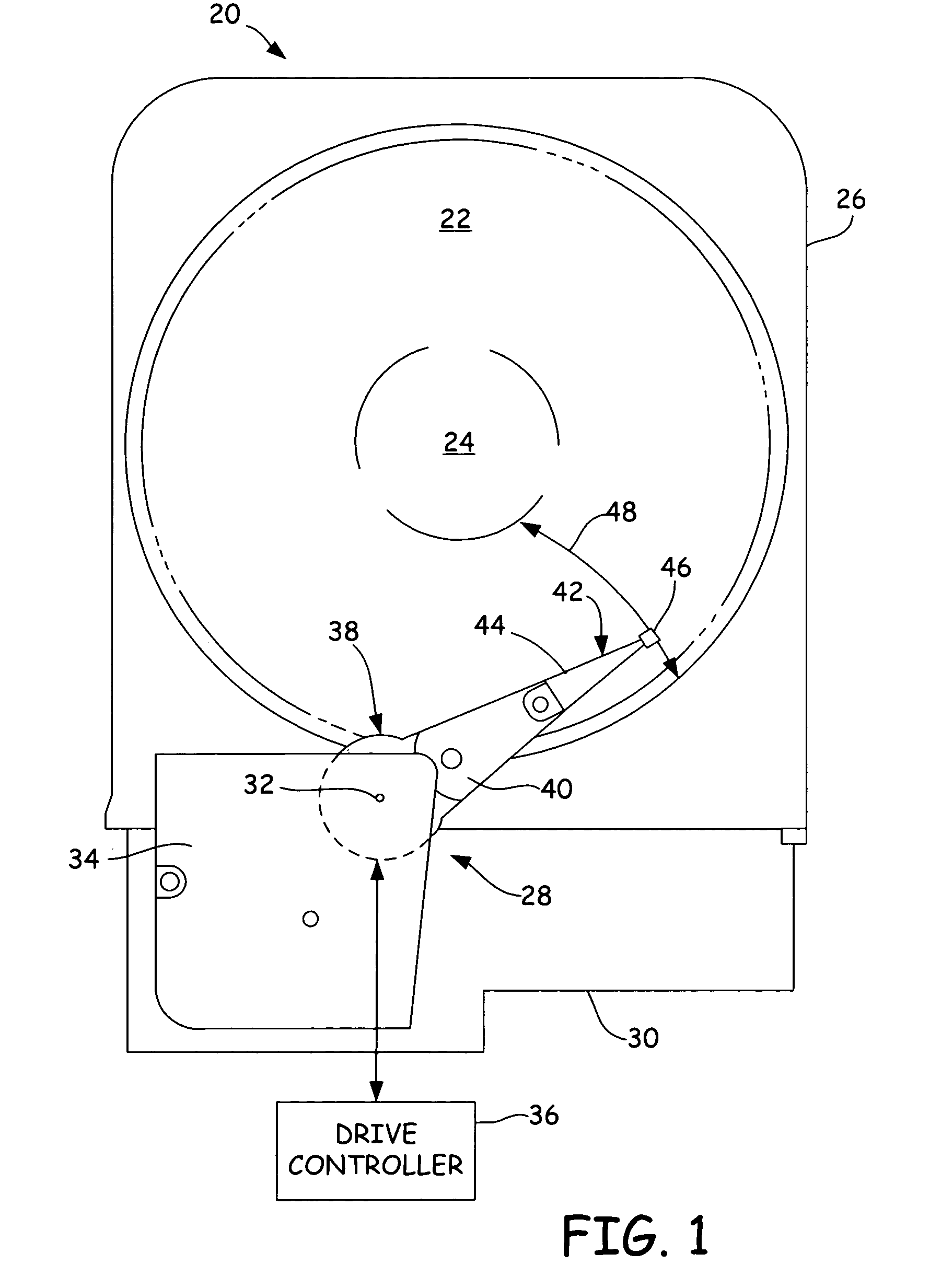

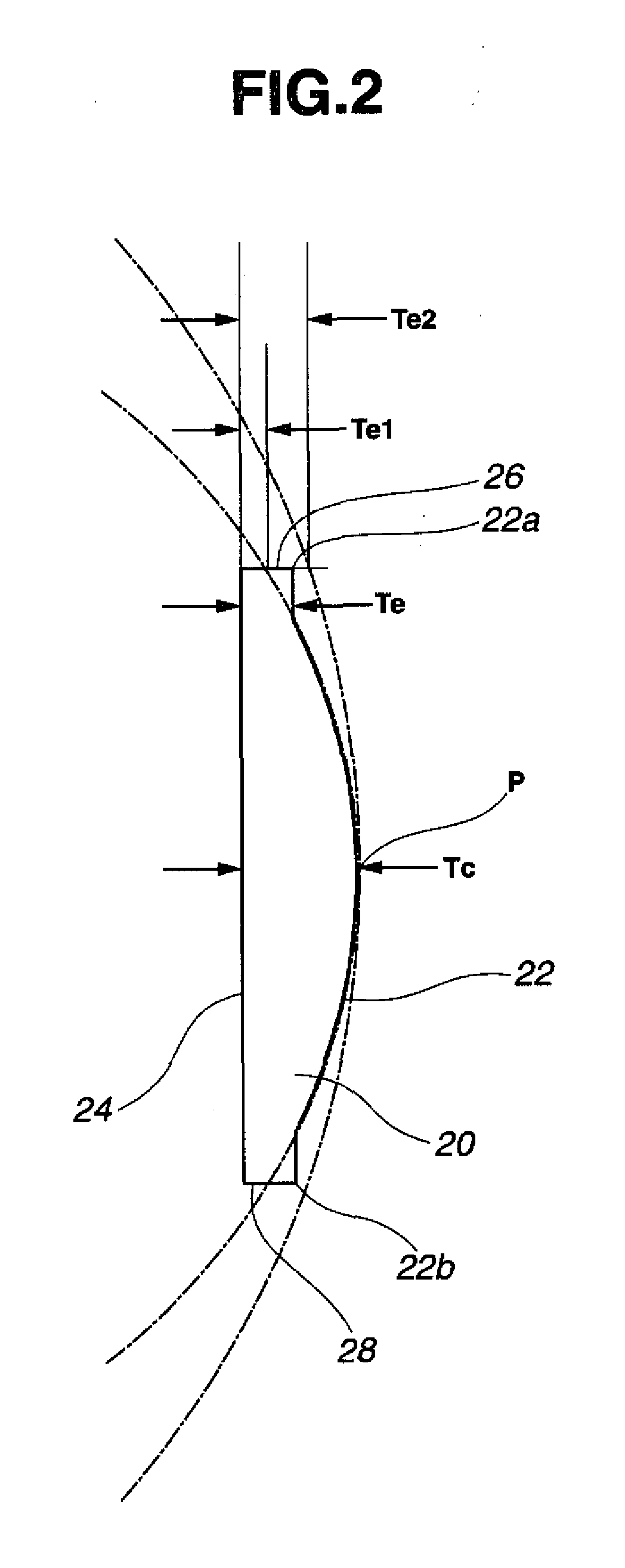

Method of servo writing for magnetic recording system, magnetic recording system

InactiveUS7075743B2Shorten the lengthReduce demagnetizationTrack finding/aligningRecord information storageRecording densityBit-length

In a method of servo writing of a magnetic recording system and the magnetic recording system, the signal is recorded in a dummy area with a higher recording density than the burst signal. Also, the maximum bit length of the burst area is shortened as compared with the maximum bit length of the data area. A servo control method for perpendicular recording similar to that for longitudinal recording can be used to reduce the development cost. The anti-signal decay performance is also improved. Further, since the variations of the burst signal along the track width is suppressed, the positioning accuracy is improved. These effects combine to produce a reliable magnetic recording system of large capacity.

Owner:WESTERN DIGITAL TECH INC +1

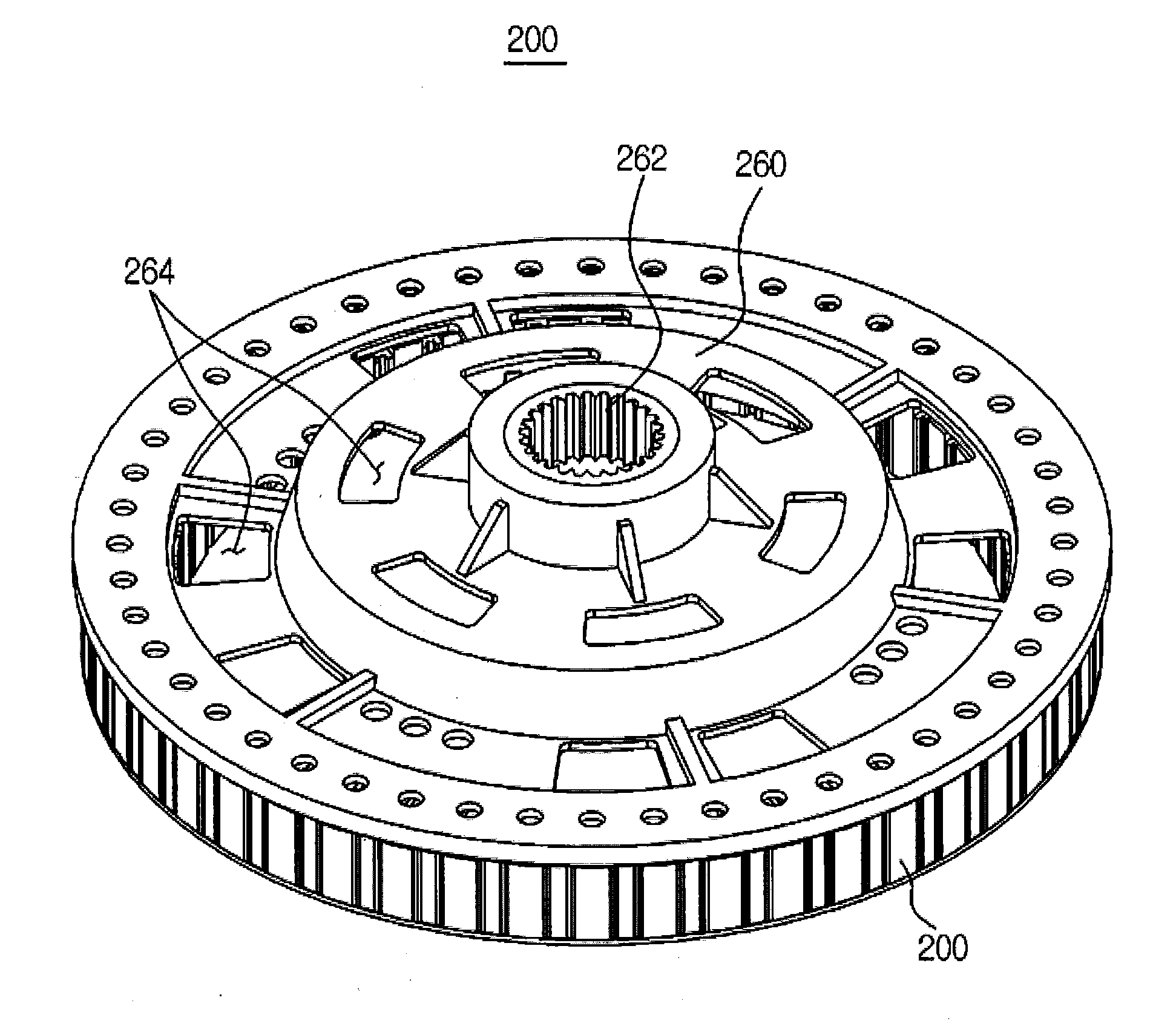

Bi-permanent magnets in synchronous machines

ActiveUS8664822B2Low costReduce in quantitySynchronous machine detailsMagnetic circuit rotating partsField strengthMagnet

A rotor for an interior permanent synchronous machine. A rotor core structure includes an outer cylindrical wall juxtaposed to an air gap. A plurality of arcuately-shaped cavities is formed within the rotor core structure. The plurality of arcuately-shaped cavities is substantially concentrically layered with respect to an outer cylindrical wall of the rotor core structure. Each arcuately-shaped cavity extending between first and second end sections is juxtaposed to the outer cylindrical surface wall of the rotor structure and includes an intervening center section. A plurality of permanent magnets is inserted within the plurality of arcuately-shaped cavities. Each first end section retains a respective first permanent magnet having a first magnet field strength. Each second end section retains a respective second permanent magnet having the first magnetic field strength. Each center section retains a respective third permanent magnet having a second magnet field strength less than the first magnetic field strength.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hybrid cooling system and method for plug-in new-energy bus motor

ActiveCN104002661AImprove operational reliabilityReduce demagnetizationCooling/ventillation arrangementPropulsion coolingAir cooling systemDrive motor

The invention discloses a hybrid cooling system and method for a plug-in new-energy bus motor. The system comprises an ECU, a motor water-cooling device and a motor air-cooling device. The motor water-cooling device and the motor air-cooling device are respectively provided with a temperature acquisition device and a temperature control device. The ECU is connected with the temperature acquisition devices and the temperature control devices. The hybrid cooling system and method for the plug-in new-energy bus motor are based on the characteristics of pure electric driving and hybrid power driving of plug-in hybrid power, and the working state of a water-cooling system and the working state of an air-cooling system are controlled according to working condition modes and motor temperature. In this way, the drive motor can work at the optimal temperature under any working condition, the usage range is wider, the reliability of a finished bus can be greatly improved, and the purposes of lowering consumption and reducing emissions are achieved.

Owner:ZHONGTONG BUS HLDG

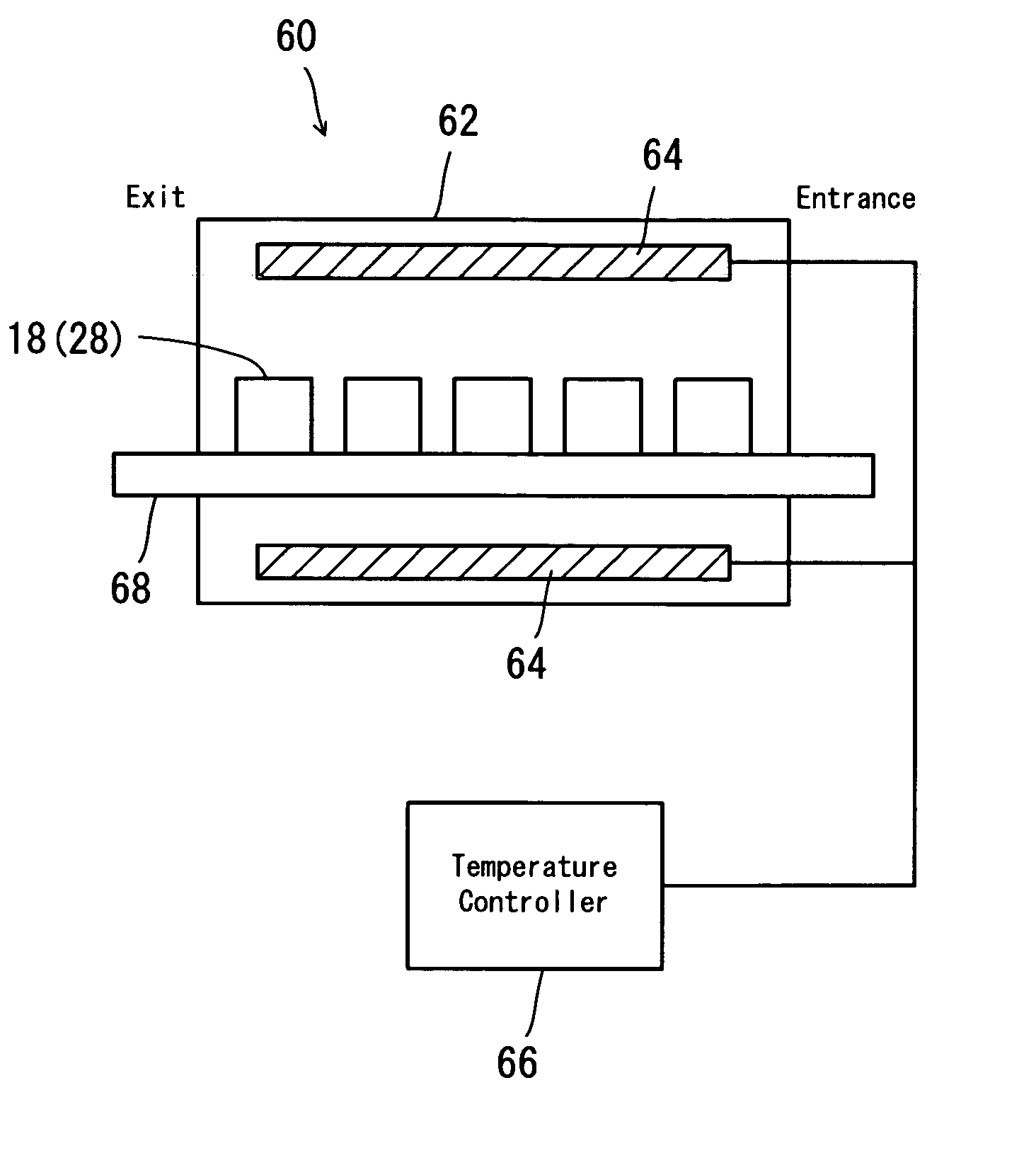

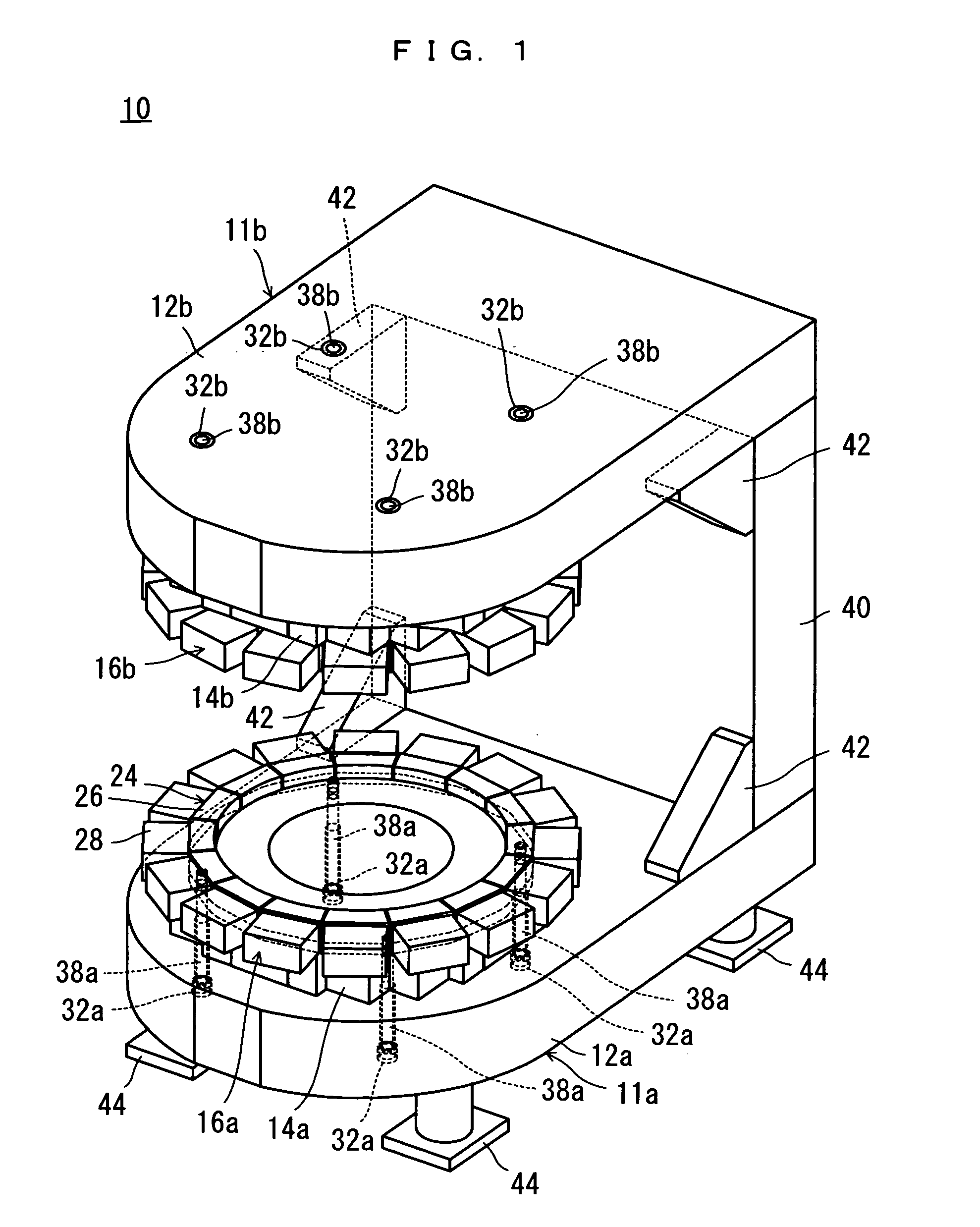

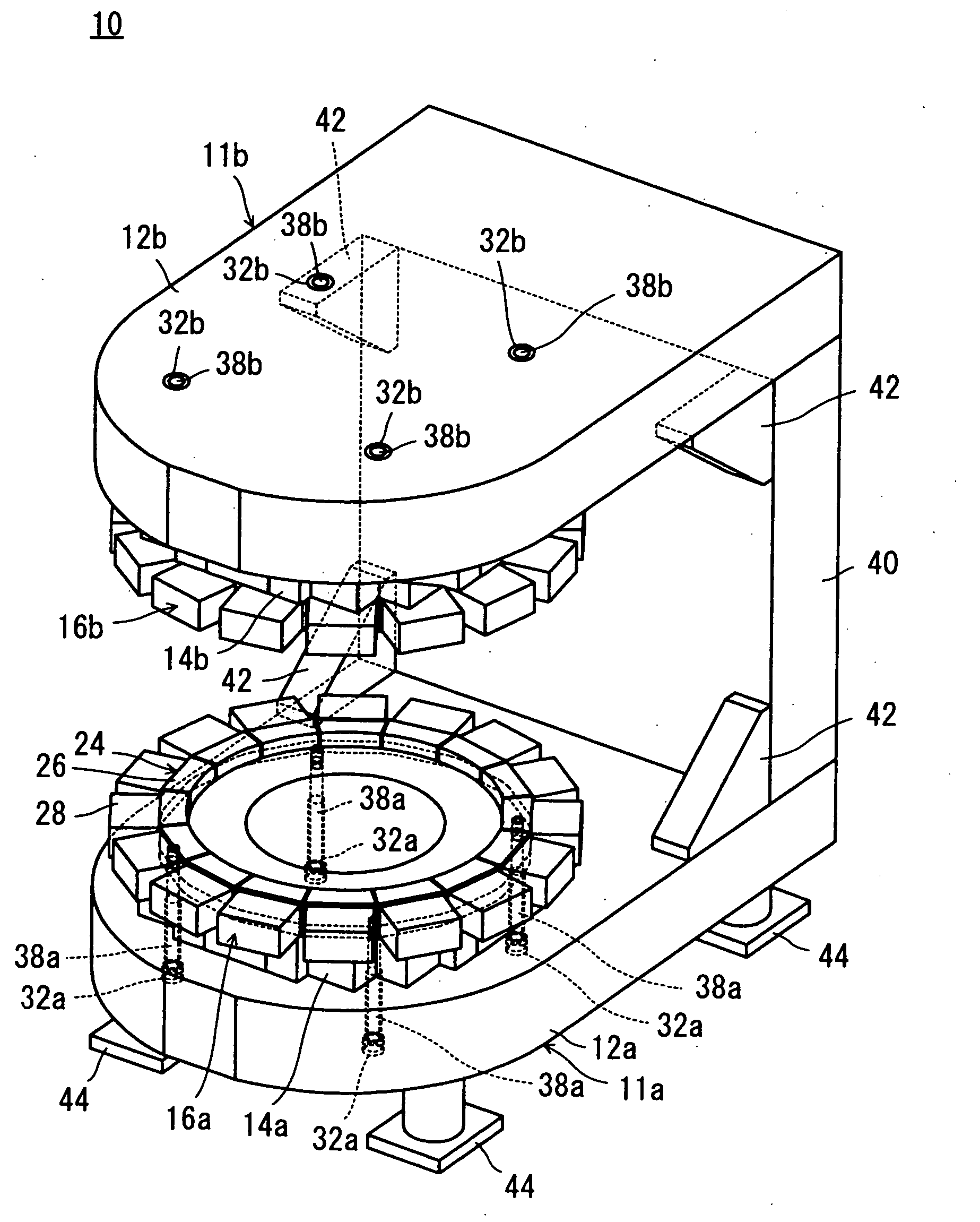

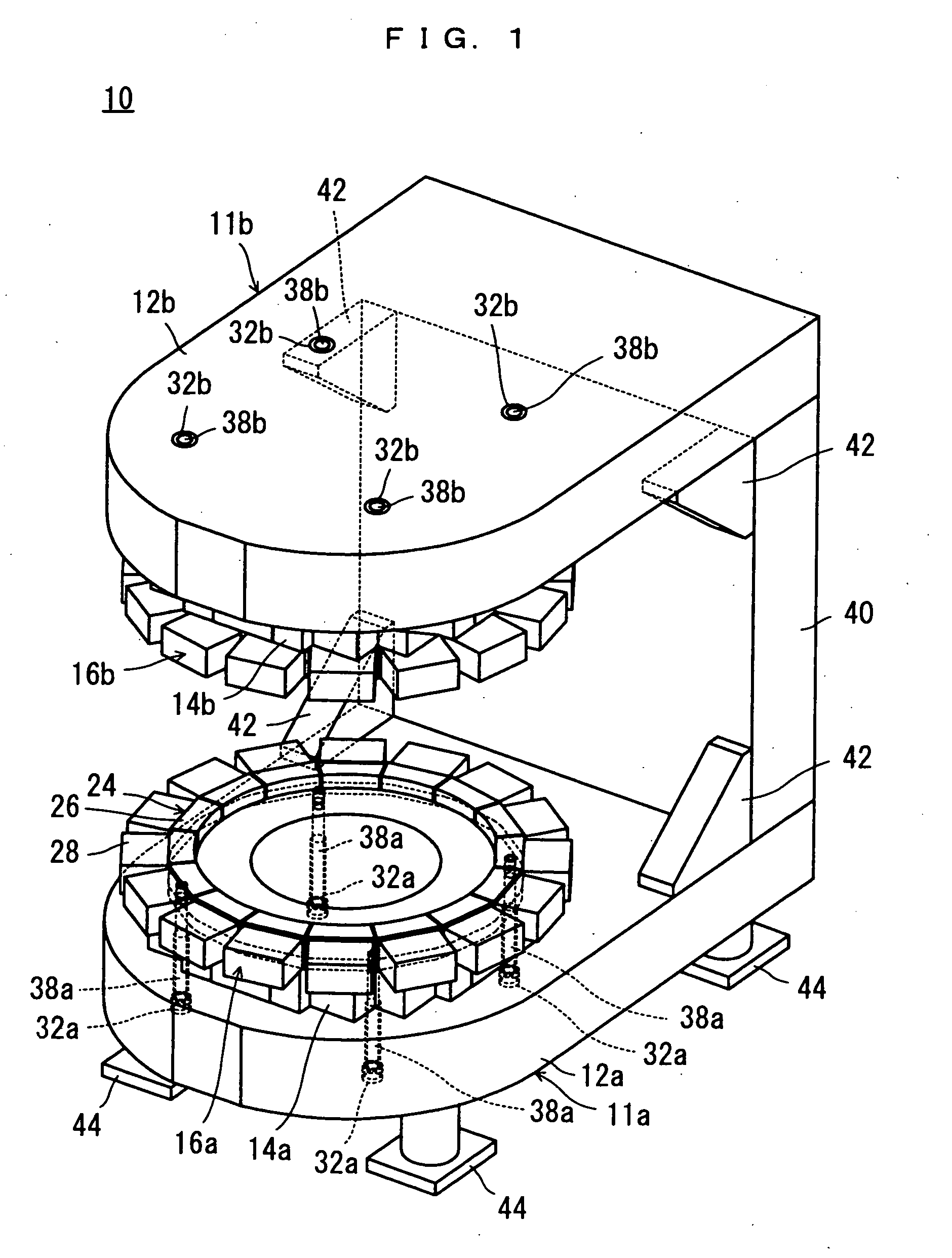

Magnetic field generator and its manufacturing method

InactiveUS20050092395A1Keep for a long timeDecline in magnetic field intensity of magnetic fieldPermanent magnetsInorganic material magnetismMagnetic susceptibilityMagnetization

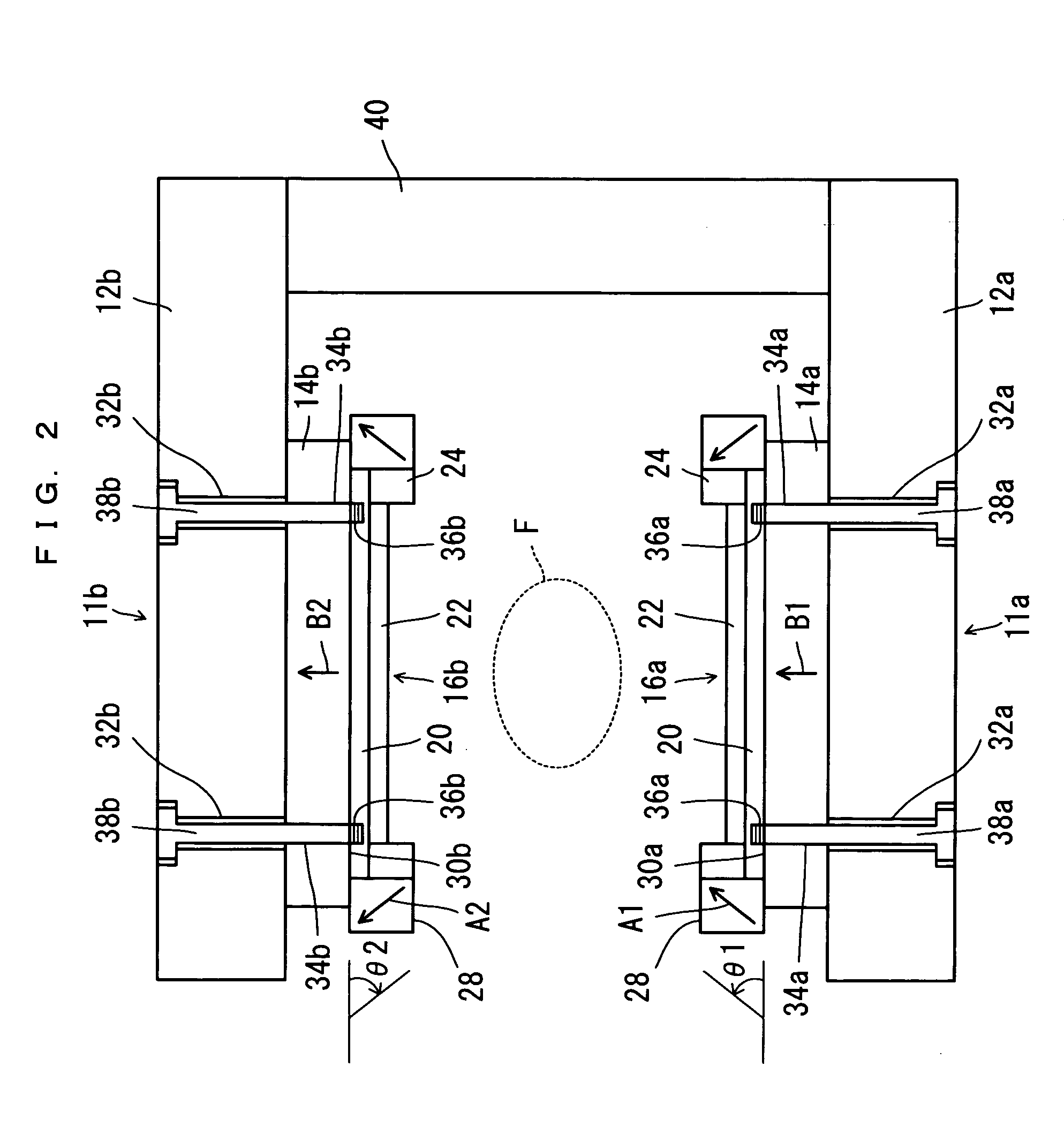

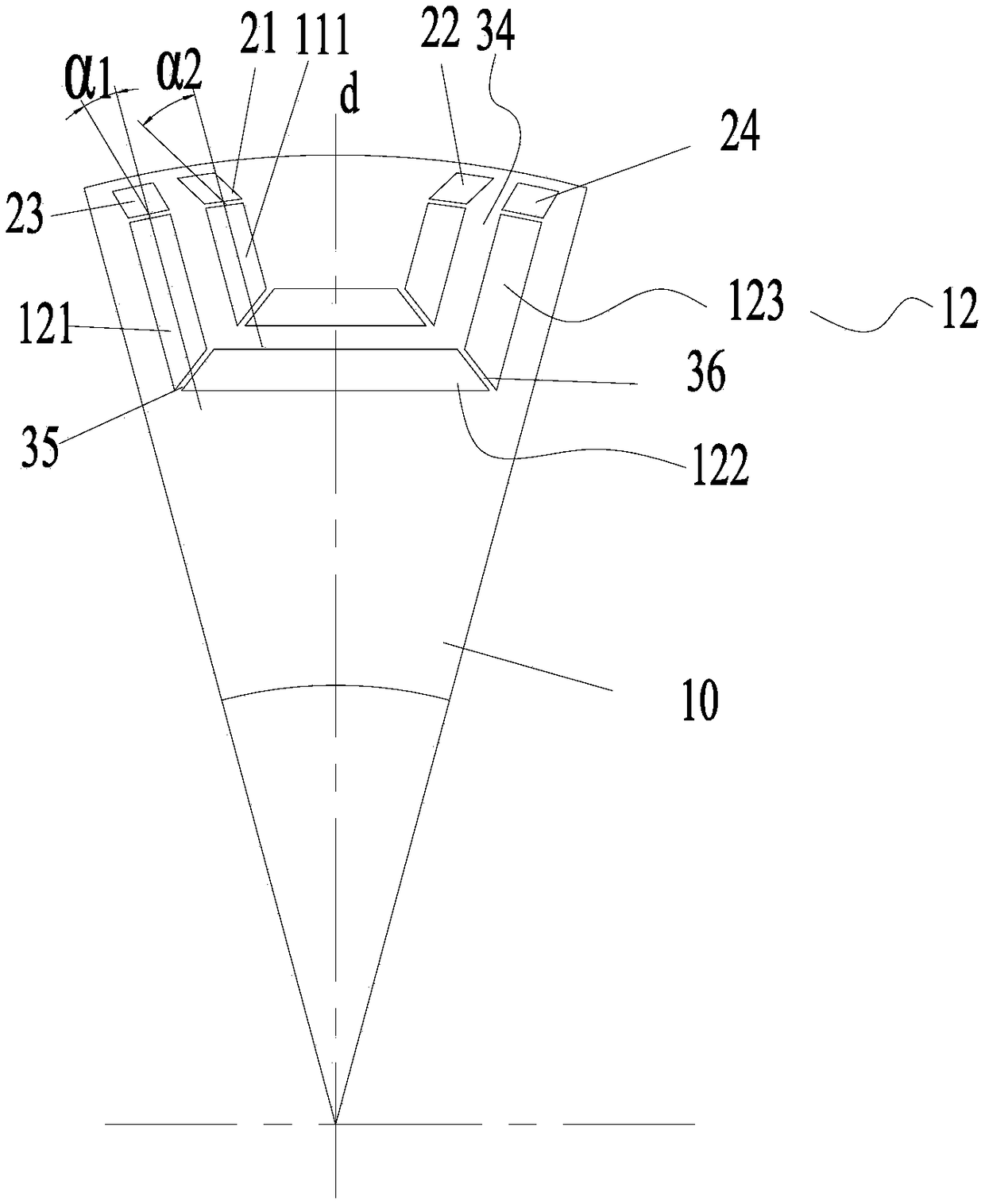

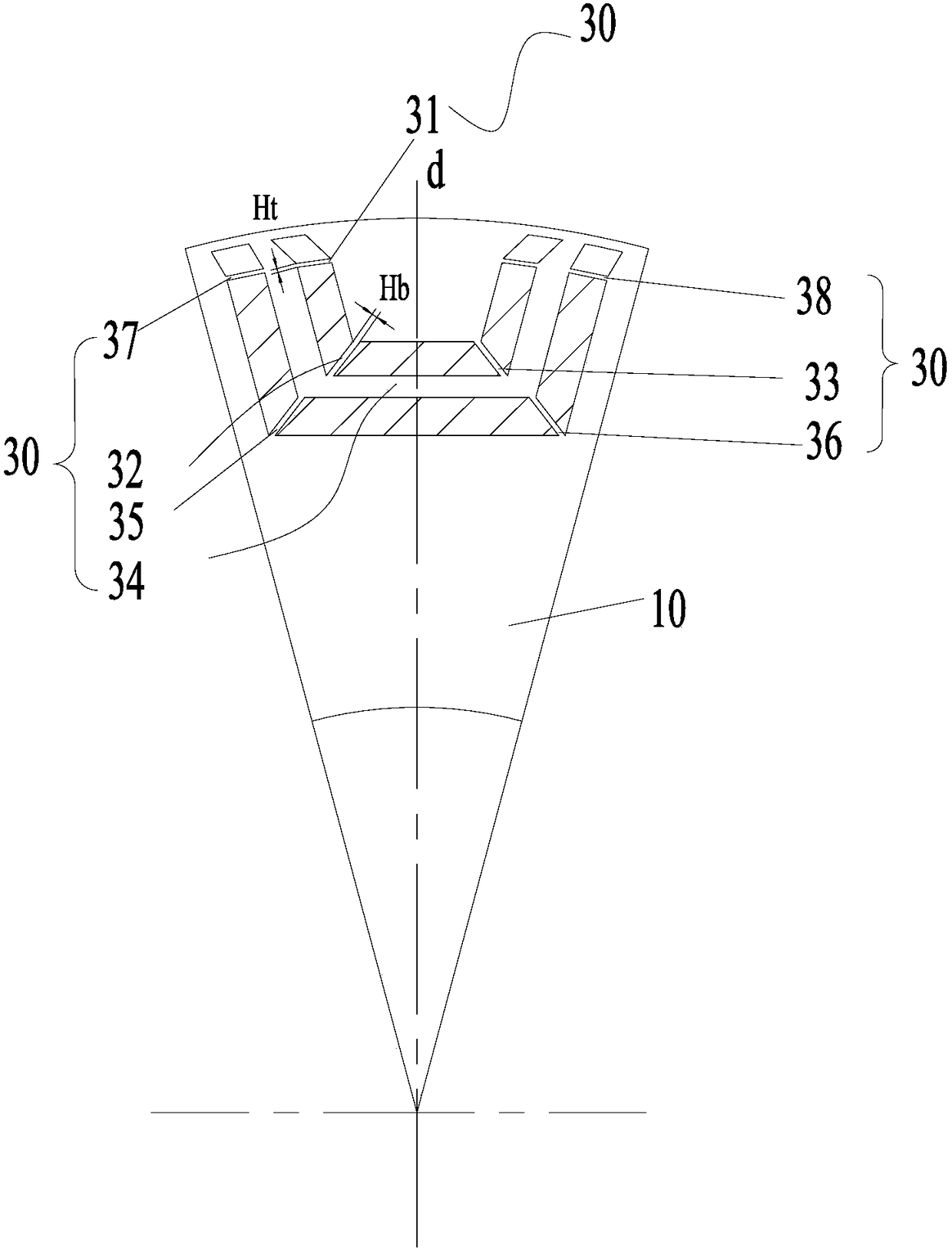

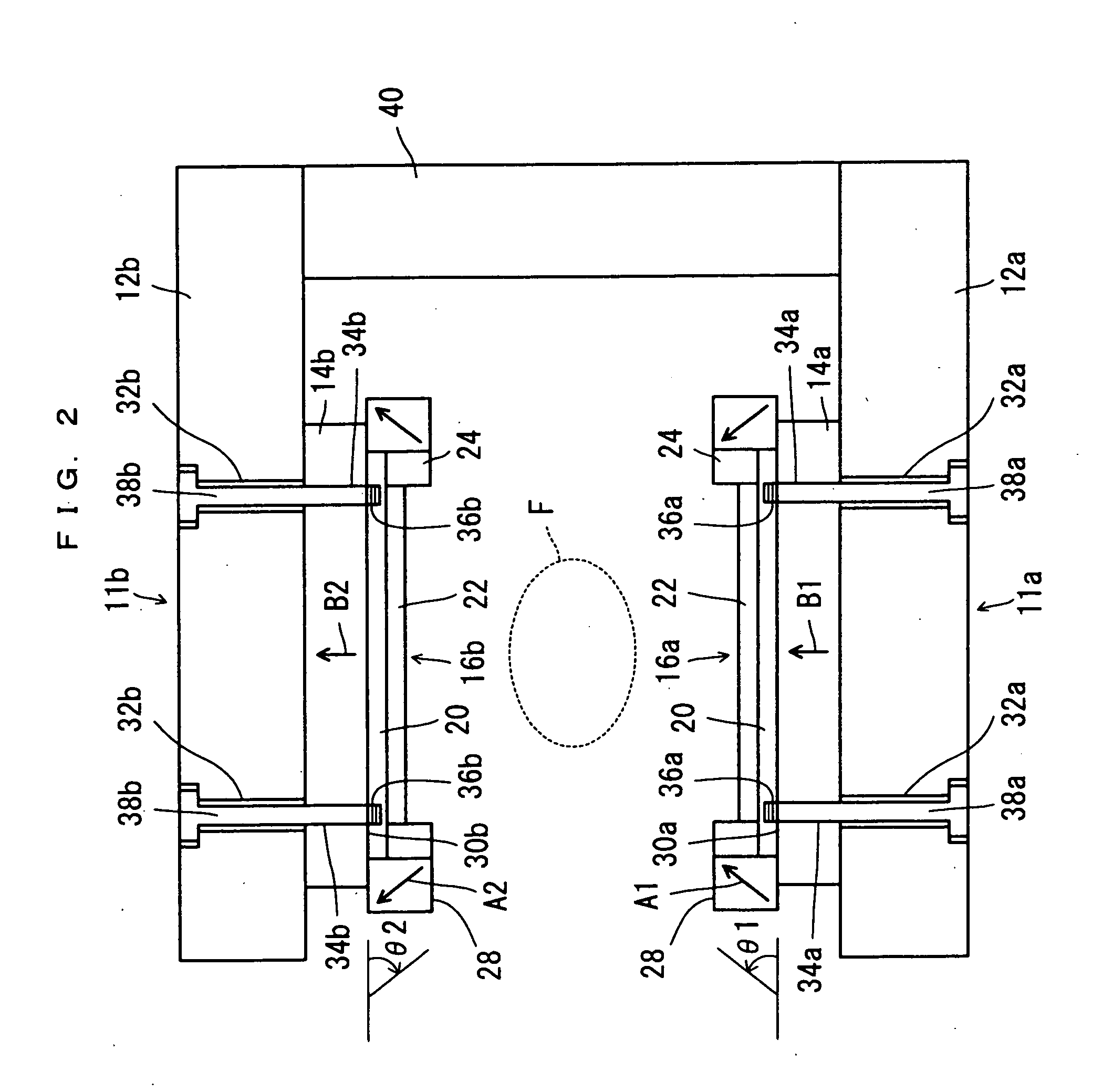

There is provided a magnetic field generator (10) and a method of manufacturing it, capable of reducing decline in the magnetic field intensity and deterioration of magnetic field uniformity during transportation. The magnetic field generator (10) includes a pair of plate yokes (12a), (12b). The plate yokes (12a), (12b) are opposed to each other, with their opposing faces provided with permanent magnet assemblies (14a), (14b) respectively. The permanent magnet assemblies (14a), (14b) have faces opposing to each other, to which pole pieces (16a), (16b) are fixed respectively. The permanent magnet assemblies (14a), (14b) include permanent magnets (18). The pole pieces (16a), (16b) include annular projection (24) and permanent magnets (28) for prevention of magnetic flux leakage provided on an outer side surface of the annular projection (24). The permanent magnets (18), (28) include R—Fe—B magnets magnetized to a magnetization rate not smaller than 80% and not greater than 99.9%. When manufactured, the assembled magnetic field generator (10) is heated in its entirety at a temperature not lower than 40° C. and not higher than 70° C.

Owner:HITACHI METALS LTD

Rotor structure, permanent magnetism auxiliary synchronization magnetic resistance motor and electric vehicle

ActiveCN108321952AReduce demagnetizationReduce Flux LeakageMagnetic circuit rotating partsElectric machinesSynchronous reluctance motorElectric vehicle

The invention provides a rotor structure, a permanent magnetism auxiliary synchronization magnetic resistance motor and an electric vehicle; the rotor structure comprises a rotor body having a permanent magnet slot set; the permanent magnet slot set comprises an outer permanent magnet slot; the rotor body is also provided with a first air slot; a first end of the first air slot and the end portionof the outer permanent magnet slot are connected or adjacent to each other; a second end of the first air slot extends to the outer edge of the rotor body and gradually gets away from the straight axle of the rotor body; when the first end of the first air slot is adjacent to the end portion of the outer permanent magnet slot, a first magnetic conductive channel is formed between the first end ofthe first air slot and the end portion of the outer permanent magnet slot. The rotor body is provided with the air slot that decides the direction of a rotor magnetic path, thus reducing magnetic flux leakage in a process in which the stator magnetic field reaches the rotor via an air gap, improving the magnetic field utilization rate, increasing torque output, minimizing demagnetization effect on the permanent magnet by a demagnetization magnetic field, and enhancing the anti-demagnetization capability.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Permanent magnet motor rotor with direct-axis inductance larger than quadrature-axis inductance

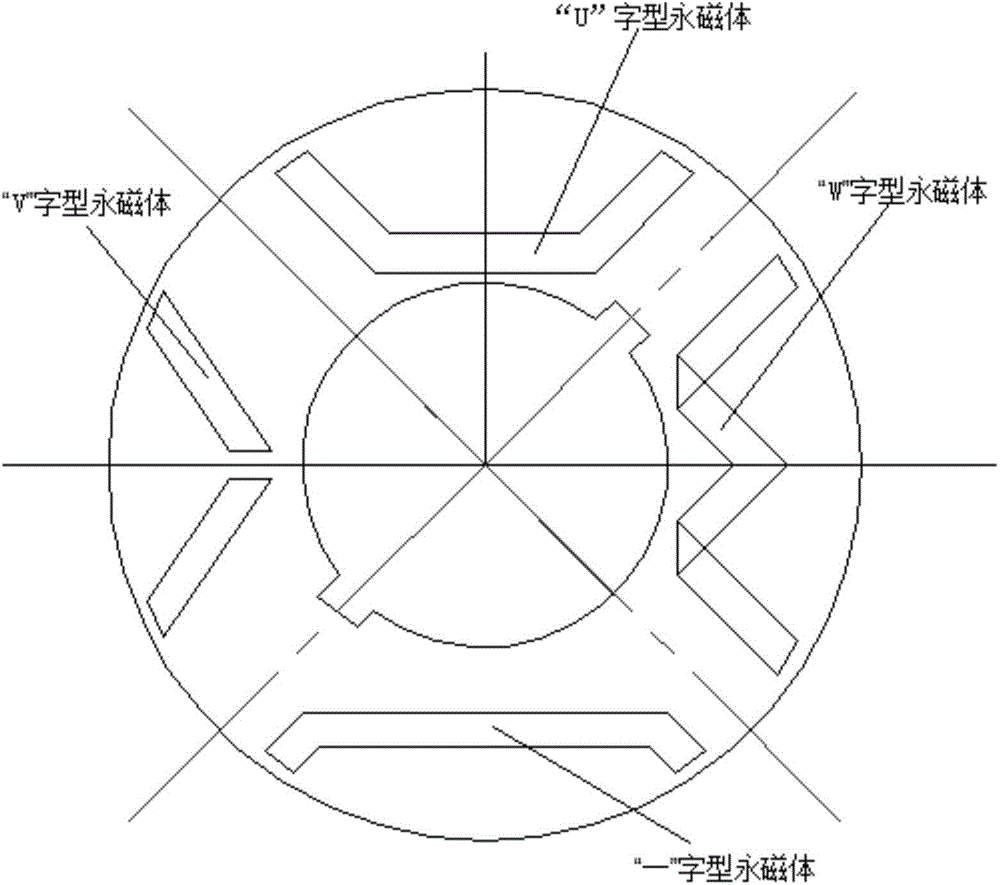

InactiveCN103607061AReduce demagnetizationHolding torque capacityMagnetic circuit rotating partsPower flowPermanent magnet motor

The invention discloses a permanent magnet motor rotor with direct-axis inductance larger than quadrature-axis inductance. The permanent magnet motor rotor comprises a rotor core formed by rotor sheets, permanent magnets and magnetic flow barriers, wherein the permanent magnets are arranged in the rotor core and are evenly distributed along the circumference of the rotor core, the magnetic flow barriers are arranged on quadrature-axis magnetic circuits between adjacent permanent magnets, the magnetic flow barriers are in one or more combined shapes of round holes, rectangles, arcs, sectors and triangles, and the permanent magnets are in the shape of U, or V, or W, or a long strip, or a rectangle and the like. Due to the fact that the magnetic flow barriers are arranged on the quadrature-axis magnetic circuits between the poles of the permanent magnets in the rotor and the poles of the permanent magnets are different in shape, the ability of generating torque of a permanent magnet motor is maintained, the demagnetizing effect of direct-axis currents on the permanent magnets in the operation process of the permanent magnet motor is lowered, thinner permanent magnets can be adopted, and cost of the permanent magnet motor is lowered.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

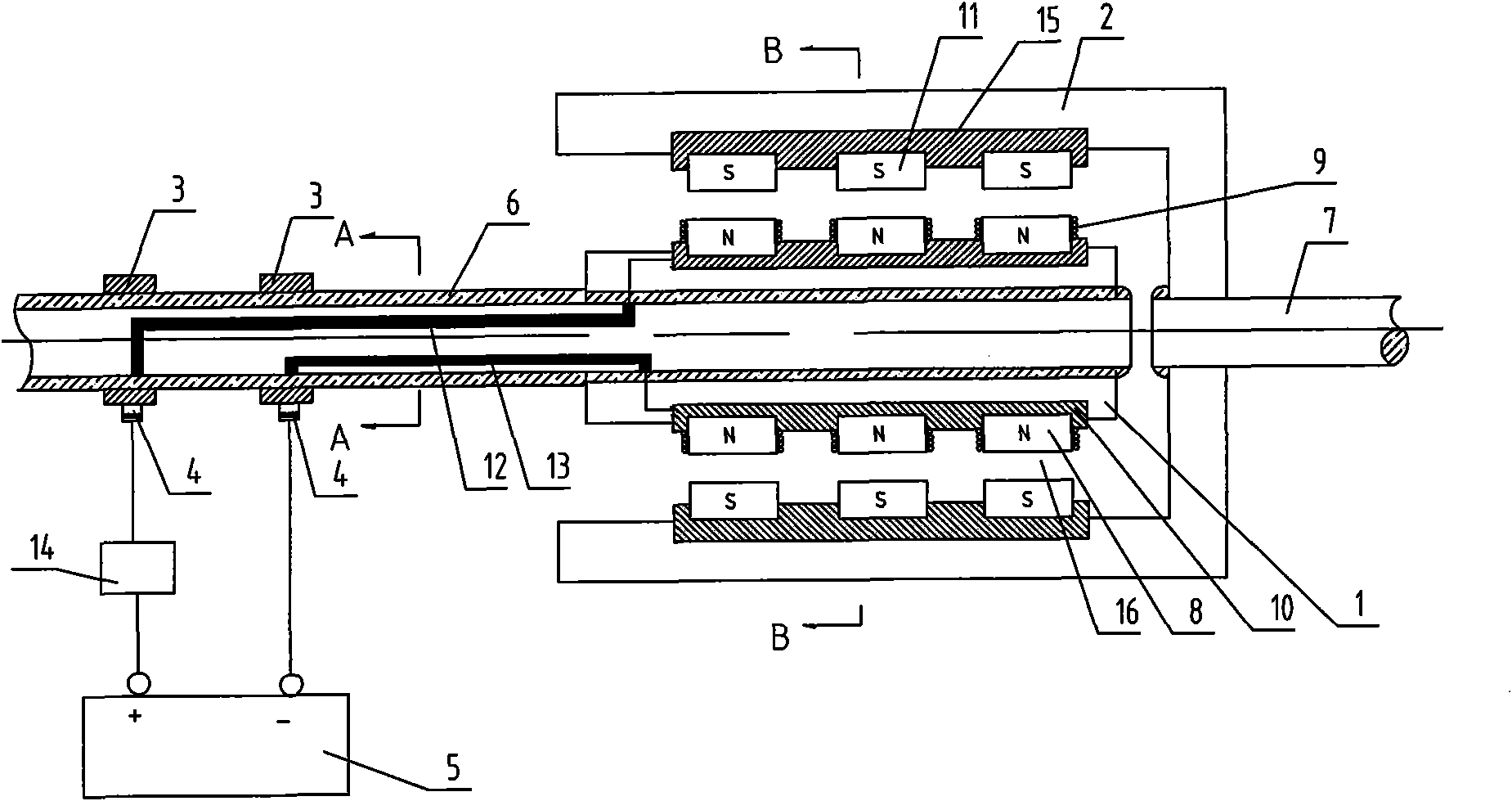

Barrel-type electromagnetic speed regulation system

InactiveCN101860314AReduced precision requirementsIncrease the areaDynamo-electric brake controlSoft magnetEngineering

The invention relates to a barrel-type electromagnetic speed regulation system, which comprises an inner barrel rotor, an outer barrel rotor, conductive slip rings, electric brushes and a DC power supply, wherein the inner barrel rotor is arranged at an input shaft end; the outer barrel rotor is arranged at an output shaft end; the inner barrel rotor and the outer barrel rotor are coaxially nested; the inner barrel rotor is provided with soft magnets of which each is provided with a coil; positions, corresponding to the soft magnets, on the outer barrel rotor are provided with permanent magnets; the input shaft is provided with the conductive slip rings which are matched with the electric brushes; the electric brushes are connected with the anode and the cathode of the DC power supply; the conductive slip rings are connected with the coils by lead wires; and the coils wound by the circumferentially adjacent soft magnets arranged on the inner barrel rotor rotate in opposite directions, while the coils wound by the axially adjacent soft magnets are in the same direction. The barrel-type electromagnetic speed regulation system has the advantages that: the soft magnets on the inner barrel rotor reduce demagnetization and realize control over a rotation speed of the output shaft; and the barrel structure can generate strong electromagnetism, and the areas of the permanent magnets are great, so working efficiency is improved.

Owner:ANSHAN QINYUAN ENERGY SAVING EQUIP MFG

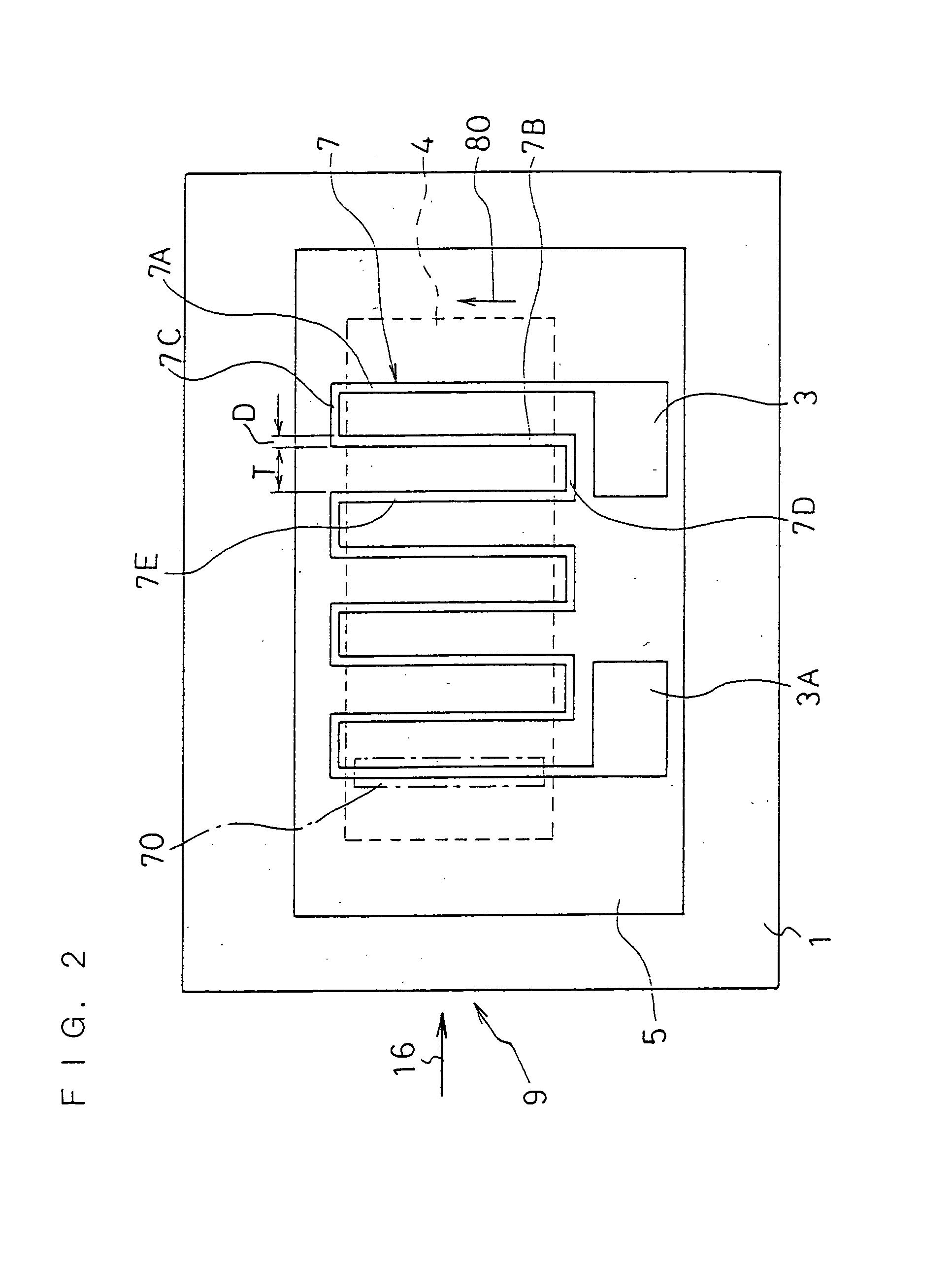

Magnetic sensor having a closed magnetic path formed by soft magnetic films

InactiveUS7145331B2Reduce demagnetizationHigh detection sensitivityRecord information storageManufacture of flux-sensitive headsBand shapeCarrier signal

In order to obtain a magneto-impedance type magnetic sensor having a soft magnetic film facing to a conductive nonmagnetic film, and available a large impedance change with a carrier signal at a relatively low frequency, the magnetic sensor comprises a meander type conductive nonmagnetic thin film of zigzag shape formed with at least one pair of electrode terminals at both ends and a soft magnetic film which is strip-shaped so as to face thereto at a plurality of regions and has an easy axis of magnetization in a width direction of the strip shape, a high frequency carrier signal is applied to the above-mentioned electrode terminals and further a direct current bias magnetic field is applied. By performing AM detection of an AM modulation signal output from the above-mentioned electrode terminals, an impedance change of the conductive nonmagnetic film which is changed by external magnetic field is detected as a change of the high frequency carrier signal, thereby the external magnetic field can be detected.

Owner:PANASONIC CORP

Magnetic field generator manufacturing method

InactiveUS20090243774A1Reduce demagnetizationDecline in intensityElectromagnets without armaturesPermanent magnetsMagnetic susceptibilityMagnetization

Owner:HITACHI METALS LTD

Permanent magnet rotating electric machine and electric power steering device using the same

ActiveUS8598762B2Cogging torque is decreasedReduce demagnetizationMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsElectric power steeringElectric machine

A permanent magnet rotating electric machine includes: a stator including: a stator core having teeth, and an armature winding wound around each of the teeth to configure the multiple phases; and a rotor including a rotor core, and permanent magnets provided in order around the rotor core. The rotor is arranged to be spaced apart from the stator with an air gap therebetween. Each of the permanent magnets has a curved surface opposed to the stator and is configured to satisfy the following relationship:0.65≤Rm×h1W(h1+g)≤1.37where Rm denotes a radius of curvature of the curved surface, h1 denotes a thickness of a central portion of the permanent magnet in the peripheral direction, W denotes a width of the permanent magnet in the peripheral direction, and g denotes an air gap length of the air gap.

Owner:MITSUBISHI ELECTRIC CORP

Domain wall free shields of MR sensors

InactiveUS20050128647A1Reduce the impactMaintaining exchange couplingCarrier constructional parts dispositionRecord information storageMagnetic shieldNon magnetic

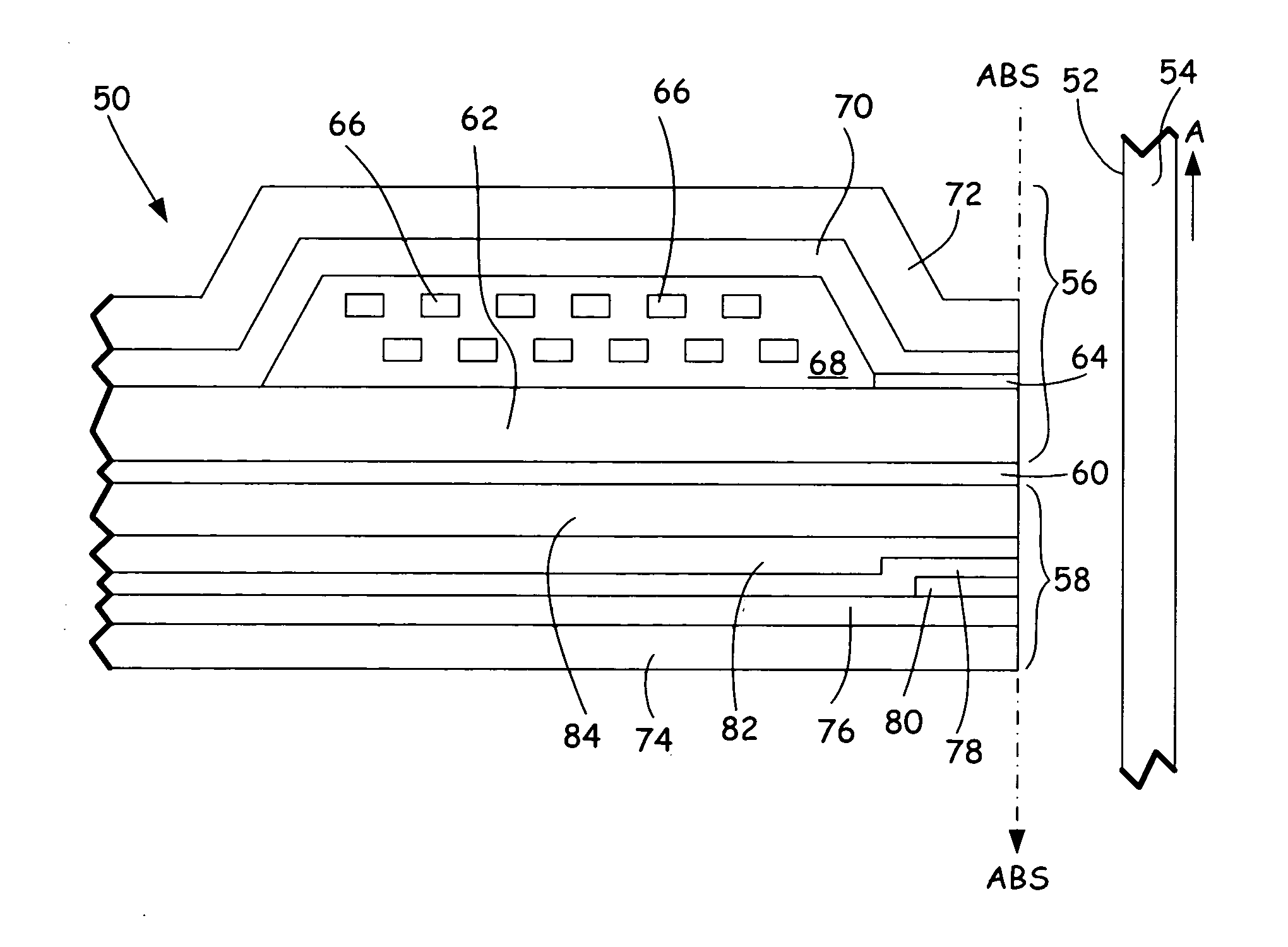

A magnetic reader of the present invention comprises an MR sensor shielded by a magnetic shield including single domain soft magnetic materials. The domain wall free magnetic shield includes an unbiased soft magnetic layer and a biased soft magnetic layer separated by a non-magnetic layer. The easy axis of the biased layer is oriented to create a path for magnetic flux through the biased and unbiased layers thereby reducing the demagnetization field of the shield. A biasing layer maintains the first and second magnetic layers as single domain magnets. The biasing layer is further shaped to define a quiet zone where the biasing layer does not overlay the MR sensor.

Owner:SEAGATE TECH LLC

MR sensor with back edge flux guide

ActiveUS20130049747A1Good performanceIncrease signalLamination ancillary operationsLayered product treatmentNuclear magnetic resonanceCoupling

An MR sensor, and a method for making it, is described. Part of the MR stack, from the free layer on up, is removed and then replaced by a flux guide. Additional stabilizing means for this flux guide are provided, either as hard bias or through exchange coupling.

Owner:HEADWAY TECH INC

Permanent magnet rotor and permanent magnet motor

InactiveCN105490415AReduce demagnetizationReduce riskMagnetic circuit rotating partsPermanent magnet rotorElectric machine

The invention discloses a permanent magnet rotor and a permanent magnet motor. The permanent magnet rotor comprises a rotor core and a rotating shaft positioned in middle of the rotor core, wherein multiple mounting grooves distributed in a radial direction of the rotor core are formed in the rotor core; a permanent magnet is mounted in each mounting groove; multiple flux-insulation grooves are formed in the regions, between the rotating shaft and the corresponding permanent magnets, of the rotor core; each flux-insulation groove is formed between two adjacent permanent magnets; and flue-insulation bridges are formed in the parts, between the corresponding flux-insulation grooves and the corresponding groove bottoms, close to the rotating shaft, of the adjacent mounting grooves, of the rotor core. The problems of degradation of motor performance, excitation loss of the permanent magnets and impossibility of motor operation caused by the reason that the parts, close to the rotating shaft, of the permanent magnets cannot be fully magnetized to reach a saturated state in the prior art are effectively solved by the permanent magnet rotor and the permanent magnet motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

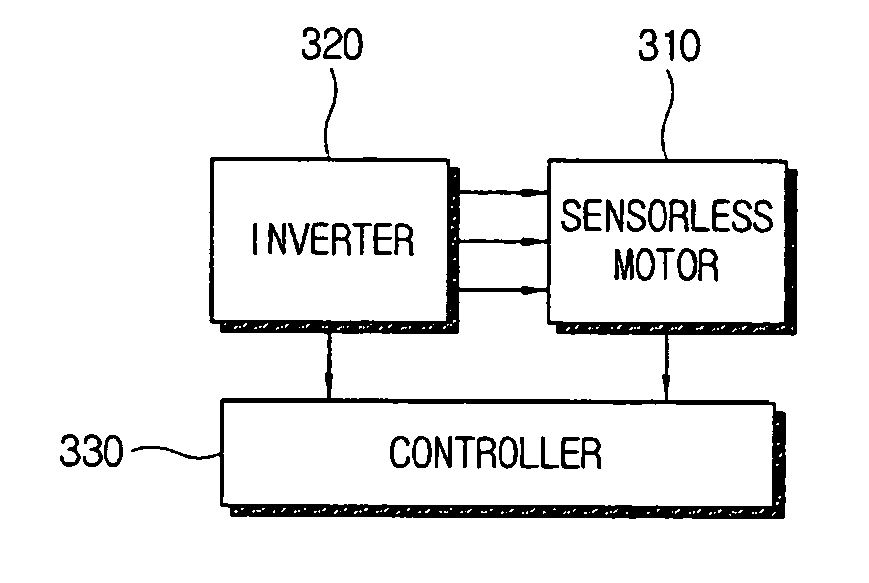

Compressor and a driving method thereof

InactiveUS20070085501A1Prevent overcurrentPrecise alignmentDC motor speed/torque controlAC motor controlTop dead centerMechanical engineering

A compressor having a sensorless motor and a driving method thereof. The compressor includes a sensorless motor having a rotation shaft connected to a rotator, a piston for performing a compression stroke and an intake stroke between a top dead center and a bottom dead center thereof, and a crank connecting the rotation shaft to the piston. The method includes forcibly aligning the rotator such that the rotator is positioned at a start position in the intake stroke of the piston, and accelerating rotation of the forcibly aligned rotator.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com