Stator core components and stator, permanent magnet motor

A technology for stator cores and components, which is applied to electric components, magnetic circuits, electrical components, etc., can solve the problems of high operating noise and poor magnetization effect of permanent magnet motors, so as to reduce operating noise, improve magnetization effect, optimize effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

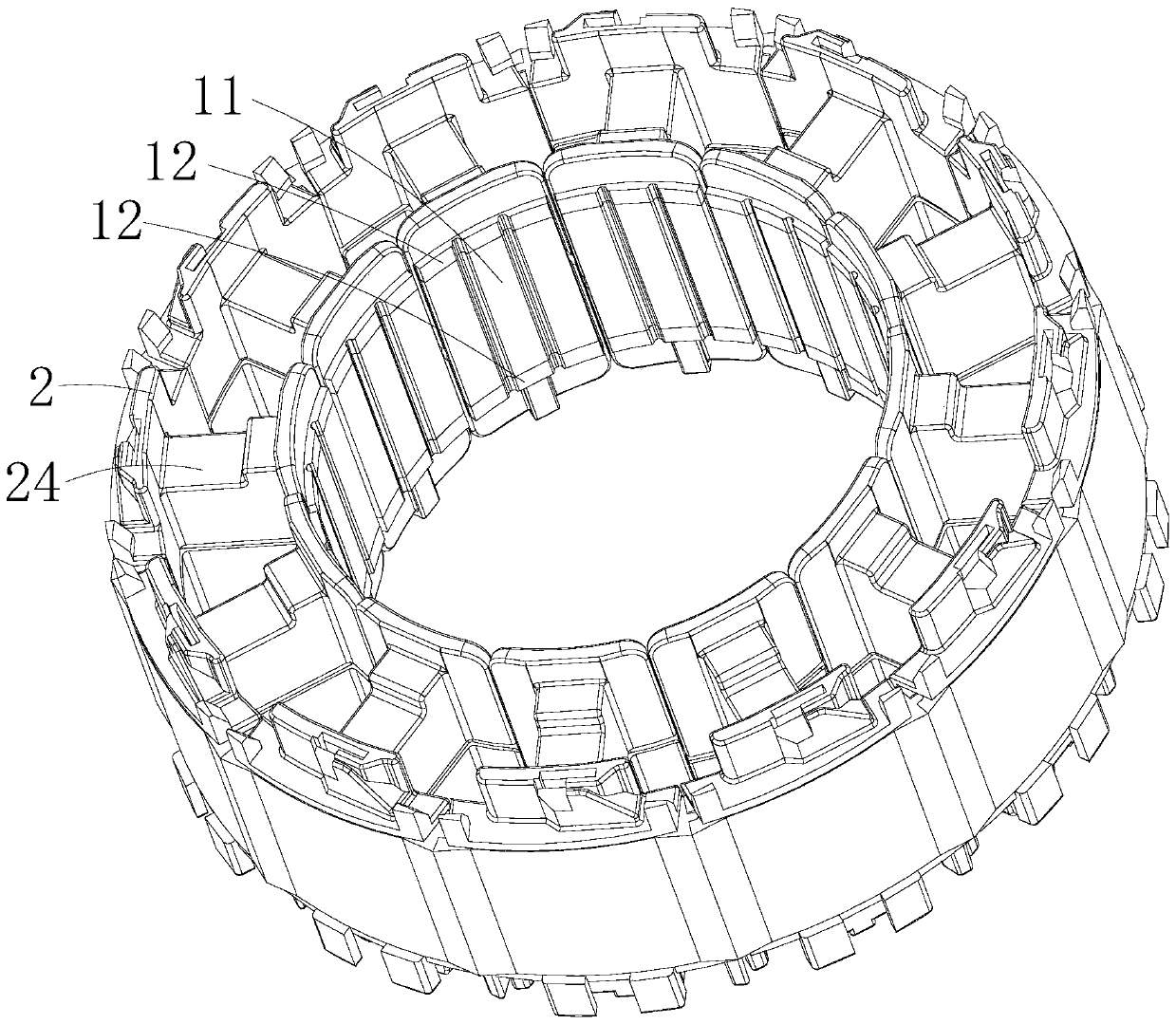

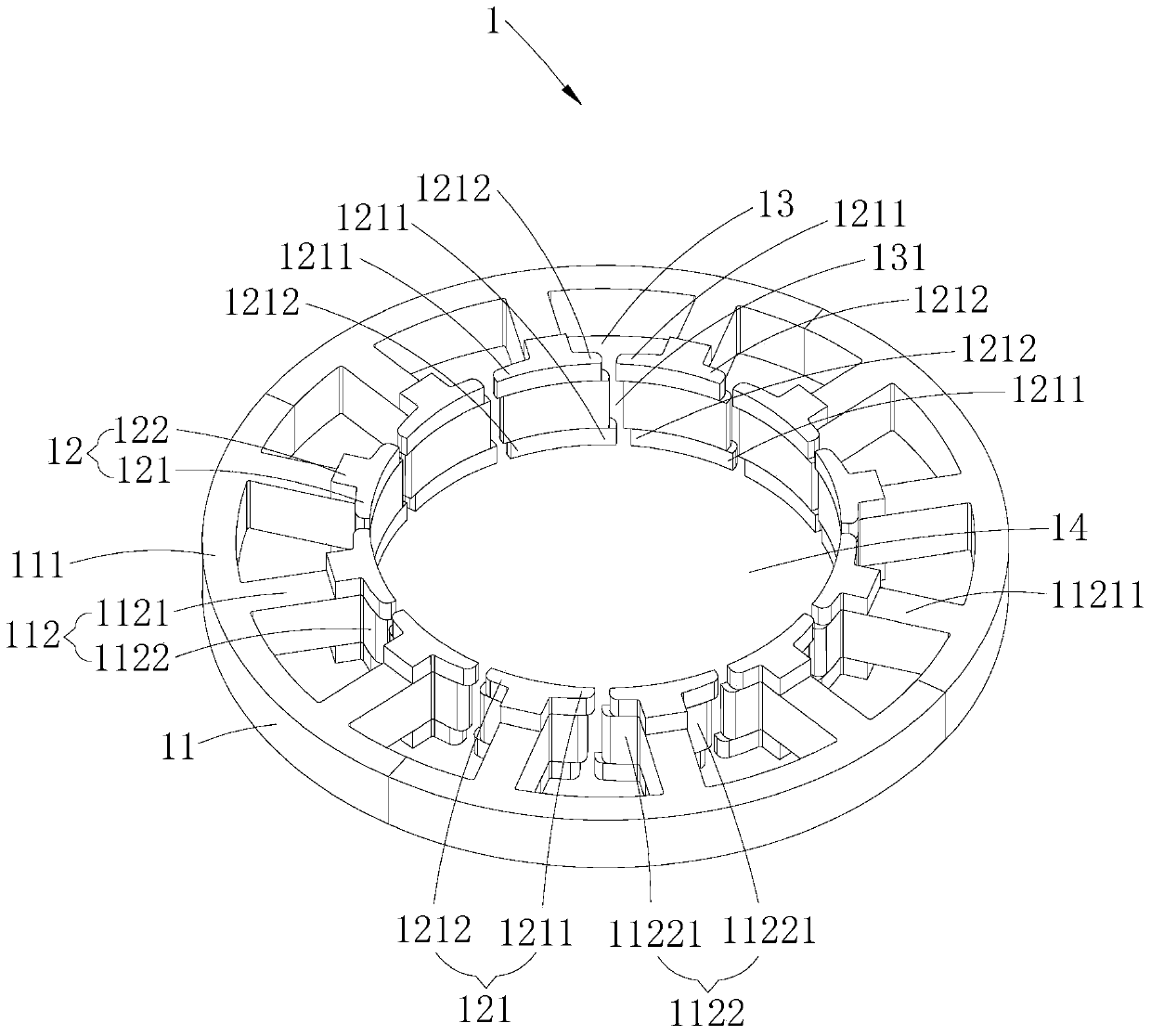

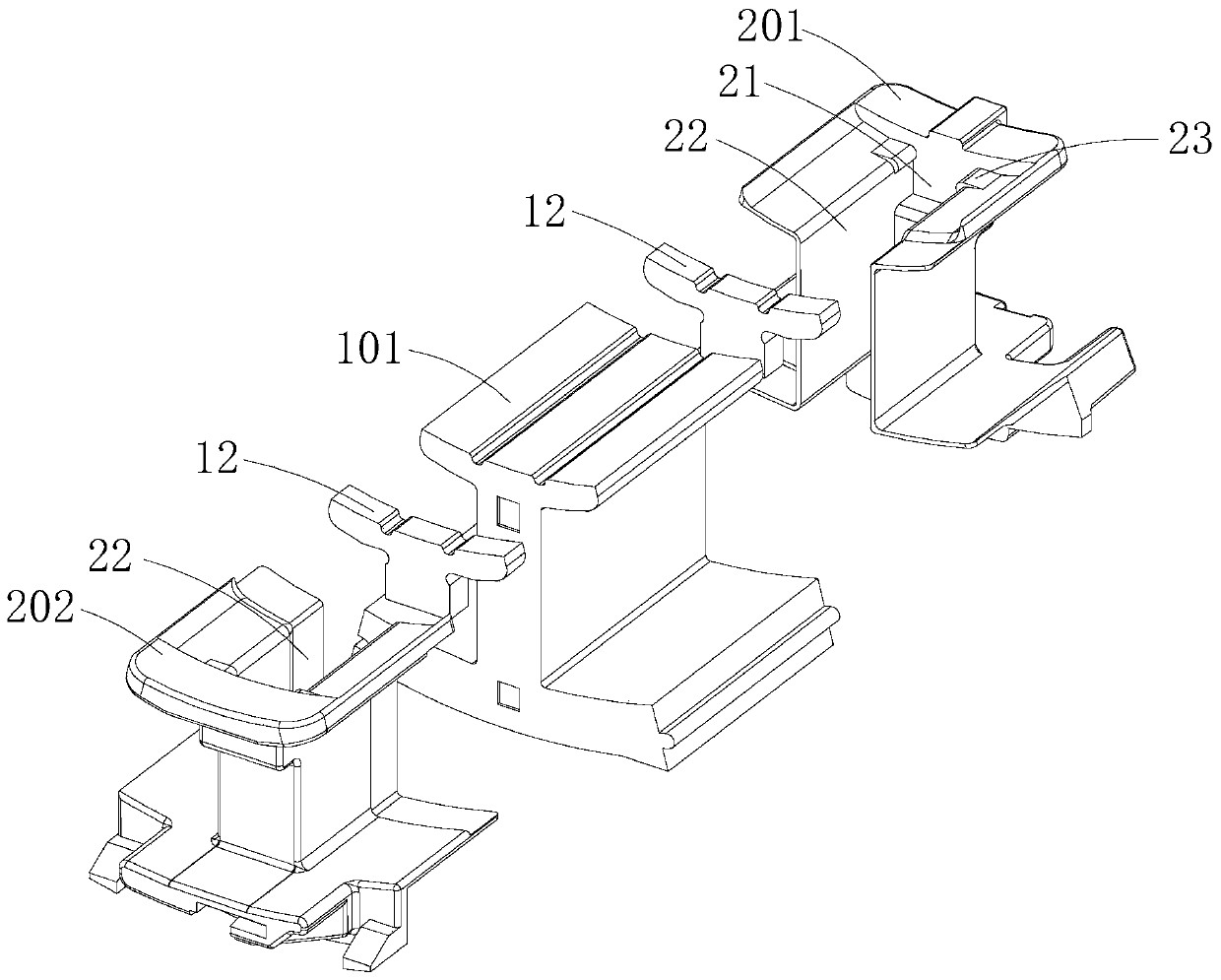

[0029] Such as Figure 1~3 As shown, the stator core assembly provided by Embodiment 1 of the present invention includes a stator core 1. The stator core 1 includes a core body 11 and several magnetically conductive bosses 12. The iron core body 11 includes a stator yoke 111 and several For the stator teeth 112 arranged on the stator yoke 111, at least one stator tooth 112 is laminated with a magnetic conduction boss 12 along the axial direction of the stator core 1 on the end of the stator tooth 112 away from the stator yoke 111, and a magnetic conduction boss 12 is laminated thereon. The stator teeth 112 of the platform 12, the stator teeth 112 adjacent to the stator teeth 112, and the magnetically conductive bosses 12 superimposed on the two stator teeth 112 surround and form a notch 131 in the circumferential direction, which is an oblique notch. The winding slot 13 , the notch 131 of the winding slot 13 is located at the end of the winding slot 13 away from the stator yok...

Embodiment 2

[0049] In the stator core assembly, the stator and the permanent magnet motor provided by Embodiment 2 of the present invention, the magnetically conductive boss 12 is laminated only on one axial side of the stator tooth 112 . And preferably, the quantity of the magnetic conduction boss 12 is the same as the number of the stator teeth 112, each stator tooth 112 is provided with a magnetic conduction boss 12, and each magnetic conduction boss 12 is arranged along the axial direction of the stator core 1 on the same side of each stator tooth 112 . The main difference between the present embodiment and the first embodiment is: in the first embodiment, the stator teeth 112 are laminated with magnetically conductive bosses 12 on both axial sides, so that the axial length of the stator core 1 is toward the The both sides of iron core body 11 lengthen, and the inclination effect of inclined notch opening is good; And in the present embodiment, only on the axial side of stator tooth 1...

Embodiment 3

[0051] In the stator core assembly, the stator and the permanent magnet motor provided by the third embodiment of the present invention, the number of magnetically conductive bosses 12 is less than twice the number of stator teeth 112, and the two adjacently arranged guides along the circumferential direction of the stator core 1 At least one stator tooth 112 is spaced between the magnetic bosses 12 . Specifically, each magnetically conductive boss 12 is laminated on each stator tooth 112 in the form of at least one stator tooth 112 along the circumferential direction of the stator core 1 , so that not every stator tooth 112 is laminated with a magnetically conductive The boss 12 can also play the role of lengthening the axial length of the stator core 1 and forming the oblique slot opening, thereby also achieving the purpose of improving the magnetization effect of the permanent magnet motor and reducing the harmonics of the permanent magnet motor. The difference between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com