Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Avoid stress changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

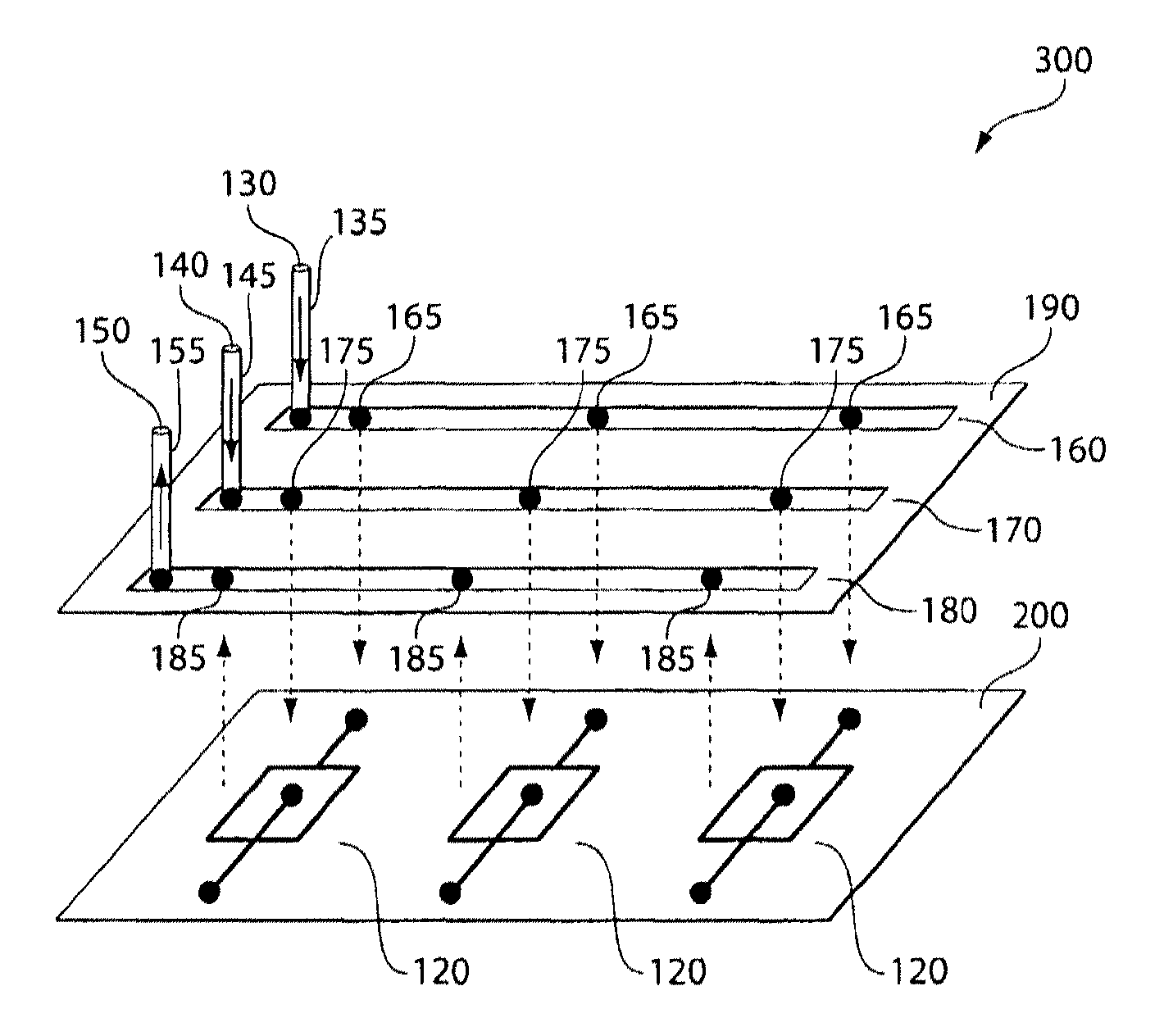

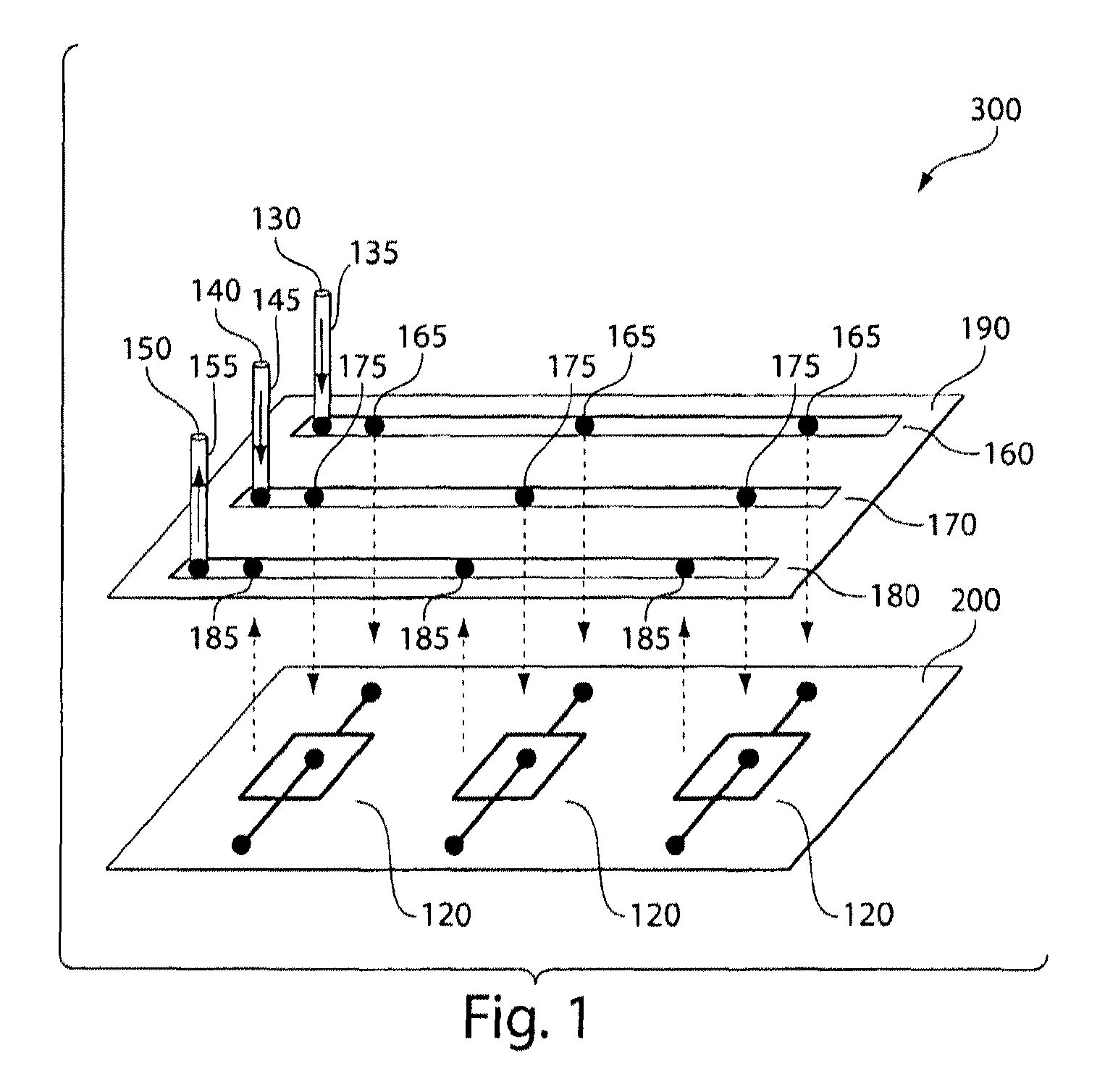

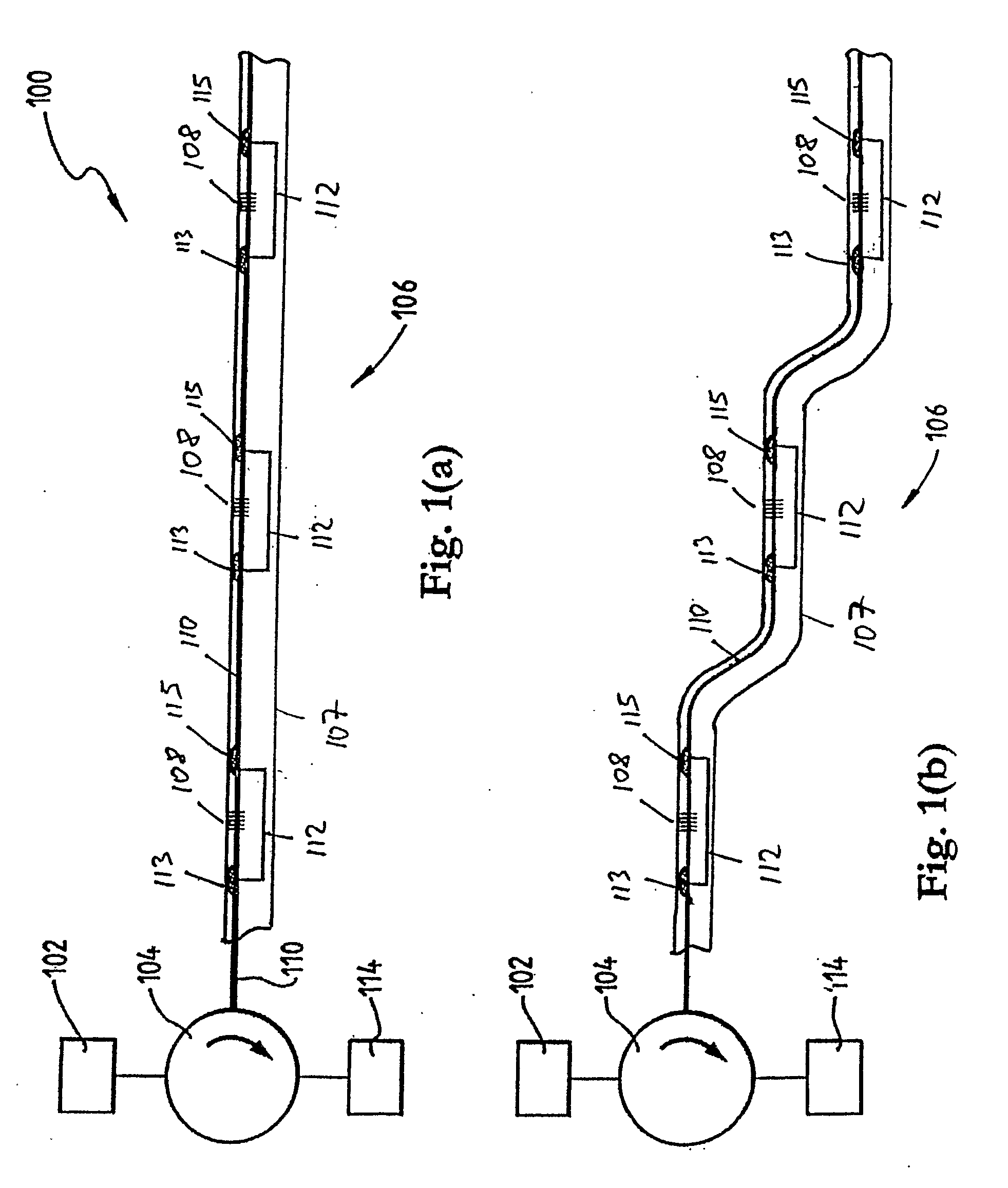

Scale-up of flow-focusing microfluidic devices

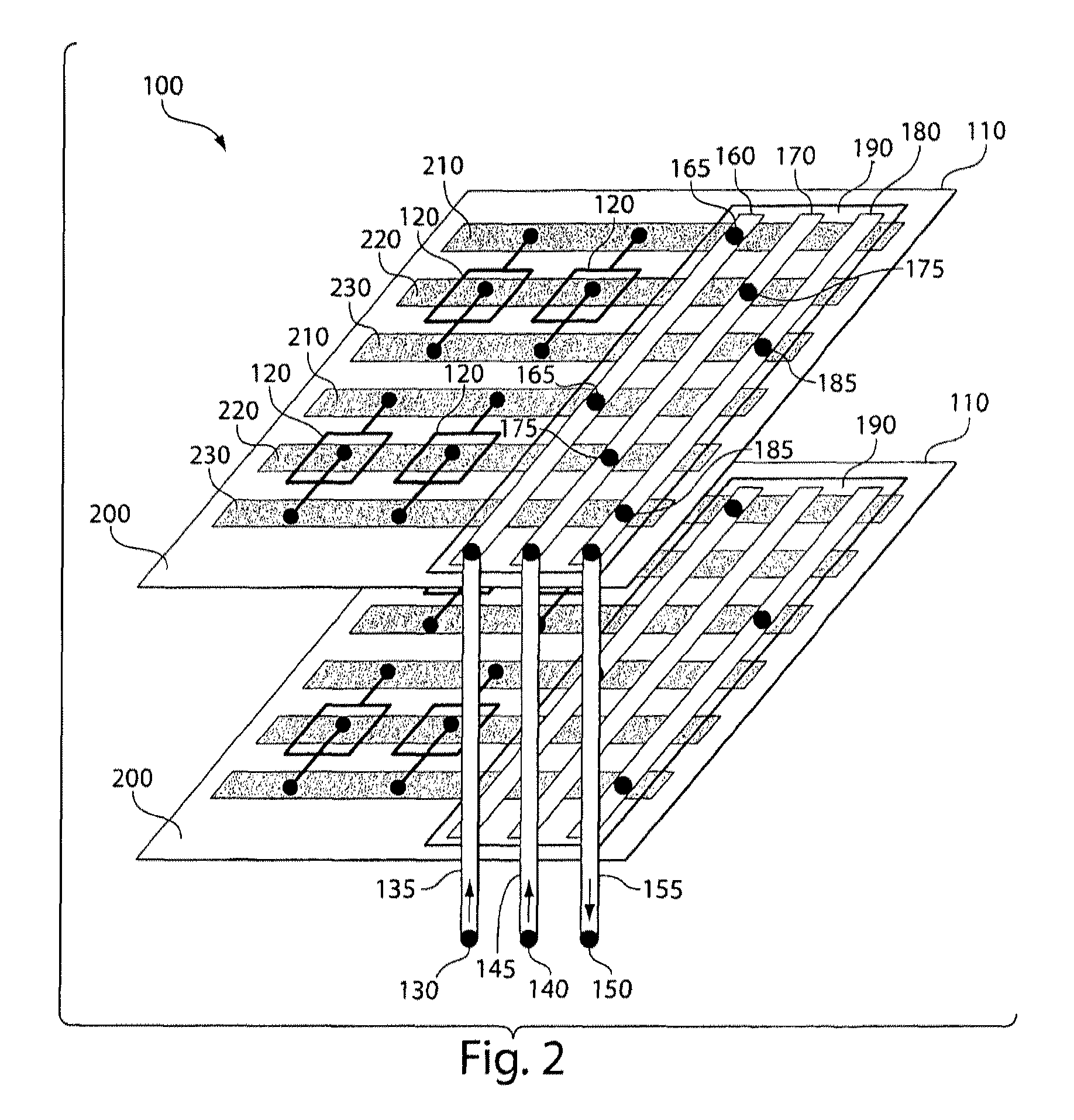

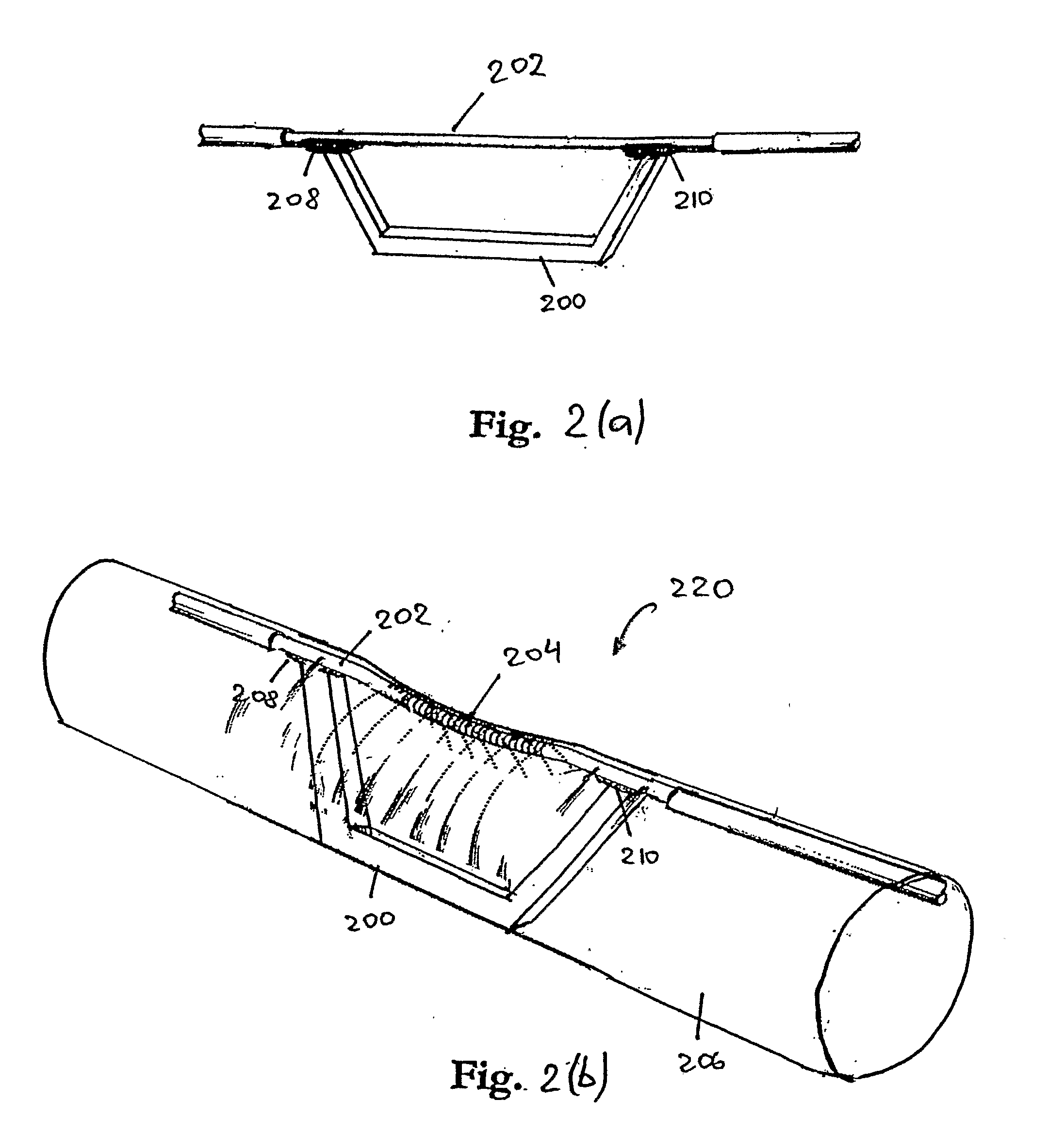

ActiveUS20120121481A1Avoid pressure fluctuationsIntroducing fluctuationPipe supportsFlow mixersMicrofluidicsMulti phase

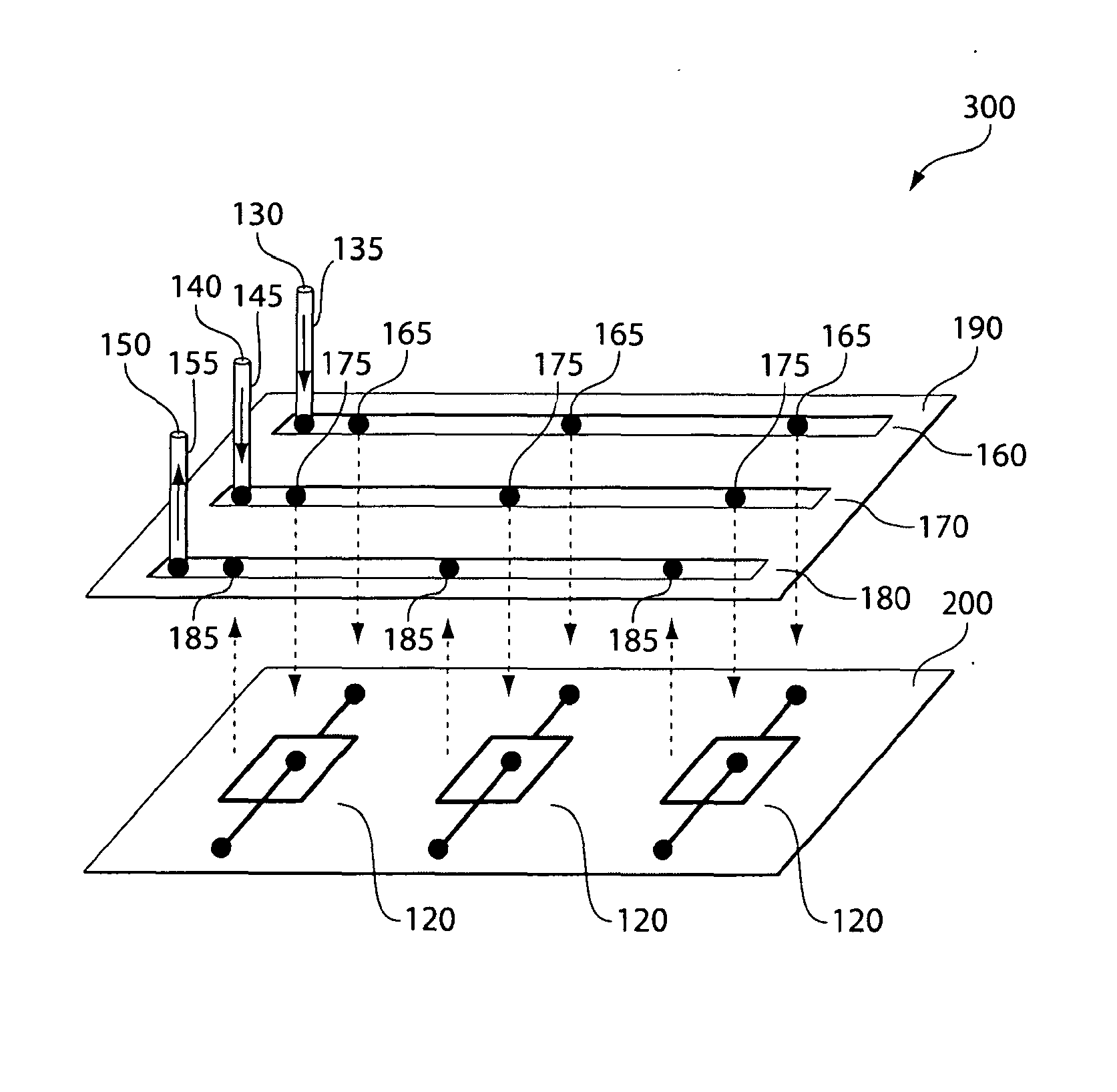

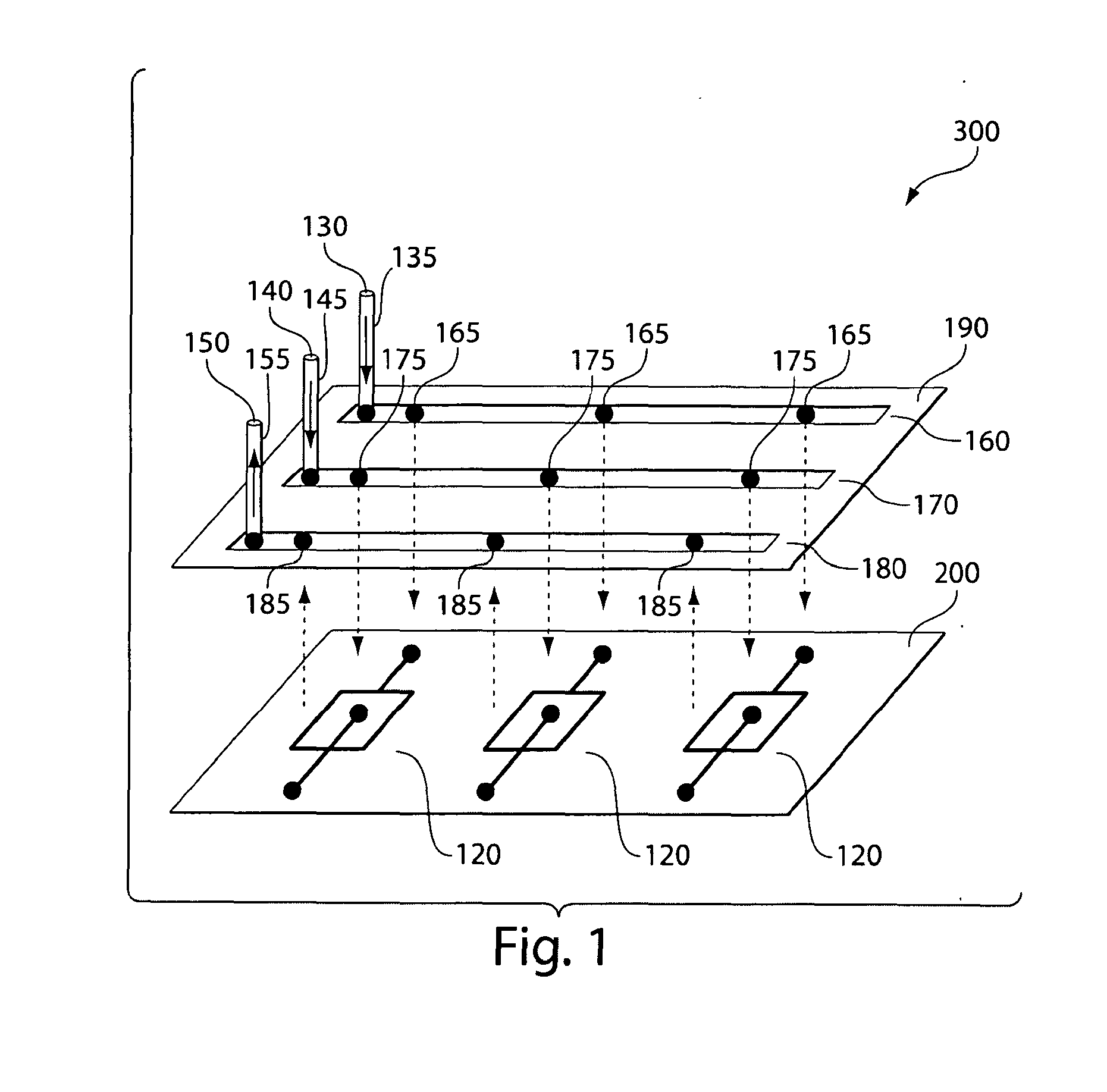

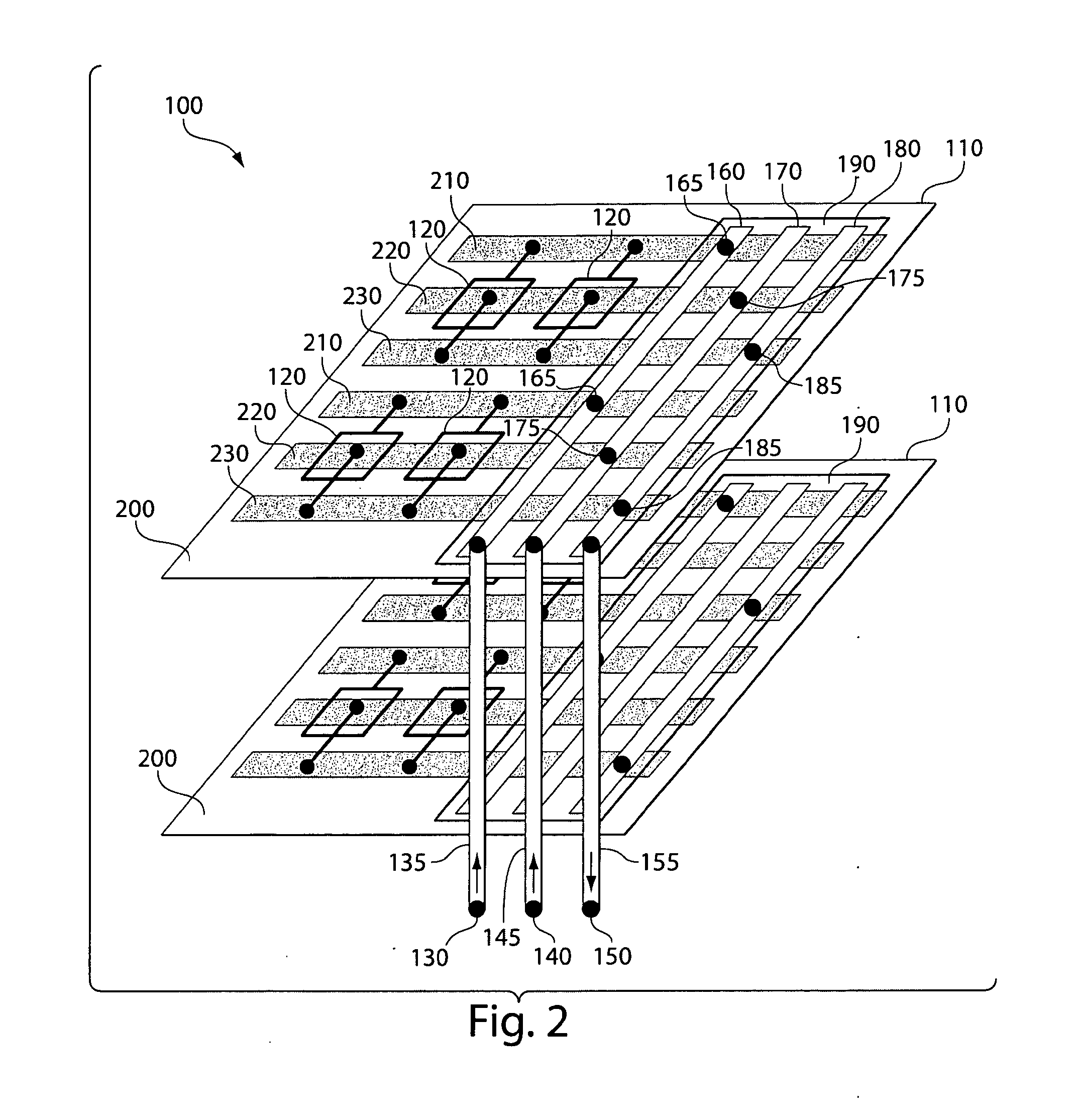

Parallel uses of microfluidic methods and devices for focusing and / or forming discontinuous sections of similar or dissimilar size in a fluid are described. In some aspects, the present invention relates generally to flow-focusing-type technology, and also to microfluidics, and more particularly parallel use of microfluidic systems arranged to control a dispersed phase within a dispersant, and the size, and size distribution, of a dispersed phase in a multi-phase fluid system, and systems for delivery of fluid components to multiple such devices.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

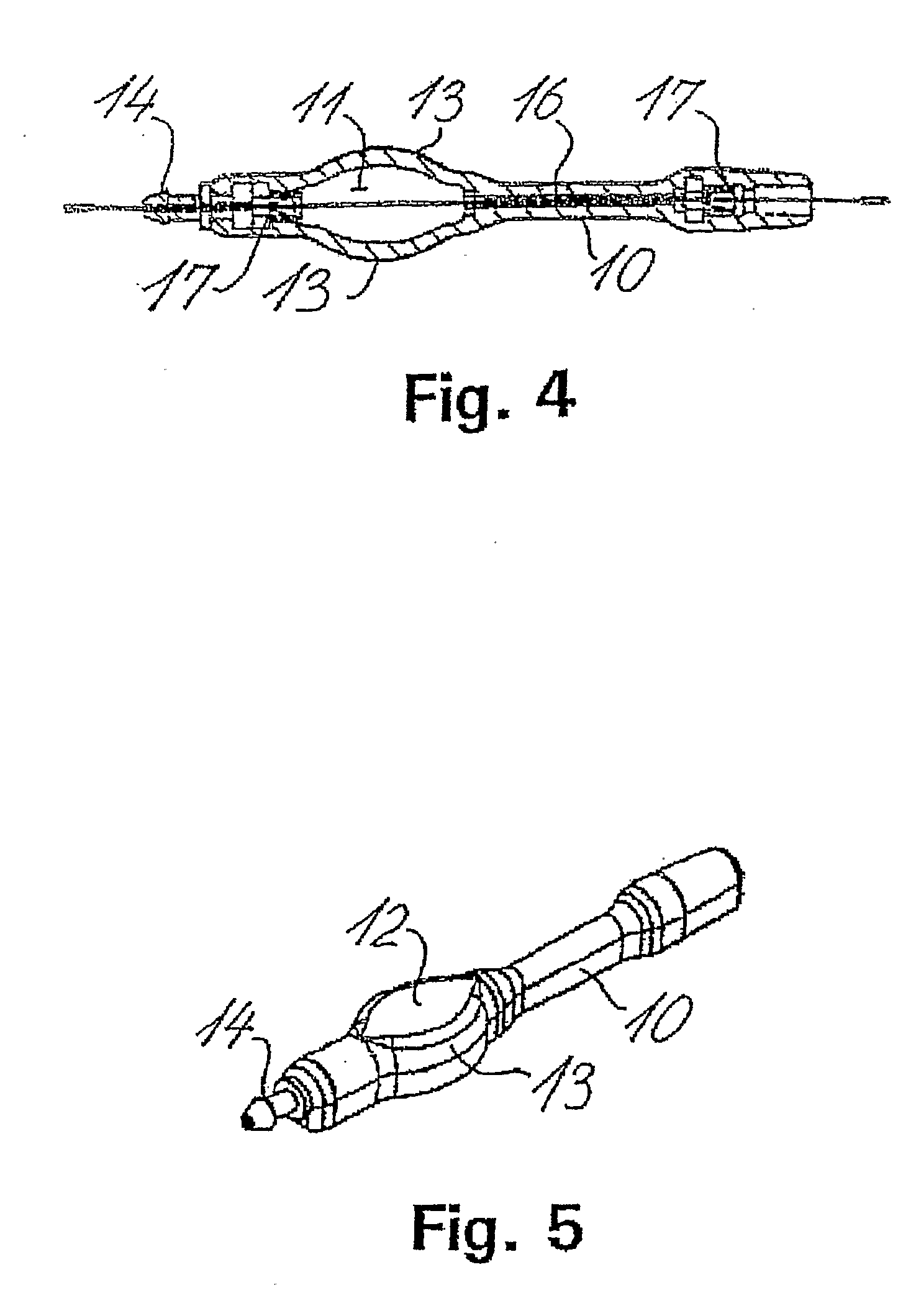

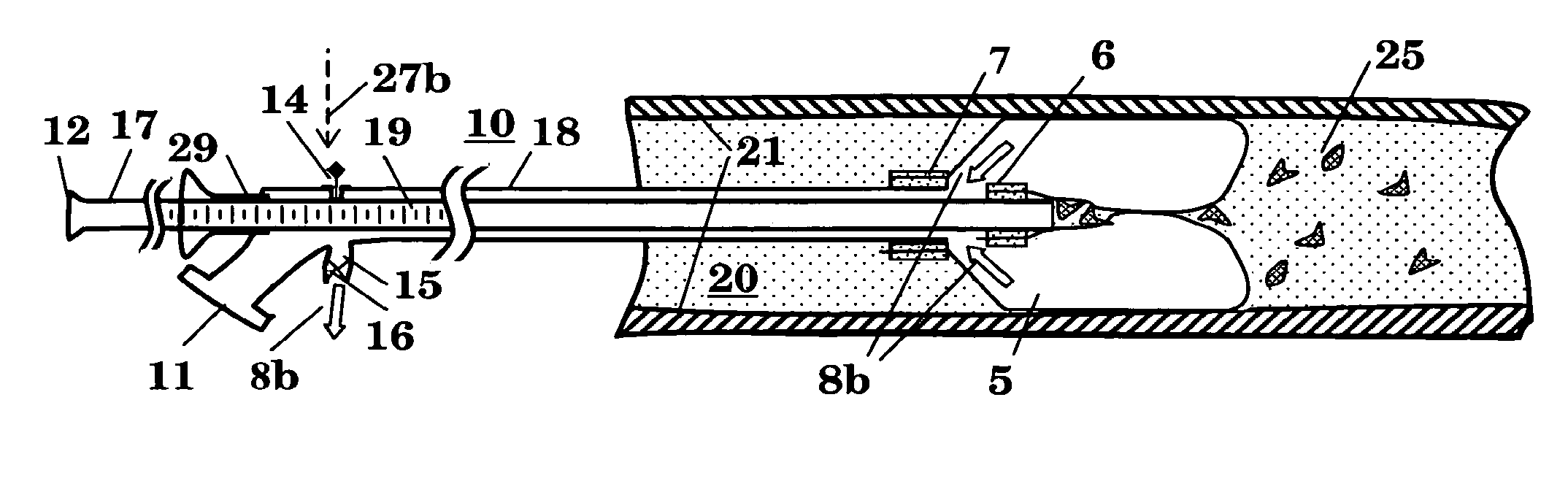

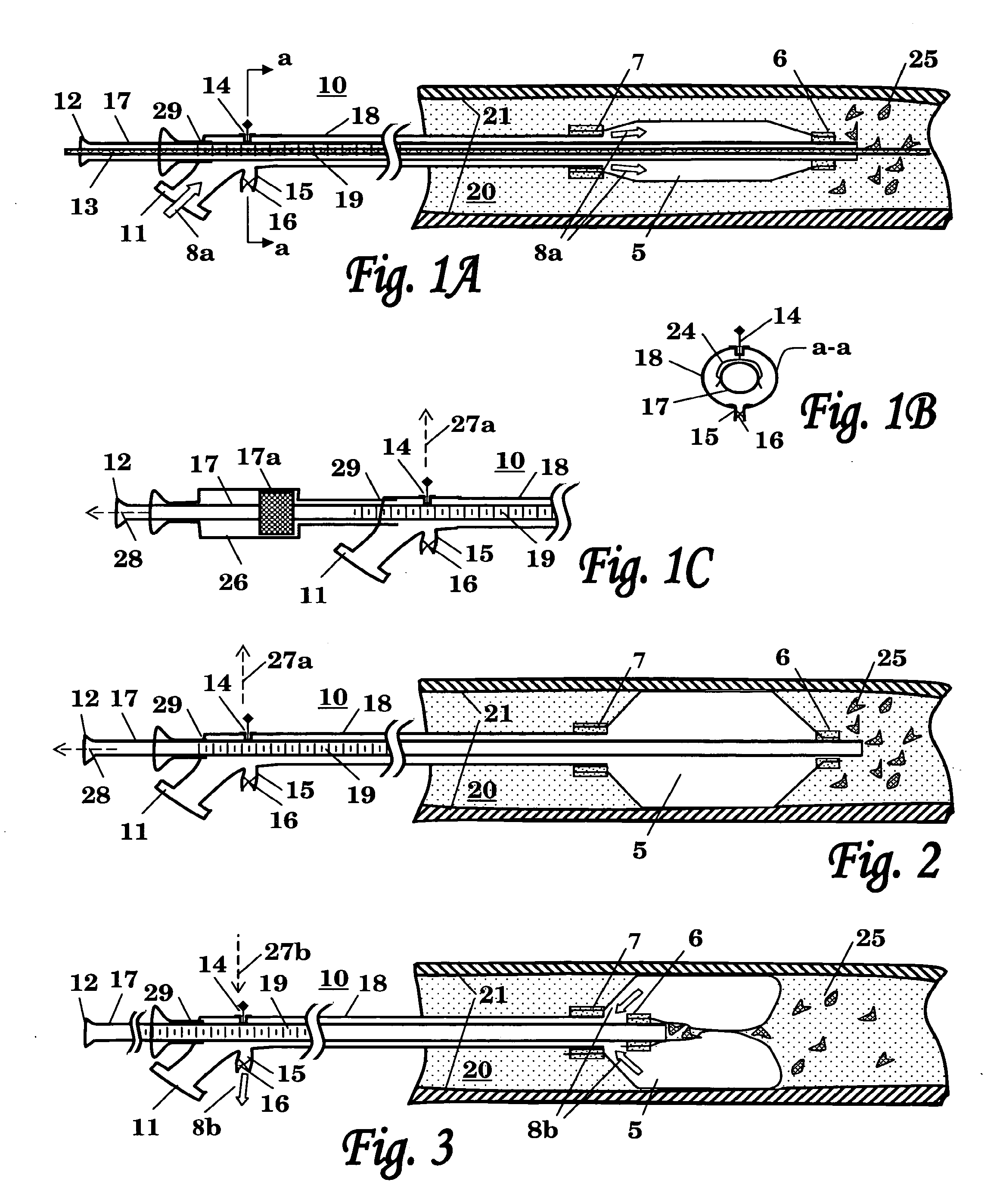

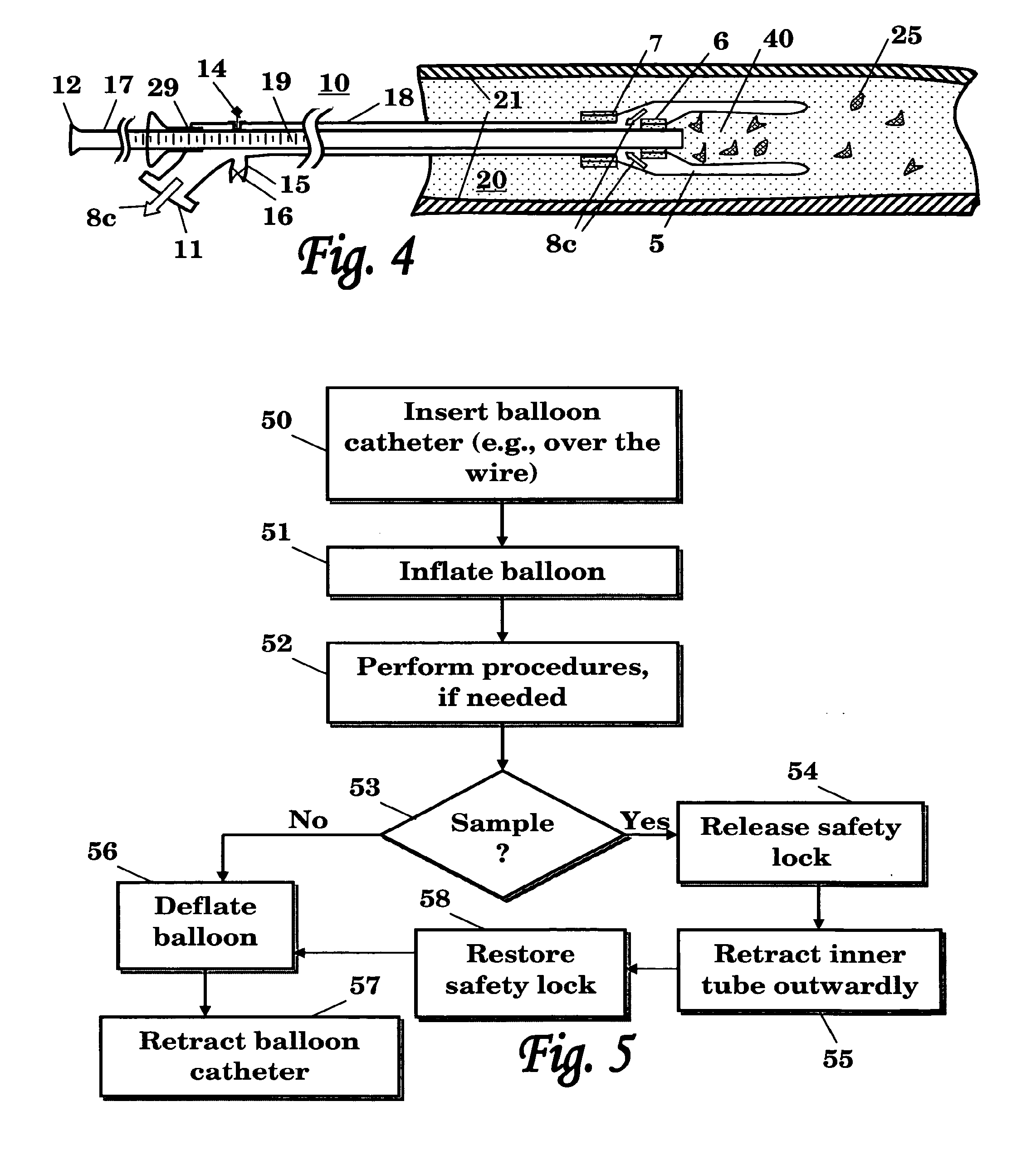

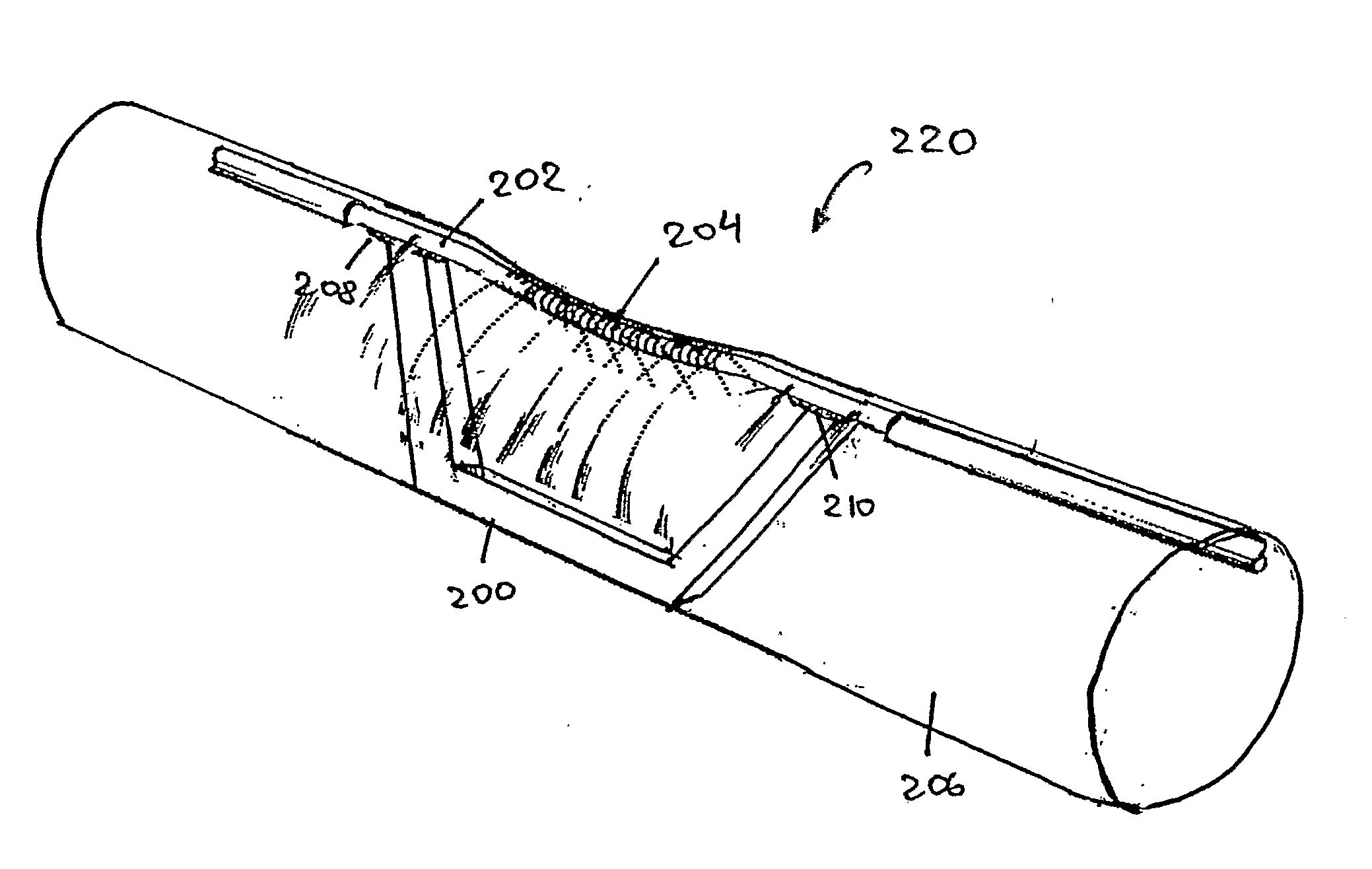

Balloon catheter

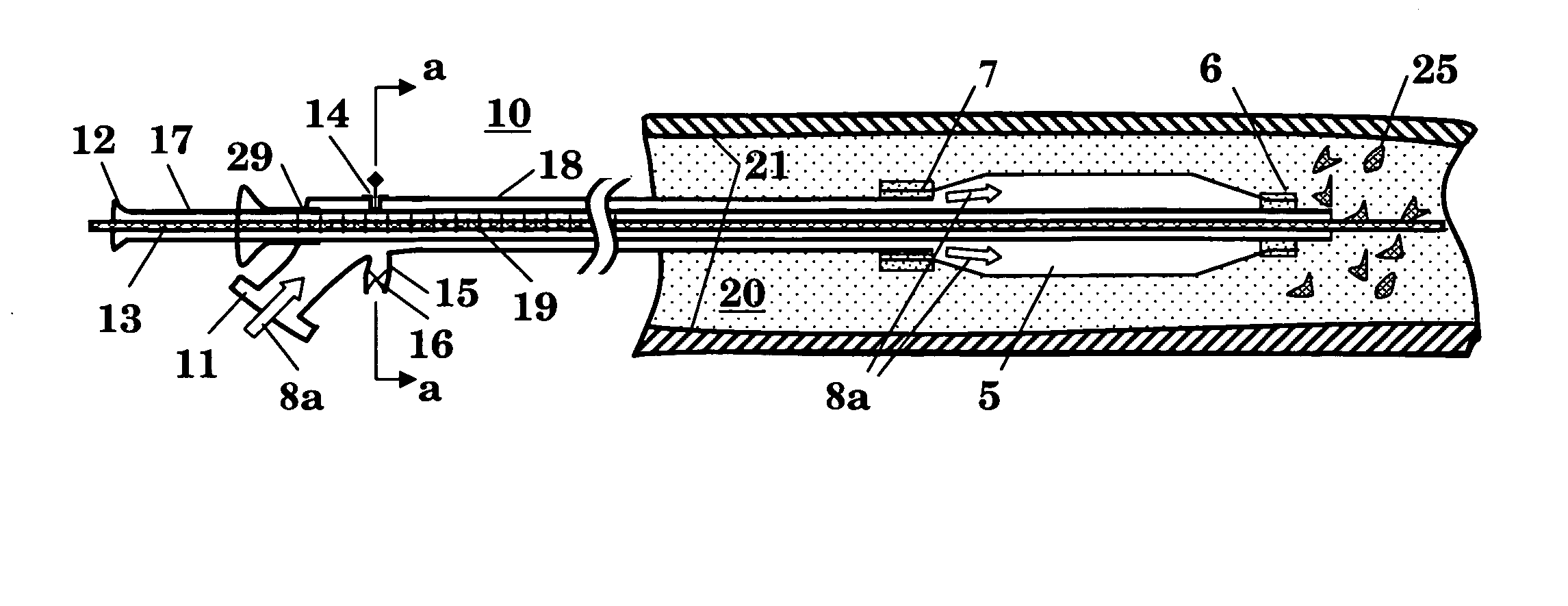

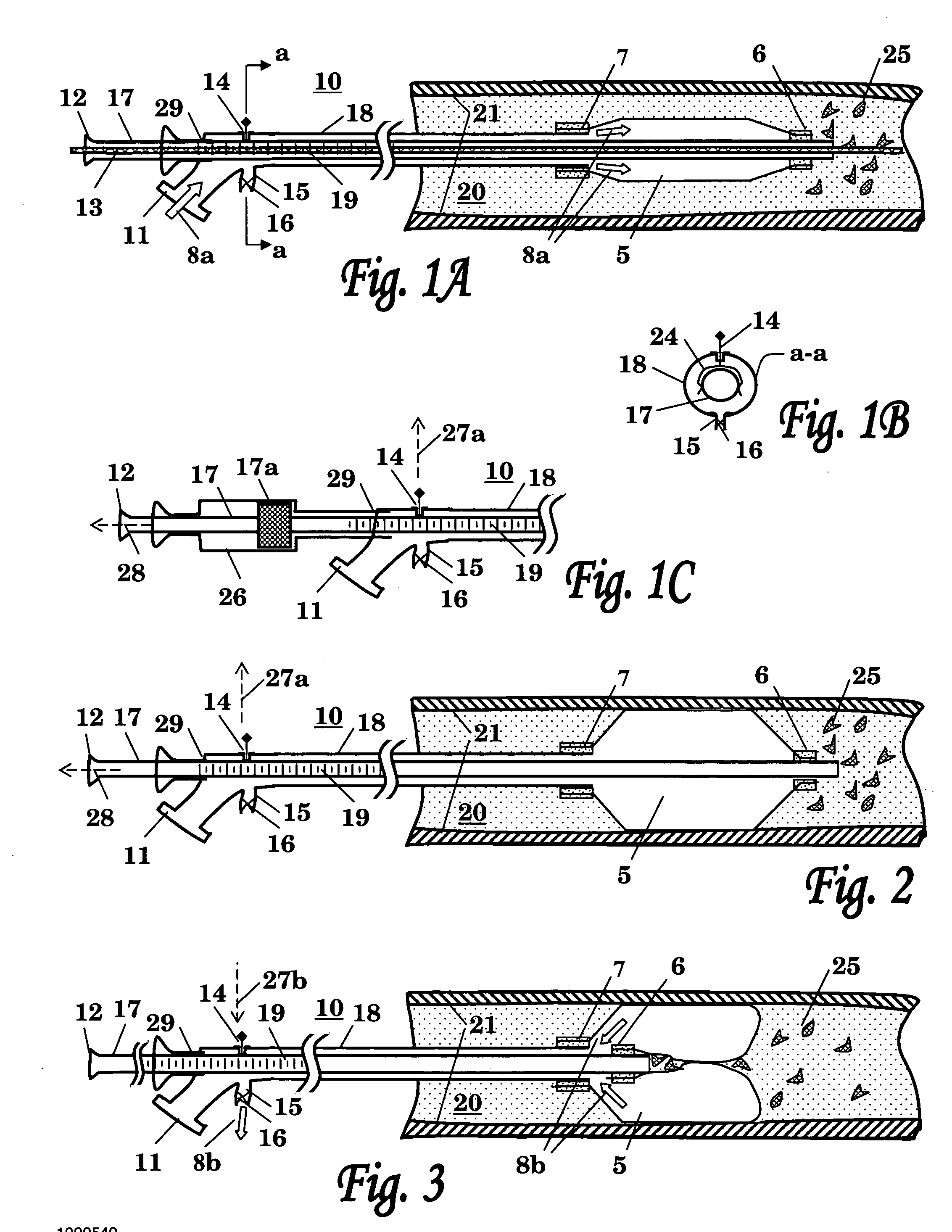

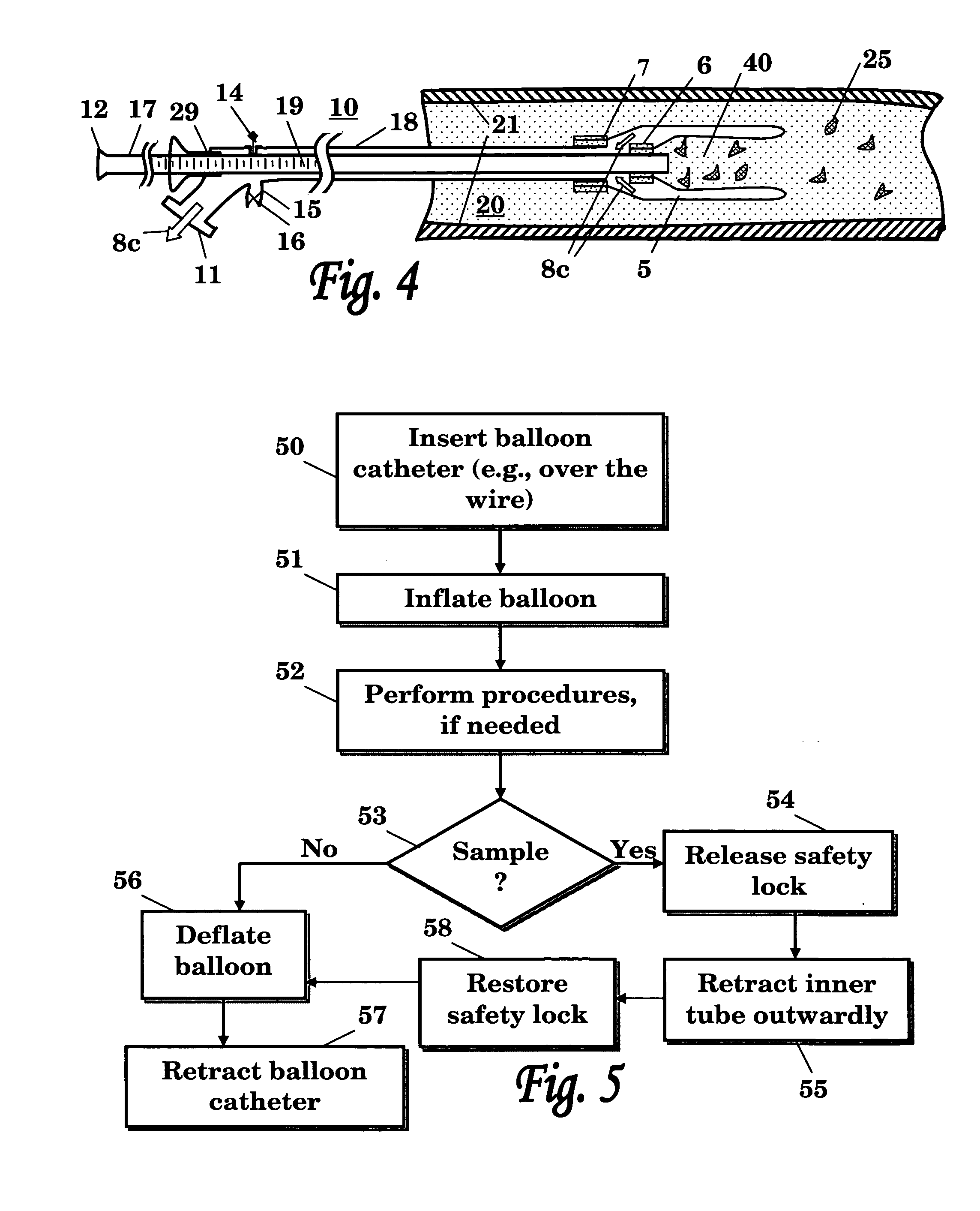

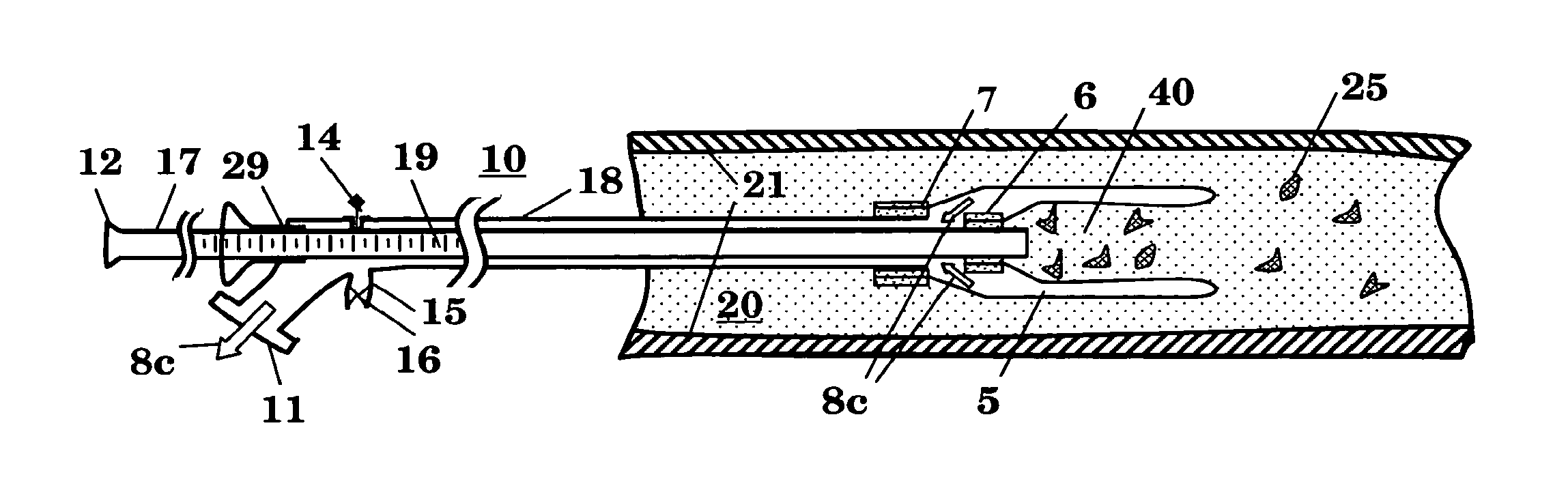

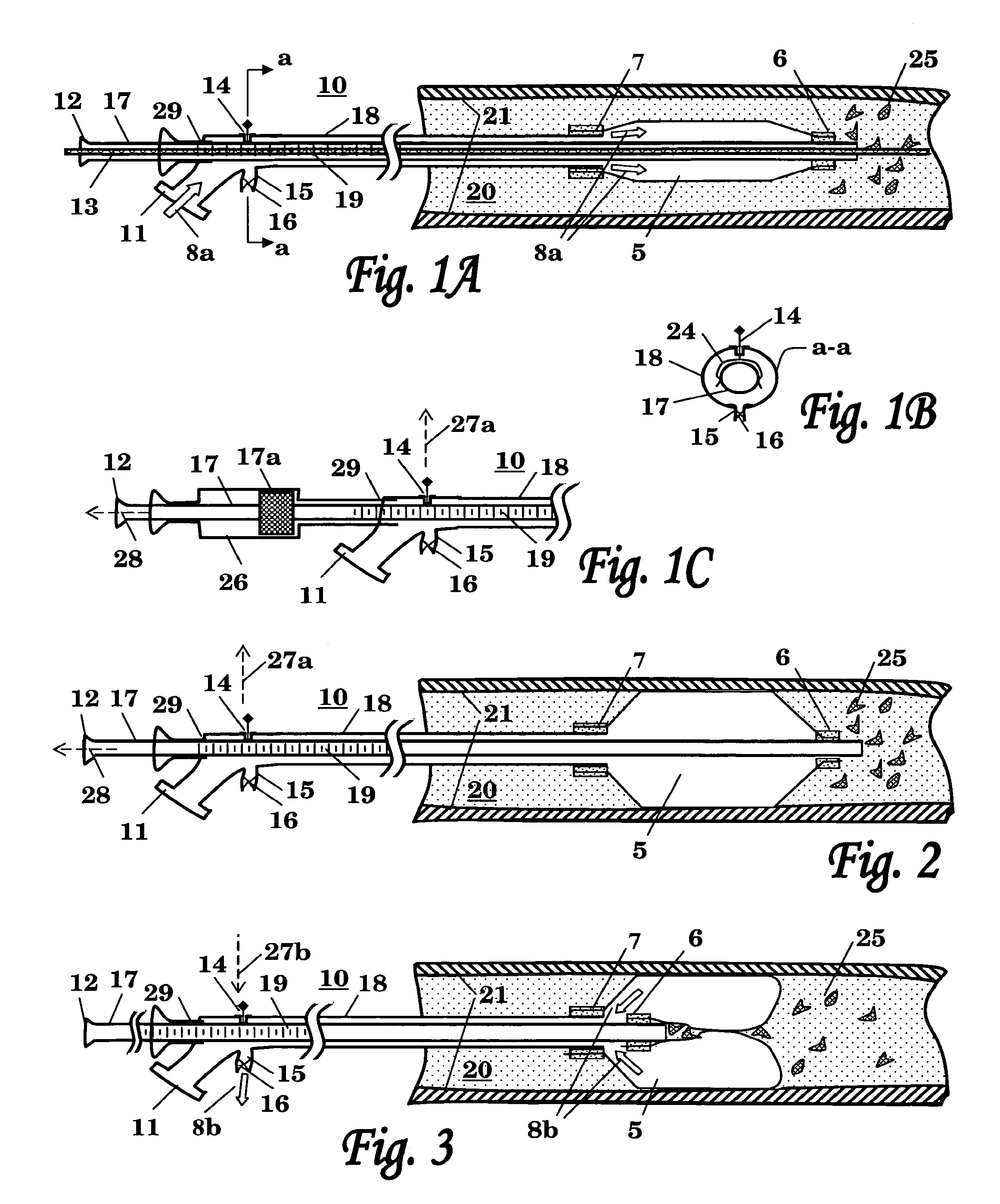

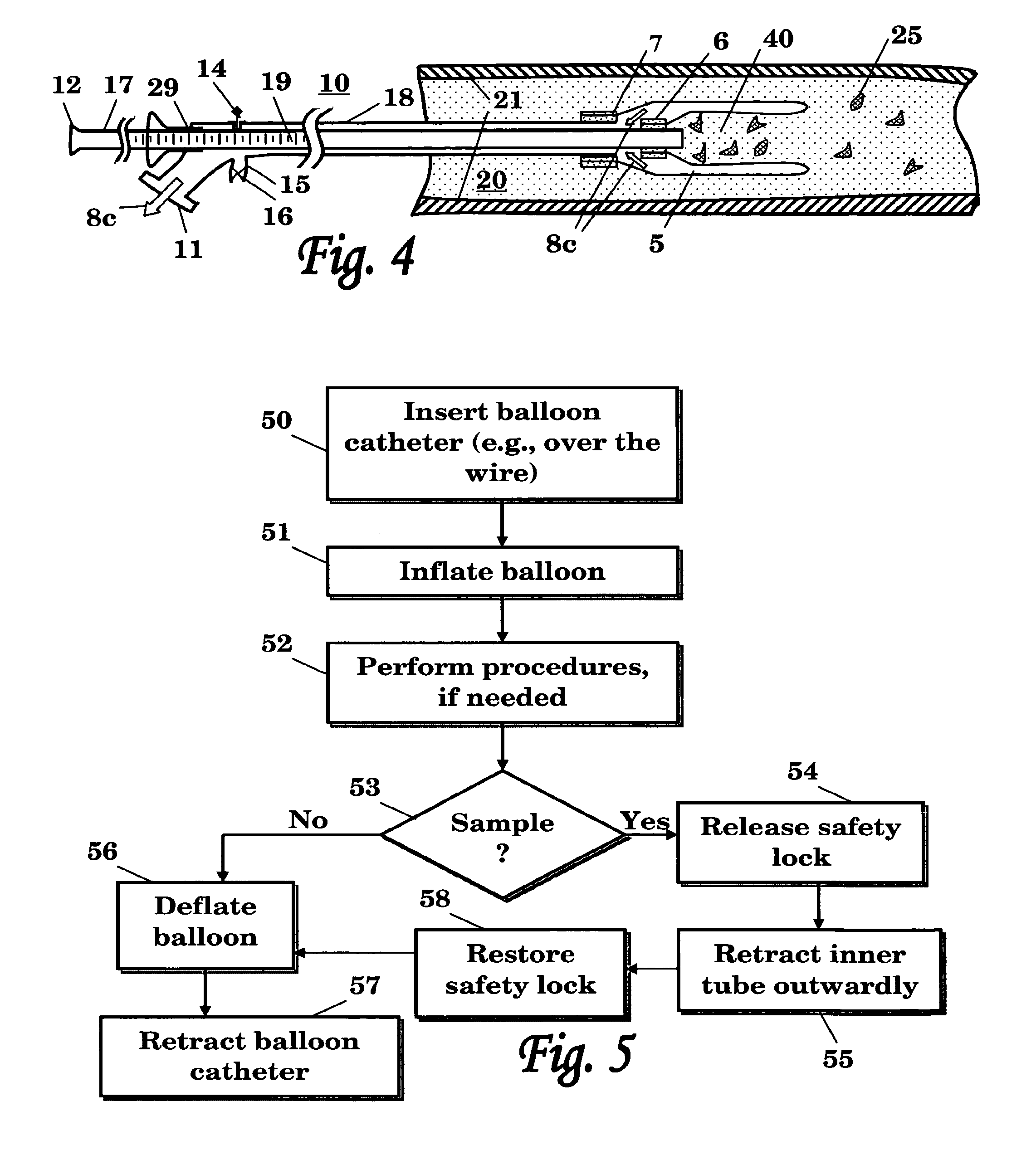

InactiveUS20070083158A1Avoid changeChange lengthStentsBalloon catheterBalloon catheterCatheter device

A catheter system suitable for the retrieval of debris and other solid or liquid matter from body passages, and the removal of said matter from the body. More particularly, a catheter system including two or more concentrically-arranged conduits and an inflatable element connected therebetween, wherein the inflatable element is arranged such that it may entrap solid or liquid matter in an internal annular cavity.

Owner:ANGIOSLIDE

Shunt system with coating and flow restricting component exerting a passive and essentially constant resistance to outflow

InactiveUS20070112291A1Reduce as muchReduce infectionWound drainsFlow monitorsCsf shuntBrain Ventricle

The present invention relates to an improved cerebrospinal fluid shunt system comprising a coating covering at least part of the system and a flow restricting component exerting a passive and essentially constant resistance to flow. The present invention also relates to methods for implanting different catheters of a cerebrospinal fluid shunt system into a brain ventricle and the sinus system, respectively, of an individual. The present invention further relates to methods for shunting cerebrospinal fluid from a brain ventricle to the sinus system of an individual.

Owner:SINU SHUNT

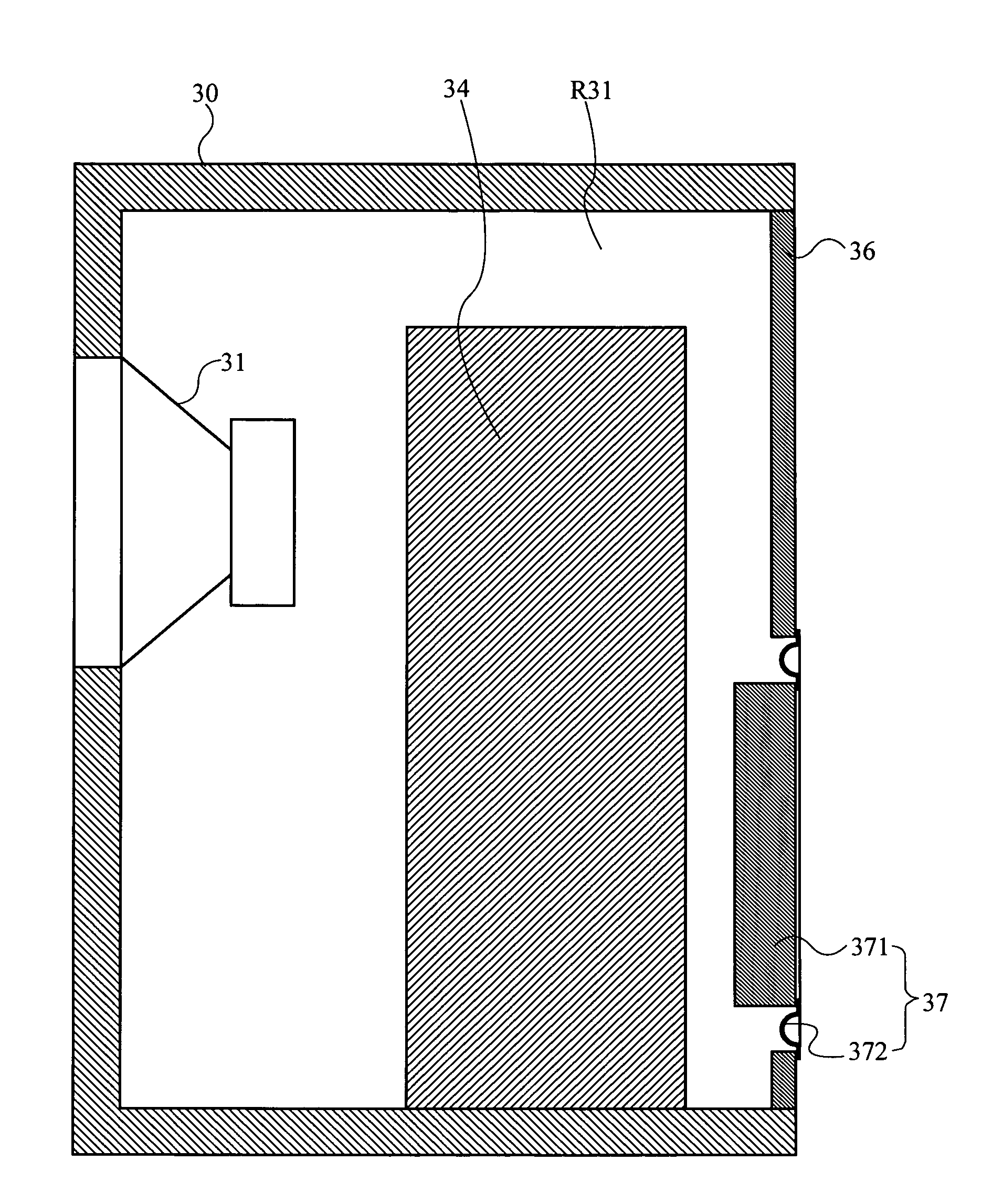

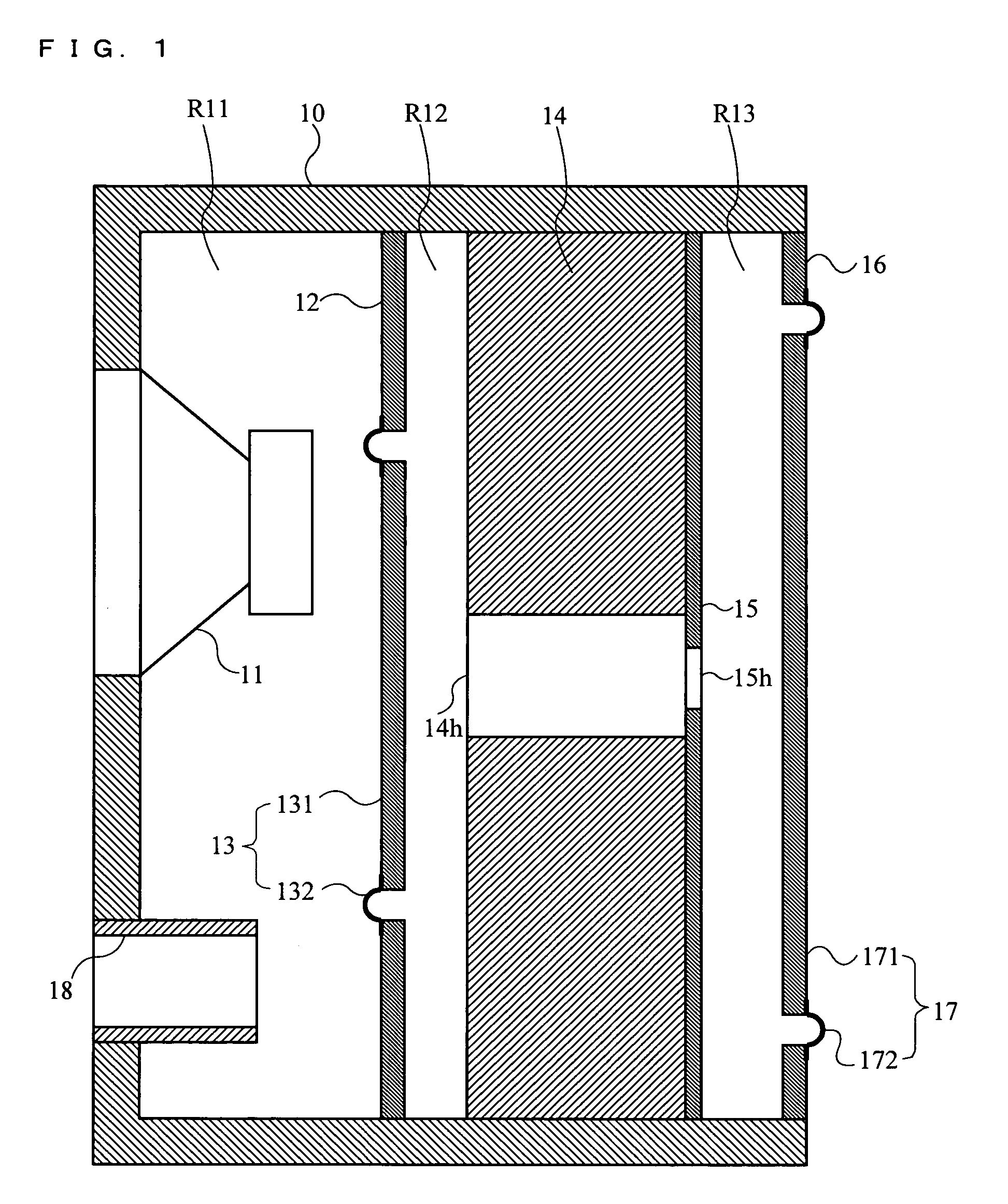

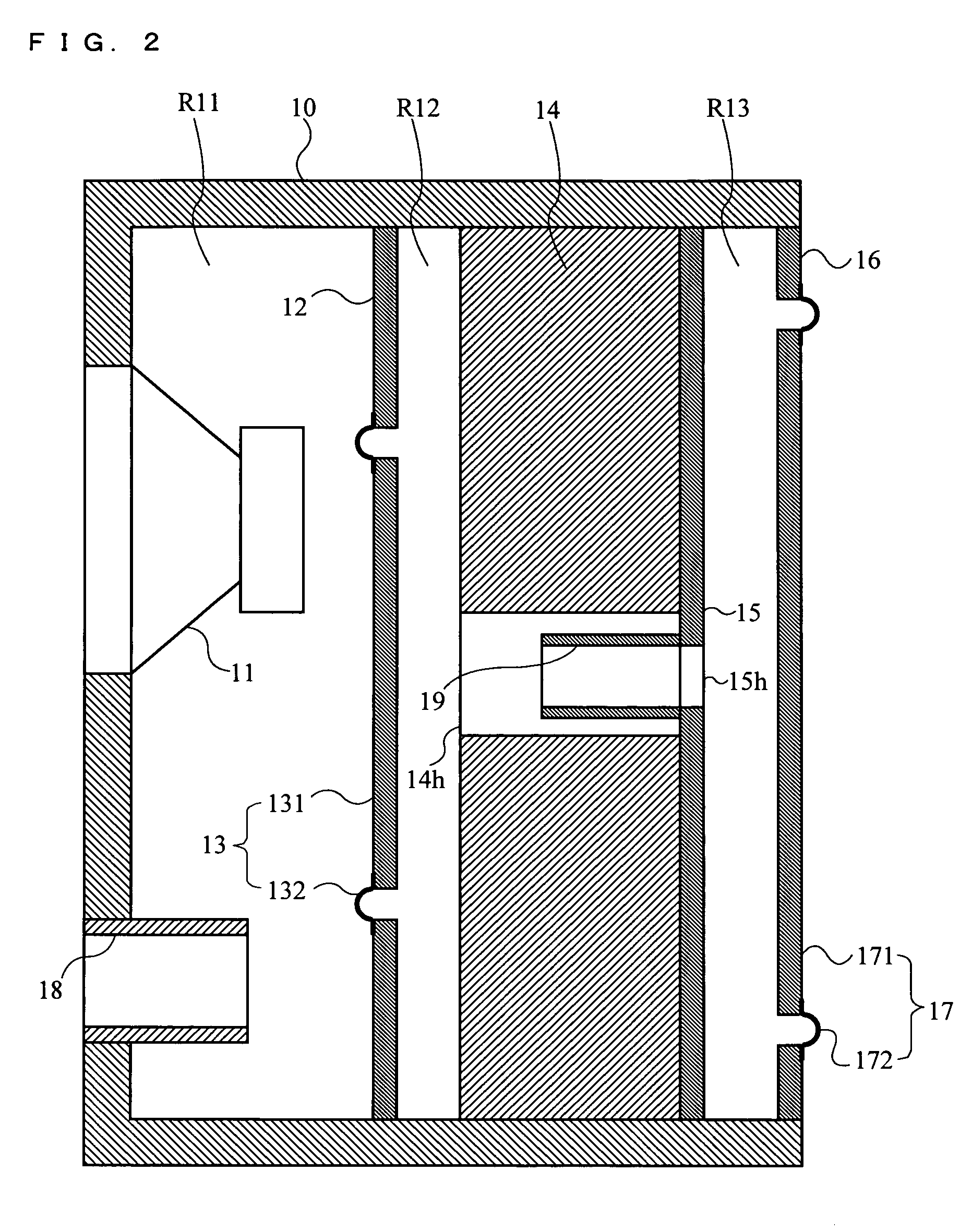

Speaker system

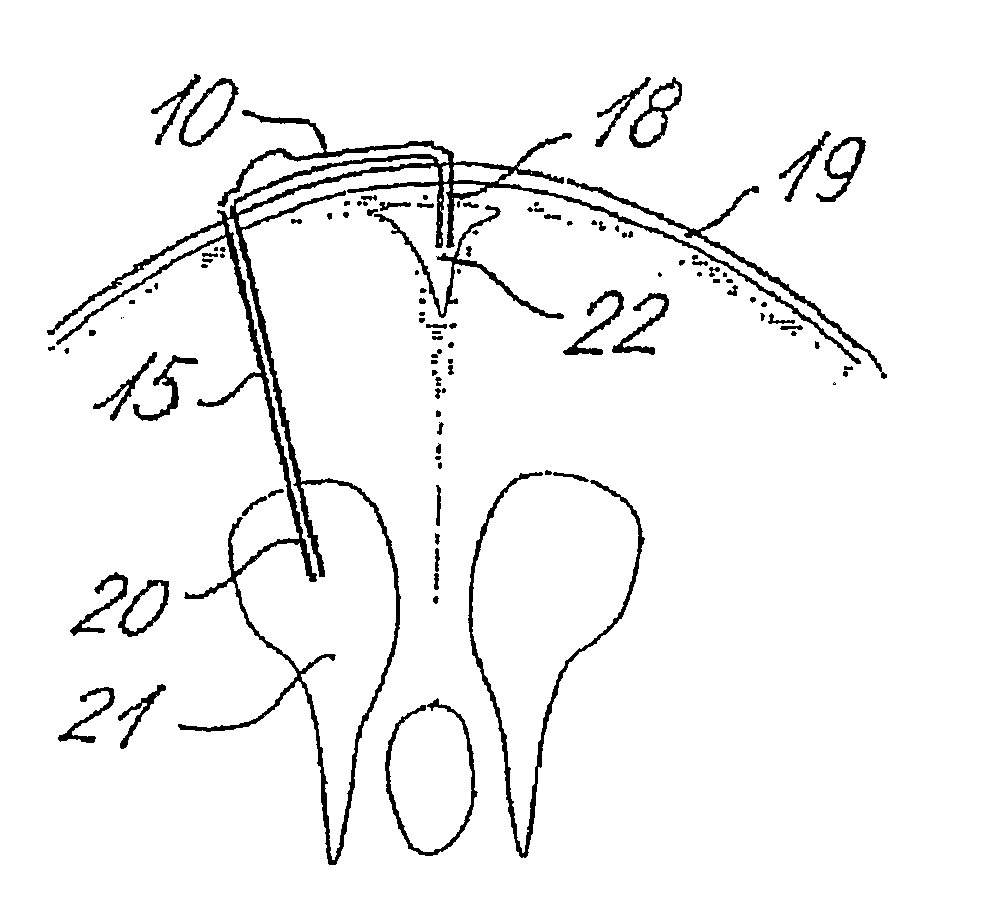

ActiveUS7477755B2Reduce pressure changesImprove acoustic performanceFrequency/directions obtaining arrangementsLoudspeaker spatial/constructional arrangementsEngineeringAtmospheric pressure

A speaker system according to the present invention comprises a cabinet (10), a speaker unit (11), a first parting board (12), a drone cone (13), an adsorption member (14), a second parting board (15), a backboard (16), a variable mechanism (17), and a port (18). A sound pressure generated by the speaker unit (11) causes a pressure variation in a second chamber (R12) via the drone cone (13). The adsorption member (14) with an effect of physical adsorption is operable to suppress the pressure variation. Furthermore, by displacing the diaphragm (171), the variable mechanism (17) is operable to reduce a pressure variation of a direct current component, which is caused by variations in ambient temperature or atmospheric pressure of the speaker system.

Owner:PANASONIC CORP

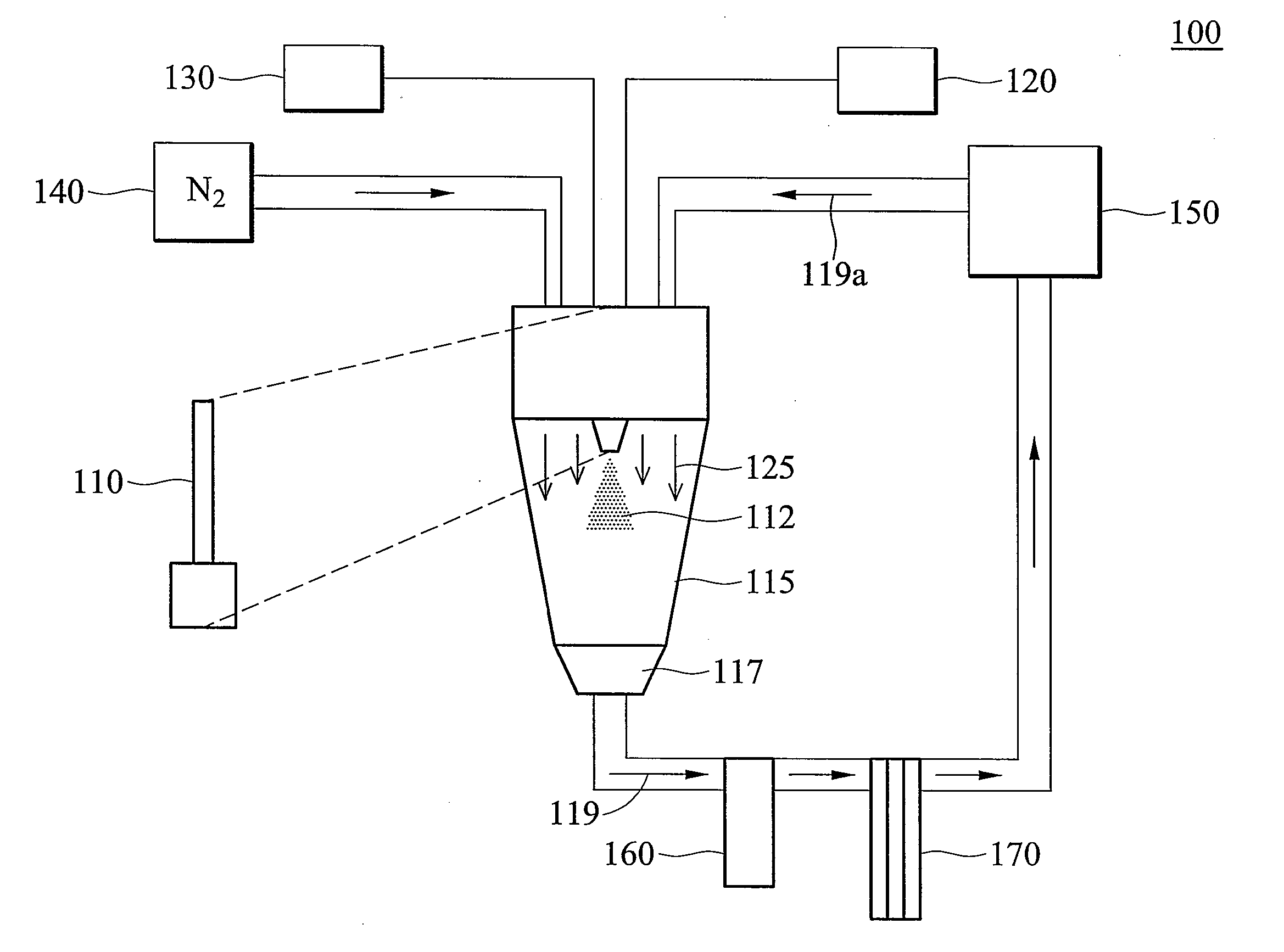

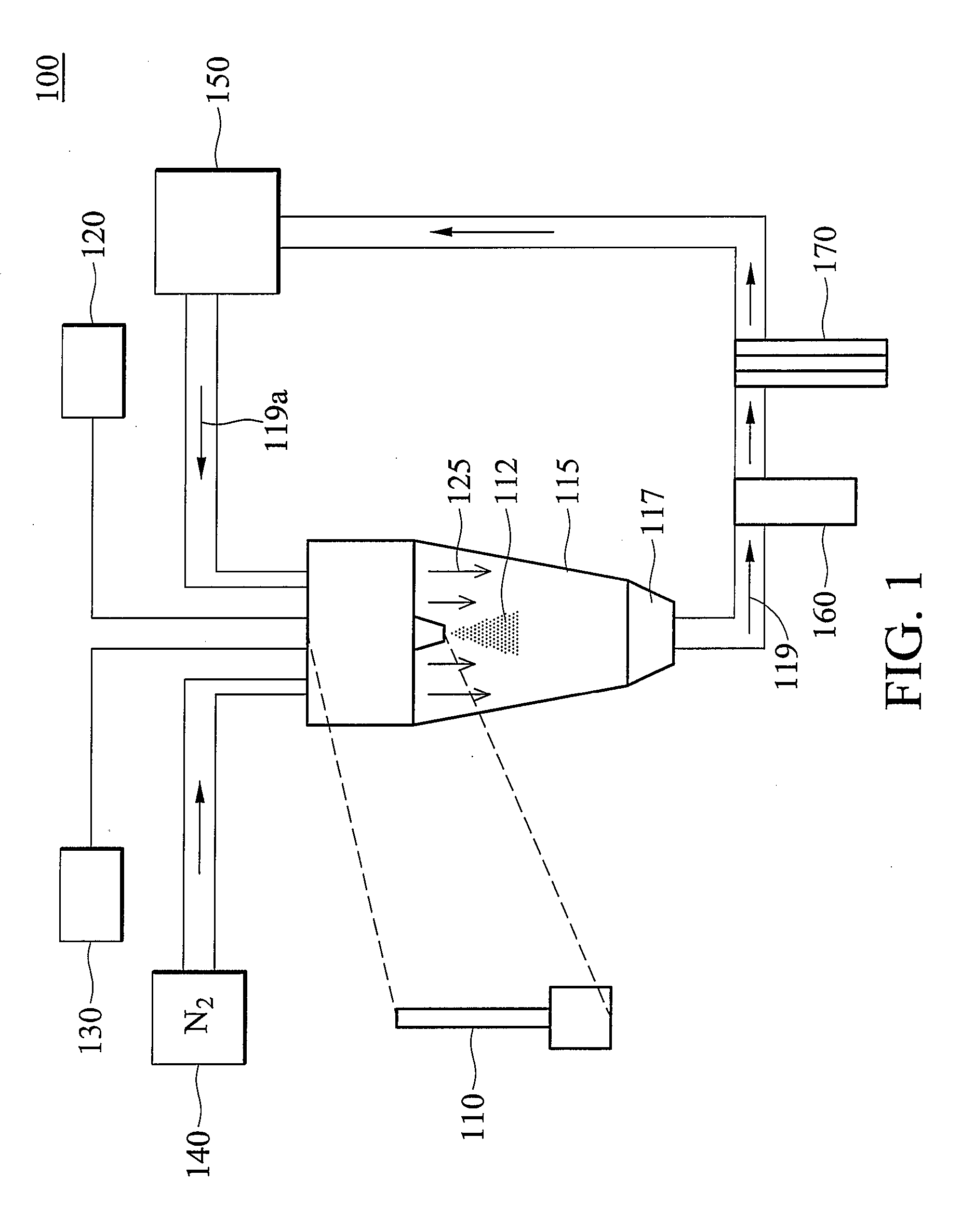

System for fabricating nanoparticles

InactiveUS20080041532A1Avoid turbulenceAvoid collisionPrintingEvaporation by sprayingNanoparticleSprayer

A system for fabricating nanoparticles that includes a micro droplet sprayer, a device, and a drying chamber is disclosed. The micro droplet sprayer, such as an inkjet sprayer, composed of a tank, a channel, an actuator, and orifices is utilized for generation of micro droplets. The device is employed to provide the micro droplet sprayer with energy, thus, forcing droplets out. The droplets are dried in the drying chamber, obtaining nanoparticles.

Owner:IND TECH RES INST

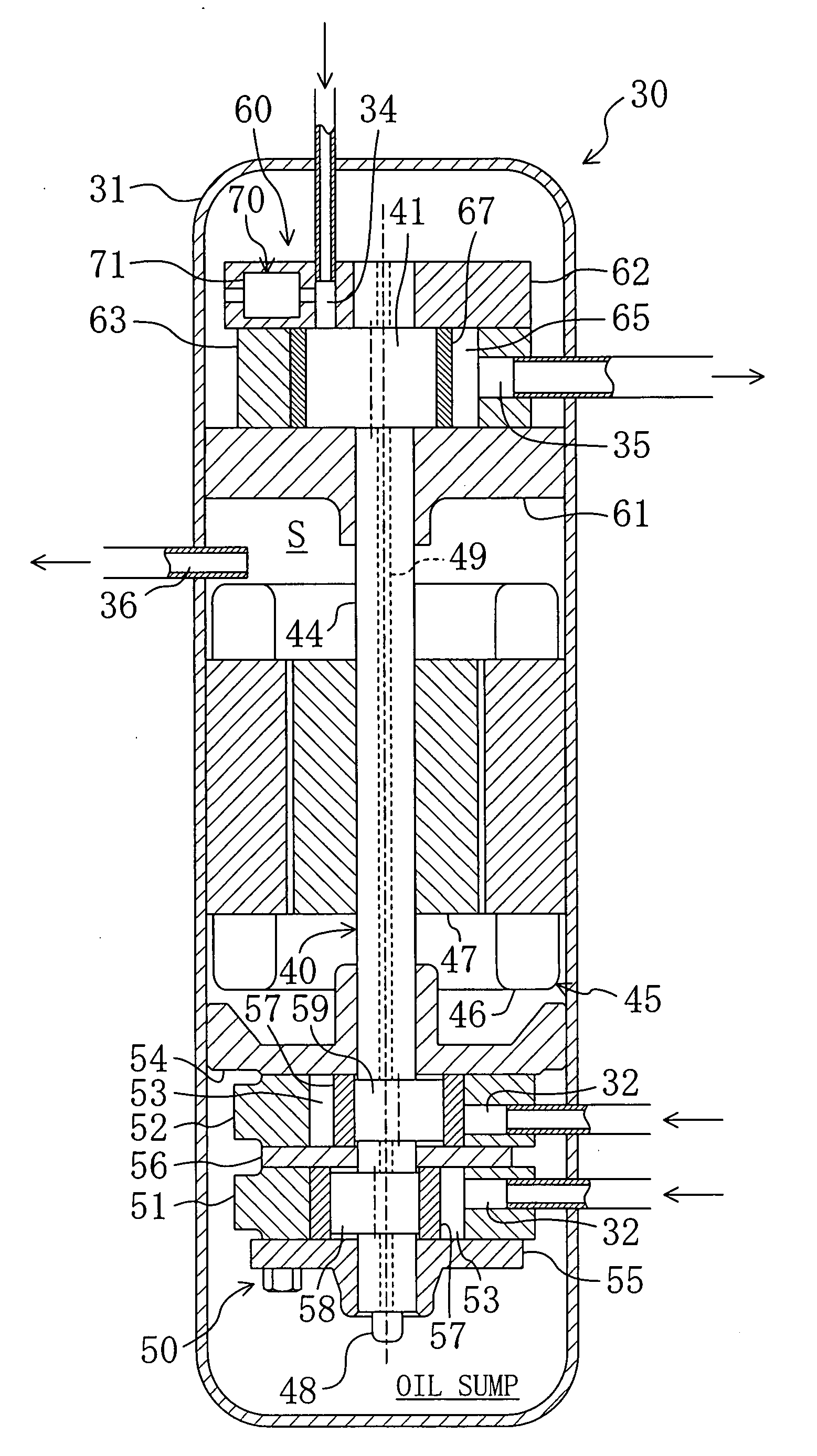

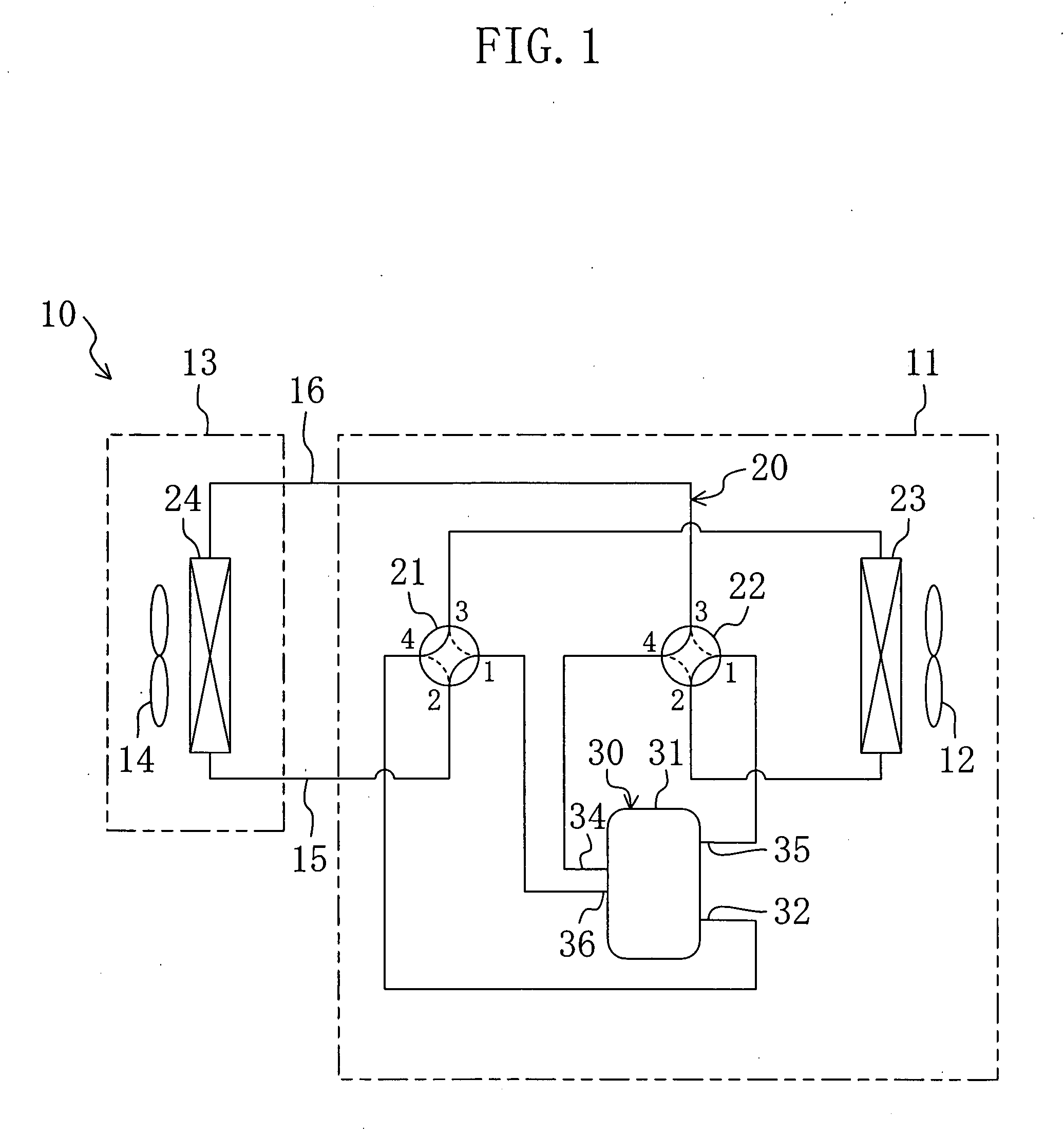

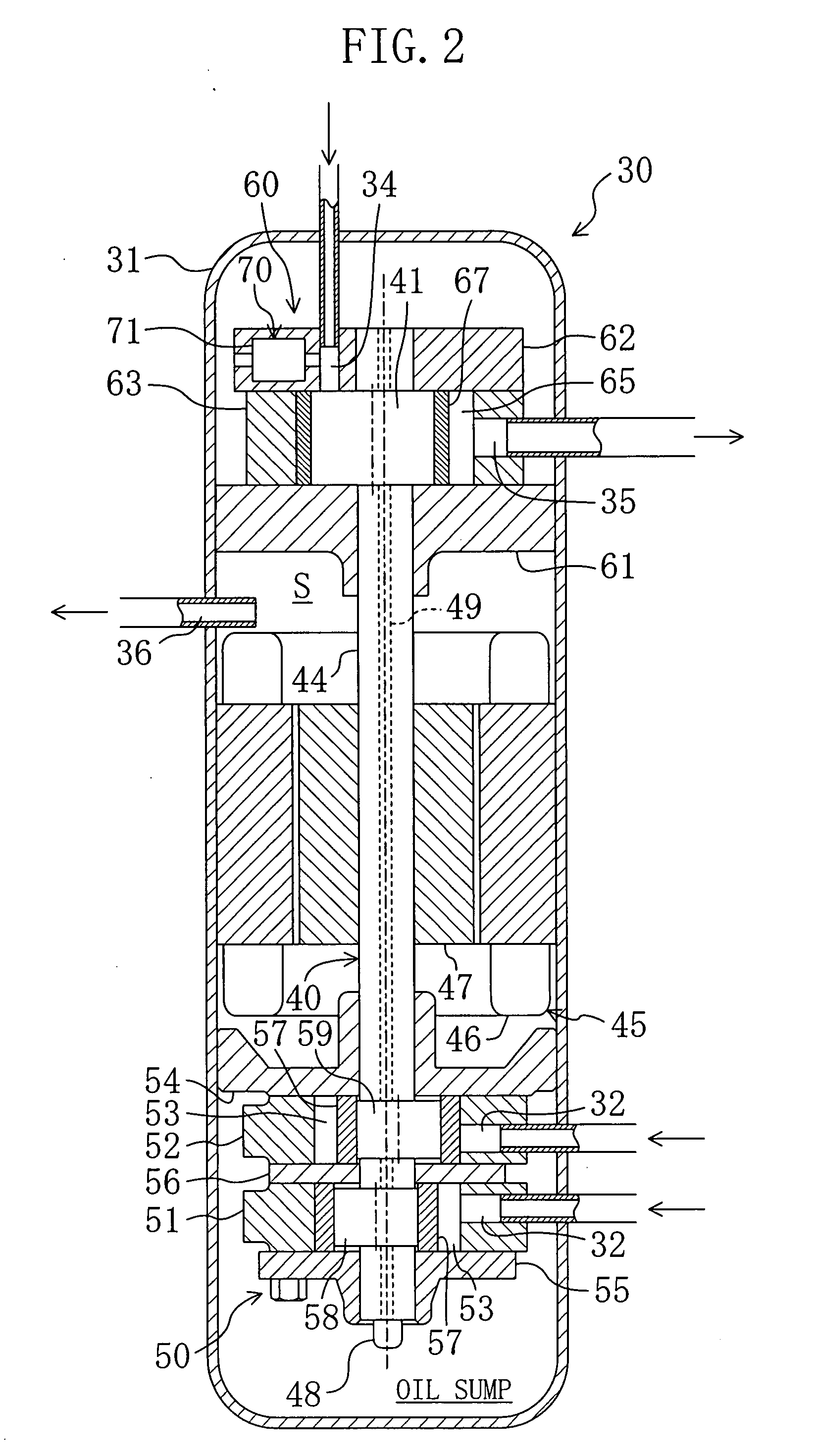

Positive displacement expander

InactiveUS20090178433A1More variationReduced effectively in vibrationDomestic cooling apparatusCombination enginesSnubbingEngineering

A casing (31) houses therein an expansion mechanism (60) and a compression mechanism (50). The expansion mechanism (60) has a rear head (62) in which a pressure snubbing chamber (71) is provided. The pressure snubbing chamber (71) is divided by a piston (77) into an inflow / outflow chamber (72) which fluidly communicates with an inflow port (34) and a back pressure chamber (73) which fluidly communicates with the inside of the casing (31). The piston (77) is displaced in response to suction pressure variation whereby the volume of the inflow / outflow chamber (72) varies. This enables the inflow / outflow chamber (72) to directly perform supply of refrigerant to or suction of refrigerant from the inflow port (34) which is a source of pressure variation, thereby making it possible to effectively inhibit suction pressure variation.

Owner:DAIKIN IND LTD

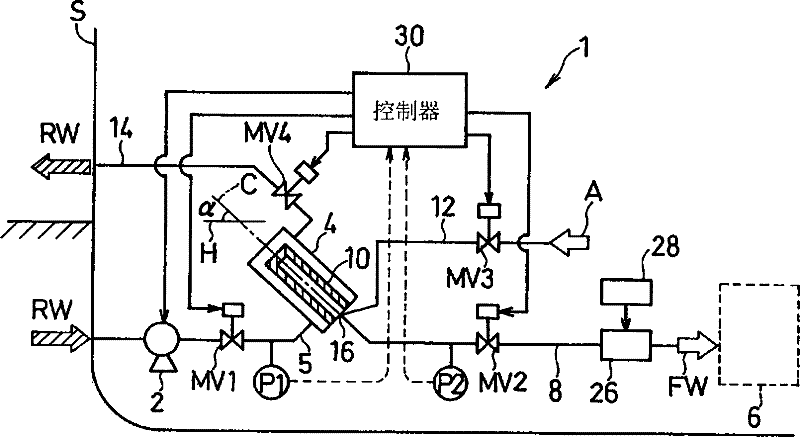

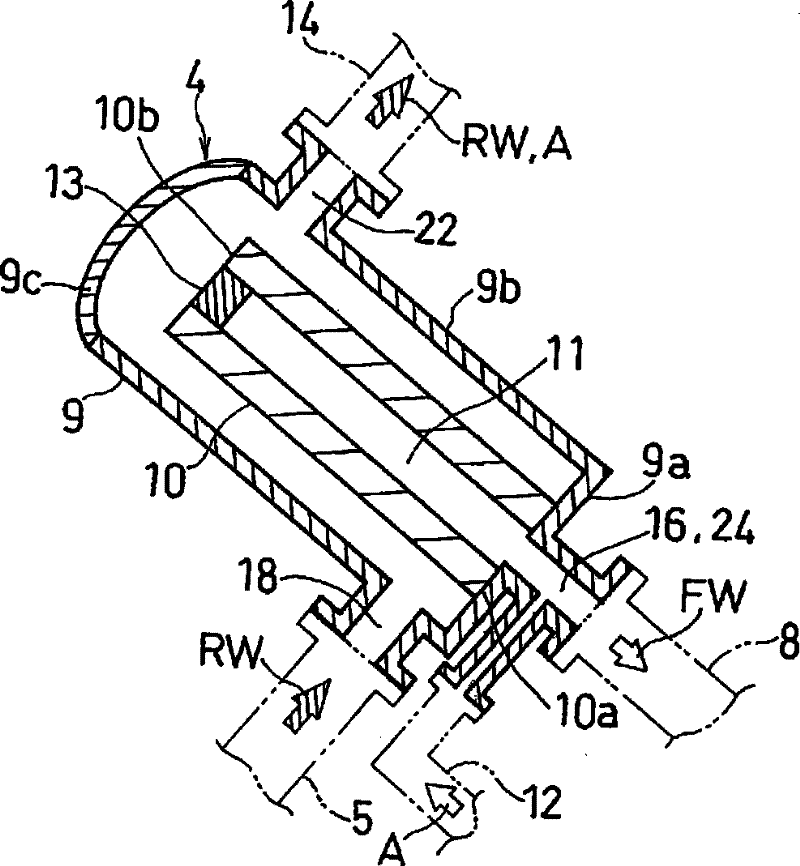

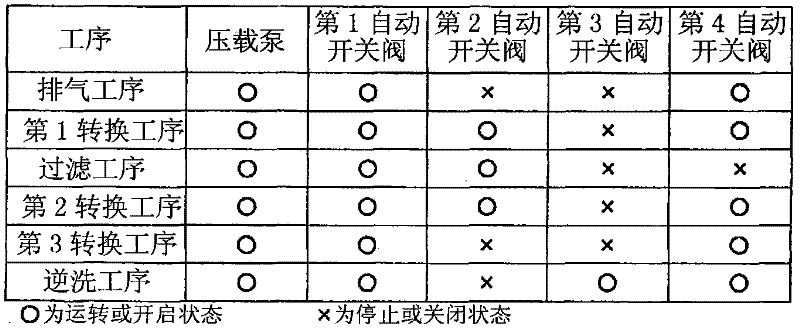

Filtering unit and ballast water production equipment provided with same

InactiveCN102316952AAvoid shockCurb processing costsWater/sewage treatment by irradiationSelf-bailing equipments/scuppersWater productionFilter system

The invention refers to a filtering unit and ballast water production equipment provided with same. The filtering system (1) in ballast water production equipment in a ship (S) is provided with a filtering unit (4) for filtering raw water (RW) taken into the ship (S) and supplying the filtered raw water to a ballast tank (6), a gas supply path (12) for supplying compressed air (A) to a depth filter (10) that forms a filtering membrane in the filtering unit (4) to thereby clean the depth filter, and a discharge path (14) for discharging the compressed air (A) that has cleaned the depth filter (10), together with the raw water (RW) in the depth filter (10), to the outside of the ship (S), the discharge path being connected to the filtering unit (4), wherein the pore diameter of the filtering membrane that forms the depth filter (10) falls within the range of 1-25 [mu]m.

Owner:KURARAY CO LTD

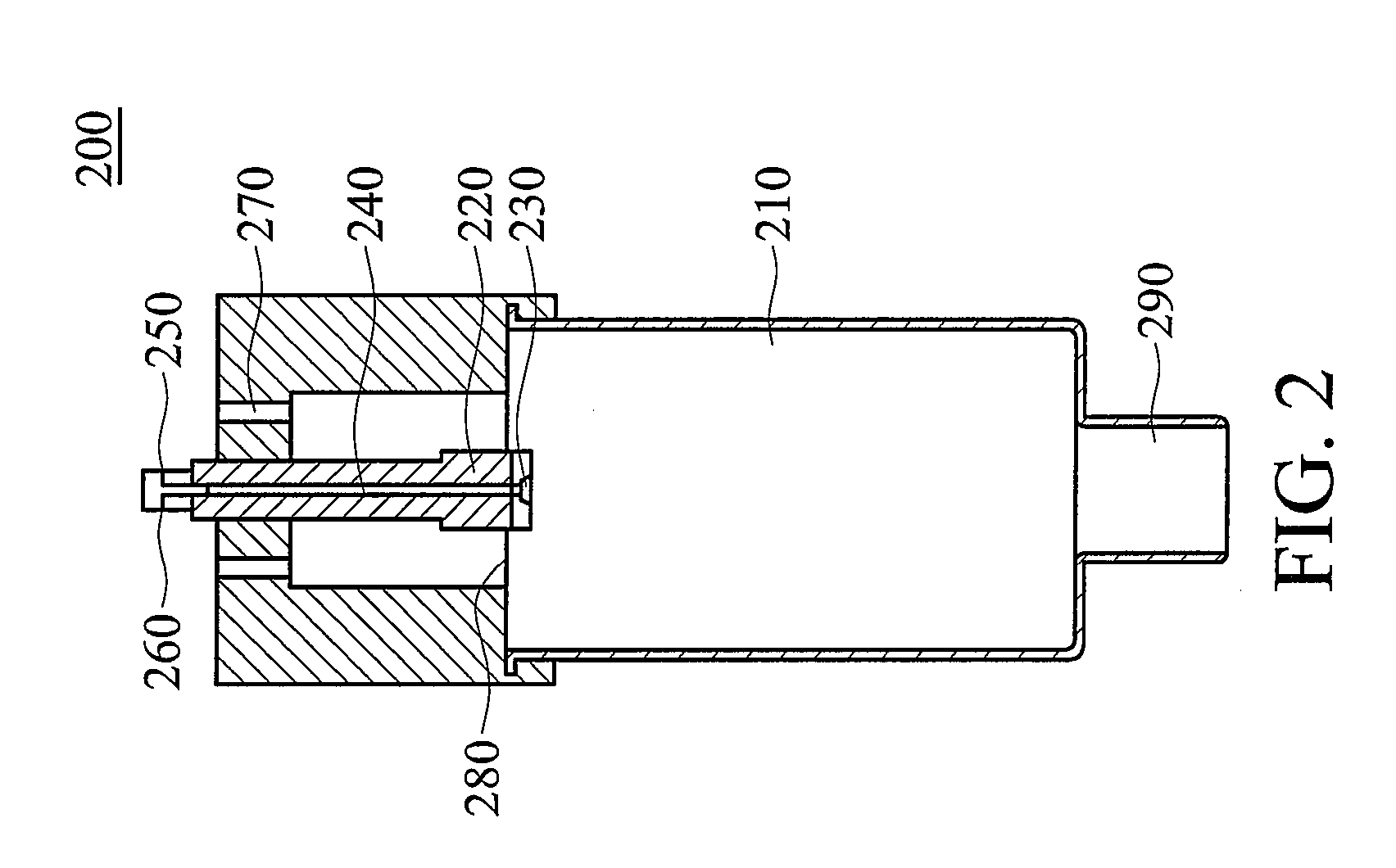

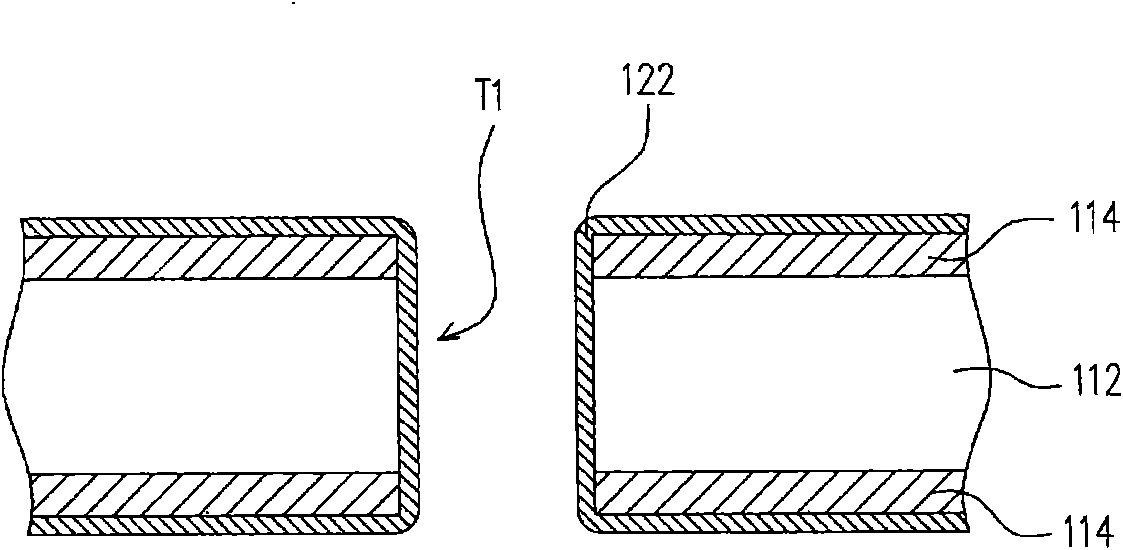

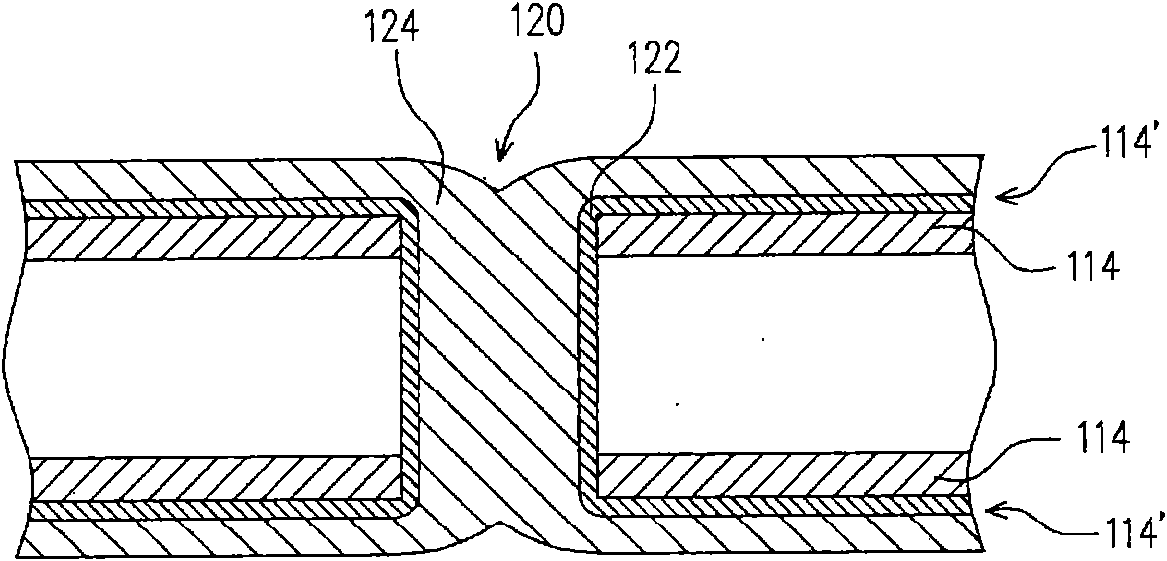

Balloon catheter

A balloon catheter includes an outer conduit having an outer surface, and an inner conduit having an outer surface. The inner conduit is suitable for passage over a guide wire, and the inner conduit is movably disposed within the lumen of the outer conduit. There is also a balloon having a proximal margin and a distal margin, such that the proximal margin of the balloon is attached to the outer surface of the distal tip of the outer conduit and the distal margin of the balloon is attached to the outer surface of the portion of the inner conduit that extends beyond the distal tip of the outer conduit. And there is a fluid port for introducing an expansion fluid into the annular space formed between the inner surface of the outer conduit and the outer surface of the inner conduit and into the lumen of the balloon, and for the removal of the expansion fluid.

Owner:ANGIOSLIDE

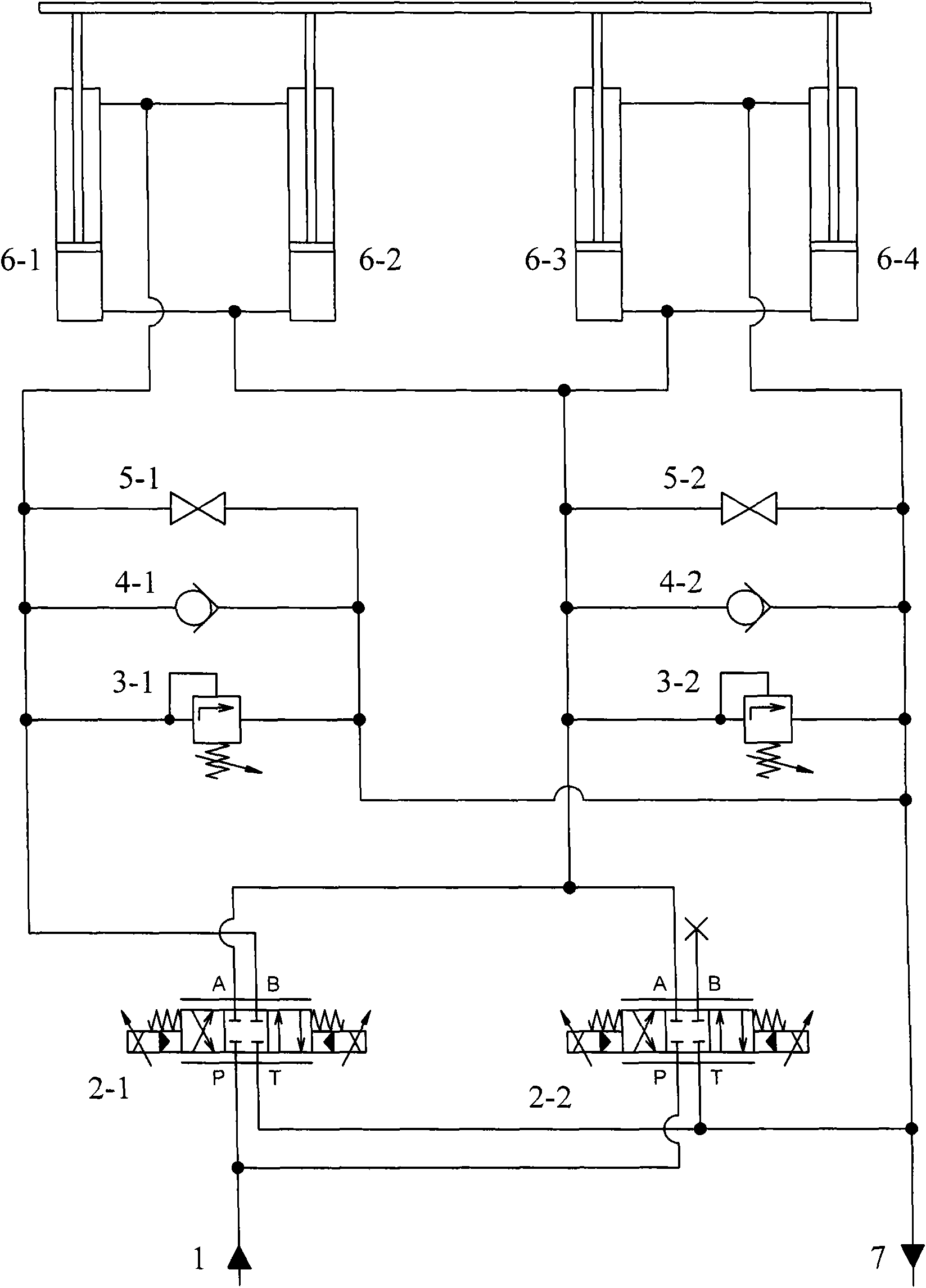

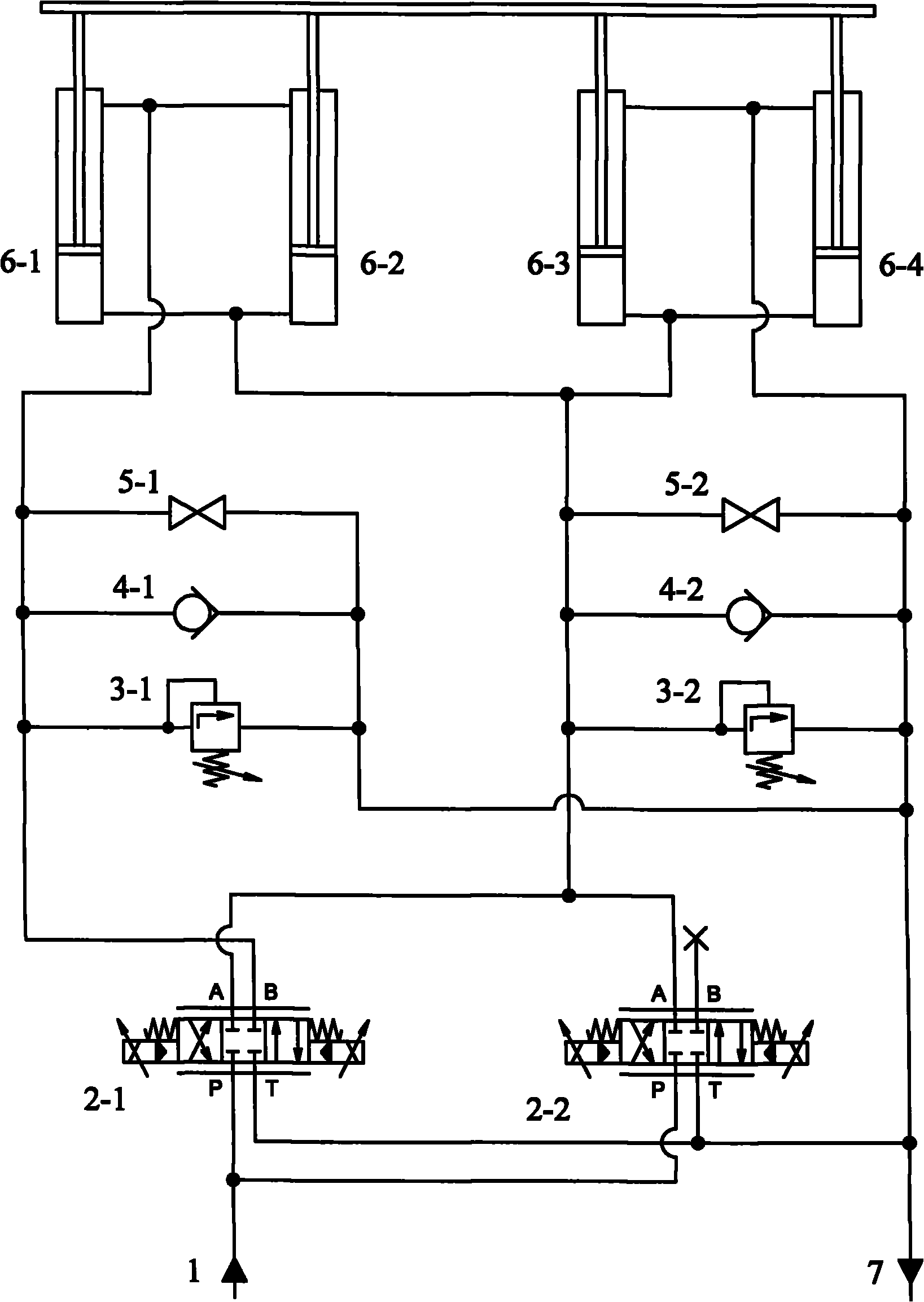

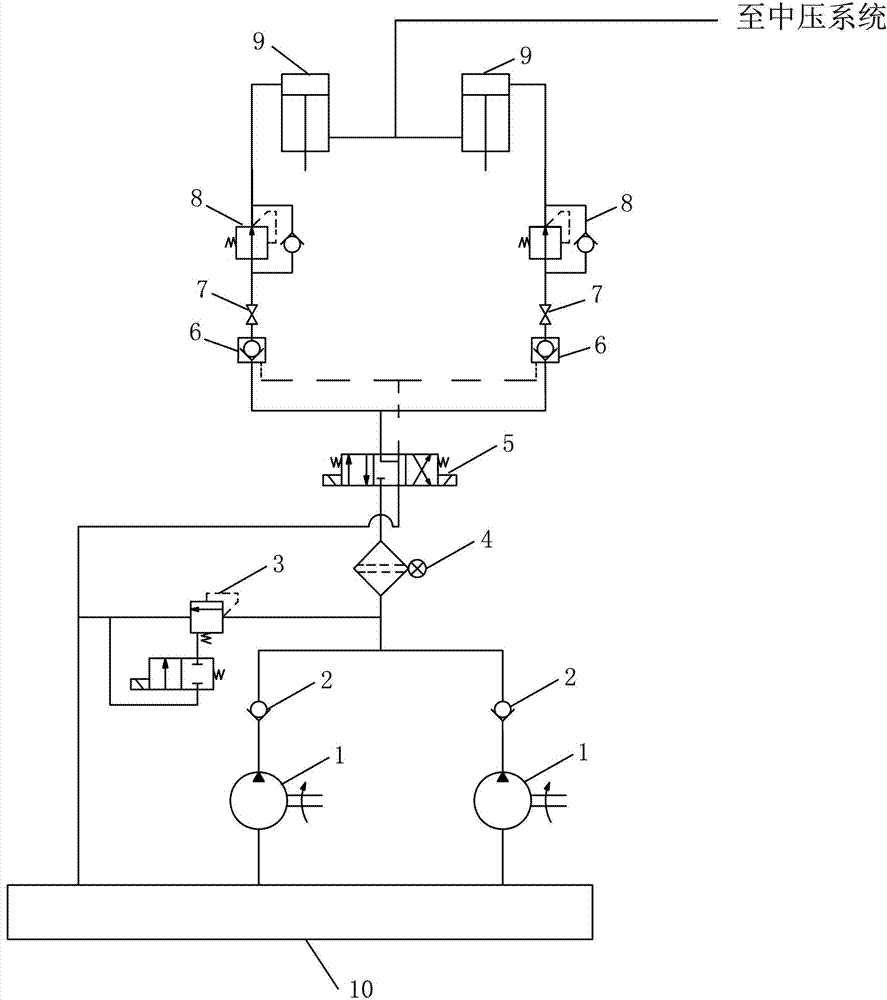

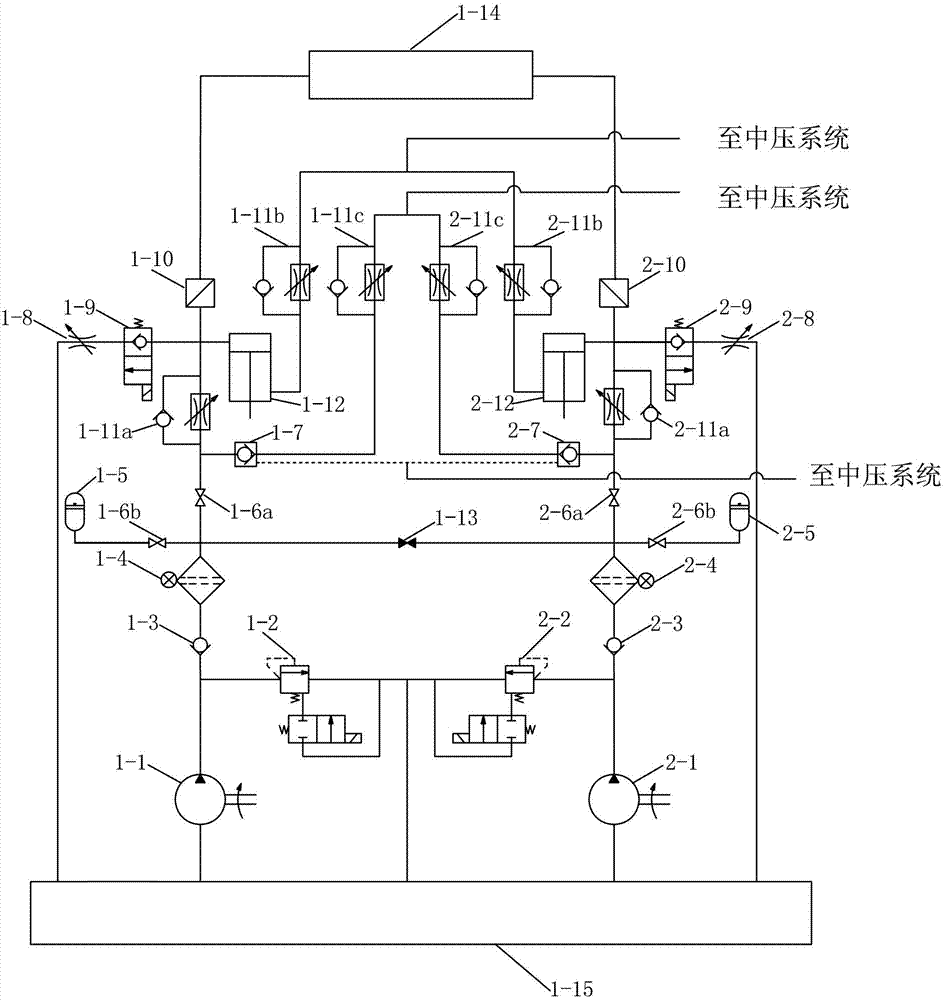

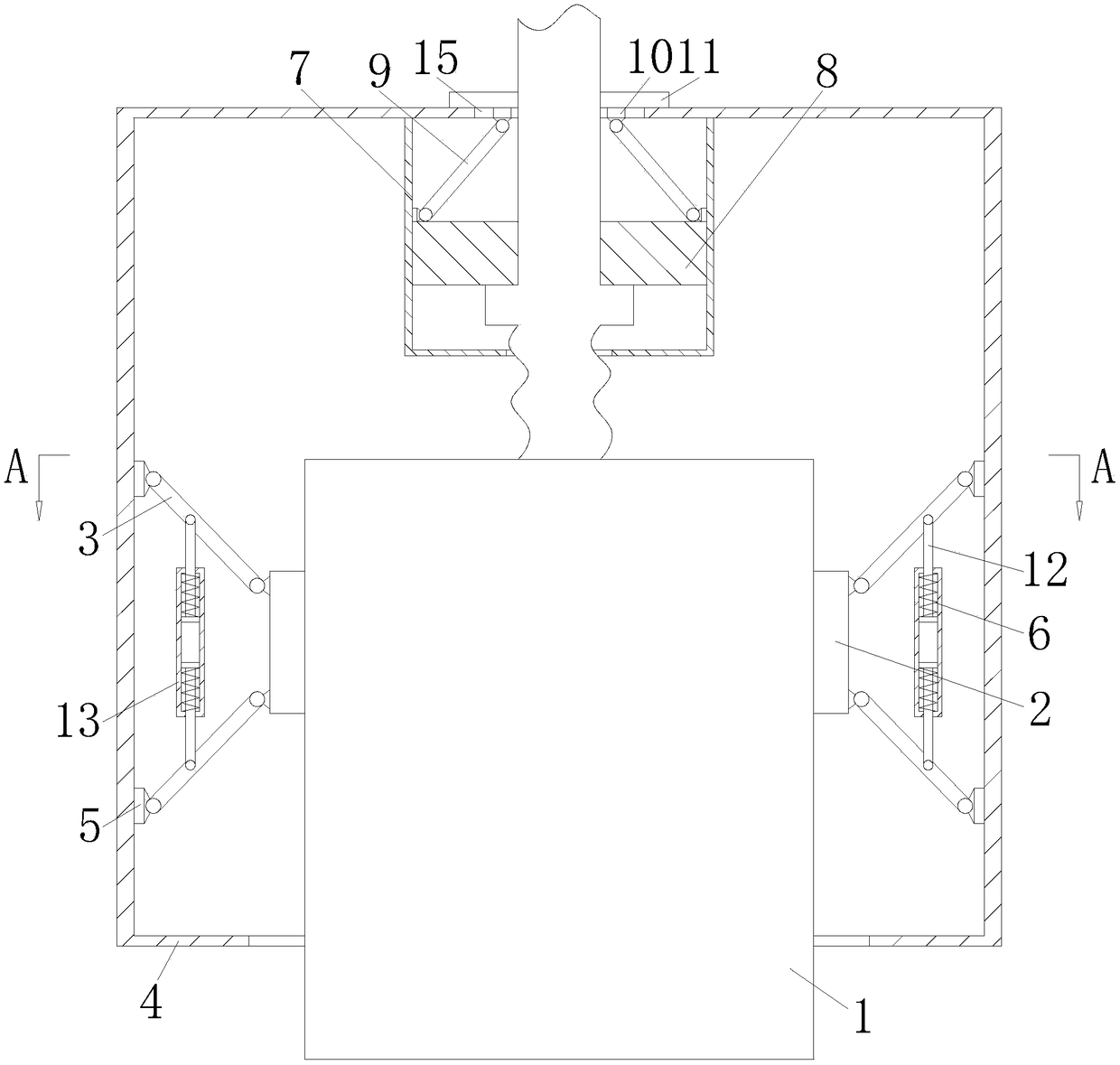

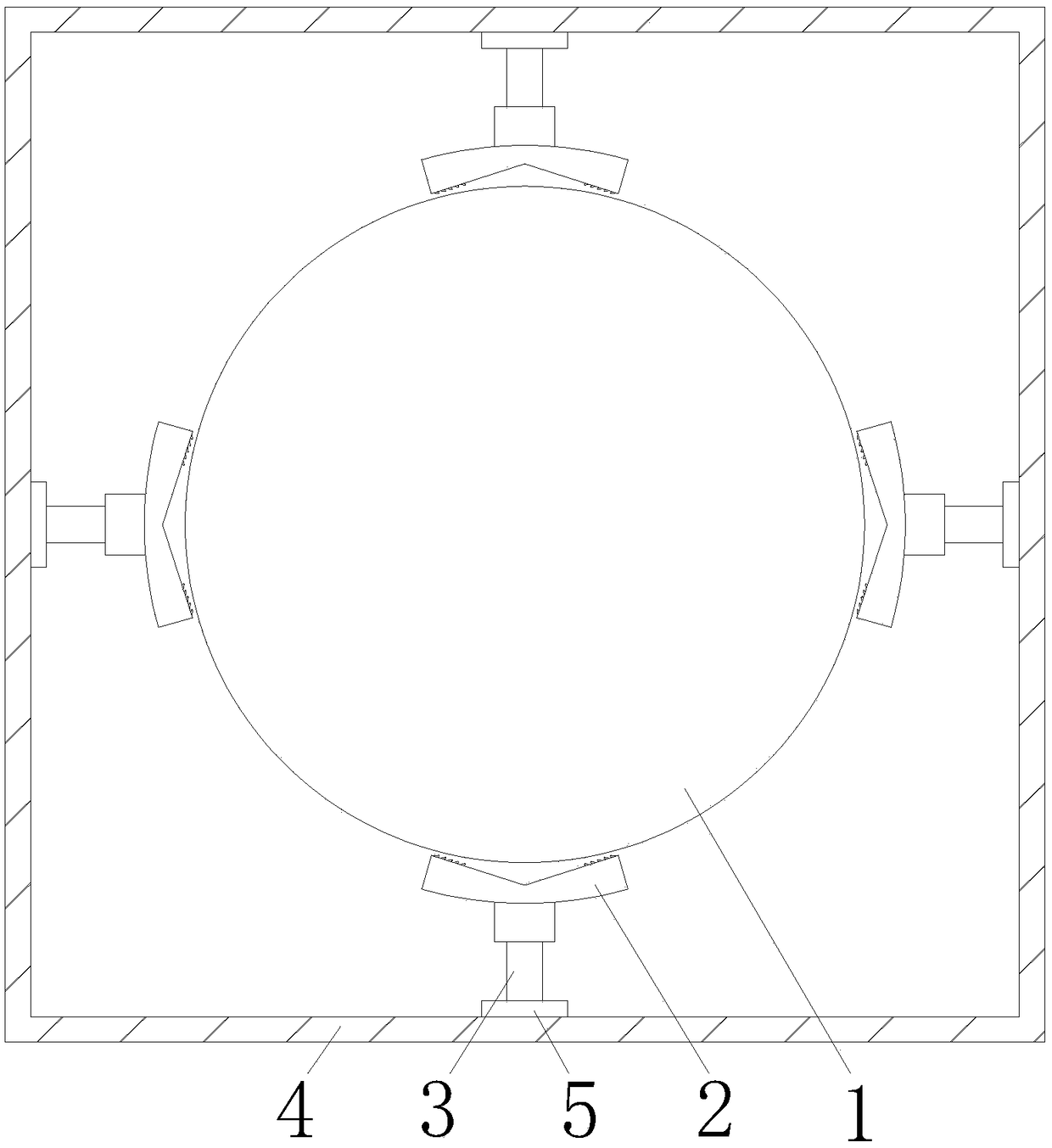

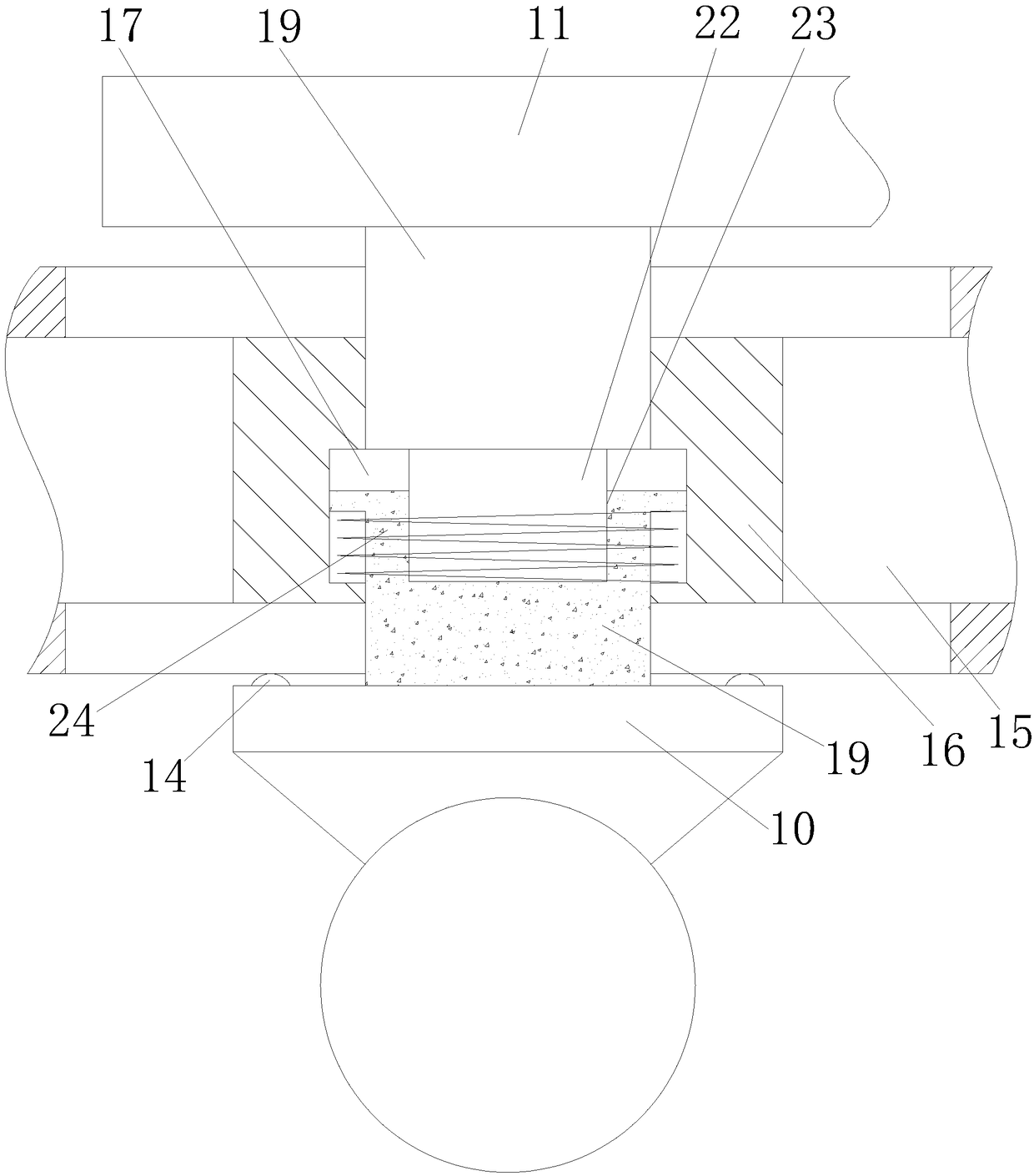

Hydraulic parallel driving system for fore-and-aft lifting of forging manipulator

InactiveCN102114516AGood synchronizationAvoid stress changesServomotorsForging/hammering/pressing machinesForging manipulatorEngineering

The invention discloses a hydraulic parallel driving system for fore-and-aft lifting of a forging manipulator. The P port of a nonsymmetrical proportional servo valve (2-1) is respectively connected with an oil supply port (1) of an oil source and the P port of a symmetrical proportional servo valve (2-2); the A port of the nonsymmetrical proportional servo valve (2-1) is respectively connected with the A port of the symmetrical proportional servo valve (2-2), the inlet of a lower cavity safety valve (3-2) and the like; the B port of the nonsymmetrical proportional servo valve (2-1) is respectively connected with the inlet of an upper cavity safety valve (3-1), the outlet of an upper cavity one-way valve (4-1), the inlet of an upper cavity cut-off valve (5-1) and the like; the B port of the symmetrical proportional servo valve (2-2) is plugged; an oil return port (7) of the oil source is respectively connected with the T port of the nonsymmetrical proportional servo valve (2-1), the T port of the symmetrical proportional servo valve (2-2), and the like; and the top ends of the piston rods of four lift cylinders are mechanically consolidated. The hydraulic parallel driving system disclosed by the invention can solve the problem of synchronous driving of fore-and-aft lifting systems of the existing forging manipulator.

Owner:ZHEJIANG UNIV

Scale-up of flow-focusing microfluidic devices

ActiveUS9056299B2Avoid pressure fluctuationsIntroducing fluctuationFlow mixersMixing methodsMicrofluidicsMulti phase

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

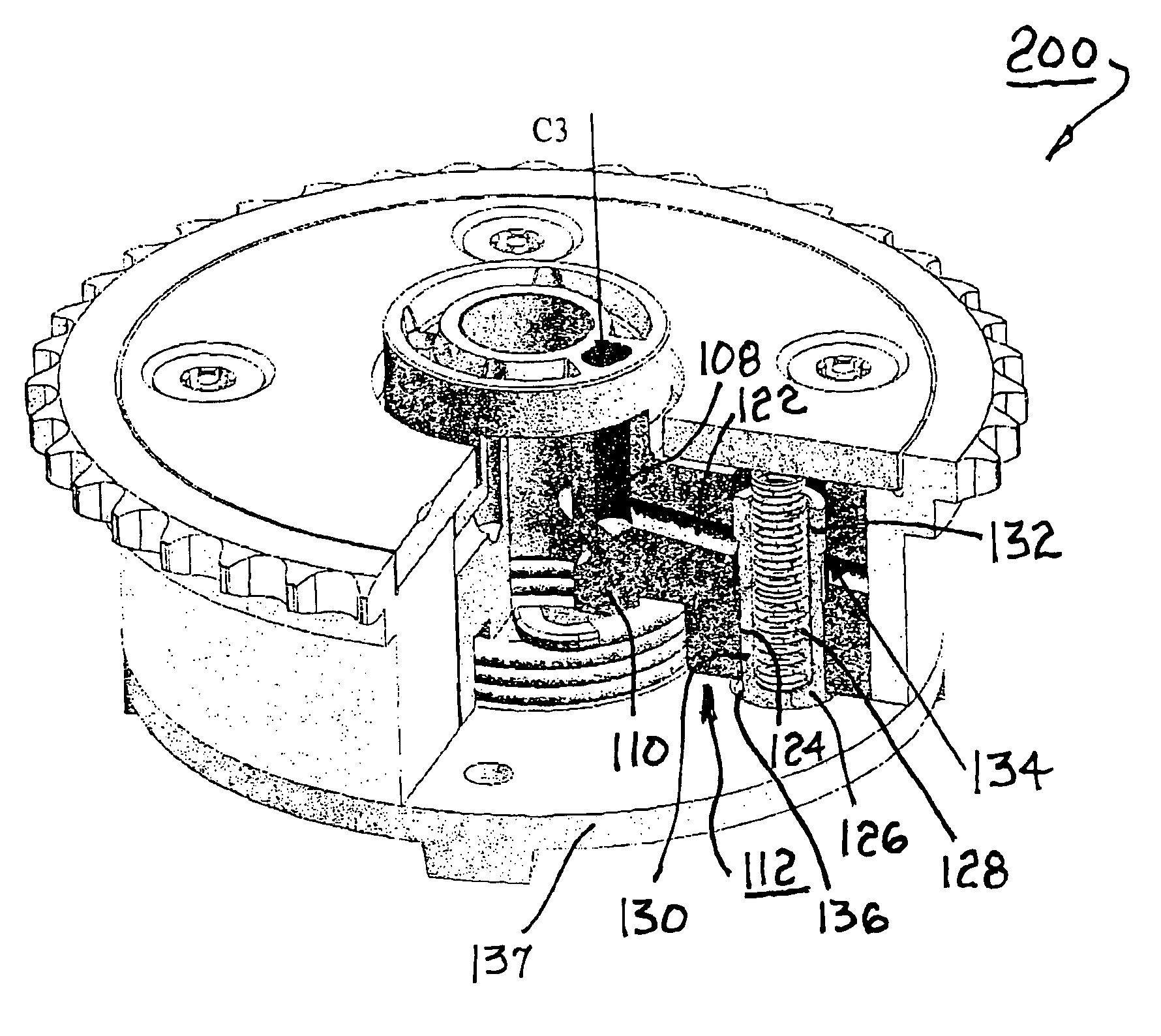

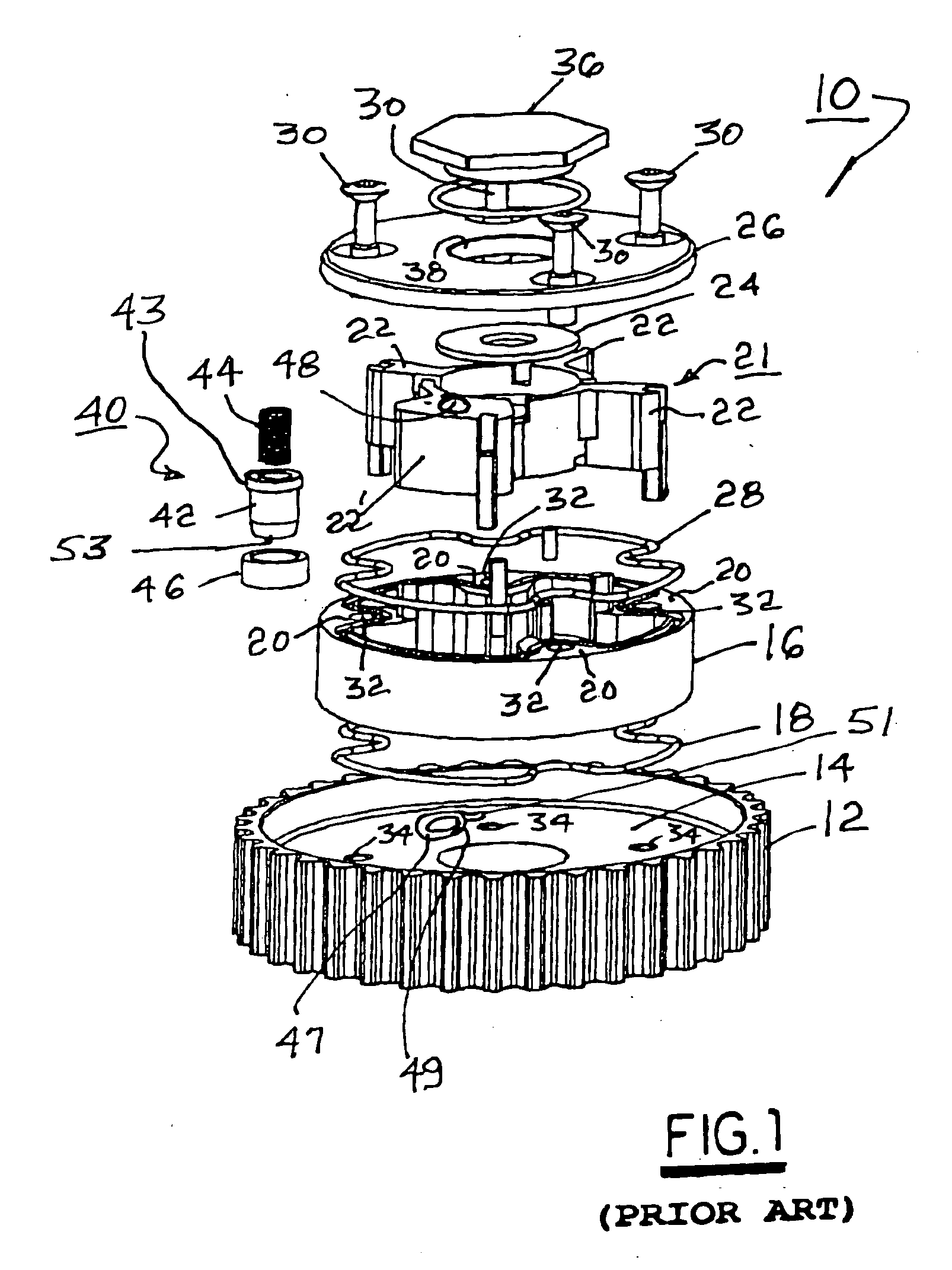

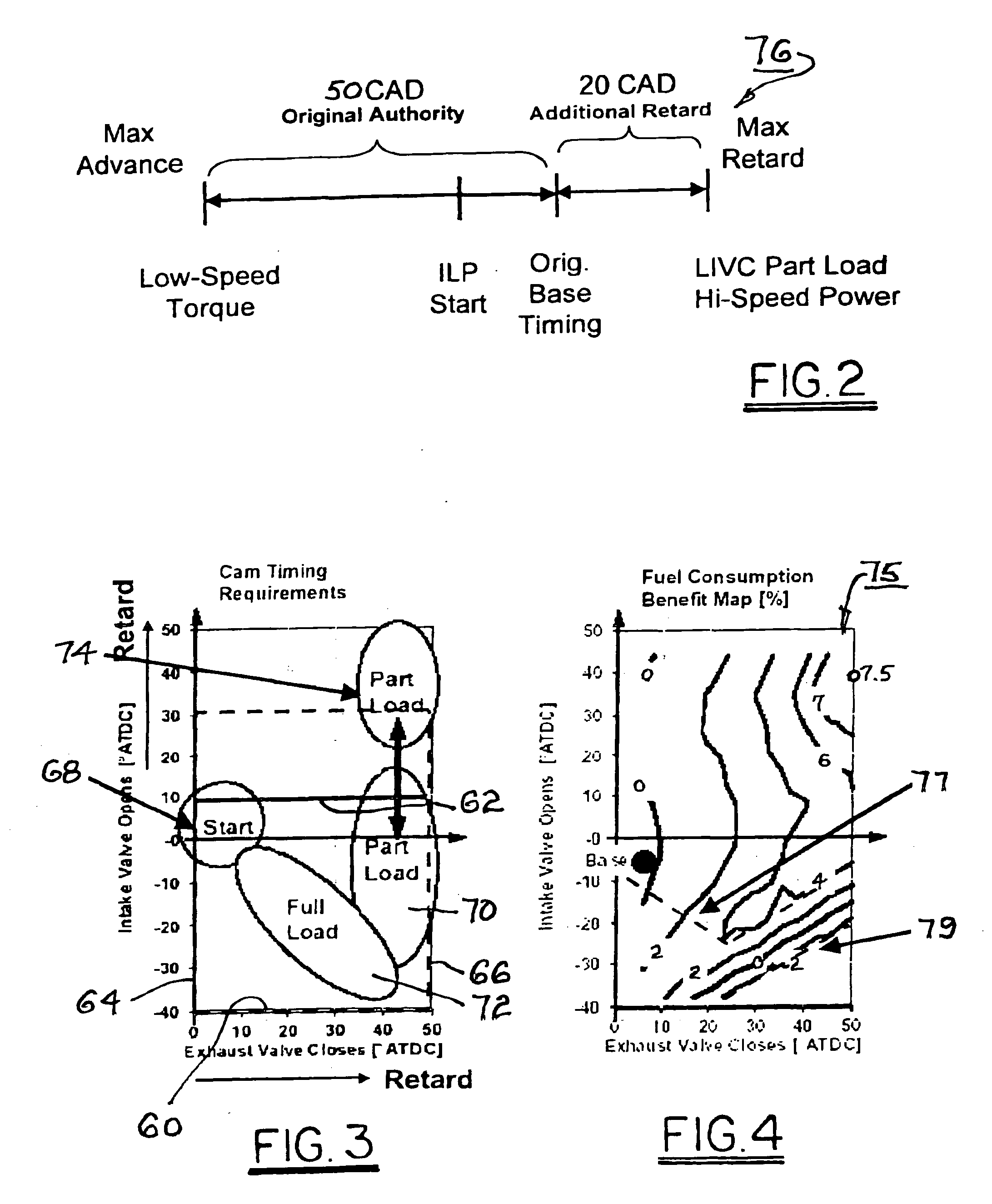

Vane-type cam phaser having increased rotational authority, intermediate position locking, and dedicated oil supply

ActiveUS20070056539A1Remove oil resistancePrevent accidental pin ejectionOscillating piston enginesValve drivesEngineeringCam

A vane-type camshaft phaser having a rotational authority between 40 crank degrees before TDC and 30 crank degrees after TDC. The phaser includes a stator seat formed at a rotation position intermediate between full advance and full retard. A locking pin in a vane of the rotor engages the seat, locking the rotor at the intermediate position. The pin is disengaged by pressurized engine oil independent of oil flows for advance and retard of the rotor. The oil is controlled by a dedicated valve. Preferably, the seat and the ends of the locking pin are vented by passages in the rotor and stator which are aligned when the rotor is at the selected locking angle to remove oil resistance to entry of the pin into the seat. To position the locking pin over the seat, phasing rate is reduced to allow time for the locking pin to engage the seat.

Owner:DELPHI TECH IP LTD

Energy storage device

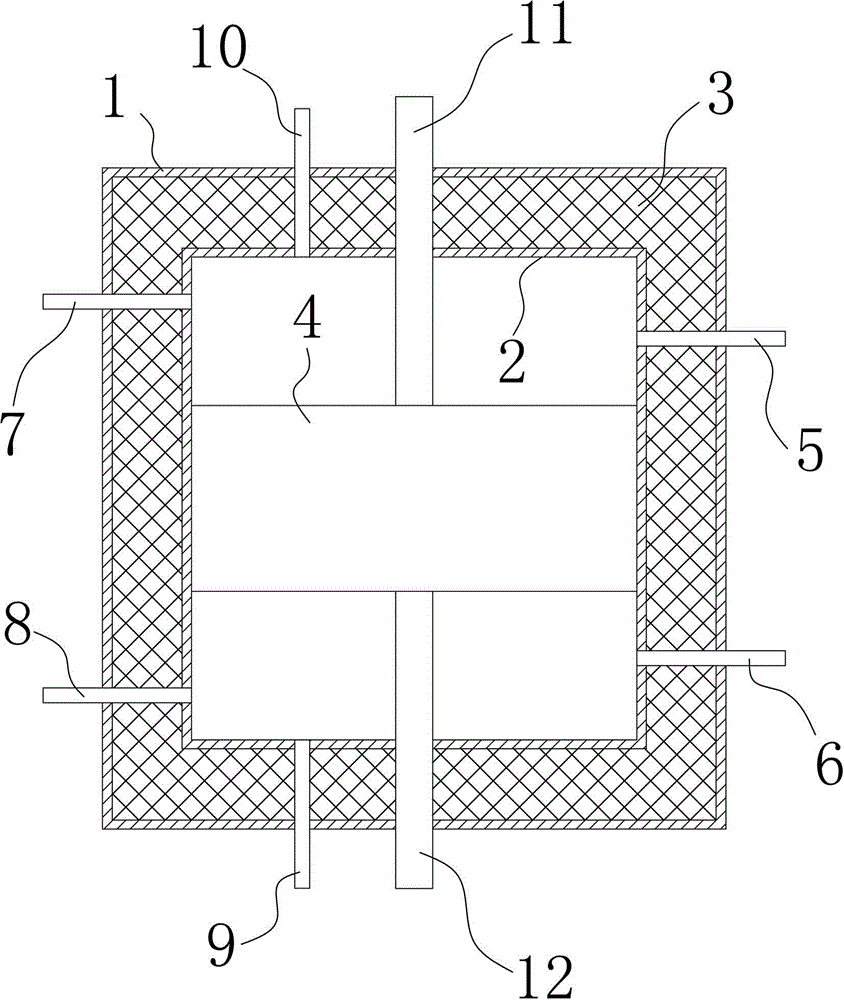

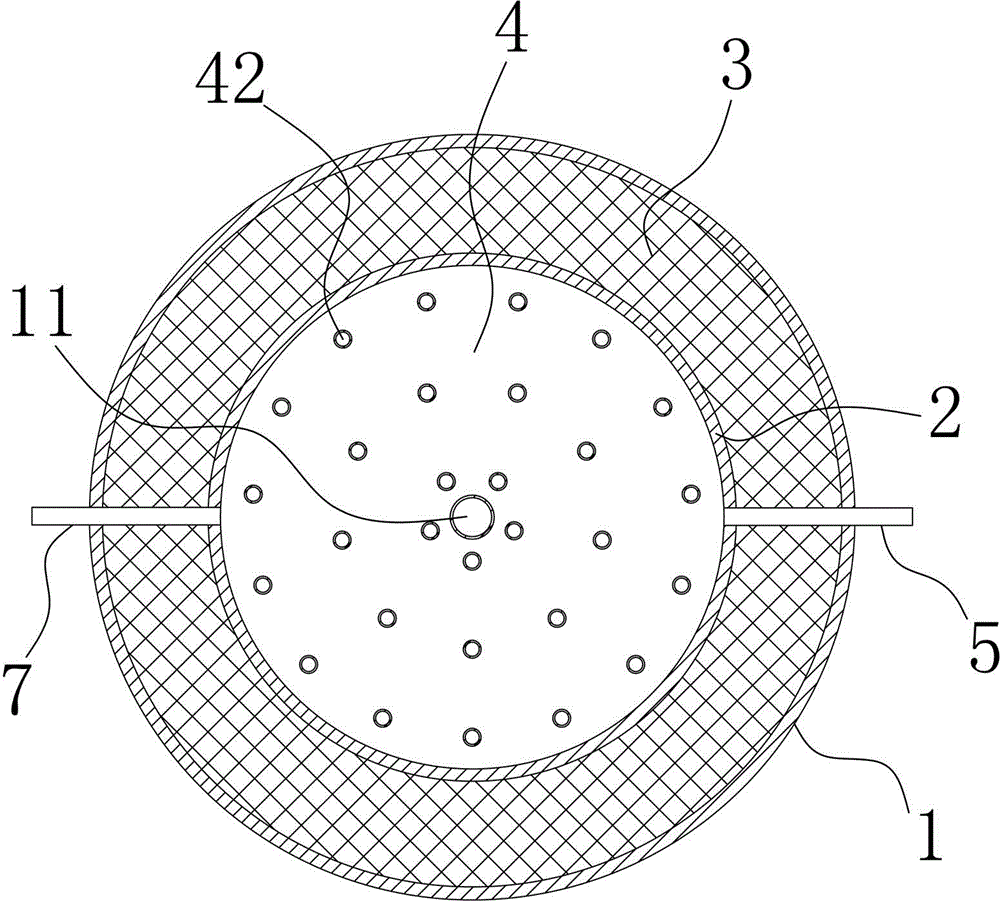

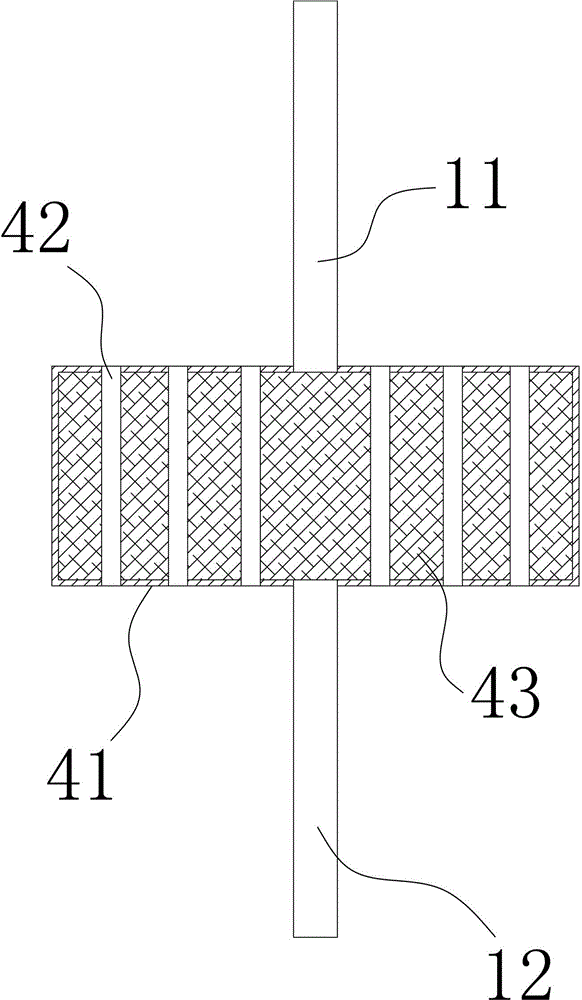

ActiveCN104359340AIncrease guarantee rateImprove heat collection efficiencySolar heat devicesHeat storage plantsRadiation lossCollector device

The invention relates to the technical field of an energy storage device and particularly relates to an energy storage device which is filled with phase change energy storage materials. The energy storage device comprises a water tank and an energy storage body arranged in the water tank, wherein the energy storage body comprises an energy storage box body which is fixedly connected with the inner wall of the water tank, a phase change material injection pipe, a phase change material leakage pipe, and a water passing pipe which is vertically arranged in the energy storage box body and is used for penetrating through the energy storage box body up and down; the energy storage box body is internally filled with phase change materials. The invention provides a heat accumulation device filled with the phase change materials; the phase change materials are used for storing solar energy and a water temperature is controlled in a certain range; not only are the requirements of heating water temperature met, but also the water supplying temperature is reduced; the heat radiation loss is reduced, the heat collection efficiency of a heat collector is improved and the heat accumulation amount is increased; the device is applied to combination use of a solar floor radiation heating system and the better effect can be obtained.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

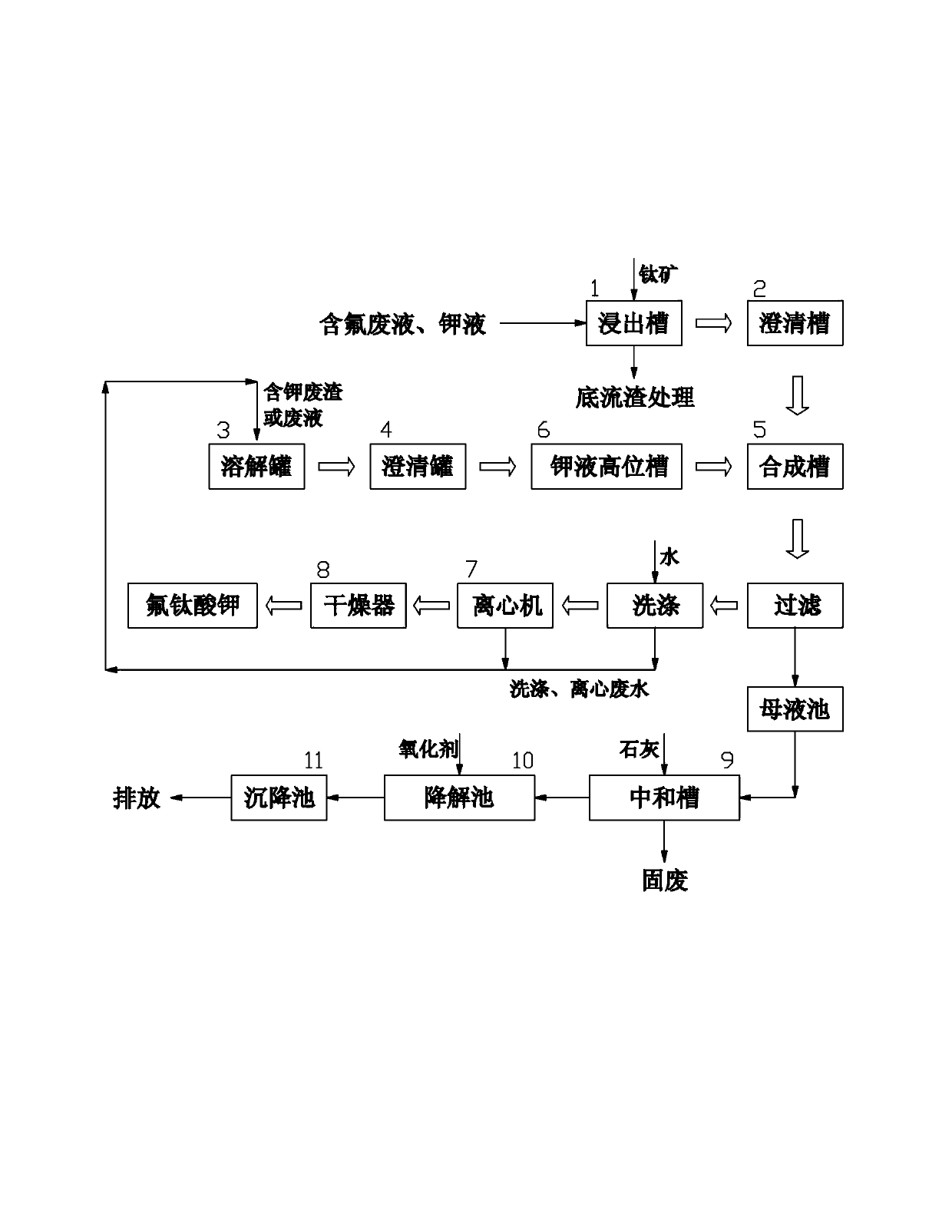

Process for producing potassium fluotitanate by environment-friendly treating fluorine-contained and potassium-contained waste

ActiveCN102897829ATake advantage ofReduce manufacturing costTitanium compoundsChemical oxygen demandSlag

The invention relates to a process for producing potassium fluotitanate by environment-friendly treating fluorine-contained and potassium-contained waste, and the process comprises the following steps of placing titanium ore with theoretical quantity into fluorine-contained waste liquid and potassium liquid to prepare potassium fluotitanate slurry; placing clear liquid after the potassium-containing slag or waste liquid is filtered into potassium fluotitanate clear liquor to prepare the potassium fluotitanate; carrying out liquid-solid separation, washing and drying of potassium fluotitanate slurry liquid, placing lime into the waste slag and the waste water to adjust the pH value, and filtering the waste slag and the waste water to obtain filter slag, placing the filter liquid into a degrading pond, adding oxidant, utilizing the ultraviolet light to radiate the filter liquid for 1 to 5h, and detecting chemical oxygen demand (COD) and analyzing F-. The fluorine-contained and potassium-contained waste is used for substituting the hydrogen fluoride and the imported potassium fluoride to produce the potassium fluotitanate, so that waste can be converted into treasure, the recycling rate of the fluorine, the titanium and the potassium is not different from the quality product raw material, fluorine and potassium are adequately utilized, the production cost of the potassium fluotitanate is reduced, and the problem of the environmental pollution caused by the fluorine-contained waste and the potassium-contained waste can be solved.

Owner:福建省漳平市九鼎氟化工有限公司

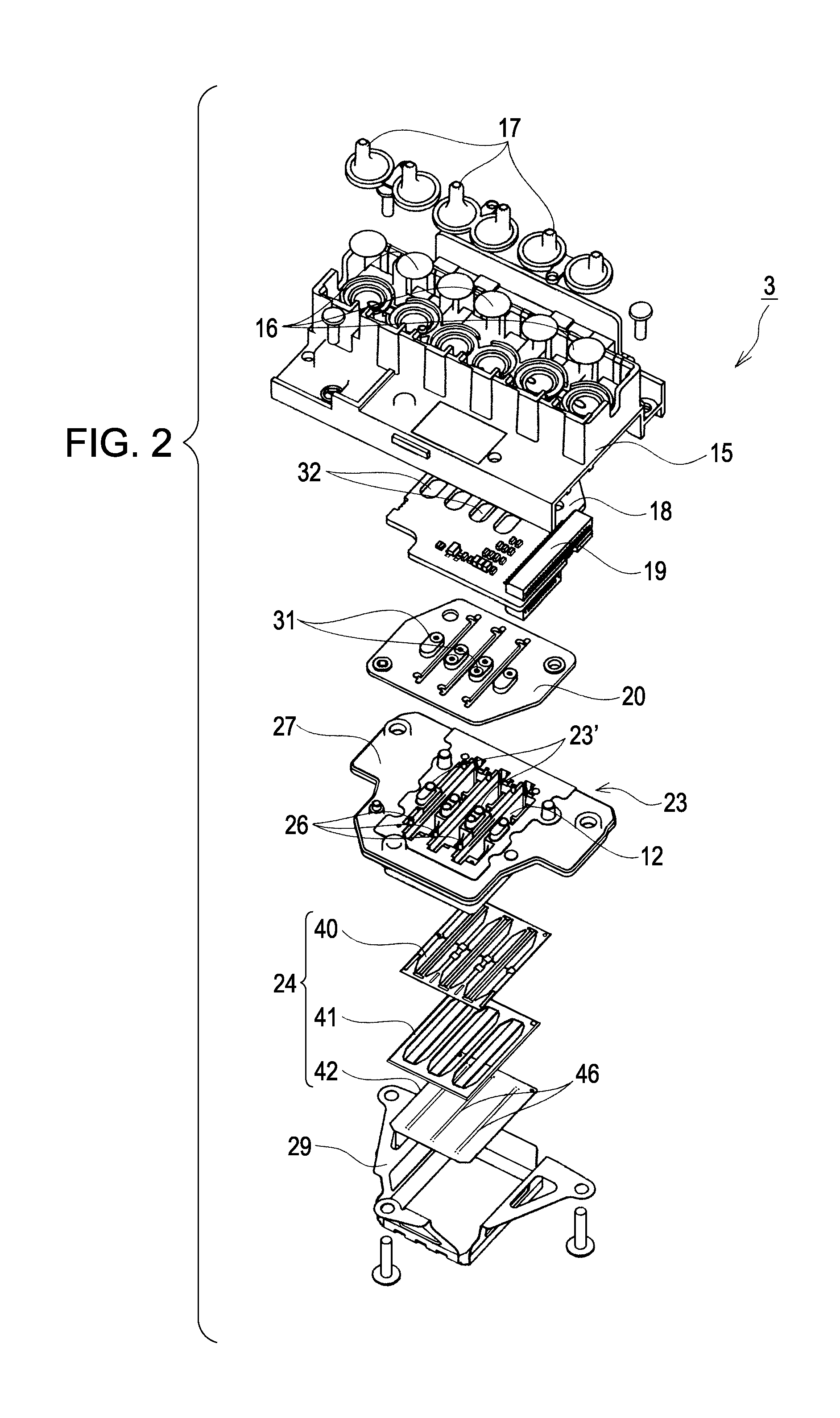

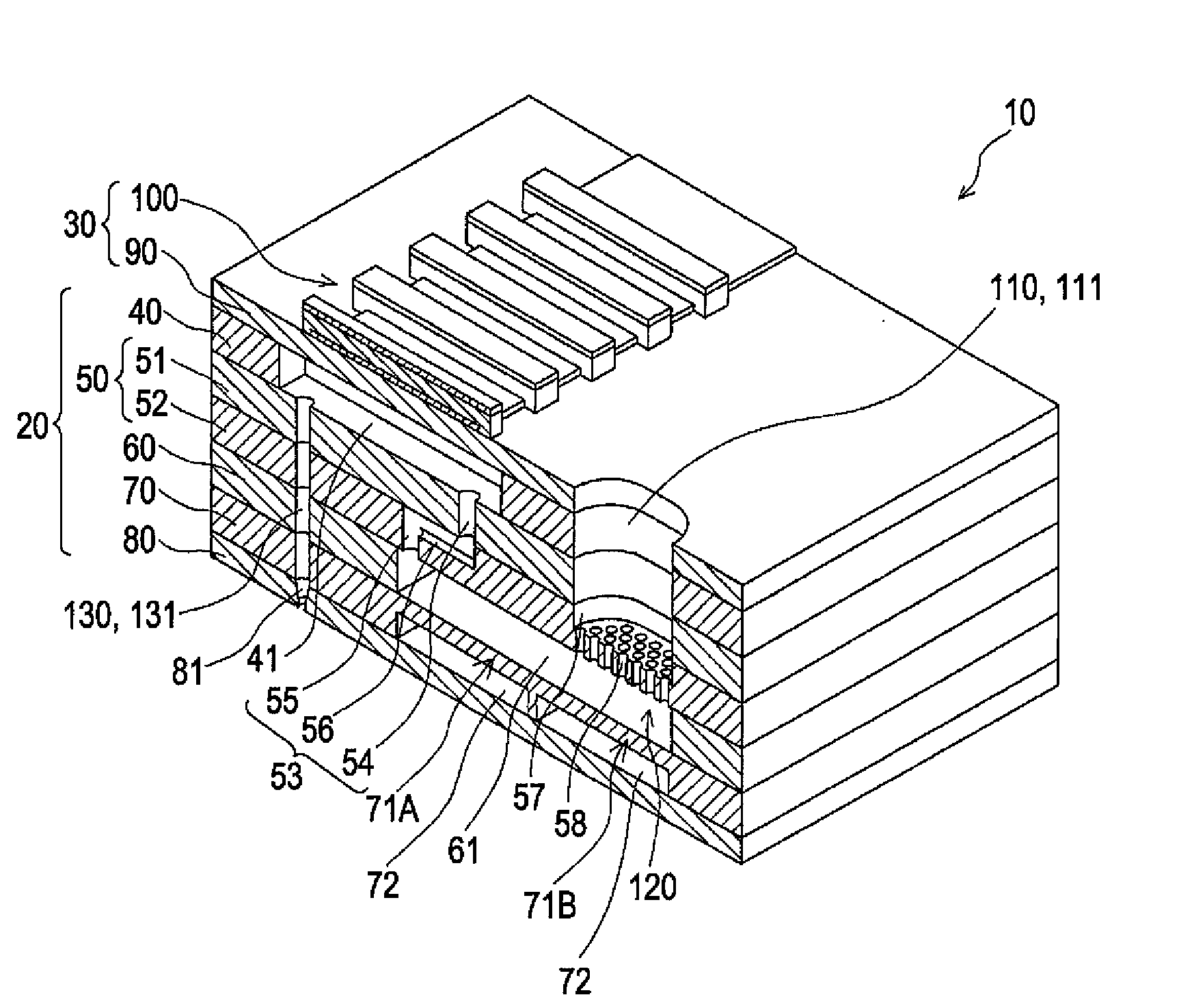

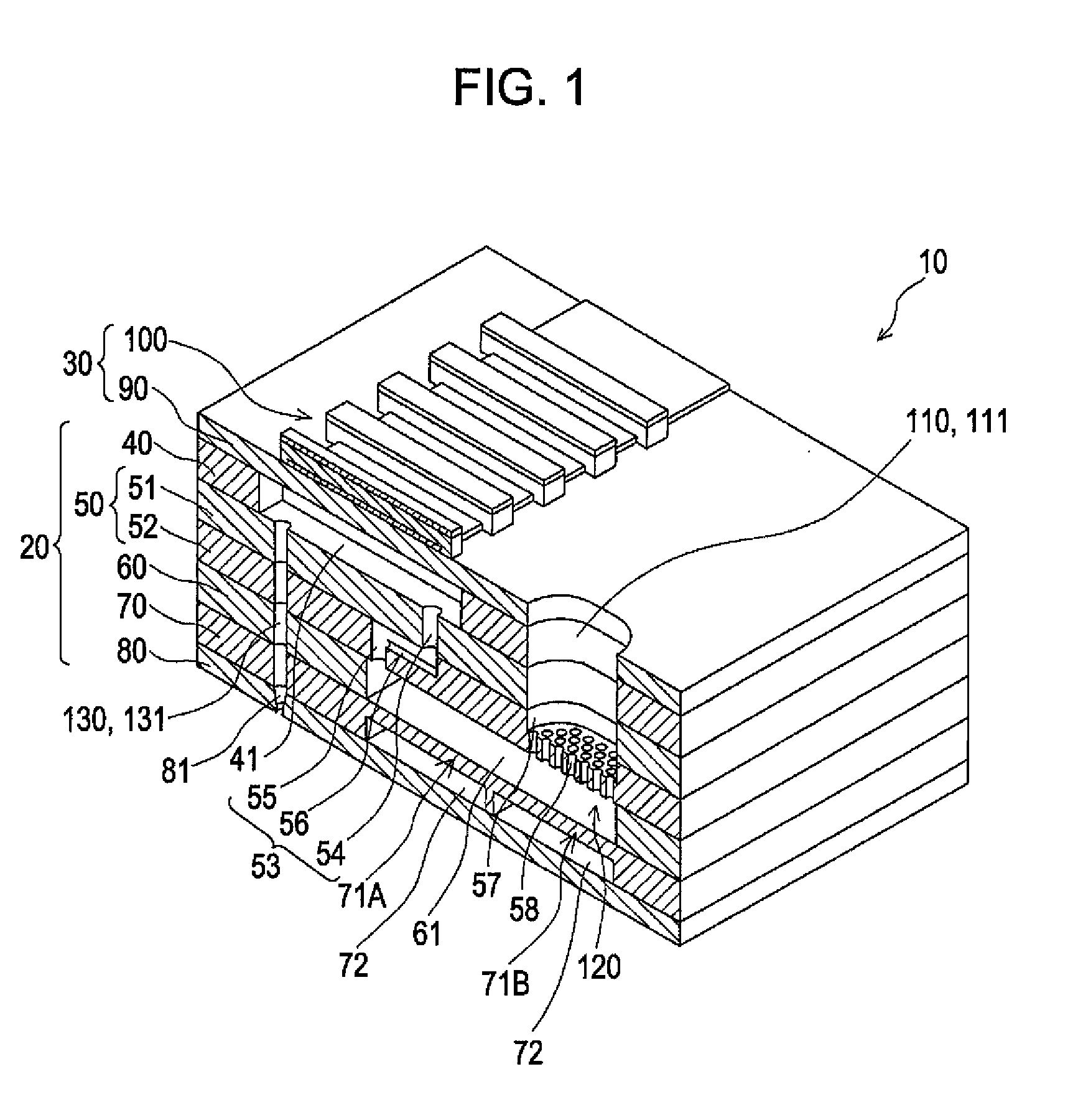

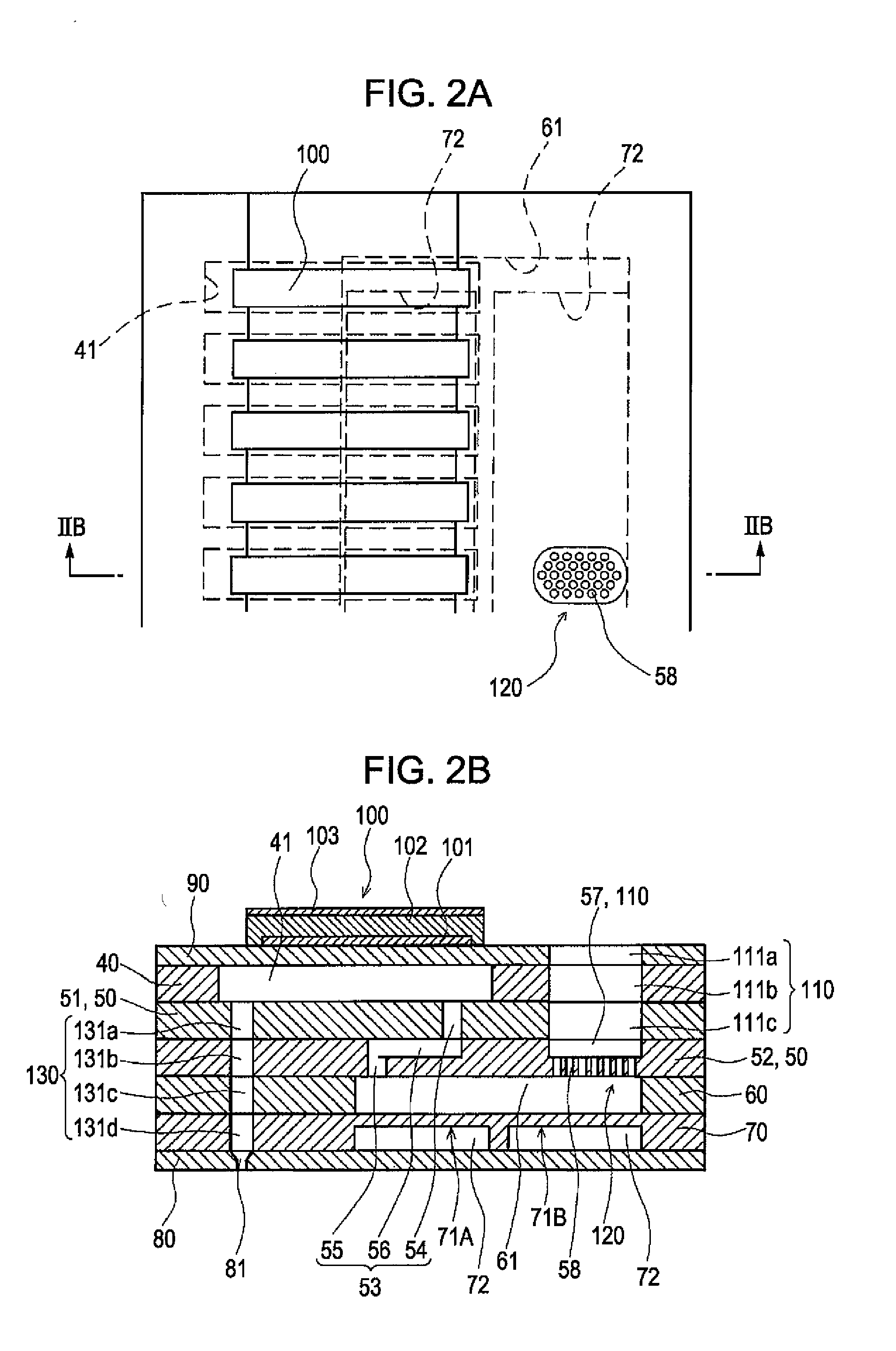

Liquid ejection head and liquid ejection apparatus

Owner:SEIKO EPSON CORP

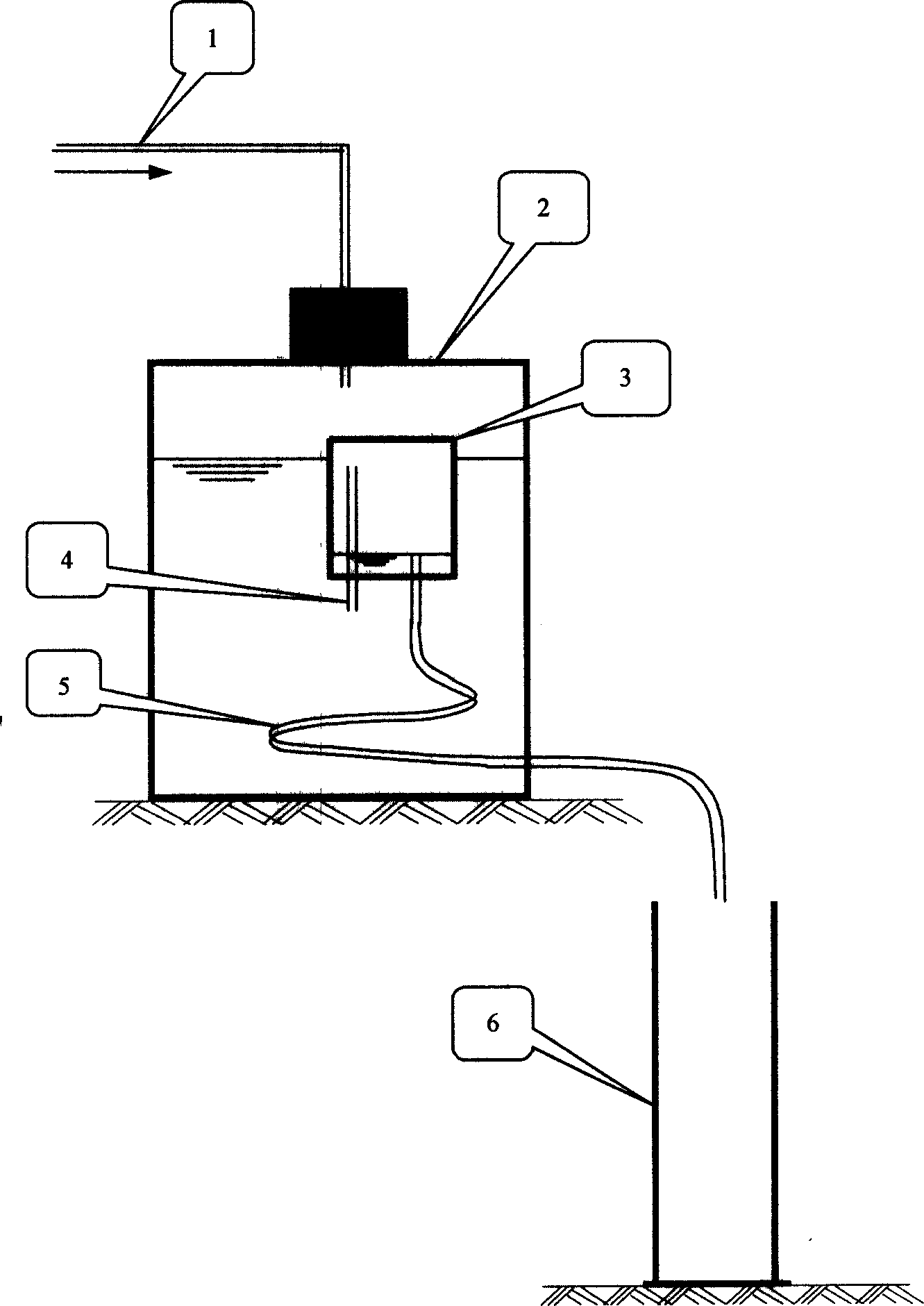

Constant presssure marsh gas measurer in testing anaerobic digestion

InactiveCN1563911AAvoid stressful changesImproving Biogas Measurement AccuracyVolume measurement apparatus/methodsBiogasPiping

The invention belongs to environmental engineering area. The measuring apparatus includes gas-collecting vessel. A biogas tube is connected to the gas-collecting vessel. A buoy is installed inside the gas-collecting vessel, and an aqueduct is connected inside the buoy. Outlet pipe in lower part of the buoy is connected to an outlet pipe outside the vessel. Then, the outlet pipe outside the vessel is connected to a measuring tank. Yield of biogas is measured indirectly from measuring water discharge. Comparing with drainage and gas collection method, the disclosed method keeps pressure stable in examination so as to raise measuring accuracy.

Owner:CHANGAN UNIV

Liquid Ejecting Head and Liquid Ejecting Apparatus

A liquid ejecting head includes: a supply channel member including a plurality of supply channel plates, and the supply channel including supply holes provided through the respective supply channel plates and a supply groove formed by removing part of one of adjacent supply channel plates in terms of the direction of thickness thereof for communicating the respective supply holes; a pressure generating element that provides a pressure to the pressure generating chamber; a supply communication channel that connects a storage unit having the liquid stored therein and a reservoir, the supply communication channel being formed through a pressure chamber plate and the supply channel member in the direction of thickness thereof, the supply channel plates having the supply groove being formed with a recess having the substantially same depth as the supply groove at an area corresponding to the supply communication channel; and a filter unit having a plurality of filter holes provided on the bottom of the recess.

Owner:SEIKO EPSON CORP

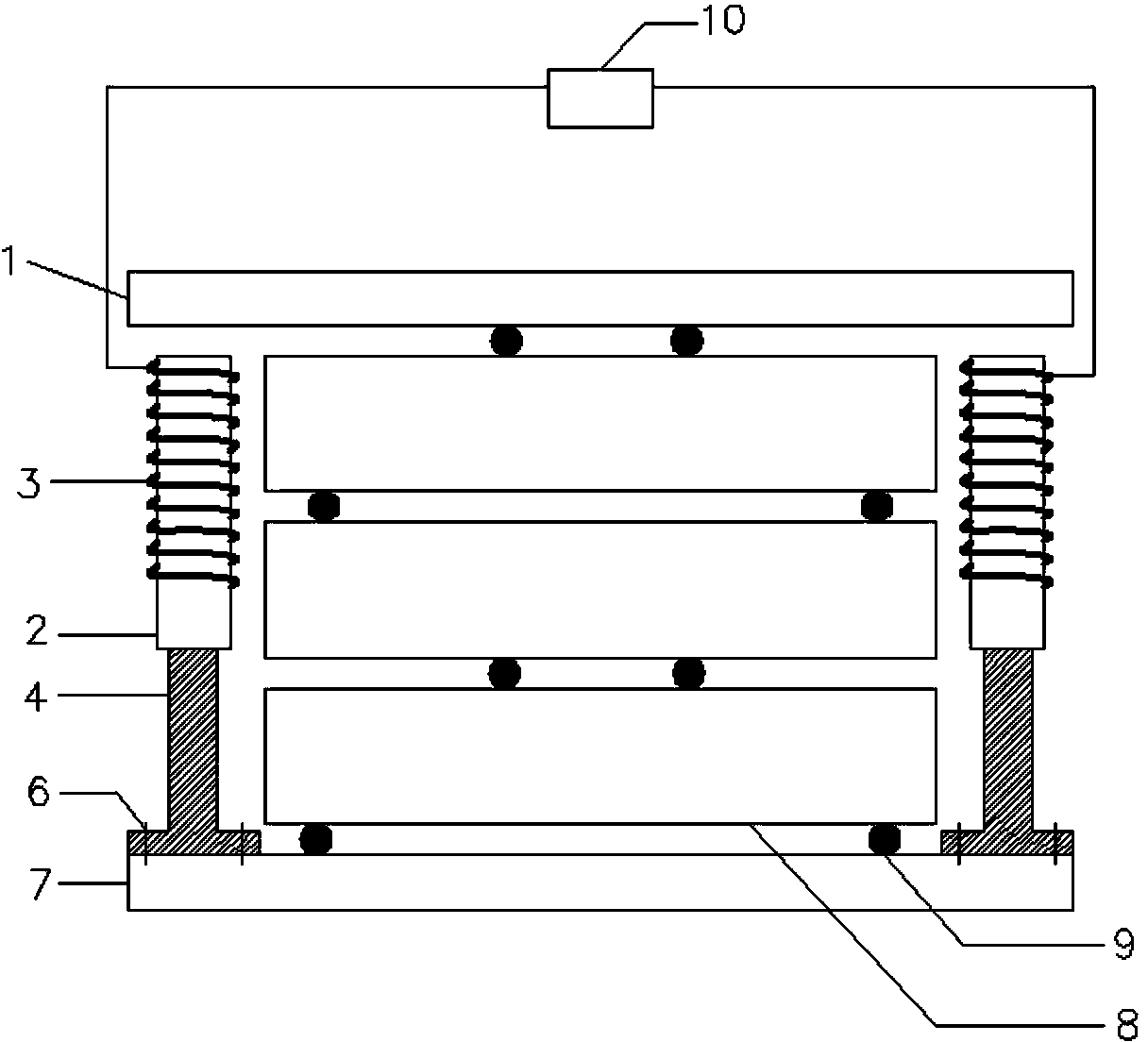

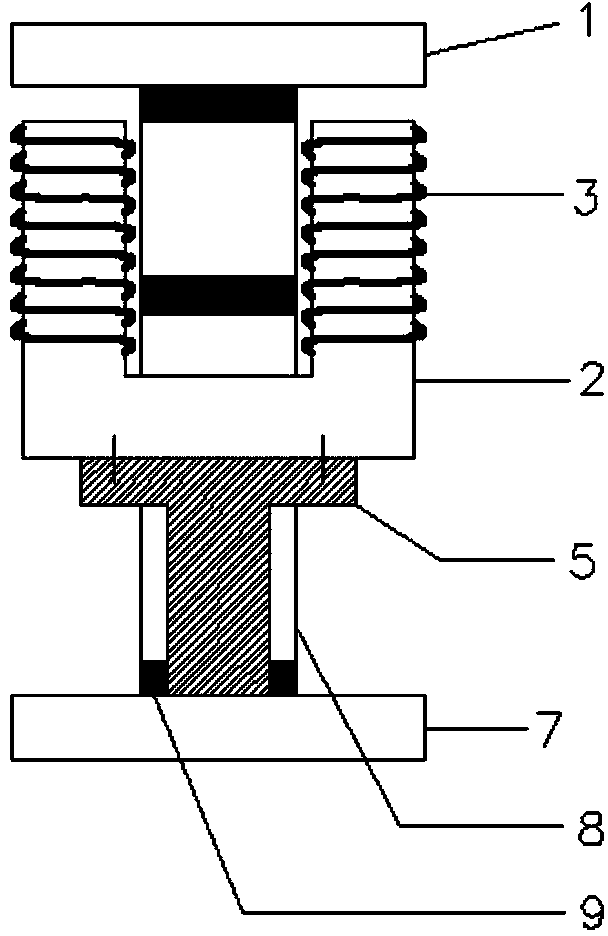

Electromagnetic loading device for concrete durability test

InactiveCN103592176ASmall footprintRealize durability testStrength propertiesStress relaxationDirect current

The invention discloses an electromagnetic loading device for a concrete durability test. The electromagnetic loading device comprises an upper pressing plate, direct-current coils, two iron cores, iron core brackets, upper bolts, lower bolts, a lower pressing plate, concrete test pieces, cushion rods and a direct-current power supply, wherein the concrete test piece is arranged between the upper pressing plate and the lower pressing plate; the cushion rods are arranged between the upper pressing plate and each concrete test piece, between the concrete test pieces and between the concrete test piece and the lower pressing plate; the iron core brackets are arranged on the two sides of the concrete test piece respectively; the lower parts of the iron core brackets are fixed to the lower pressing plate through the lower bolts; the upper parts of the iron core brackets are connected with the iron cores through the upper bolts; the two iron cores are wound with the direct-current coils respectively; the direct-current coils are connected with the direct-current power supply. The electromagnetic loading device is suitable for the durability test of a concrete material under the coupling effect of load and corrosion environment factors, and can be used for achieving accurate load application and keeping non stress relaxation in a long-term loading process.

Owner:NANJING UNIV OF TECH

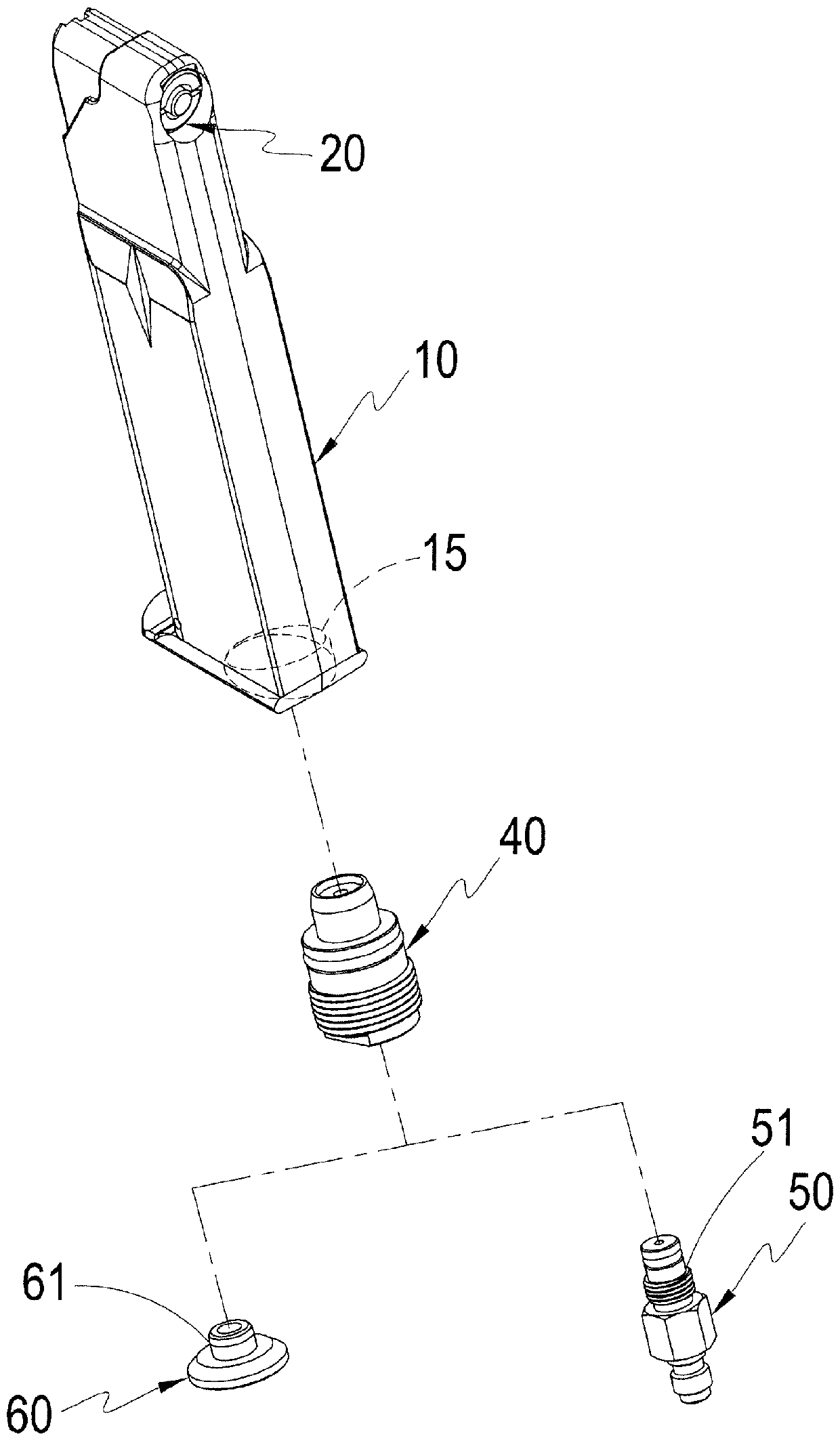

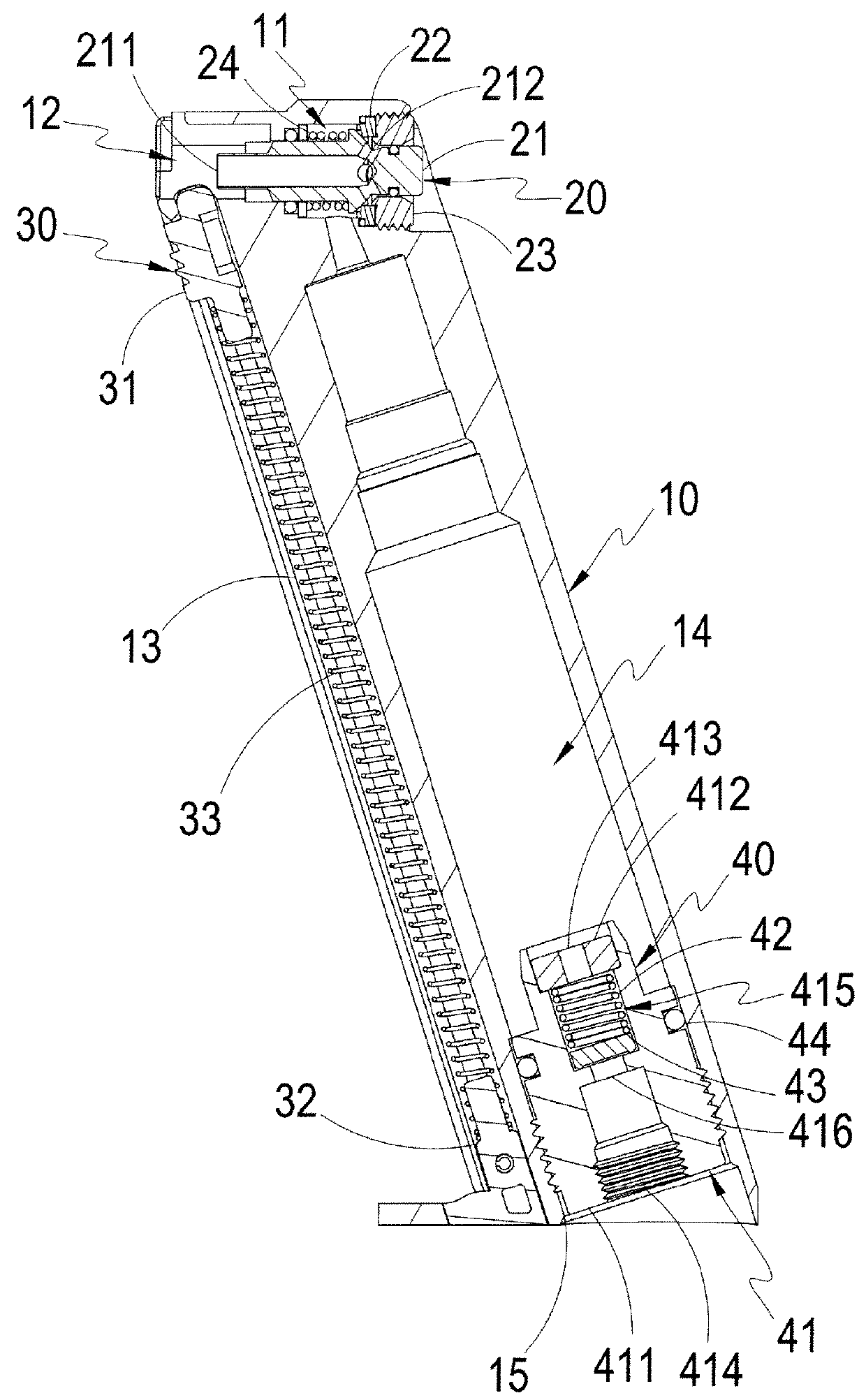

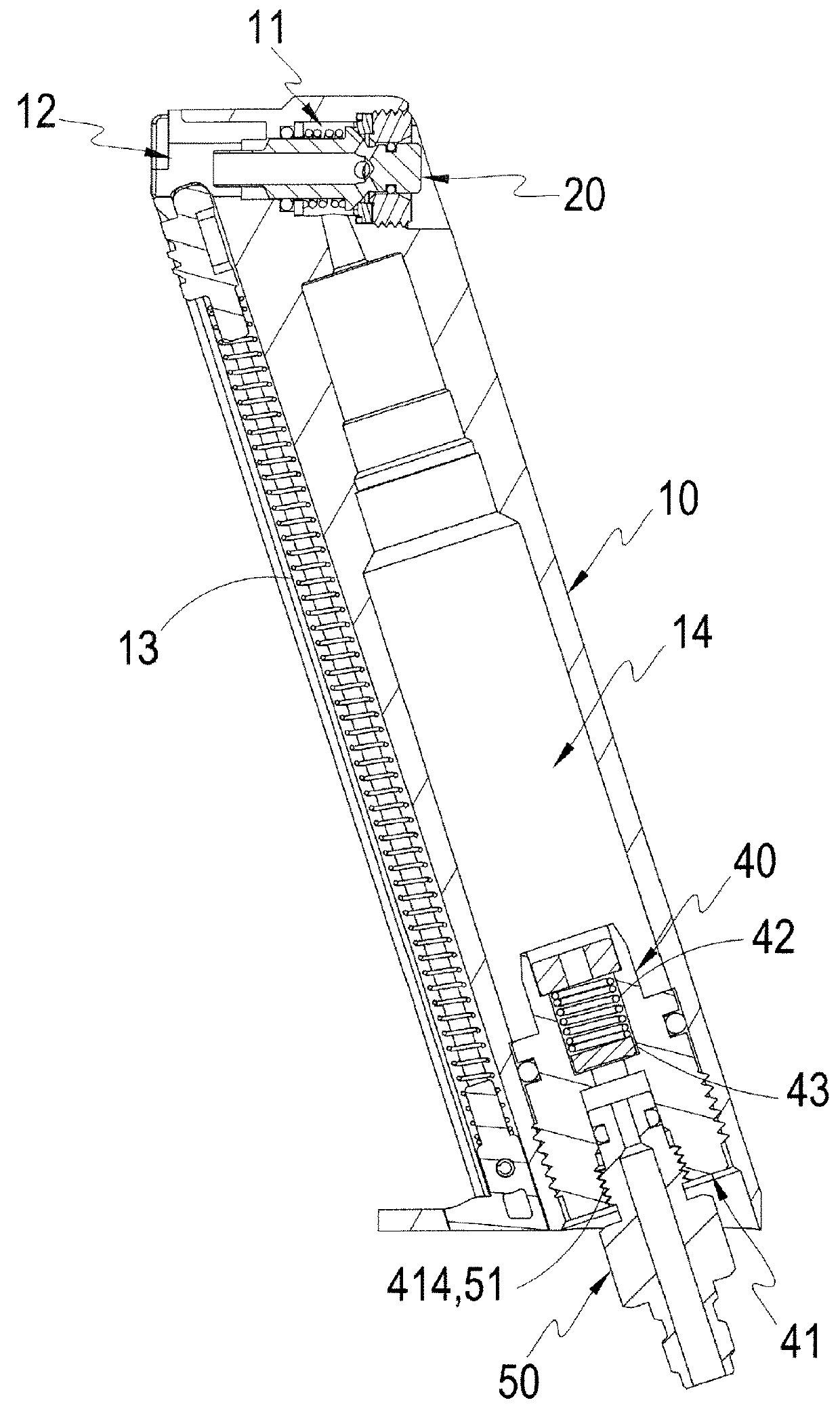

Toy gun magazine module

InactiveUS20180164069A1Convenient and portable for useReduce weightCompressed gas gunsEngineeringHigh pressure

A toy gun magazine module includes a magazine body having a gas storage space, gas inlet in communication with the gas storage space and check valve set configured on the gas inlet; the check valve set allows the gas inlet to be in normally closed state, and may be acted to open to allow the unidirectional input of high pressure gas in gas storage space to provide firing power. When the input of the high pressure gas is stopped, the check valve set is closed, preventing the high pressure gas from flowing reversely to leak out, thereby allowing the direct gas filling and repeated use of the present invention.

Owner:KIEN WELL TOY IND

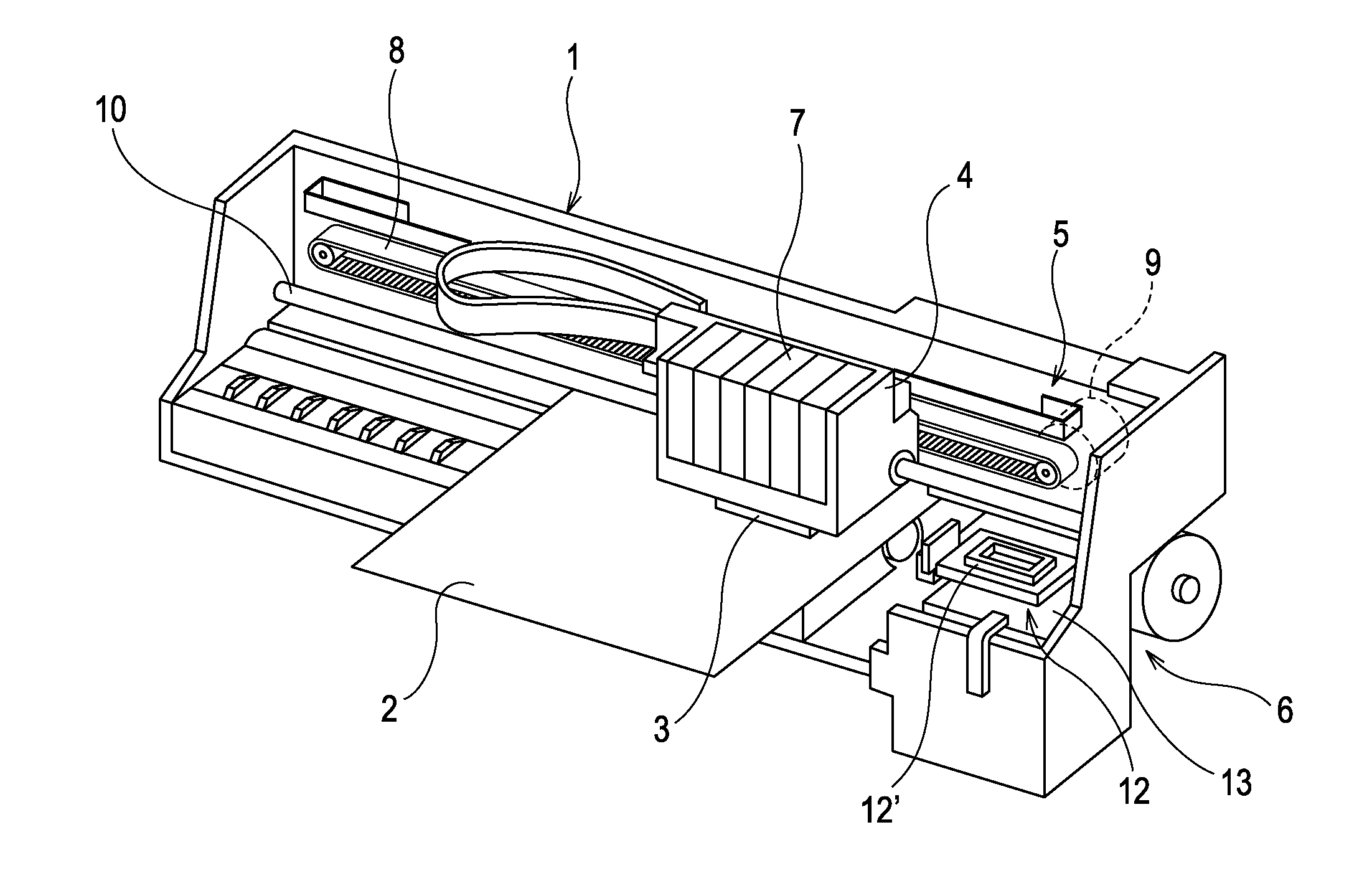

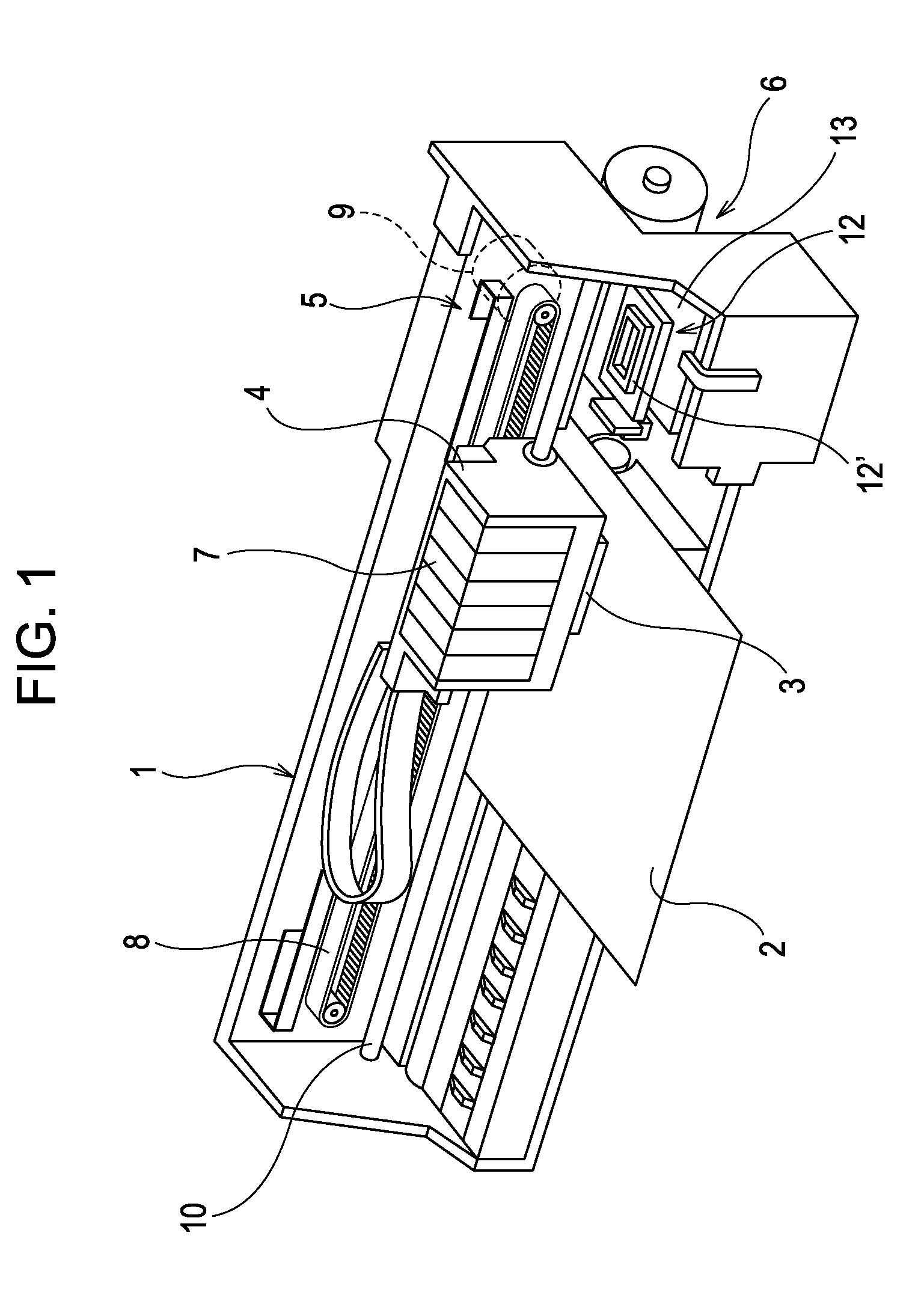

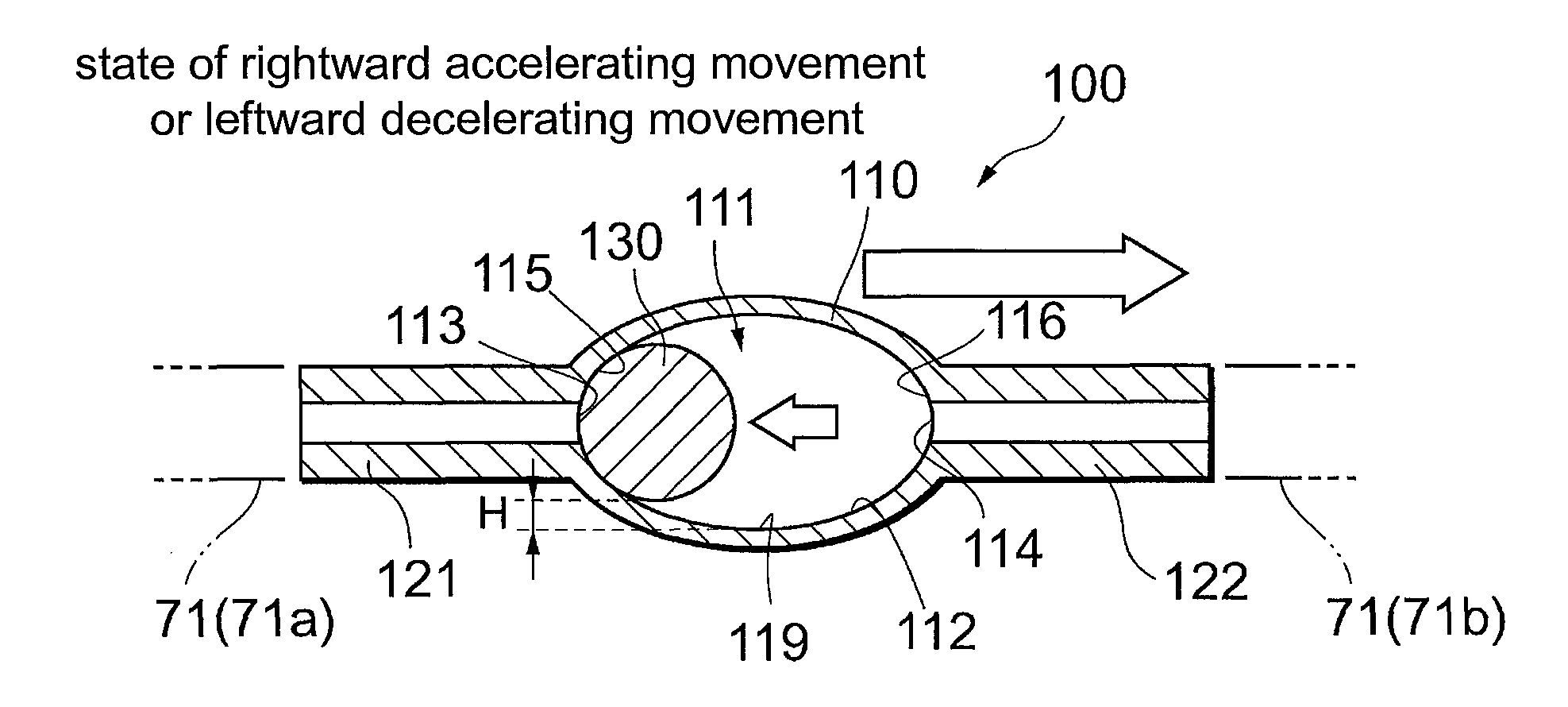

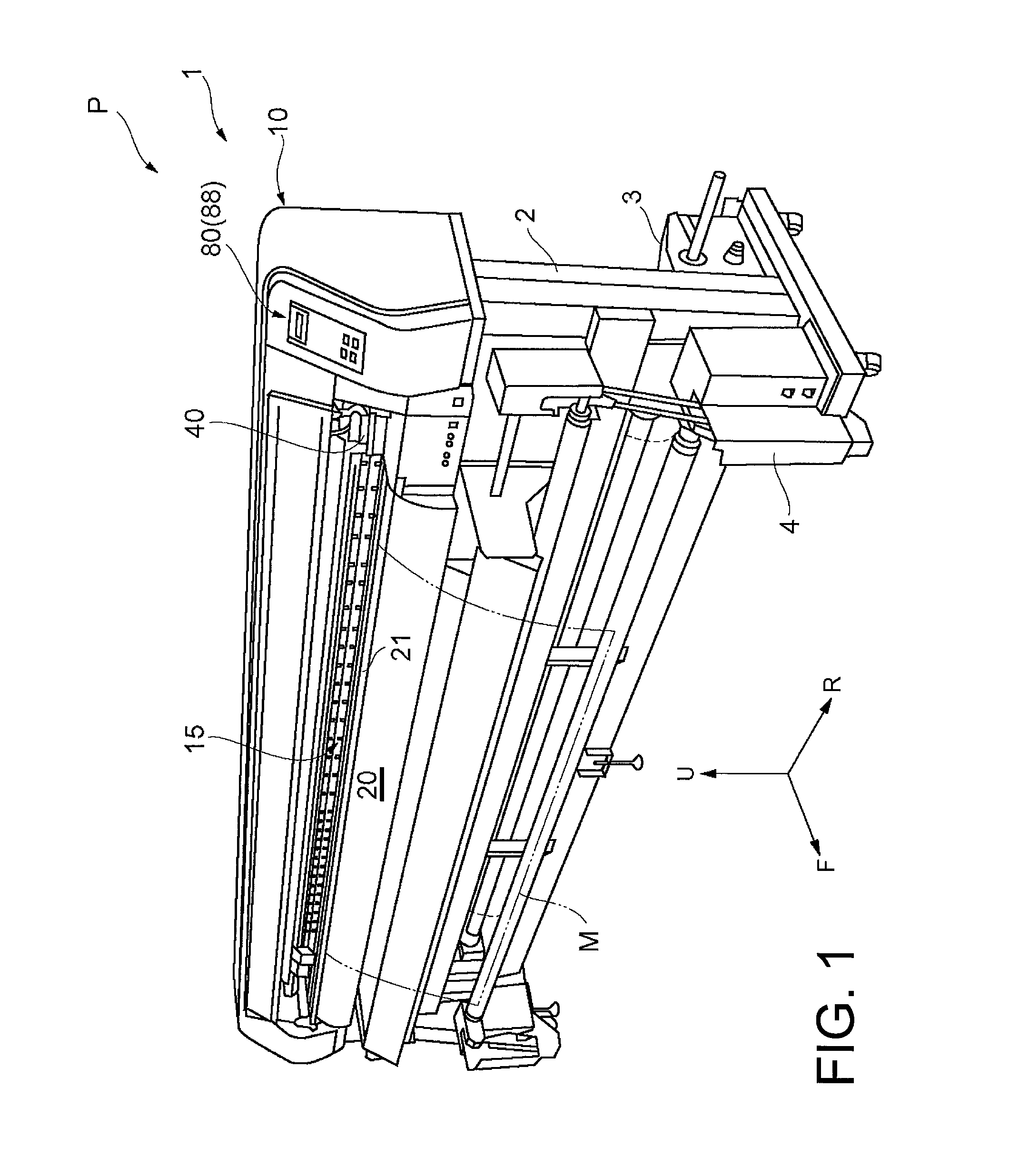

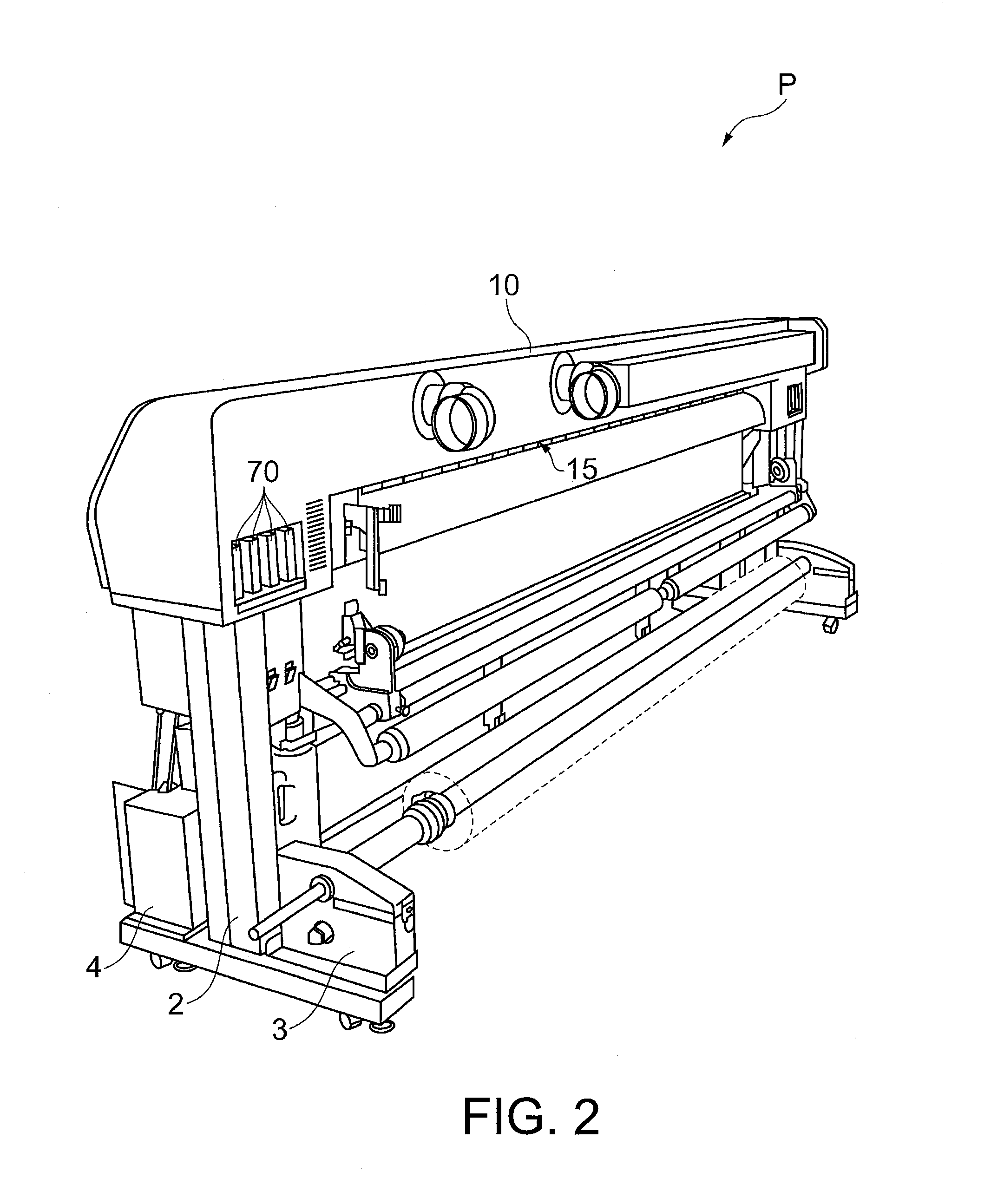

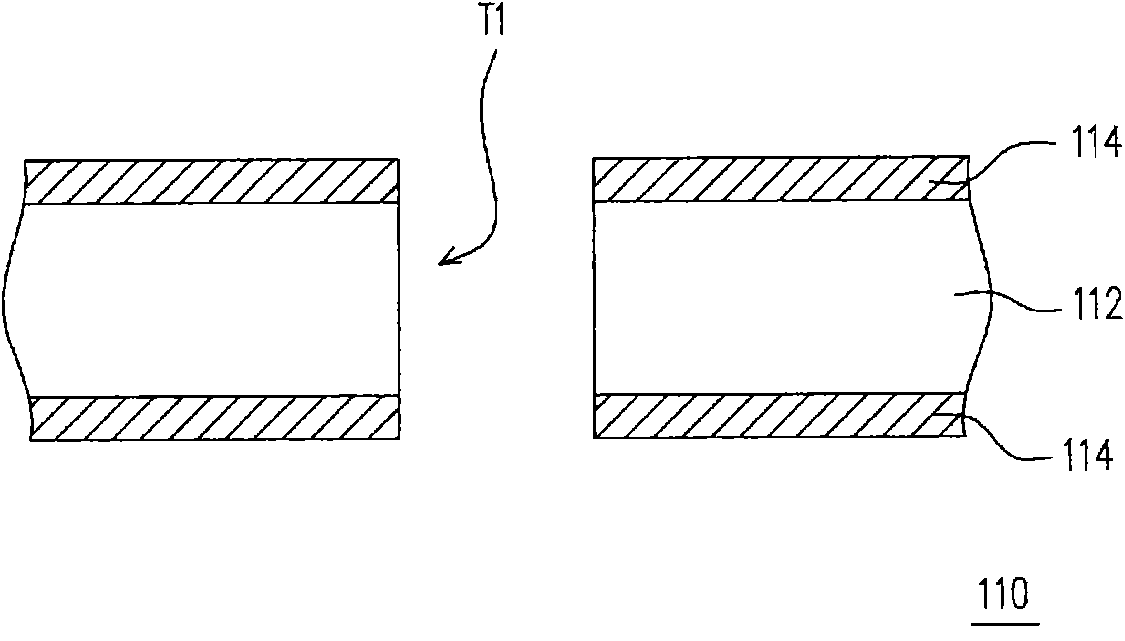

Damper apparatus, damper tube assembly, and ink jet printer

InactiveUS8708472B2Avoid stress changesReduce component countOther printing apparatusInk printerEngineering

The invention provides a damper apparatus including a housing having a valve chamber and reciprocally moving integrally with a carriage, an inlet port communicating an ink flow channel on the upstream side and the valve chamber, an outlet port communicating the ink flow channel on the downstream side and the valve chamber, and a spherical valve body stored so as to be movable in the valve chamber, wherein the valve body moves relatively to a position for closing the inlet port or the outlet port upon reception of the inertial force in association with the acceleration and deceleration to close the ink flow channel when the carriage is accelerated or decelerated, and the valve body moves relatively to a position for opening the inlet port and the outlet port under its own weight to open the ink flow channel when the carriage is not accelerated and decelerated.

Owner:MIMAKI ENG

Circuit board and manufacture method thereof

ActiveCN101600307AReduce thicknessImprove yieldElectrical connection printed elementsMultilayer circuit manufactureInsulation layerEngineering

The invention relates to a manufacture method of a circuit board. The manufacture method comprises the following steps: firstly, providing a basal board comprising two conductive layers and an insulation layer arranged between the conductive layers; then, forming a hydrophobic film on one conductive layer; forming a hole extending form one conductive layer to the other conductive layer; forming a conductive connecting structure in the hole and connecting the conductive connecting structure between the conductive layers; removing the hydrophobic film after forming the conductive connecting structure; and finally, patterning the conductive layers to form two line layers.

Owner:UNIMICRON TECH CORP

Gas-Dissolving Device and Gas-Dissolving Method

ActiveUS20170065940A1Easily attached to water serverSuppress mutationFlow mixersTransportation and packagingPressure reductionDissolved hydrogen

Provided is a gas dissolving device capable of dissolving gas in a liquid in a supersaturated state and maintaining such a saturated state in a stable manner, and being easily attached to a water server or the like.The gas dissolving device generates hydrogen water by dissolving hydrogen in water, and discharges the hydrogen water from an outlet. The gas dissolving device includes a dissolving chamber that stores under pressure generated hydrogen water introduced therein, and pressure reduction and transfer means for preventing pressure variation in a tube-shaped passage that connects the dissolving tank and the outlet due to an action of discharging the hydrogen water from the outlet, and for forming a laminar flow.

Owner:HIKARIMIRAI

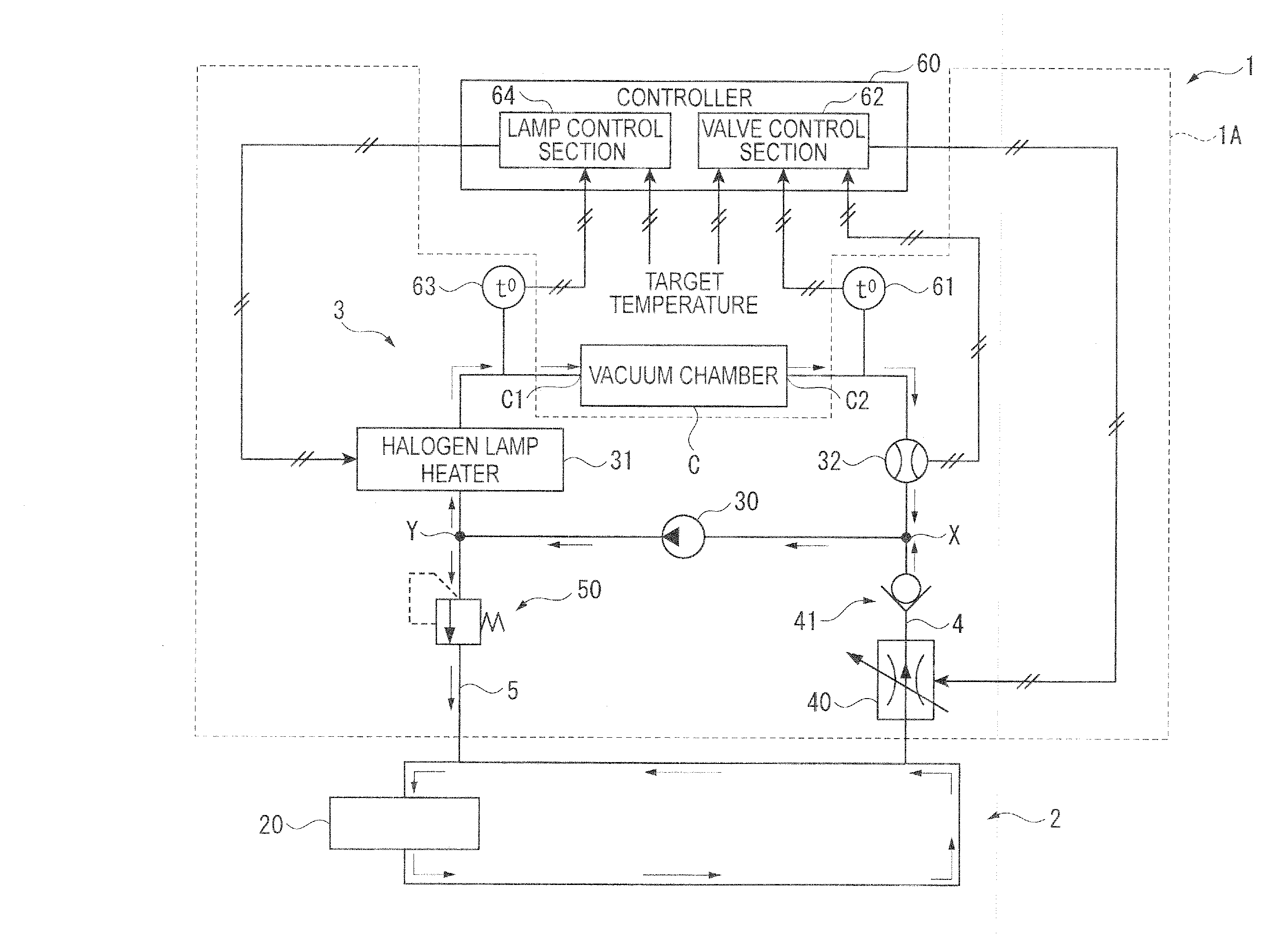

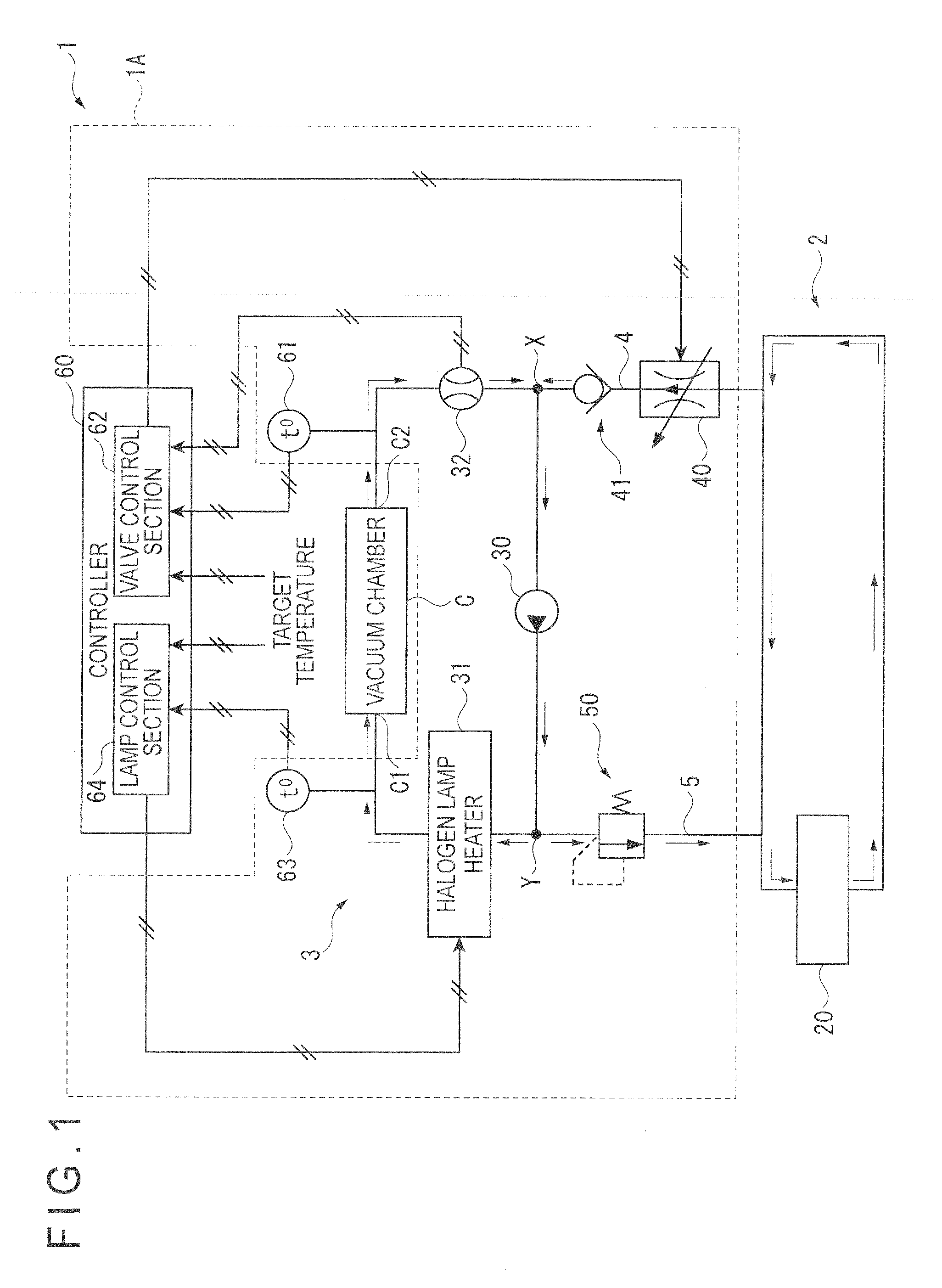

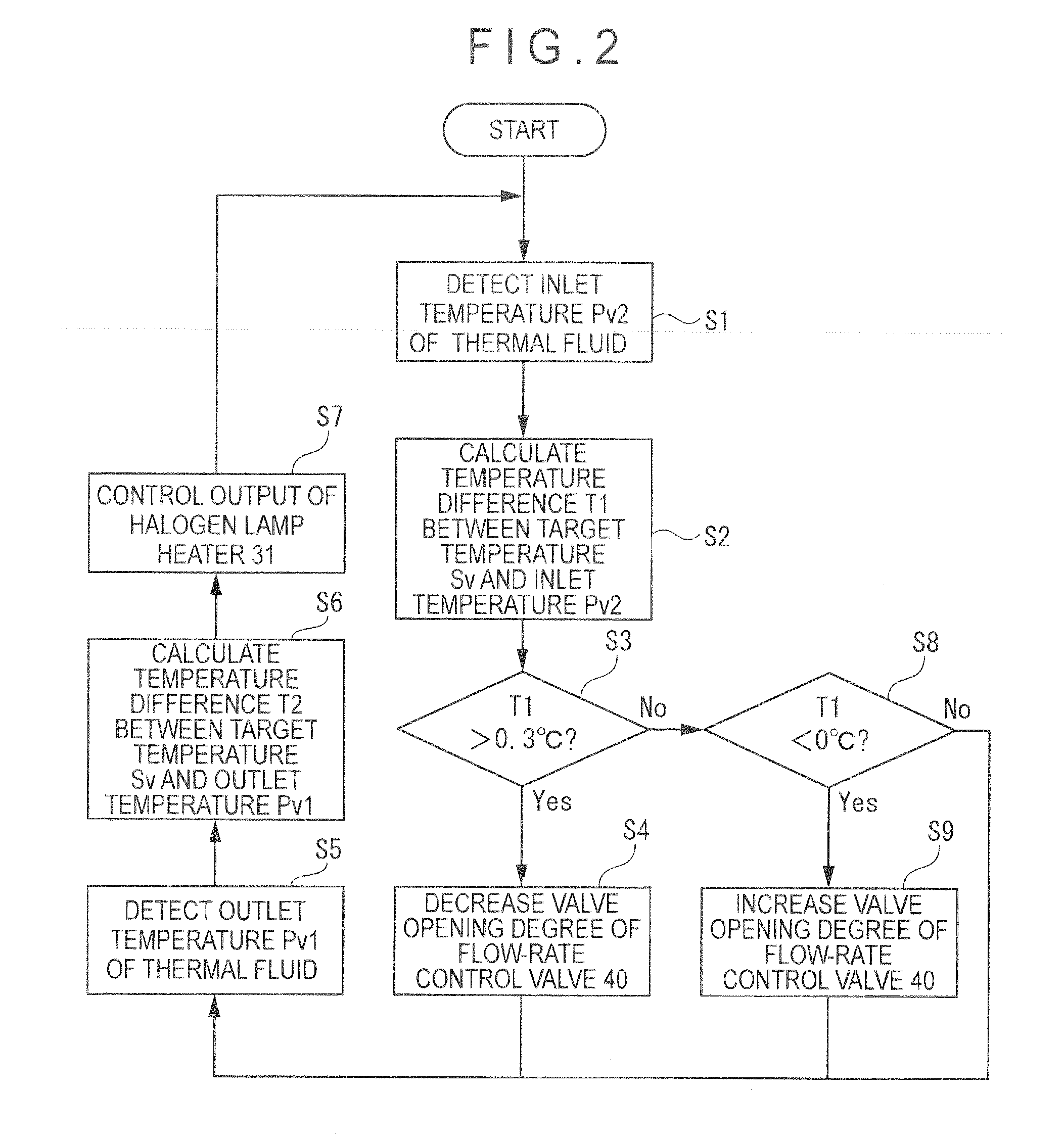

Temperature controller, fluid circulator and temperature control method using temperature controller

InactiveUS20110277983A1Reducible in manufacturing costSave energyValve members for heating/coolingTemperatue controlTemperature controlEngineering

A temperature controller includes: a closed first circulation circuit having a fluid cooler; a closed second circulation circuit having a halogen lamp heater as a fluid heater and feeding a thermal fluid heated by the halogen lamp heater to a vacuum chamber as an object to be temperature-controlled; a feed path that feeds the thermal fluid from the first circulation circuit to the second circulation circuit; and a discharge path that discharges the thermal fluid from the second circulation circuit and returns the thermal fluid to the first circulation circuit. A flow-rate control valve that adjusts and controls a feed flow-rate of the thermal fluid from the first circulation circuit is provided in the feed path. A pressure control valve that compensates a pressure of the thermal fluid at a predetermined pressure level or less is provided in the discharge path.

Owner:KELK LTD

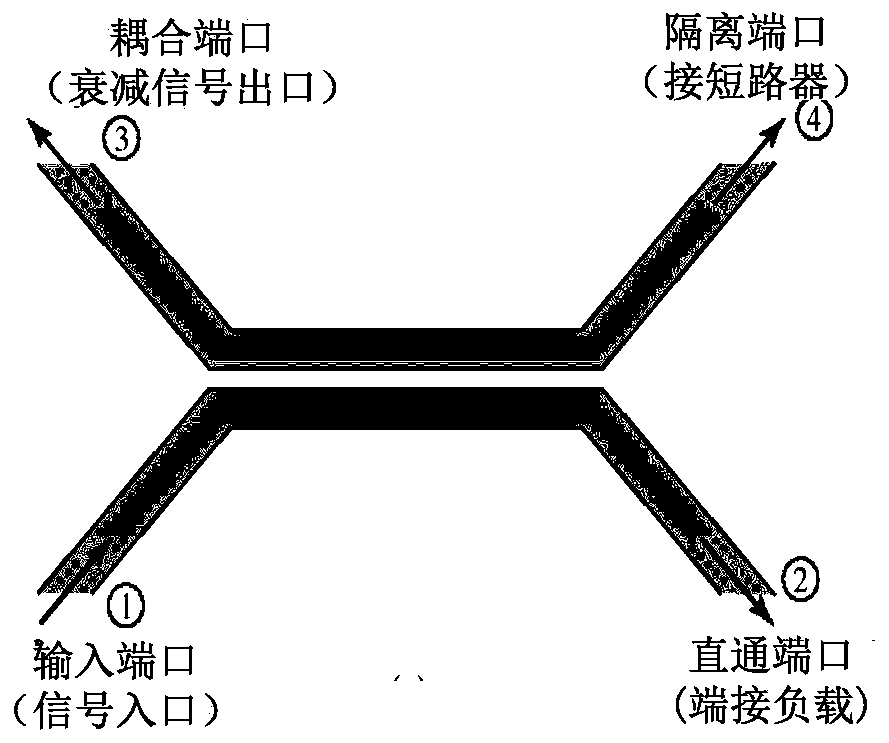

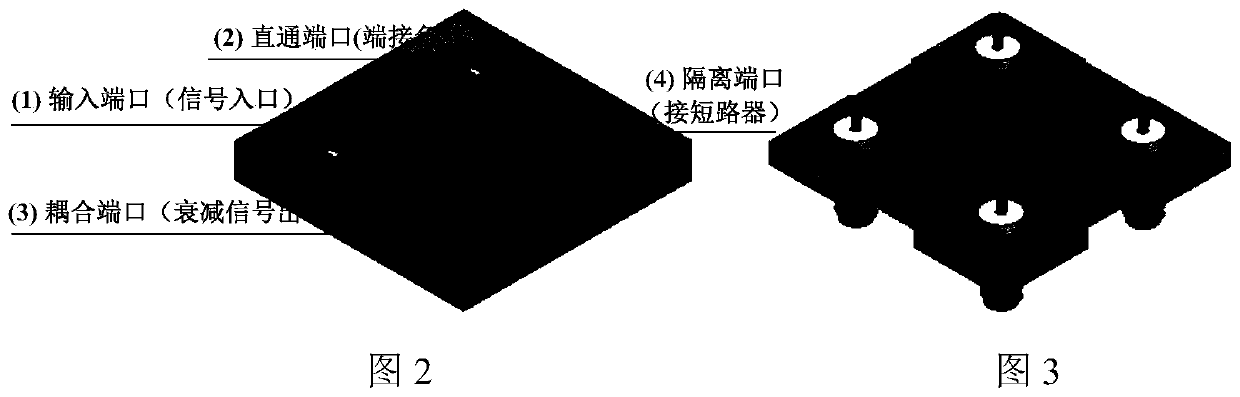

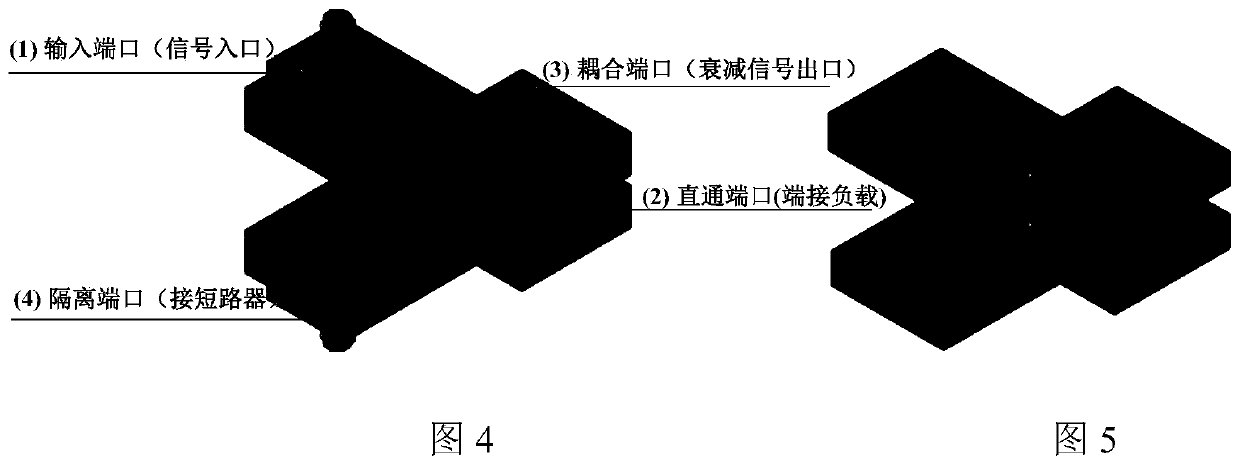

Low-noise attenuator based on microwave directional coupler

ActiveCN110197942AReduce thermal noiseImprove electrical performanceCoupling devicesUltrasound attenuationLow noise

The invention provides a low-noise attenuator based on a microwave directional coupler. The low-noise attenuator based on the microwave directional coupler adopts a four-port microwave directional coupler as a low-noise attenuator. The four-port microwave directional coupler is made of a low-temperature superconducting metal material; the four-port microwave directional coupler is provided with amicrowave signal input port, a microwave signal straight-through port, a microwave signal coupling port and a microwave signal isolation port; the microwave signal straight-through port is connected with a microwave matching load; the microwave signal isolation port is short-circuit, so that most of the signals coupled to the microwave signal isolation port from the microwave signal input port areshort-circuit to the microwave signal coupling port, and the rest of the signals return to the microwave signal input port and the microwave signal straight-through port; the amplitude of the microwave signal input port coupled to the microwave signal coupling port meets the set microwave signal attenuation requirement; the low noise attenuator is placed in a low temperature environment of a K level. The low-noise attenuator based on a microwave directional coupler can only generate thermal noise equivalent to that generated by the attenuator under the extremely low temperature condition onlyby a low temperature environment without the extremely low temperature condition.

Owner:CHINA ELECTRONICS TECH GRP NO 39 RES INST

Dual-roll rolling machine hydraulic pressing down system and operation method thereof

InactiveCN103111471AGood pressure retentionReduce consumptionRoll force/gap control deviceSystem pressureThrottle

The invention relates to a dual-roll rolling machine hydraulic pressing down system and an operation method thereof and belongs to the technical field of hydraulic system pressurizing. The system comprises two symmetrical oil circuits. Each oil circuit comprises a plunger pump, a pressing down oil cylinder, an electromagnetic overflow valve, a one-way valve, a filter, an energy accumulator, an electromagnetic ball valve, a throttling valve, a first one-way throttling valve, a pressure sensor and the like. Due to the fact that the one-way valve, a hydraulic one-way valve and the electromagnetic ball valve in the work circuit of the hydraulic pressing down system is good in pressurizing performance and the energy accumulator can supplement system pressure, the system is long in pressurizing time, stable in pressure and reliable in pressurizing. In the mean time, a plunger stops during pressurizing, up and down waving of pressure during operation is eliminated completely, plate shape quality is improved greatly, and power consumption during production is saved.

Owner:浙江远景铝业有限公司

Apparatus for pressure sensing

InactiveUS20100069785A1Difference in pressureReduce differential pressureForce measurementDiagnostic recording/measuringInterior spaceGrating

The present invention provides an apparatus for pressure sensing. The apparatus comprises a series of Bragg gratings and a light guide incorporating the series of Bragg gratings. The apparatus also comprises a plurality of moveable wall portions having opposite first and second sides. Each moveable wall portion is positioned so that a change in pressure at one of the sides relative to a pressure at the other side will move the moveable wall portion that is coupled to respective Bragg gratings so that the movement of one of the moveable wall portion causes a force on the respective Bragg grating resulting in a change in strain of the respective Bragg grating. An internal space at each Bragg grating is in fluidal communication with an internal space at an adjacent Bragg grating whereby pressure differences between adjacent internal spaces are reduced.

Owner:COMMONWEALTH SCI & IND RES ORG

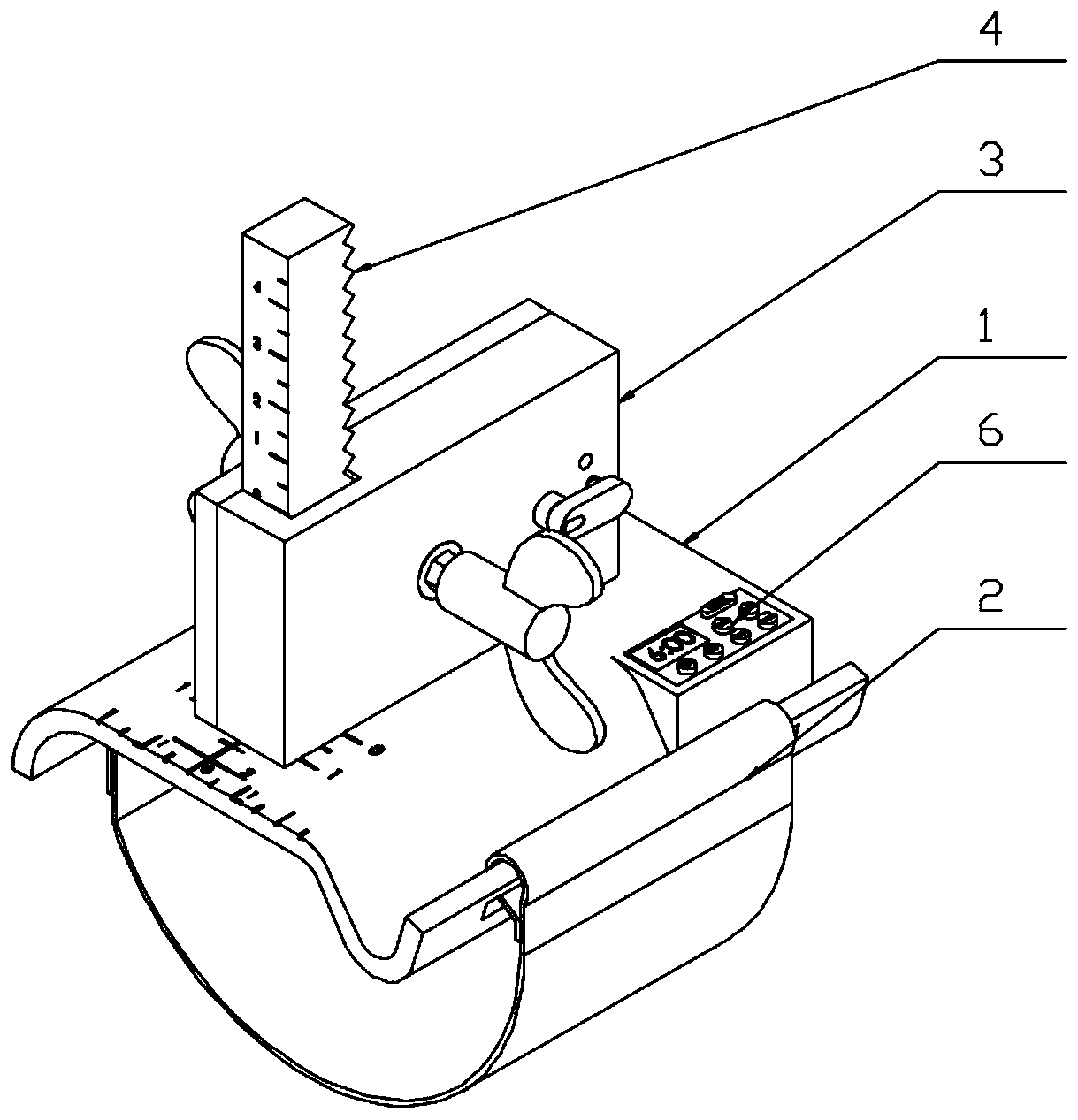

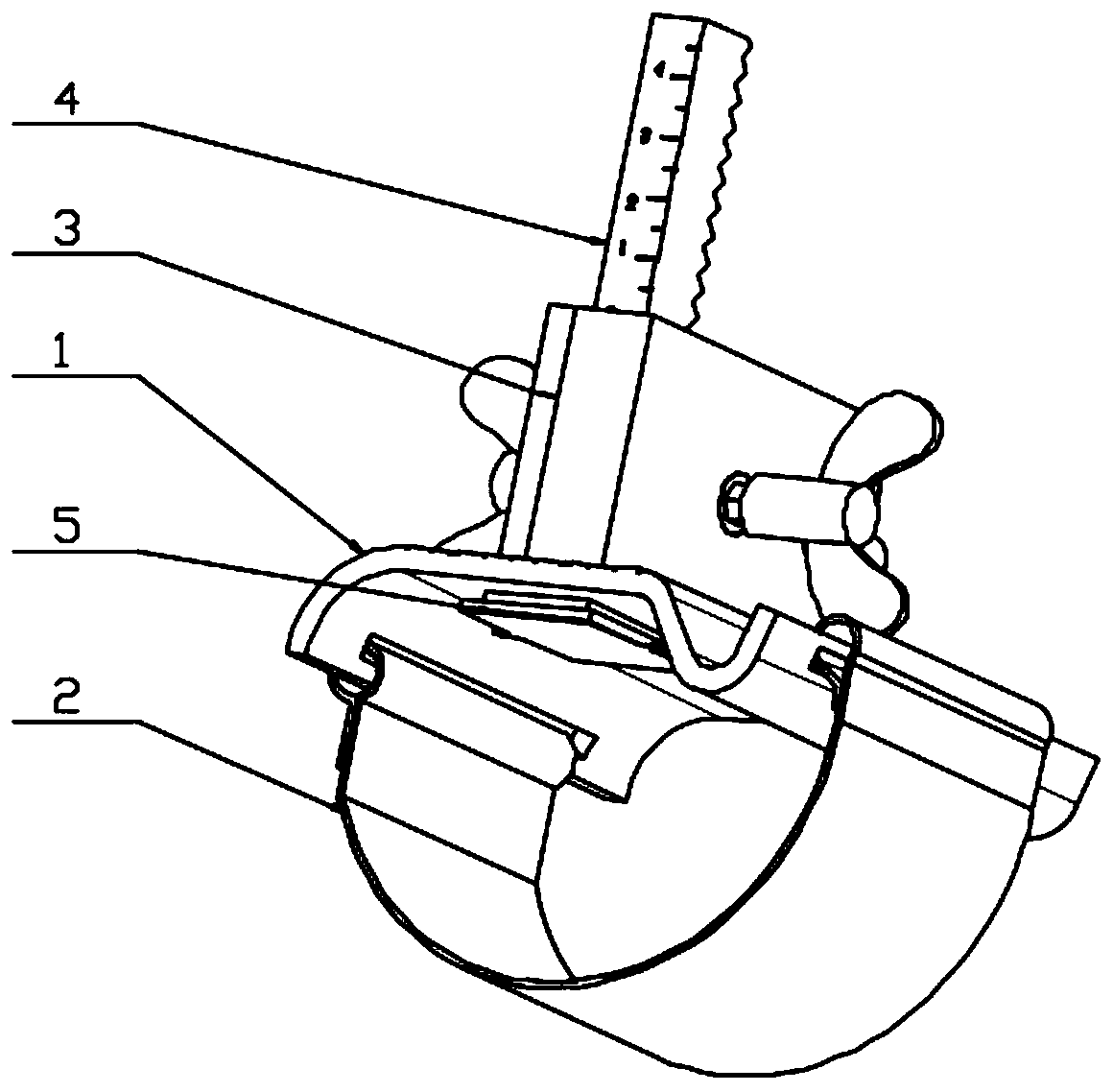

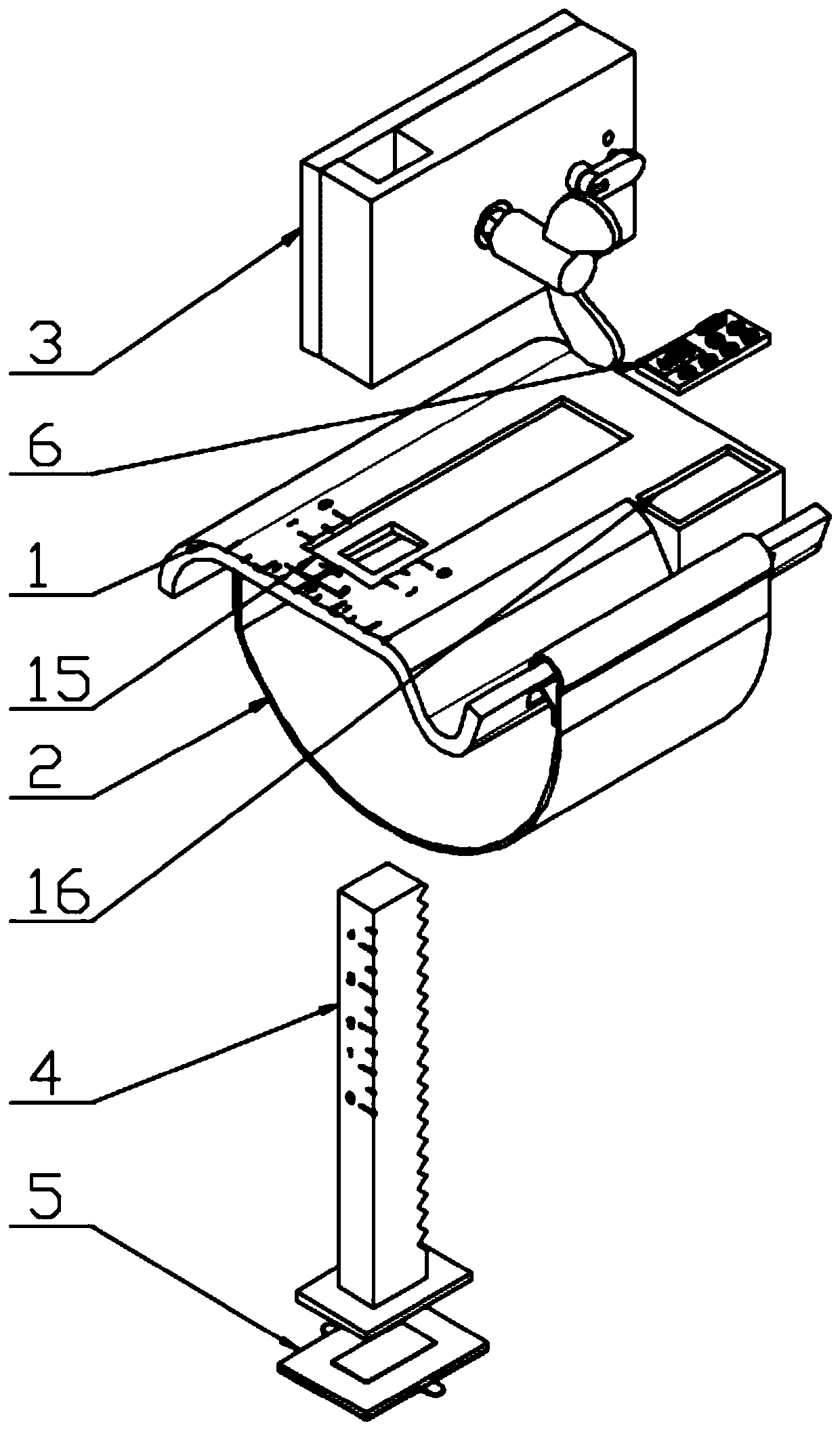

Self-locking radial artery compression hemostat

The invention relates to the technical field of medical auxiliary equipment, and particularly relates to a self-locking radial artery compression hemostat. The self-locking radial artery compression hemostat comprises a fixing assembly, a compression hemostasis assembly and an adjusting mechanism, wherein the fixing assembly is used for fixing the hemostat at a puncture position, the compression hemostasis assembly comprises a compression rod and a hemostasis pad connected to the lower end of the compression rod, the compression rod comprises a rack structure, and the adjusting mechanism is installed on the fixing assembly and used for adjusting the position of the compression hemostasis assembly. The self-locking radial artery compression hemostat is reasonable in design, and the problemsthat an existing hemostat is unstable, complex in structure, prone to accidental touch, incapable of accurately timing and the like are solved.

Owner:SHENYANG MASTECH MEDICAL DEVICE CO LTD

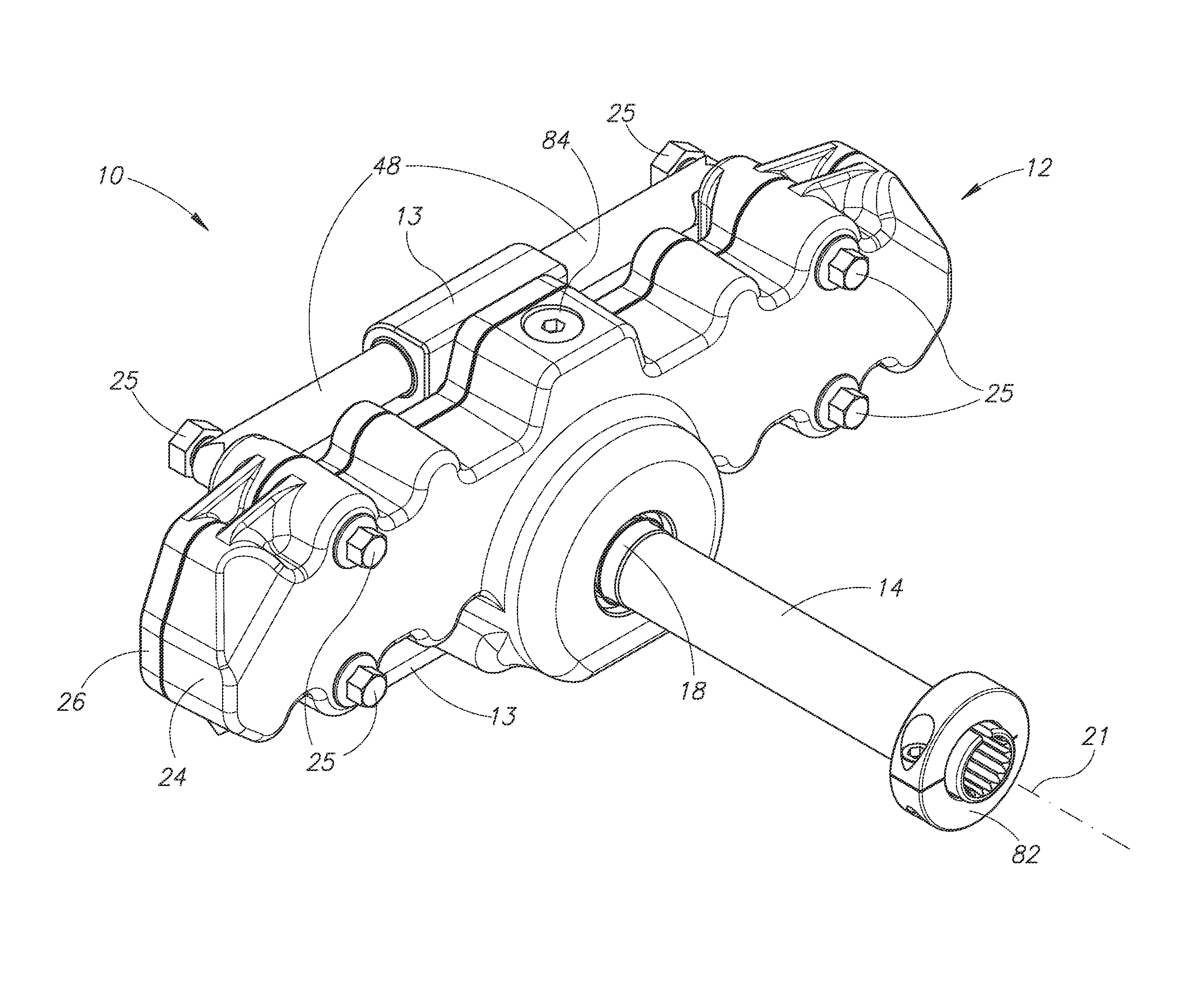

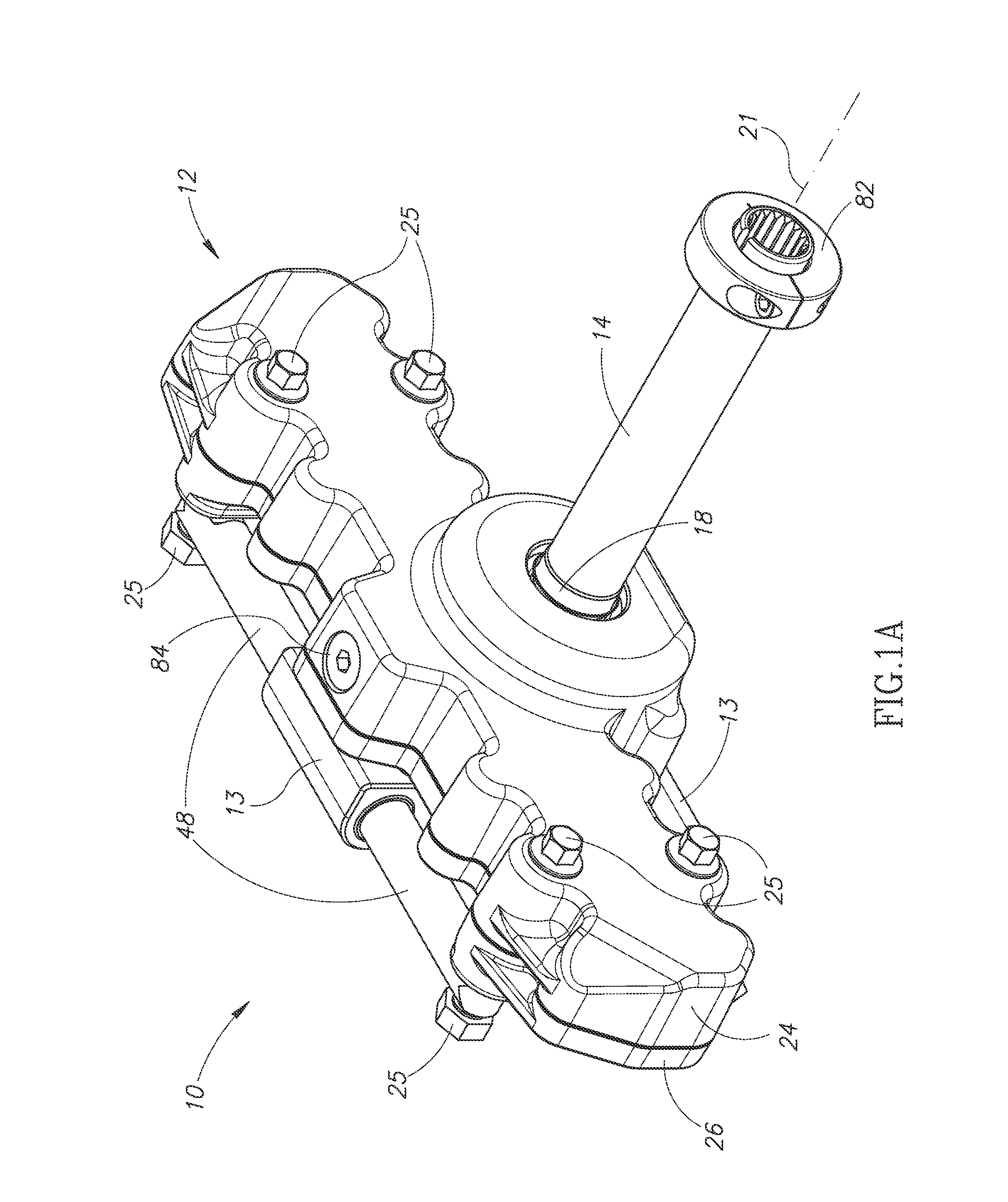

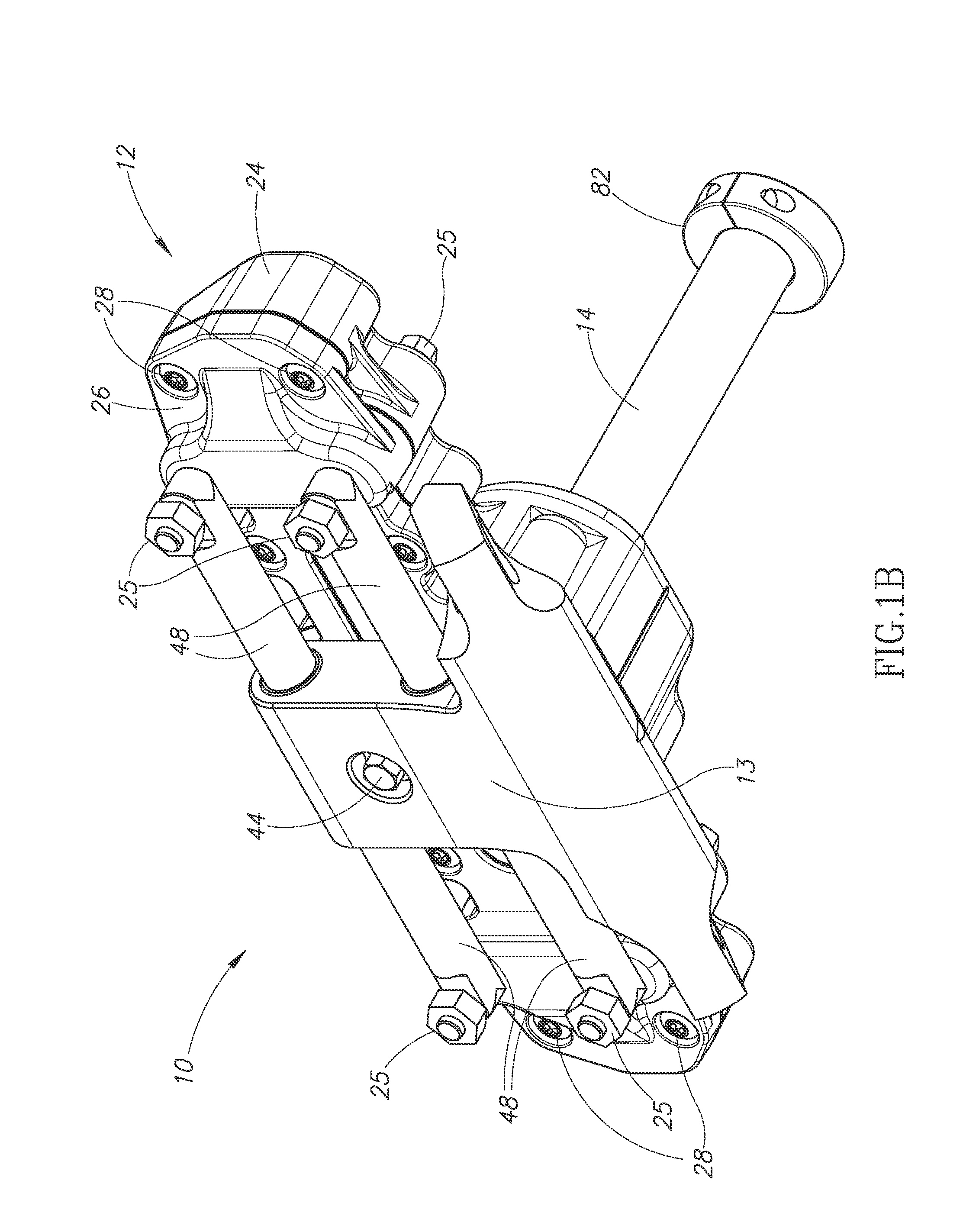

Compact steering mechanism

ActiveUS20130277935A1Avoid stress changesReduce frictionCyclesEngine sealsControl theoryRack and pinion

A compact steering mechanism for steering a vehicle having a steering input being a pinion shaft coupled to a pinion meshing with a rack, and a steering output member coupled to the rack. The pinion is positioned at a middle portion of the rack and the output member is positioned between opposing ends of a rack. The mechanism includes a compact steering housing supporting the pinion shaft and containing the rack-and-pinion. The pinion and pinion shaft have a center axis parallel to an axis of the output member. The output member, being a steering pin and rack carrier, a gear, or a flange, is coupled to left and right tie rod assemblies and wheels for steering the vehicle to improve handling.

Owner:ARCTIC CAT

Sealed temperature sensor

ActiveCN109459154ACushion the shockWon't fallThermometer detailsThermometer applicationsEngineeringElectric wire

The invention relates to the technical field of sensors, in particular to a sealed temperature sensor. The sensor comprises a sensor body, wherein clamping blocks are arranged on the side walls of thesensor body and connected with sliding blocks through rotating rods; a first spring is arranged between every two rotating rods, an electric wire is connected above the sensor body, passes through asealing box and extends out of a mounting box, and a moving block is arranged in the sealing box and connected with one ends of sliding rods; the other ends of the sliding rods are connected with a sliding seat, and the sliding seat is connected with an arc-shaped plate outside the mounting box. According to the sealed temperature sensor, the four clamping blocks clamp the sensor body together toensure that the sensor body cannot fall off; by pulling the electric wire upwards to drive the moving block to move, the moving block can adjust the movement of the sliding rods; through the movementof the sliding rods, the arc-shaped plate can be adjusted to compress the electric wire; the arc-shaped plate can only move in a one direction, and therefore, the electric wire cannot be loosened after being locked. The pressure change in the mounting box caused by the random movement of the electric wire is avoided, and the poor contact between the electric wire and the sensor body caused by excessive extraction of the electric wire can be avoided by adopting buckles.

Owner:合肥亿珀电子材料有限公司

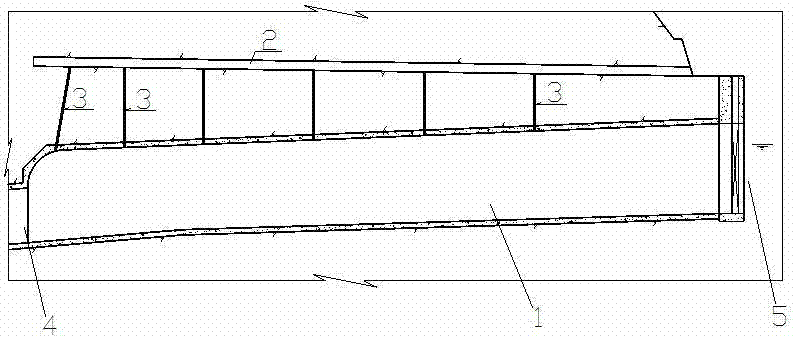

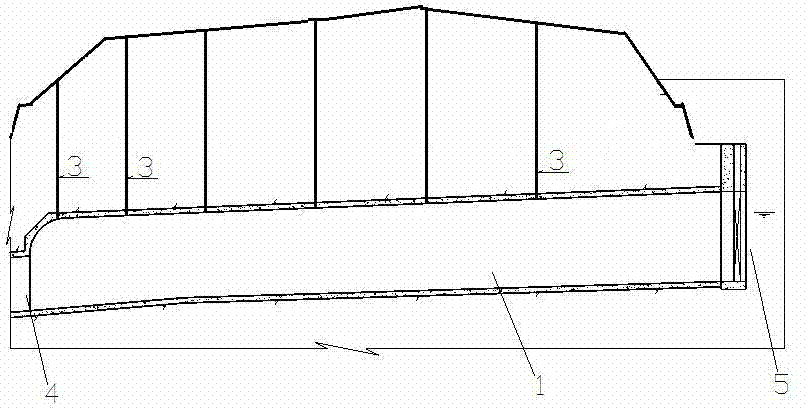

Tailrace tunnel with variable crest elevation

InactiveCN104499466AReduce impactEnsure structural safetyWater-power plantsHydro energy generationWater flowStructural safety

The invention discloses a tailrace tunnel with variable crest elevation. The tailrace tunnel comprises a tailrace tunnel main body with instantly-increasing top height, wherein the top of the tailrace tunnel main body is provided with at least one vent hole communicated with the outside along the way. According to the tailrace tunnel with variable crest elevation, the problem of pressure change brought by alternate changes of non-full water flows and full water flows in the tunnel is thoroughly solved, alternating pressures of the water flows on a tailrace tunnel lining are eliminated, and thus the structural safety of the tailrace tunnel with variable crest elevation is effectively ensured.

Owner:POWERCHINA ZHONGNAN ENG

Balloon catheter

A balloon catheter includes an outer conduit having an outer surface, and an inner conduit having an outer surface. The inner conduit is suitable for passage over a guide wire, and the inner conduit is movably disposed within the lumen of the outer conduit. There is also a balloon having a proximal margin and a distal margin, such that the proximal margin of the balloon is attached to the outer surface of the distal tip of the outer conduit and the distal margin of the balloon is attached to the outer surface of the portion of the inner conduit that extends beyond the distal tip of the outer conduit. And there is a fluid port for introducing an expansion fluid into the annular space formed between the inner surface of the outer conduit and the outer surface of the inner conduit and into the lumen of the balloon, and for the removal of the expansion fluid.

Owner:ANGIOSLIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com