Dual-roll rolling machine hydraulic pressing down system and operation method thereof

A technology for hydraulic pressing and casting and rolling mills, which is applied in the field of hydraulic system pressure maintenance, can solve the problems of pressure fluctuation at the outlet of the pressure reducing valve, affecting the pressure, and increasing energy consumption, so as to eliminate the phenomenon of pressure fluctuations, maintain reliable pressure and save energy. The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

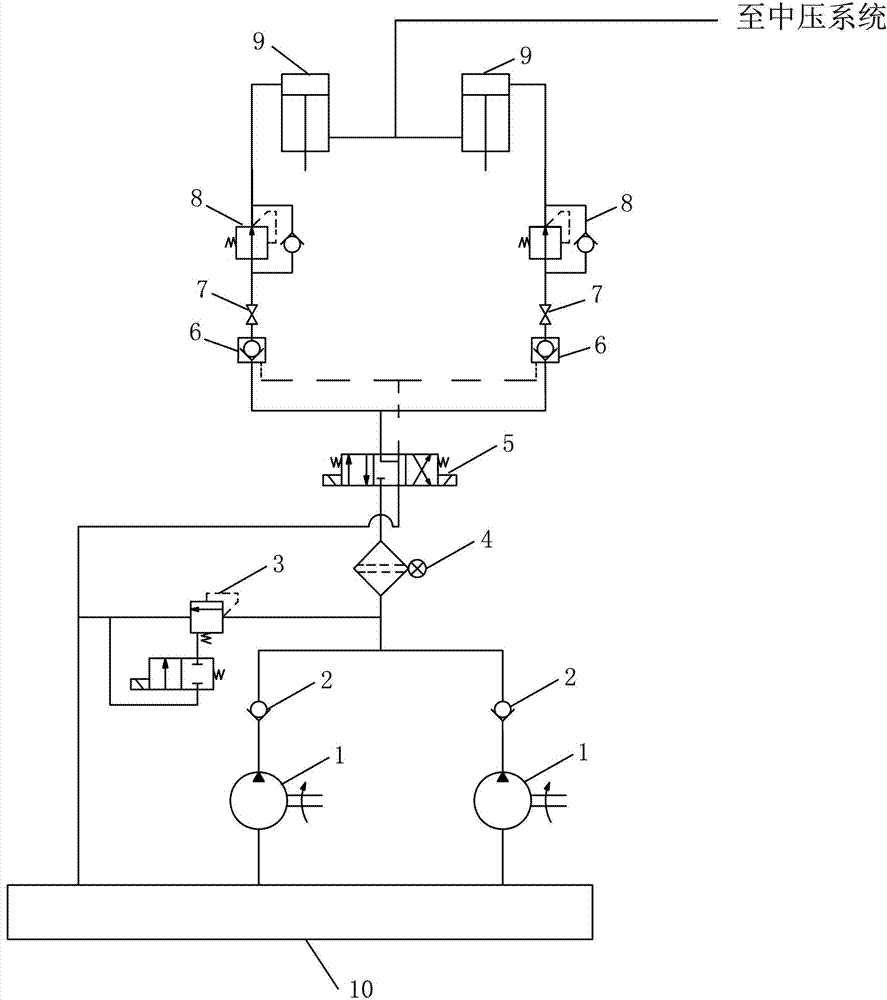

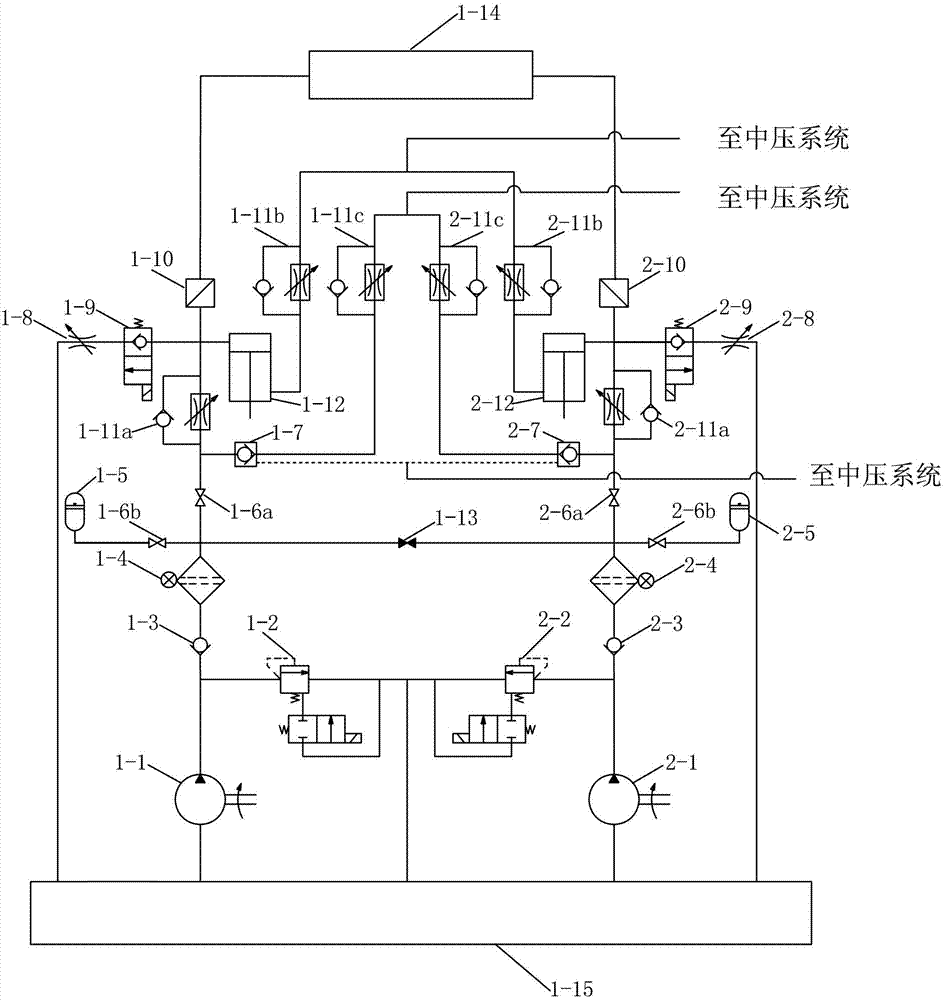

[0027] Such as figure 1 As shown, a double-roll cast-rolling mill hydraulic pressure system is composed of two symmetrical oil circuits. Take one of the oil circuits as an example to describe the connection and function of its components. One end of the plunger pump 1-1 is connected to the oil tank 1-15, and the other end passes through the one-way valve 1-3, the oil filter 1-4, The first stop valve 1-6a and the first one-way throttle valve 1-11a supply oil to the rodless cavity of the depressing cylinder 1-12, and the accumulator 1-5 passes through the second stop valve 1-6b and the oil filter 1 The output end of -4 is connected, the electromagnetic overflow valve 1-2 is connected in parallel to the plunger pump 1-1, which is used to adjust the pressure of the hydraulic depression system, the pressure sensor 1-10 is connected with the depression cylinder 1-12, and the depression cylinder The pressure of 1-12 is fed back to the processor of the control unit 1-14 through the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com