Magnetic field modulation type magnetic gear

A magnetic gear and magnetic field modulation technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of increased volume and insufficient mechanical strength, etc., to reduce torque ripple, increase magnetic concentration effect, and optimize torque pulsating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

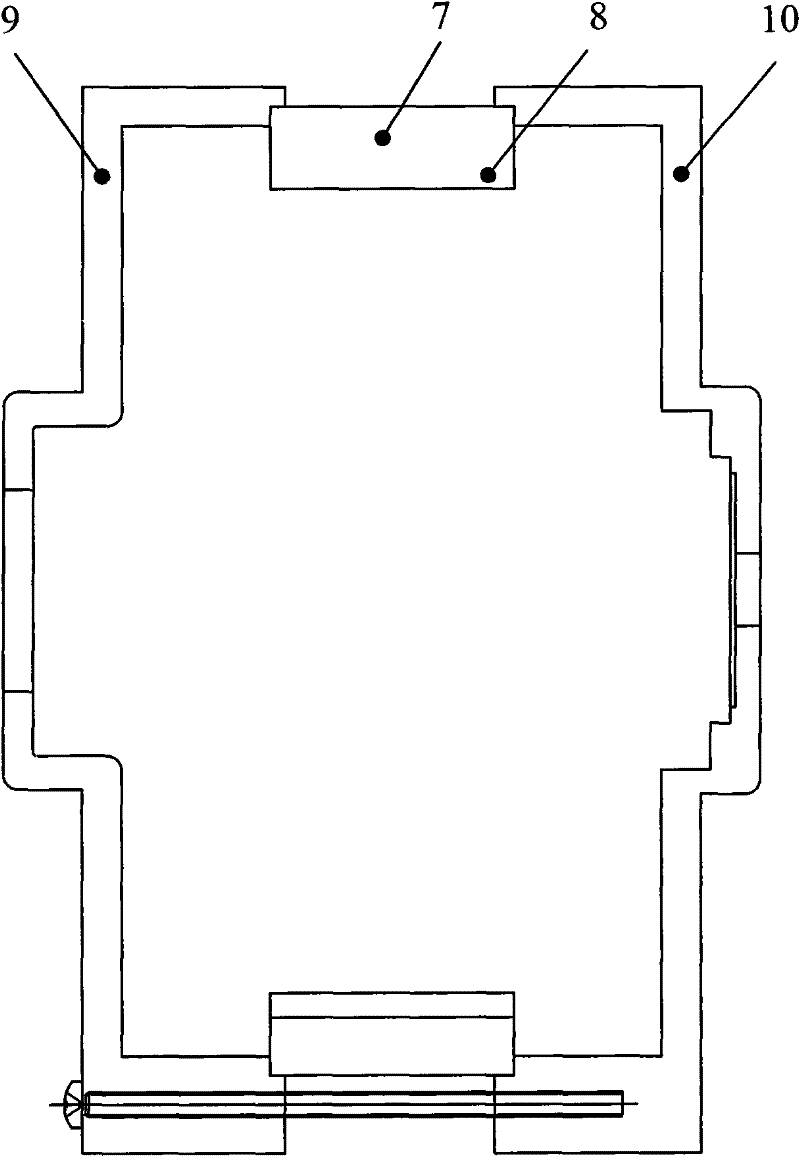

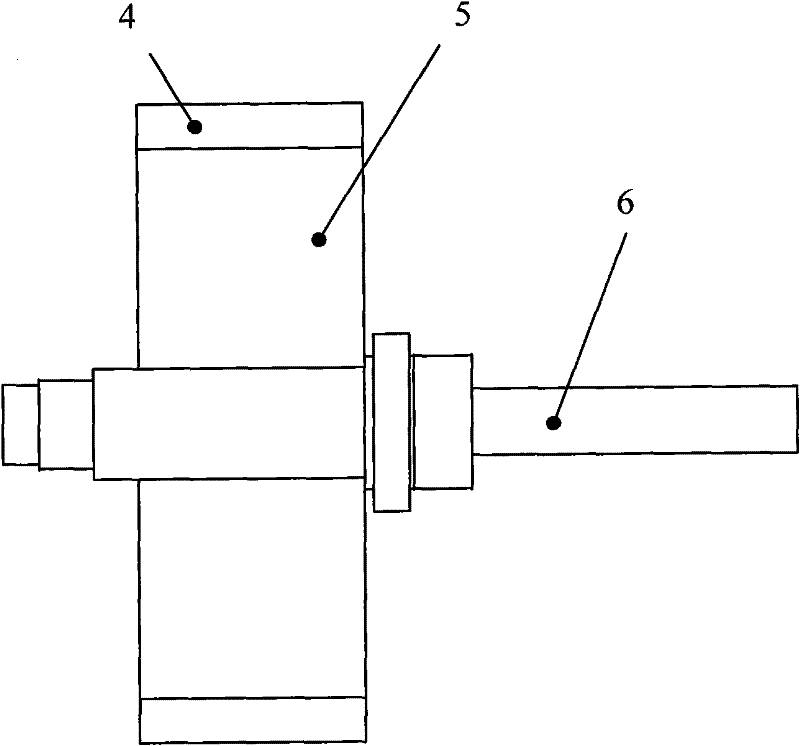

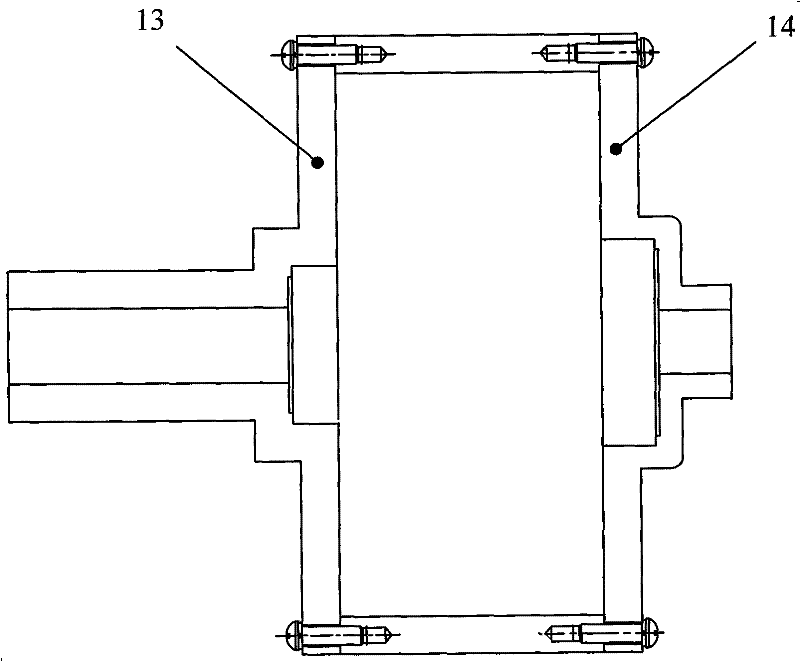

[0012] The figure includes outer stator 1, inner rotor 2, magnetic adjustment ring 3, inner rotor permanent magnet 4, inner rotor core 5, inner rotor shaft 6, outer stator core 7, outer stator permanent magnet 8, outer stator front end plate 9, outer Stator rear end plate 10, magnetic ring core block 11, magnetic ring epoxy block 12, magnetic ring front plate 13, magnetic ring rear end plate 14, magnetic ring front bearing 15, magnetic ring rear bearing 16, Inner rotor front bearing 17, inner rotor rear bearing 18.

[0013] Such as figure 1 As shown, the outer stator 1 includes the outer stator core 7, and the outer stator core 7 is provided with 2N 2 (N 2 >=1) One piece of outer stator permanent magnet 8, and the adjacent permanent magnets have different polarities, and the outer stator is pressed and fixed by the outer stator front end cover 9 and the outer stator rear end cover 10. Such as figure 2 As shown, the inner rotor 2 includes the inner rotor core 4, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com