Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Snubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Snubbing is a type of heavy well intervention performed on oil and gas wells. It involves running the BHA on a pipe string using a hydraulic workover rig. Unlike wireline or coiled tubing, the pipe is not spooled off a drum but made up and broken up while running in and pulling out, much like conventional drill pipe. Due to the large rigup, it is only used for the most demanding of operations when lighter intervention techniques do not offer the strength and durability. Unlike conventional drilling and completions operations, snubbing can be performed with the well still under pressure. When done so, it is called hydraulic workover. It can also be performed without having to remove the Christmas tree from the wellhead.

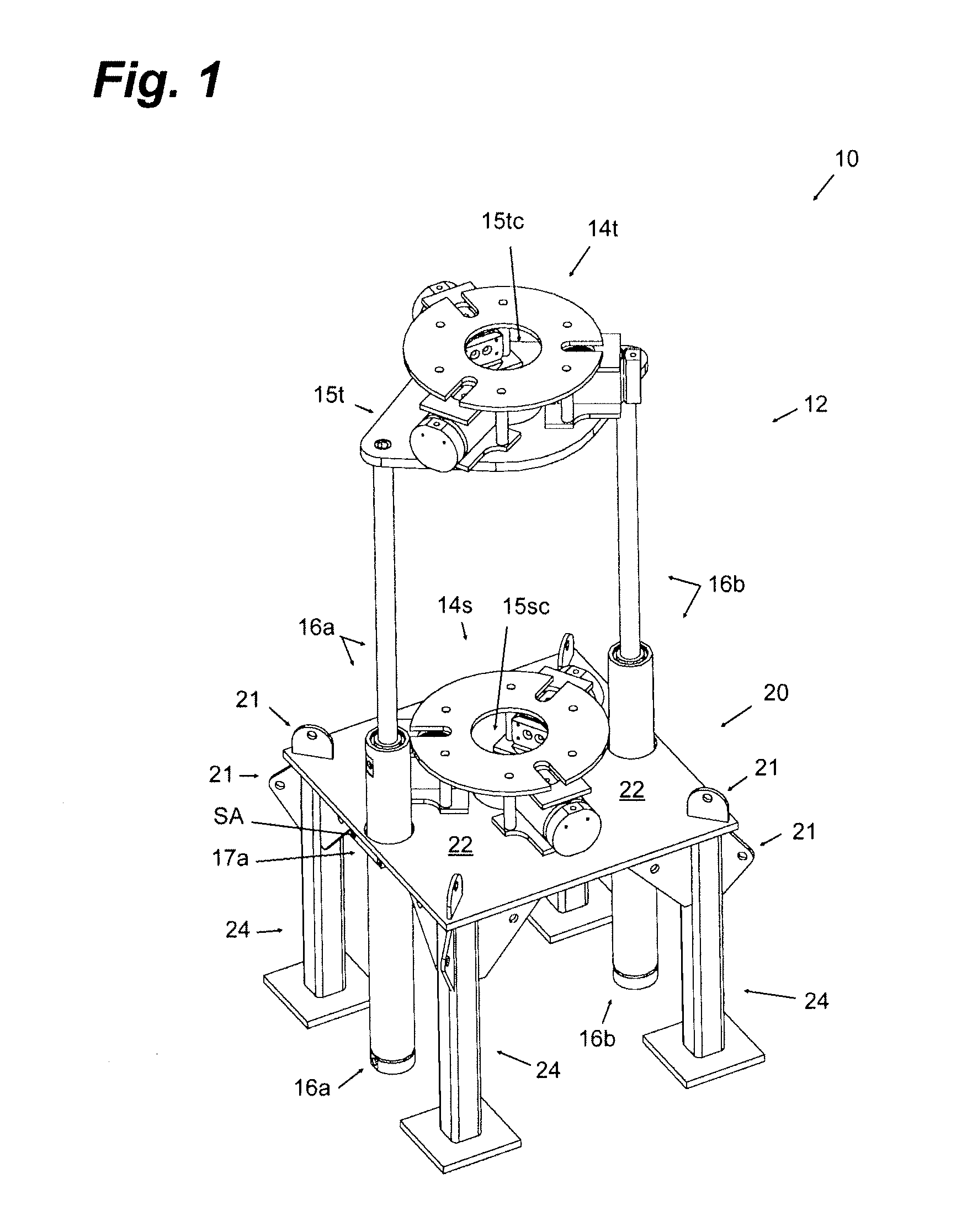

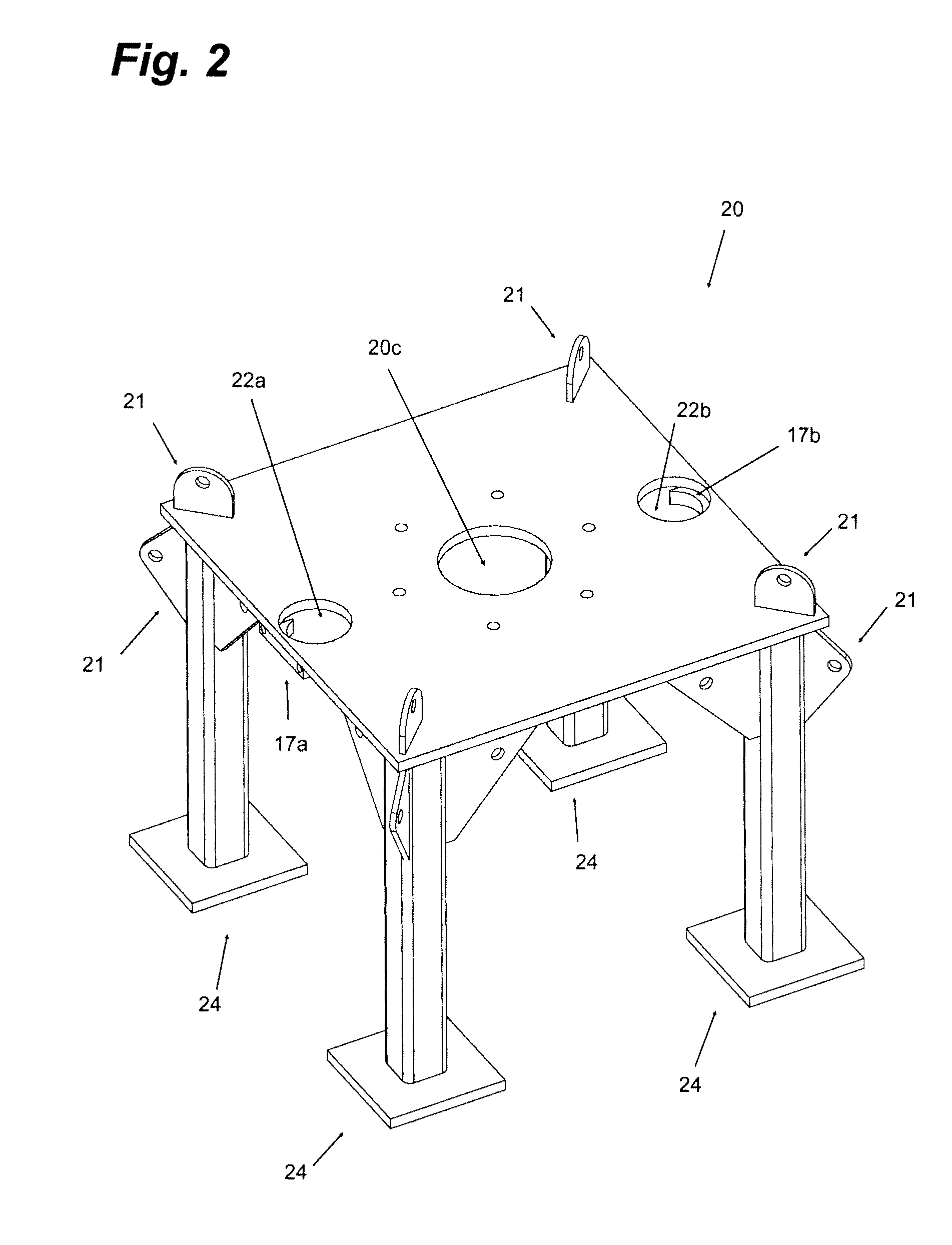

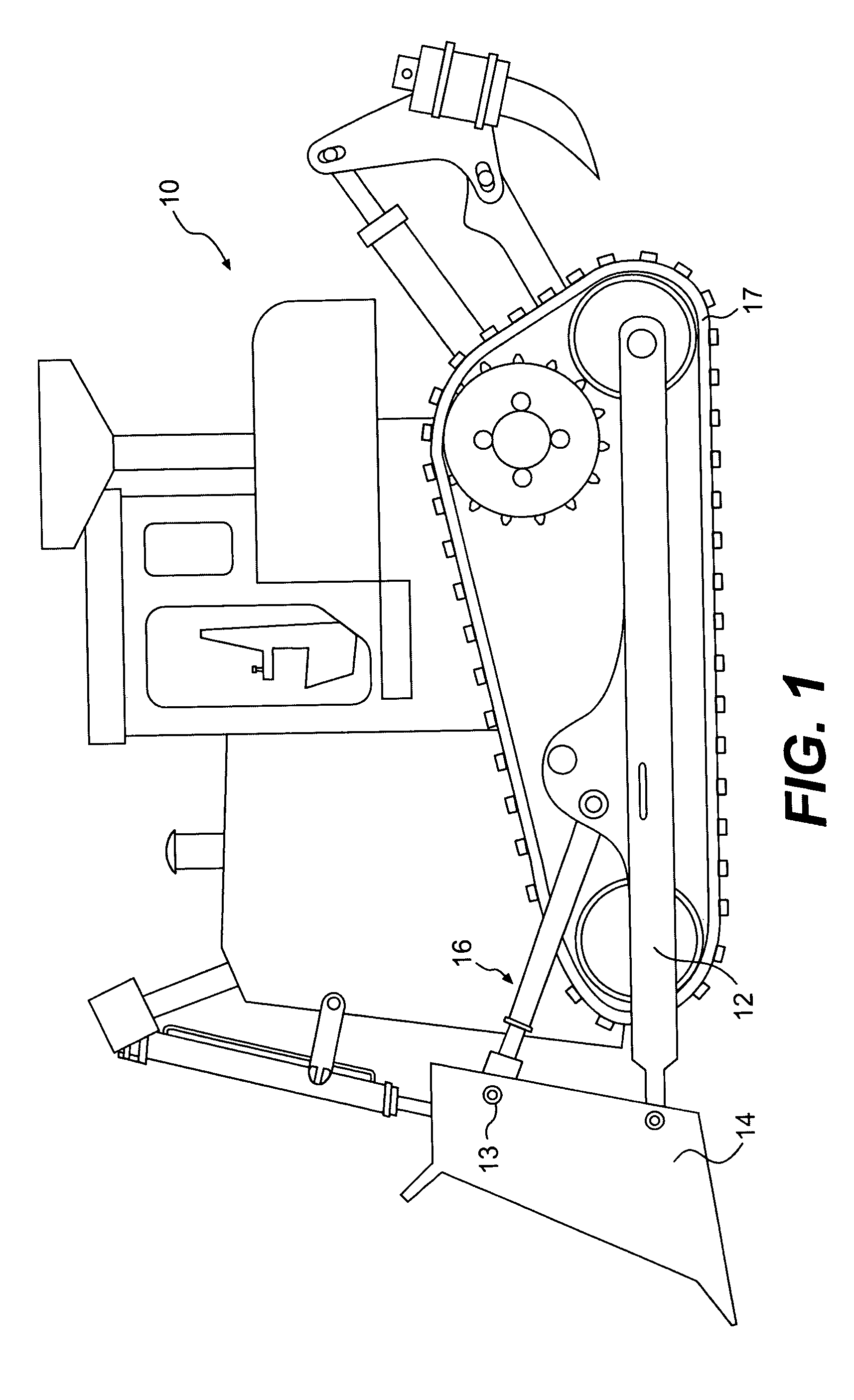

Mobile snubbing system

ActiveUS20070193749A1Maximizing bed area lengthMeet the requirementsDrilling rodsFluid removalEngineeringSnubbing

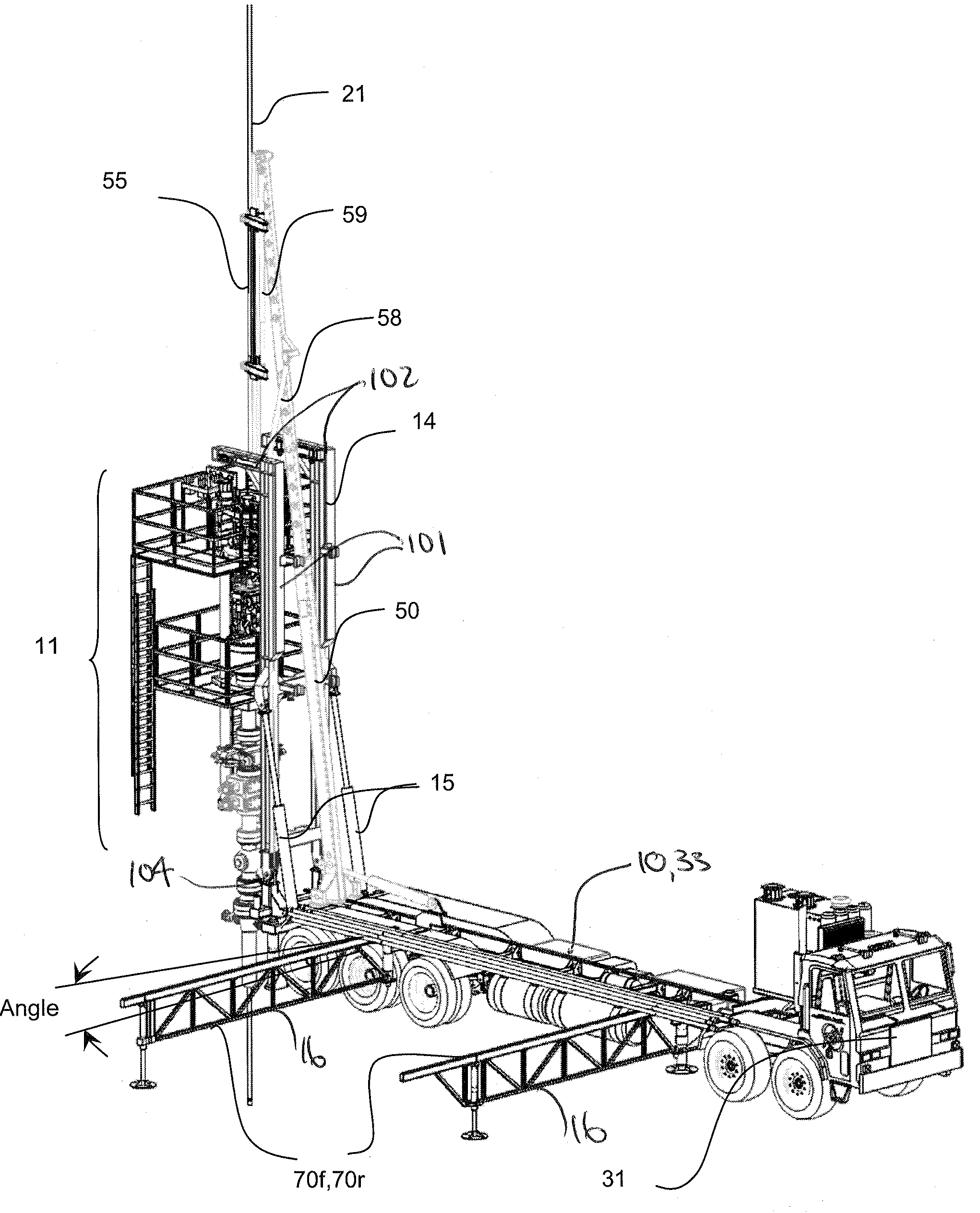

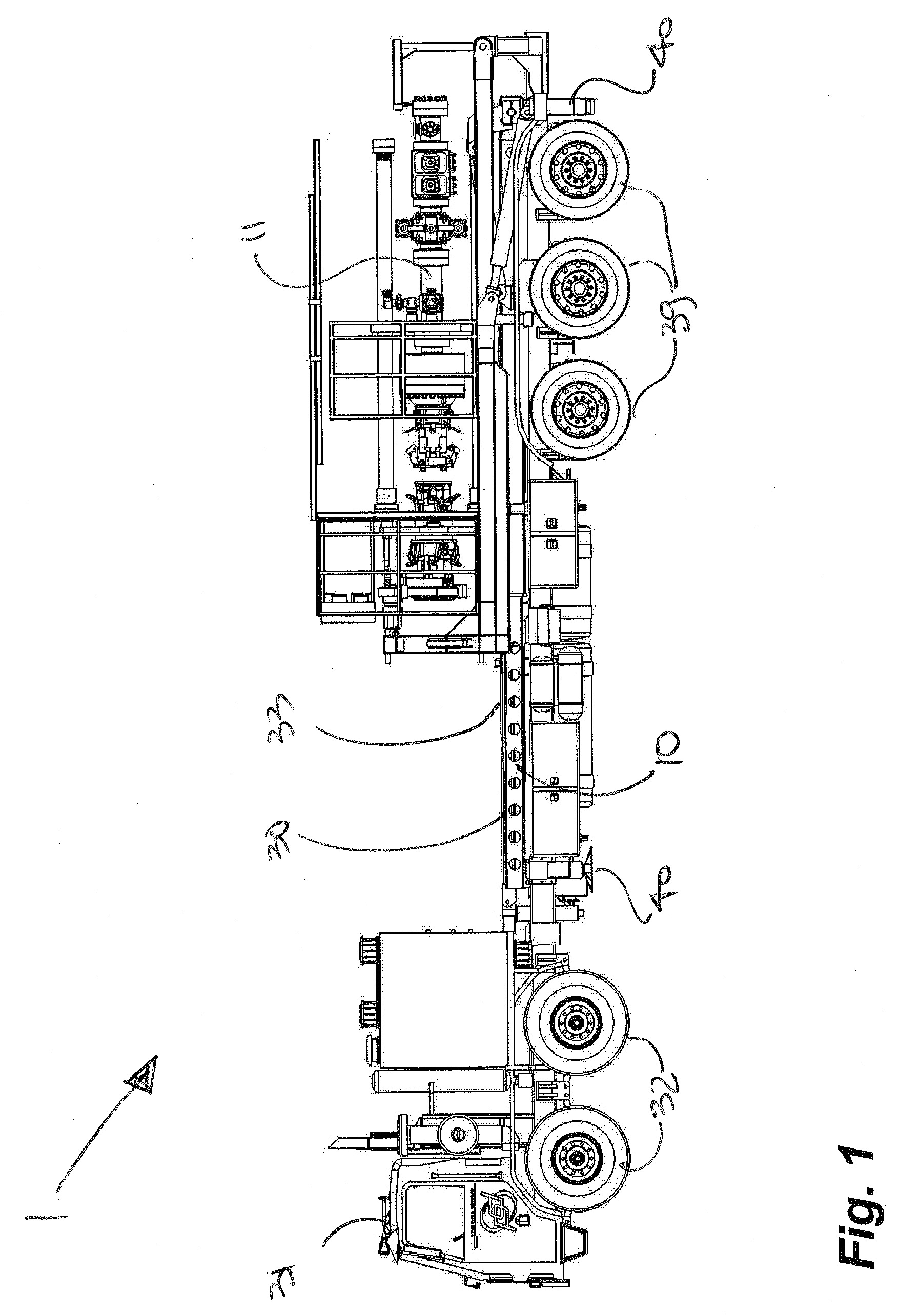

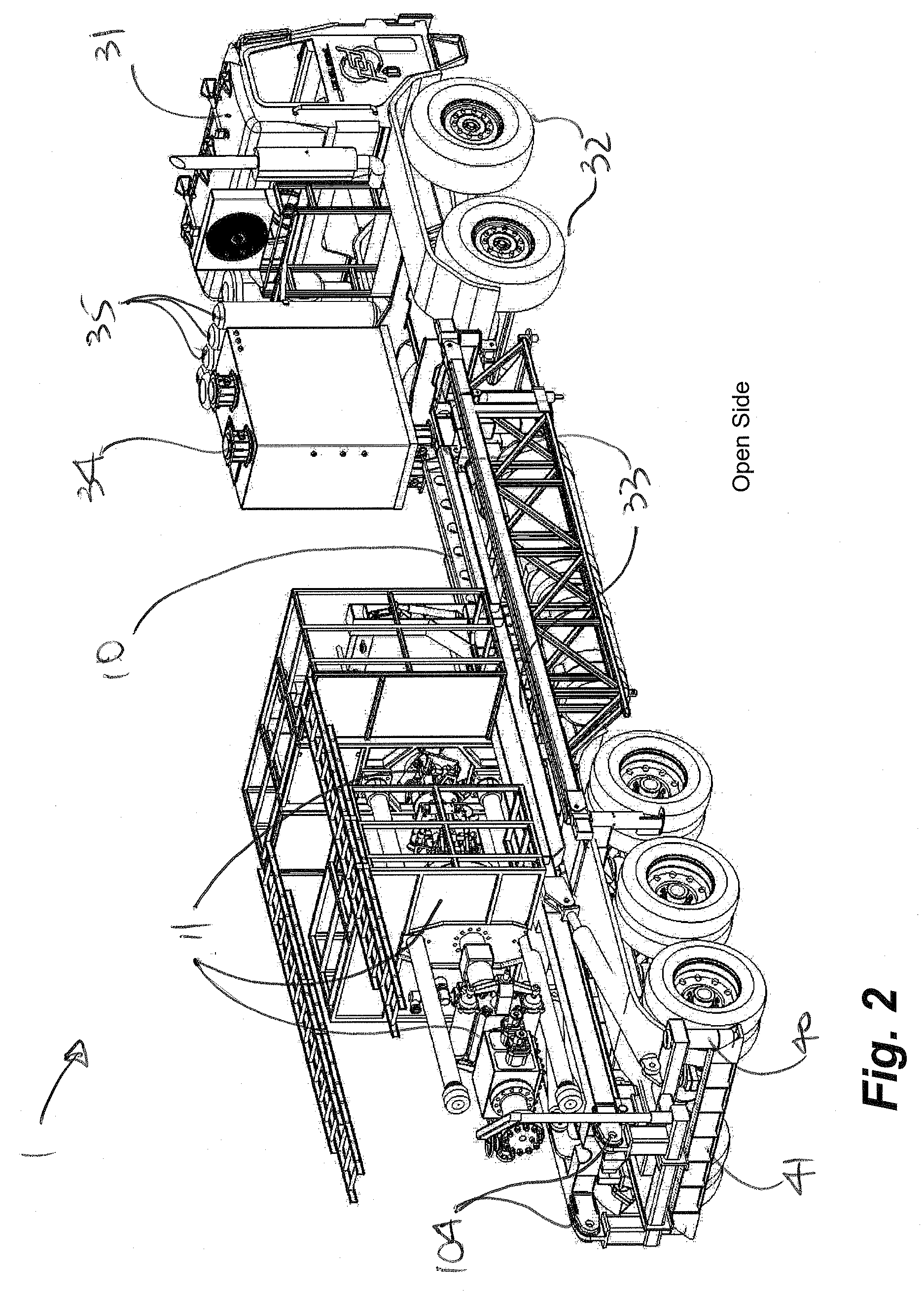

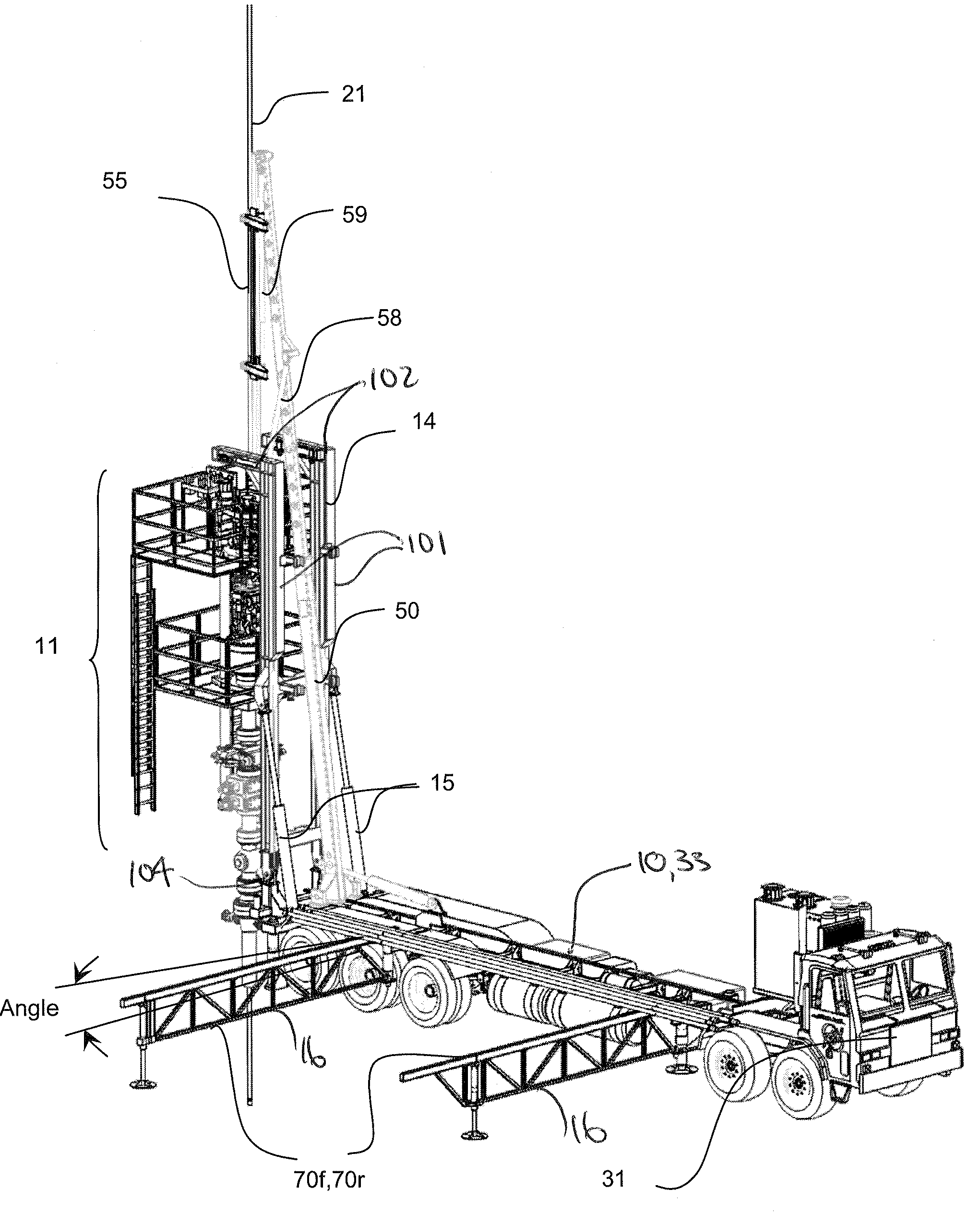

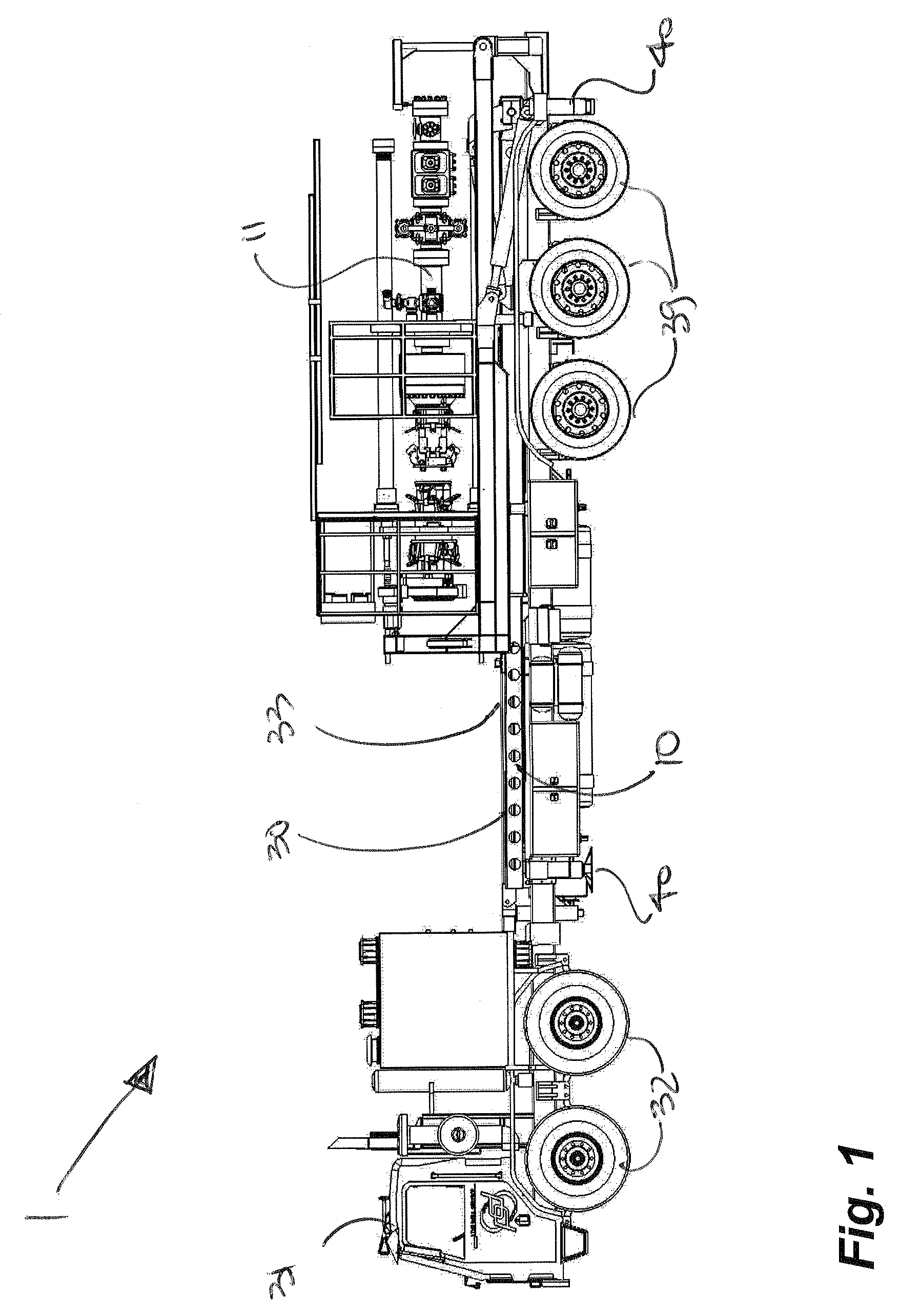

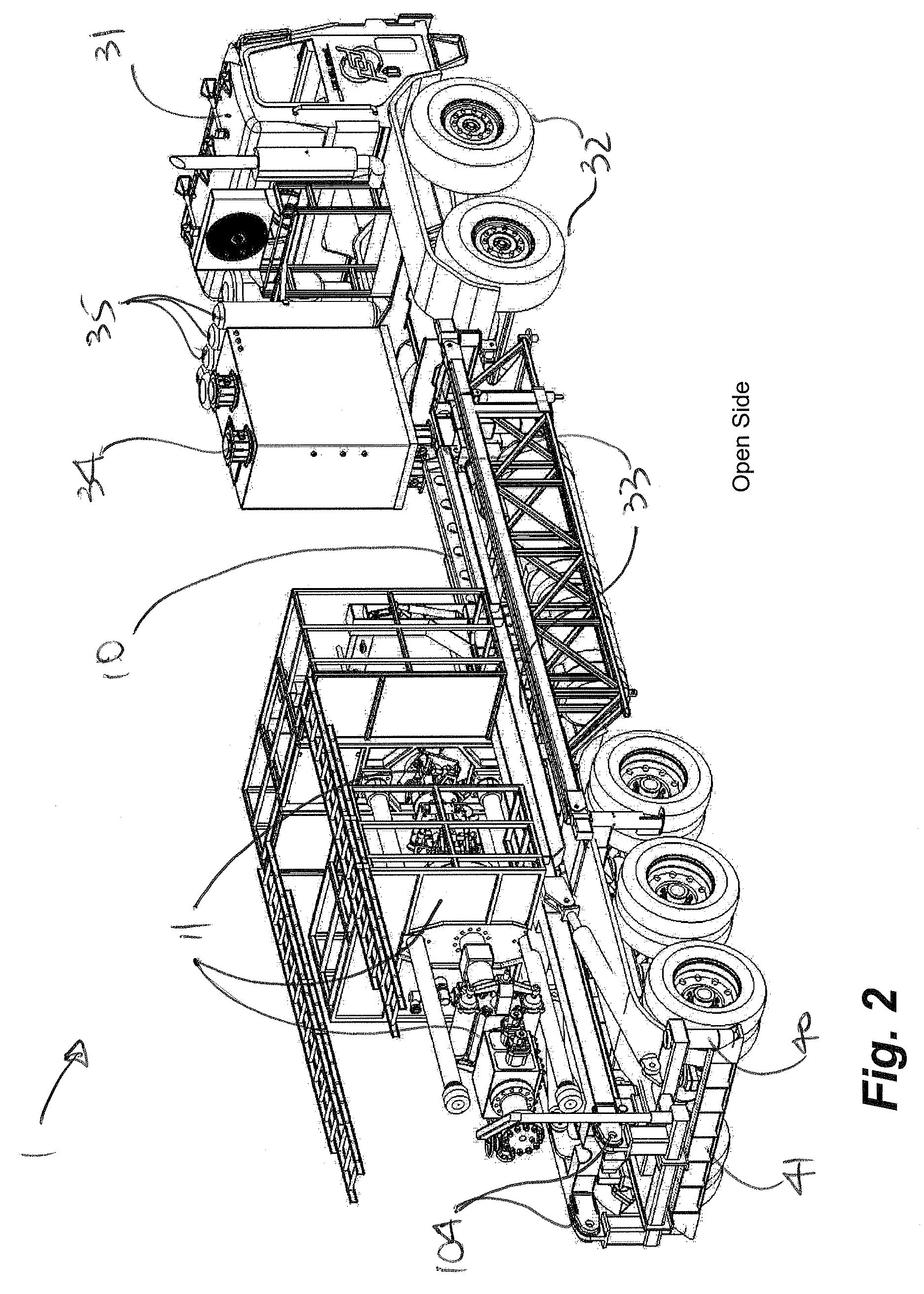

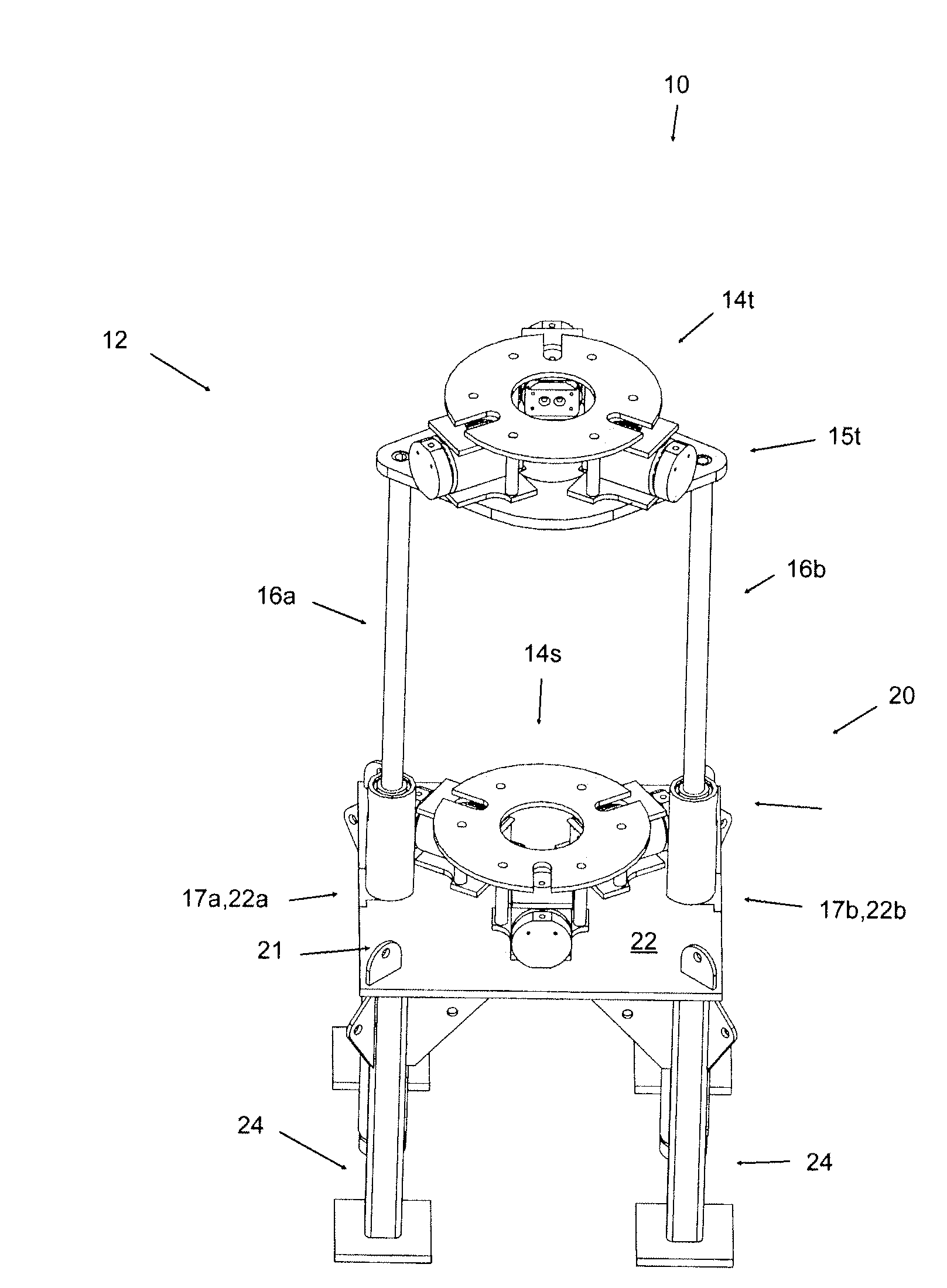

A mobile snubbing system and method of operation transports a snubbing unit to a wellhead on a mobile platform. The snubbing unit is supported by a frame pivotable about a wellhead end of the platform for aligning the snubbing unit with the wellhead. A pipe handler boom is operable between a platform position for loading and off-loading tubulars at an open side of the platform and a second snubbing position for loading and off-loading tubulars at the top end of the snubbing unit. The boom can be telescopic for extending to the top of the snubbing unit and can be automated after learning tubular manipulation at the wellhead. Pipe racks can be deployable from the open side of the platform and an indexer and kicker in the platform enables loading and off-loading tubulars at the pipe handler.

Owner:TEAM SNUBBING SERVICES

Mobile snubbing system

A mobile snubbing system and method of operation transports a snubbing unit to a wellhead on a mobile platform. The snubbing unit is supported by a frame pivotable about a wellhead end of the platform for aligning the snubbing unit with the wellhead. A pipe handler boom is operable between a platform position for loading and off-loading tubulars at an open side of the platform and a second snubbing position for loading and off-loading tubulars at the top end of the snubbing unit. The boom can be telescopic for extending to the top of the snubbing unit and can be automated after learning tubular manipulation at the wellhead. Pipe racks can be deployable from the open side of the platform and an indexer and kicker in the platform enables loading and off-loading tubulars at the pipe handler.

Owner:TEAM SNUBBING SERVICES

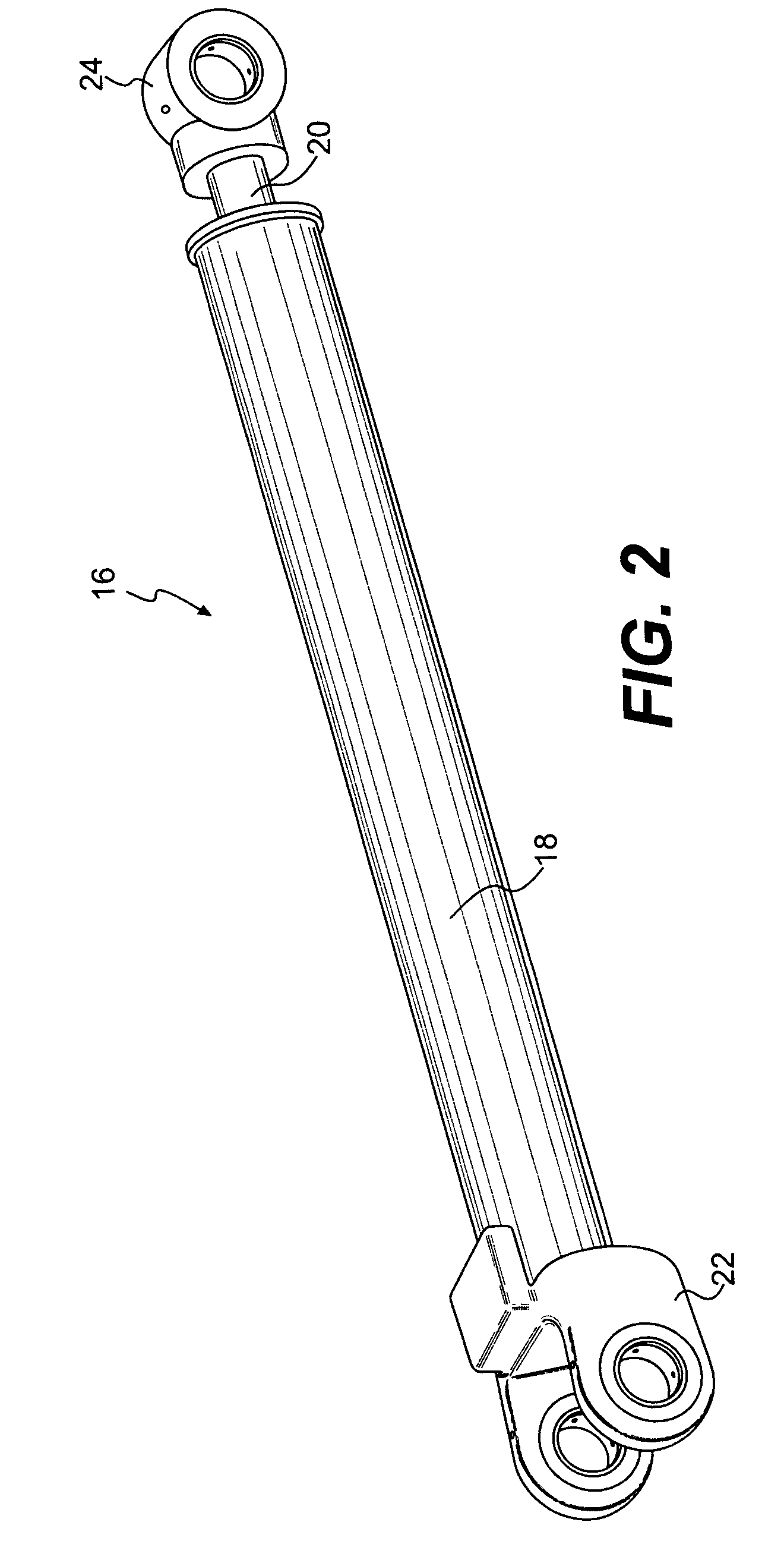

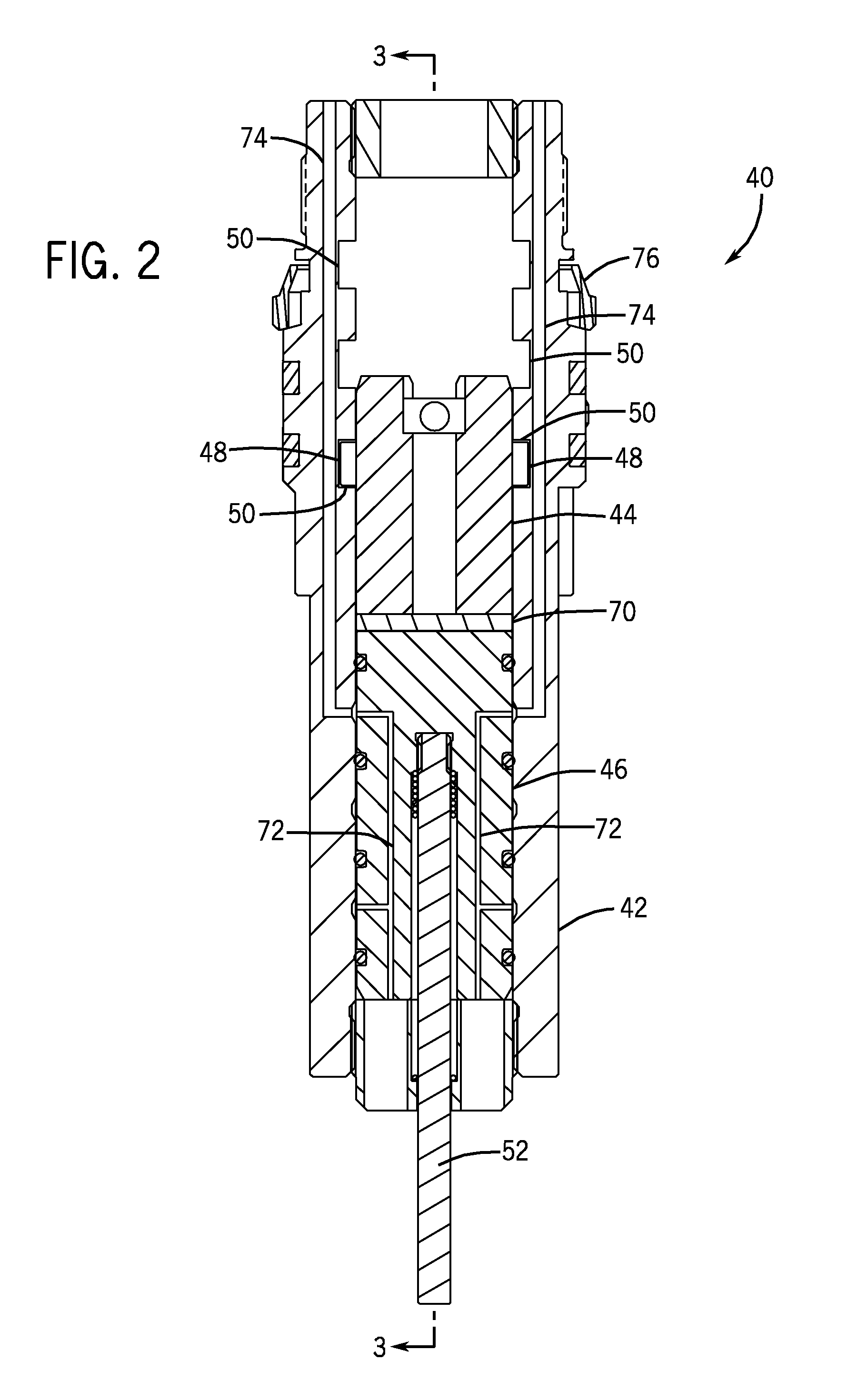

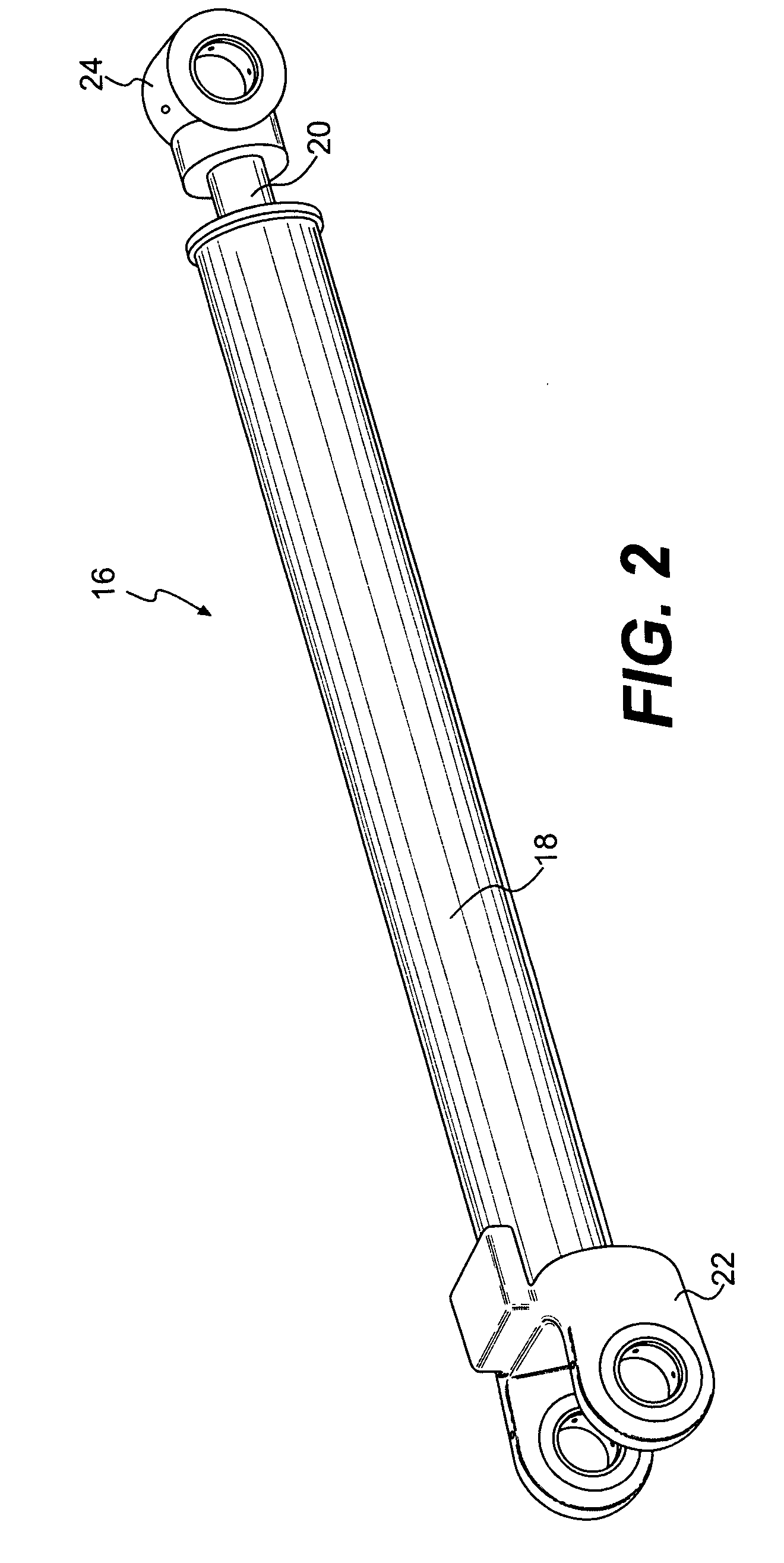

Hydraulic cylinder having a snubbing valve

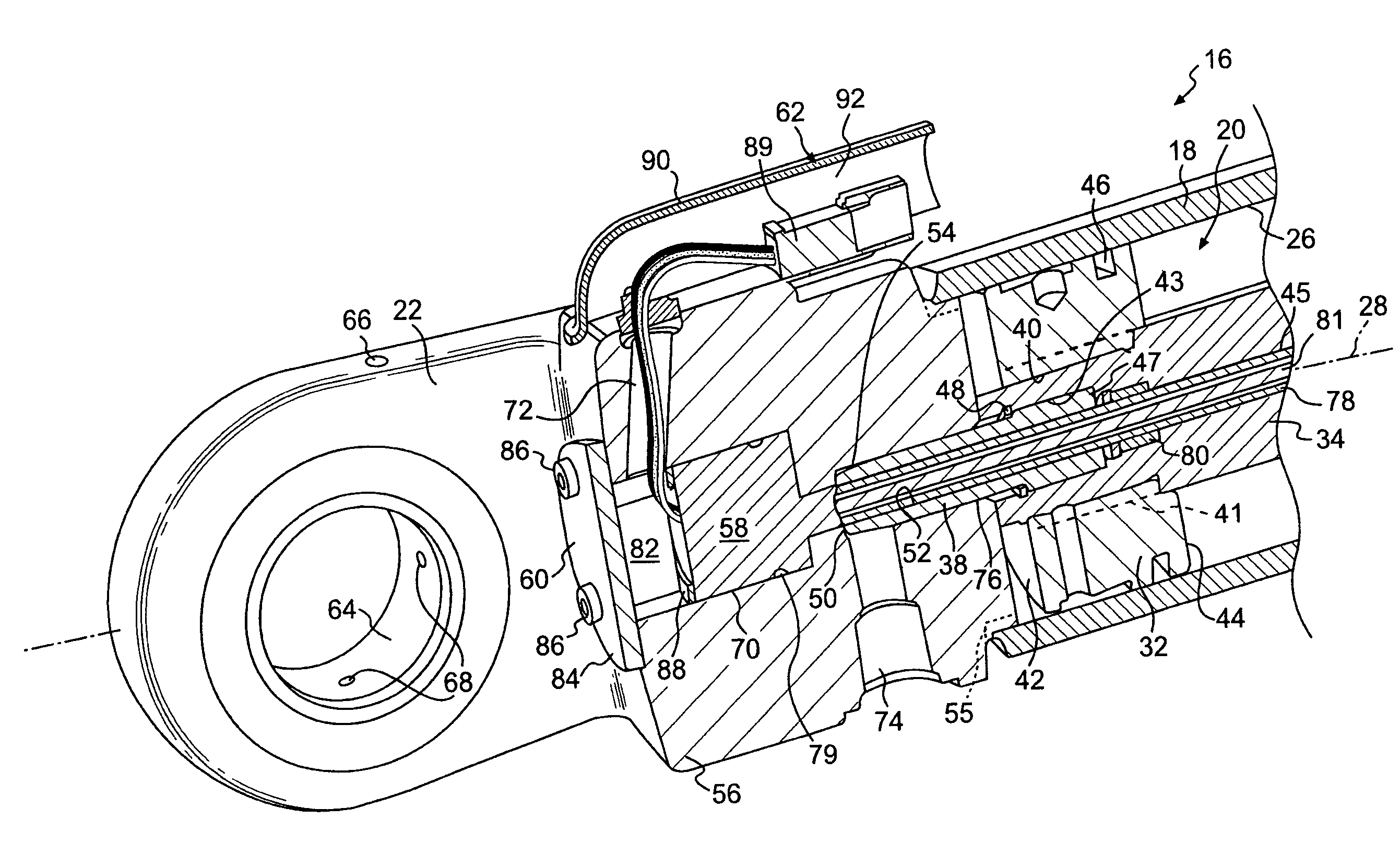

A hydraulic cylinder has a tube with a first end and a section end. The hydraulic cylinder also has a piston assembly movably disposed within the tube and configured to move between the first and second ends of the tube. The hydraulic cylinder further has a valve plunger connected to the piston assembly and having an axial bore. The hydraulic cylinder additionally has a cap assembly connected to the tube to close off the first end of the tube. The cap assembly has a fluid passageway and the valve plunger is configured to progressively restrict fluid flow through the fluid passageway as the piston assembly approaches the first end of the tube.

Owner:CATERPILLAR INC

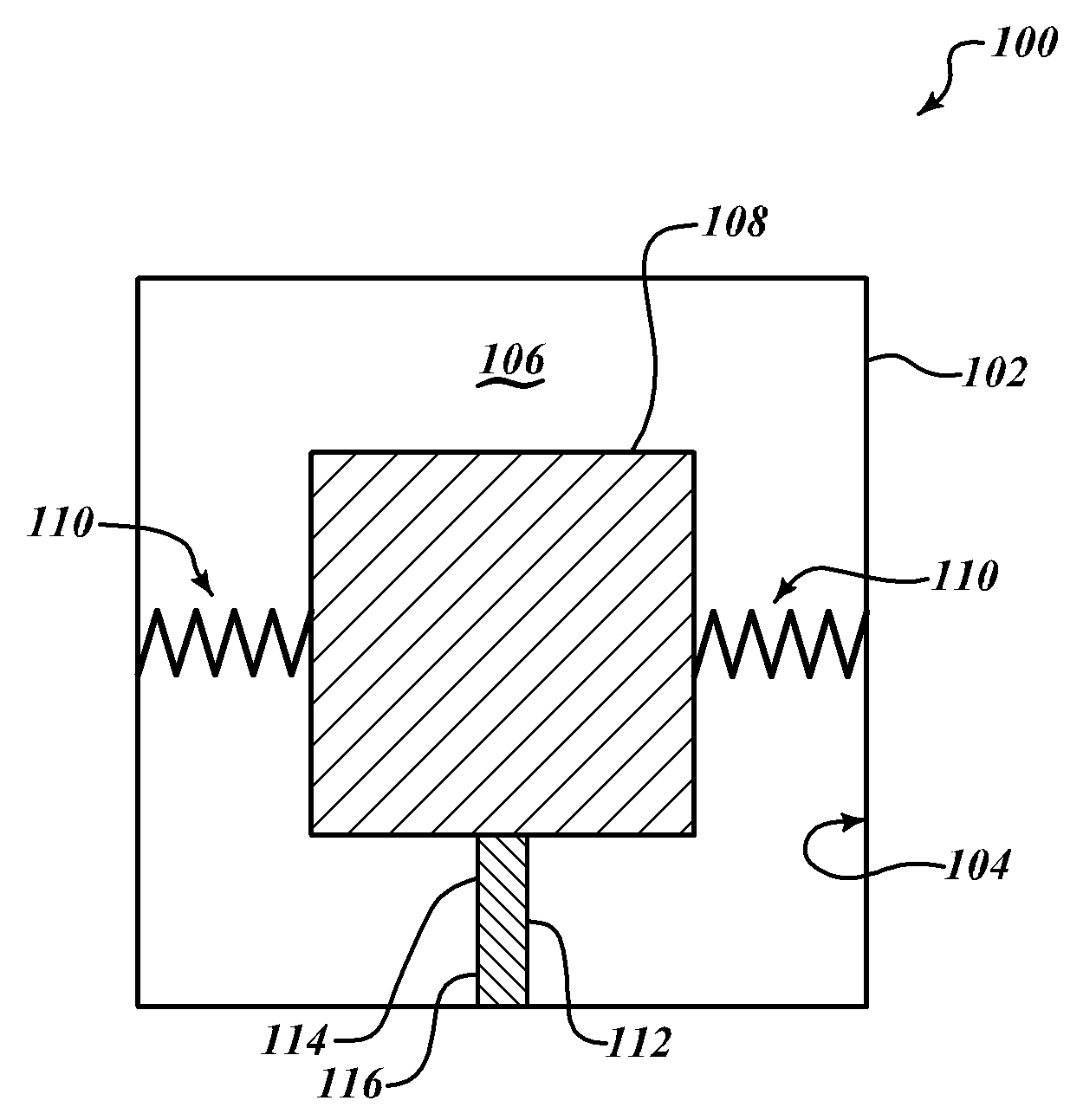

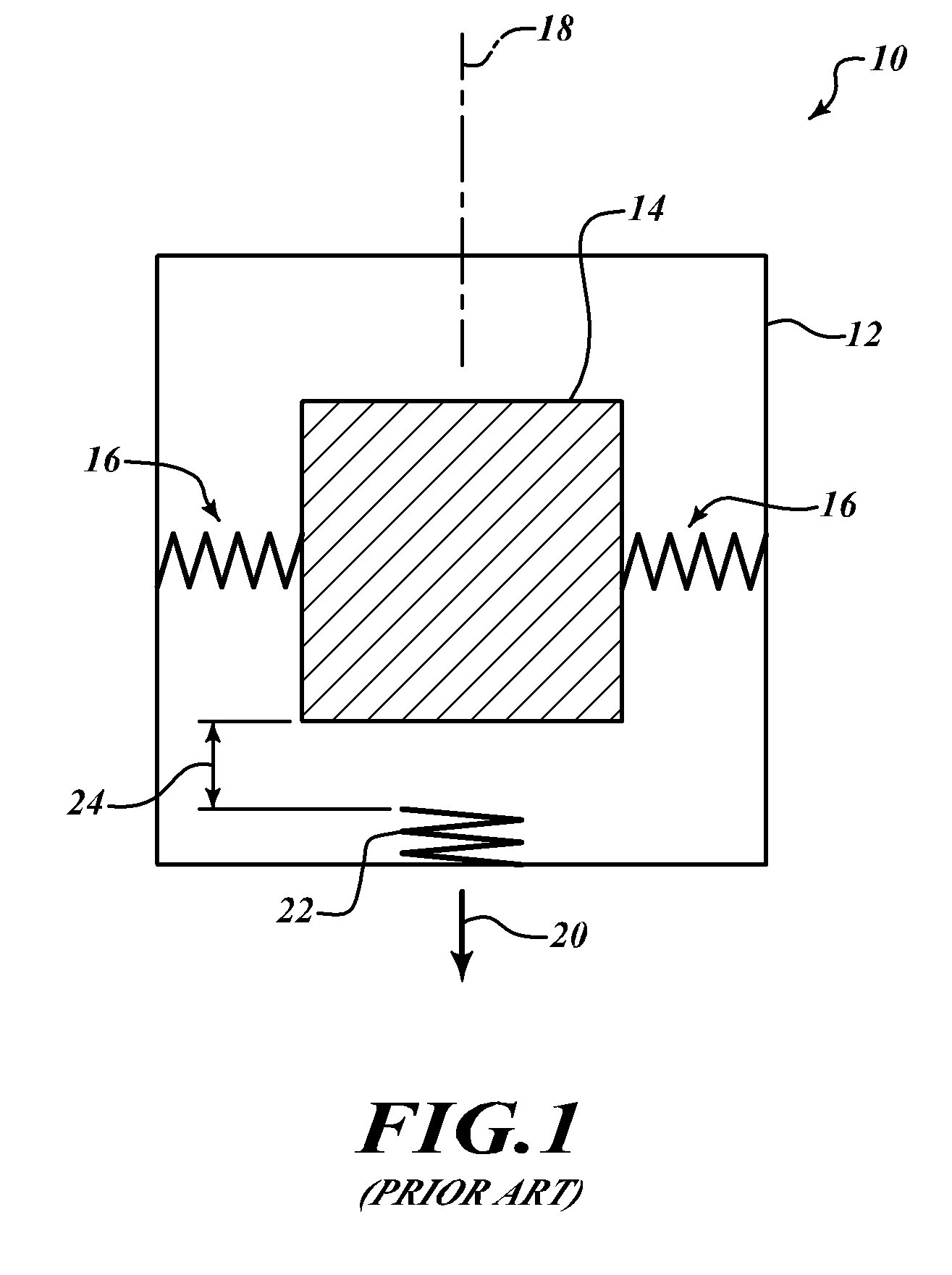

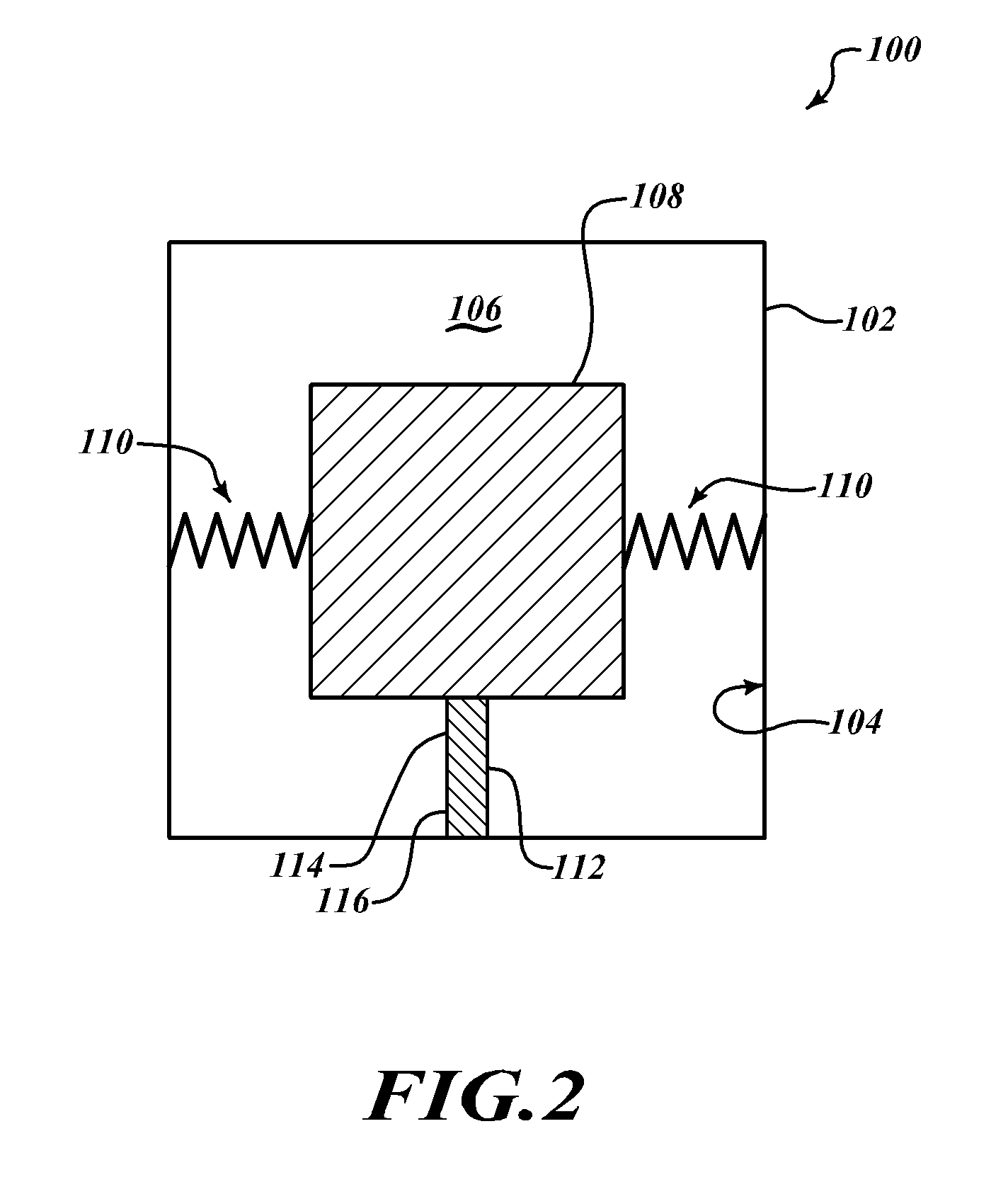

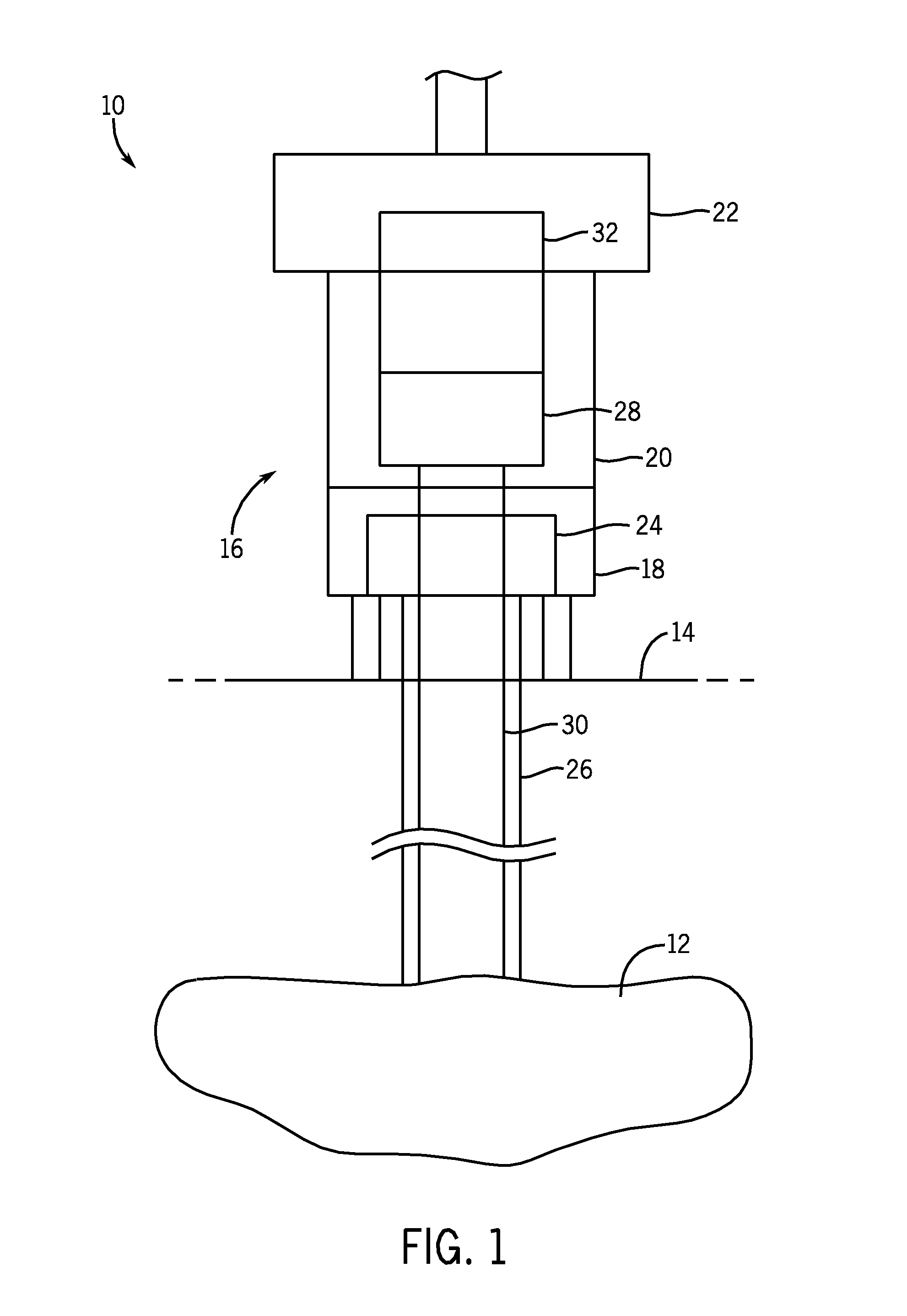

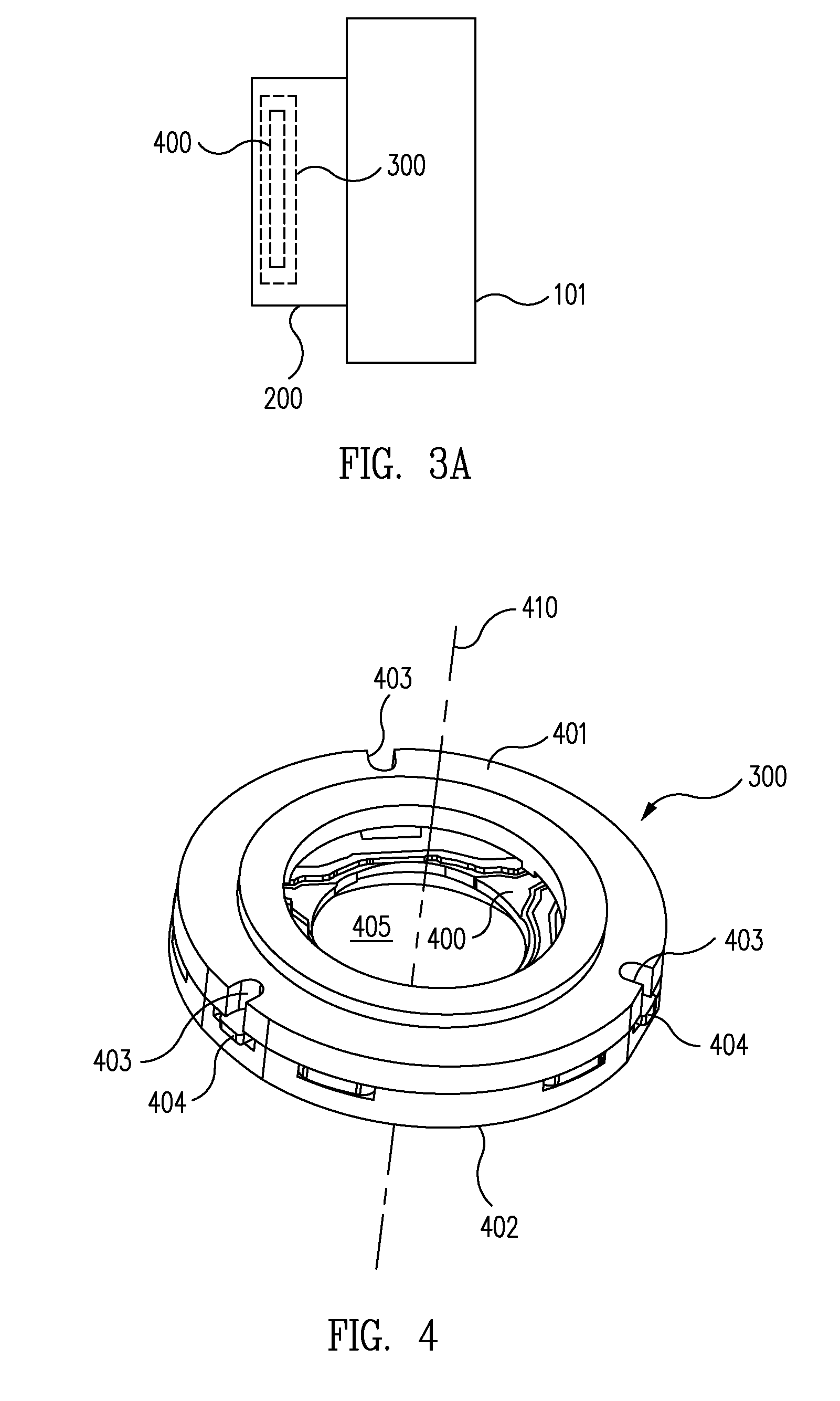

Snubbing system for a suspended body

The present invention generally relates to a snubbing or damping system for reducing a shock impact on an isolated body within a shock sensitive device, which may take the form of an inertial measurement unit (IMU). The shock sensitive device includes a housing with an inertial body suspended in an isolated manner within the housing and engaged with the snubbing system. By way of example, the inertial body may take the form of an inertial sensor assembly. Further, the snubbing system may take the form of a plastically deformable snubbing mechanism positioned between the housing and the inertial body along a line of action of the inertial body during an acceleration (e.g. shock) event.

Owner:HONEYWELL INT INC

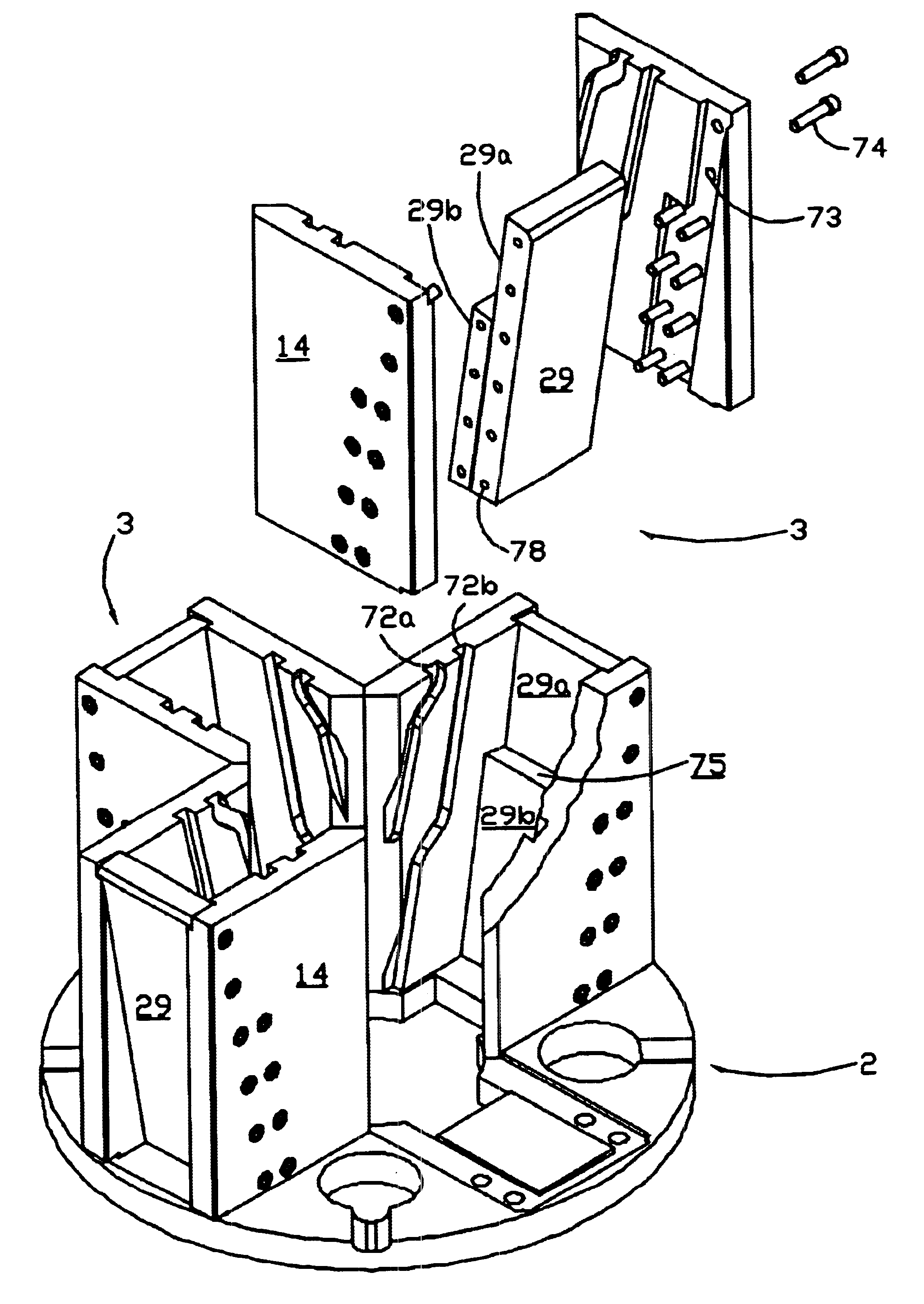

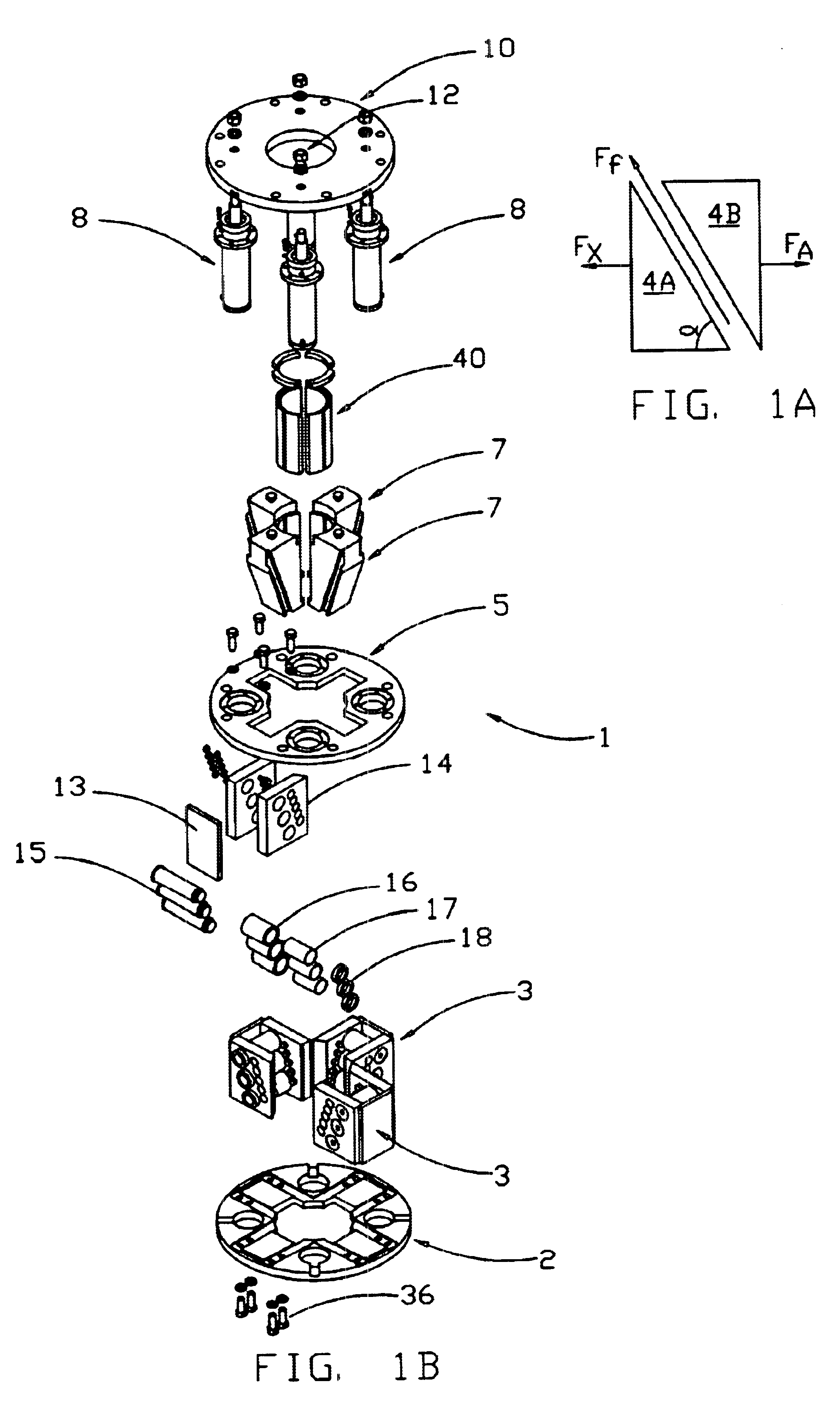

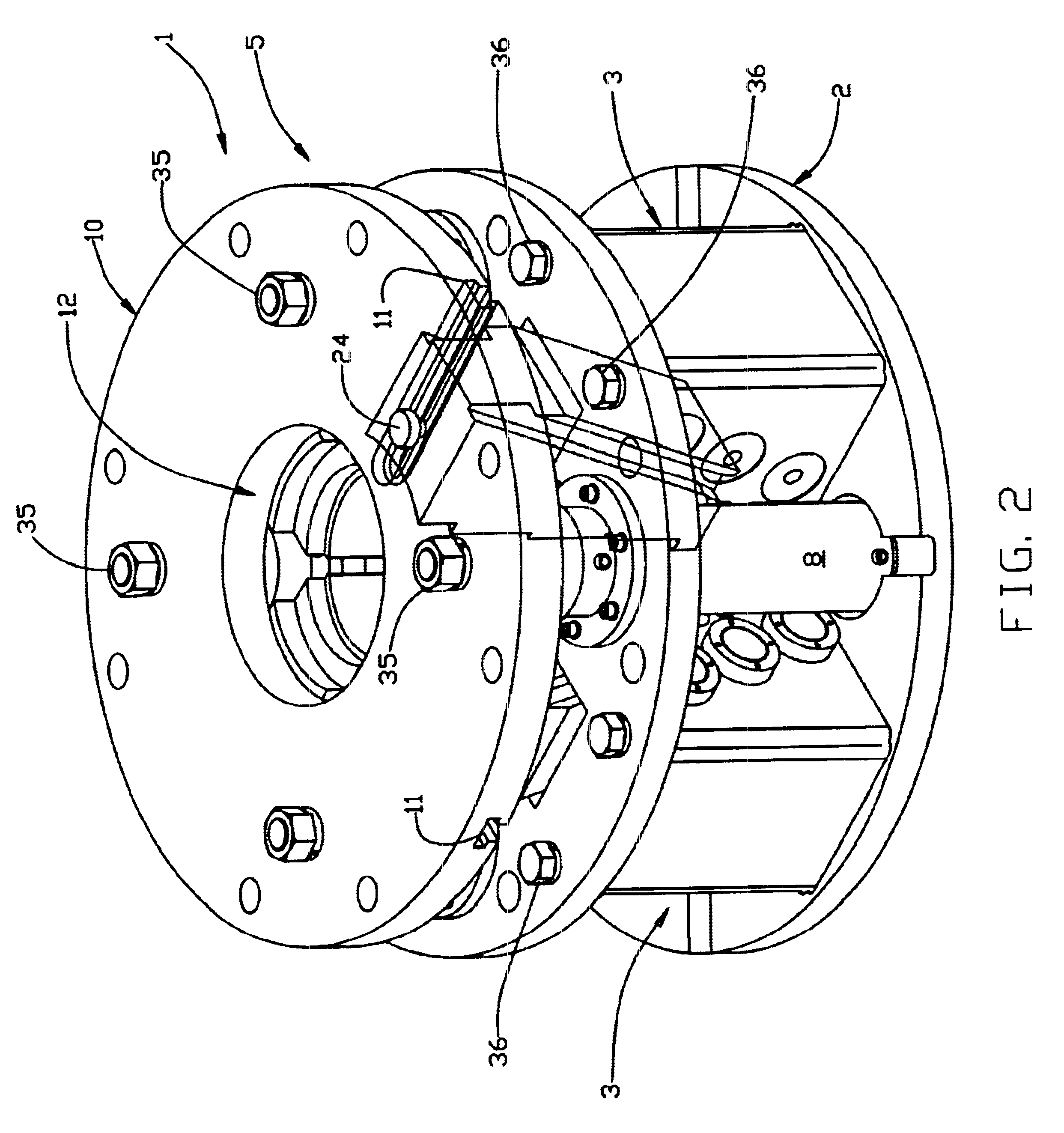

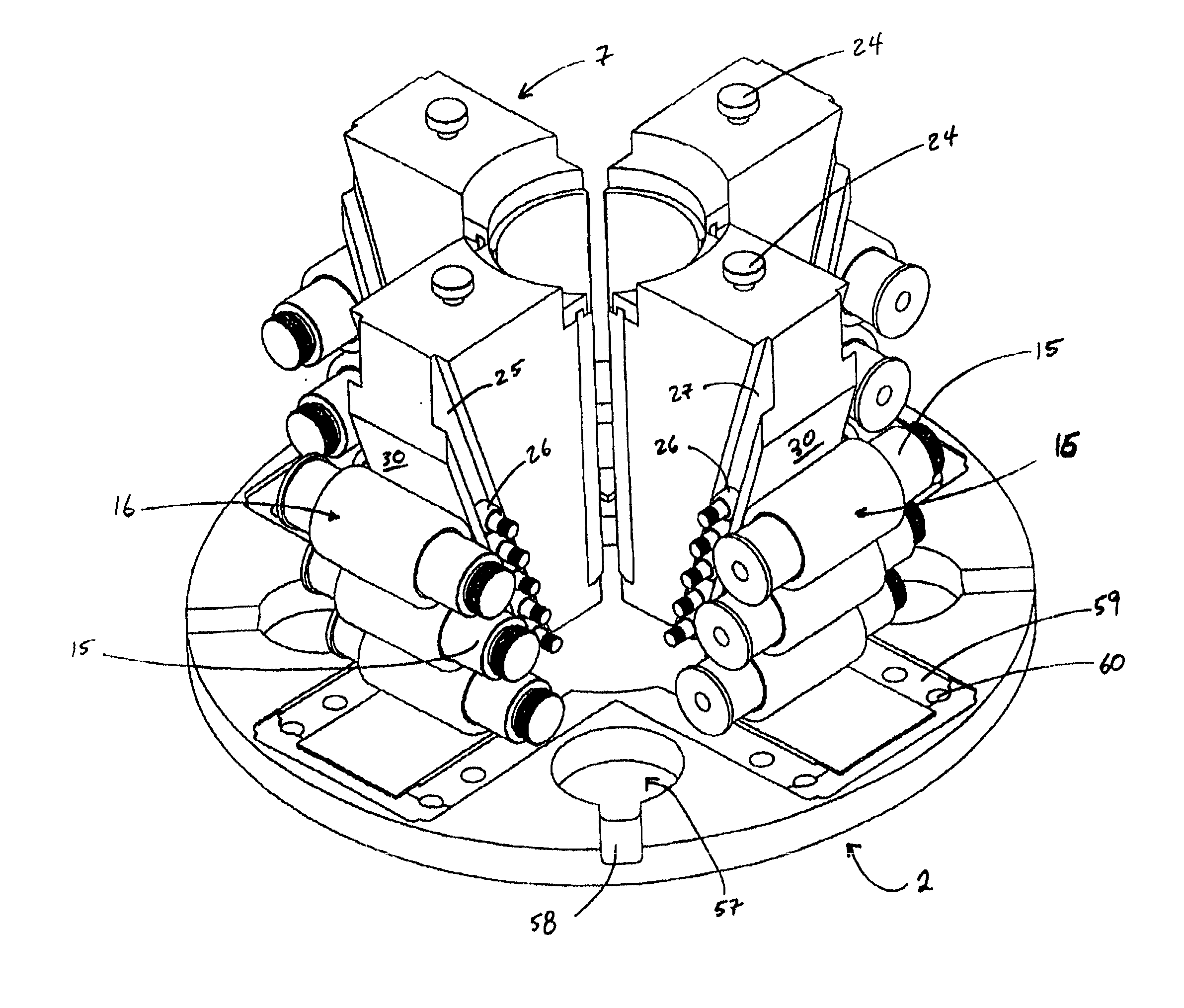

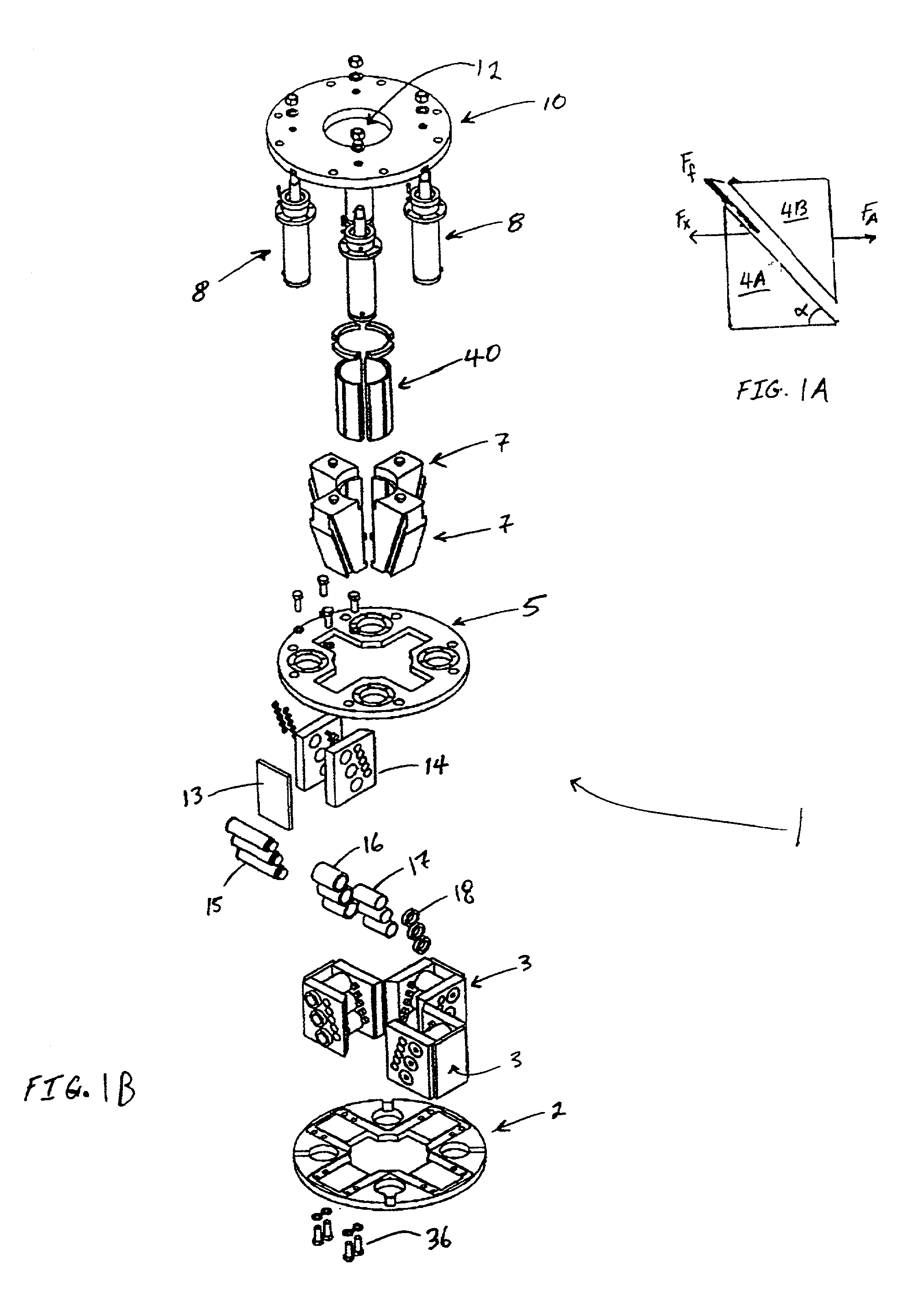

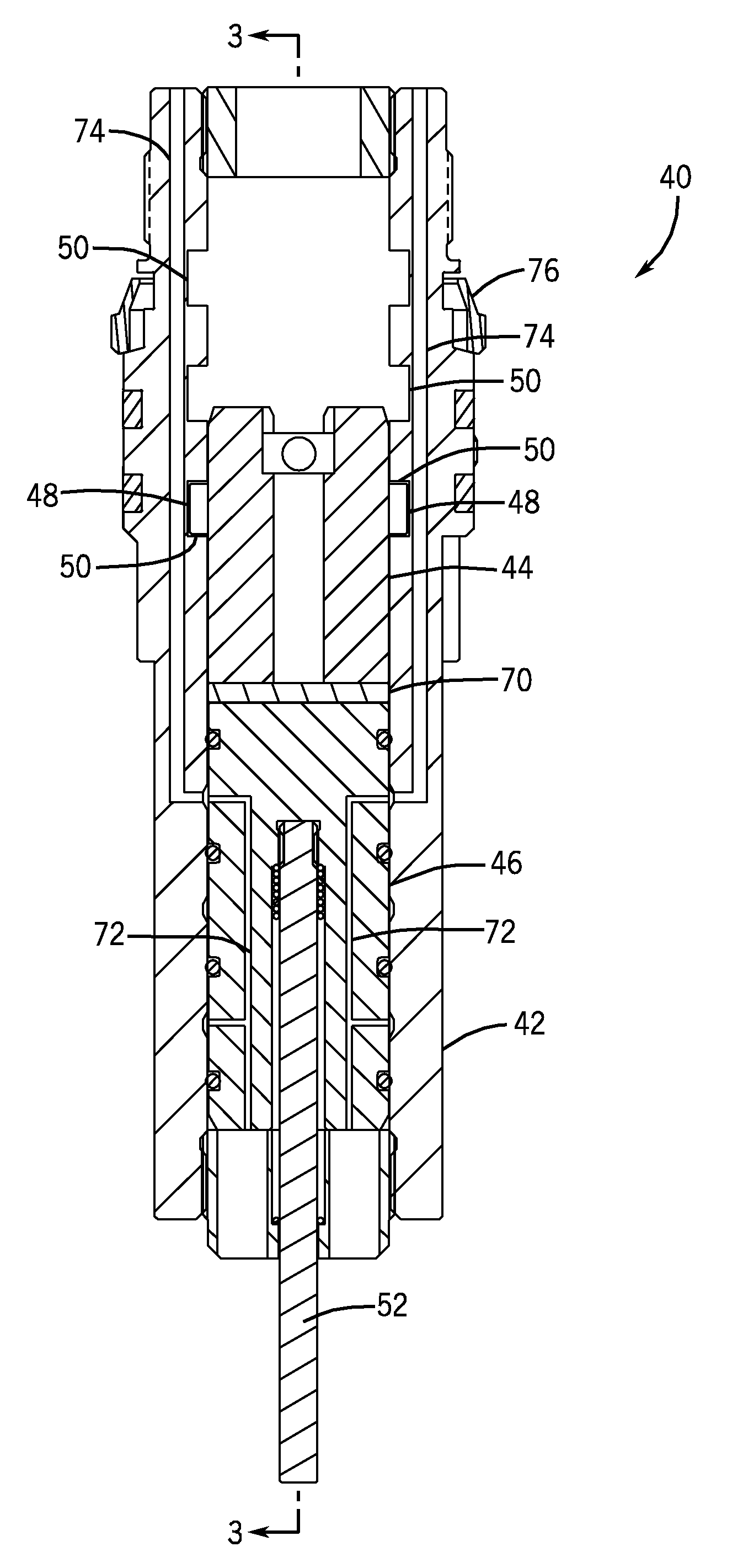

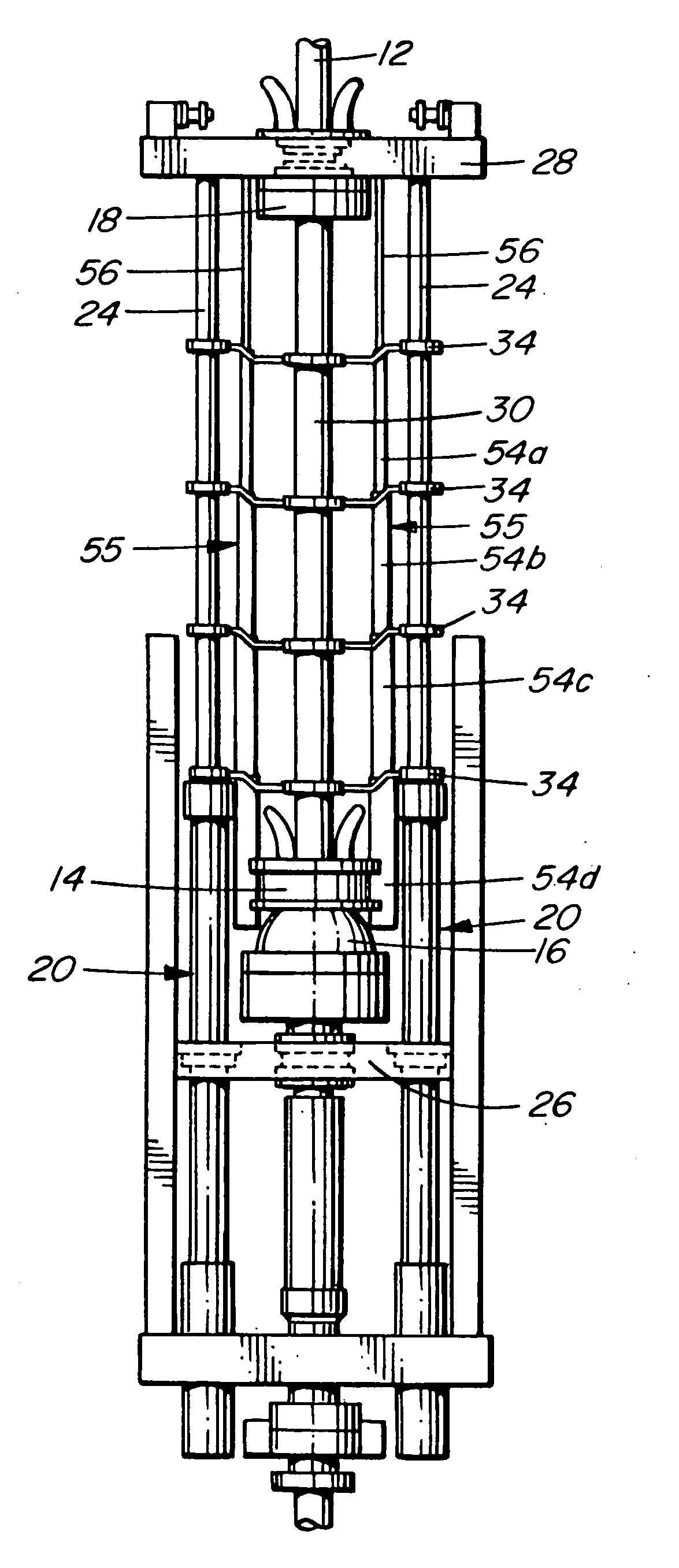

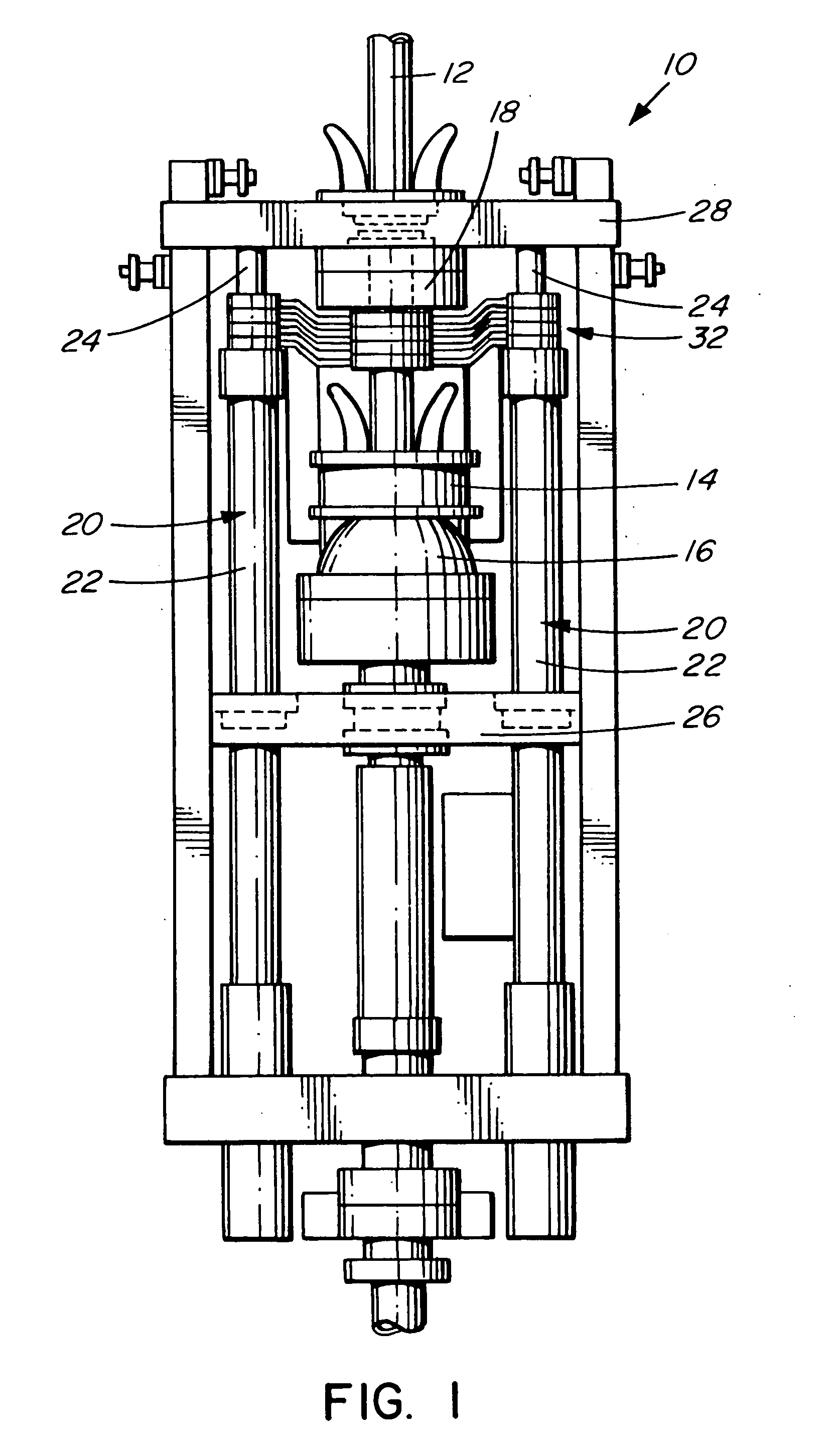

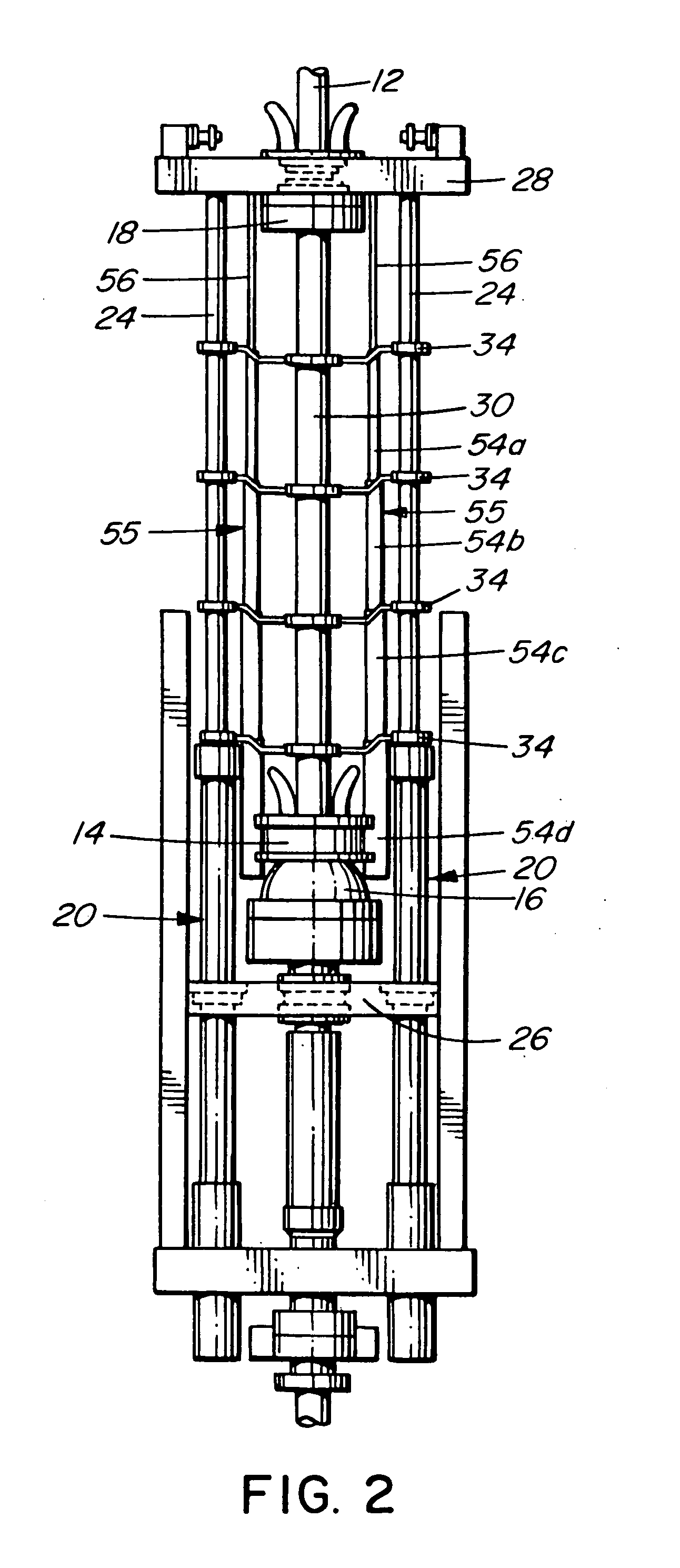

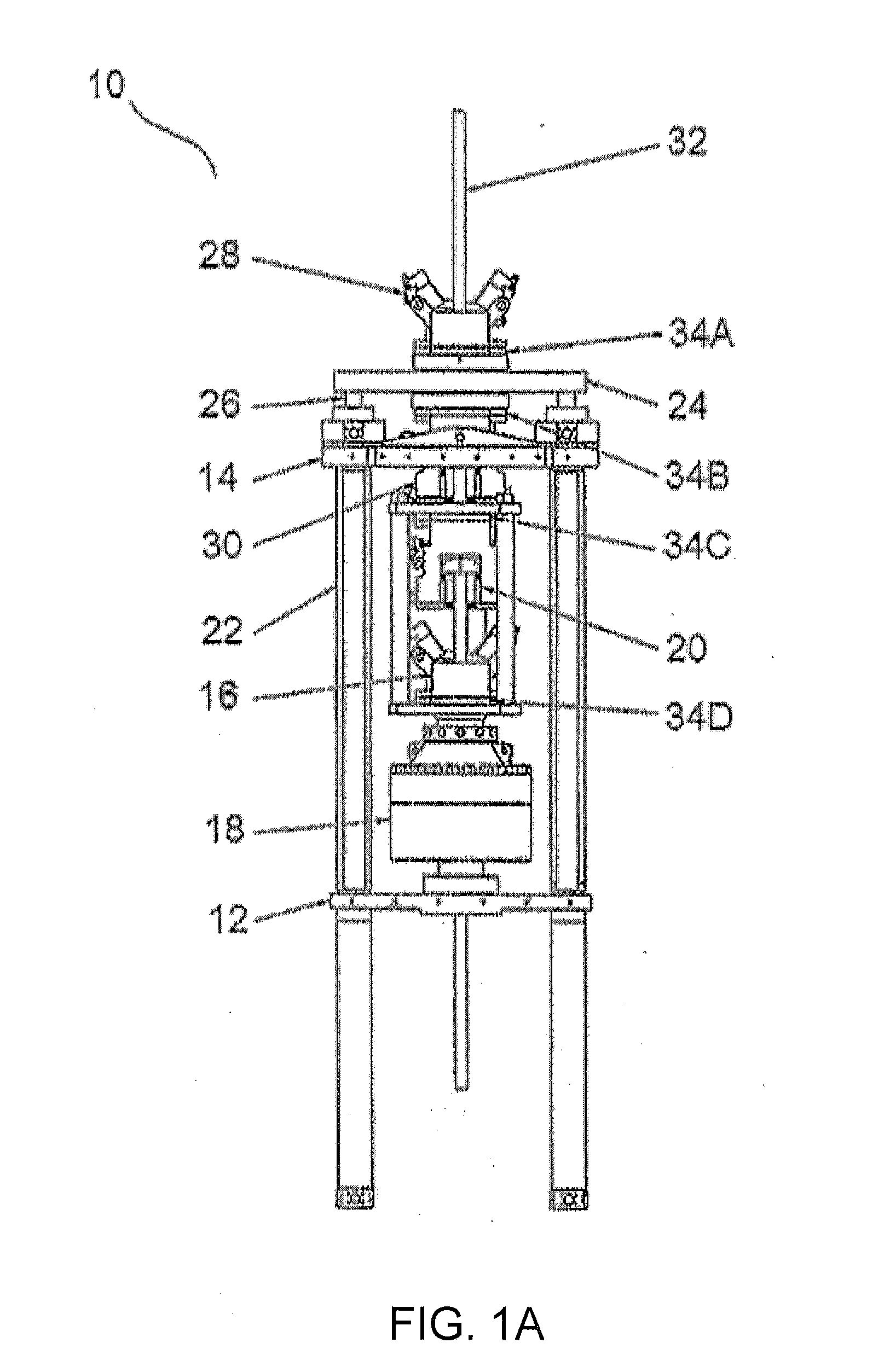

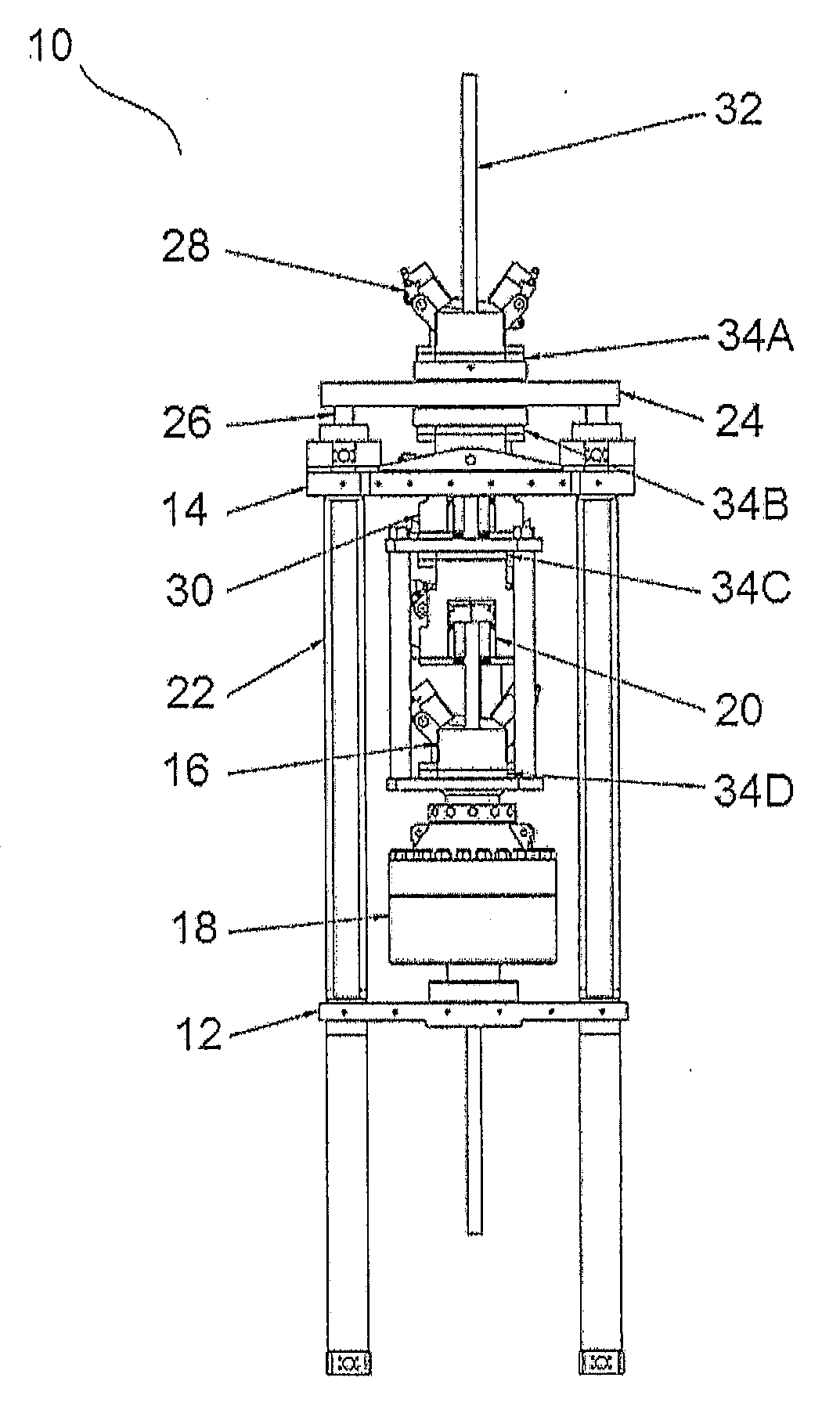

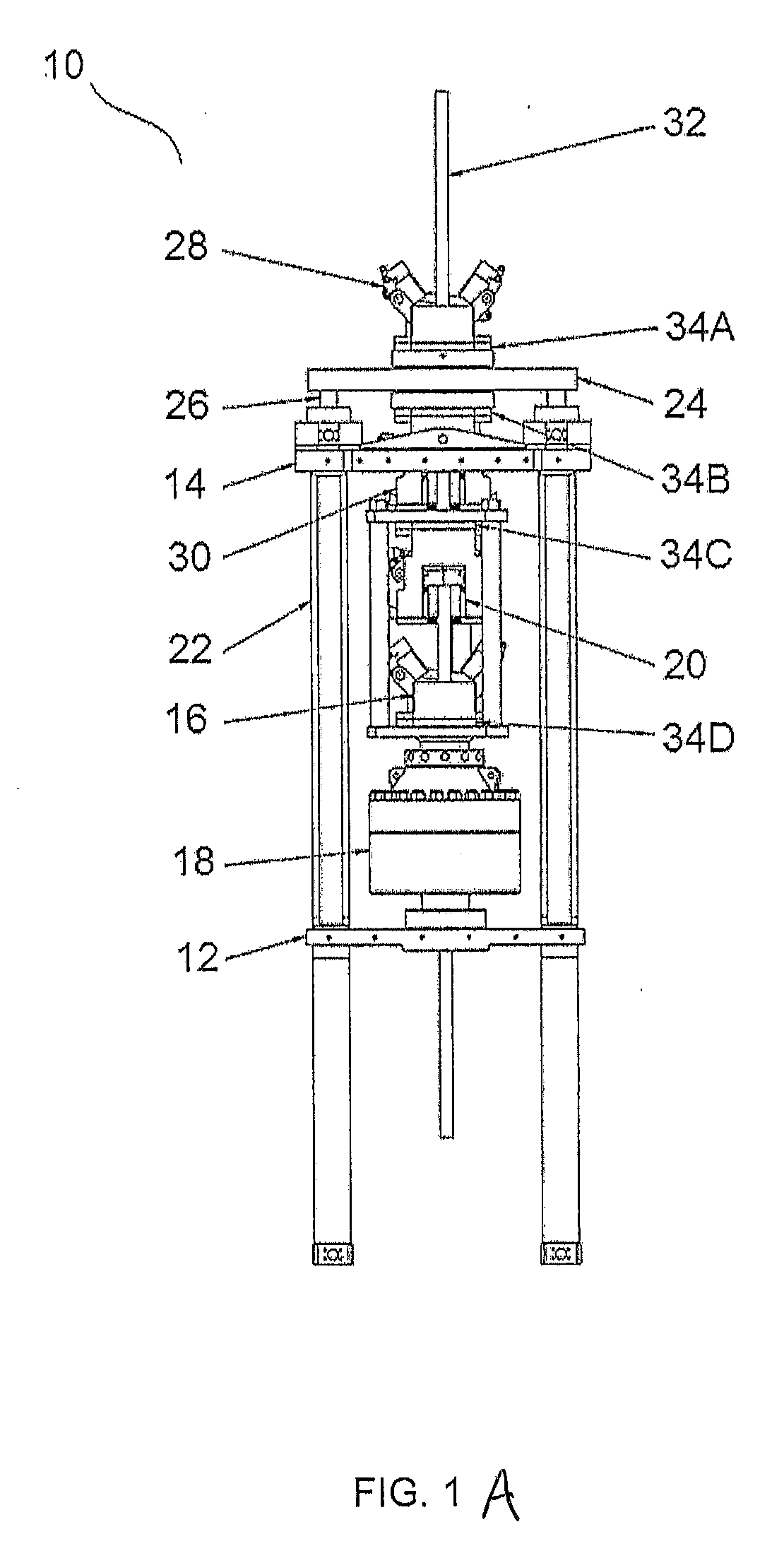

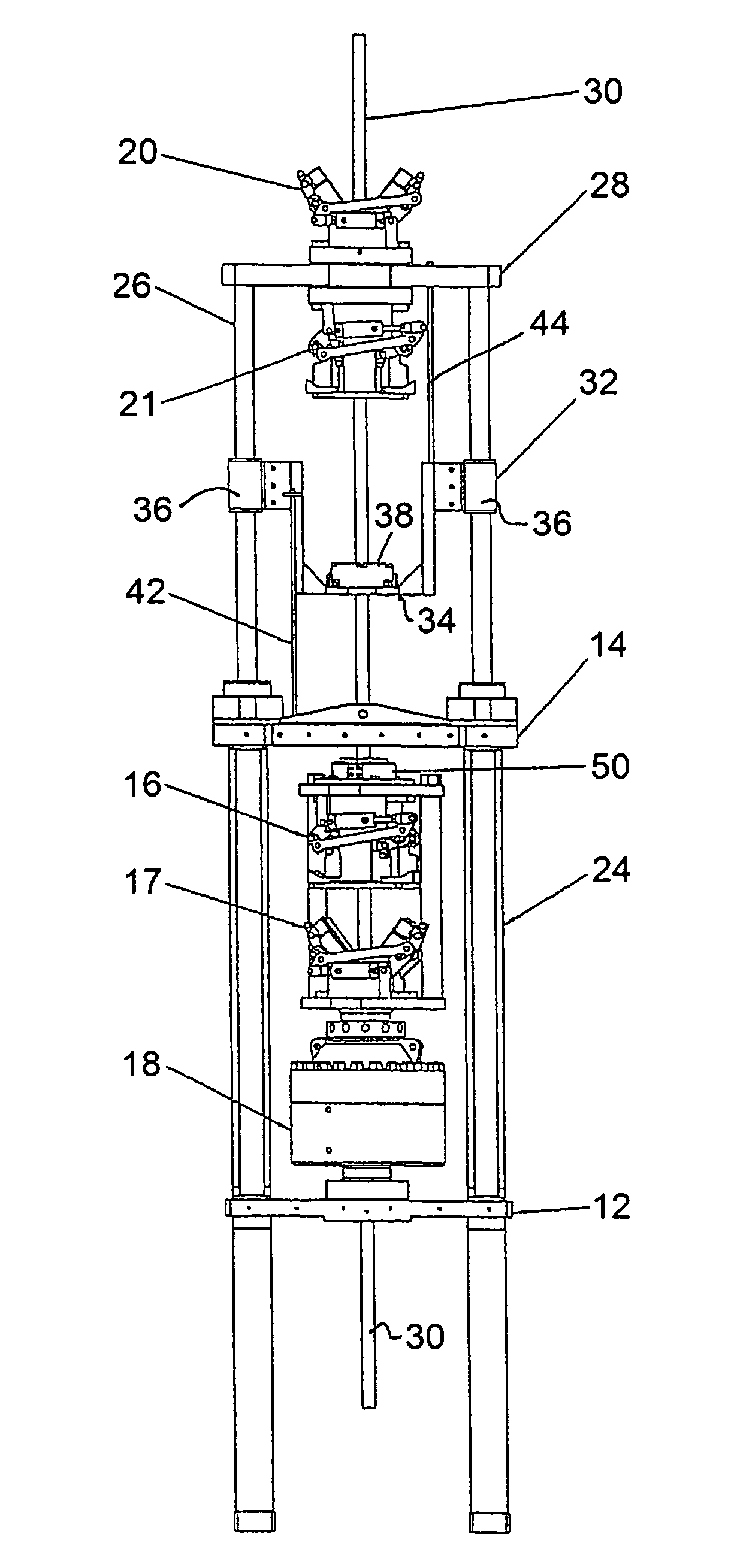

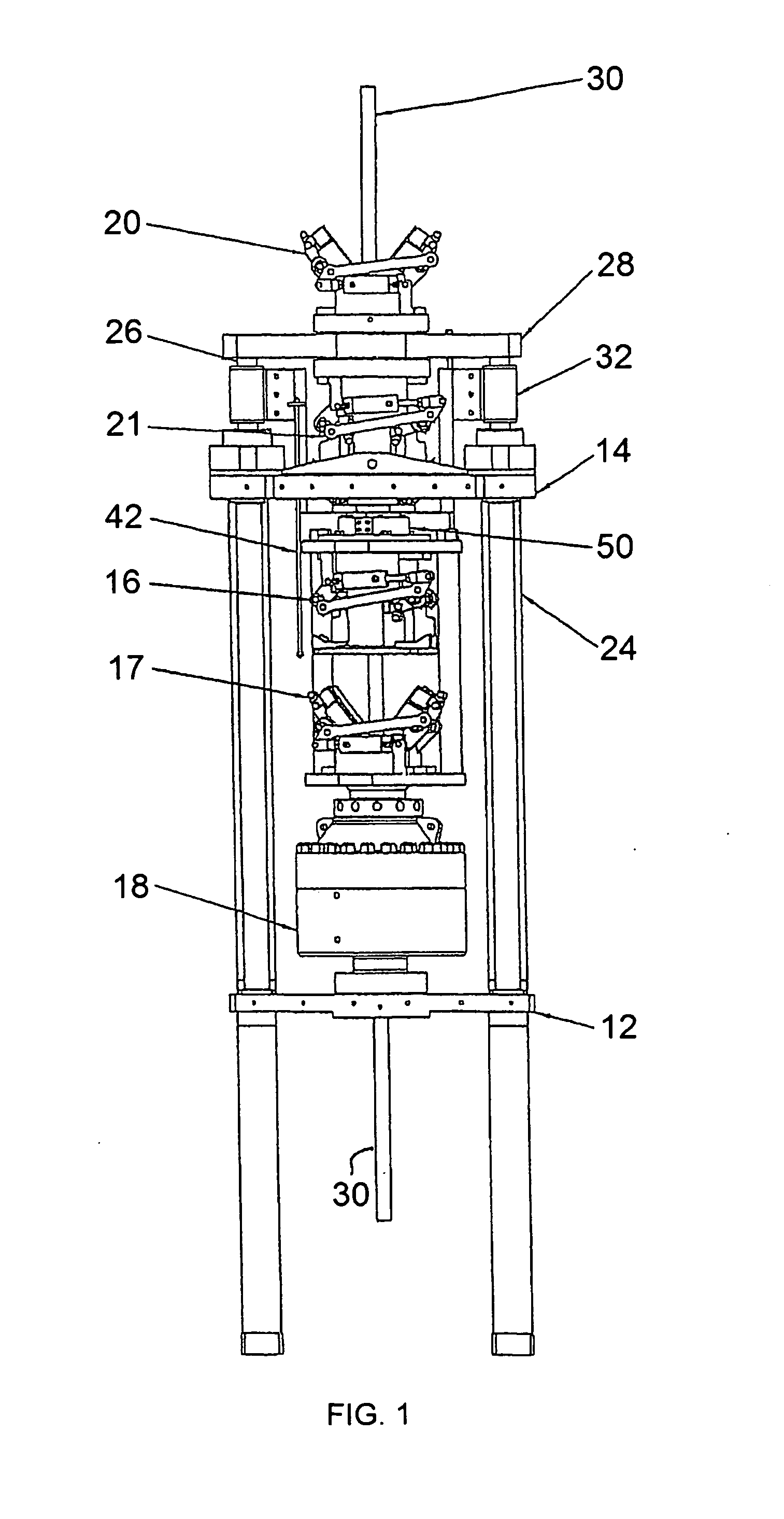

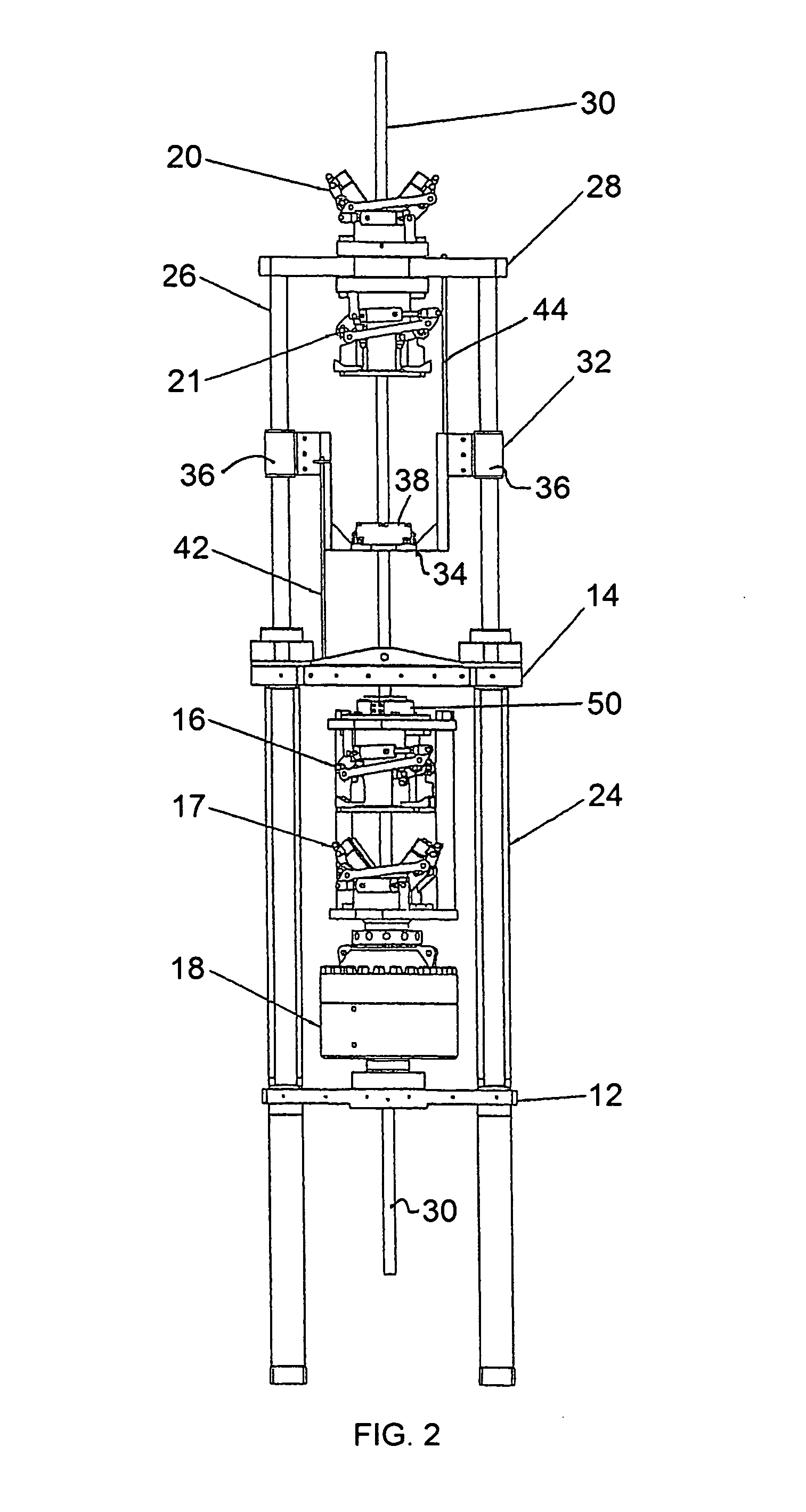

Snubbing unit with improved slip assembly

An improved snubbing unit including a snubbing unit base, a lifting assembly having a platform positioned above the base, a rotary table positioned on the snubbing unit, and a first slip assembly positioned on the rotary table. The first slip assembly further includes a base plate with a center aperture formed therein, at least two separate slip frames positioned on the base plate around the center aperture, wherein each of the slip frames includes a slip surface, and a die carrier positioned within each of the slip frames, wherein each of the die carriers also includes a surface for engagement with the slip surfaces of said slip frames. Additionally, a second slip assembly will be positioned on the snubbing unit.

Owner:MCCOY CORPORATION

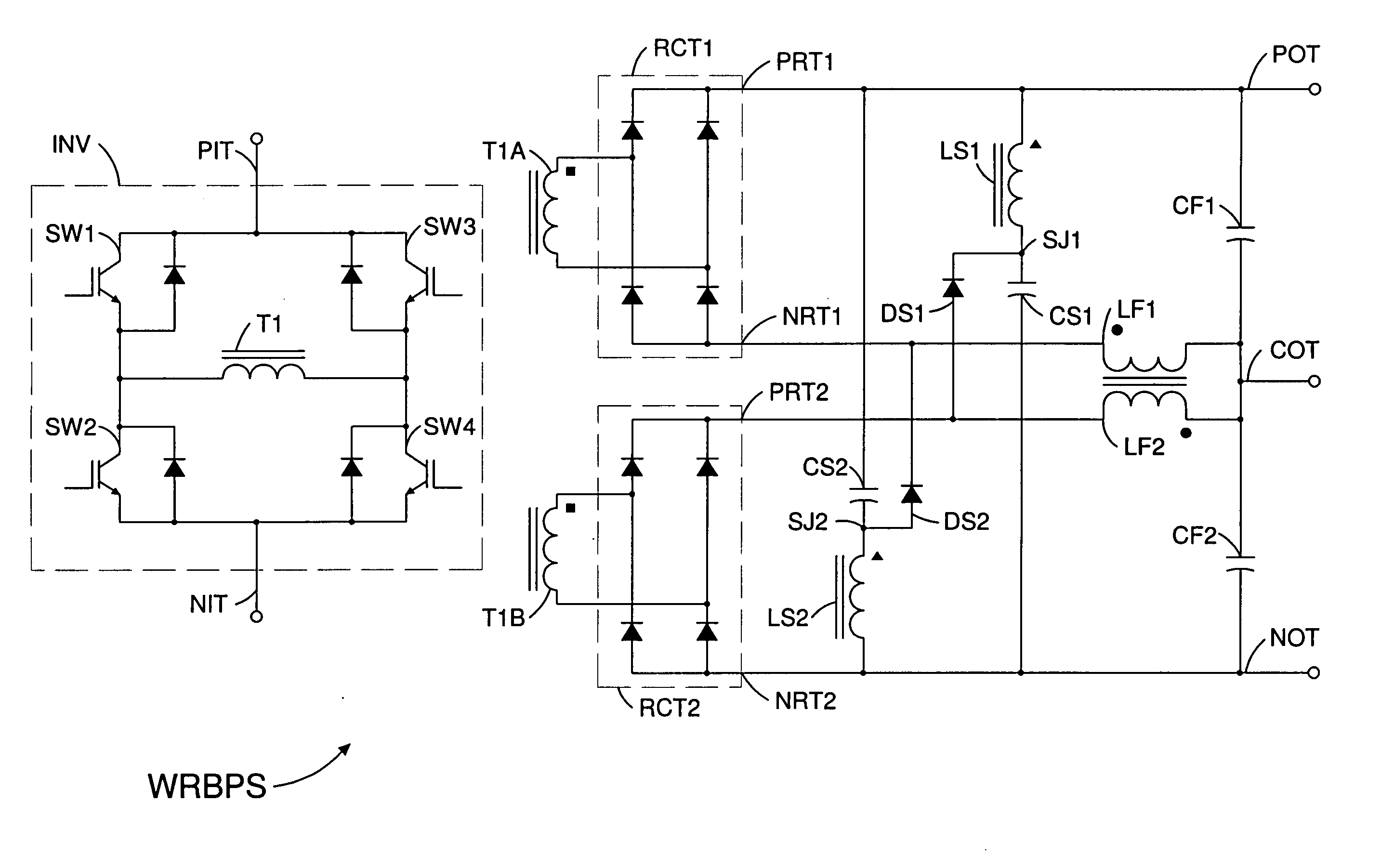

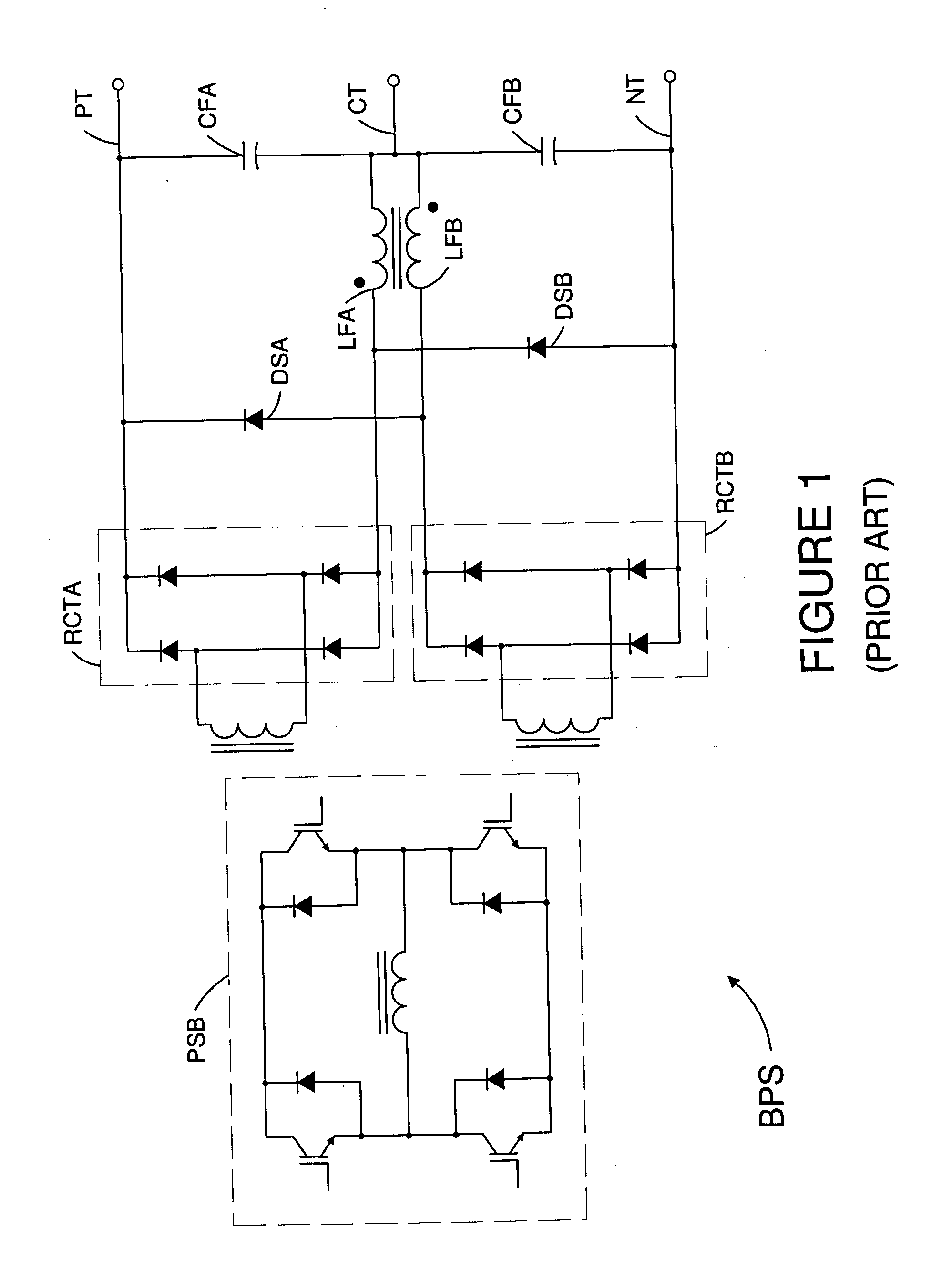

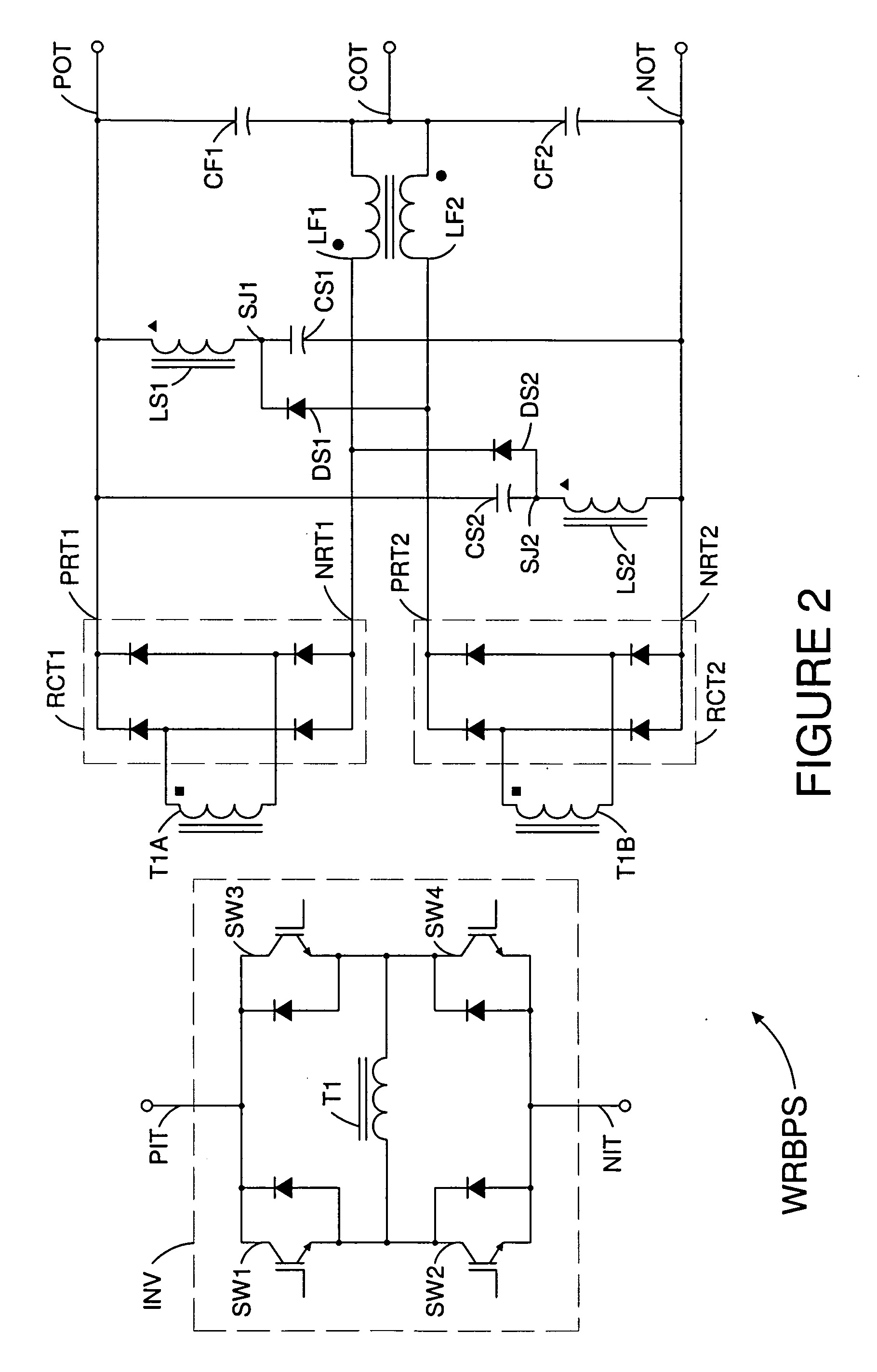

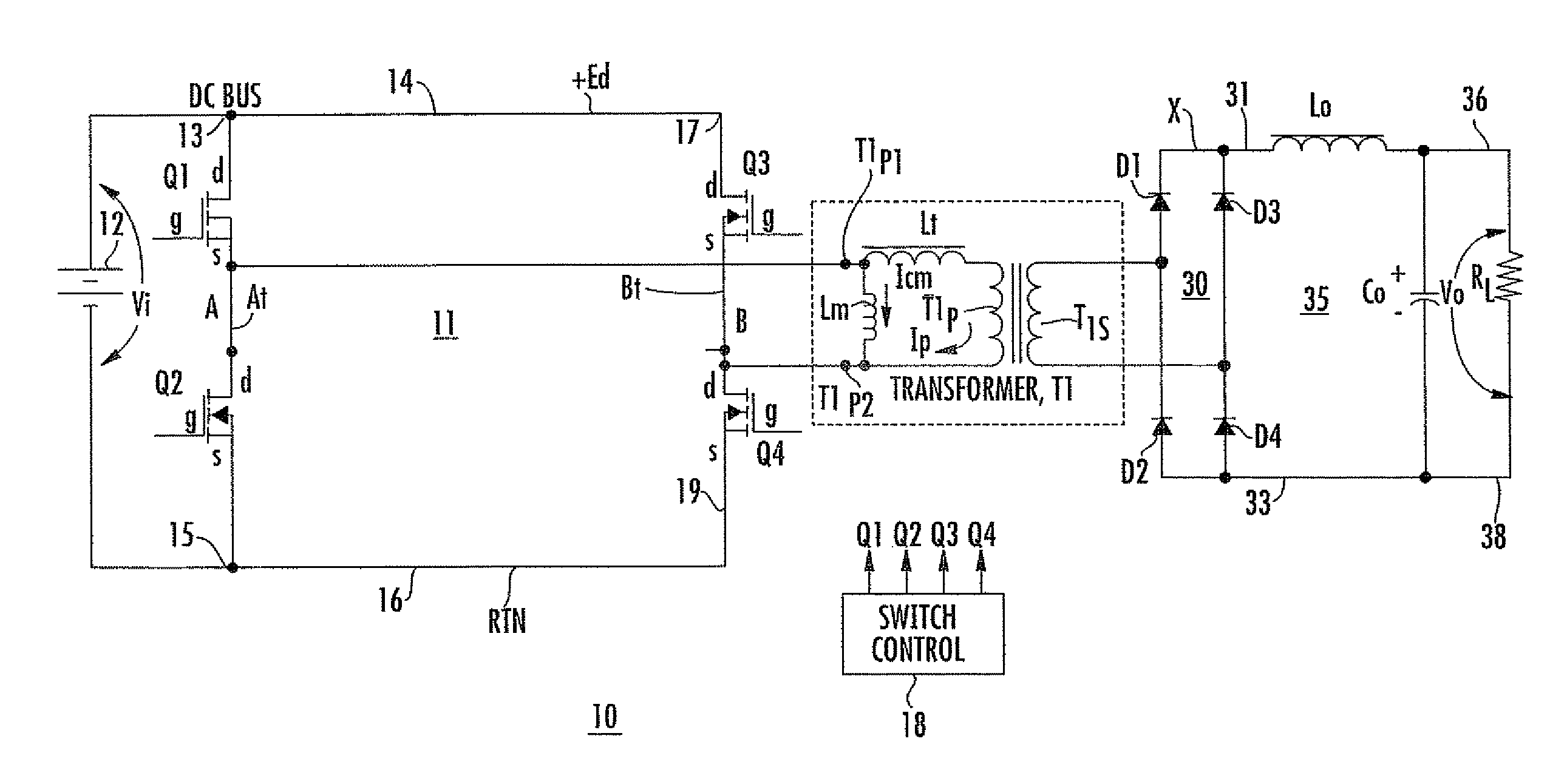

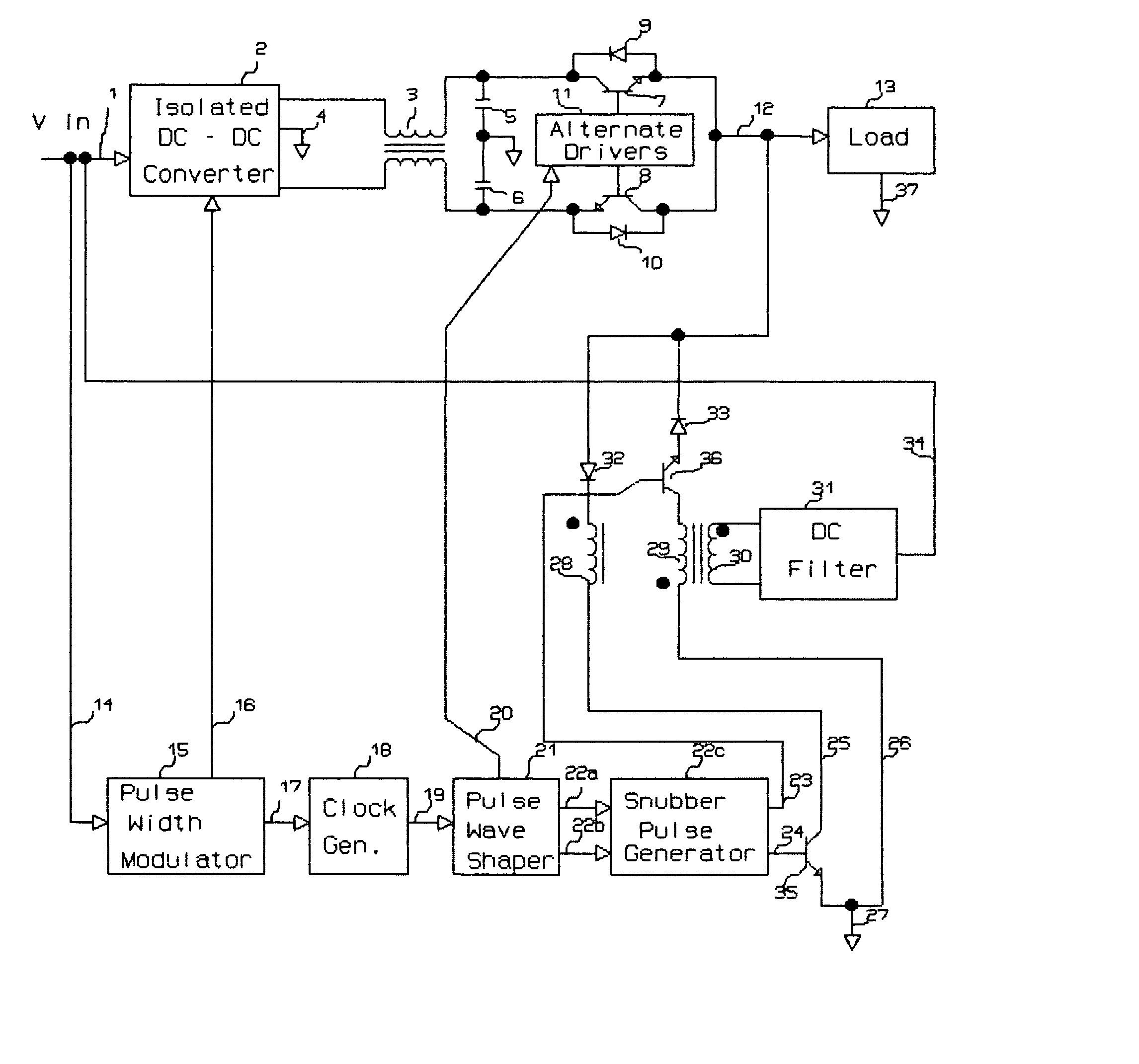

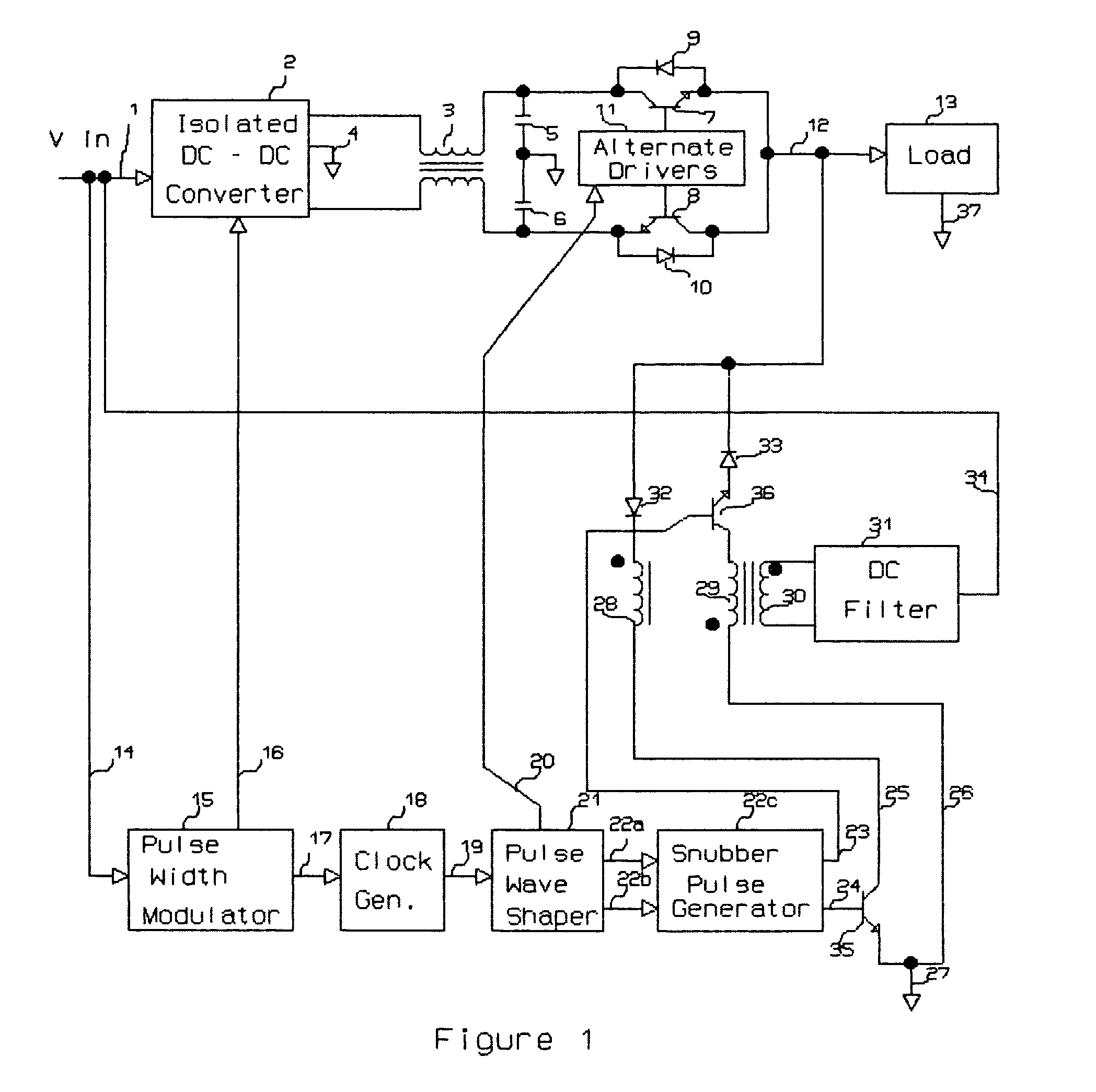

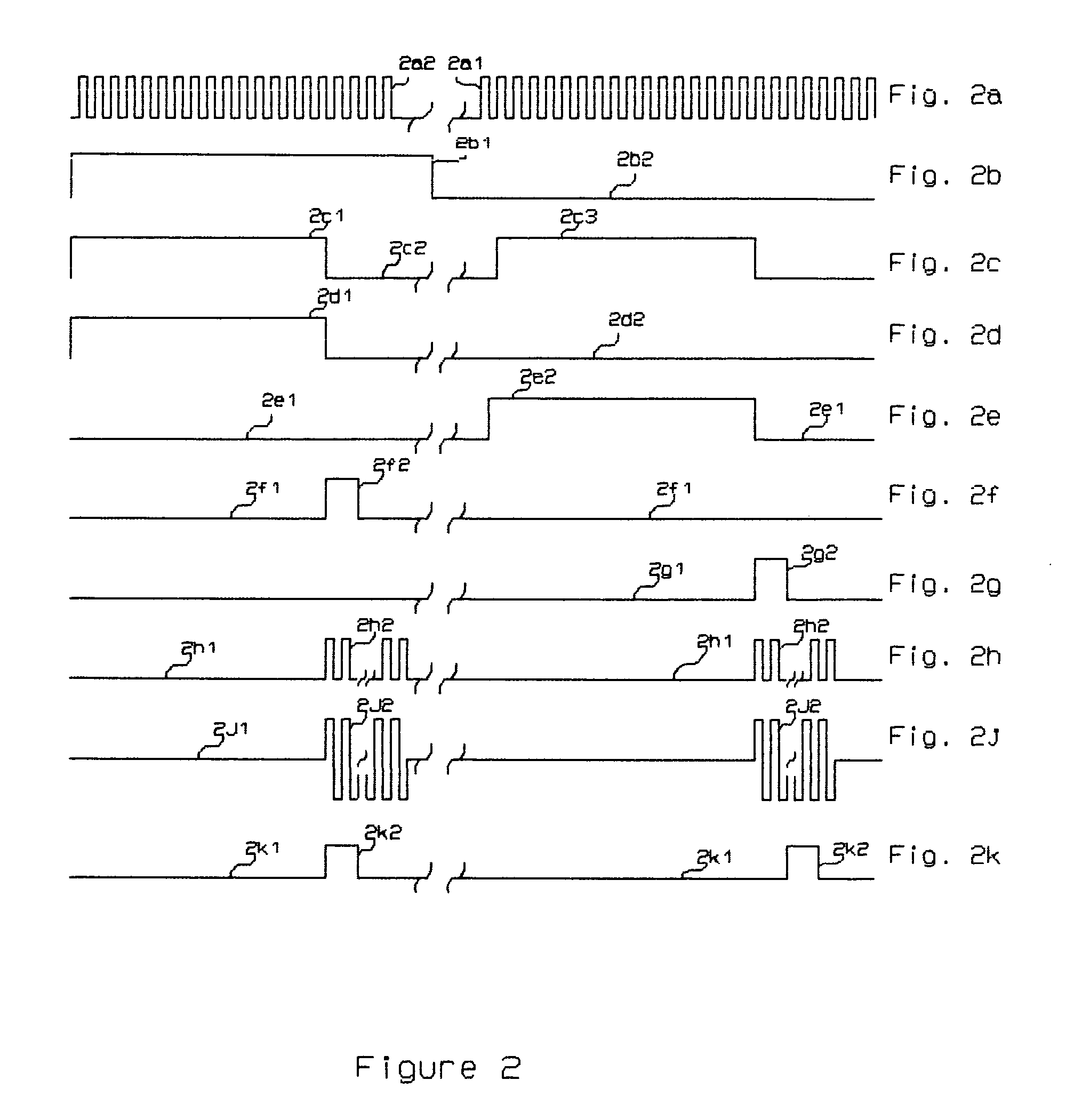

Bipolar power supply with lossless snubber

InactiveUS20070047275A1High voltage capabilityWide output voltage rangeConversion with intermediate conversion to dcDc-dc conversionAc power systemFilter capacitor

In one aspect of the invention, an isolated power converter suitable for high power and high voltage applications comprises stacked rectifiers and lossless snubber circuits with inductors that prevent snubber diodes from delivering large current pulses into output filter capacitors when the duty cycle of the inverter is low, thereby allowing effective snubbing without unduly restricting the voltage conversion range of the power supply. In another aspect of the invention, control circuitry of a power supply comprises both a high bandwidth input current regulator and a low bandwidth output voltage regulator. The combination of a wide bandwidth input current regulator and a low bandwidth output voltage regulator allows the power supply to emulate an inductively loaded uncontrolled rectifier while restricting negative input impedance characteristics to frequencies that are substantially lower than the frequency of the ac power system.

Owner:ADVANCED ENERGY IND INC

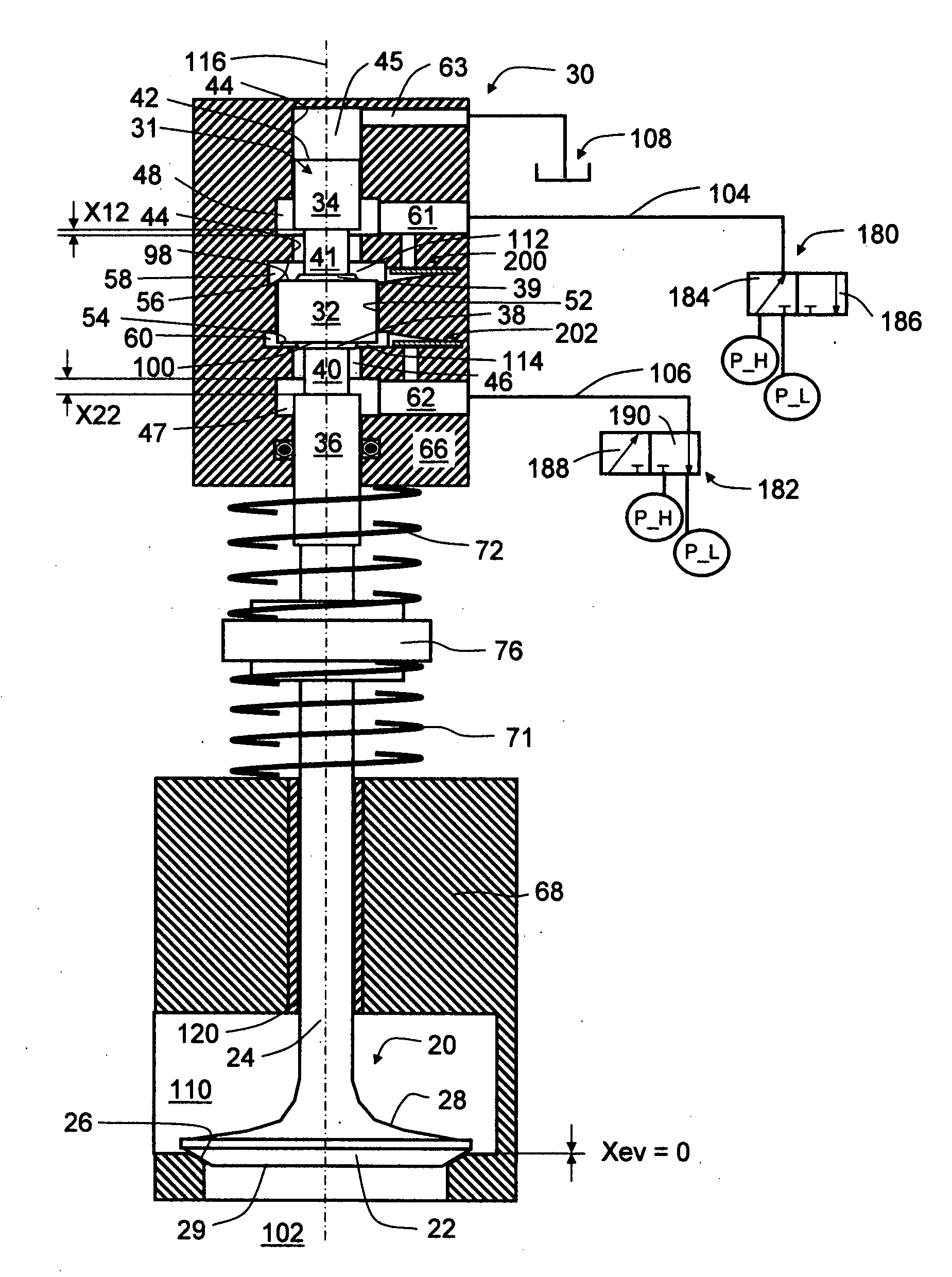

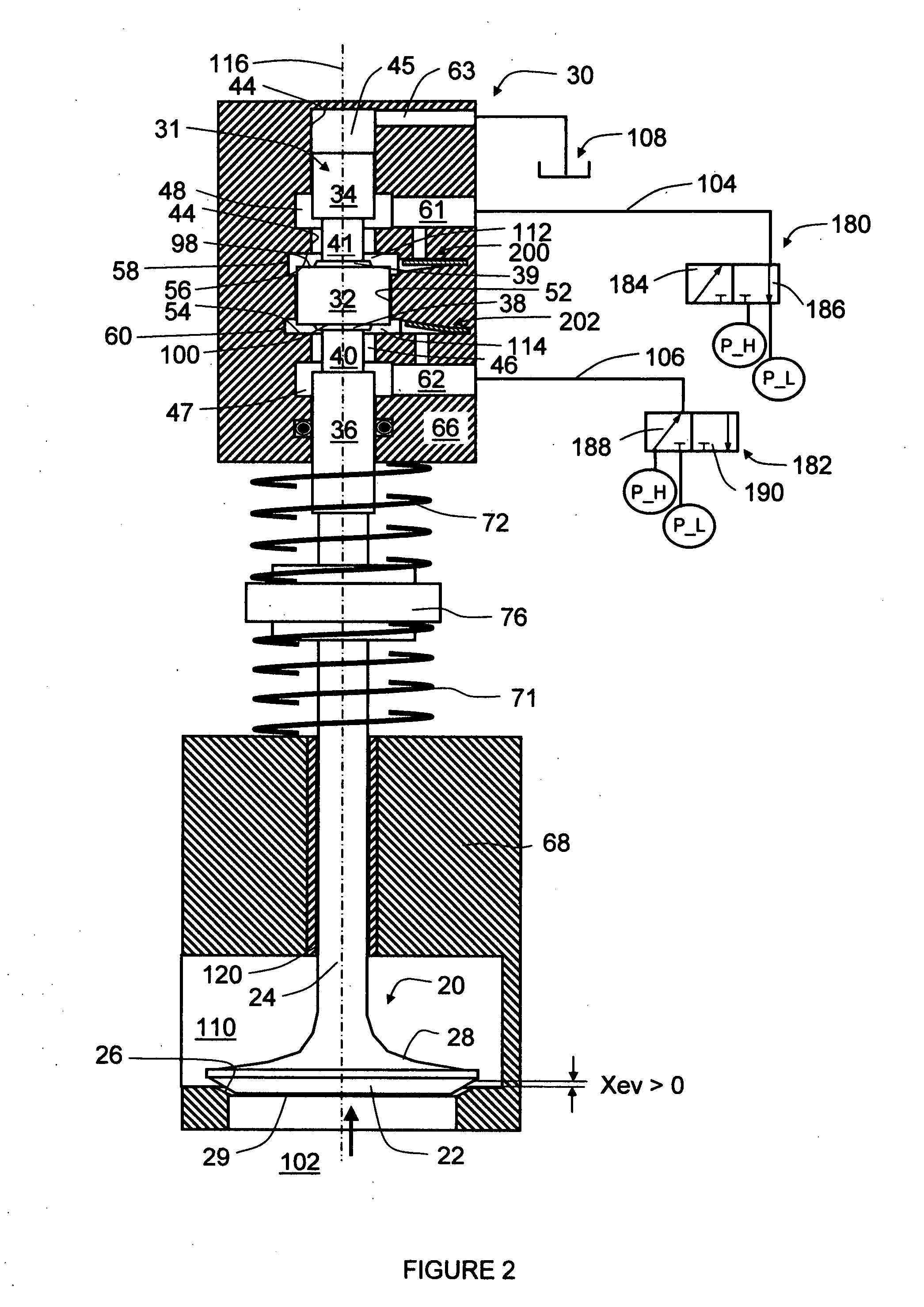

Variable valve actuator with latches at both ends

InactiveUS20080054205A1High forceImprove power densityOperating means/releasing devices for valvesMachines/enginesValve actuatorSpring force

Actuators and corresponding methods and systems for controlling such actuators offer efficient, fast, flexible control with large forces. In an exemplary embodiment, an fluid actuator includes a housing having first and second fluid ports, an actuation cylinder in the housing defining a longitudinal axis and having first and second ends in first and second directions, an actuation piston in the cylinder with first and second surfaces moveable along the longitudinal axis, a spring subsystem biasing the actuation piston to a neutral position, a first fluid space defined by the first end of the actuation cylinder and the first surface of the actuation piston, and a second fluid space defined by the second end of the actuation cylinder and the second surface of the actuation piston. A first flow mechanism controls fluid communication between the first fluid space and the first port, whereas a second flow mechanism controls fluid communication between the second fluid space and the second port. The first and second flow mechanisms are substantially restricted through two integrated snubbing mechanisms when the actuation piston approaches the first and second direction ends of its travel, respectively. In addition to a differential fluid force on the actuation piston, there is a centering or returning spring force available to help open the engine valve against the high cross-over passage pressure, without the need for the fluid actuation system to be bulky and consume too much energy.

Owner:LGD TECH LLC

Snubbing unit with improved slip assembly

An improved snubbing unit including a snubbing unit base, a lifting assembly having a platform positioned above the base, a rotary table positioned on the snubbing unit, and a first slip assembly positioned on the rotary table. The first slip assembly further includes a base plate with a center aperture formed therein, at least two separate slip frames positioned on the base plate around the center aperture, wherein each of the slip frames includes a slip surface, and a die carrier positioned within each of the slip frames, wherein each of the die carriers also includes a surface for engagement with the slip surfaces of said slip frames. Additionally, a second slip assembly will be positioned on the snubbing unit.

Owner:MCCOY CORPORATION

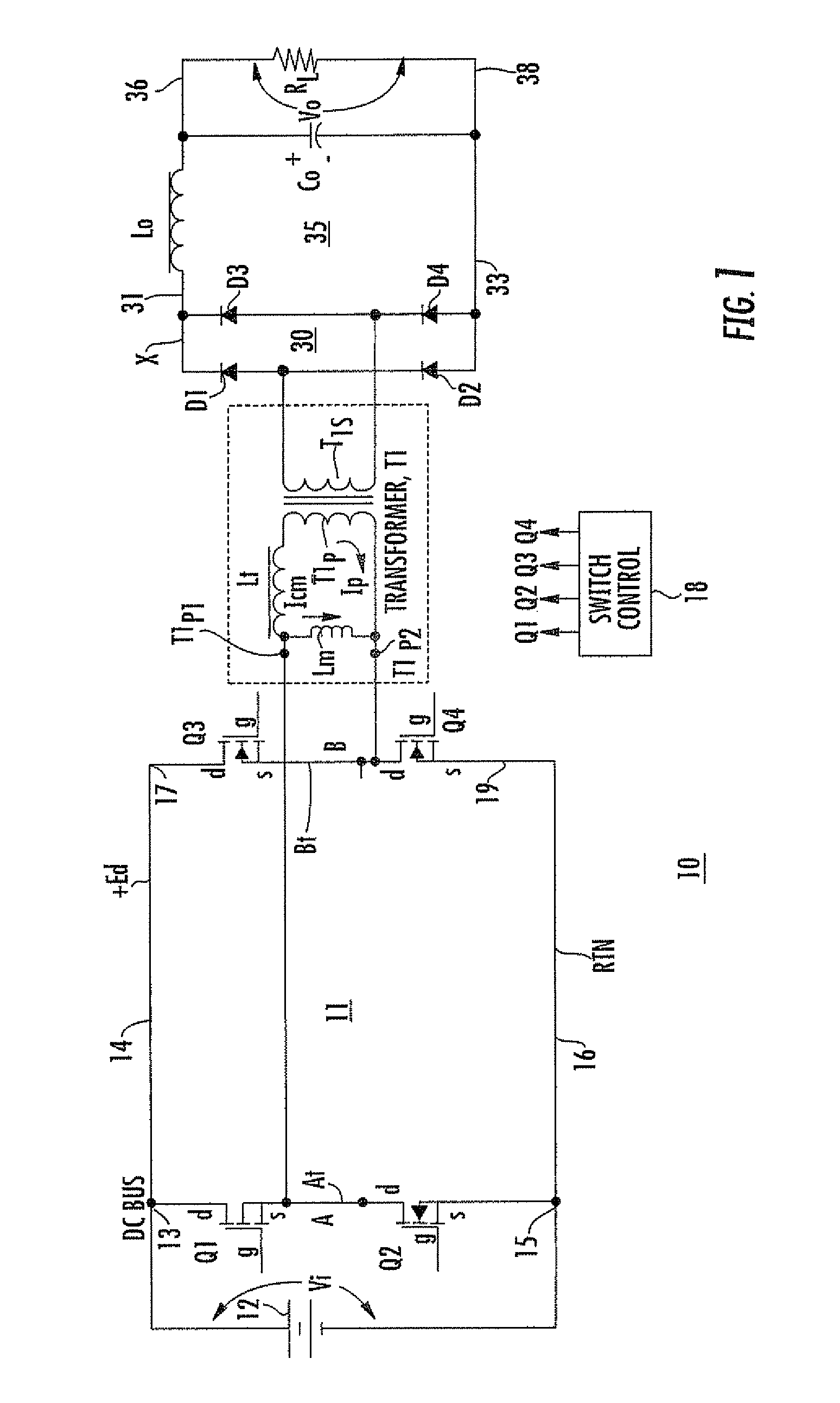

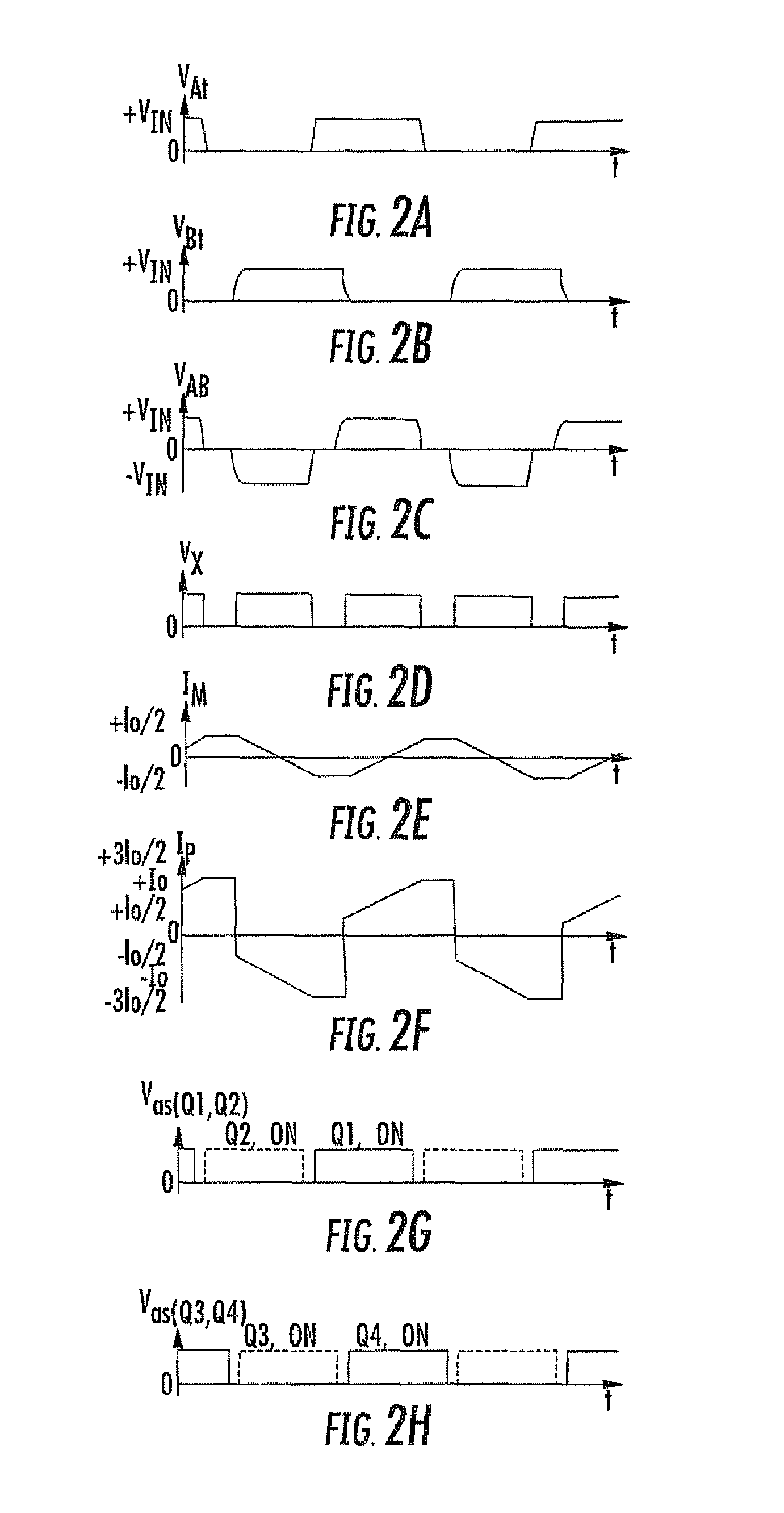

Voltage clamps for energy snubbing

InactiveUS7859870B1Ac-dc conversion without reversalEfficient power electronics conversionOutput transformerPhase shifted

A power converter generates direct voltage and includes a phase-shifted PWM bridge with first and second controllable switches connected as a half-bridge with a first tap, for generating AC at the first tap. An output transformer includes a primary winding coupled to the first tap. A full-wave rectifier is connected to a secondary winding of the output transformer. A filter is coupled to the full-wave rectifier for producing filtered output direct voltage. Resonances create surges which may undesirably result in energy loss. A second transformer includes a primary winding coupled to receive the resonant surges and a secondary winding at which transformed surges appear. A second rectifier is coupled to the secondary winding of the second transformer, for rectifying the surges. The energy of the surges is returned or coupled to the source or load. In one embodiment, the full-wave rectifier is a bridge rectifier.

Owner:LOCKHEED MARTIN CORP

Combination burst-disc subassembly for horizontal and vertical well completions

A combination profile and burst-disc subassembly is provided for use in directional, horizontal or deviated or vertical wells during snubbing, bridge plug retrieval or zone separation operations in combination with packers and / or completion strings; the sub provides an plug for non-vertical situations which can be opened without wireline, while providing a landing for a wireline plug which may be required for vertical well sections during related operations.

Owner:ARMOR TOOLS INT INC

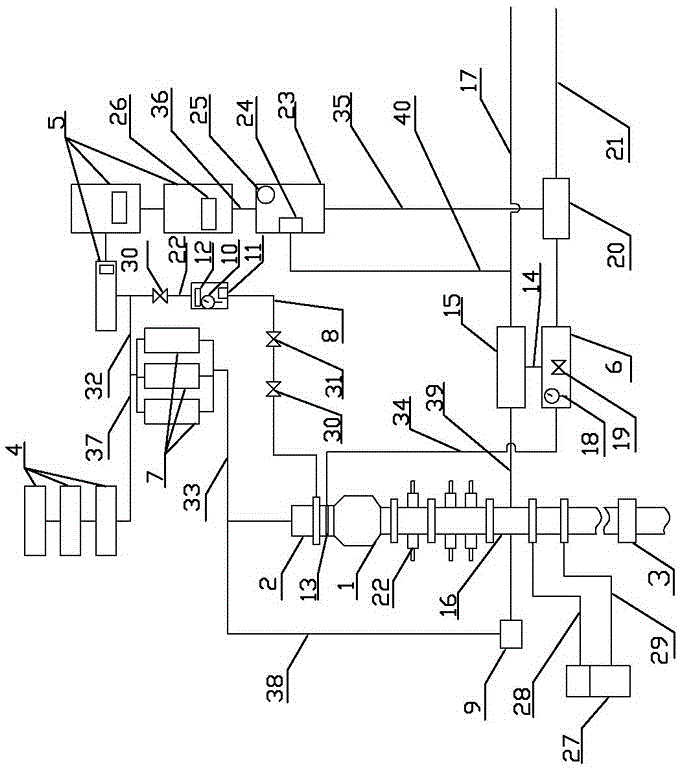

Overall process under-balance drilling pressure compensation system and method

InactiveCN101929331APressure balanceEnsure safe implementationFlushingSealing/packingHigh pressureBlowout preventer

The invention relates to an overall process under-balance drilling pressure compensation system and a method for oil and gas drilling, an underground casing valve (10) is connected on a superior casing string, a wellhead rotary blowout preventer (11) is arranged at an upper end of a wellhead blowout preventer group and is connected with an under-balance throttle manifold (8) through a high-pressure hose (9), a well control manifold (12) which is connected out of a normal wellhead control device by four-pass is connected with a drilling fluid continuous pouring system in parallel by two-pass; and drilling is pulled to the front of the underground casing valve (10), the drilling fluid continuous pouring system grouts, the under-balance throttle manifold (8) controls the pressure in a shaft, and the drilling fluid which is circulated out enters a normal drilling fluid circulating system. In the drilling pulling process, the drilling fluid can be continuously poured into the shaft by a ground pressure compensation system and the bottom-hole pressure can be dynamically controlled simultaneously, thus effectively preventing formation fluid from intruding into the shaft in the drilling pulling process and keeping the steady under-balance state of the shaft.

Owner:中国石油集团西部钻探工程有限公司克拉玛依钻井工艺研究院

Internal lockdown snubbing plug

A snubbing plug is configured to be secured within a component of a mineral extraction system by an internal locking mechanism. In addition, the snubbing plug enables pressure equalization of regions above and below the plug before removal of the plug. Upon insertion of the snubbing plug into a well component, pressure may be equalized via fluid pathways through the snubbing plug. The pathways are sealed closed during snubbing operations and opened again when snubbing operations are complete. Manipulation of the fluid pathways may be accomplished via rotation of a load ring within the snubbing plug.

Owner:CAMERSON INT CORP

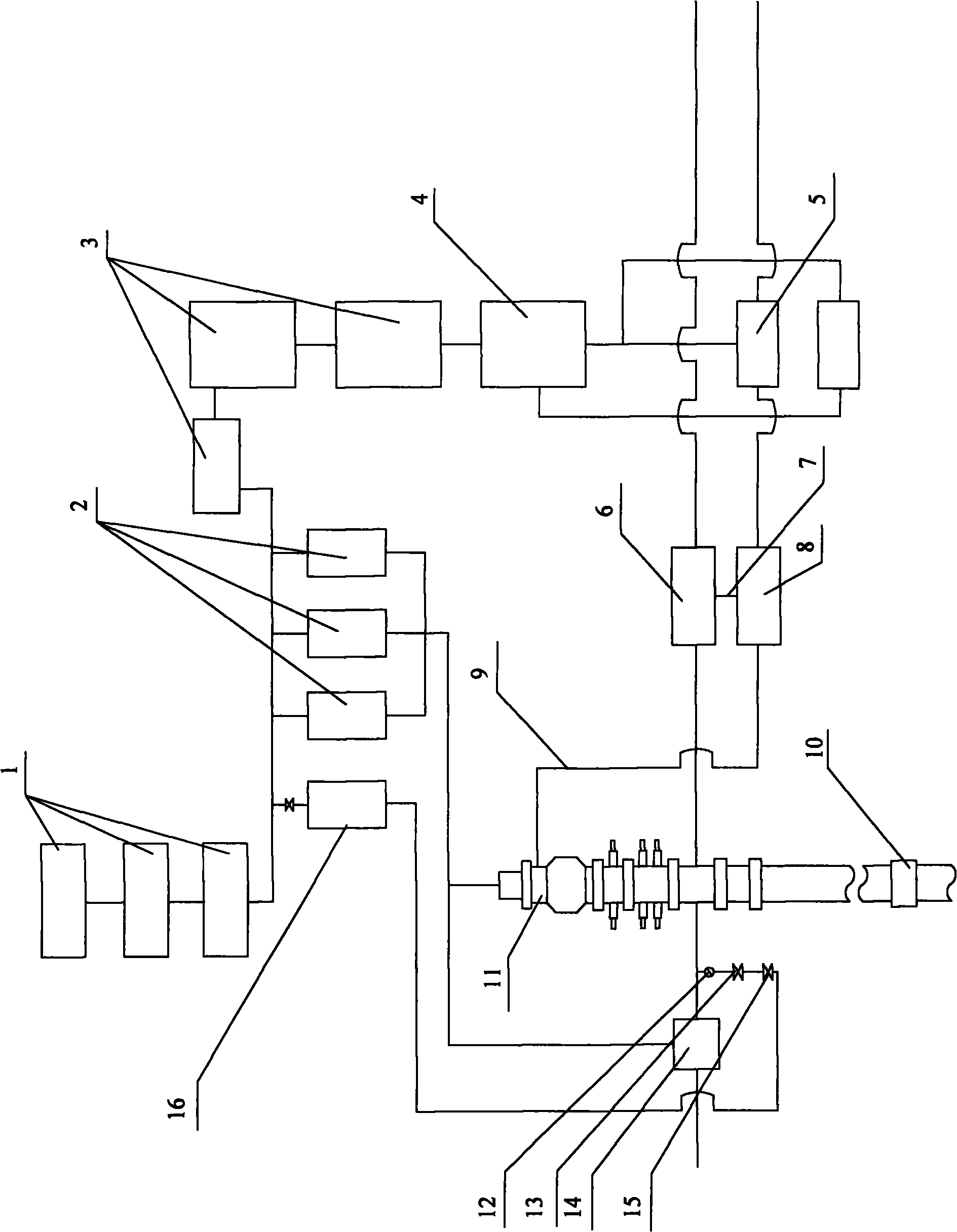

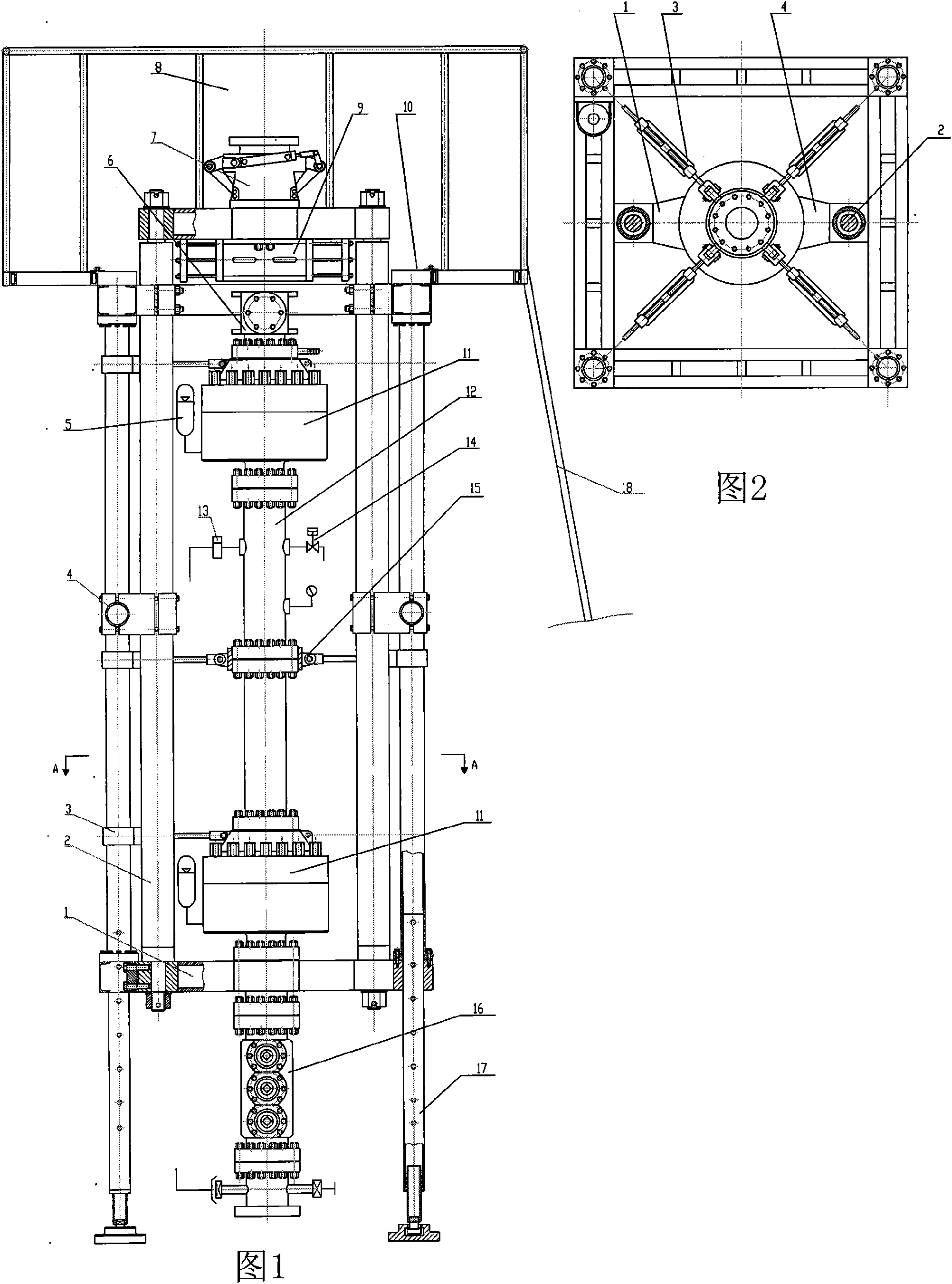

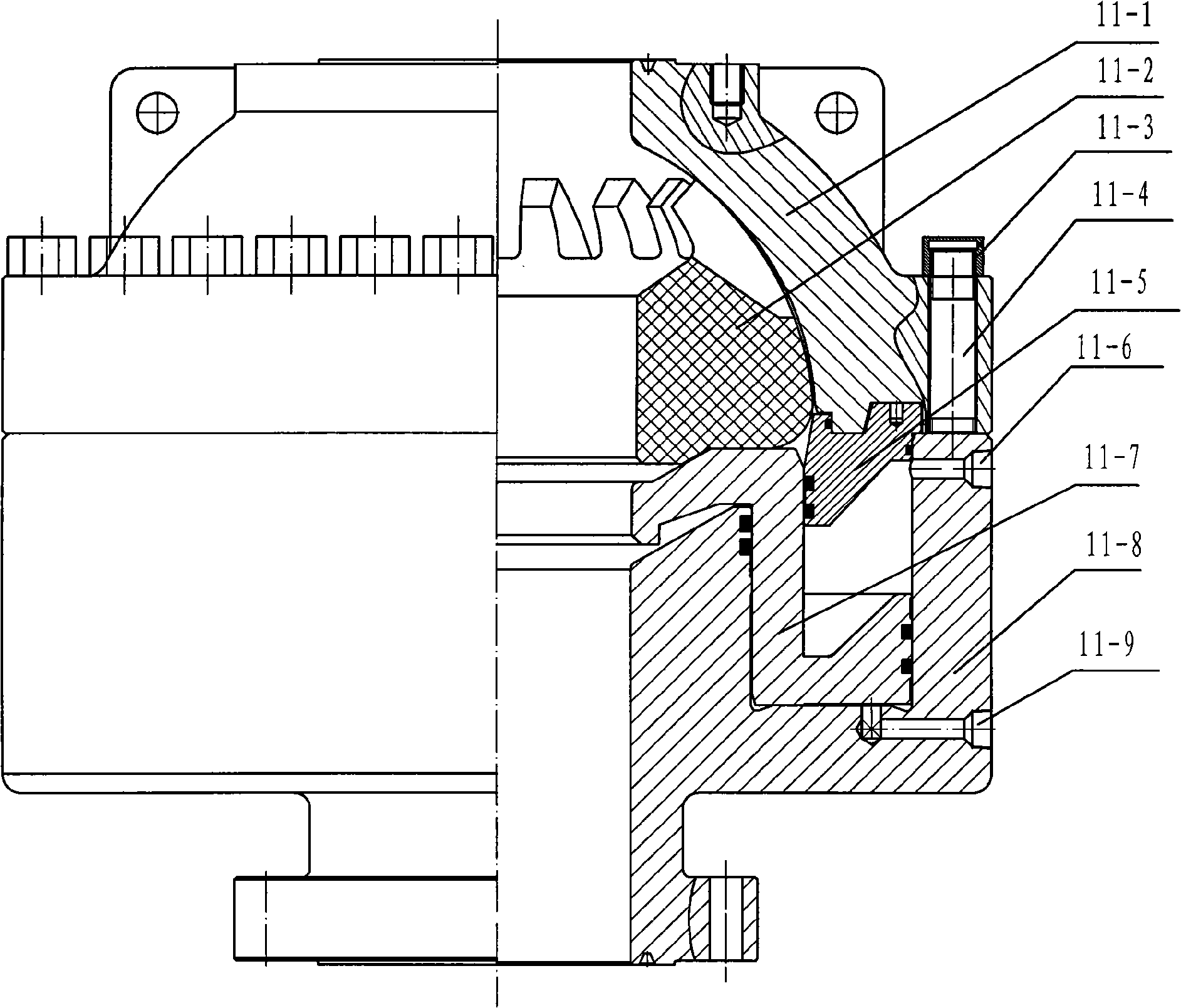

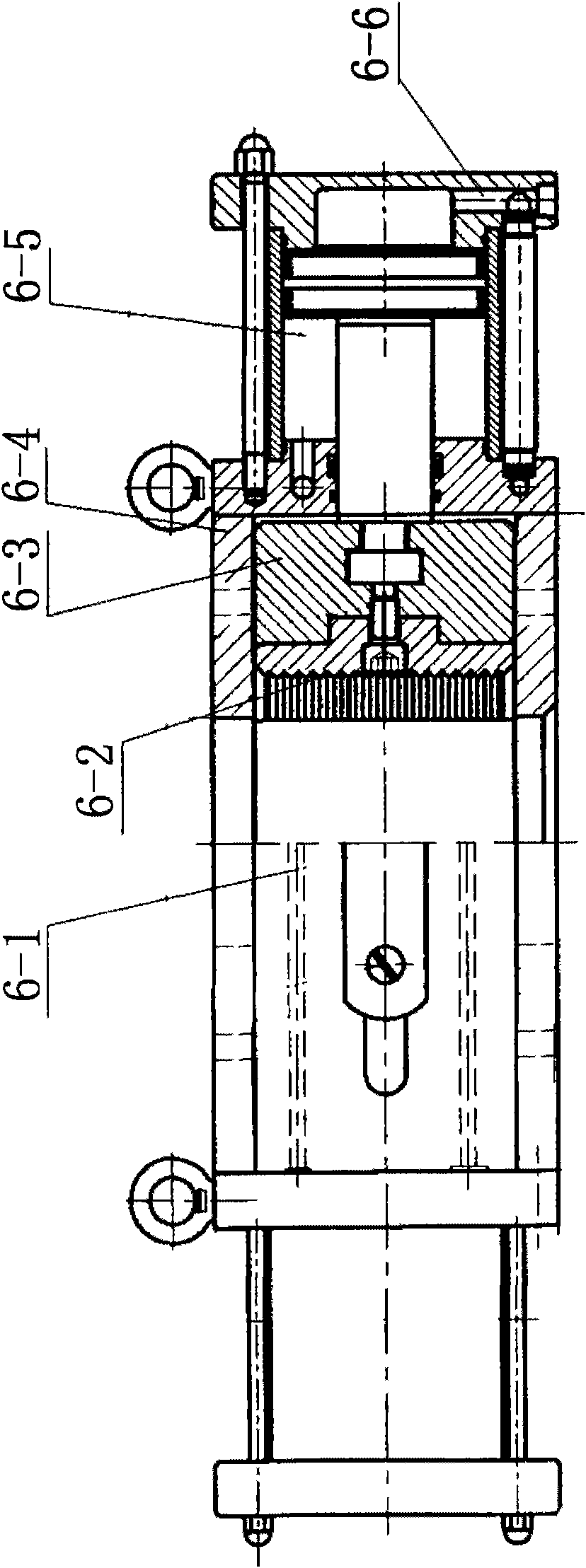

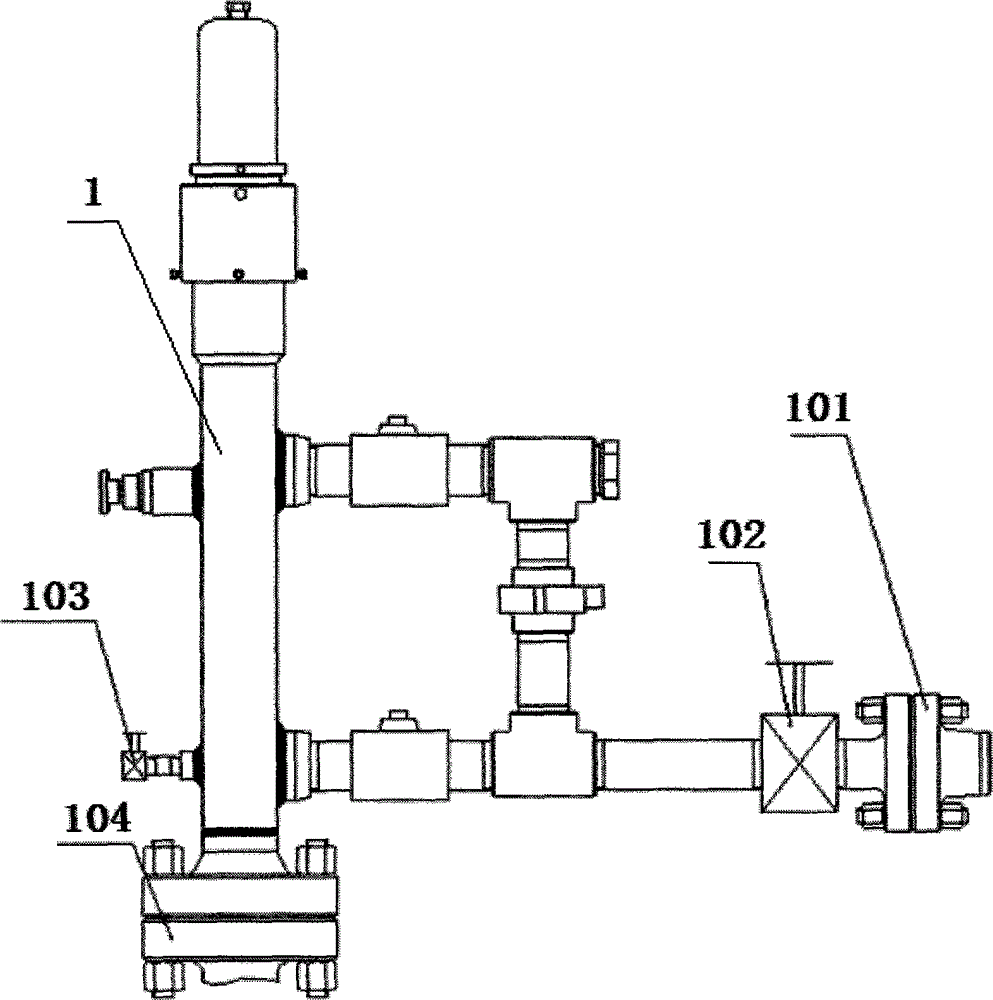

Snubbing serving device of combined type hydraulic oil-water well

InactiveCN101525984ASolve complexitySolve well workover problemsSealing/packingCross connectionEngineering

The invention relates to a snubbing serving device of a combined type hydraulic oil-water well, which comprises a hydraulic triple ram preventer, a first annular preventer, a second annular preventer, a fixing top clamp resisting tile, a self-tightening hydraulic top clamp resisting tile, a rectangular vertical frame, two oil cylinders, a lifting cross connection, a hydraulic balanced valve, a hydraulic pressure release valve, a hydraulic equilibrium valve, a hydraulic pressure relief valve, a hydraulic source pipeline and a hydraulic source, wherein the hydraulic triple ram preventer is fixed on an oil well large cross joint, the second annular preventer is used for lifting the cross joint; the first annular preventer, the second annular preventer, the fixing top clamp resisting tile and the self-tightening hydraulic top clamp resisting tile are sequentially arranged on the hydraulic triple ram preventer, the rectangular vertical frame is erected at the periphery of the well, the two oil cylinders are symmetrically on an upright column of the rectangular vertical frame, the lifting cross connection is connected with pistons of the two oil cylinders, the self-tightening hydraulic clamp tile and the lower fixing top clamp resisting tile are arranged on the upper part of the lifting cross connection, the hydraulic balanced valve and the hydraulic pressure release valve are arranged on two through holes of both sides of the two joints of the lifting cross joint, and the hydraulic equilibrium valve and the hydraulic pressure relief valve are arranged on openings on two sides of the two connections of the lifting cross connection, the hydraulic source pipeline and the hydraulic source are matched with the snubbing serving device in an assistant mode.

Owner:胜利方兰德石油装备股份有限公司

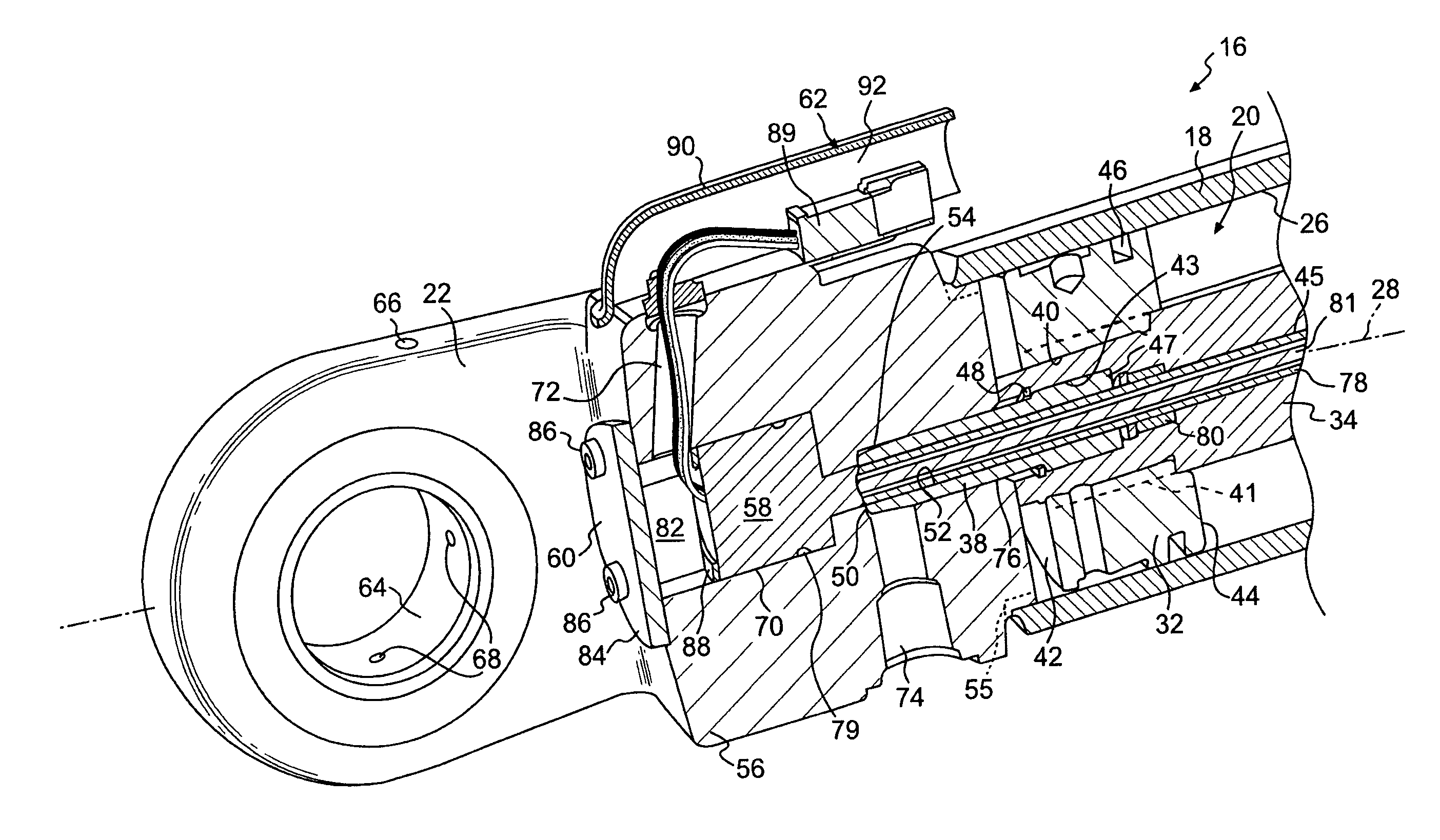

Positive displacement expander

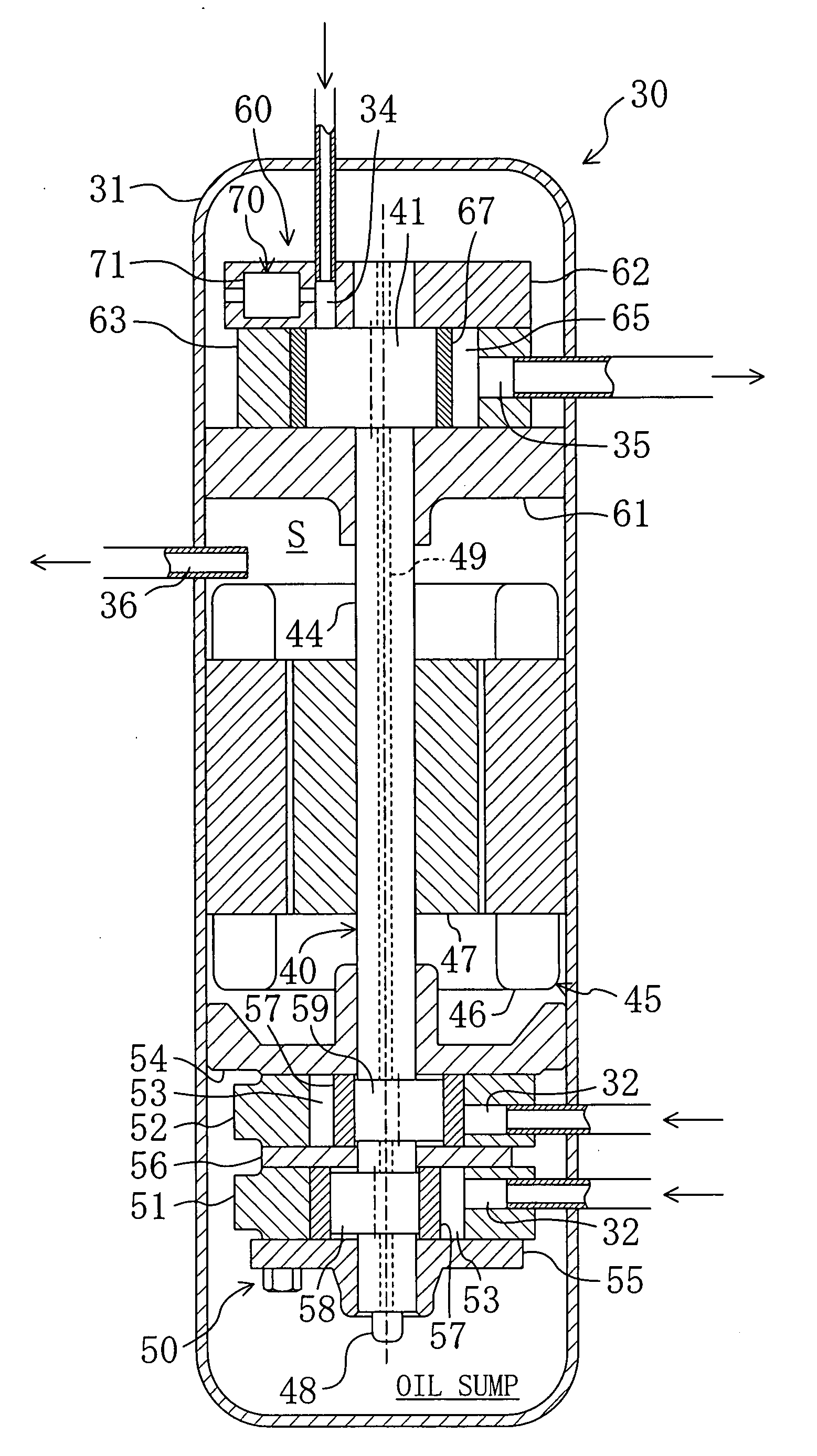

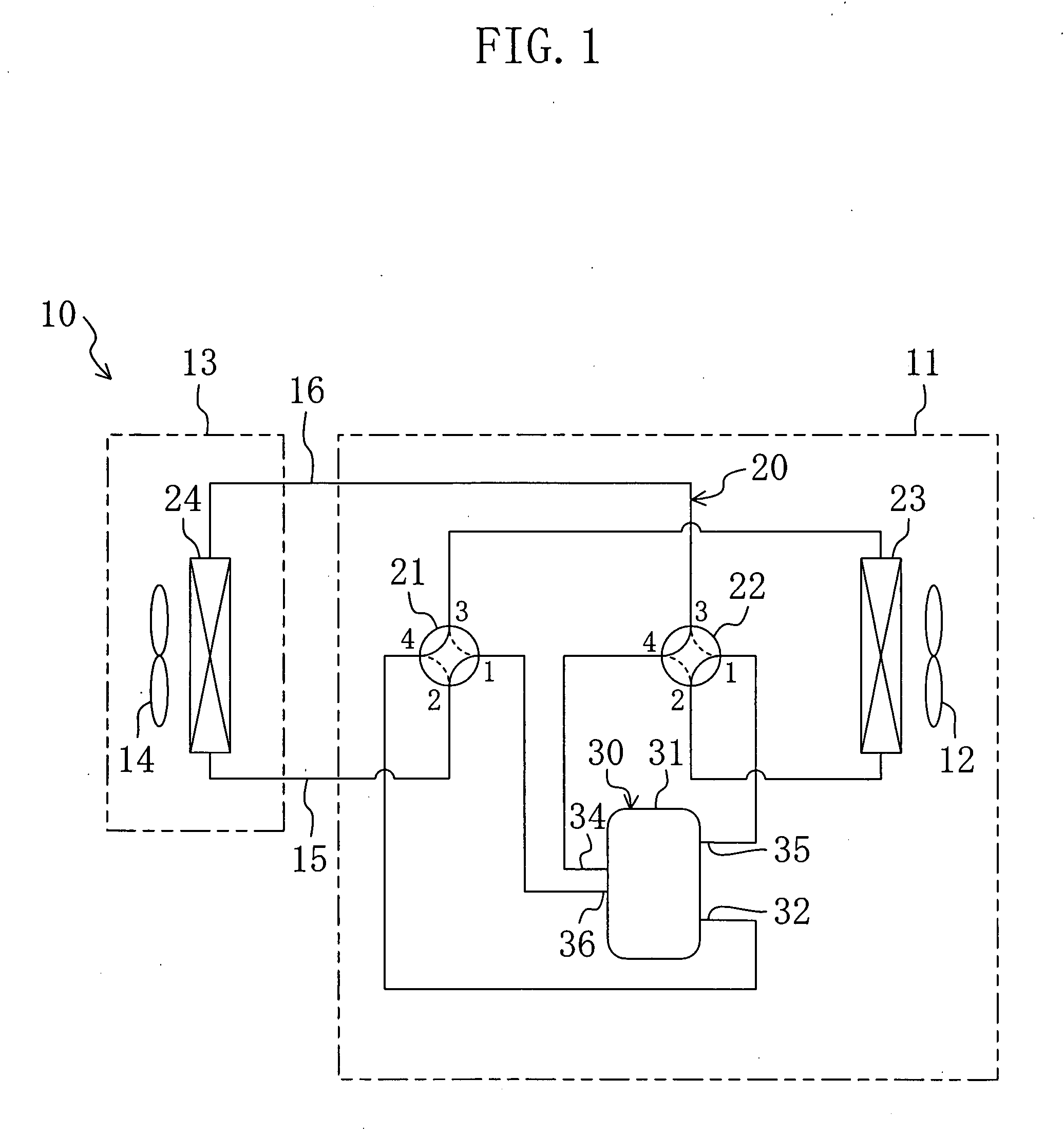

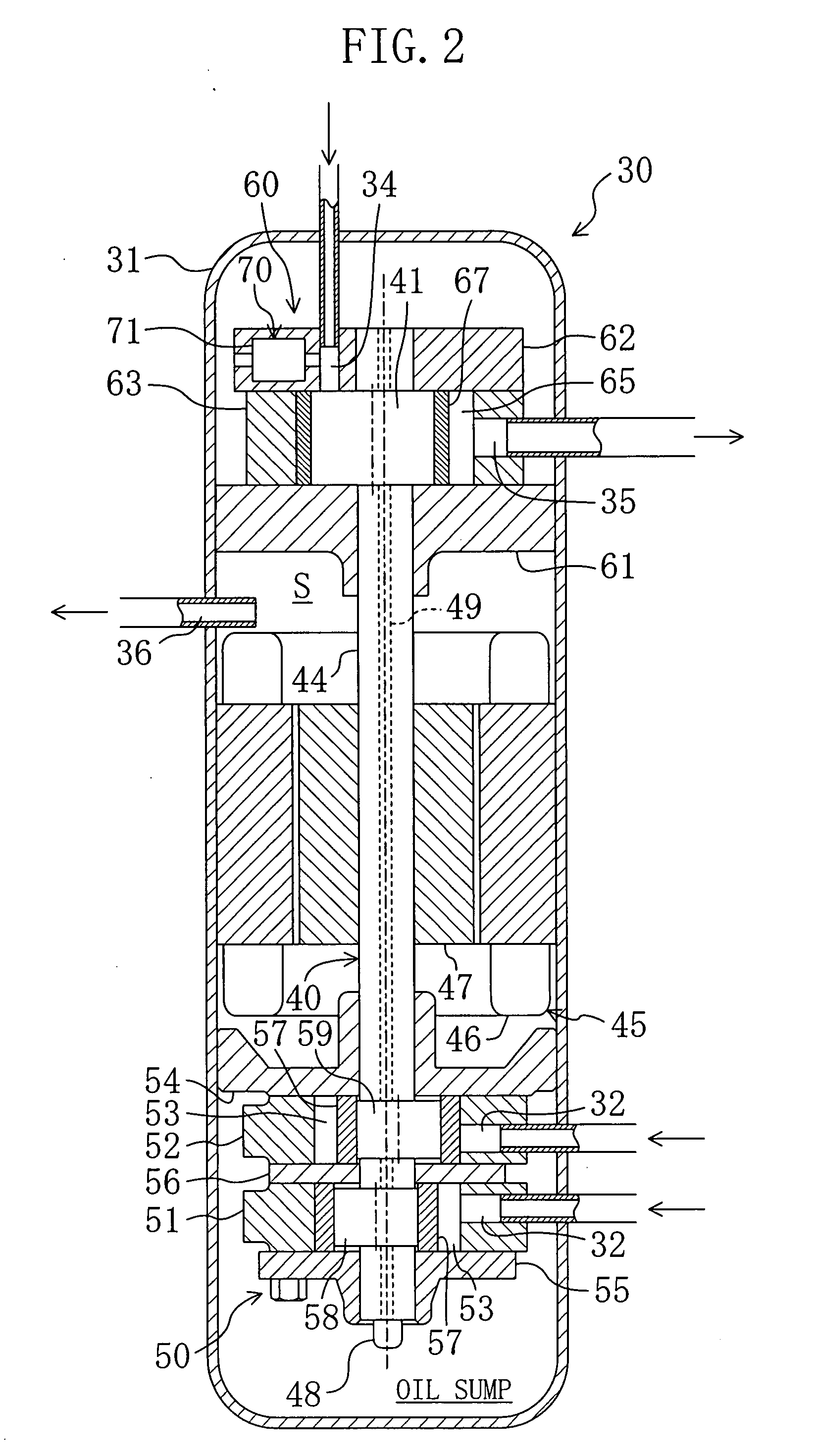

InactiveUS20090178433A1More variationReduced effectively in vibrationDomestic cooling apparatusCombination enginesSnubbingEngineering

A casing (31) houses therein an expansion mechanism (60) and a compression mechanism (50). The expansion mechanism (60) has a rear head (62) in which a pressure snubbing chamber (71) is provided. The pressure snubbing chamber (71) is divided by a piston (77) into an inflow / outflow chamber (72) which fluidly communicates with an inflow port (34) and a back pressure chamber (73) which fluidly communicates with the inside of the casing (31). The piston (77) is displaced in response to suction pressure variation whereby the volume of the inflow / outflow chamber (72) varies. This enables the inflow / outflow chamber (72) to directly perform supply of refrigerant to or suction of refrigerant from the inflow port (34) which is a source of pressure variation, thereby making it possible to effectively inhibit suction pressure variation.

Owner:DAIKIN IND LTD

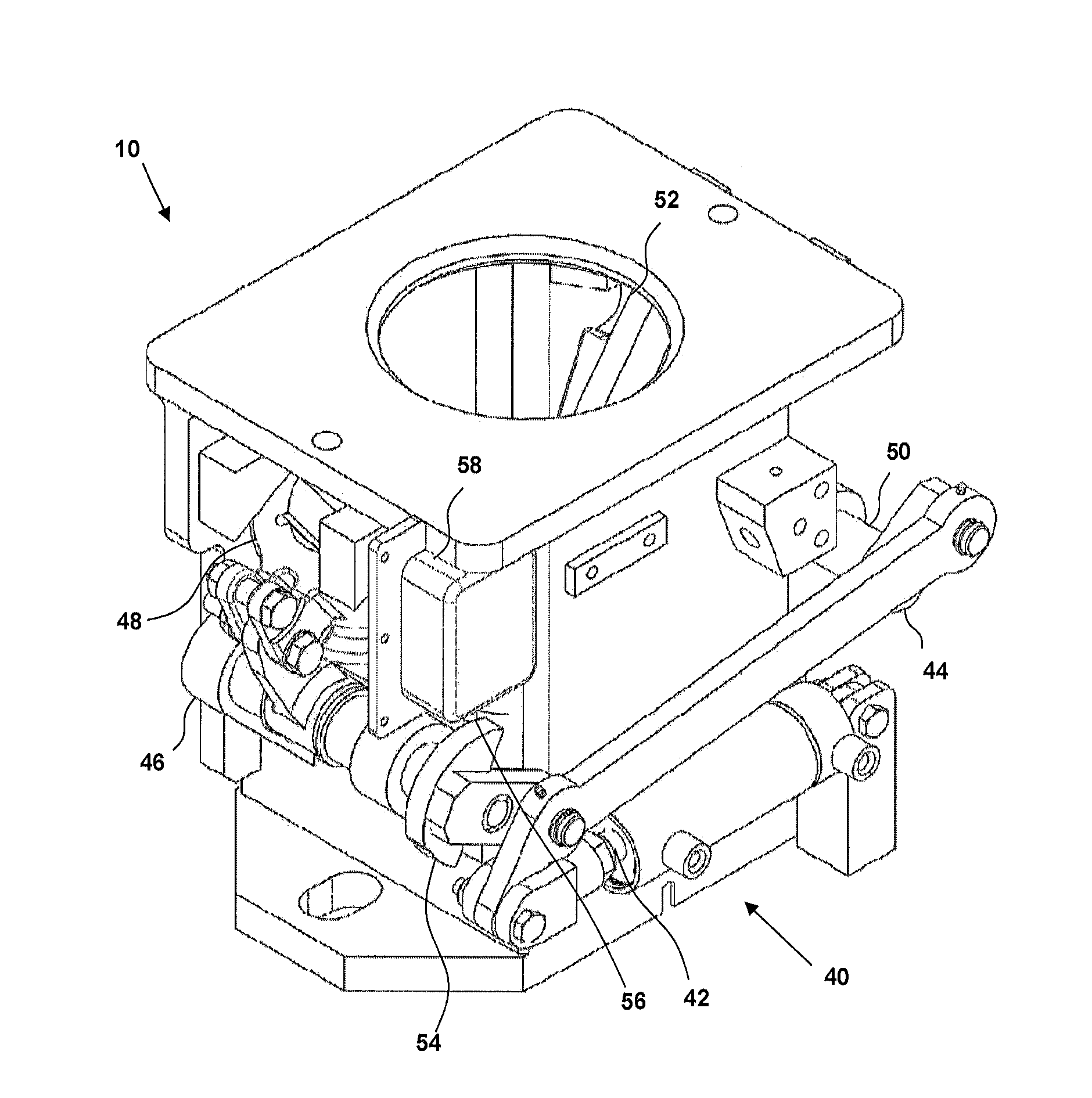

Push / pull system and support structure for snubbing unit or the like on a rig floor

In one embodiment, a support structure for use on a rig floor and for supporting a unit used to manipulate tubular components through a wellhead comprises a support plate adapted to securely mount the support structure to said unit, a passage in the support plate of sufficient diameter to allow tubular components to pass therethrough, a plurality of rig engaging members and at least one tensile member mount. The unit used to manipulate tubular components through a wellhead may be a compact snubbing unit or may be a push / pull unit. The support structure may further comprise a worker platform to support a worker above the rig floor. Various push / pull system embodiments, for use on a rig to manipulate tubular components through a wellhead, are also taught.

Owner:TEAM SNUBBING SERVICES

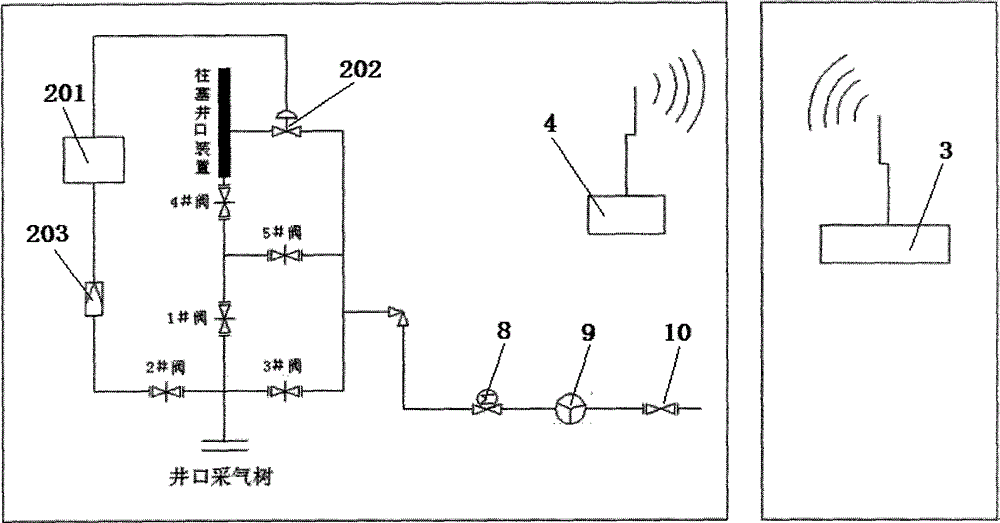

Intelligent control plunger gas lift water drainage and gas recovery system and realizing method thereof

InactiveCN105888608ATimely adjustment of gas lift operating parametersFluid removalWell/borehole valve arrangementsLine tubingControl system

The invention discloses an intelligent control plunger gas lift water drainage and gas recovery system and a realizing method thereof. The intelligent control plunger gas lift water drainage and gas recovery system is characterized by being composed of a well mouth blowout preventing device, a ground control device, a data processing station, a well mouth RTU, a plunger, a buffer and a clamping and fixing device. The invention further discloses the realizing method. The realizing method includes the steps that the well mouth blowout preventing device is connected with a well mouth detecting valve and a ground outer conveying pipeline through a flange to buffer plunger upward force, capturing the plunger and externally outputting gas liquid; the ground control device starts or stops gas liquid outer conveying; the optimal plunger gas lift well opening and closing mechanism is achieved through a control system in the data processing station; the well mouth RTU is used for transmitting data and sending out an instruction; the clamping and fixing device is located at the designed position in an oil pipe through steel wire snubbing operation; by means of steel wire snubbing operation, the buffer is put on the clamping and fixing device to offset downward impact of the plunger; the plunger runs in a reciprocating mode in a wellbore to achieve gas liquid lift. The control system in the data processing station determines the optimal plunger gas lift well opening and closing mechanism and sends the control instruction to the well mouth RTU in time, a control box receives the optimal mechanism of the well mouth RTU and adjusts gas lift operation parameters of the plunger in time, and gas well productivity is given into full play to the maximum.

Owner:XIAN JINLI PETRO TECH

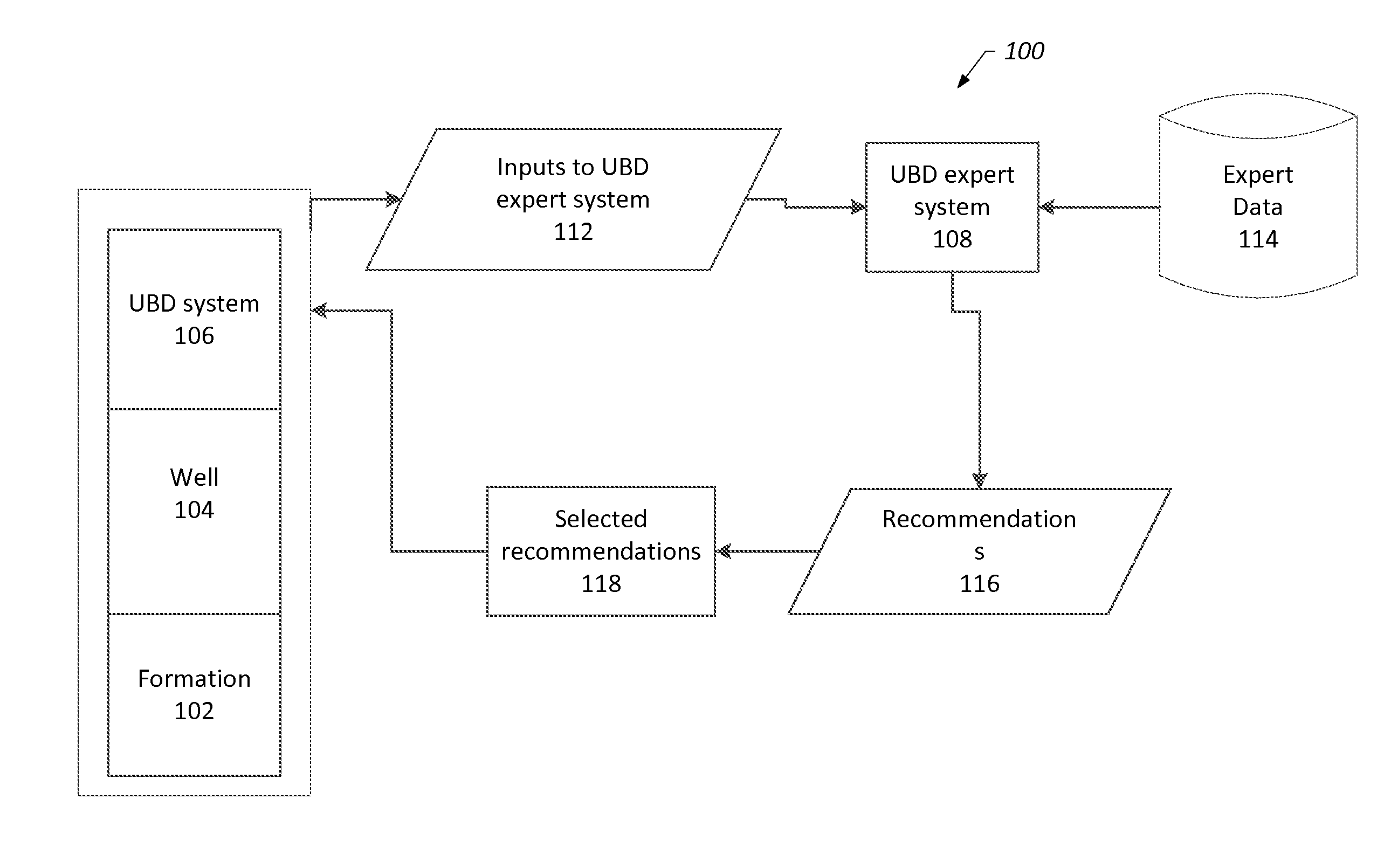

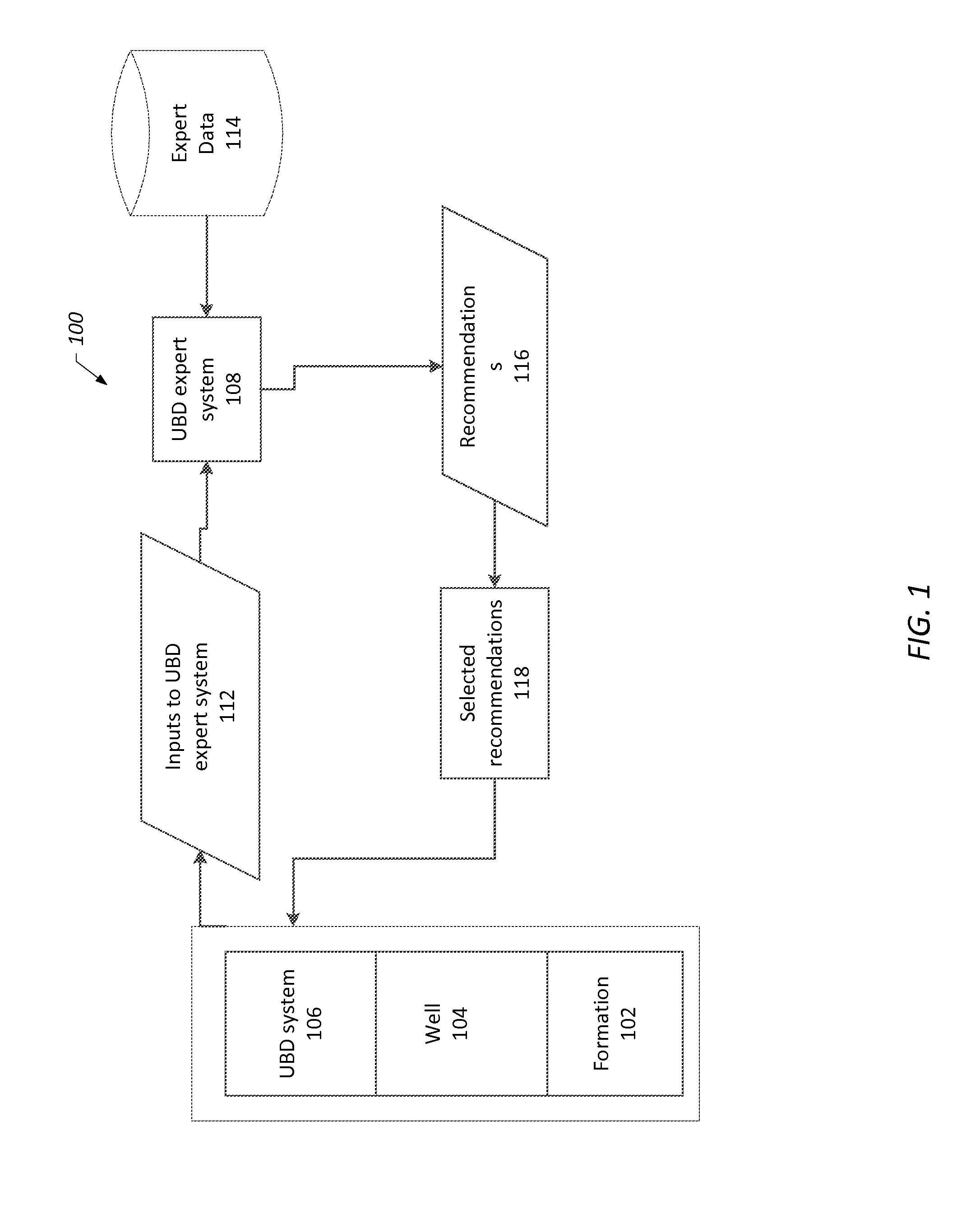

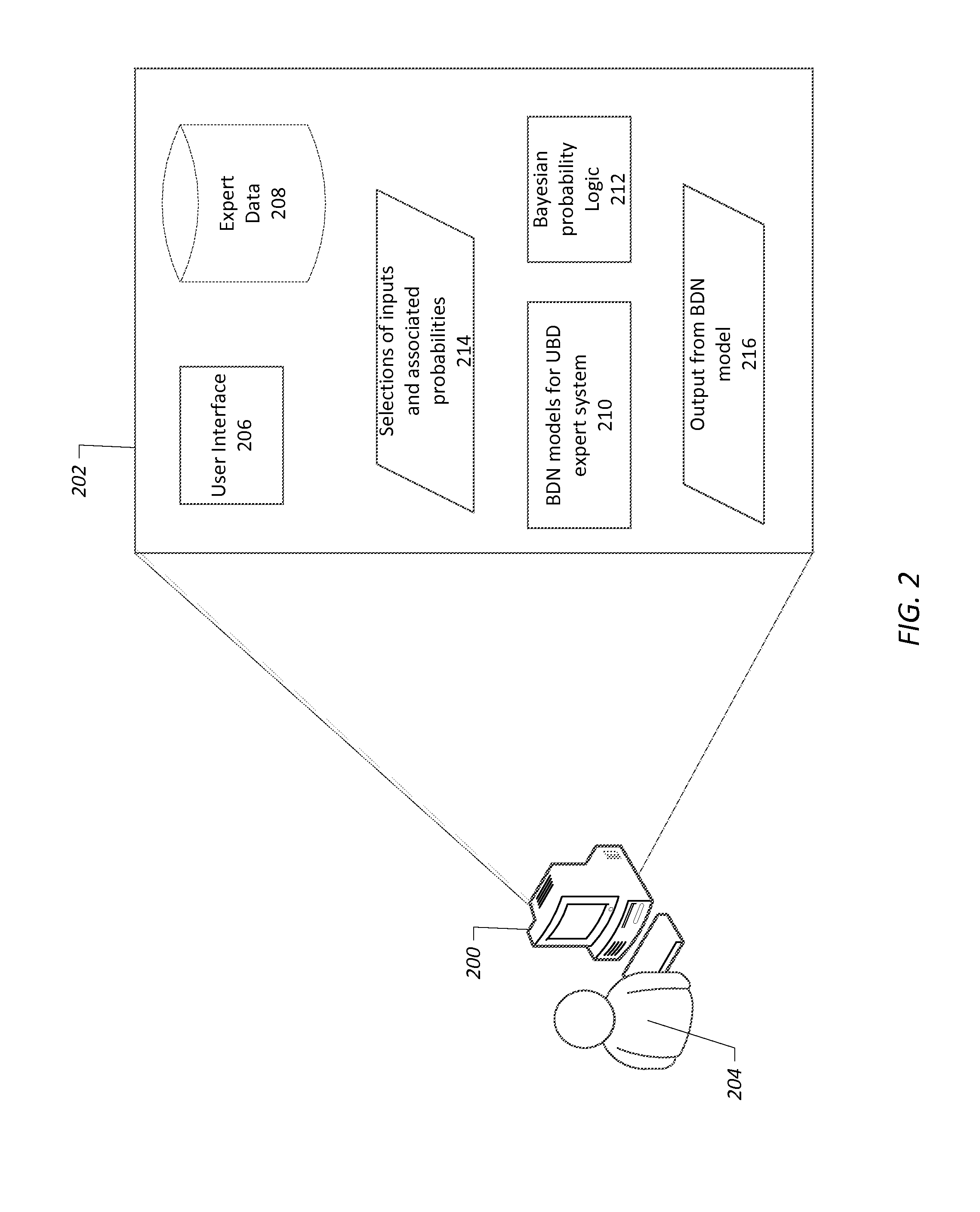

Systems and methods for expert systems for underbalanced drilling operations using bayesian decision networks

InactiveUS20140124265A1Mathematical modelsAutomatic control for drillingDecision networksGood practice

Systems and methods are provided for an underbalanced drilling (UBD) expert system that provides underbalanced drilling recommendations, such as best practices. The UBD expert system may include one or more Bayesian decision network (BDN) model that receive inputs and output recommendations based on Bayesian probability determinations. The BDN models may include: a general UBD BDN model, a flow UBD BDN model, a gaseated (i.e., aerated) UBD BDN model, a foam UBD BDN model, a gas (e.g., air or other gases) UBD BDN model, a mud cap UBD BDN model, an underbalanced liner drilling (UBLD) BDN model, an underbalanced coil tube (UBCT) BDN model, and a snubbing and stripping BDN model.

Owner:SAUDI ARABIAN OIL CO +1

Downhole gel slug and preparation method thereof

InactiveCN102276771ASafe and effective containmentHigh strengthSealing/packingSnubbingVolumetric Mass Density

The invention relates to a downhole gel slug and a preparation method thereof, which is characterized in that it consists of a monomer, a crosslinking agent, an initiator, a density modifier, a viscosity modifier and water; wherein the weight percentage of each component is: Monomer: 4.5-9%; Cross-linking agent: 0.1-0.14%; Initiator: 0.005-0.06%; Density modifier: 5-10%; Viscosity modifier: 0.1-1.0%; Ratio, dissolve the monomer and cross-linking agent in water, then add the viscosity modifier and stir to disperse evenly, then add the density modifier and stir to disperse evenly, and finally add the initiator before injection, and make the gel slug base after mixing evenly The gel slug base fluid is injected into the predetermined position of the wellbore to form the gel slug. The gel slug of the present invention can safely and effectively seal the wellbore downhole, realize snubbing tripping, and has the characteristics of high strength, good temperature resistance, simple preparation method and good economic benefit.

Owner:YANGTZE UNIVERSITY

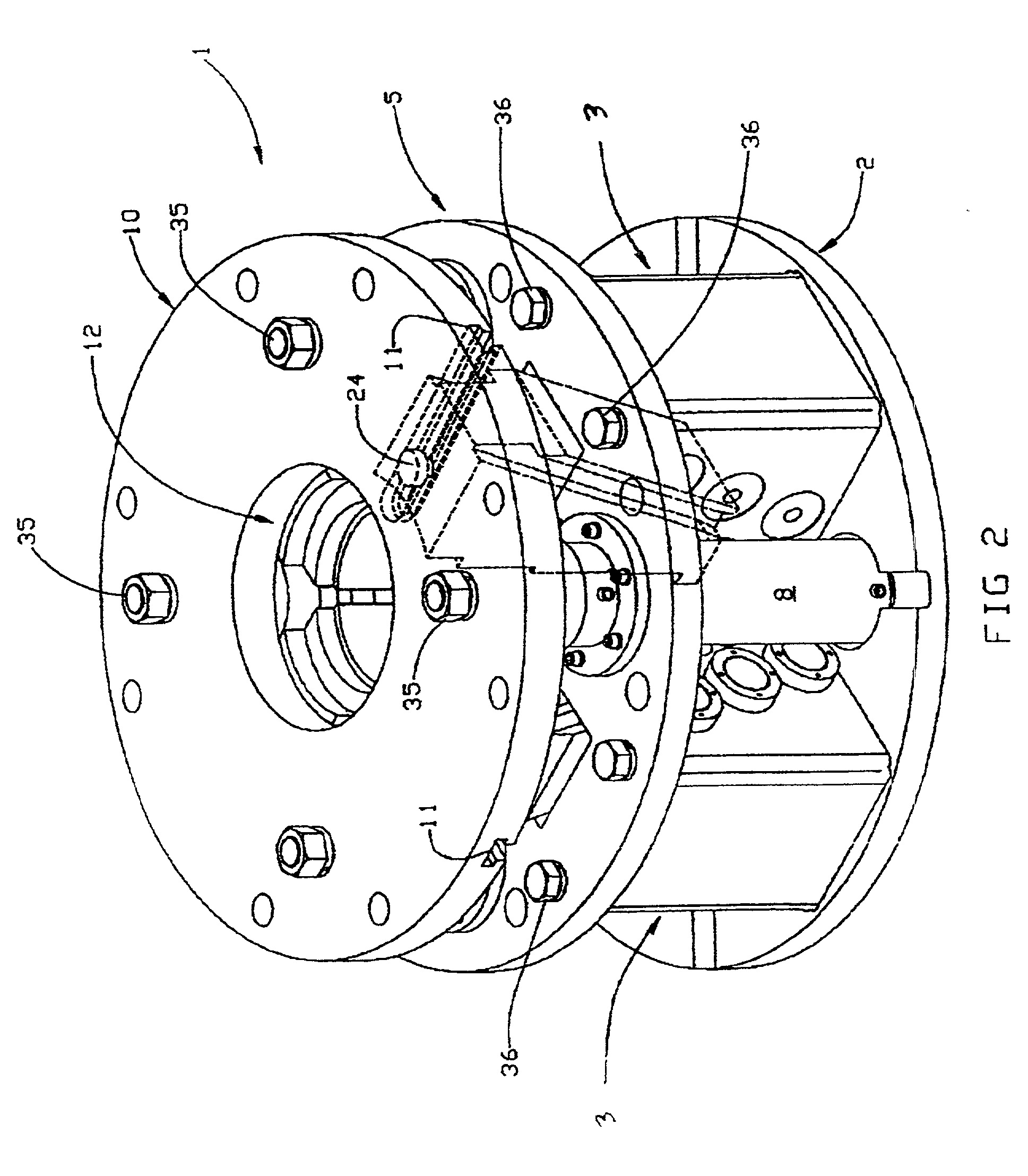

Pipe guides and methods of guiding pipes in snubbing units

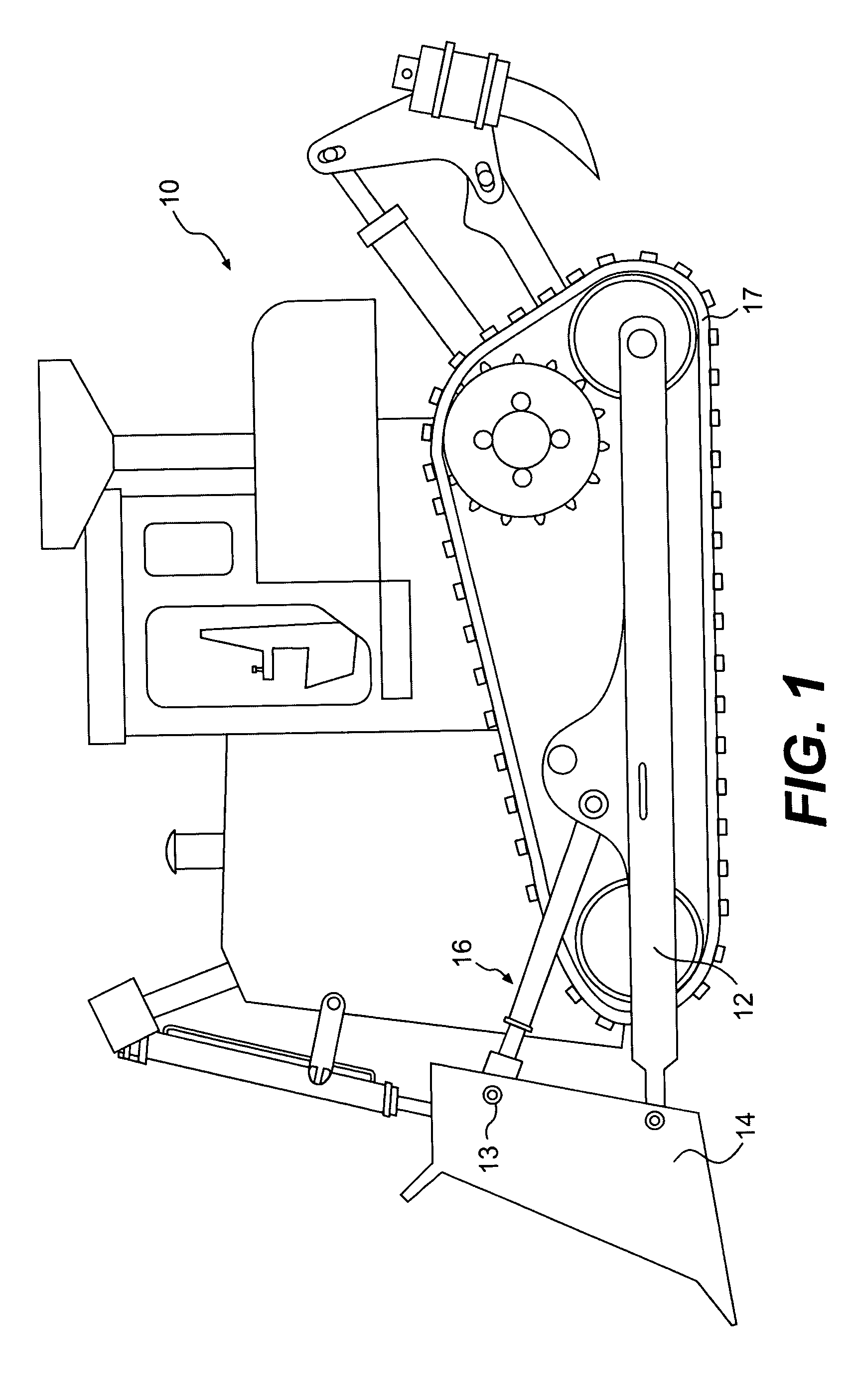

An hydraulic snubbing unit has a pair of hydraulic cylinders for moving travelling snubbing slips towards and away from stationary snubbing slips to snub a pipe through the snubbing unit, the hydraulic cylinders having spaced, parallel cylinder rods. A pipe guidance apparatus has pipe guides between the stationary snubbing slips and the travelling snubbing slips, the pipe guides each having a pair of cylinder rod openings spaced apart from one another and slidably receiving the rods of the hydraulic cylinders and a pipe guidance opening located between the cylinder rod openings and slidably guiding the pipe, and a pipe guide spacer having extendable and contractible interconnections between the pipe guides. In a contracted condition of the pipe guide spacer, the interconnections are contracted and the pipe guides are moved into proximity to one another by the simultaneous movement of the cylinder rods slips towards the stationary slips, and in an expanded condition, the interconnections are extended and the pipe guides are moved apart from one another by the simultaneous movement of the cylinder rods away from the stationary slips to provide lateral support of the pipe at intervals along the pipe.

Owner:FUNK KELLY

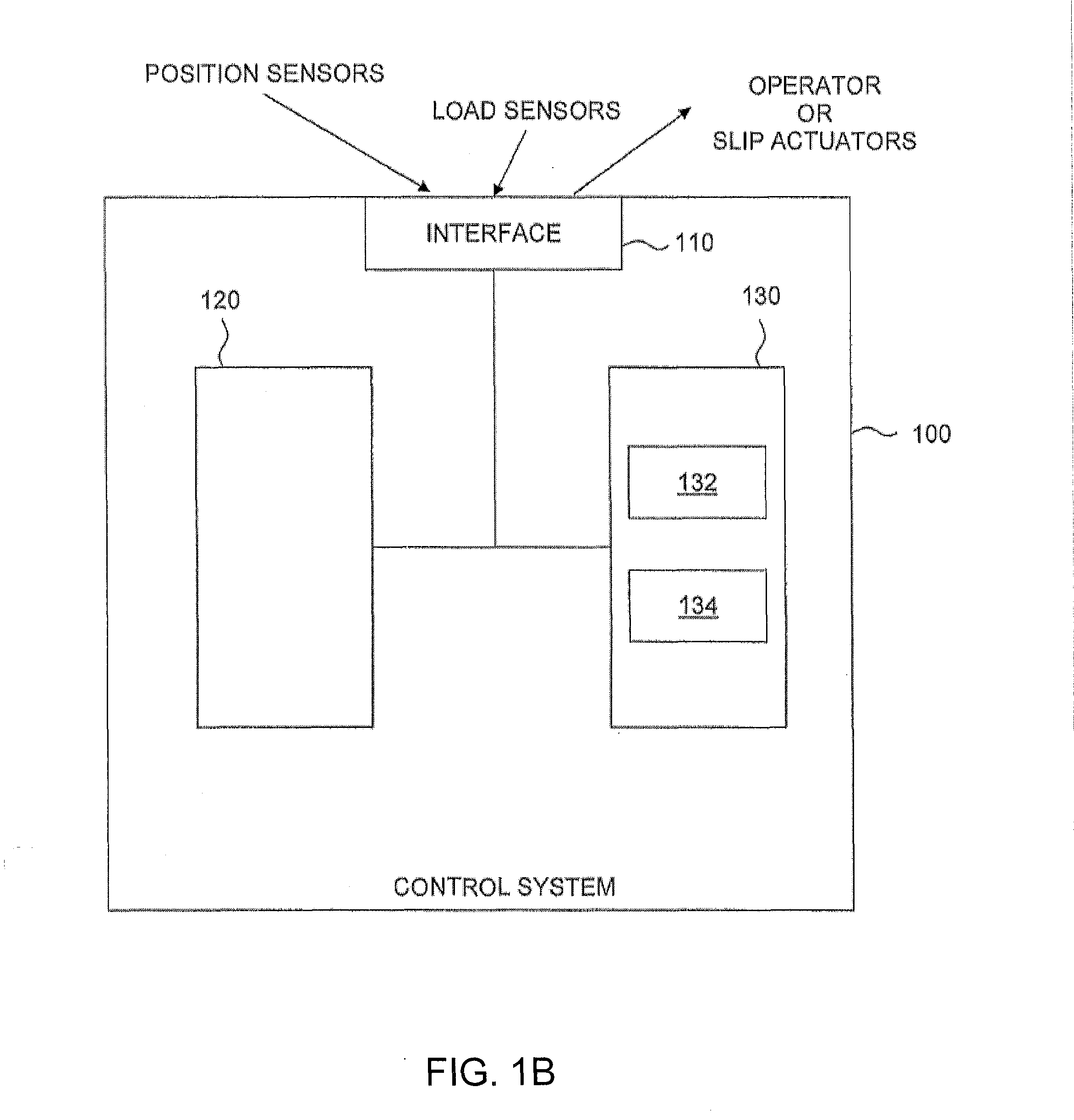

System and method for monitoring and controlling snubbing slips

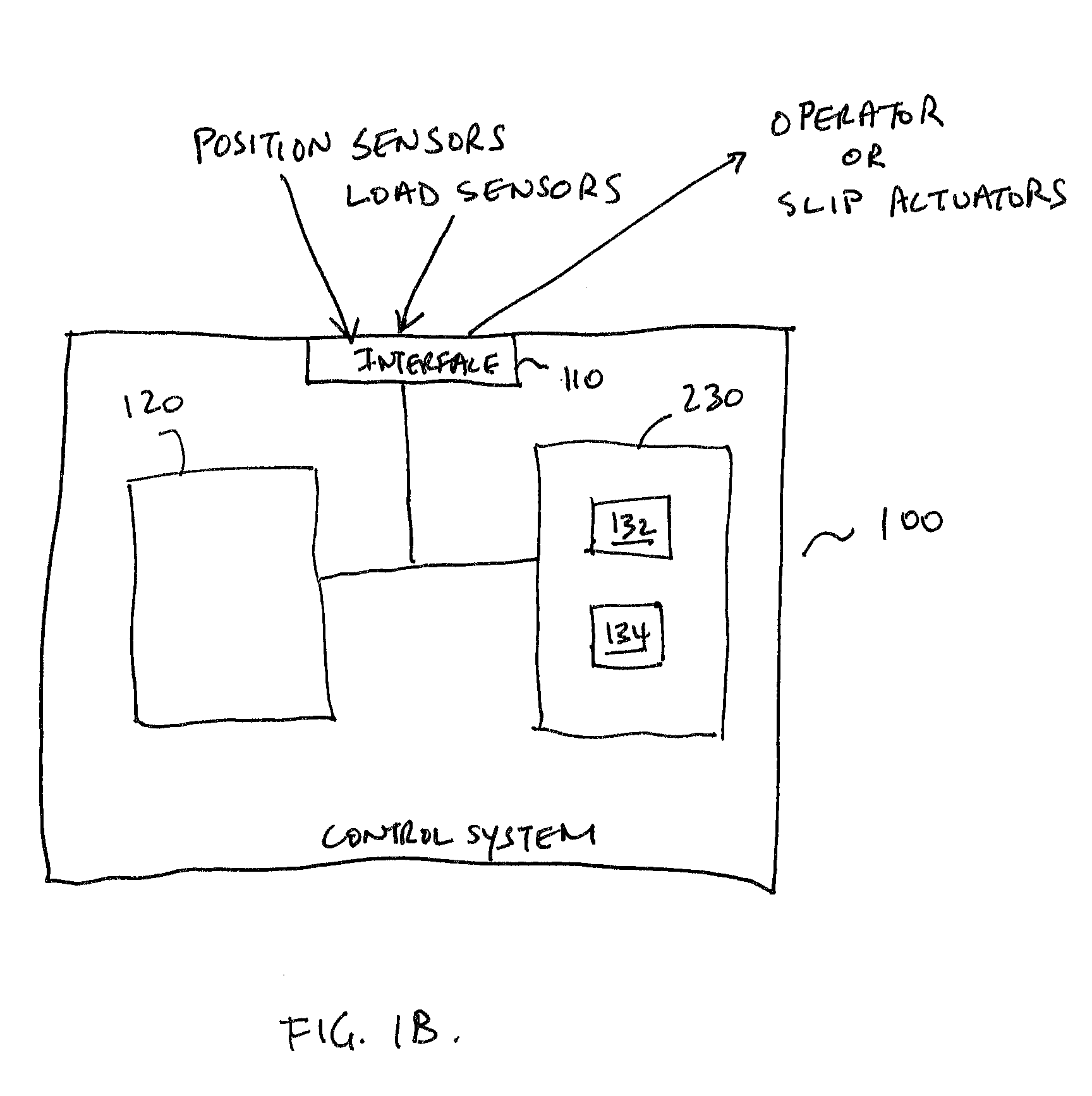

InactiveUS20150167446A1Complete release is preventedInhibition releaseSurveyDrilling rodsControl systemSnubbing

A system and method for monitoring and controlling a snubbing unit having traveling slips and stationary slips are provided. Position sensors are associated with the slips for directly or indirectly detecting opened and closed positions of the slips, including detecting a rotational position of a crankshaft that drives the slips into engagement with a pipe. Load sensors are associated with the slips for detecting load status of the slips. A control system receives input signals from the sensors, and confirms that either the traveling slips or the stationary slips are loaded before releasing or allowing the release the opposing set of slips, when transferring the pipe string load from the one set of slips to the other set of slips.

Owner:SNUBCO MFG

System and method for monitoring and controlling snubbing slips

The invention is directed to a system and method for monitoring and controlling a snubbing unit having traveling slips and stationary slips. Position sensors are associated with the slips for detecting opened and closed positions of the slips. Load sensors are associated with the slips for detecting load status of the slips. A control system receives input signals from the sensors, and confirms that either the traveling slips or the stationary slips are loaded before releasing or allowing the release the opposing set of slips, when transferring the pipe string load from the one set of slips to the other set of slips.

Owner:SNUBCO MFG

Bi-directionally driven forward converter for neutral point clamping in a modified sine wave inverter

InactiveUS7072162B2Dc-dc conversionEmergency protective arrangement detailsTransformerConductor Coil

Owner:DAMATO JAMES

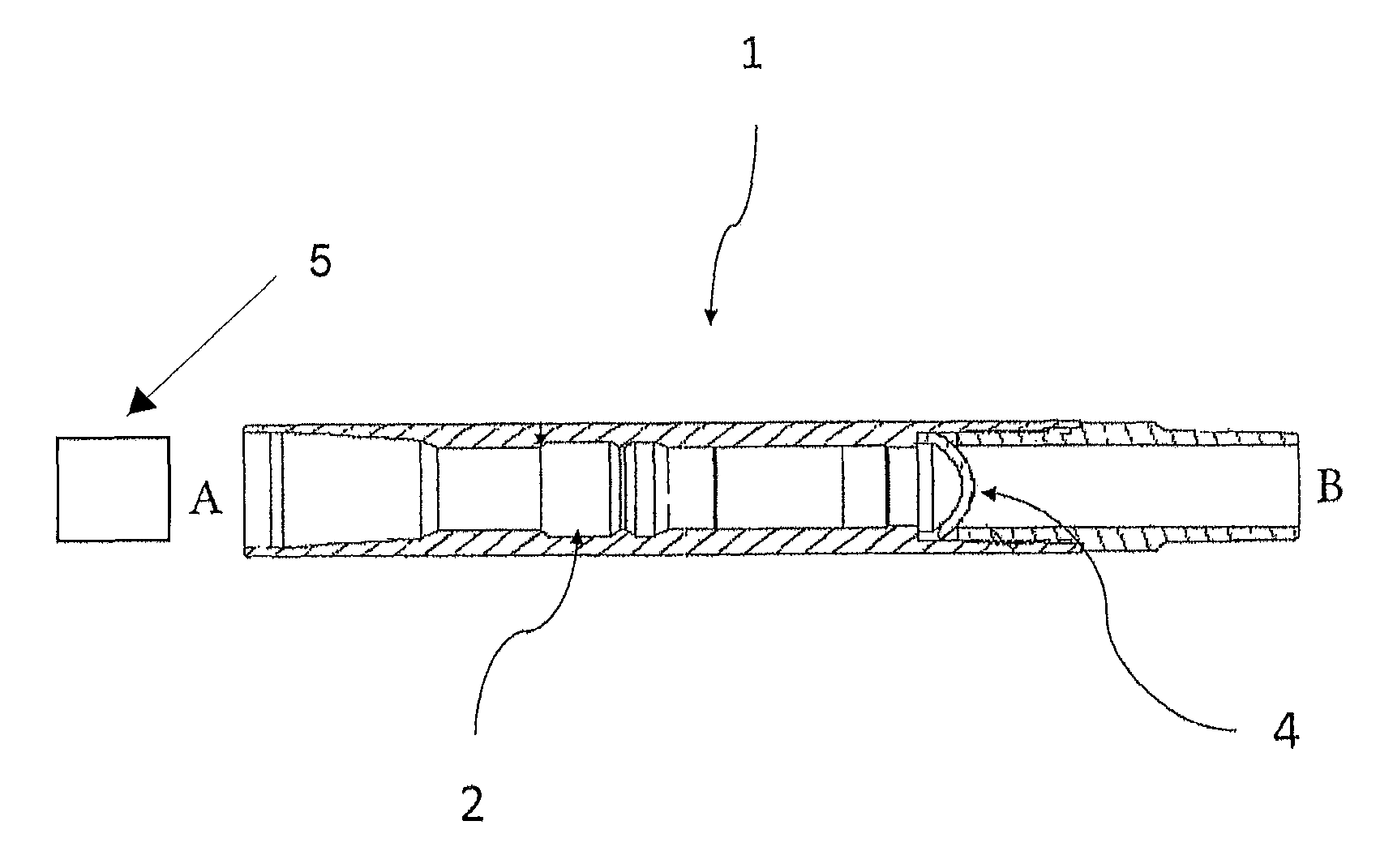

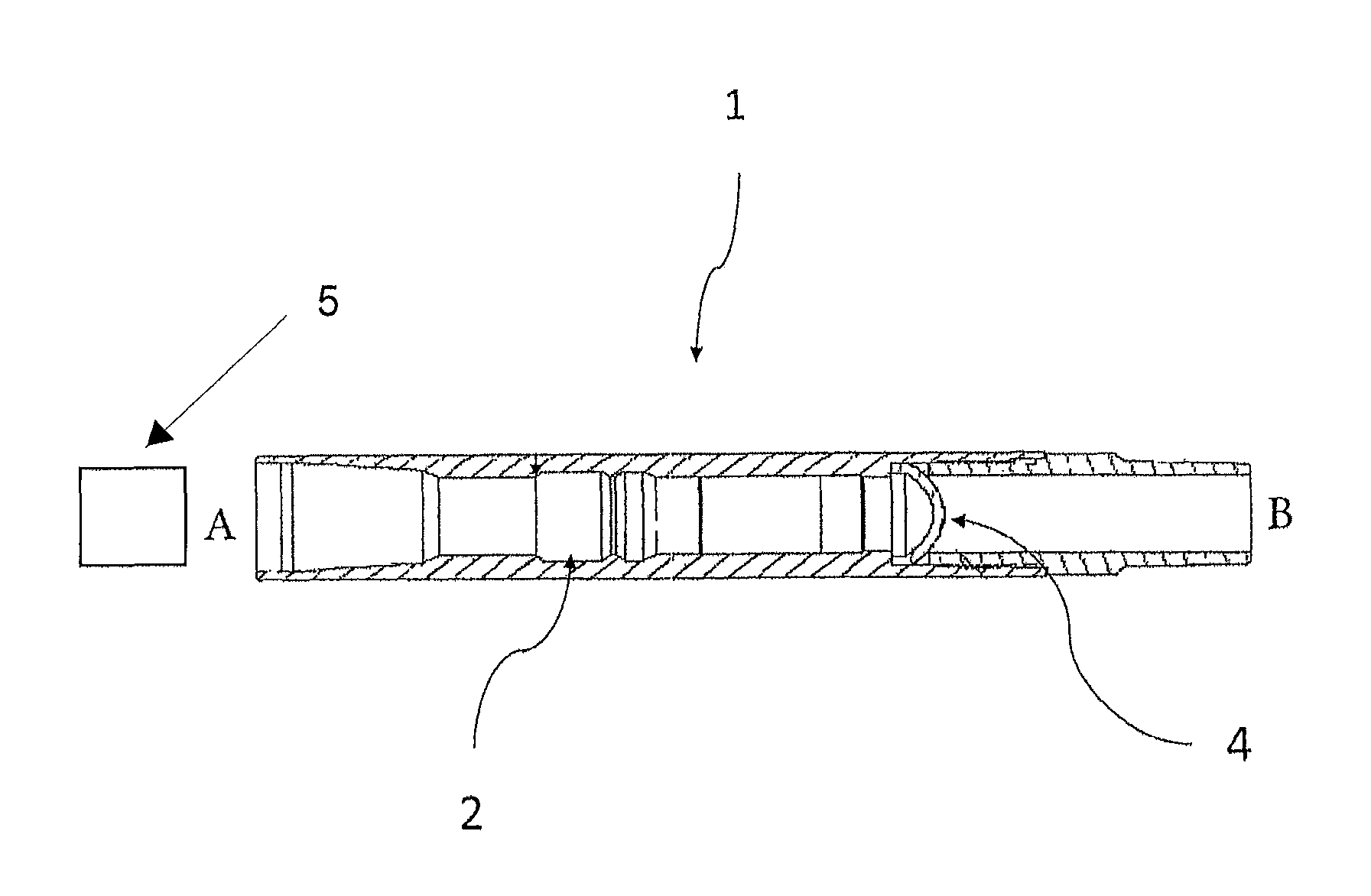

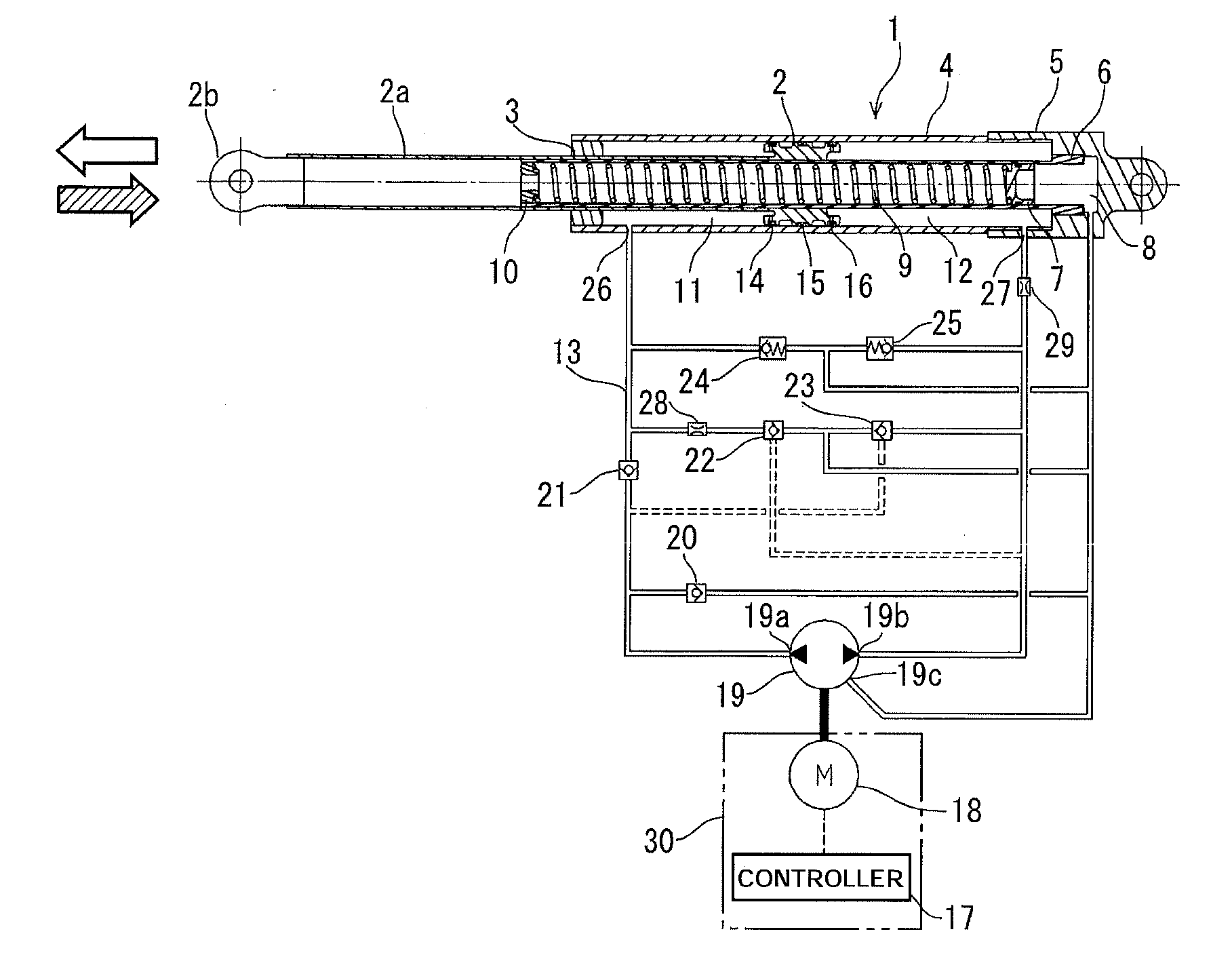

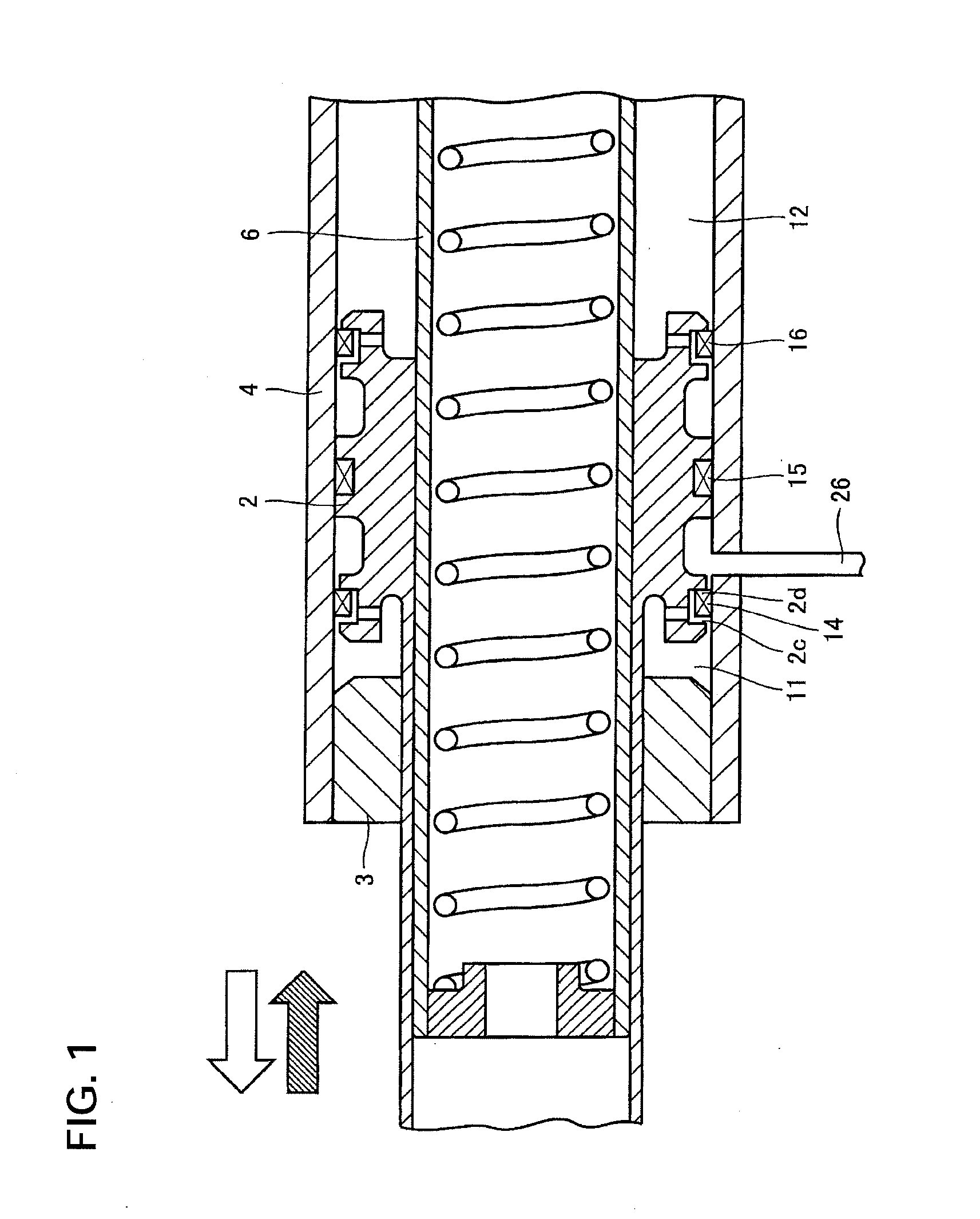

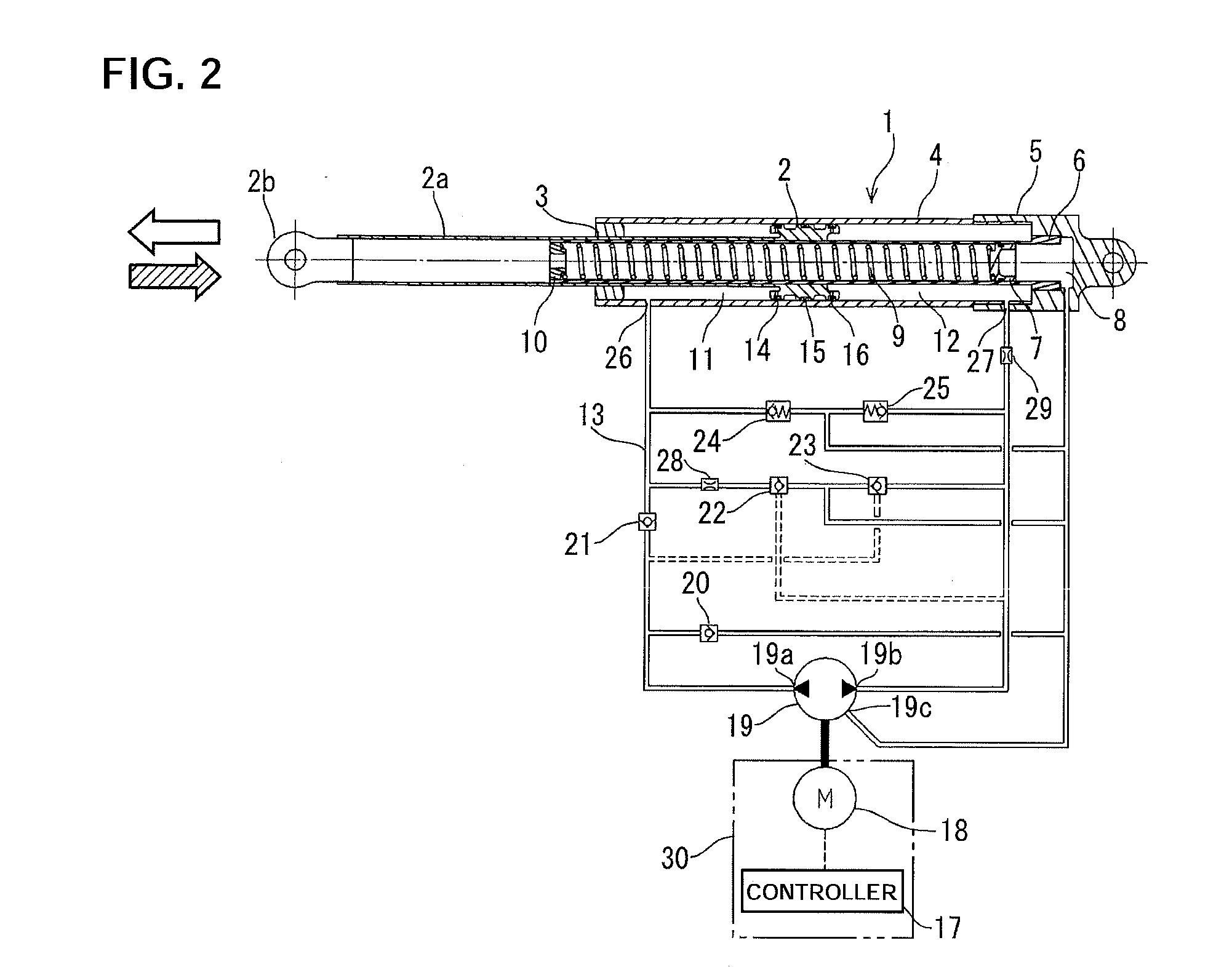

Electro-hydrostatic actuator excellent in snubbing characteristic, and drive device used for the same, and control method used for the same

ActiveUS20110107756A1Improve energy efficiencySuppressing increase in temperature of fluidFluid couplingsAircraft controlLoad torqueSnubbing

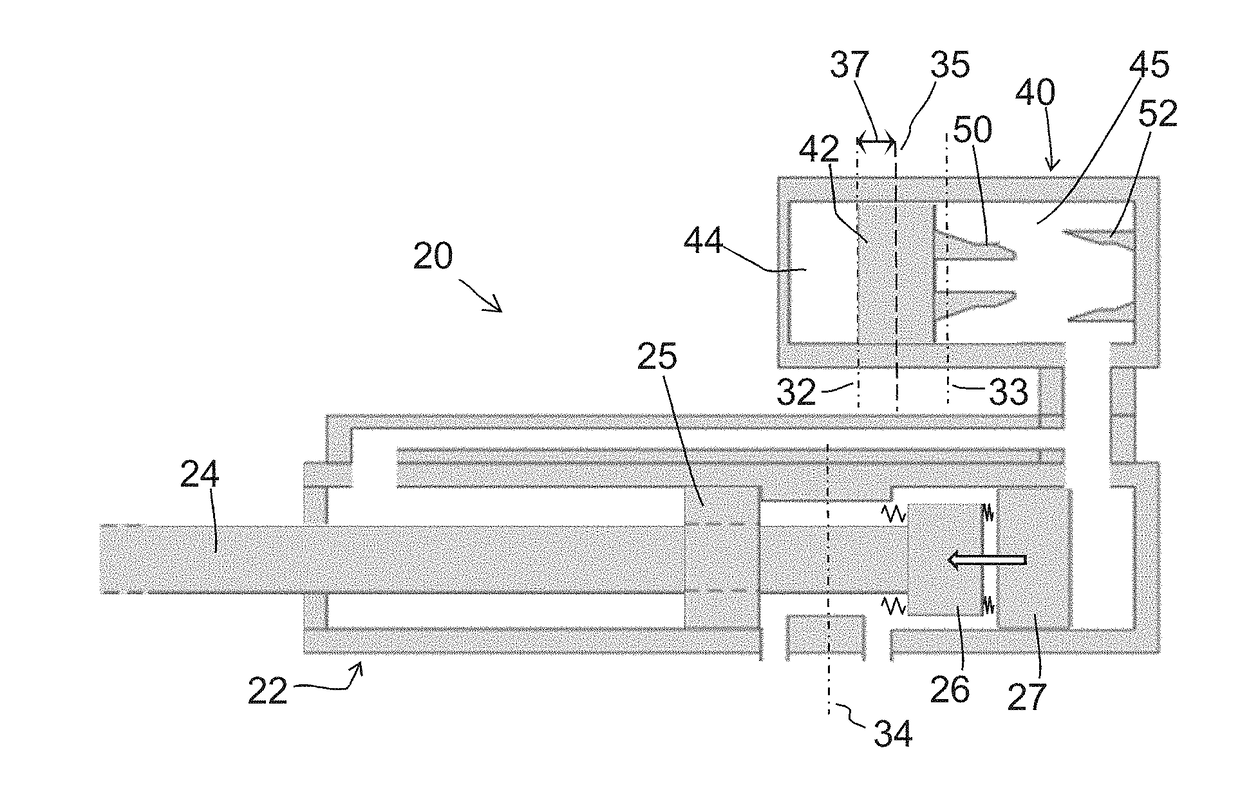

The present invention is to provide an electro hydrostatic actuator excellent in a snubbing characteristic including a cylinder type actuator main body 1, a piston 2 having a piston rod, the piston slidingly moving in a cylinder of the actuator main body, a motor 18, a pump 19 for supplying fluid according to the rotation of the motor, a mechanism for adjusting a running amount of the fluid into and from the cylinder according to the motion of the piston, and a reservoir 8 for adjusting the supply of the fluid corresponding to a volume difference generated according to the motion of the piston, and a controller 17 which controls the number of revolutions of the motor according to the calculated load torque, and a snubbing control method used for this. An electro hydrostatic actuator of realizing a snubbing mechanism capable of increasing energy efficiency, when used for a landing gear retraction / extension device of an airplane, can be provided.

Owner:SUMITOMO PRECISION PROD CO LTD +1

Hydraulic cylinder having a snubbing valve

A hydraulic cylinder has a tube with a first end and a section end. The hydraulic cylinder also has a piston assembly movably disposed within the tube and configured to move between the first and second ends of the tube. The hydraulic cylinder further has a valve plunger connected to the piston assembly and having an axial bore. The hydraulic cylinder additionally has a cap assembly connected to the tube to close off the first end of the tube. The cap assembly has a fluid passageway and the valve plunger is configured to progressively restrict fluid flow through the fluid passageway as the piston assembly approaches the first end of the tube.

Owner:CATERPILLAR INC

Long hinge actuator snubbing

InactiveUS8337103B2Restrict movementMitigate double bending of a hinge flexureProjector focusing arrangementDigital data processing detailsEngineeringSnubbing

A device may comprise an upper module cover, a lower module cover, an outer frame, and an actuator having a movable frame. The movable frame may be at least partially disposed intermediate the upper module cover and the lower module cover. A hinge flexure may interconnect the outer frame and the movable frame such that the movable frame is rotatable with respect to the outer frame. The upper module cover and / or the lower module cover may be adapted to limit a movement of the movable frame.

Owner:DIGITALPTICS MEMS

Method and apparatus for motion compensation during active intervention operations

Owner:COLES ROBERT A

Pipe guide for snubbing units

A pipe guide apparatus for guiding a pipe during snubbing of the pipe includes a pair of hydraulic cylinders and cylinder rods; a stationary guide affixed between a bottom jack plate and a top jack plate, comprising a stationary pipe guide; a travelling jack plate affixed to the cylinder rods; a travelling pipe guide in sliding engagement with the cylinder rods and connected to the travelling jack plate by a lift rod. The stationary pipe guide and the travelling pipe guide each define a pipe opening and has a flexibly resilient guide member having an opening with a diameter closely matching the outside diameter of the pipe being snubbed.

Owner:SNUBCO MFG

Hydraulic actuator and accumulator arrangement

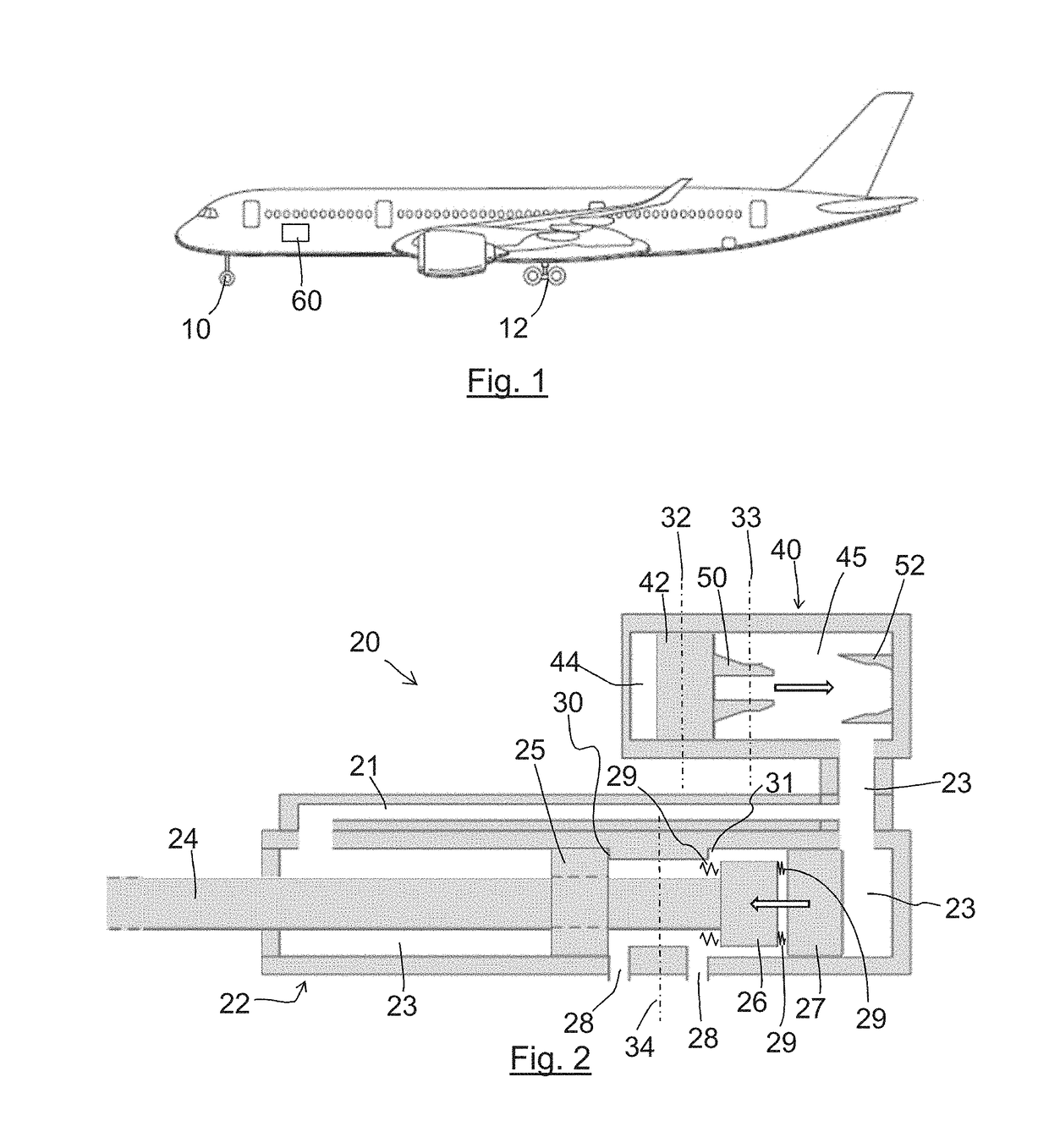

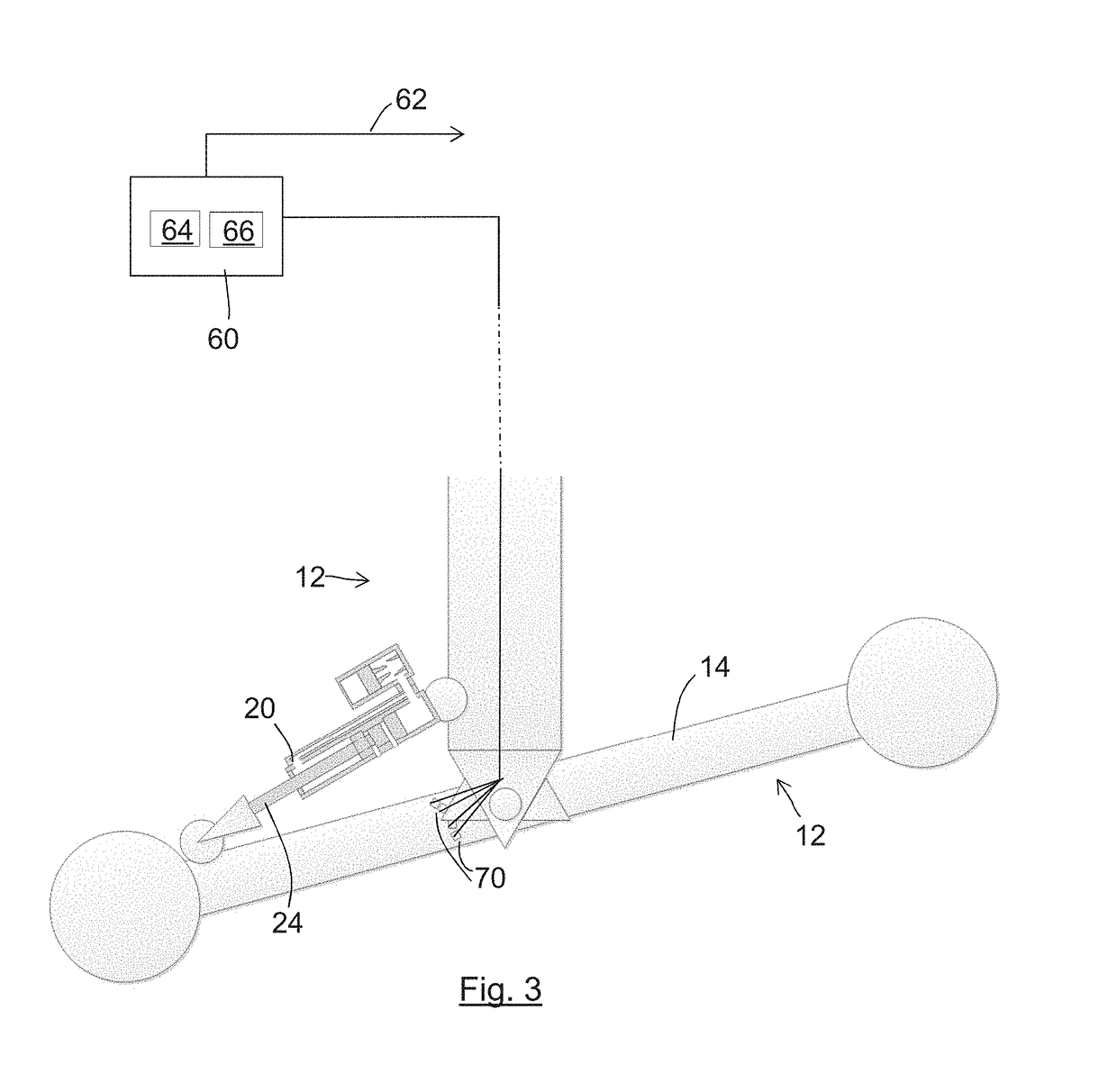

ActiveUS20180222599A1Reduced flow areaEasy to moveFluid-pressure actuator testingAircraft health monitoring devicesBogieMonitoring system

A landing gear system for an aircraft includes a retractable landing gear assembly, a hydraulic actuator for actuating movement part, for example a bogie of the landing gear assembly, and an accumulator associated with the actuator. The accumulator comprises a volume of pressurised gas separated from hydraulic fluid by a separator piston. Travel of the separator piston beyond a certain position is indicative of a fault. The accumulator includes a snubbing device that acts to slow movement of the separator piston beyond that position. A monitoring system measures the time taken for the movement of the landing gear part effected by the hydraulic actuator. If the measured time is longer than a threshold time, that is indicative of a possible fault in the accumulator, that might, without the snubbing, remain undetected and / or hidden from view.

Owner:AIRBUS OPERATIONS LTD

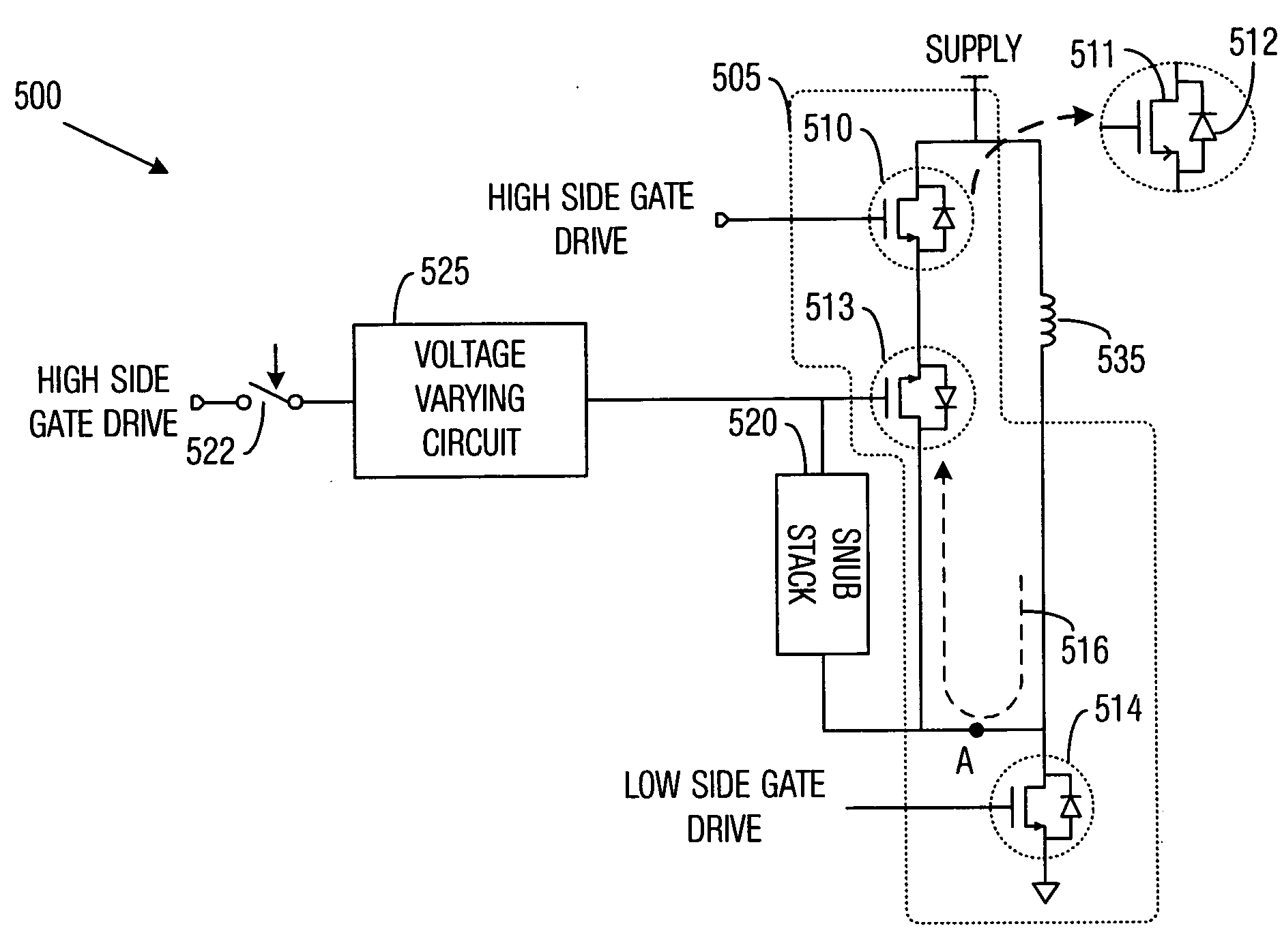

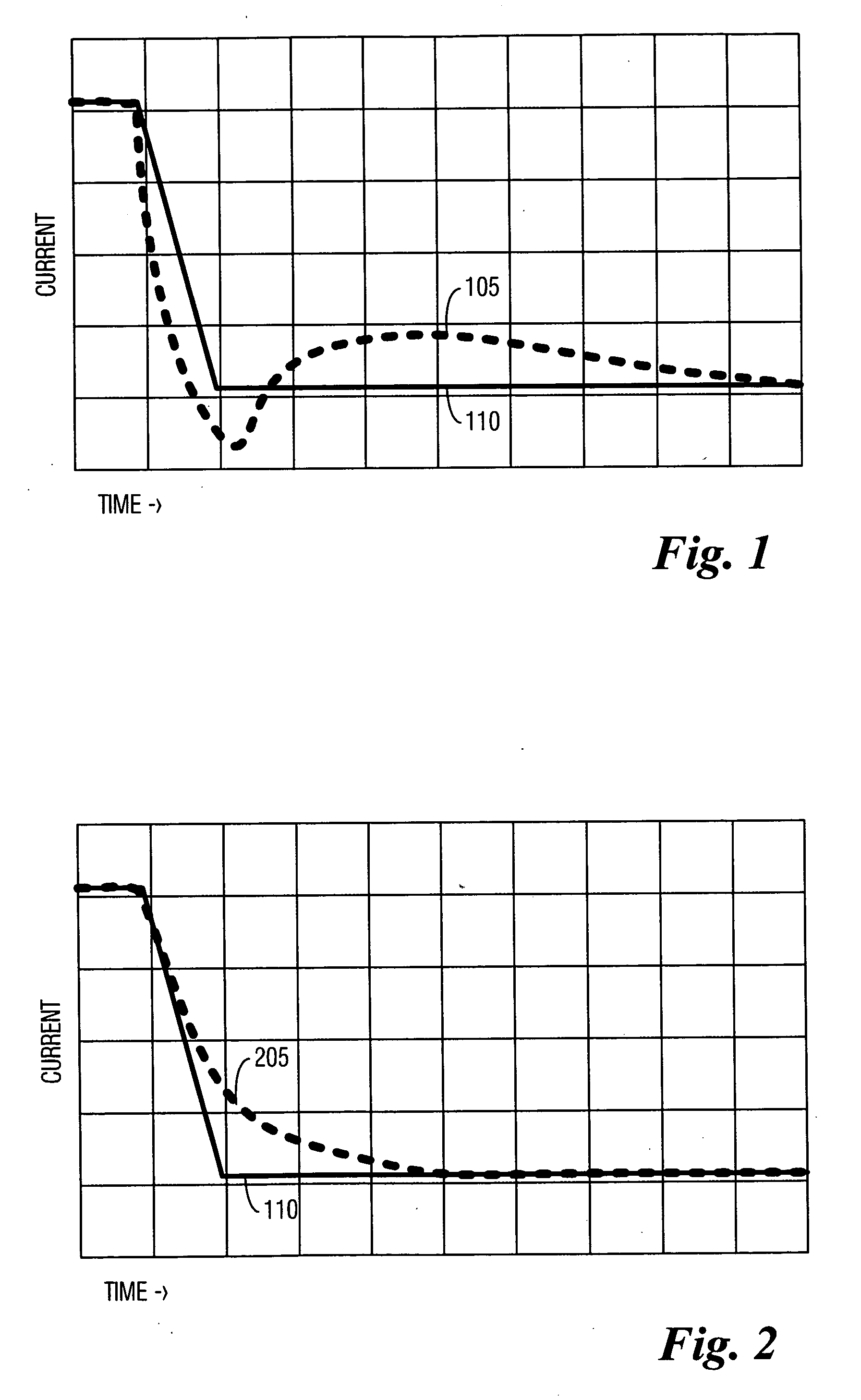

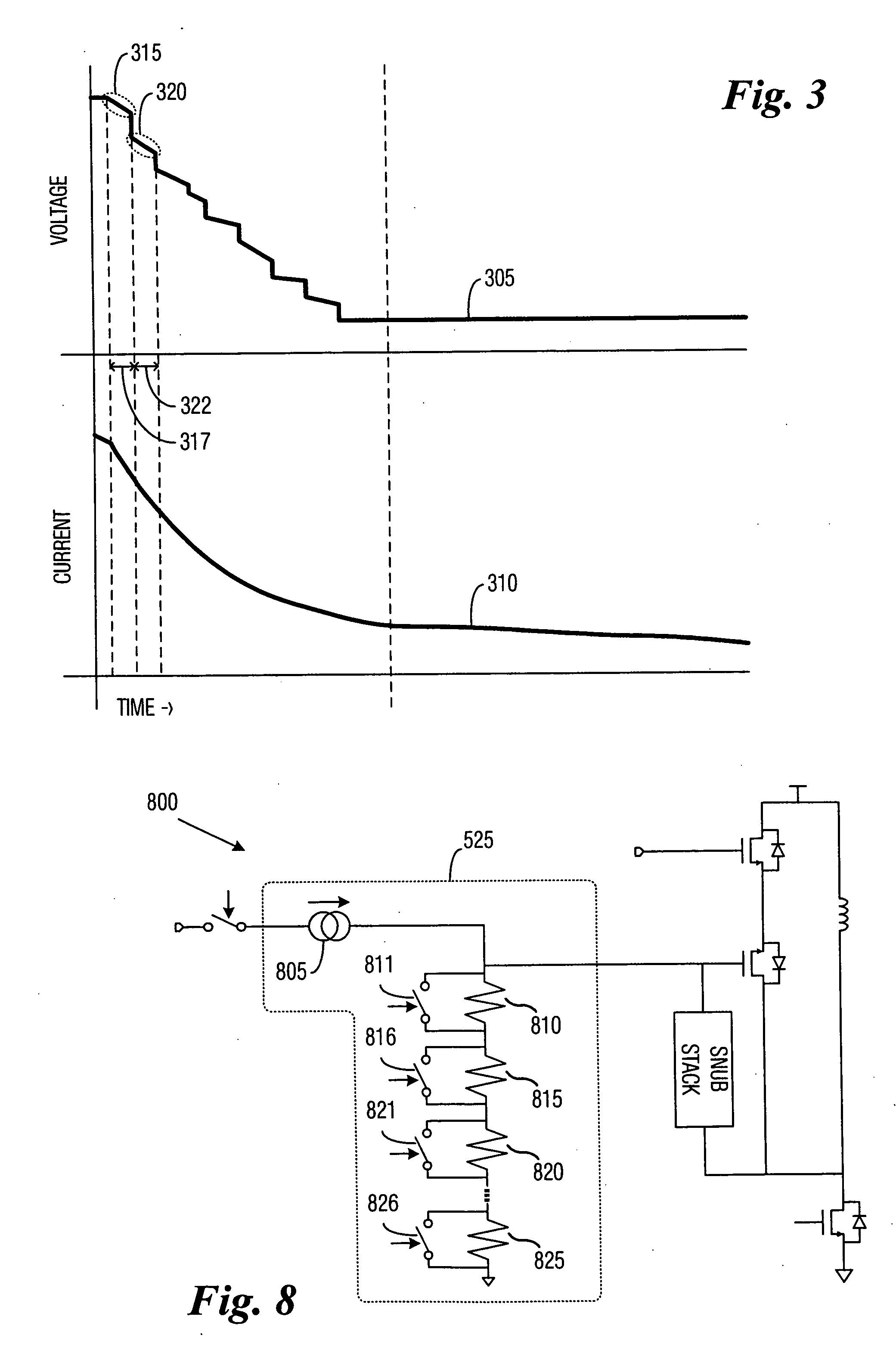

Current control via a variable voltage snubbing network

ActiveUS20050117265A1Prevent current undershootInhibit currentEmergency protective arrangements for limiting excess voltage/currentArrangements responsive to excess voltageDriver circuitVoltage drop

System and method for controlling current across a load. A preferred embodiment comprises a current varying circuit (such as current varying circuit 525) that can create a sequence of voltage drops in a driver circuit (such as the driver circuit 505) coupled to an inductive load (such as the inductive load 535). By initially producing a large voltage drop and then stepping the voltage drop down gradually, the current in the inductive load can be rapidly removed without producing a current undershoot, which, in certain applications, can result in unwanted noise and vibration.

Owner:TEXAS INSTR INC

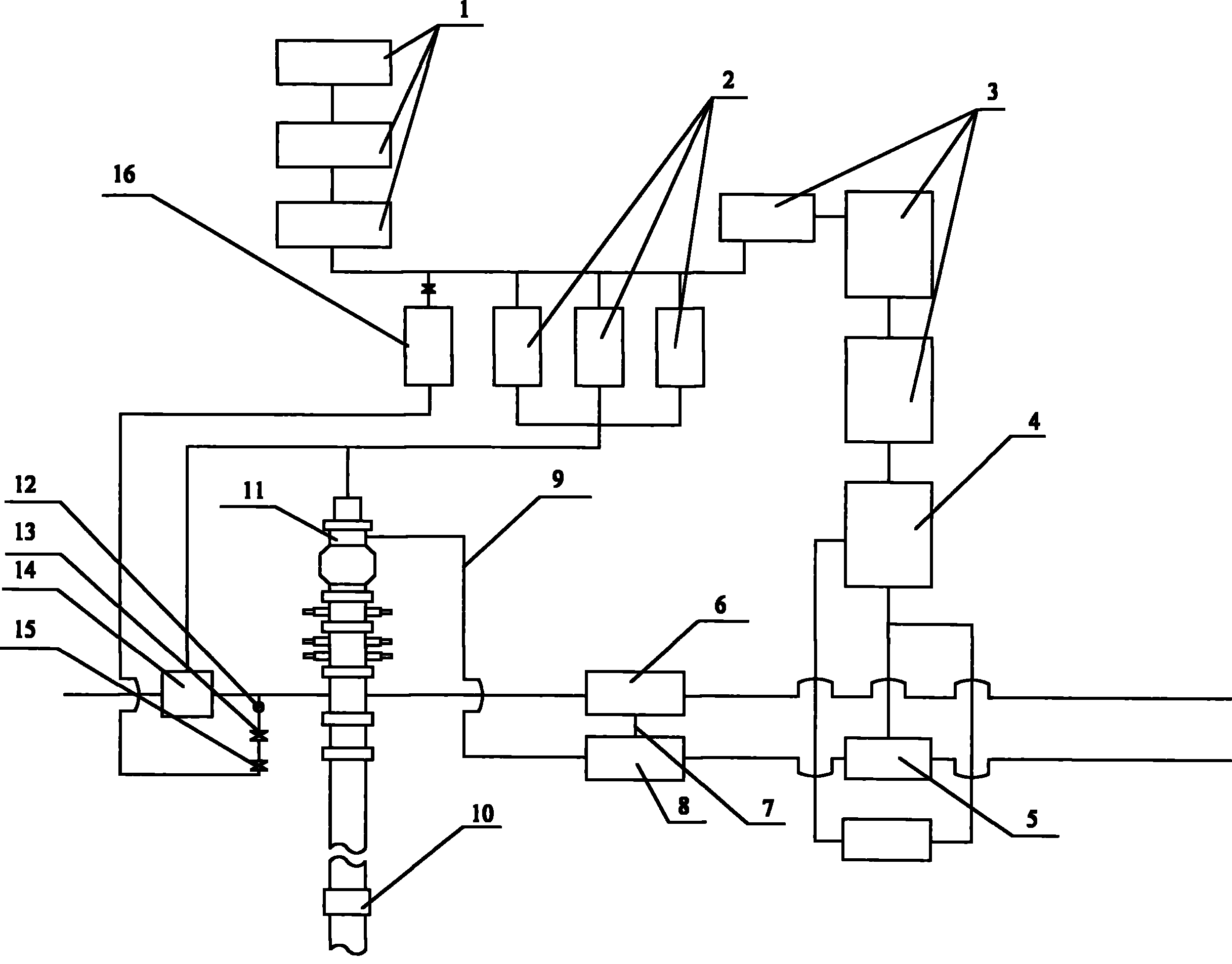

Pressure control device for whole-process underbalanced drilling and use method

InactiveCN105971536AEnsure safetyEffectively control the amount of invasion into the wellboreFlushingBlowout preventerRotation control

The invention relates to the technical field of unbalanced drilling in oil and gas fields and provides a pressure control device for whole-process underbalanced drilling and a use method. The pressure control device comprises a wellhead blowout preventer stack, a rotary control head, a downhole deployment valve, a casing string, a drilling fluid circulating processing device, a special choke manifold, a drilling pump unit and a drilling fluid continuous pouring device which is capable of detecting injecting pressure and flow, wherein the downhole deployment valve is fixedly mounted on the casing string on the upper layer, a ground control device for opening and closing the downhole deployment valve is connected onto the downhole deployment valve, and the rotary control head and the wellhead blowout preventer stack are fixedly mounted sequentially from top to bottom at the top of the casing string above the downhole deployment valve. Reasonable back pressure is applied to a wellhead by regulating the opening degree of a throttle valve of the special choke manifold, so that downhole pressure is controlled dynamically, the downhole is enabled to be in a controllable unbalanced state all along, accordingly, the quantity of a formation fluid invading a shaft in a snubbing process is controlled effectively, reservoirs of the oil and gas fields can be protected, and the drilling operation safety is guaranteed effectively.

Owner:CNPC XIBU DRILLING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com