Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Reduce pressure changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

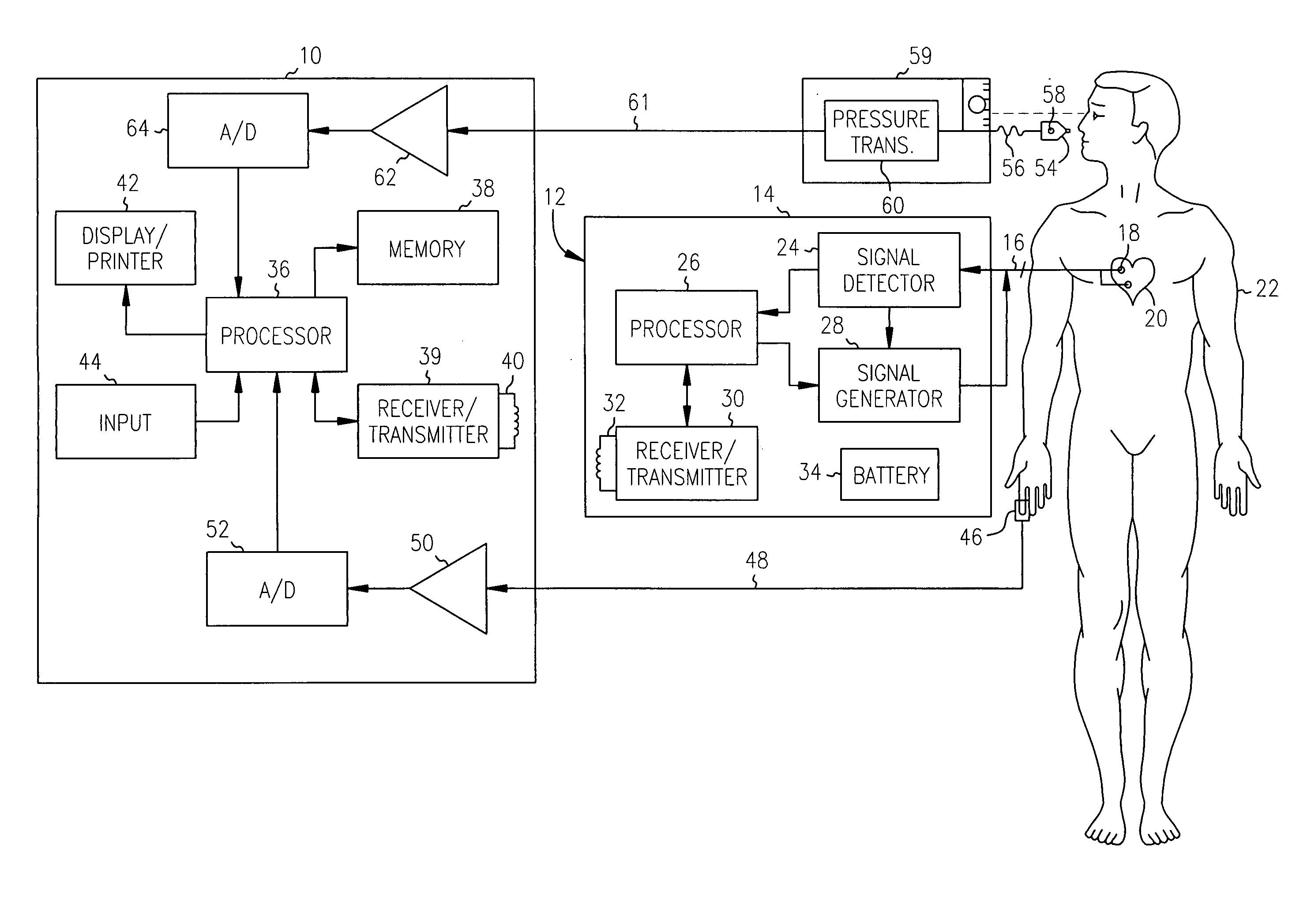

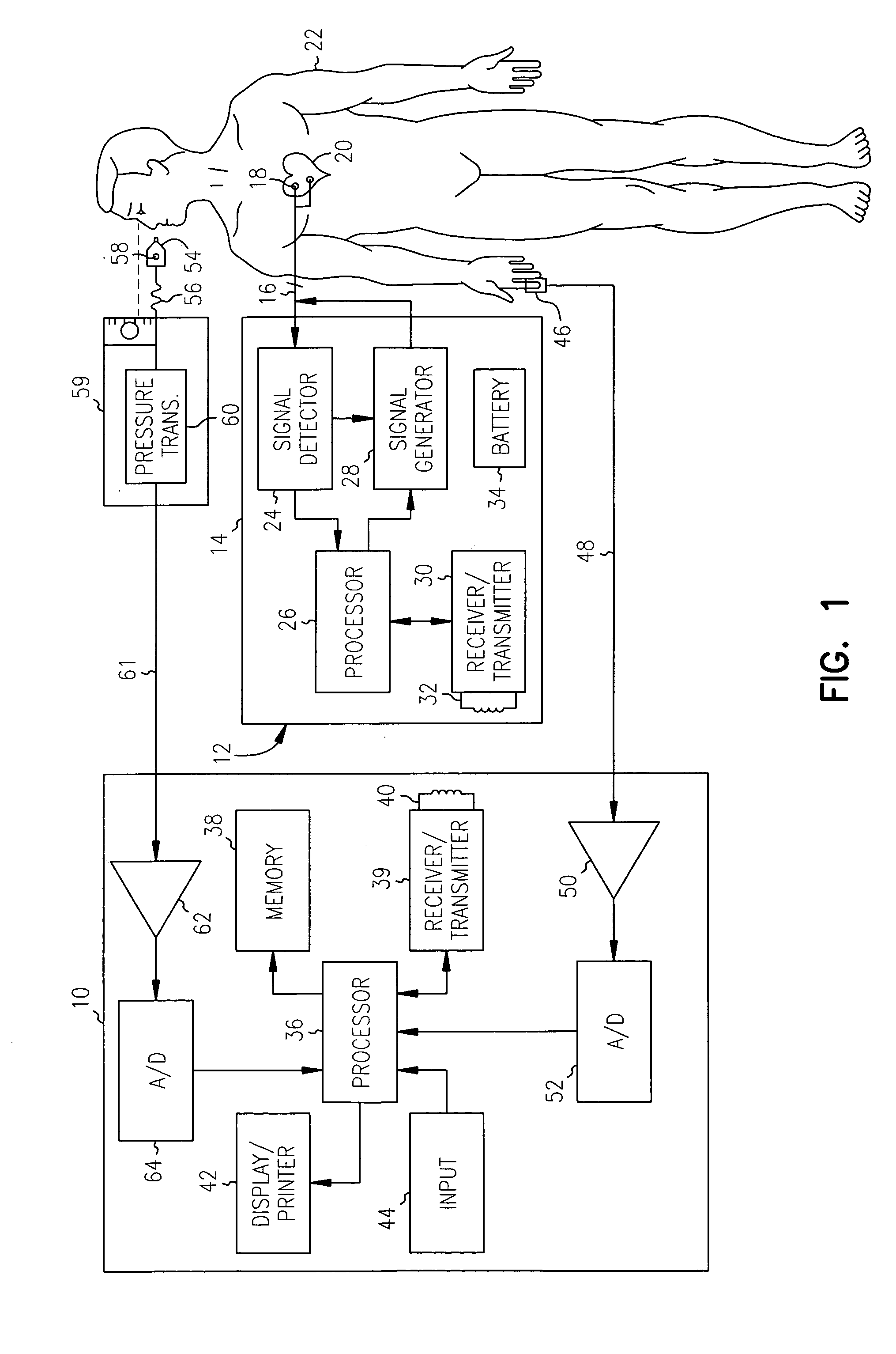

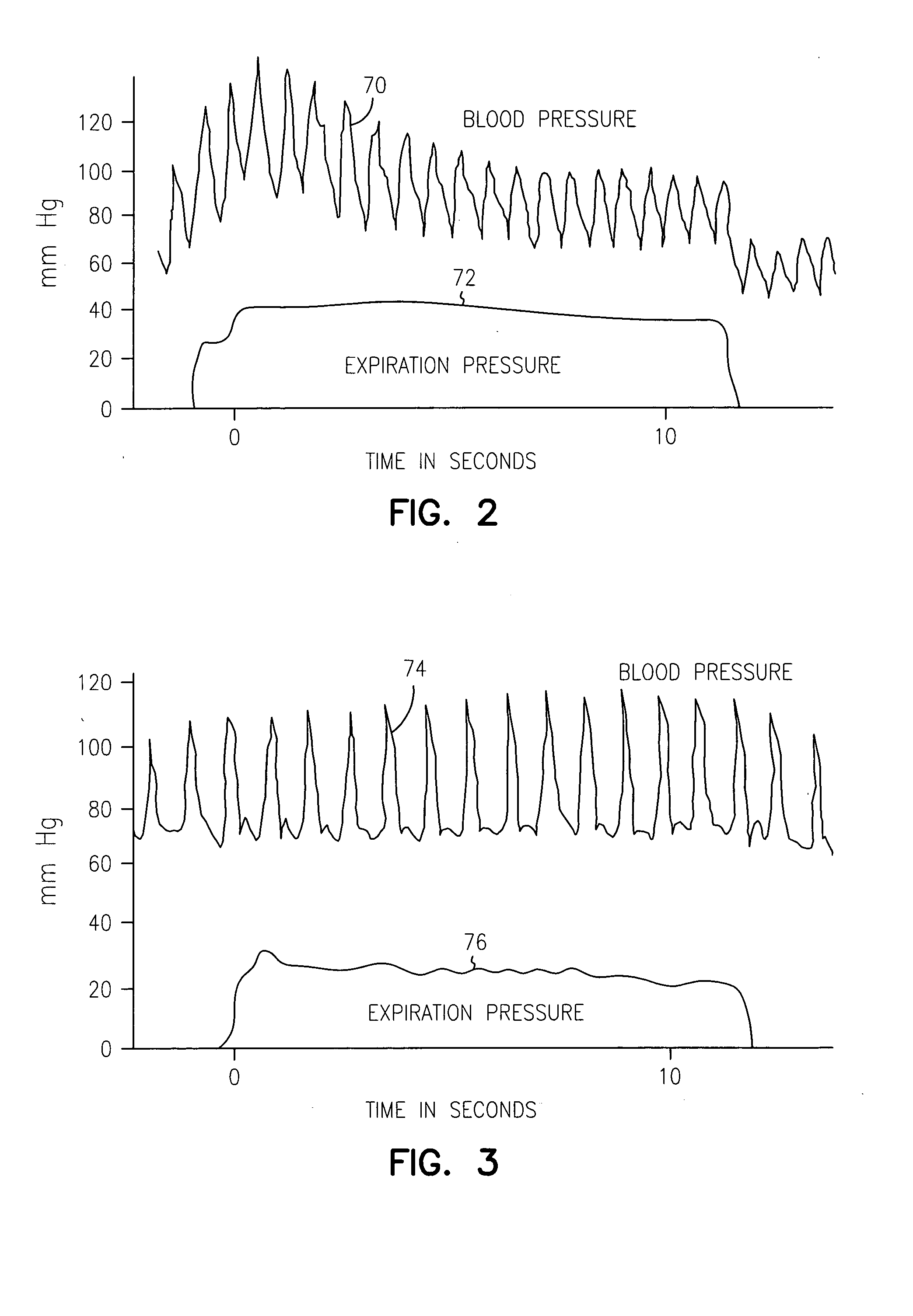

Non-invasive method and apparatus for cardiac pacemaker pacing parameter optimization and monitoring of cardiac dysfunction

InactiveUS20050043767A1Uniform peak amplitudeEasy to detectHeart stimulatorsCardiac dysfunctionAmplitude response

A plethysmogram signal is sensed from a patient and provided to a programmer device for monitoring the condition of the patient and for optimizing pacing parameters of a cardiac device implanted in the patient. The programmer device analyzes the plethysmogram signal for cardiac performance associated with different pacing parameters. The cardiac performance is indicated by, for example, a pulse amplitude response, a degree of pulsus alternans, or irregularity in the pressure pulses detected in an atrial fibrillation patient. The pacing parameters resulting in the best cardiac performance are selected as the optimum pacing parameters. In one embodiment, the programmer device monitors a Valsalva maneuver performed by a patient. Optimum pacing parameters are derived by analysis of the plethysmogram signals obtained during performance of the Valsalva maneuver while the patient is paced using different pacing parameters.

Owner:CARDIAC PACEMAKERS INC

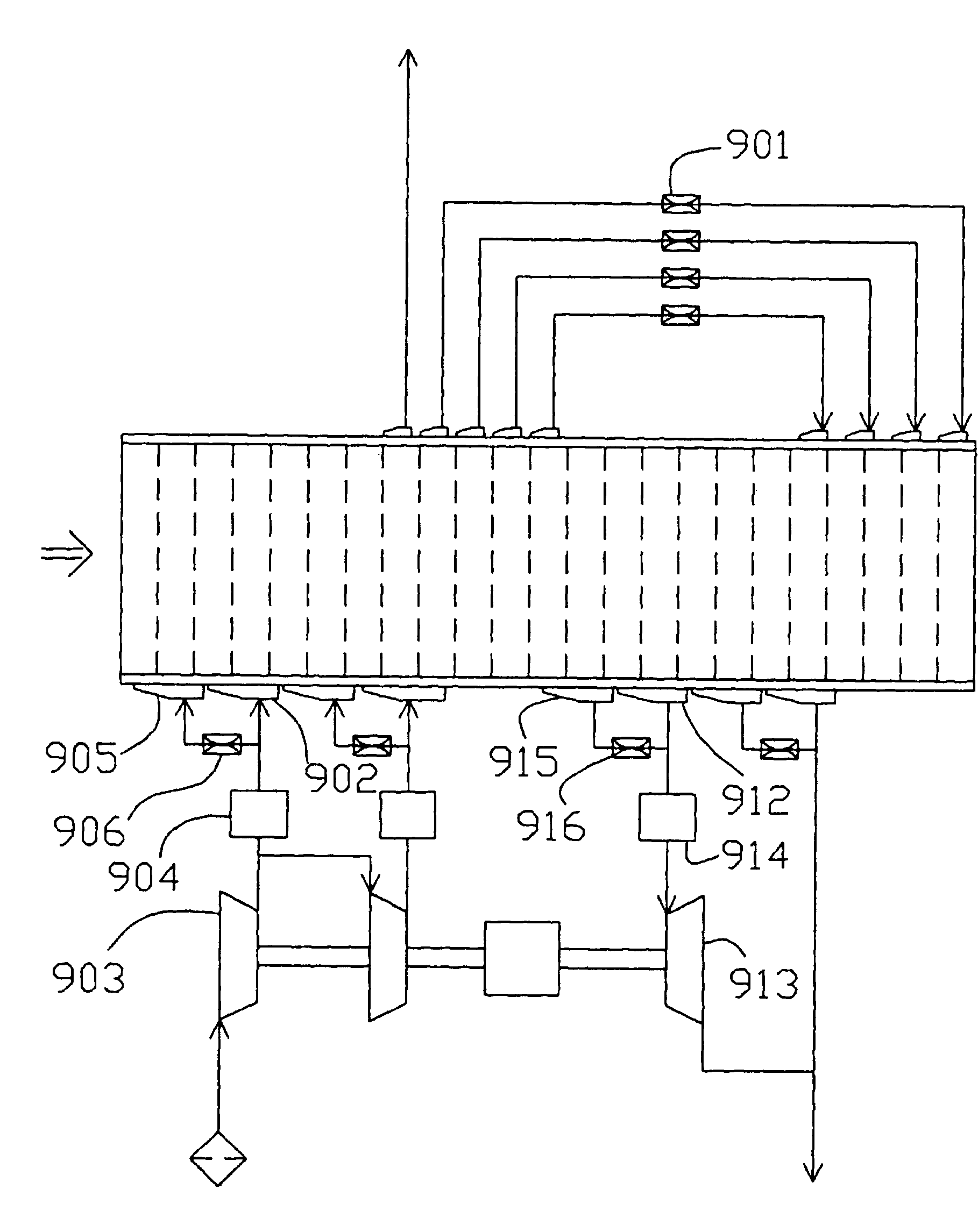

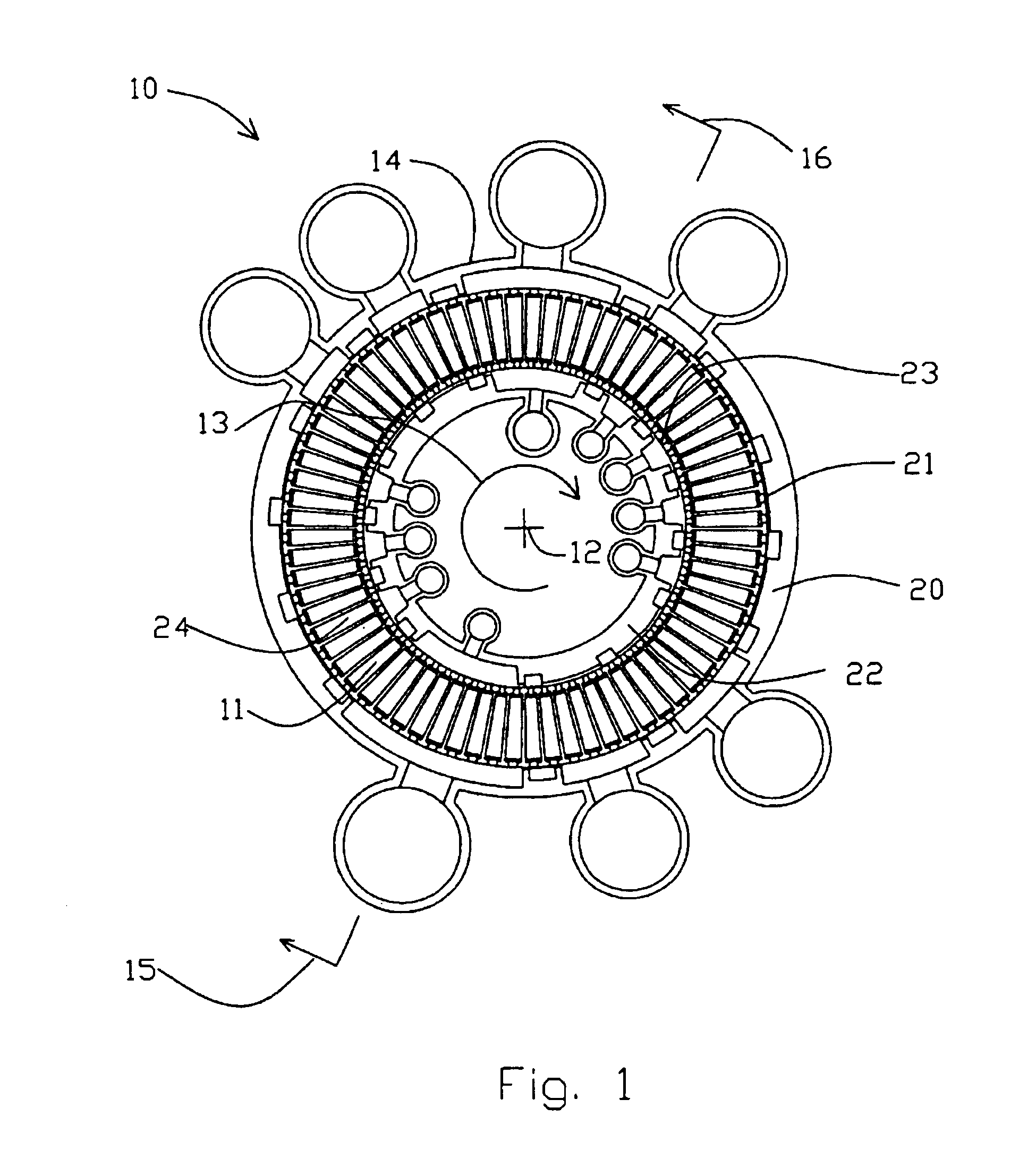

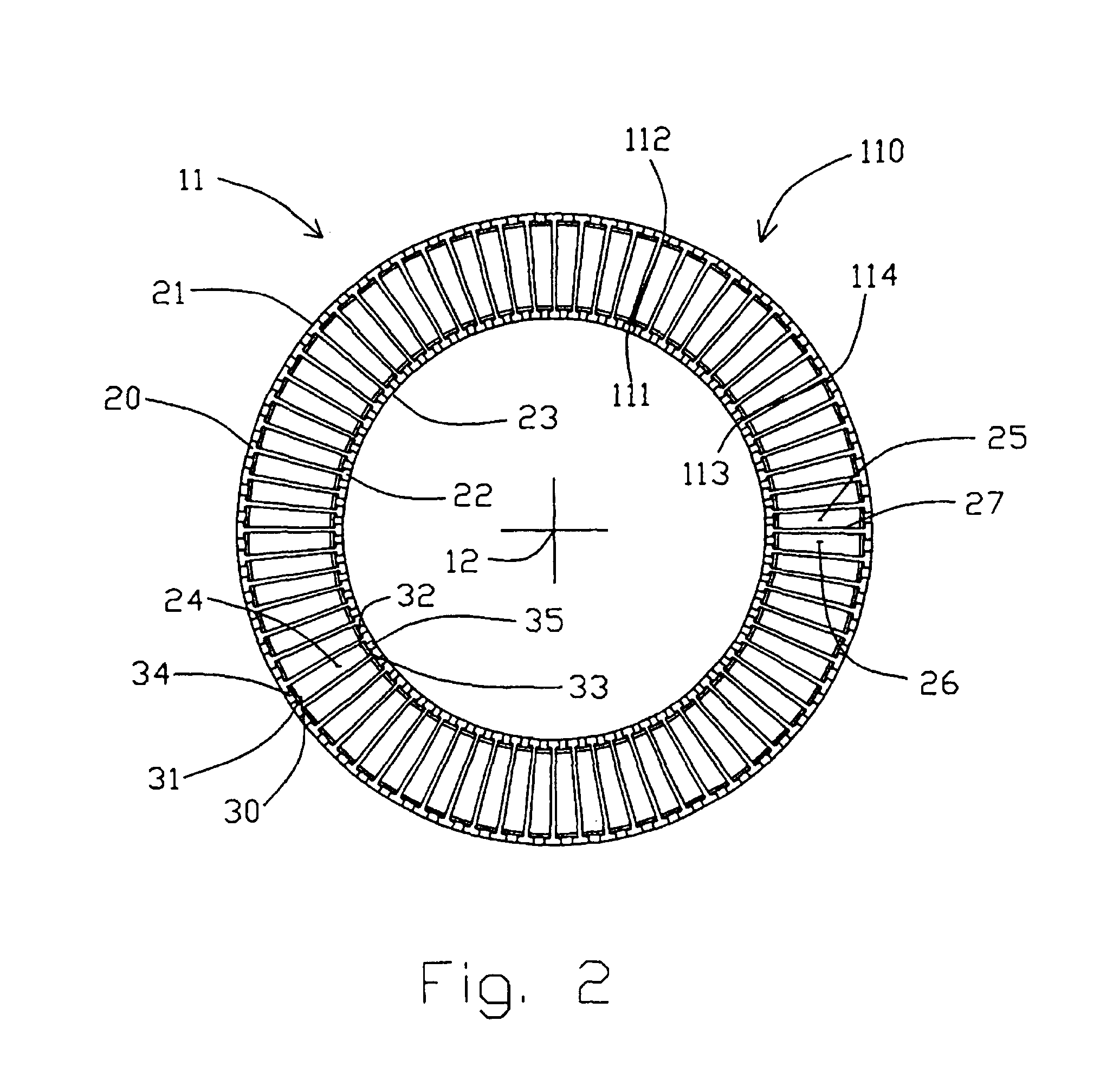

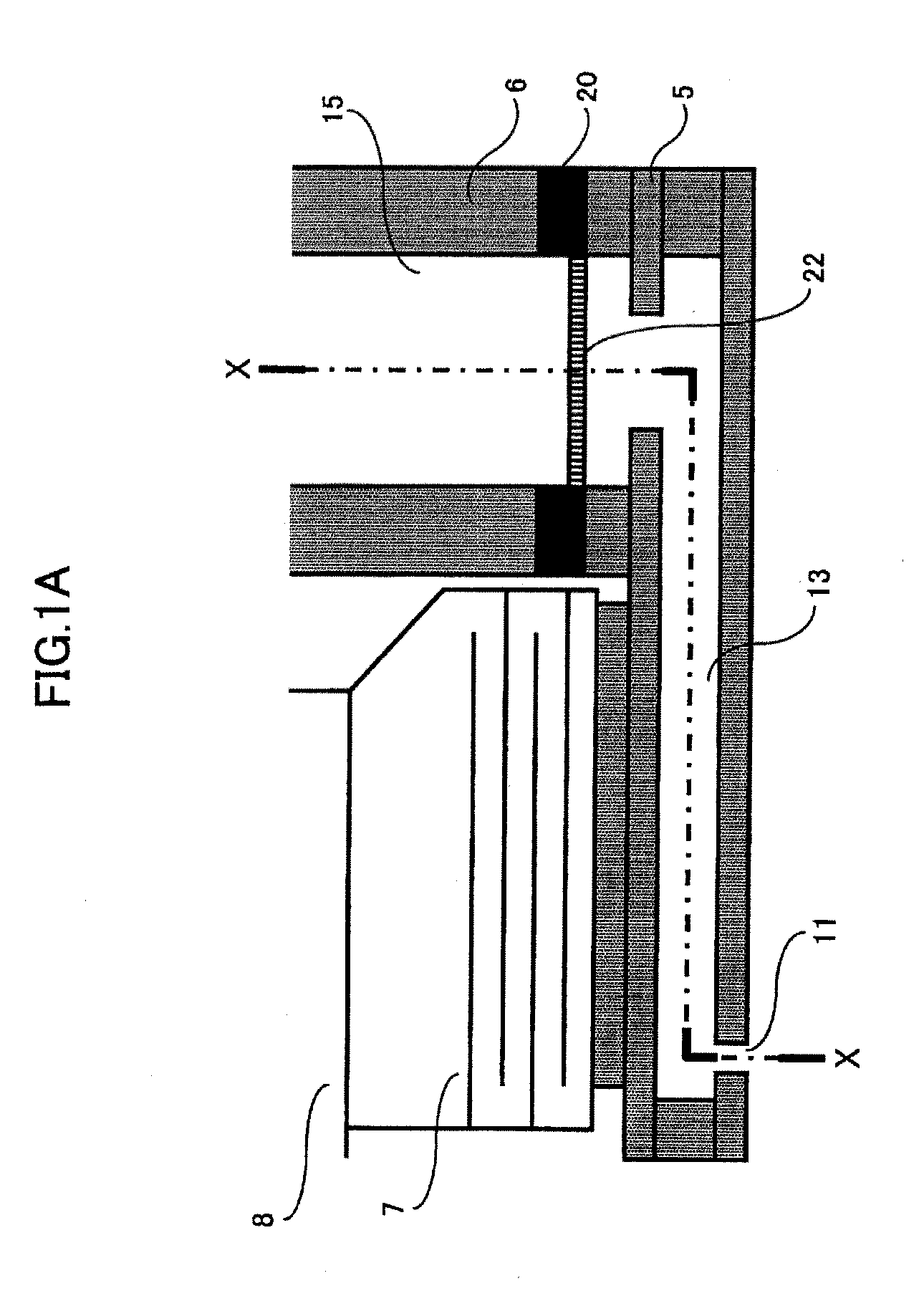

Surge absorber flow regulation for modular pressure swing adsorption

InactiveUS6840985B2Contribute to dead volumeReduce dead volumeGas treatmentIsotope separationEngineeringStreamflow

A gas separation system includes a stator, and a rotor rotatably coupled to the stator, and at least one surge absorber in communication with the stator. The stator includes a stator valve surface and a plurality of function compartments opening into the stator valve surface. The rotor includes a rotor valve surface in communication with the stator valve surface, and a plurality of flow paths for receiving adsorbent material therein. The rotor also includes a plurality of apertures provided in the rotor valve surface and in communication with the flow paths for cyclically exposing the flow paths to the function compartments. The surge absorbers are configured to reduce pressure variations in the function compartments and to maintain each function compartment at one of a plurality of discrete pressure levels. In this manner, substantially uniform gas flow can be maintained through the function compartments and the flow paths without recourse to multistage compression machinery.

Owner:AIR PROD & CHEM INC

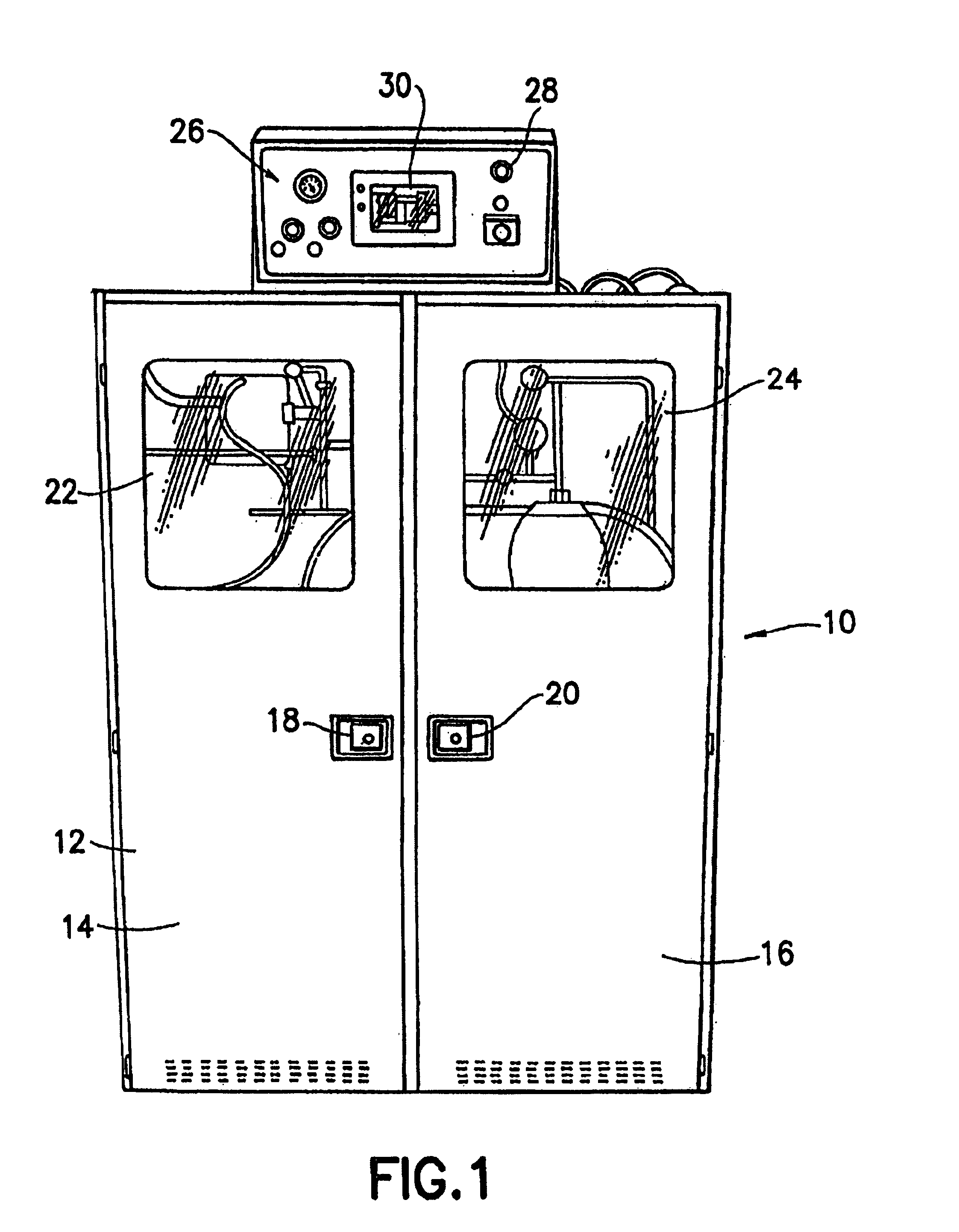

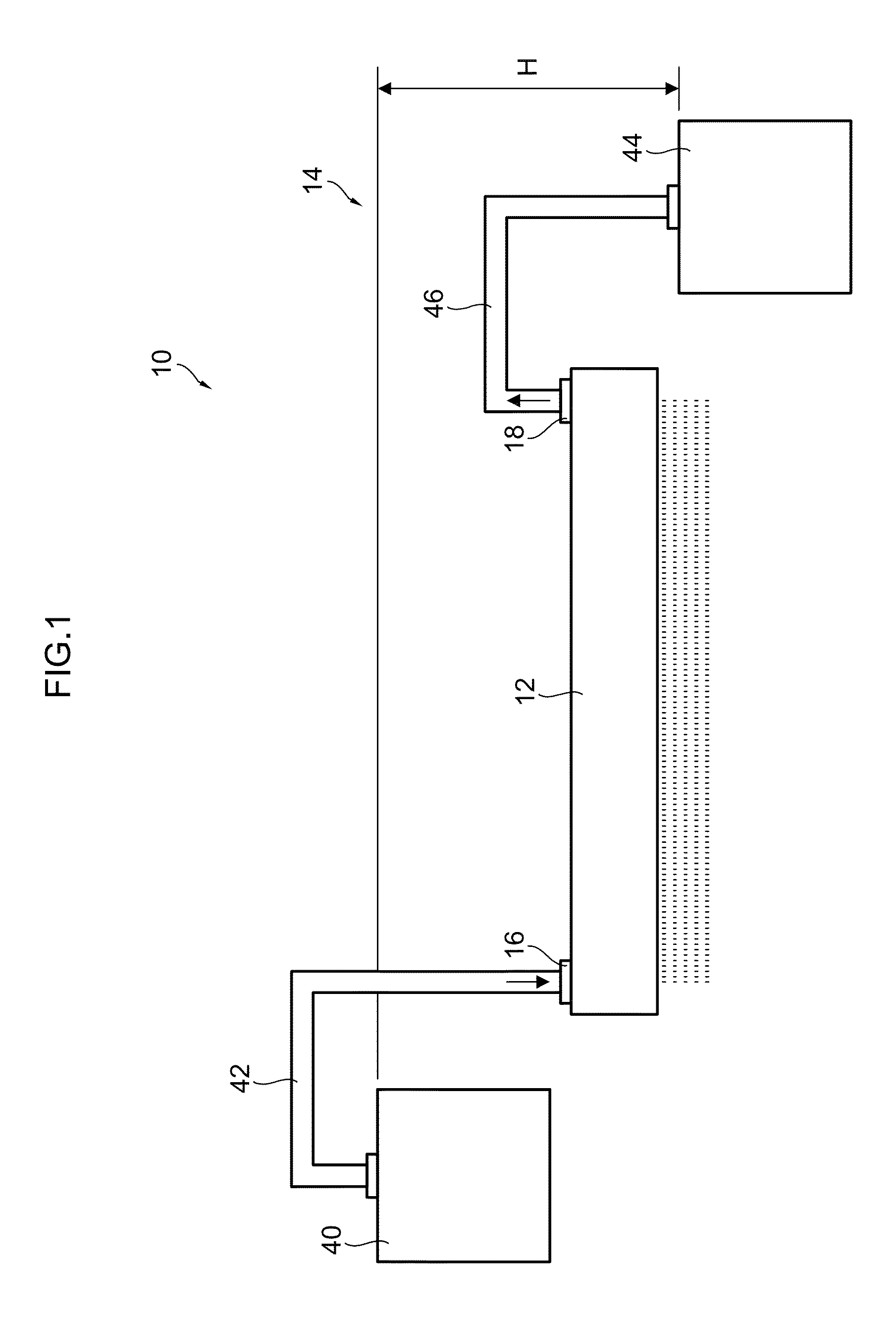

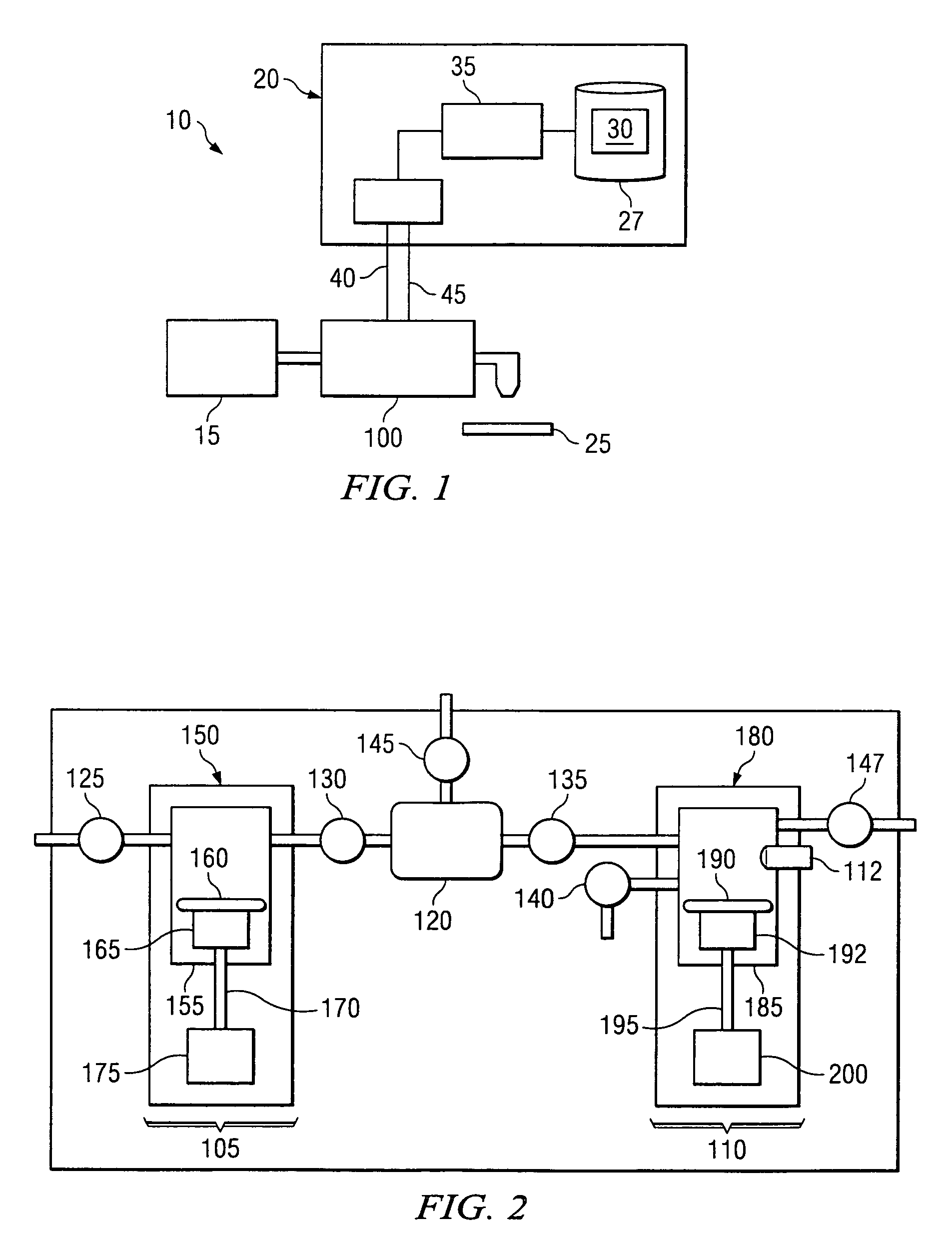

Auto-switching system for switch-over of gas storage and dispensing vessels in a multi-vessel array

InactiveUS6955198B2Reduce pressure changesVessel mounting detailsLiquid fillingEngineeringGas supply

A gas storage and dispensing system, including multi-vessel arrays of gas dispensing vessels that require successive change-over to provide ongoing supply of gas to a gas-consuming process, with a pump coupled in gas flow communication with the array. The system is provided with capability for time delay auto-switchover sequencing of the switchover operation in which an endpoint limit sensing of an on-stream gas dispensing vessel is responsively followed by termination of gas flow to the pump, inactivation of the pump, autoswitching of vessels, reinitiation of gas flow to the pump and reactivation of the pump. The system minimizes the occurrence of pressure spikes at the pump outlet in response to pressure variation at the pump inlet incident to switchover of gas supply from one vessel to another in the multi-vessel array.

Owner:ENTEGRIS INC

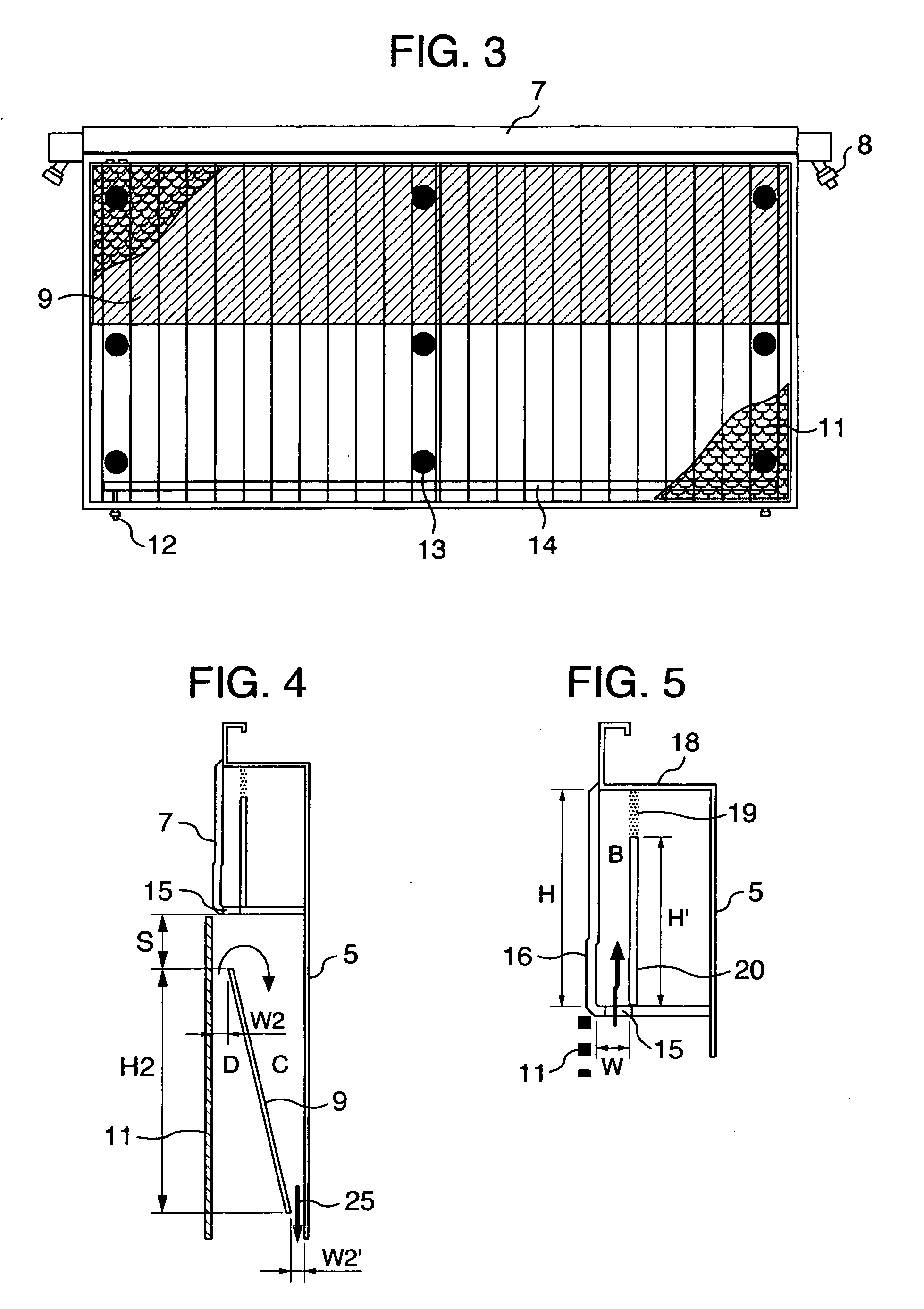

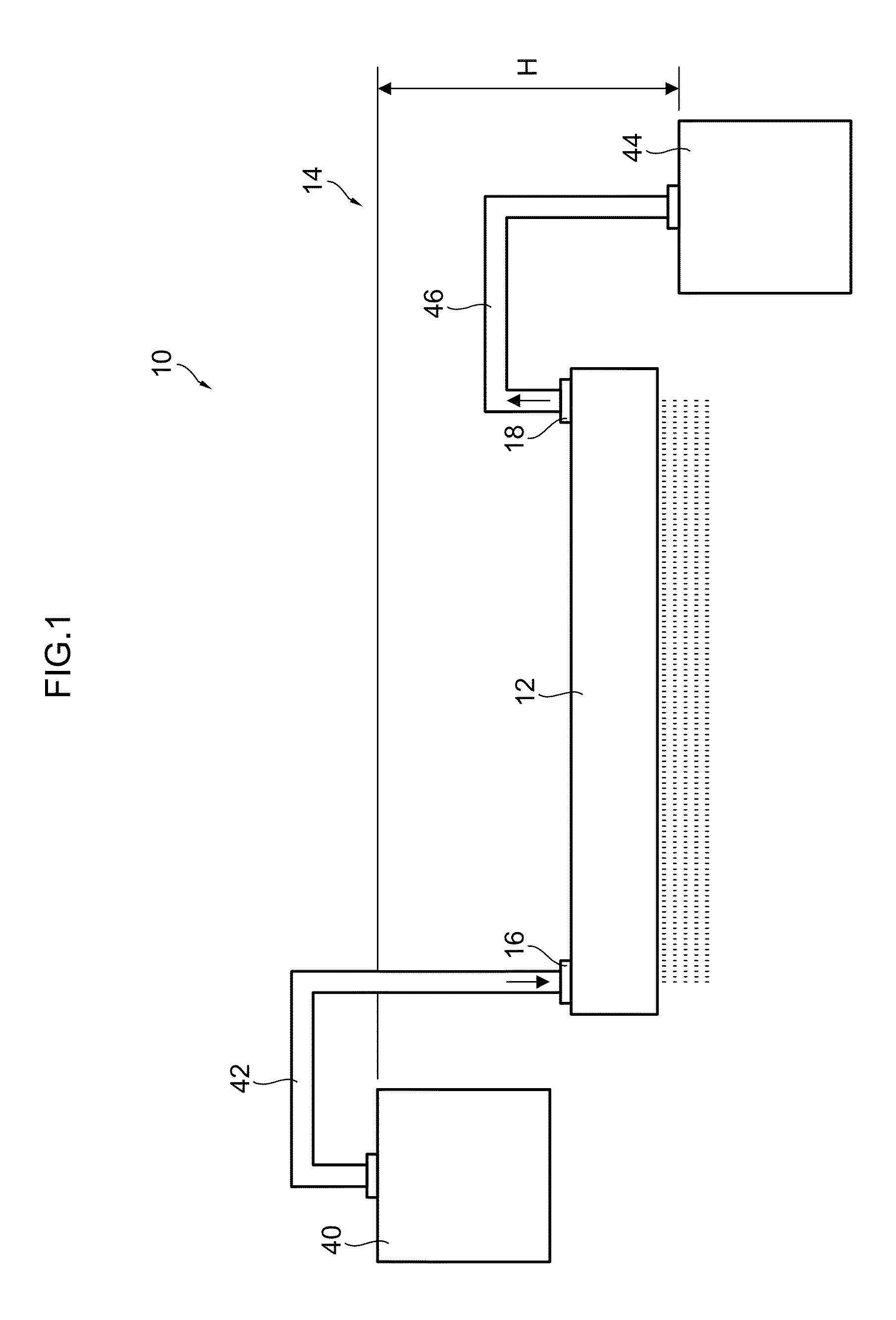

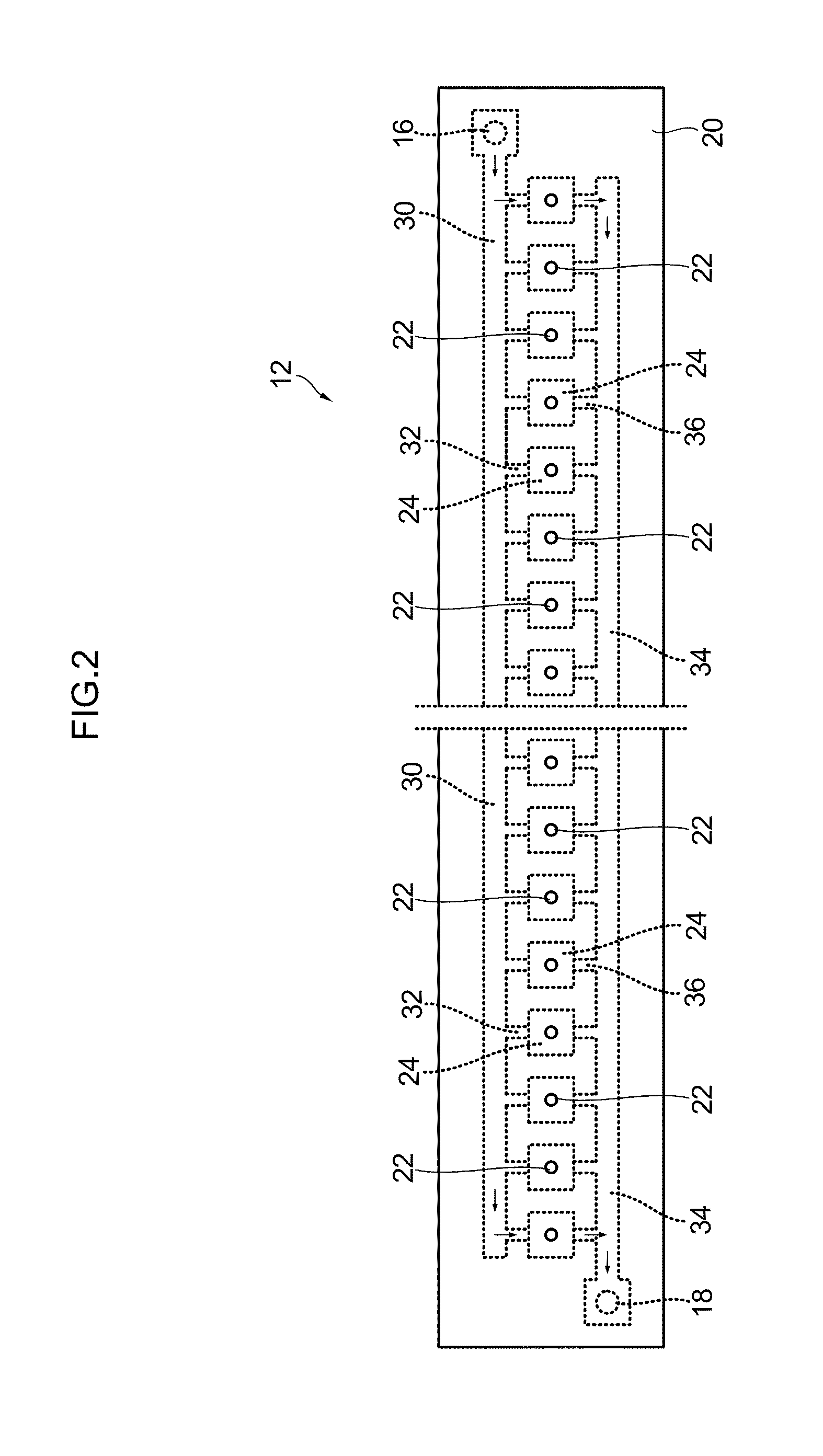

Liquid ejection apparatus

A liquid ejection apparatus includes: a head including: a nozzle configured to eject liquid; a supply port to which the liquid is continuously supplied; and a recovery port from which the liquid is continuously recovered; a supply flow channel through which the liquid is supplied to the head; and a recovery flow channel through which the liquid is recovered from the head. A flow channel resistance inside the head from the supply port to the nozzle is R_HEAD_IN. A flow channel resistance inside the head from the nozzle to the recovery port is R_HEAD_OUT. A flow channel resistance of the supply flow channel is R_CHANNEL_IN. A flow channel resistance of the recovery flow channel is R_CHANNEL_OUT. The supply and recovery flow channels are laid out so as to satisfy a condition of R_CHANNEL_IN>R_CHANNEL_OUT when R_HEAD_IN>R_HEAD_OUT, or a condition of R_CHANNEL_IN<R_CHANNEL_OUT when R_HEAD_IN<R_HEAD_OUT.

Owner:FUJIFILM CORP

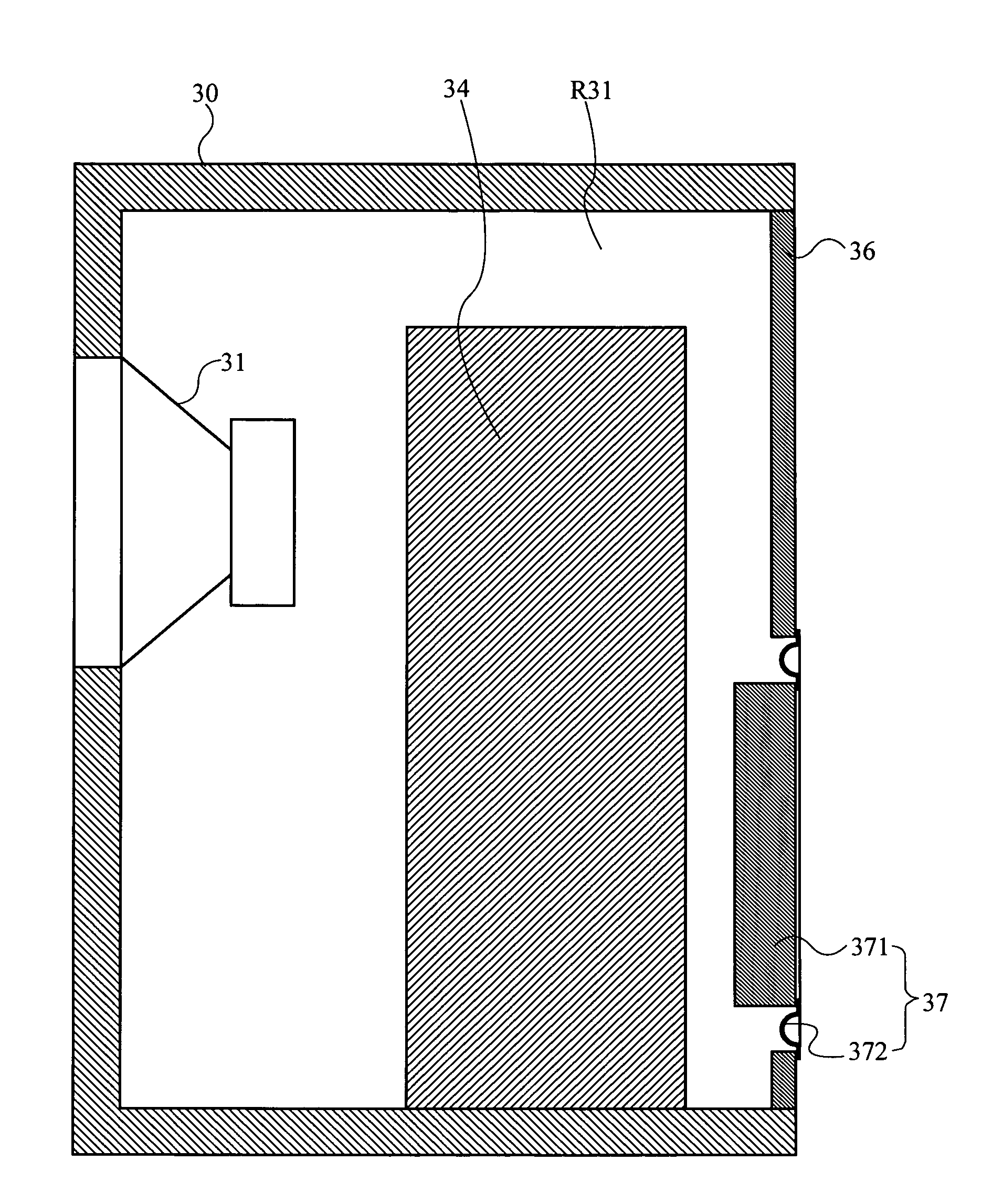

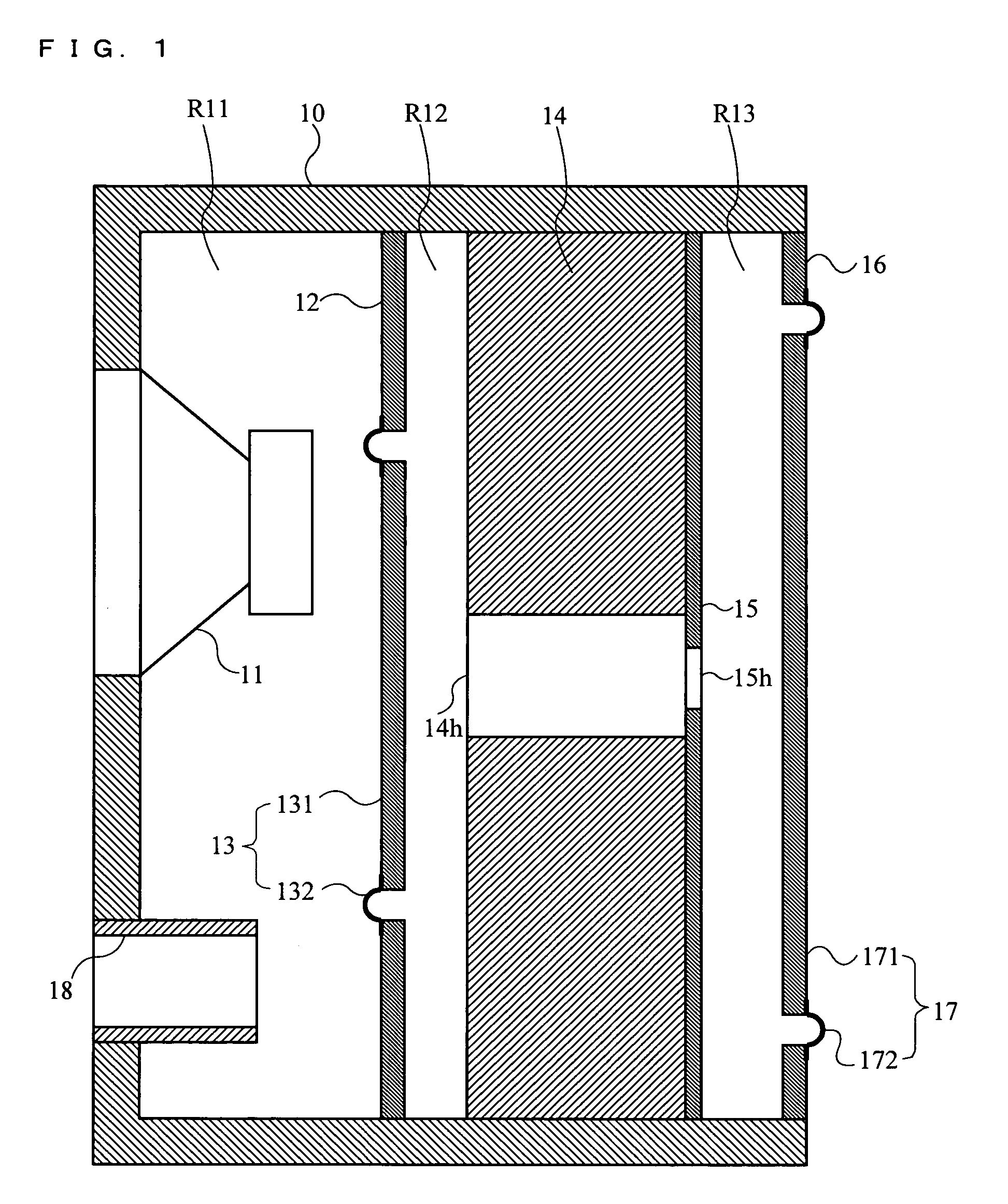

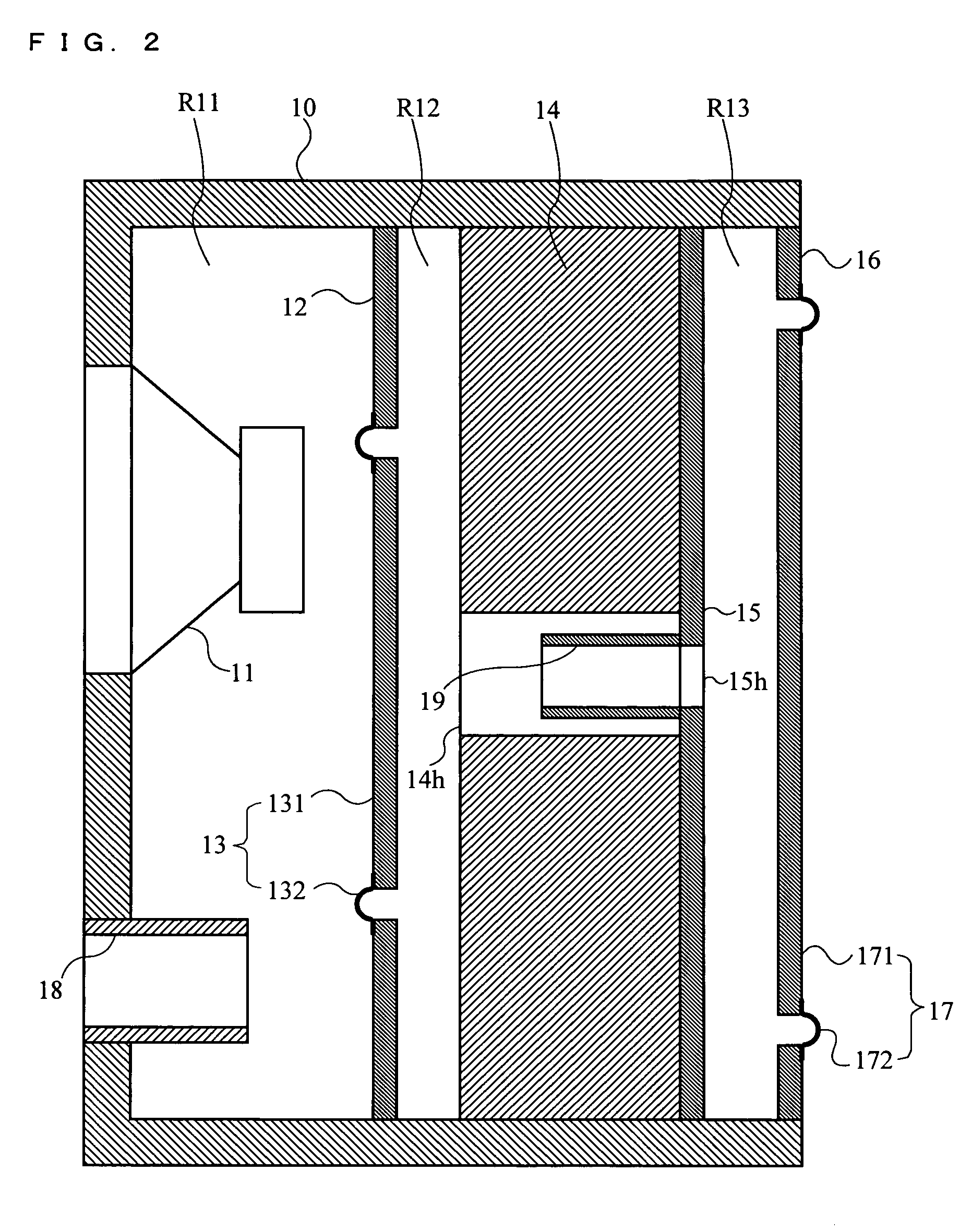

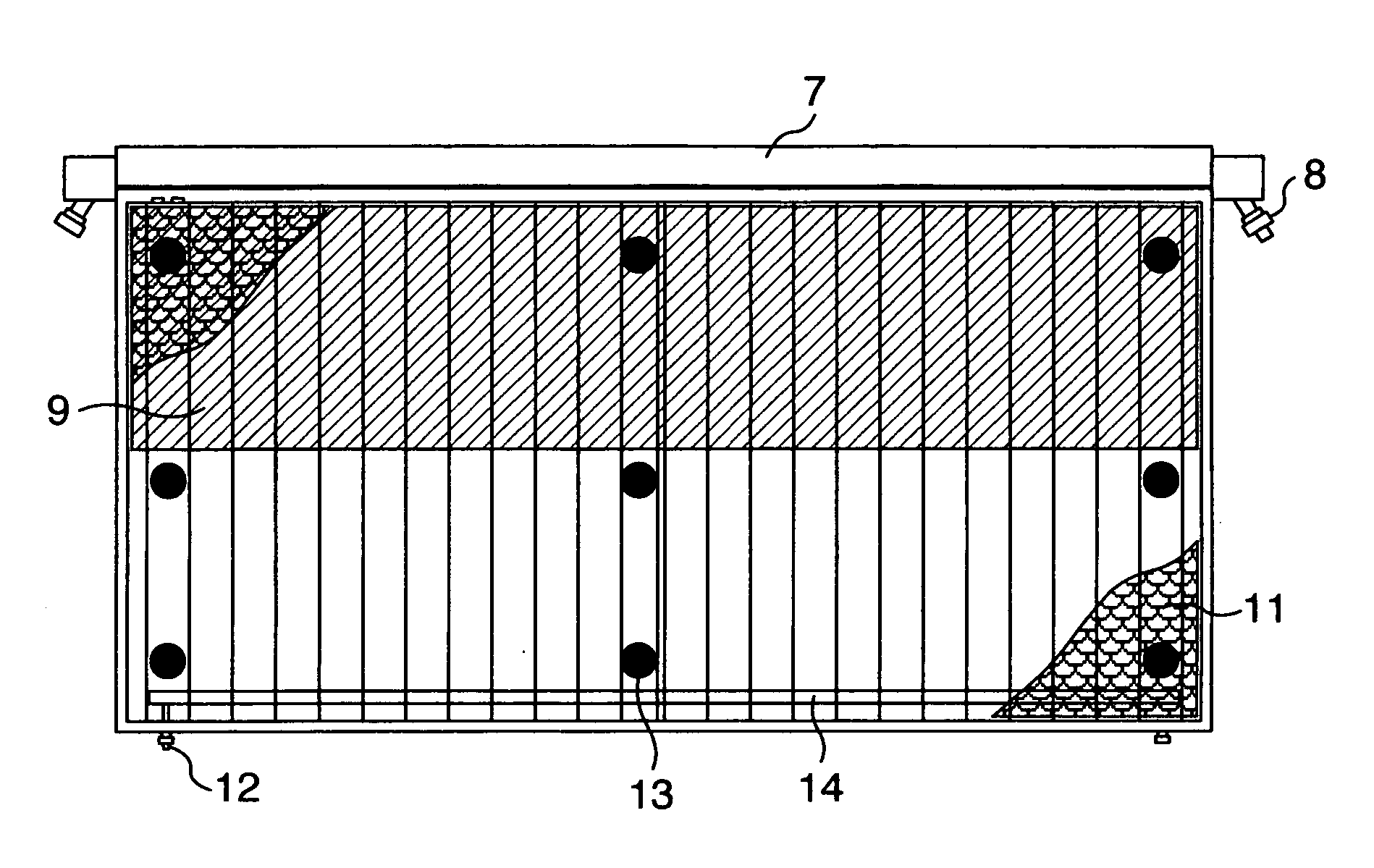

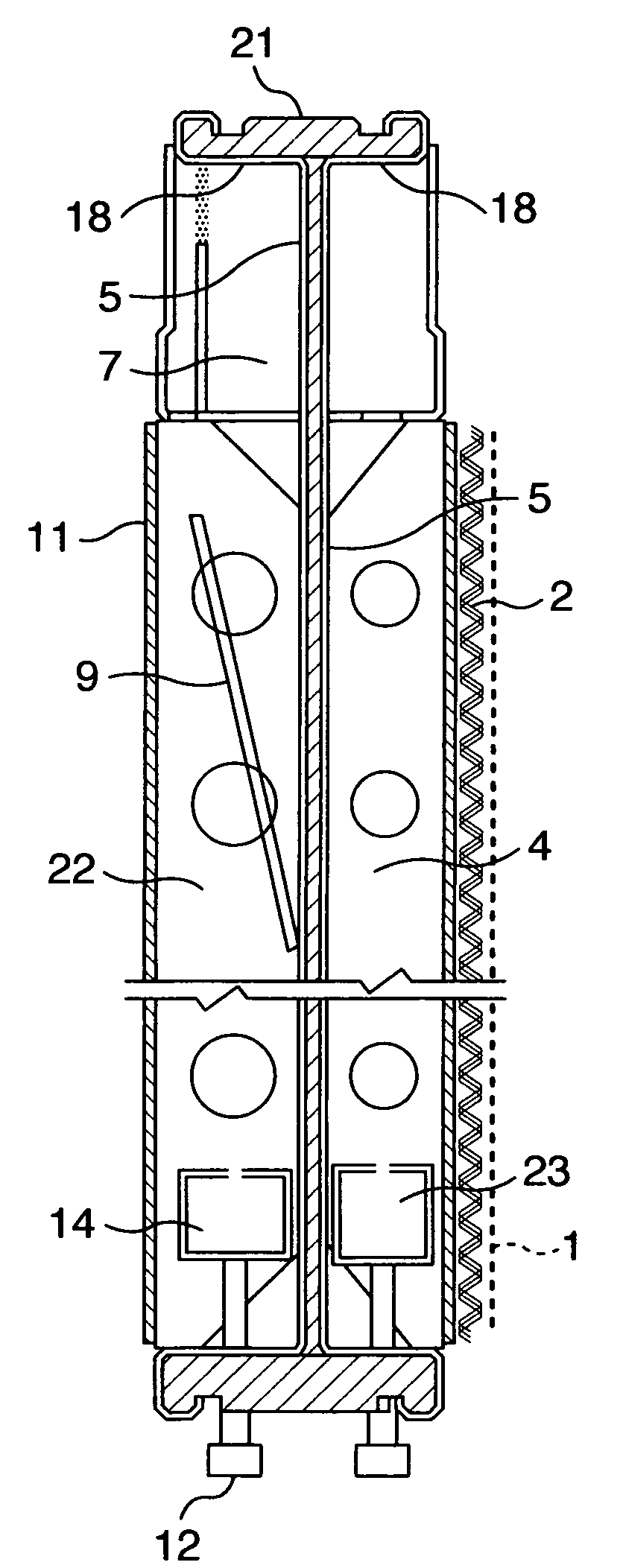

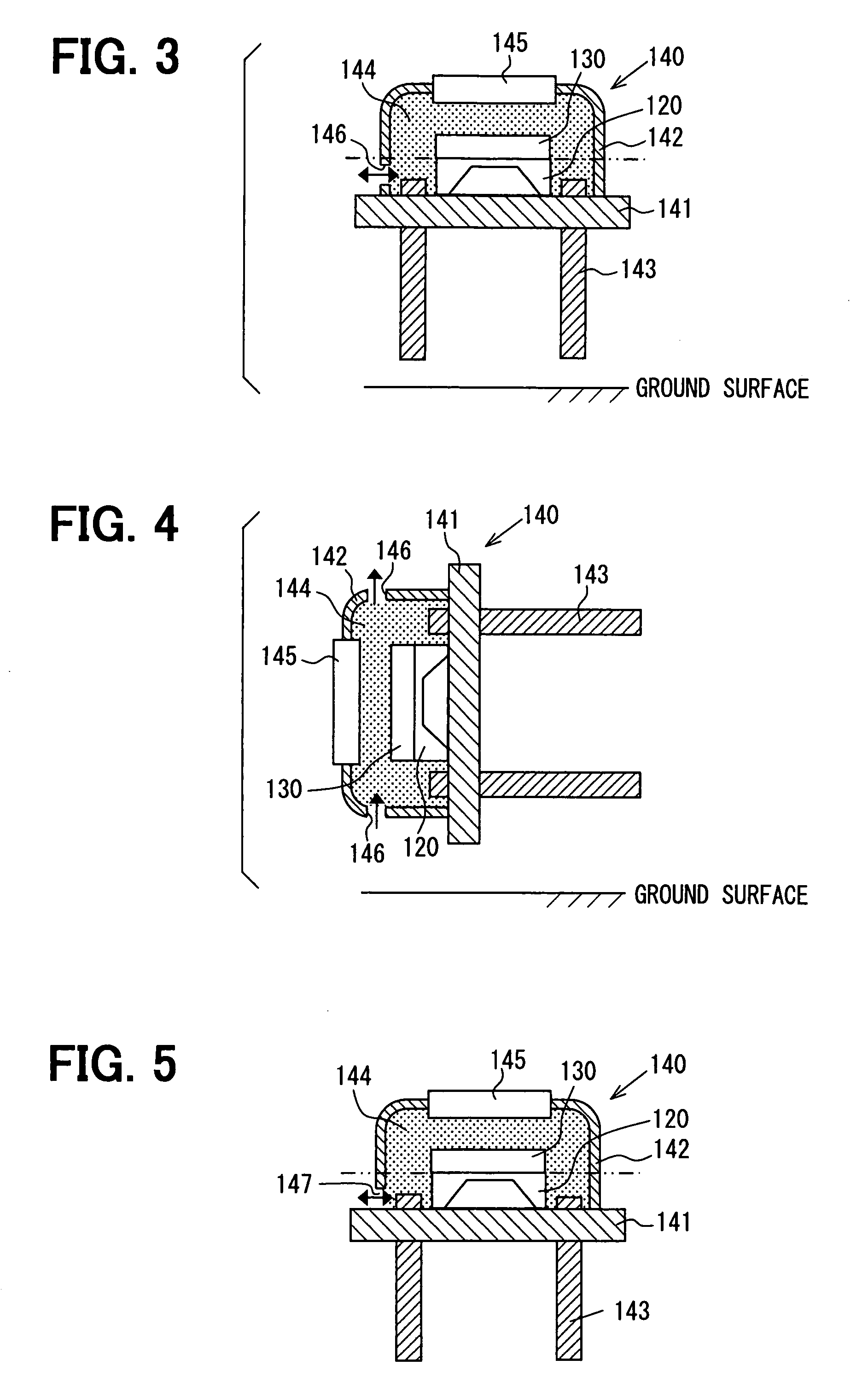

Speaker system

ActiveUS7477755B2Reduce pressure changesImprove acoustic performanceFrequency/directions obtaining arrangementsLoudspeaker spatial/constructional arrangementsEngineeringAtmospheric pressure

A speaker system according to the present invention comprises a cabinet (10), a speaker unit (11), a first parting board (12), a drone cone (13), an adsorption member (14), a second parting board (15), a backboard (16), a variable mechanism (17), and a port (18). A sound pressure generated by the speaker unit (11) causes a pressure variation in a second chamber (R12) via the drone cone (13). The adsorption member (14) with an effect of physical adsorption is operable to suppress the pressure variation. Furthermore, by displacing the diaphragm (171), the variable mechanism (17) is operable to reduce a pressure variation of a direct current component, which is caused by variations in ambient temperature or atmospheric pressure of the speaker system.

Owner:PANASONIC CORP

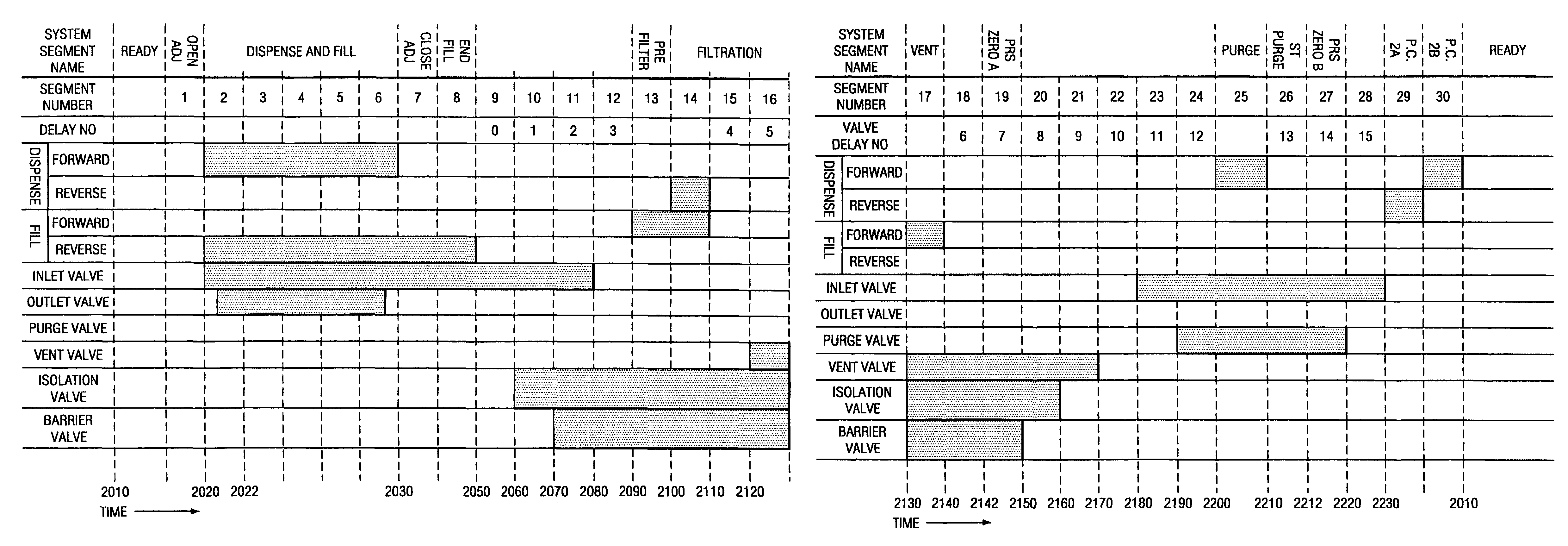

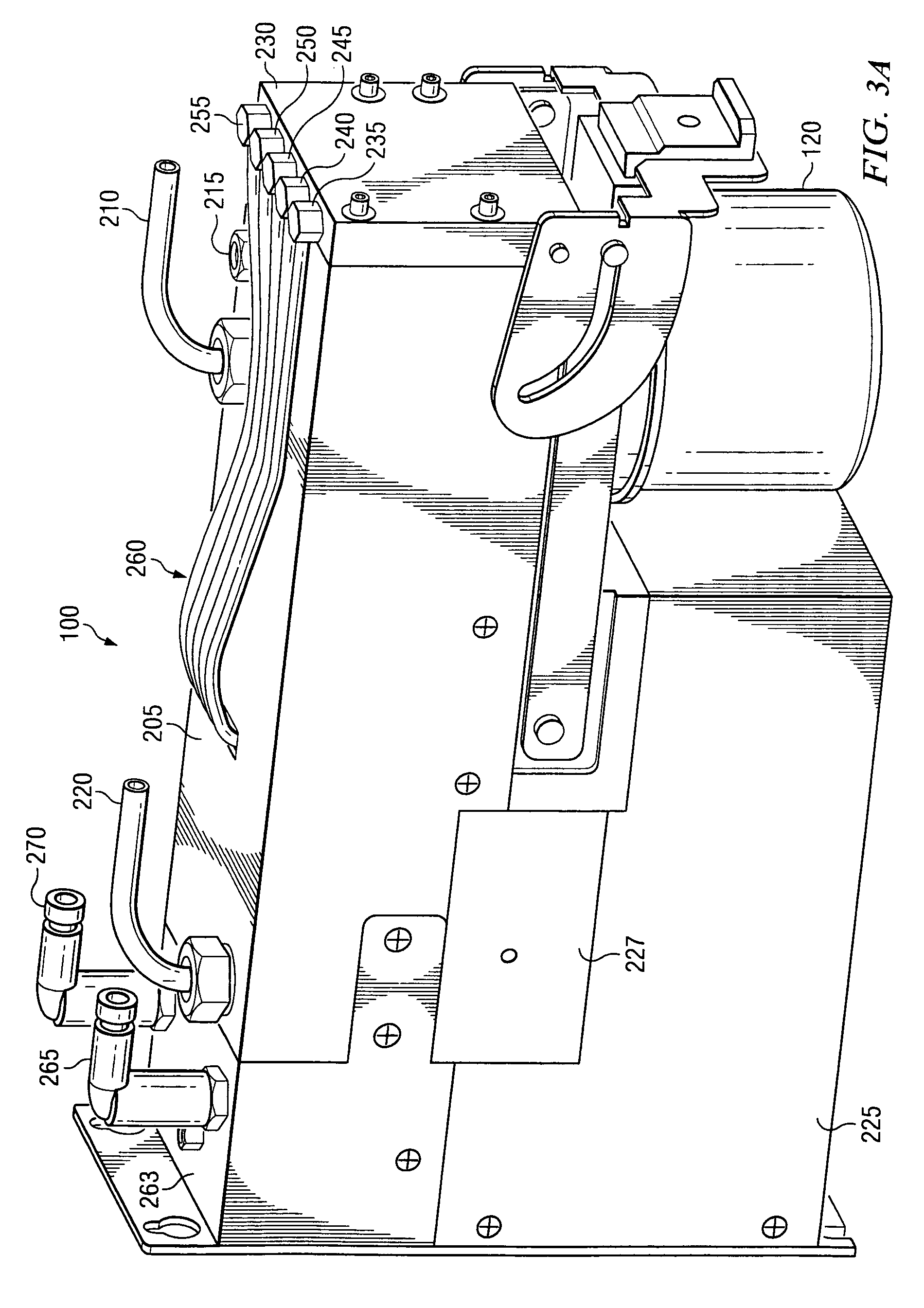

System and method for valve sequencing in a pump

ActiveUS8025486B2Minimizes pressure fluctuationReduce pressure changesServomotor componentsLarge containersEngineeringMechanical engineering

Systems and methods for minimizing pressure fluctuations within a pumping apparatus are disclosed. Embodiments of the present invention may serve to reduce pressure variations within a fluid path of a pumping apparatus by avoiding closing a valve to create a closed or entrapped space in the fluid path and similarly, avoiding opening a valve between two entrapped spaces. More specifically, embodiments of the present invention may serve to operate a system of valves of the pumping apparatus according to a valve sequence configured to substantially minimize the time the fluid flow path through the pumping apparatus is closed (e.g. to an area external to the pumping apparatus).

Owner:ENTEGRIS INC

Bipolar zero-gap type electrolytic cell

ActiveUS20060042935A1Preventing gas vibrationStable electrolysisCellsElectrode shape/formsInternal pressureTitanium metal

A bipolar zero-gap electrolytic cell comprising an anode comprising an anode substrate constituted of a titanium expanded metal or titanium metal net of 25 to 70% opening ratio, which anode after coating the substrate with a catalyst has a surface of 5 to 50 μm unevenness difference maximum and has a thickness of 0.7 to 2.0 mm. In this electrolytic cell, the possibility of breakage of ion exchange membrane is low, and the anolyte and catholyte have a concentration distribution falling within given range. With this electrolytic cell, stable electrolysis can be performed for a prolonged period of time with less variation of cell internal pressure.

Owner:ASAHI KASEI KK

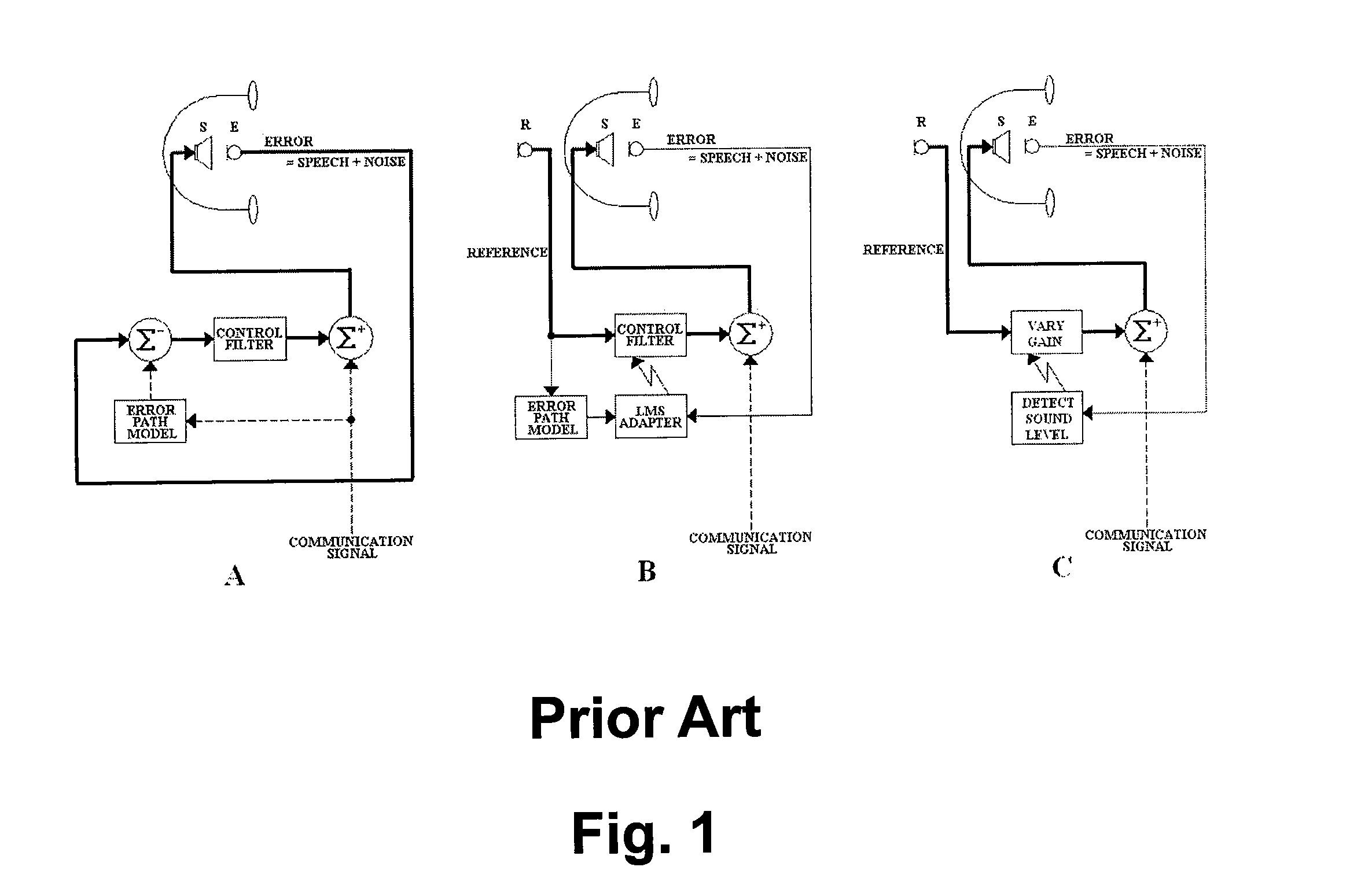

Method and device for improving the audibility, localization and intelligibility of sounds, and comfort of communication devices worn on or in the ear

InactiveUS20130094657A1Reduce user discomfortCut skinEar treatmentNoise generationHearing preservationHeadphones

Owner:UNIV OF CONNECTICUT

Gaskets for substrate containers and substrate container equipped with the same

InactiveUS20040041355A1Increase flexibilityRaise the possibilityEngine sealsOther chemical processesElastomerPolyester

Provided are a gasket member for a substrate-holding container which is little liable to contamination of the substrate materials contained with organic matters due to the low content of organic matters to be emitted as a gas still without decreasing the operability in opening and closing of the covering as well as a substrate-holding container by using the same. The gasket member for a substrate-holding container provided is formed from a thermoplastic polyester-based elastomer resin containing absolutely no softening agent and having a surface hardness not exceeding 80A by the hardness testing method specified in JIS K6301, of which the amount of gas emission as determined under heating conditions for 60 minutes at 80° C. does not exceed 10 ppm based on the weight of the material. Disclosure is given of a polyester-based block copolymer suitable as a molding material of the said gasket member.

Owner:SHIN-ETSU POLYMER CO LTD

Infrared-type gas detector

ActiveUS20080062426A1Unevenness of gapUnevenness of on resistanceInterferometric spectrometryAbsorption/flicker/reflection spectroscopyInfraredGas detector

An infrared-type gas detector is provided with a Fabry-Perot filter through which infrared having a predetermined wavelength is selected to pass, a first detection unit for receiving the infrared having passed through the Fabry-Perot filter and outputting a detection signal corresponding to an absorption amount of the infrared, and a case member having a window portion through which the infrared passes and housing therein the first detection unit and the Fabry-Perot filter in an inner space of the case member. The case member has at least one ventilation portion through which the inner space of the case member is communicated with the exterior of the case member.

Owner:DENSO CORP

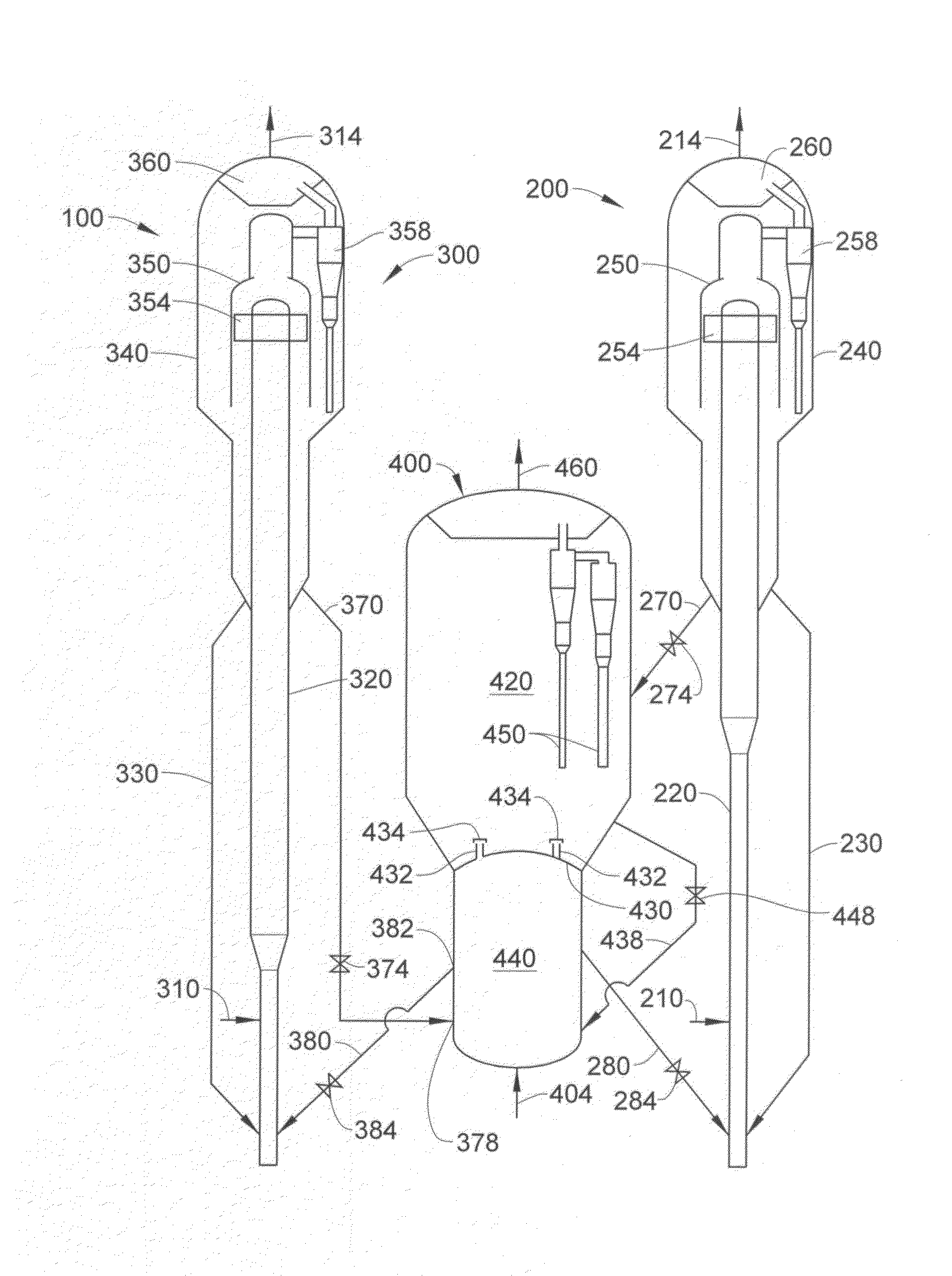

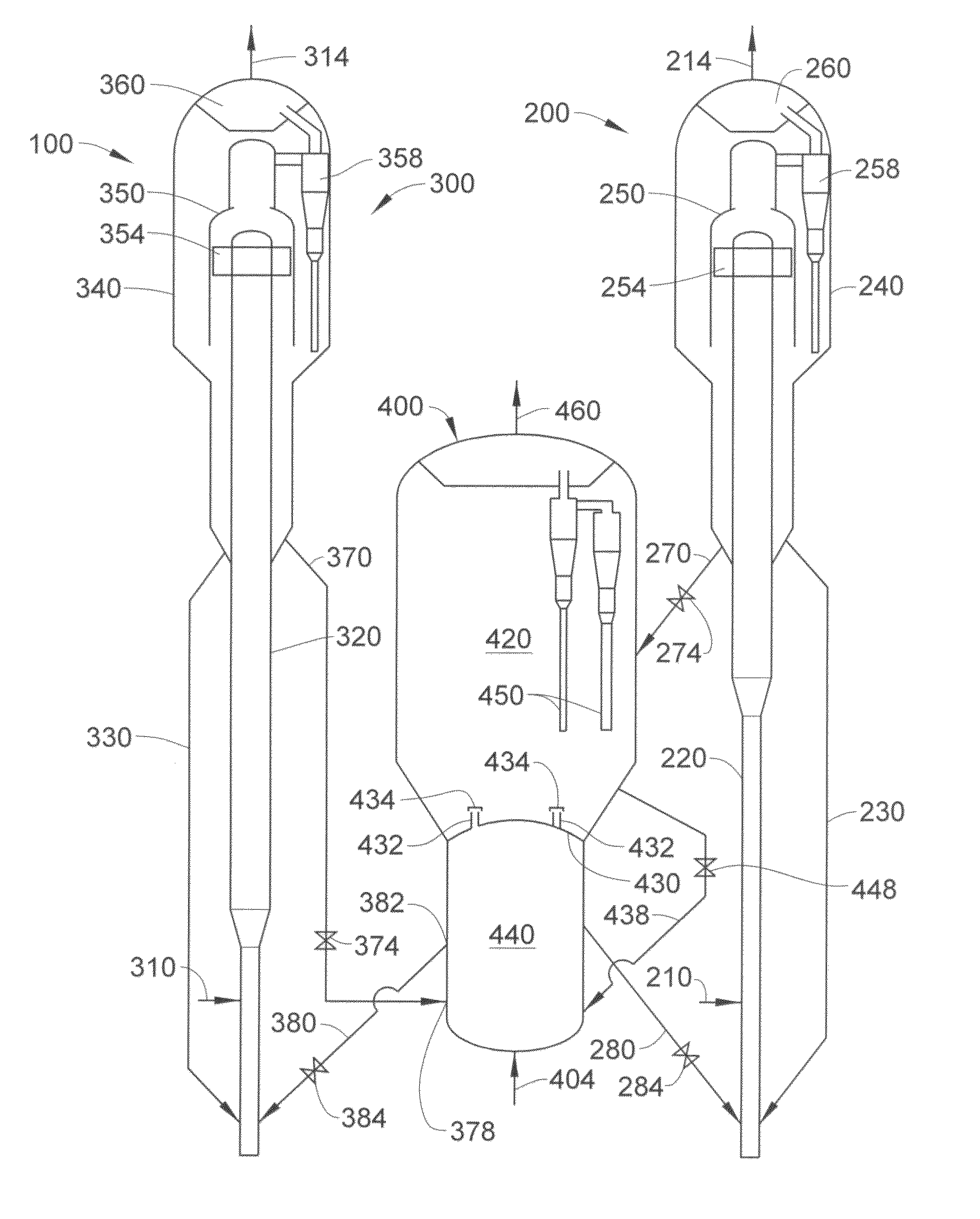

Process and apparatus for fluid catalytic cracking

ActiveUS20130248420A1Reduces pressure varianceReduce pressure changesTreatment with plural serial cracking stages onlyCatalytic crackingProcess engineeringFluid catalytic cracking

One exemplary embodiment can be a process for fluid catalytic cracking. The process can include sending a first catalyst from a first riser reactor and a second catalyst from a second riser reactor to a regeneration vessel having a first stage and a second stage. The first catalyst may be sent to the first stage and the second catalyst may be sent to the second stage of the regeneration vessel. Generally, the first stage is positioned above the second stage.

Owner:UOP LLC

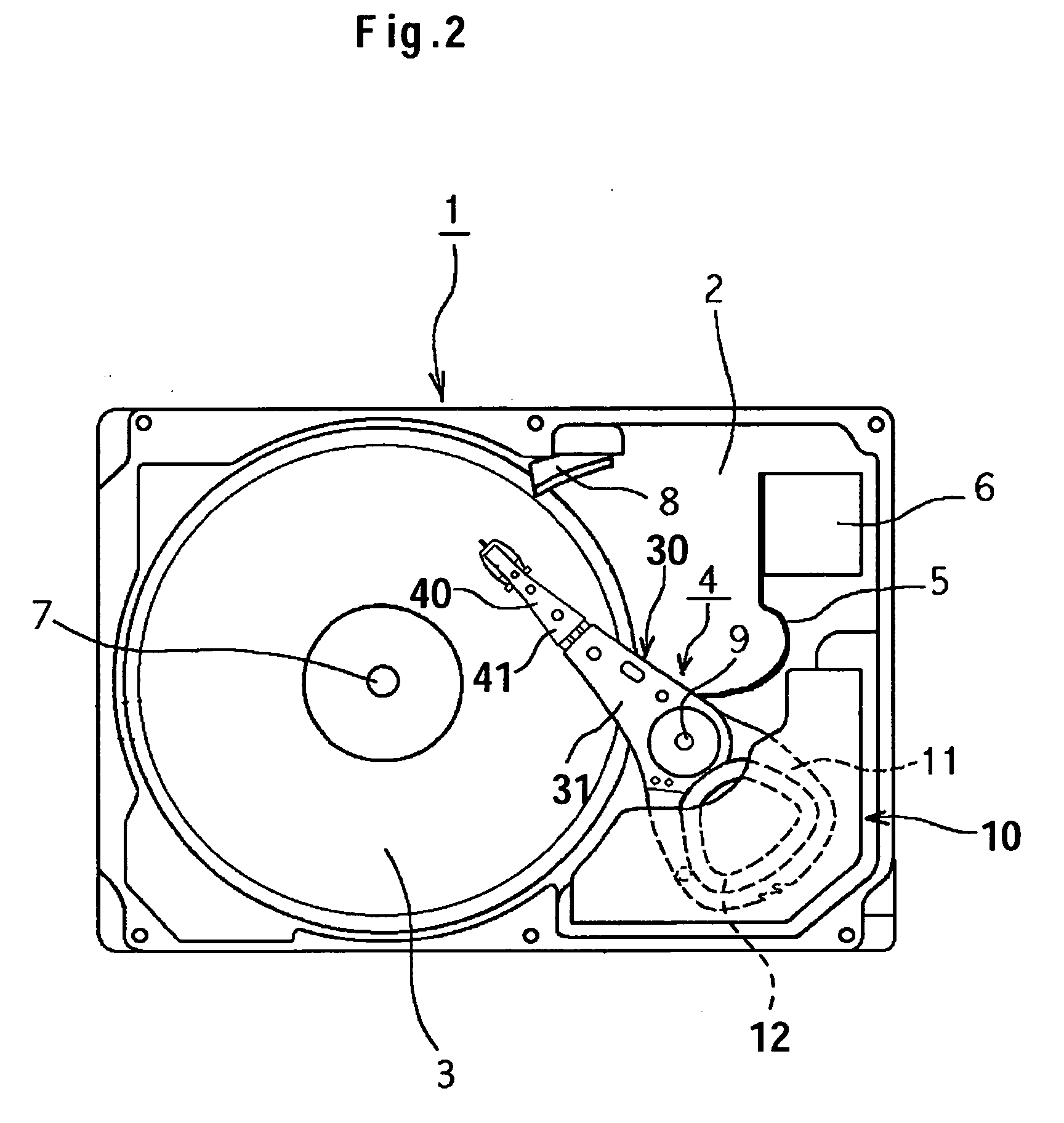

Slider and rotating disk type storage device

InactiveUS20050280943A1Improve dynamic performancePrevent deterioration in follow-up performanceRecord information storageFluid-dynamic spacing of headsLeading edgeTrailing edge

A stable kinetic performance is to be exhibited even in the case of such a small-sized slider as Femto slider. In one embodiment, an air bearing surface (ABS) of a slider comprises a first pad constituting portion extending from a leading edge side to a trailing edge side, a second pad constituting portion and a third pad constituting portion formed on both sides of the first pad constituting portion and extending from the leading edge side to the trailing edge side, a connecting pad for connecting the first, second, and third pad constituting portions on the leading edge side, a first negative pressure portion formed by the first and second pad constituting portions and the connecting pad, a second negative pressure portion formed by the first and third pad constituting portions and the connecting pad, and an air trap portion formed on the leading edge side of the connecting pad.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Process and apparatus for fluid catalytic cracking

ActiveUS8864979B2Reduce pressure changesClosely matchedThermal non-catalytic crackingCatalytic crackingEngineeringProcess engineering

Owner:UOP LLC

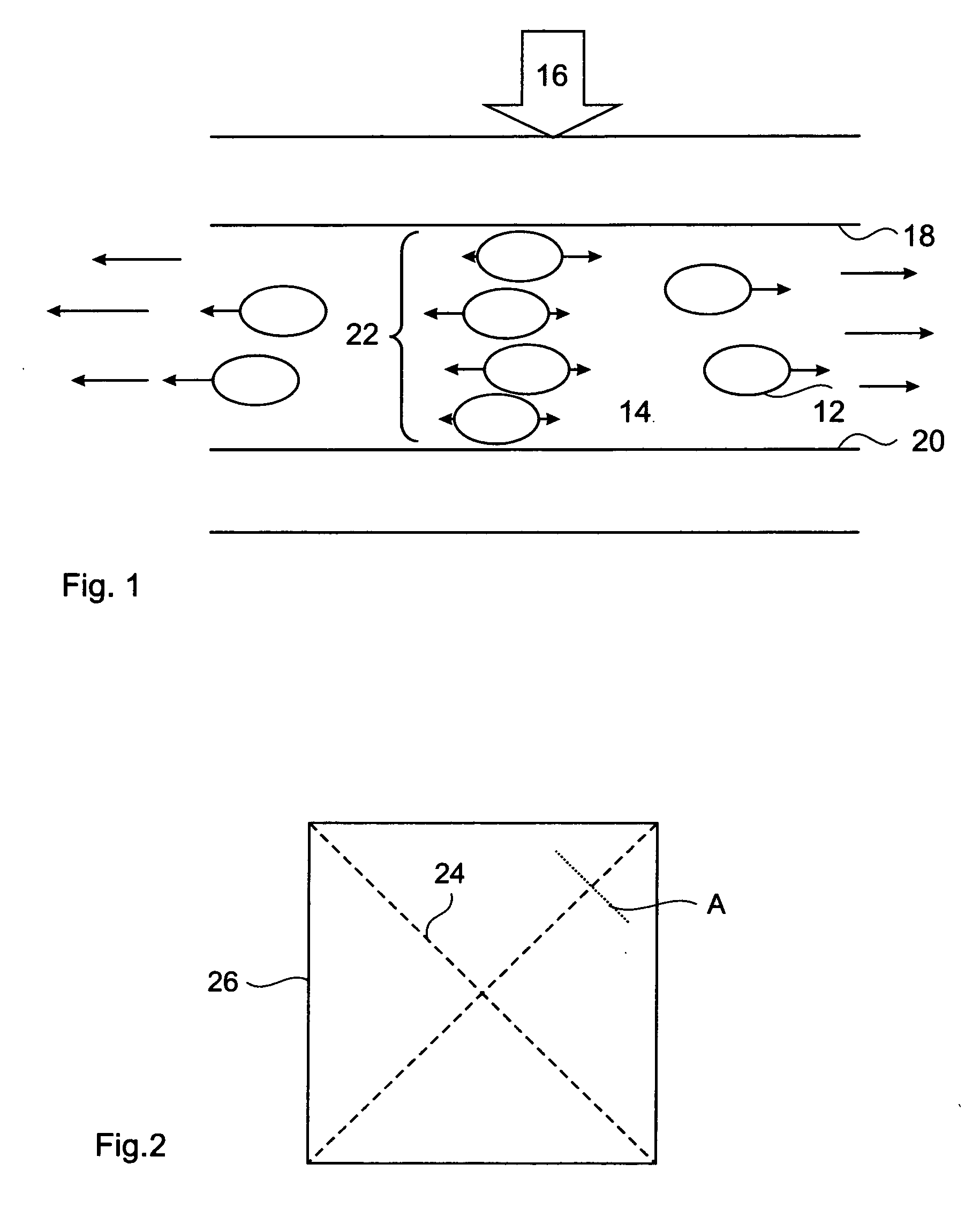

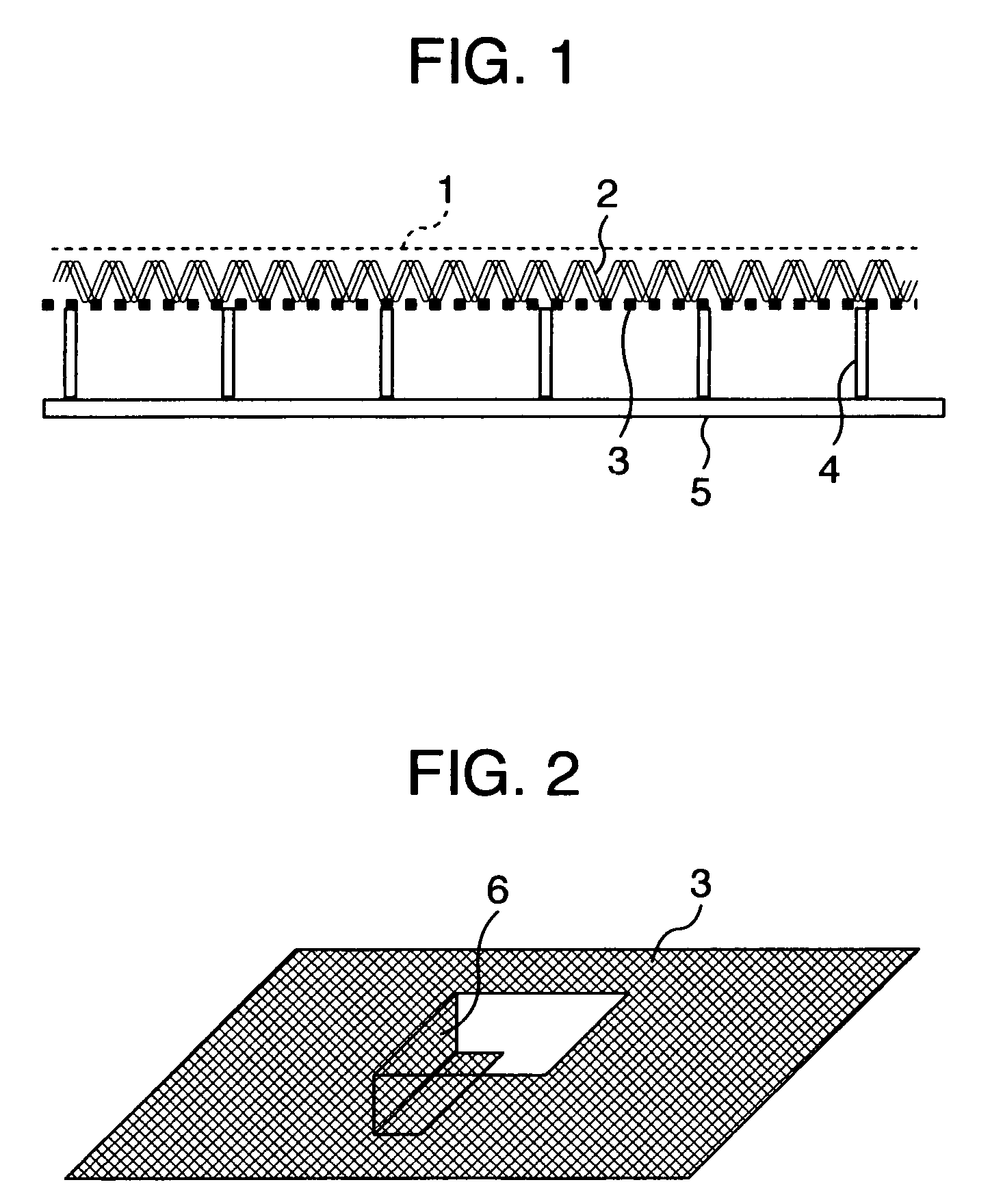

Thermal interface with a patterned structure

InactiveUS20060286712A1Uniform and improved thermalUniform and improved and mechanical propertySemiconductor/solid-state device detailsSolid-state devicesNanometreMaterials science

An interface is formed by pressing a patterned first surface and a second surface together, with a particle-loaded interface material in between. The first surface is fabricated with a pattern of channels designed to redistribute the velocity gradients that occur in the interface material during interface formation in order to control the arrangement, orientation and concentration of particles at the end of the interface formation. The concept finds application in thermal interfaces and controlled placement of nano and micro particles and biological molecules.

Owner:GLOBALFOUNDRIES INC

Liquid supply apparatus and method, and image recording apparatus

InactiveUS20110227971A1Operational defects of the valve arranged in the flow channel can be eliminatedReduce pressure changesInking apparatusOperating means/releasing devices for valvesImage recordingActuator

A liquid supply apparatus includes: a liquid supply flow channel which is connected to a liquid ejection head; a valve which is arranged in the liquid supply flow channel and opens and closes in accordance with voltage applied to an actuator of the valve; and a voltage control device which controls the voltage applied to the actuator of the valve, and gradually changes the voltage applied to the actuator of the valve from an initial voltage that is lower than a threshold voltage required for the valve to operate to a final voltage that is higher than the threshold voltage.

Owner:FUJIFILM CORP

Inkjet recording apparatus and method

ActiveUS20090244131A1Carry-out stablyStable pressure controlInking apparatusOther printing apparatusPositive pressureEngineering

The inkjet recording apparatus includes: an inkjet recording head which includes a nozzle through which liquid is ejected; a pressure regulating unit which includes a liquid chamber that communicates with the nozzle and a gas chamber that is partitioned from the liquid chamber by a flexible film; and a liquid chamber pressure controlling device which controls a pressure of the liquid chamber to a predetermined negative pressure when carrying out back pressure control in which back pressure is applied to the liquid inside the nozzle, wherein: the flexible film causes change in the pressure of the liquid chamber when the liquid is supplied for at least a predetermined supply amount to the liquid chamber in a state where the gas chamber is open to air; and the liquid chamber pressure controlling device carries out the back pressure control after controlling the pressure of the liquid chamber to a predetermined value of positive pressure by supplying the liquid of at least the predetermined supply amount to the liquid chamber.

Owner:FUJIFILM CORP

Driver device

ActiveUS20150155759A1Reduce pressure changesReduce detectionAssociation with control/drive circuitsCooling/ventillation arrangementEngineeringHeat sink

In a driver device, a controller substrate has a center part on which a rotation angle sensor is attached and an outer periphery portion which is fixed onto a heat sink. The heat sink has a cylinder part extending in an axial direction of the rotation shaft to contact the outer periphery portion of the controller substrate. The cylinder part of the heat sink is continuously formed along an entire periphery and has the same height at all portions. Such configuration provides an even deformation distribution of the cylinder part due to a temperature change, thereby reducing unevenness of heat stress distribution along a substrate plane and decreasing stress applied to the sensor, which facilitates a reduction of a detection error of the sensor.

Owner:DENSO CORP

Gaskets for substrate containers

InactiveUS6951340B2Prevent intrusionReduce pollutionEngine sealsOther chemical processesElastomerPolyester

Provided are a gasket member for a substrate-holding container which is little liable to contamination of the substrate materials contained with organic matters due to the low content of organic matters to be emitted as a gas still without decreasing the operability in opening and closing of the covering as well as a substrate-holding container by using the same. The gasket member for a substrate-holding container provided is formed from a thermoplastic polyester-based elastomer resin containing absolutely no softening agent and having a surface hardness not exceeding 80A by the hardness testing method specified in JIS K6301, of which the amount of gas emission as determined under heating conditions for 60 minutes at 80° C. does not exceed 10 ppm based on the weight of the material. Disclosure is given of a polyester-based block copolymer suitable as a molding material of the said gasket member.

Owner:SHIN-ETSU POLYMER CO LTD

Bipolar zero-gap type electrolytic cell

ActiveUS7323090B2Stable electrolysisHigh densityCellsElectrode shape/formsInternal pressureTitanium metal

A bipolar zero-gap electrolytic cell comprising an anode comprising an anode substrate constituted of a titanium expanded metal or titanium metal net of 25 to 70% opening ratio, which anode after coating the substrate with a catalyst has a surface of 5 to 50 μm unevenness difference maximum and has a thickness of 0.7 to 2.0 mm. In this electrolytic cell, the possibility of breakage of ion exchange membrane is low, and the anolyte and catholyte have a concentration distribution falling within given range. With this electrolytic cell, stable electrolysis can be performed for a prolonged period of time with less variation of cell internal pressure.

Owner:ASAHI KASEI KK

Liquid ejection apparatus

A liquid ejection apparatus includes: a head including: a nozzle configured to eject liquid; a supply port to which the liquid is continuously supplied; and a recovery port from which the liquid is continuously recovered; a supply flow channel through which the liquid is supplied to the head; and a recovery flow channel through which the liquid is recovered from the head. A flow channel resistance inside the head from the supply port to the nozzle is R_HEAD_IN. A flow channel resistance inside the head from the nozzle to the recovery port is R_HEAD_OUT. A flow channel resistance of the supply flow channel is R_CHANNEL_IN. A flow channel resistance of the recovery flow channel is R_CHANNEL_OUT. The supply and recovery flow channels are laid out so as to satisfy a condition of R_CHANNEL_IN>R_CHANNEL_OUT when R_HEAD_IN>R_HEAD_OUT, or a condition of R_CHANNEL_IN<R_CHANNEL_OUT when R_HEAD_IN<R_HEAD_OUT.

Owner:FUJIFILM CORP

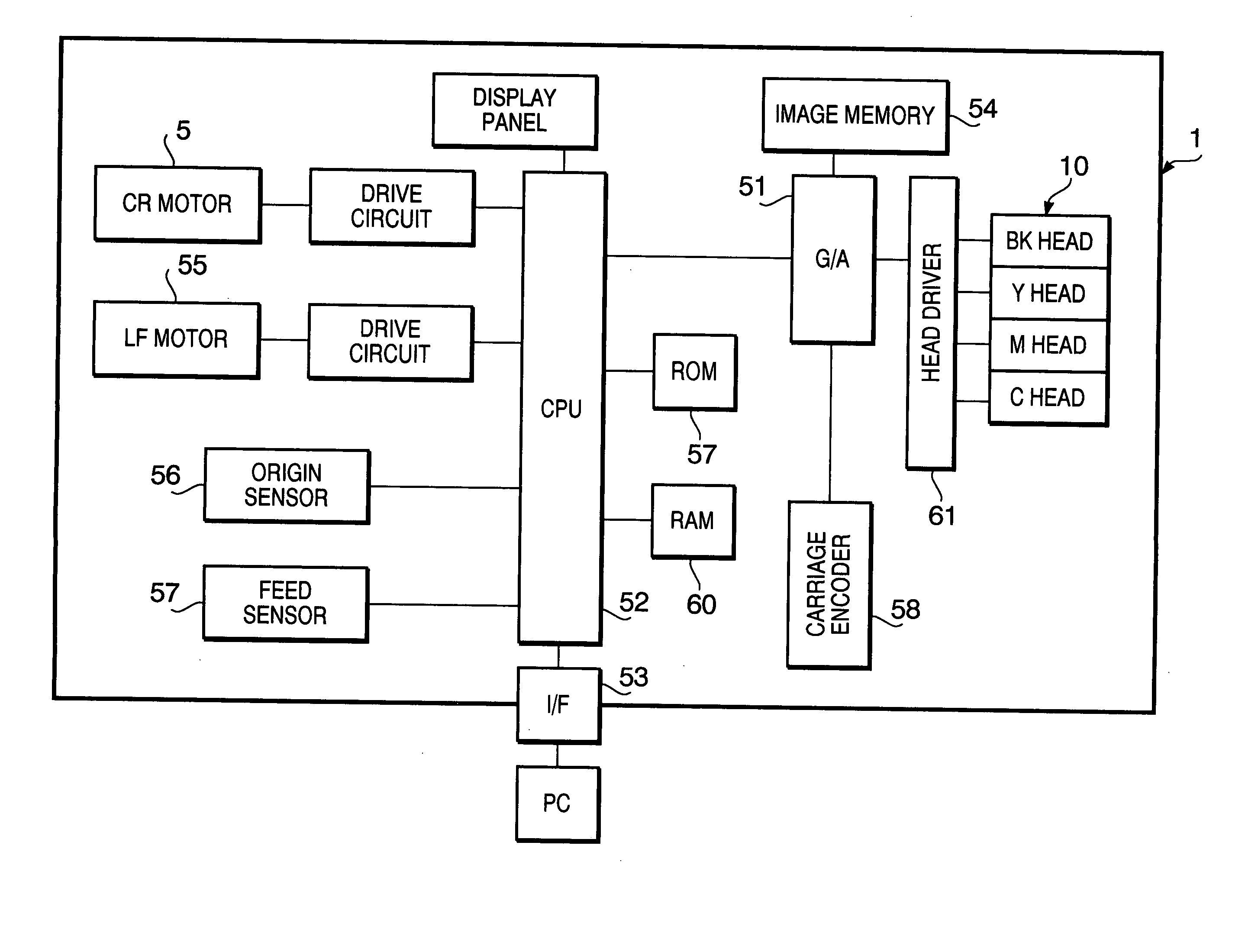

Ink ejection method and inkjet ejection device

An ink ejecting device includes a plurality of nozzles, a plurality of pressure chambers respectively corresponding to the plurality of nozzles, an actuator capable of changing capacity of each of the plurality of pressure chambers. A first drive pulse signal is selected in accordance with dot information indicating dots to be formed on a recording medium successively. When the dot information for the current ejection cycle and the dot information for the succeeding ejection cycle indicate a first condition where ejection of a large amount of ink drop and no ejection of an ink drop, respectively, driving pulse signals for the current ejection cycle and the succeeding ejection cycle are selected, respectively. The driving pulse signals for the current ejection cycle and the succeeding ejection cycle are then output in the current ejection cycle and within the succeeding ejection cycle, respectively.

Owner:BROTHER KOGYO KK

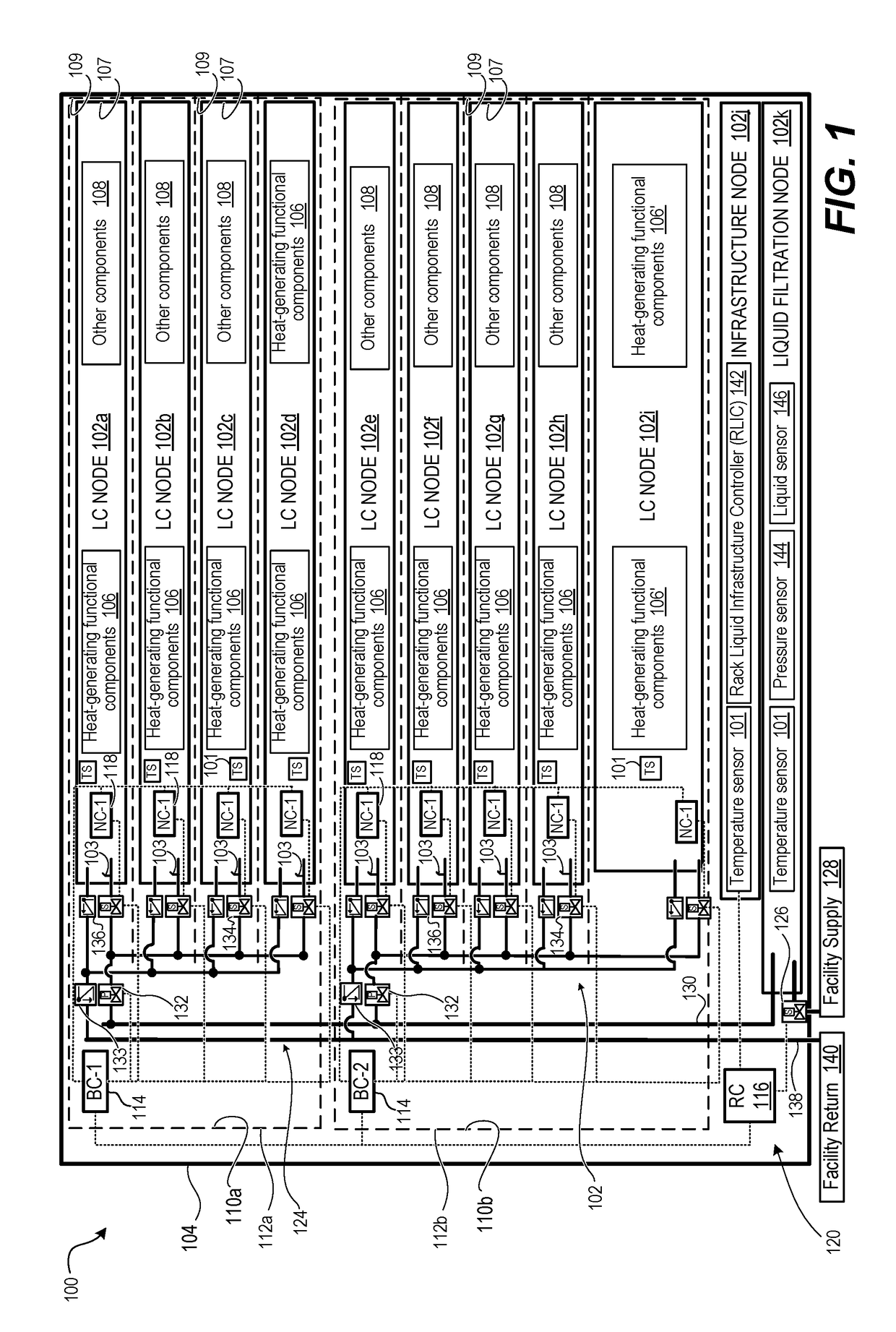

Integrated air-spring for hydraulic force damping of a rigid liquid cooling subsystem

ActiveUS20170181324A1Lower insertion forceMitigate abrupt pressure changeCooling/ventilation/heating modificationsAir springCompressible fluid flow

A direct-interface liquid-cooled (DL) Rack Information Handling System (RIHS) includes liquid cooled (LC) nodes that include a system of conduits supplying cooling liquid through the node enclosure and including a supply conduit extending from a node inlet coupling and a return conduit terminating in a node outlet coupling. The node inlet port and the node outlet port are positioned in an outward facing direction at a rear of the node enclosure and aligned to releasably seal to the respective inlet liquid port and outlet liquid port in the node-receiving slot for fluid transfer through the system of conduits. An air-spring reducer conduit is in fluid communication with the system of conduits and shaped to trap an amount of compressible fluid that compresses during sealing engagement between the node inlet coupling and node outlet coupling and the inlet liquid port and outlet liquid port, respectively.

Owner:DELL PROD LP

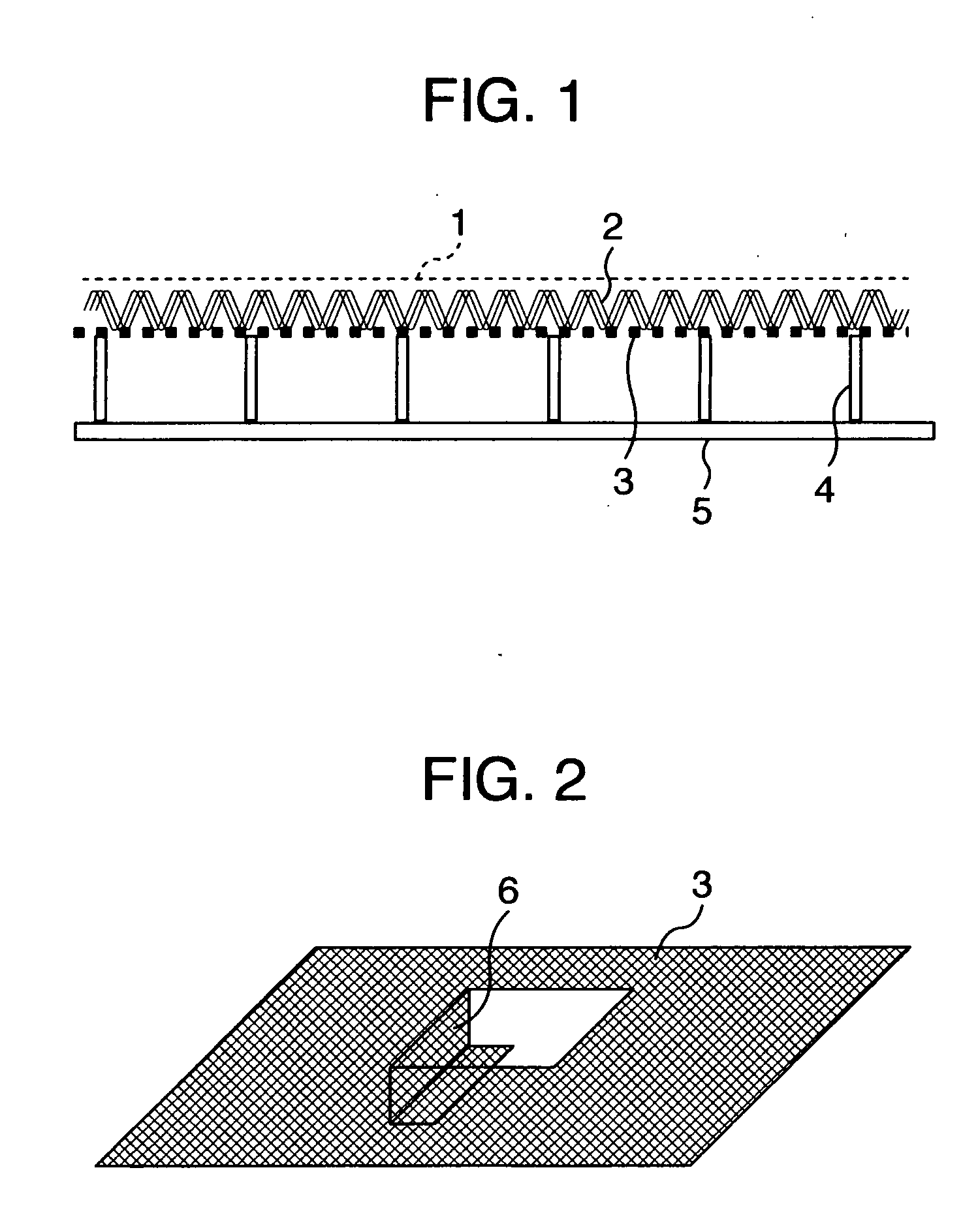

Liquid discharge head and image forming apparatus

ActiveUS20130147887A1Reduce pressure changesStable liquid discharge performancePrintingEngineeringShock absorber

A liquid discharge head includes a nozzle that discharges liquid droplets, a common liquid chamber that supplies liquid to an individual liquid chamber that is in communication with the nozzle, and a filter plate that is arranged in a liquid flow path of the common liquid chamber. The filter plate includes a filter part that filters the liquid and a damper part that reduces a pressure variation in the common liquid chamber, and the filter part is arranged to be thicker than the damper part.

Owner:RICOH KK

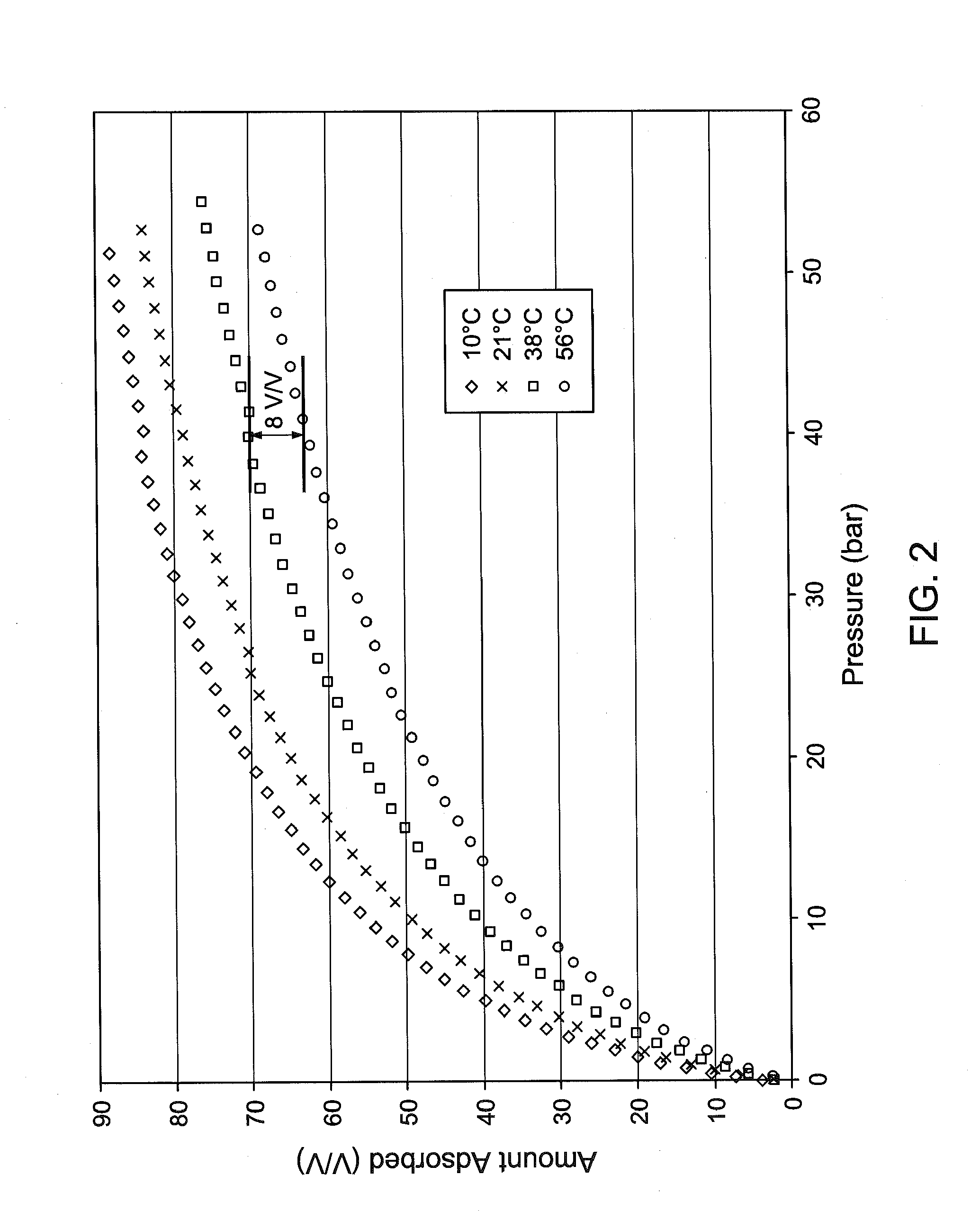

Adsorbed Natural Gas Storage Facility

ActiveUS20130283854A1Reduce pressureReduce decreaseSolidificationLiquefactionNatural gas storageAdsorbed natural gas

A method of using the natural gas storage facility to reduce the effect of diurnal demand on a natural gas source includes introducing natural gas into the natural gas storage facility, separating the natural gas into a heavy natural gas component and a light natural gas component, and retaining the components during a non-peak period of demand. The natural gas storage facility includes a guard bed system and an adsorption bed system. The method also includes releasing the heavy and light natural gas components, mixing them into a released natural gas component product and introducing it to the natural gas source during a peak period of demand.

Owner:SAUDI ARABIAN OIL CO

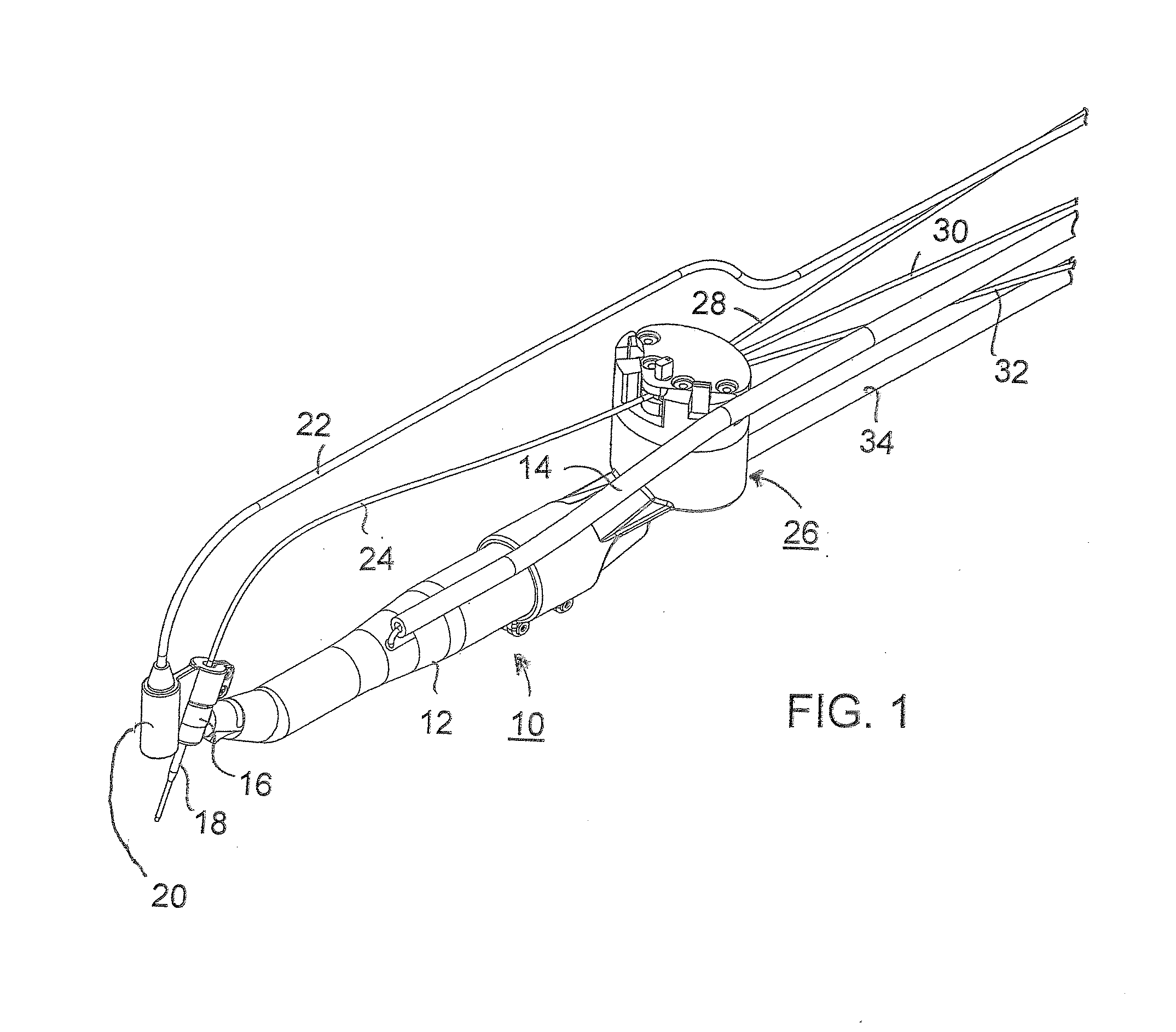

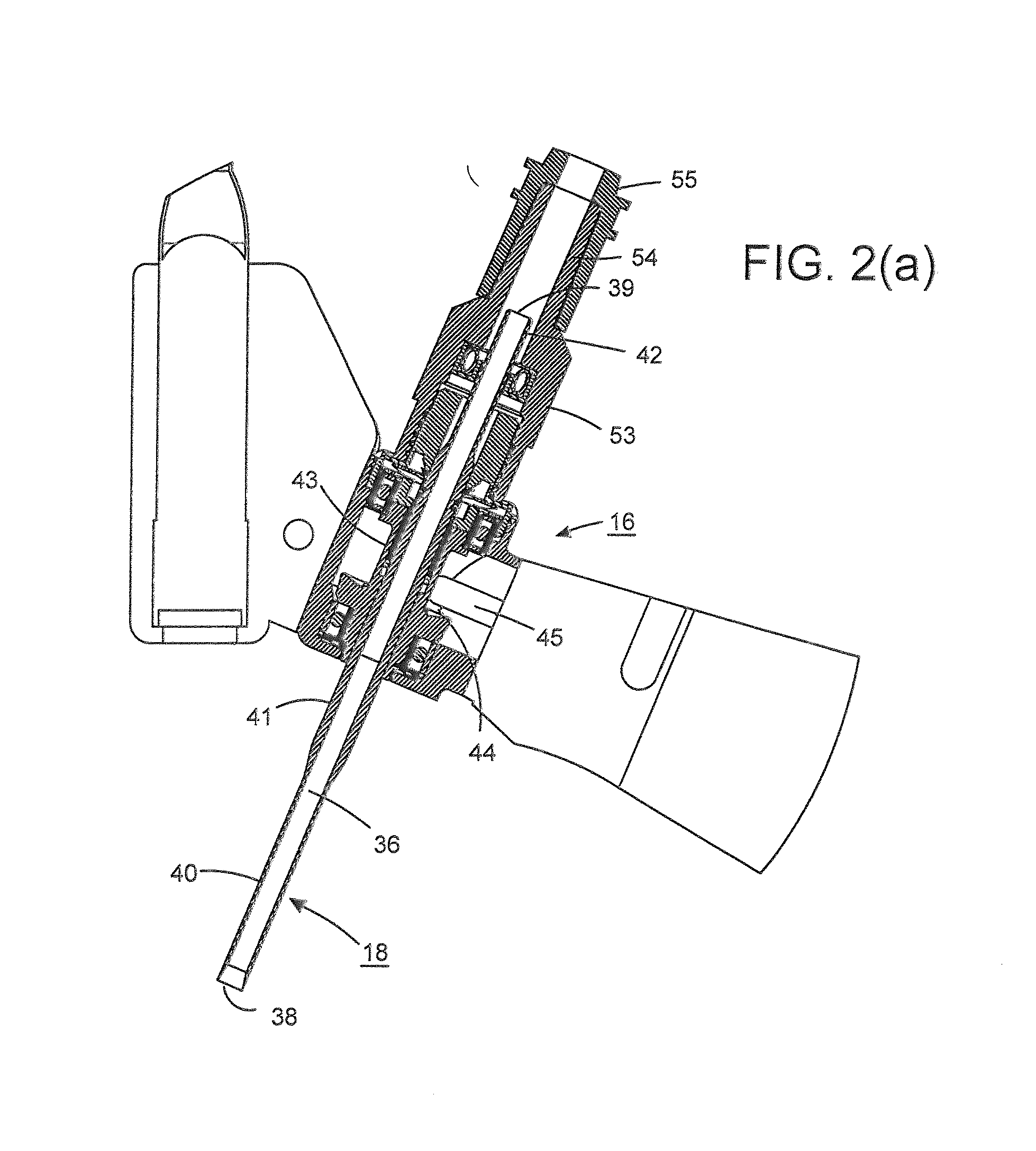

Apparatus for extracting hair follicles for use in transplantation

InactiveUS20160235441A1Avoid flowReduce accumulationSurgical needlesExcision instrumentsHair follicleScalp

An apparatus for surgical extraction of hair follicles for transplantation uses a rotating needle for cutting follicular units from a patient's scalp. Each follicular unit is drawn through the needle and transported through a diverter unit to a selected one of plural collectors, in which the follicular units are accumulated for transplantation. The rotating needle is extends through a seal compartment in which a seal, composed of a spring inside a spring carrier, engages both the needle and a cylindrical inner wall of the seal compartment.

Owner:PARKIN ROGER

Thermal interface with a patterned structure

InactiveUS7282799B2Reduce pressure changesUniform and improved thermal and mechanical propertySemiconductor/solid-state device detailsSolid-state devicesNanometreMaterials science

An interface is formed by pressing a patterned first surface and a second surface together, with a particle-loaded interface material in between. The first surface is fabricated with a pattern of channels designed to redistribute the velocity gradients that occur in the interface material during interface formation in order to control the arrangement, orientation and concentration of particles at the end of the interface formation. The concept finds application in thermal interfaces and controlled placement of nano and micro particles and biological molecules.

Owner:GLOBALFOUNDRIES INC

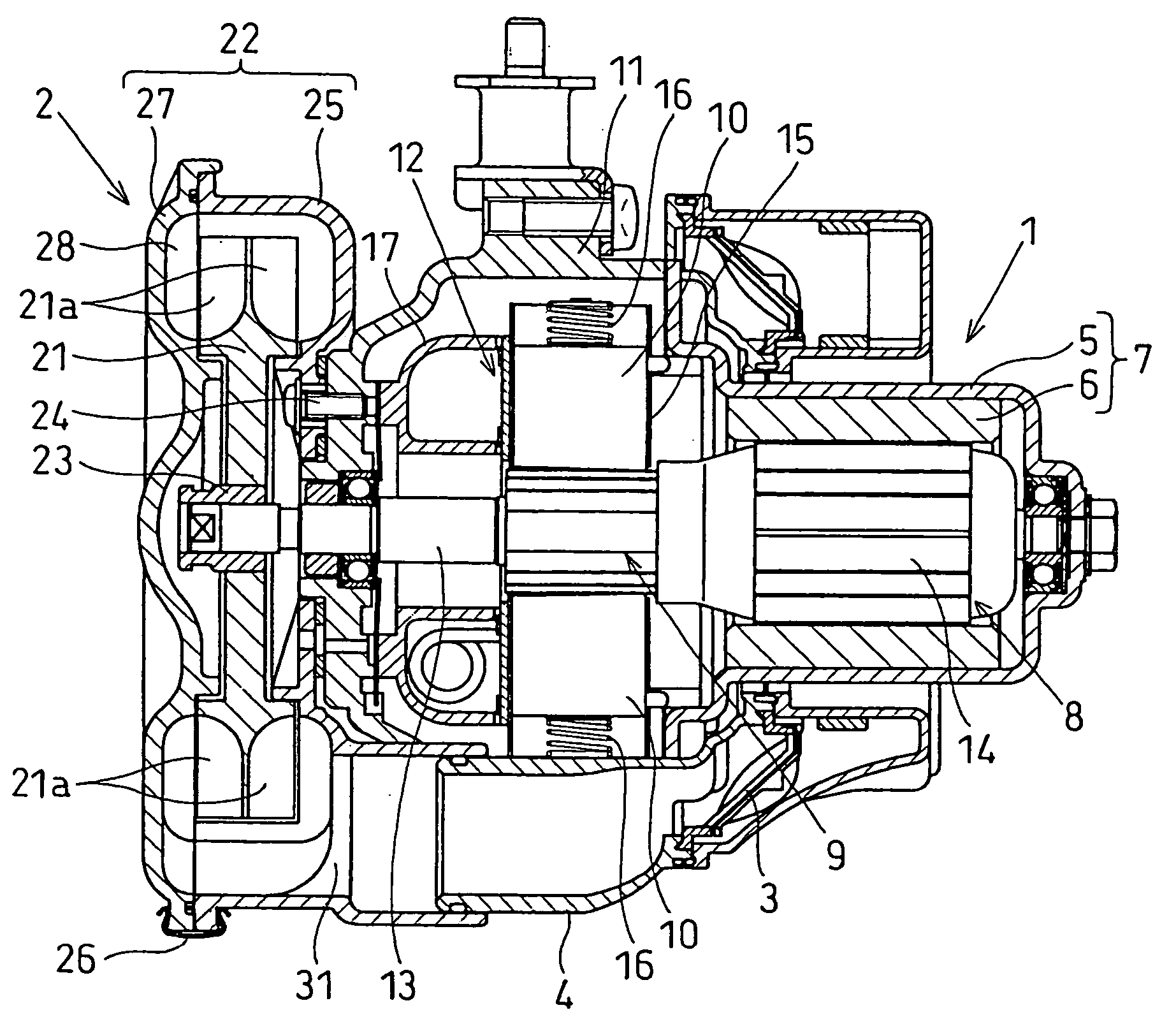

Fluid pump apparatus

In an air supply pump, having an electric motor and a blower driven by the electric motor, the blower has an impeller having multiple blades for compressing and pumping out the air. A value (F) obtained by a formula (F=N×S) is made to be higher than the audible frequency band to the human beings, wherein “N” means number of blades of the impeller, and “S” means a number of rotation of the impeller for each second at a normal rotational speed. (“×” is a symbol for a mathematical multiplication.) The frequency (F=N×S) of fan noises at a primary peak appears at higher frequencies out of the audible frequency band, so that the noises audible to the human beings can be reduced.

Owner:DENSO CORP

Infrared-type gas detector

ActiveUS7514685B2Unevenness of gapReduce unevennessInterferometric spectrometryAbsorption/flicker/reflection spectroscopyInterior spaceInfrared

An infrared-type gas detector is provided with a Fabry-Perot filter through which infrared having a predetermined wavelength is selected to pass, a first detection unit for receiving the infrared having passed through the Fabry-Perot filter and outputting a detection signal corresponding to an absorption amount of the infrared, and a case member having a window portion through which the infrared passes and housing therein the first detection unit and the Fabry-Perot filter in an inner space of the case member. The case member has at least one ventilation portion through which the inner space of the case member is communicated with the exterior of the case member.

Owner:DENSO CORP

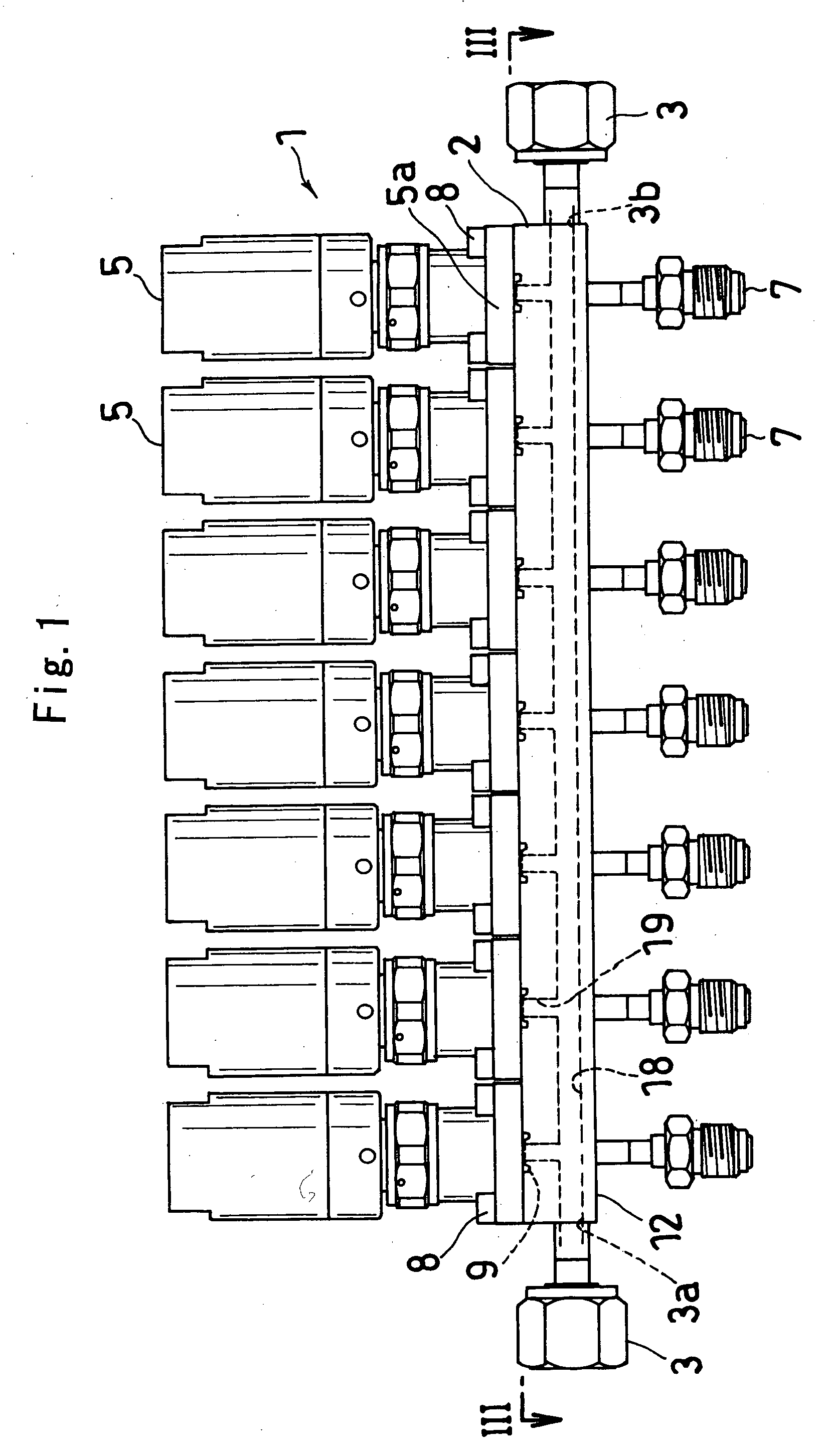

Fluid control device

InactiveUS20060096533A1Suppress pressure differenceEasy and less-costly to fabricateSemiconductor/solid-state device manufacturingMultiple way valvesFluid controlMain channel

A body 2 comprises a center channel block 11 and side channel blocks 12, 13. Each of shut-off valves 5, 6 is removably mounted on both the center channel block and one of the side channel blocks. The center channel block has Y-shaped channels 22 identical in number with the number of the subgas inlets 23 and each comprising one common channel 22a and two branched channels 22b, 22c. The common channel 22a of the Y-shaped channel 22 has an opening serving as the subgas inlet 23 and the branched channels 22b, 22c of the Y-shaped channel 22 communicate with the inlet ports of the corresponding pair of shut-off valves 5, 6 to thereby provide the subgas inflow channels. The main gas channel 18 and the main channel communication passageways 19 are formed in one of the side channel blocks 12, and the vent gas channel 20 and the vent channel communication passageways 21 are formed on the other side channel block 13.

Owner:FUJIKIN INC

System and method for valve sequencing in a pump

ActiveUS20100262304A1Minimizes pressure fluctuationReduce pressure changesServomotor componentsLarge containersEngineeringMechanical engineering

Systems and methods for minimizing pressure fluctuations within a pumping apparatus are disclosed. Embodiments of the present invention may serve to reduce pressure variations within a fluid path of a pumping apparatus by avoiding closing a valve to create a closed or entrapped space in the fluid path and similarly, avoiding opening a valve between two entrapped spaces. More specifically, embodiments of the present invention may serve to operate a system of valves of the pumping apparatus according to a valve sequence configured to substantially minimize the time the fluid flow path through the pumping apparatus is closed (e.g. to an area external to the pumping apparatus).

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com