Circuit board and manufacture method thereof

A manufacturing method and circuit board technology, which is applied in the direction of multilayer circuit manufacturing, printed circuit components, and electrical connection formation of printed components, can solve problems such as multilayer circuit board 100 change, stress change, and influence, and improve yield , to avoid the effect of stress changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

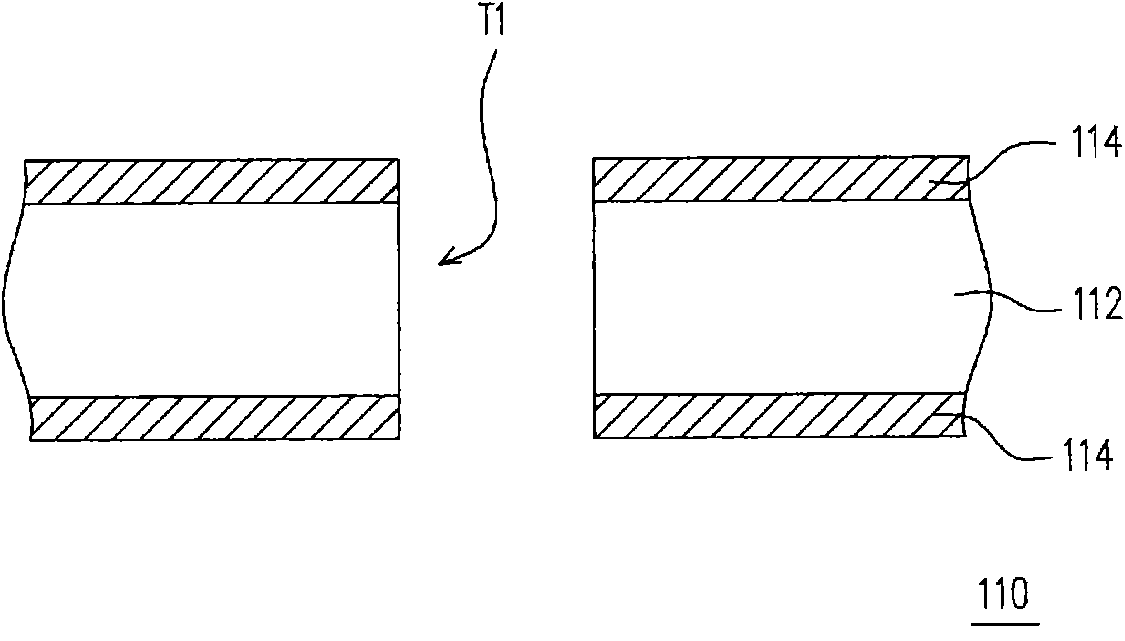

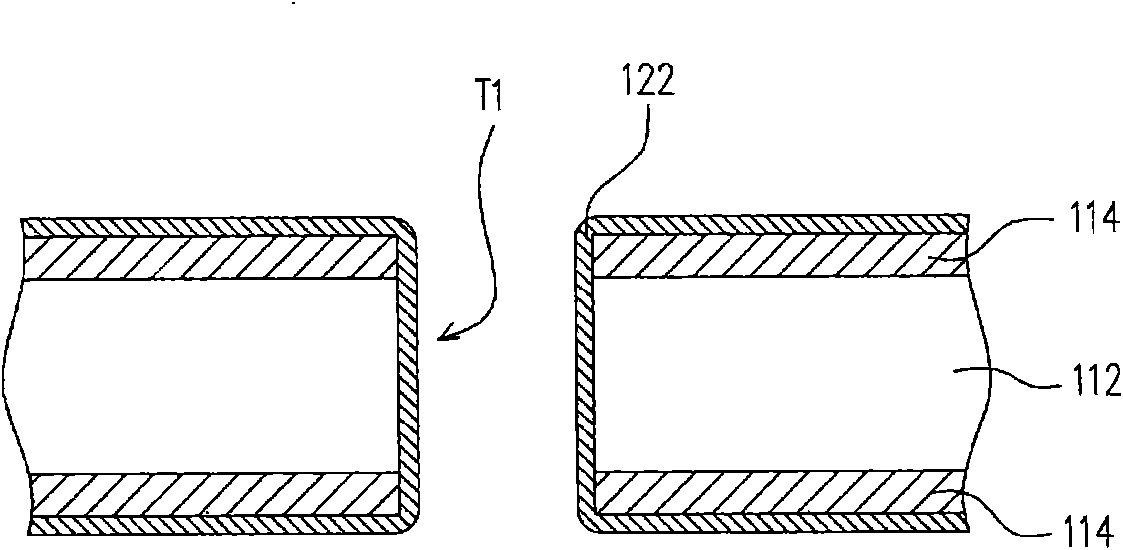

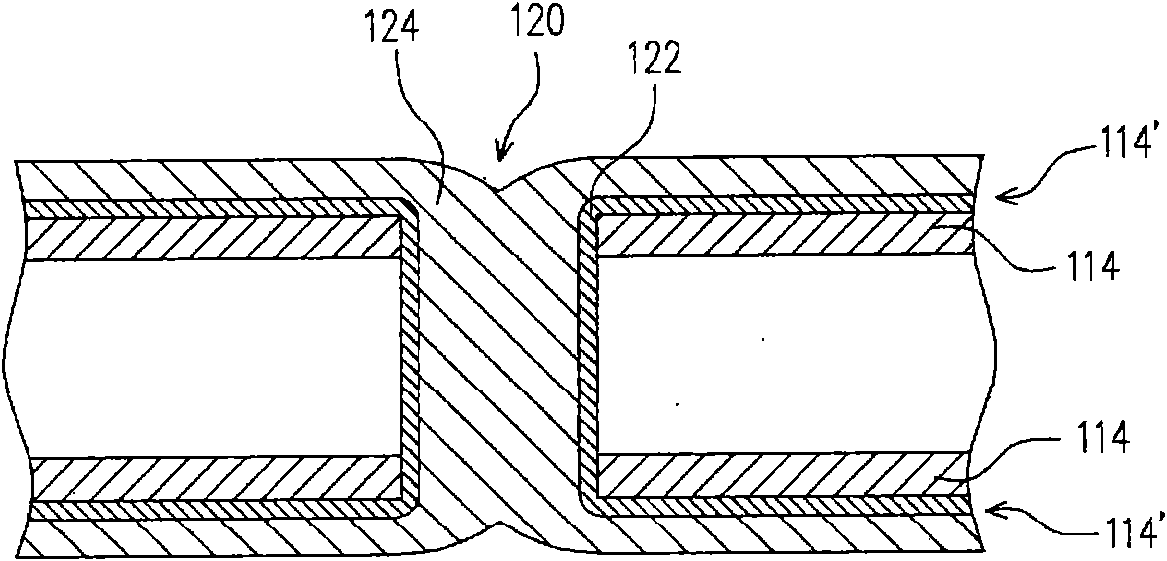

[0066] figure 2 It is a schematic cross-sectional view of a circuit board according to an embodiment of the present invention. see figure 2 , the circuit board 200 has at least one hole H1 , and the circuit board 200 includes a first circuit layer 210 , a second circuit layer 220 , an insulating layer 230 and a conductive connection structure 240 . The first circuit layer 210 and the second circuit layer 220 are disposed on opposite surfaces of the insulating layer 230 , that is, the insulating layer 230 is disposed between the first circuit layer 210 and the second circuit layer 220 . also, figure 2 The circuit board 200 shown can be regarded as a double sided circuit board or as one of the inner circuit substrates in a multilayer circuit board.

[0067] The hole H1 extends from the first circuit layer 210 to the second circuit layer 220, and the hole H1 may be a blind via or a through hole (such as figure 2 shown). The hole H1 has a hole wall S1, and the hole wall S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com