Gear and rack transmission mechanism suitable for circular motion

A technology of rack and pinion, transmission mechanism, applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems of not being able to do circular motion and circular transmission, etc. The effect of adaptive, good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

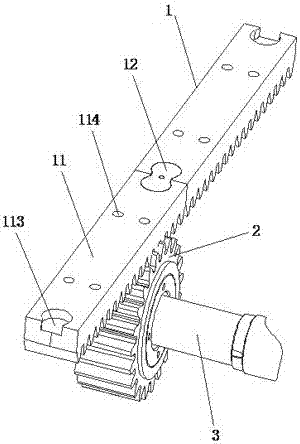

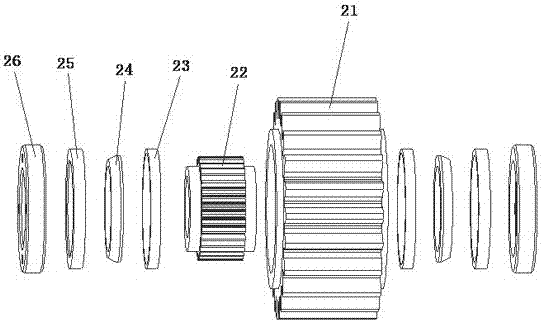

[0022] Such as Figures 1 to 7 As shown, the present invention is applicable to a circular motion rack and pinion transmission mechanism, including a circumferential rack arrangement assembly 1 and a drive gear assembly 2 .

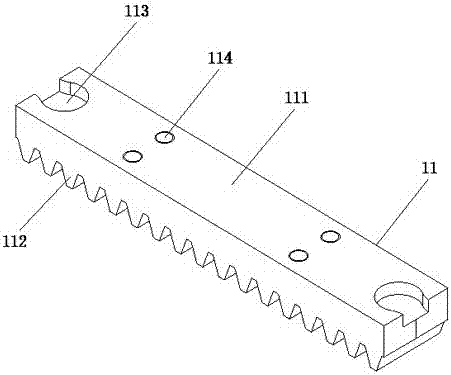

[0023] The circumferential rack arrangement assembly 1 is fixed on the arc-shaped base frame, which includes a rack 11 and a rack positioning connection 12; two adjacent racks 11 are connected by a rack positioning connection 12, realizing The reliable positioning of the rack 11, the continuous force of the rack 11; wherein, each segment of the rack 11 is linear and is arranged in a straight line instead of a curve, and each segment of the rack 11 is composed of a rectangular rack block 111 and Composed of a plurality of teeth 112 evenly arranged on the front of the rack block 11, the two ends of the back of the rack block 111 are symmetrically provided with a half drum-shaped keyway 113, and there are two sets of assembly parts between the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com