Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

255results about "Cork treatment details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

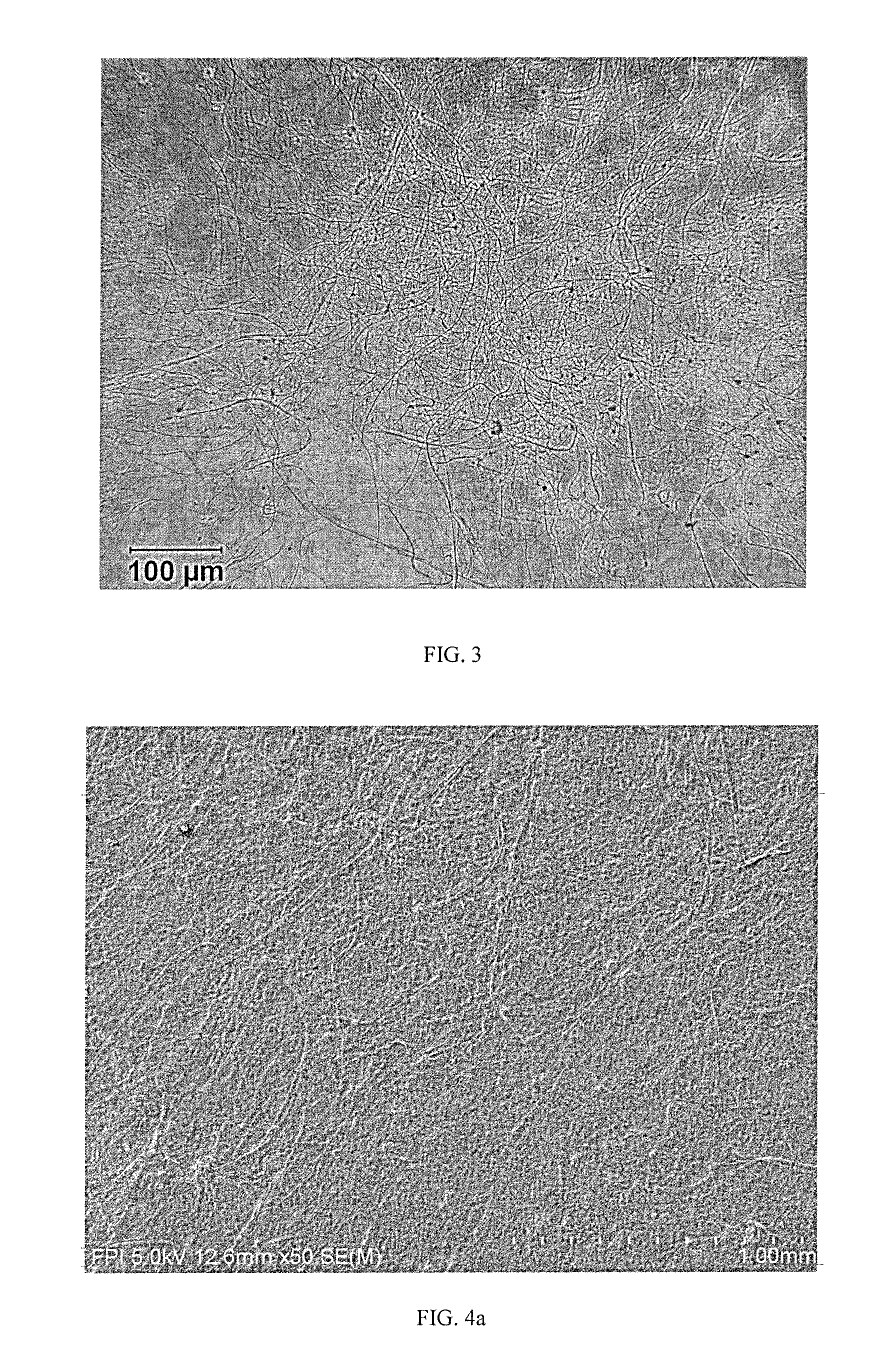

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

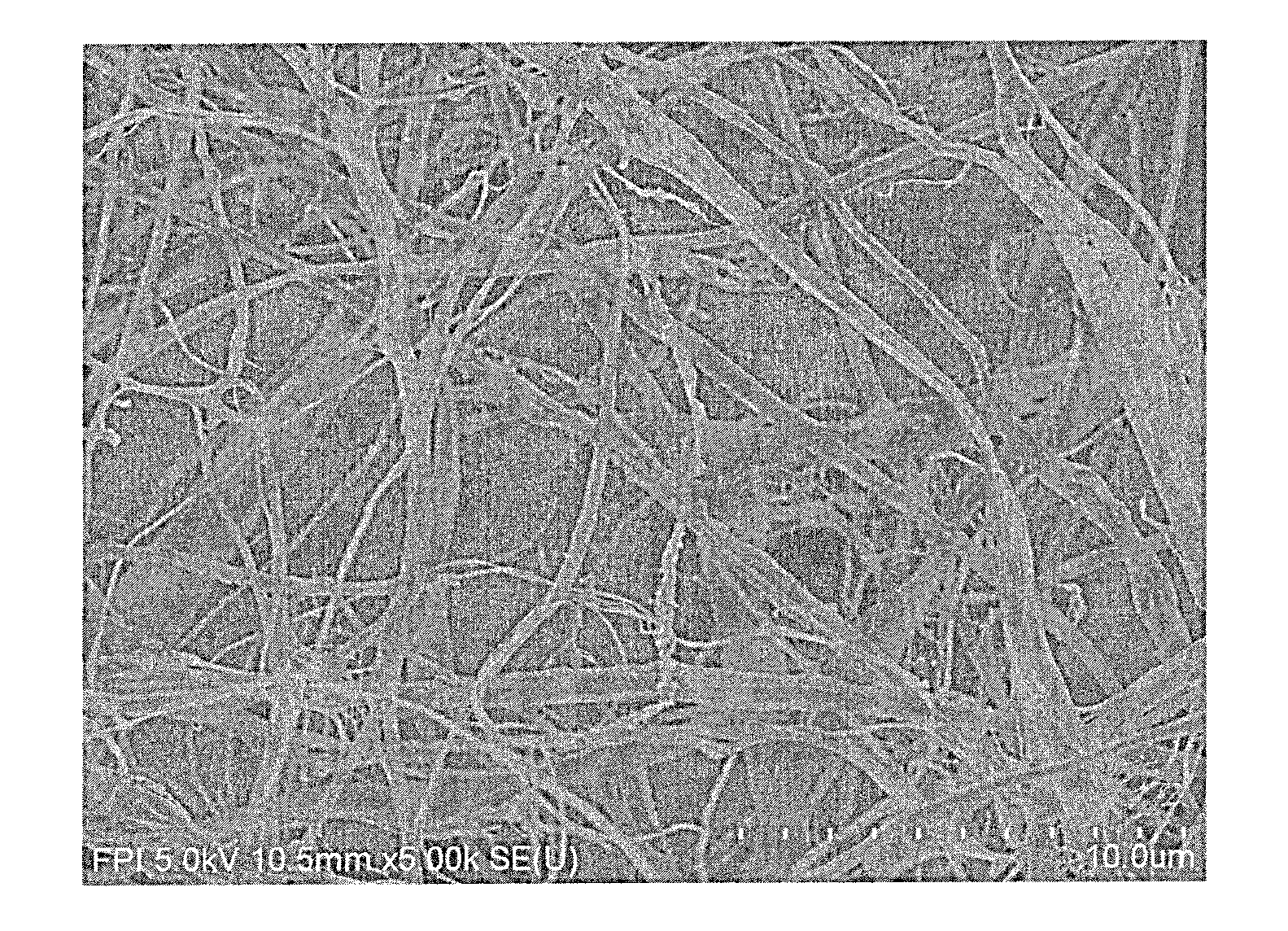

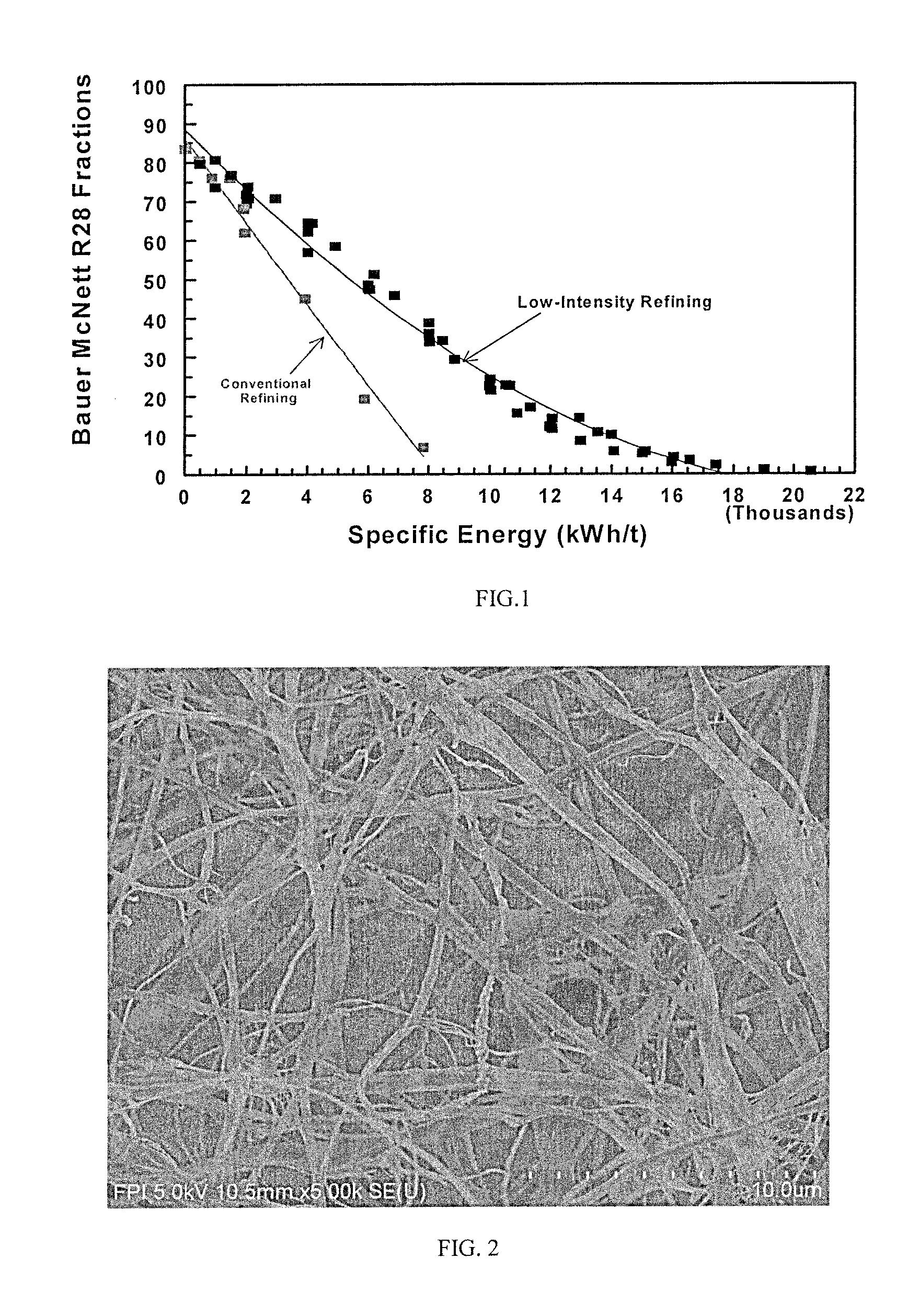

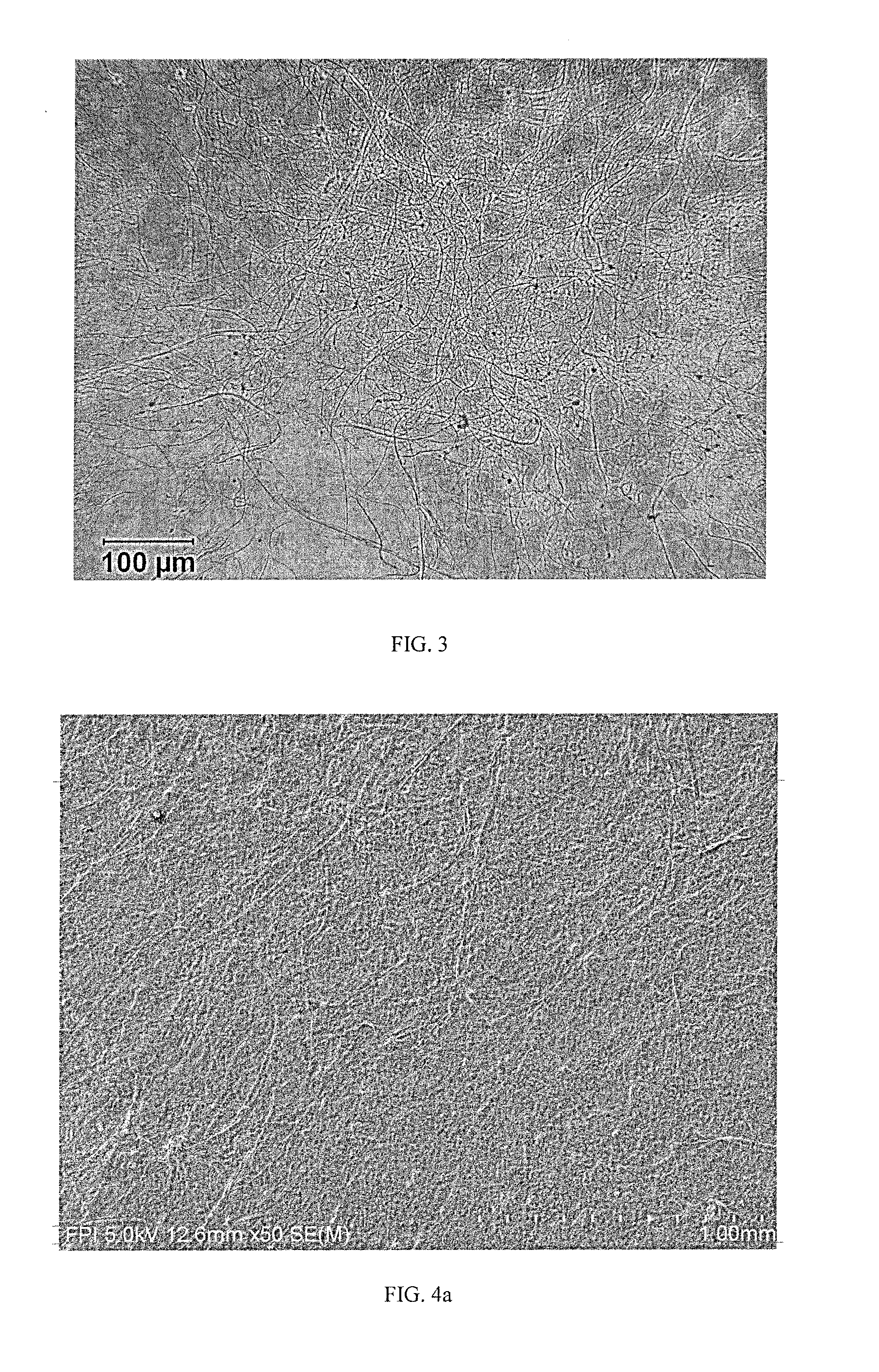

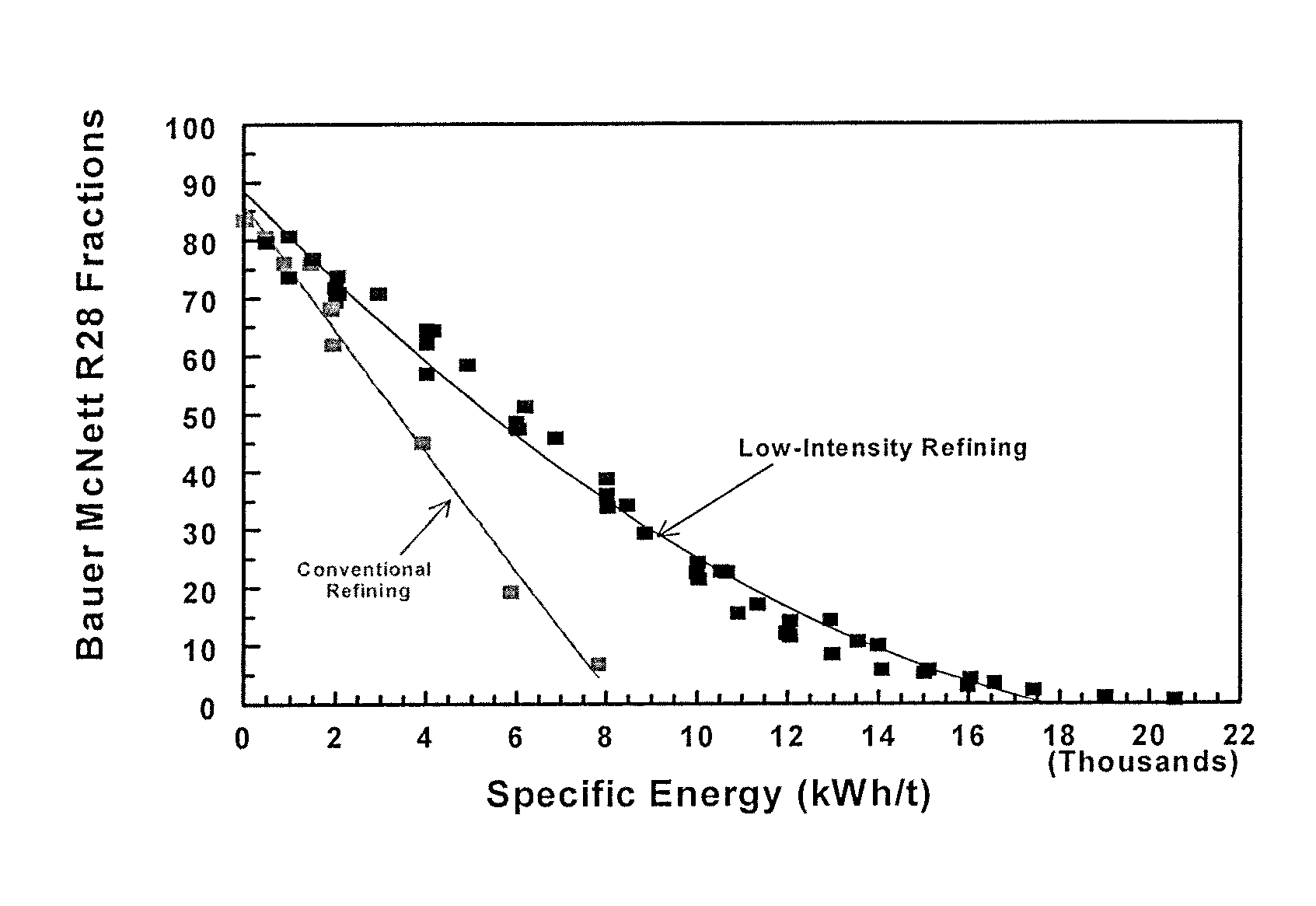

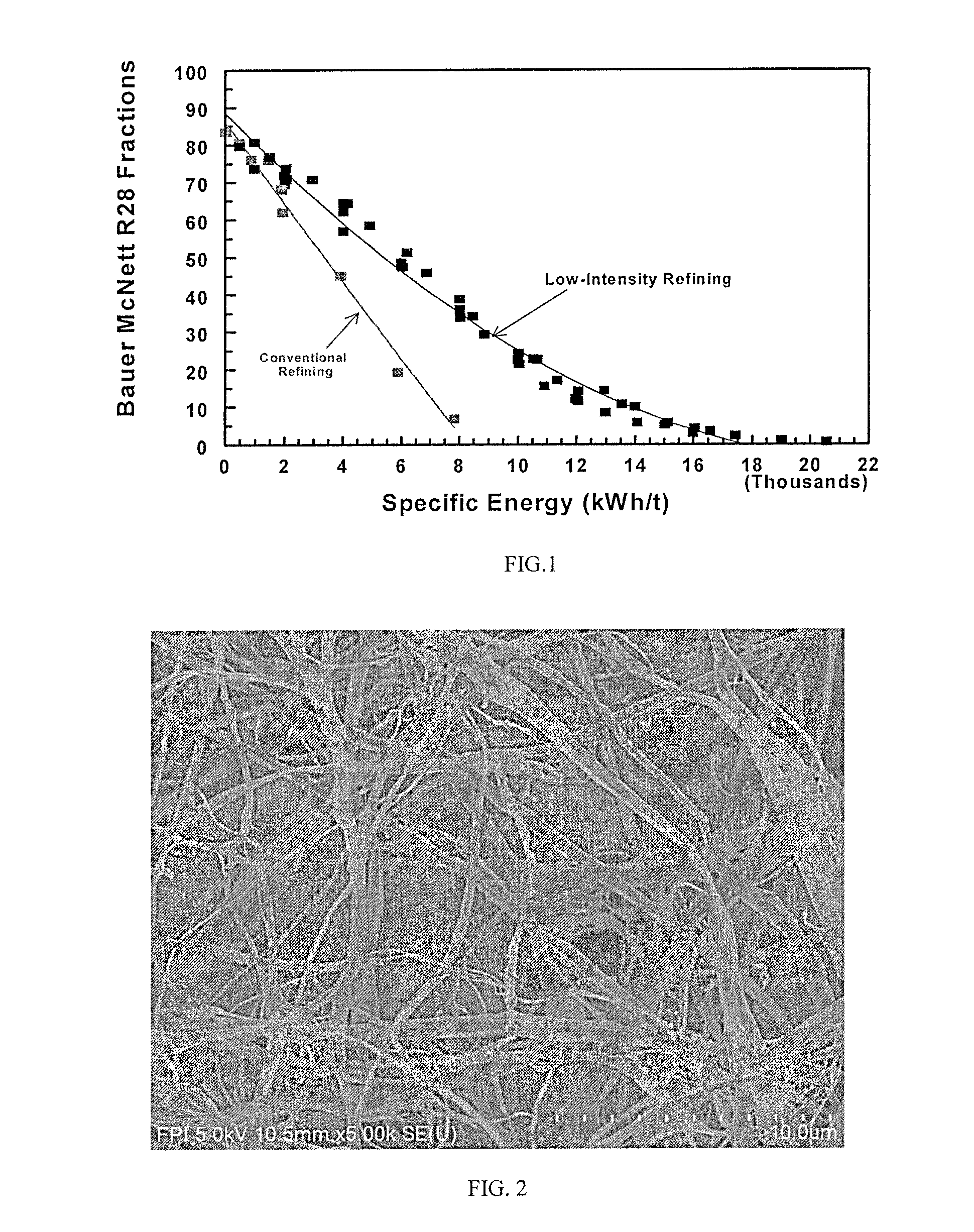

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

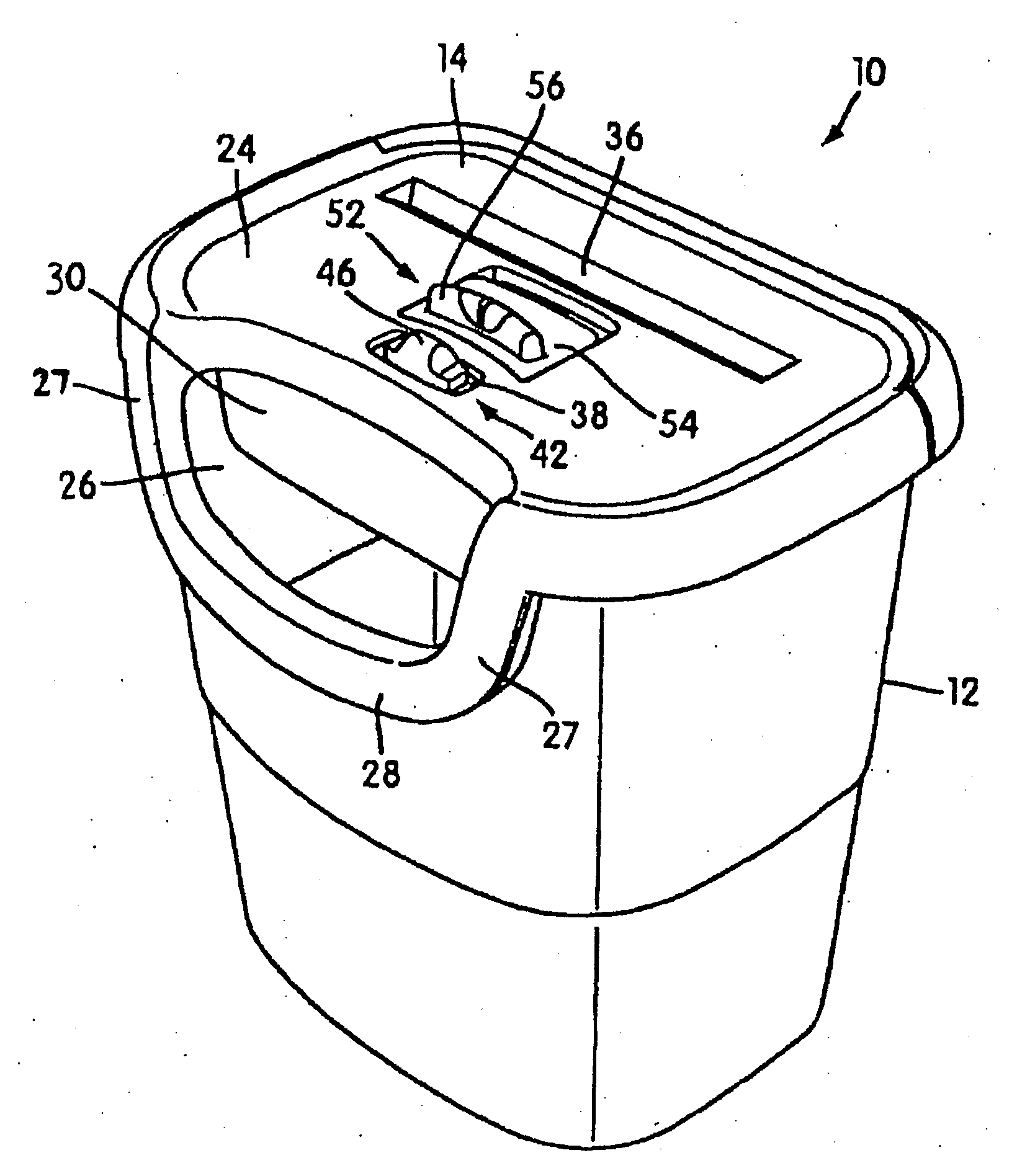

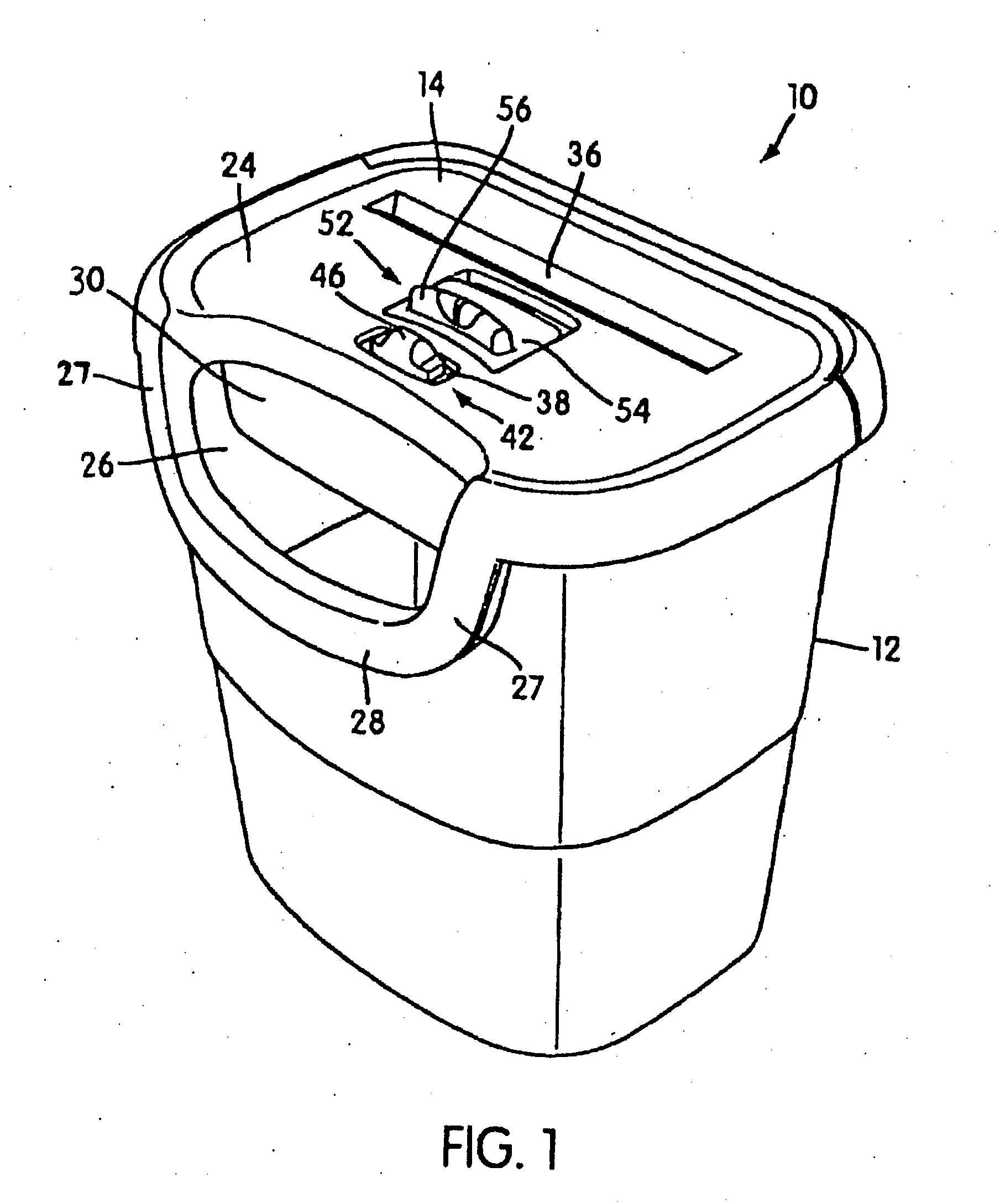

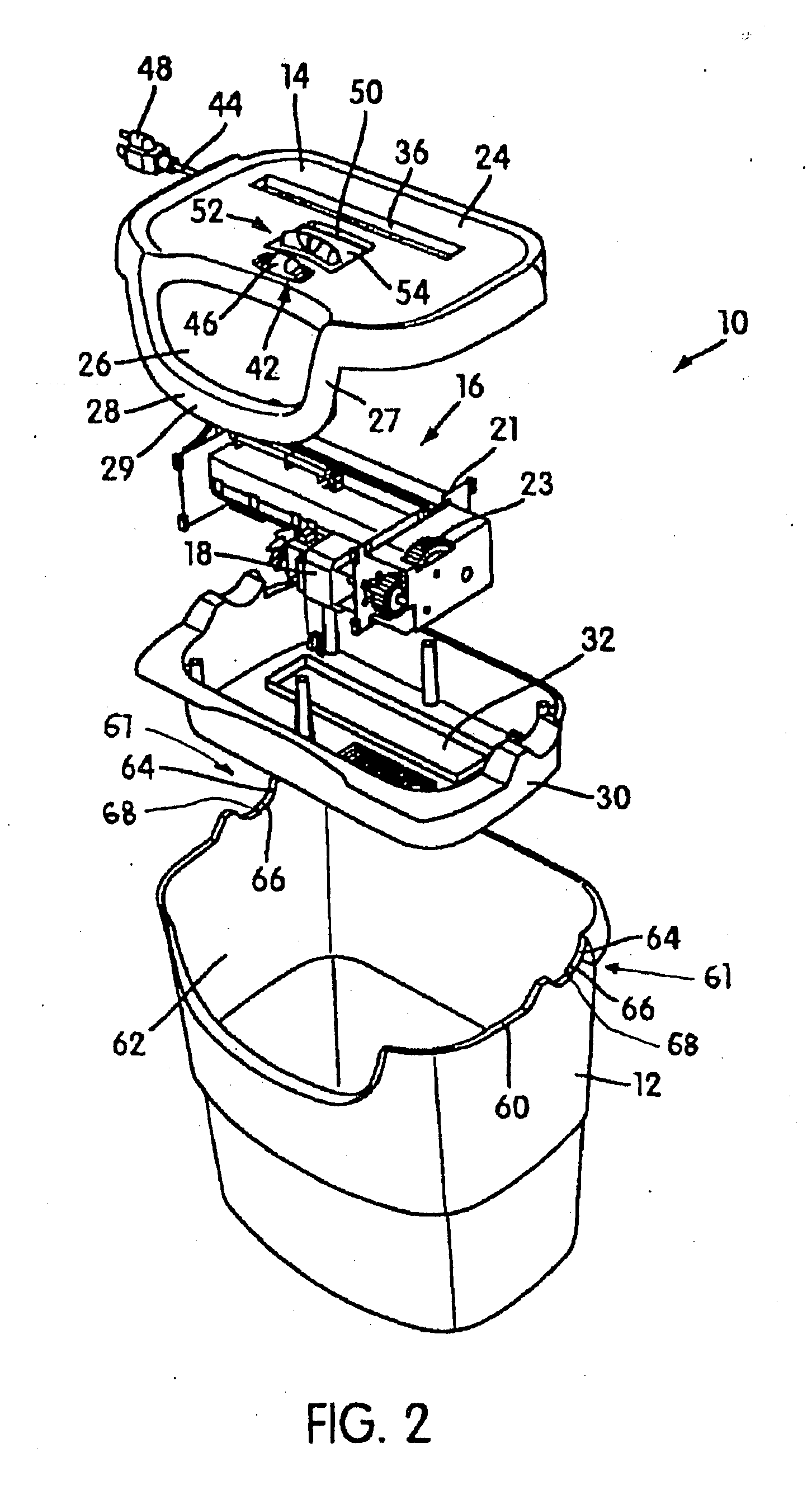

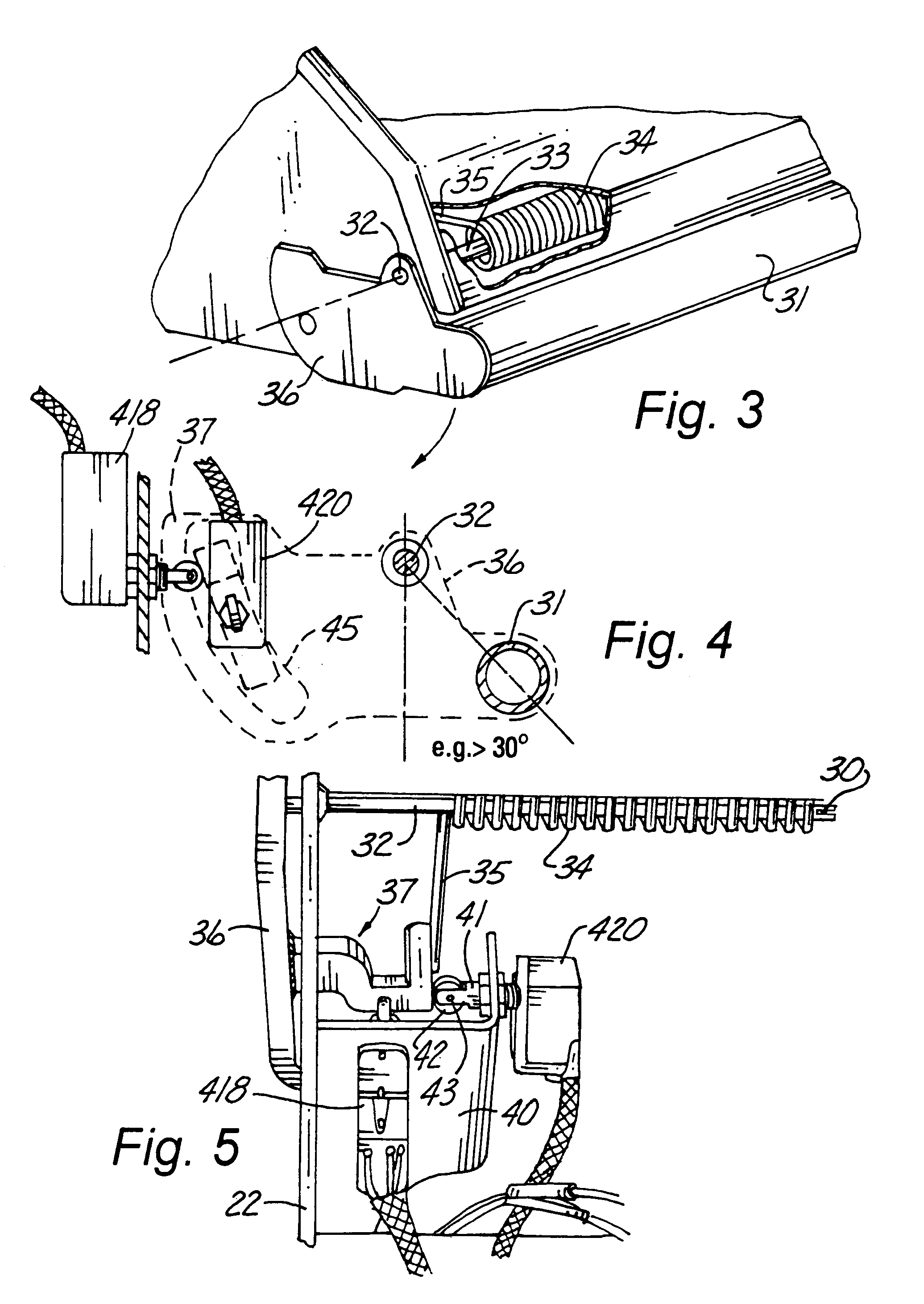

Shredder thickness with Anti-jitter feature

A shredder includes a housing having a throat for receiving at least one article to be shredded, and a shredder mechanism received in the housing and including an electrically powered motor and cutter elements. The shredder also includes a detector that is configured to detect a thickness of the at least one article being received by the throat, and a controller that is configured to operate the motor to drive the cutter elements to shred the at least one article and to set a flutter threshold higher than the predetermined maximum thickness threshold, if the detected thickness is less than a predetermined maximum thickness threshold. The controller is also configured to thereafter continuously detect the thickness of the at least one article being inserted into a throat of the shredder; and to perform a predetermined operation responsive to the thickness detector detecting that the thickness of the at least one article is greater than the flutter threshold.

Owner:FELLOWES INC

Making process of E1/E0 level green artificial plate

InactiveCN1526528AThe effect of free formaldehyde content is obviousGuarantee market supplyWood veneer joiningFlat articlesFiberHigh density

The present invention discloses one kind of making process of E1 / E0 level environment protection artificial plate. After plain plate with free formaldehyde releasing amount greater than or equal to E2 level is made with common urea resin adhesive, the plain plate is processed through ammonia vacuum process to lower the free formaldehyde releasing amount to E1 / E0 level. According to the density and initial formaldehyde releasing amount of the plain plate, the ammonia consumption and formaldehyde lowering time are regulated to control the processing effect. The said process has stable product quality and low cost, and is suitable for various artificial plates, including plywood, medium density fiber plate, high density fiber plate and shaving board.

Owner:NANJING FORESTRY UNIV

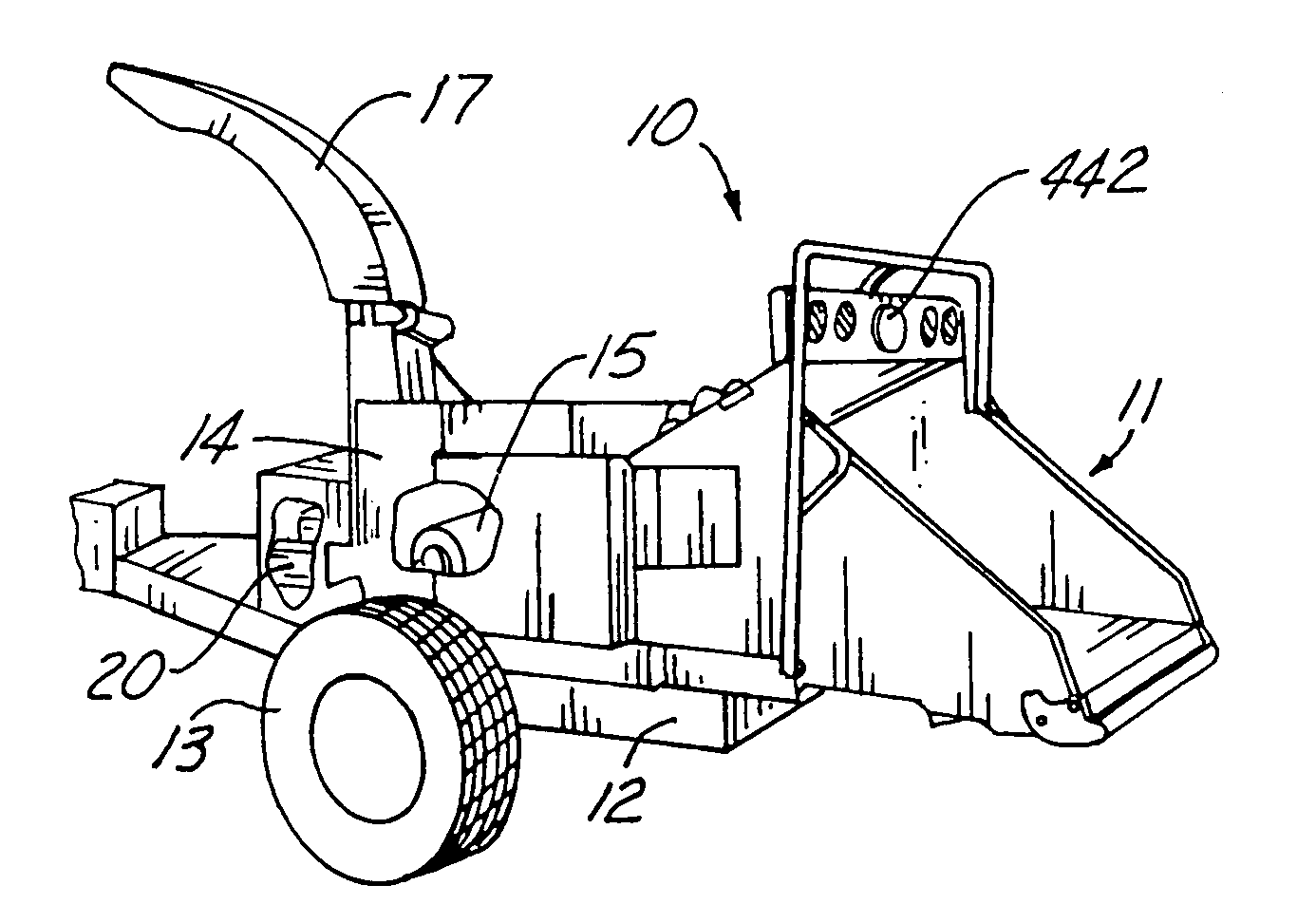

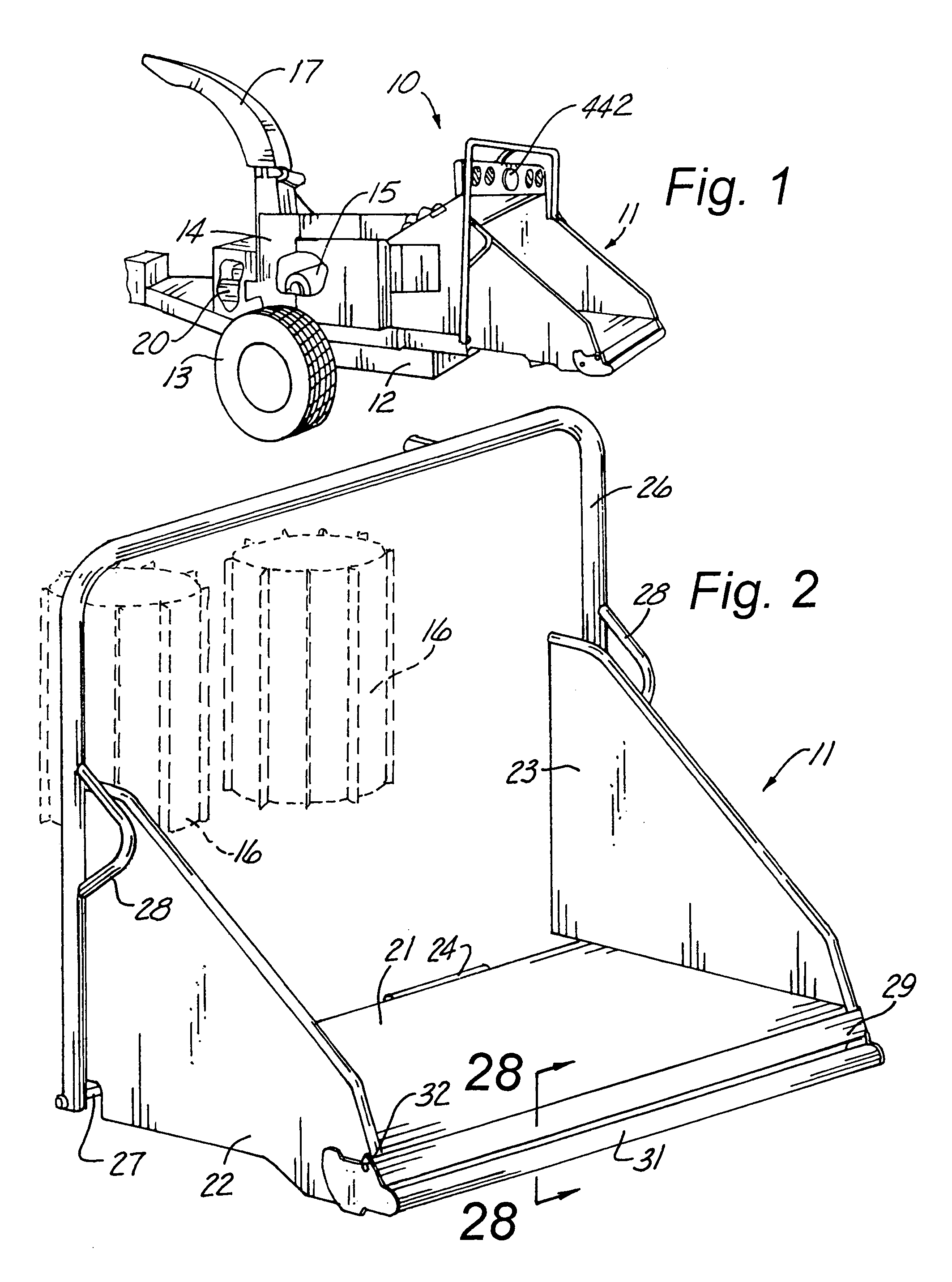

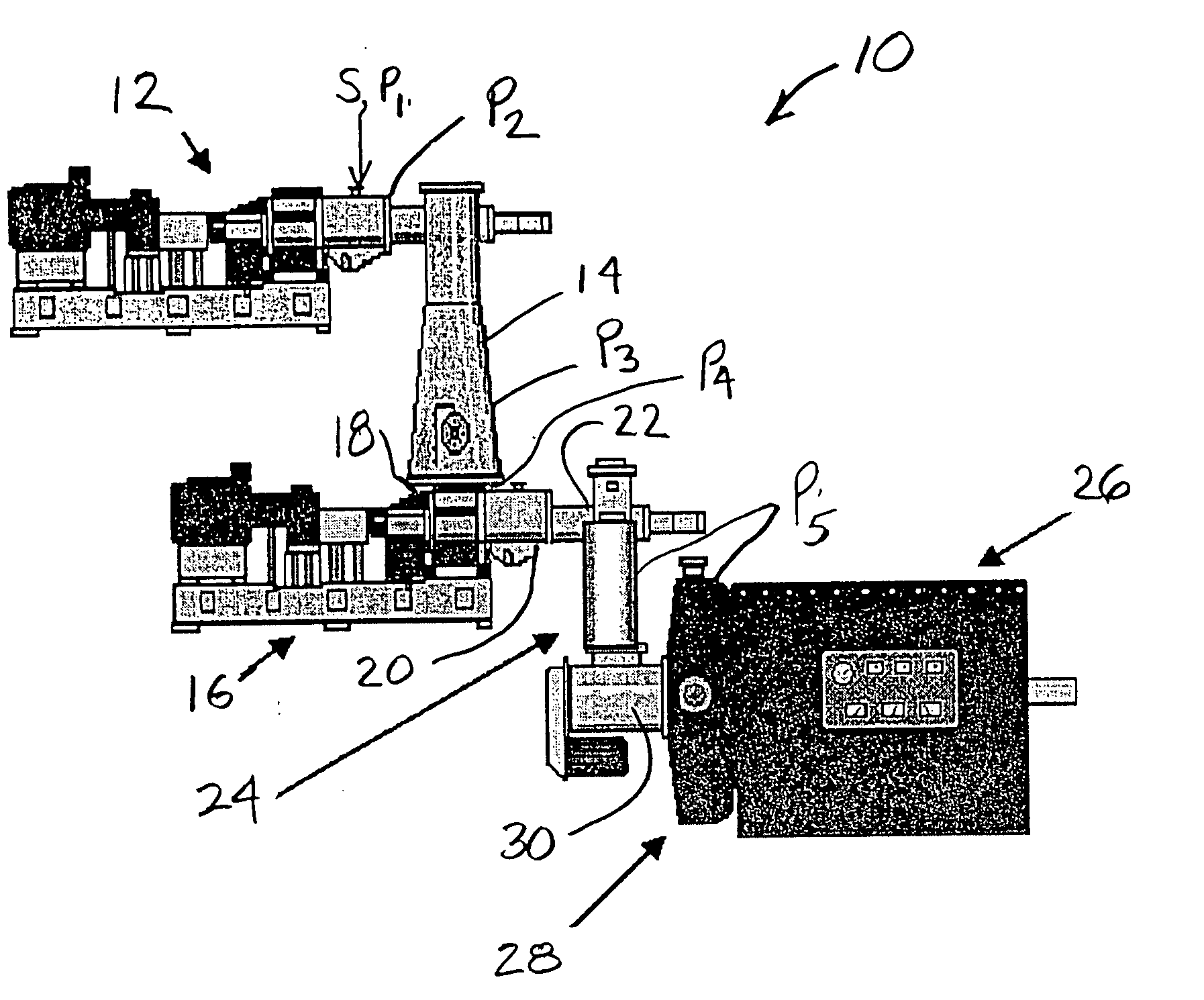

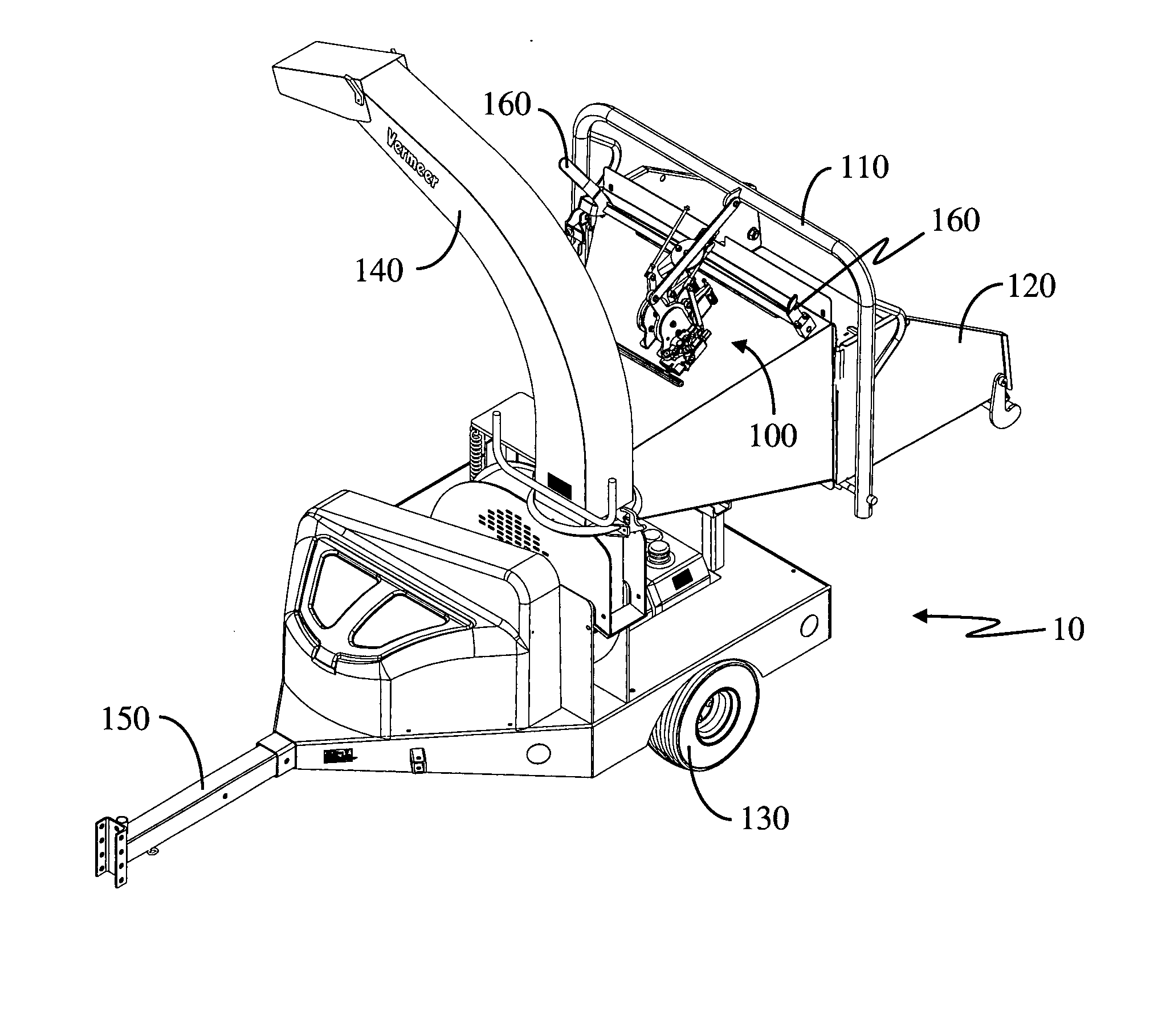

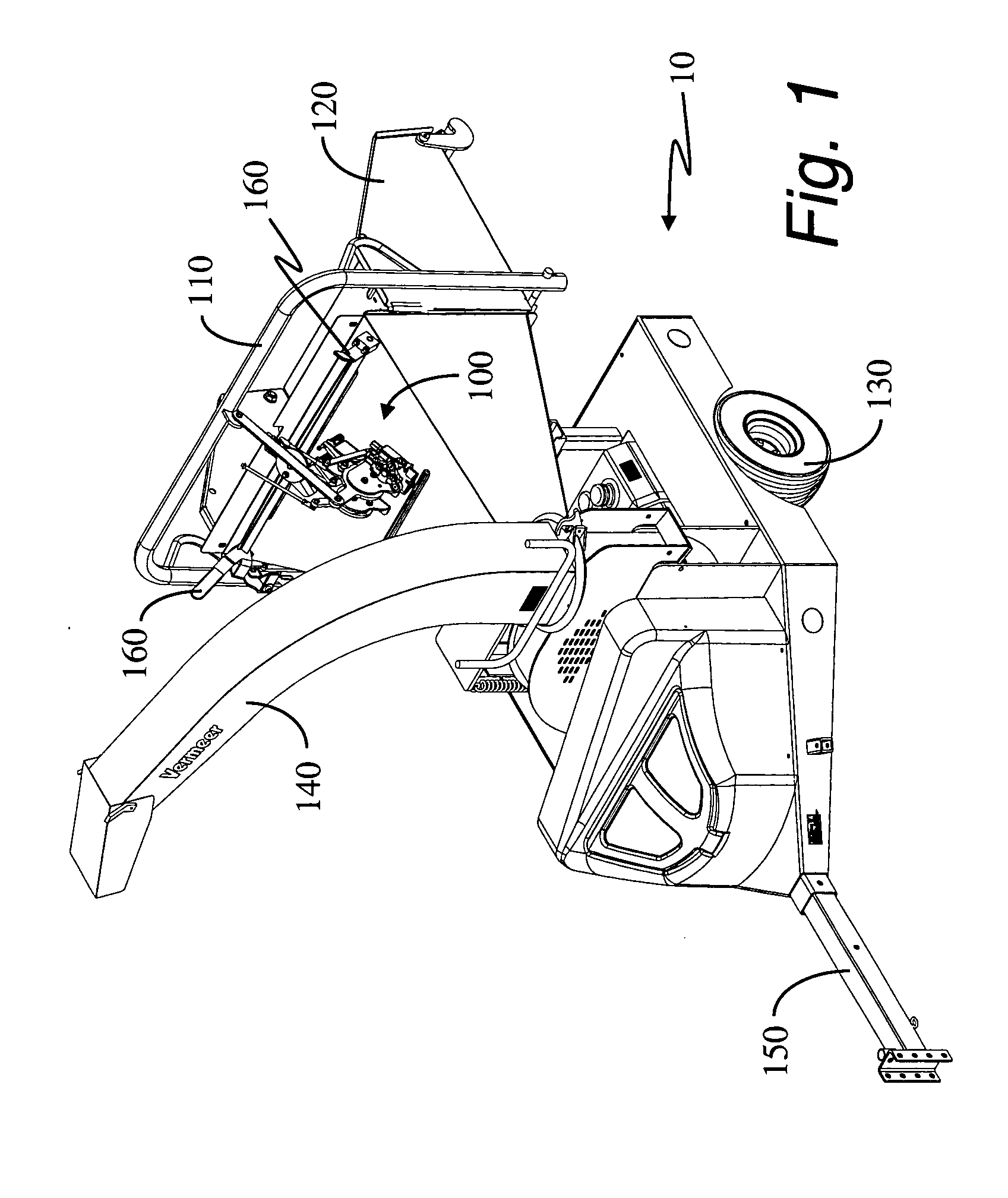

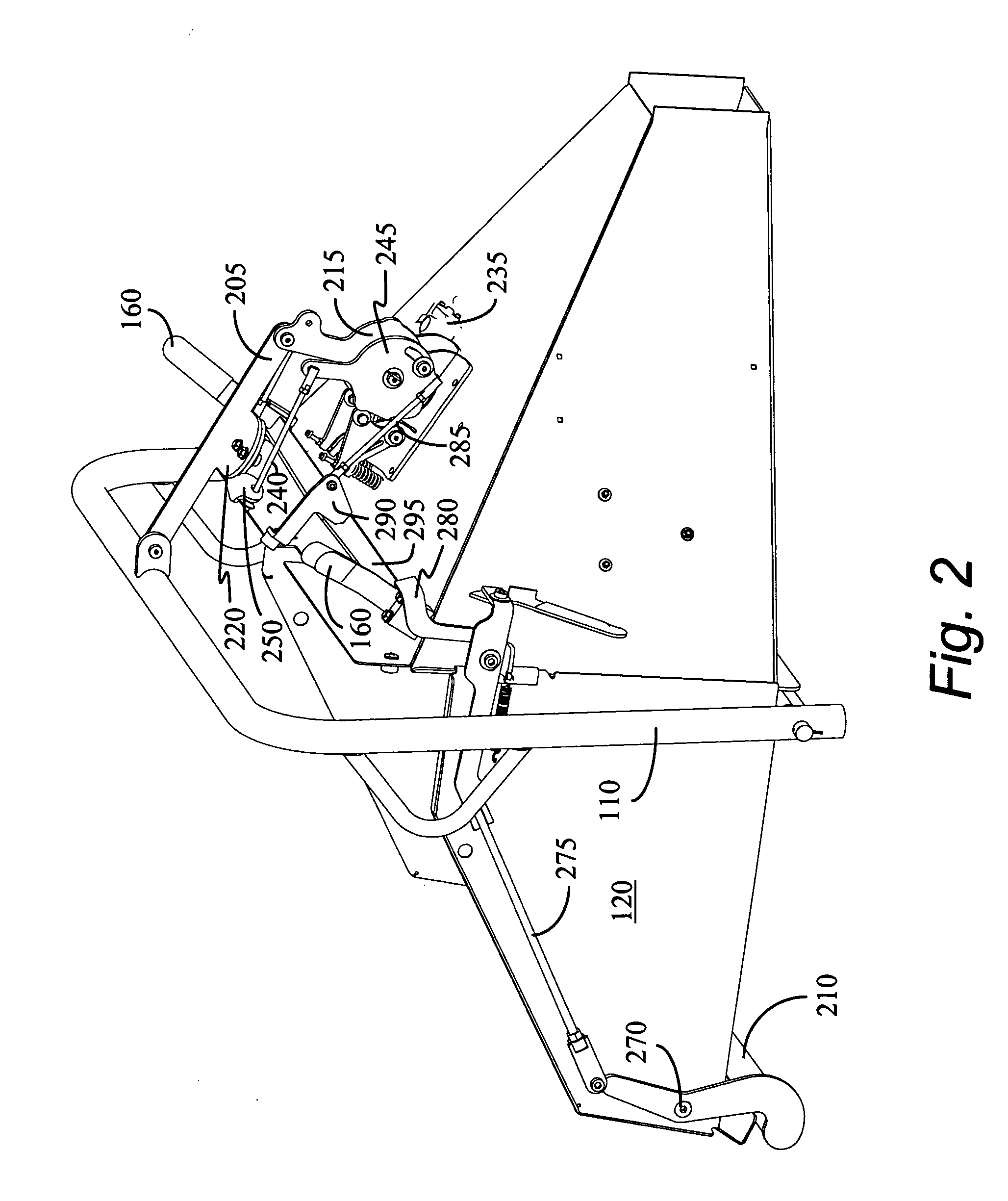

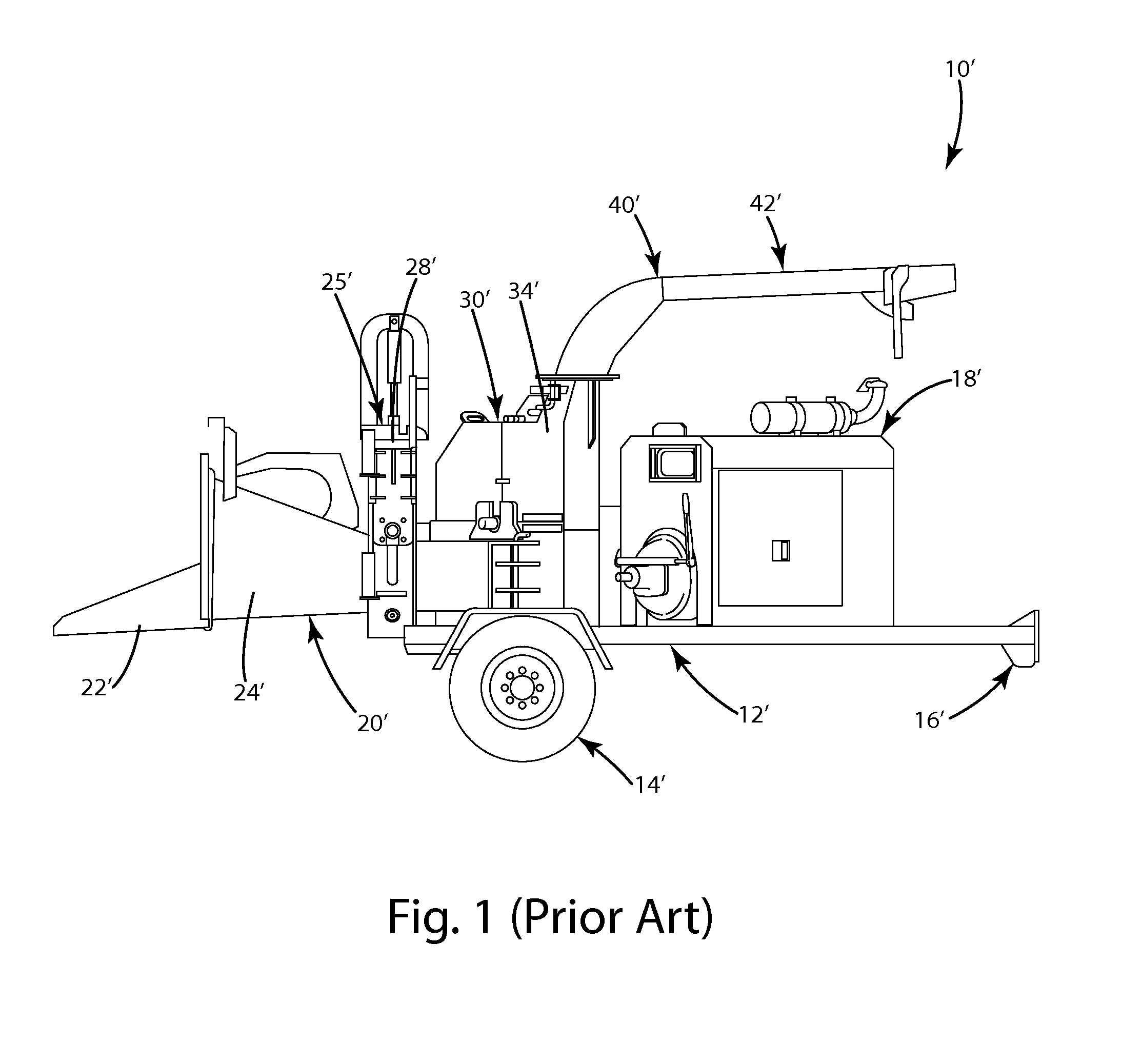

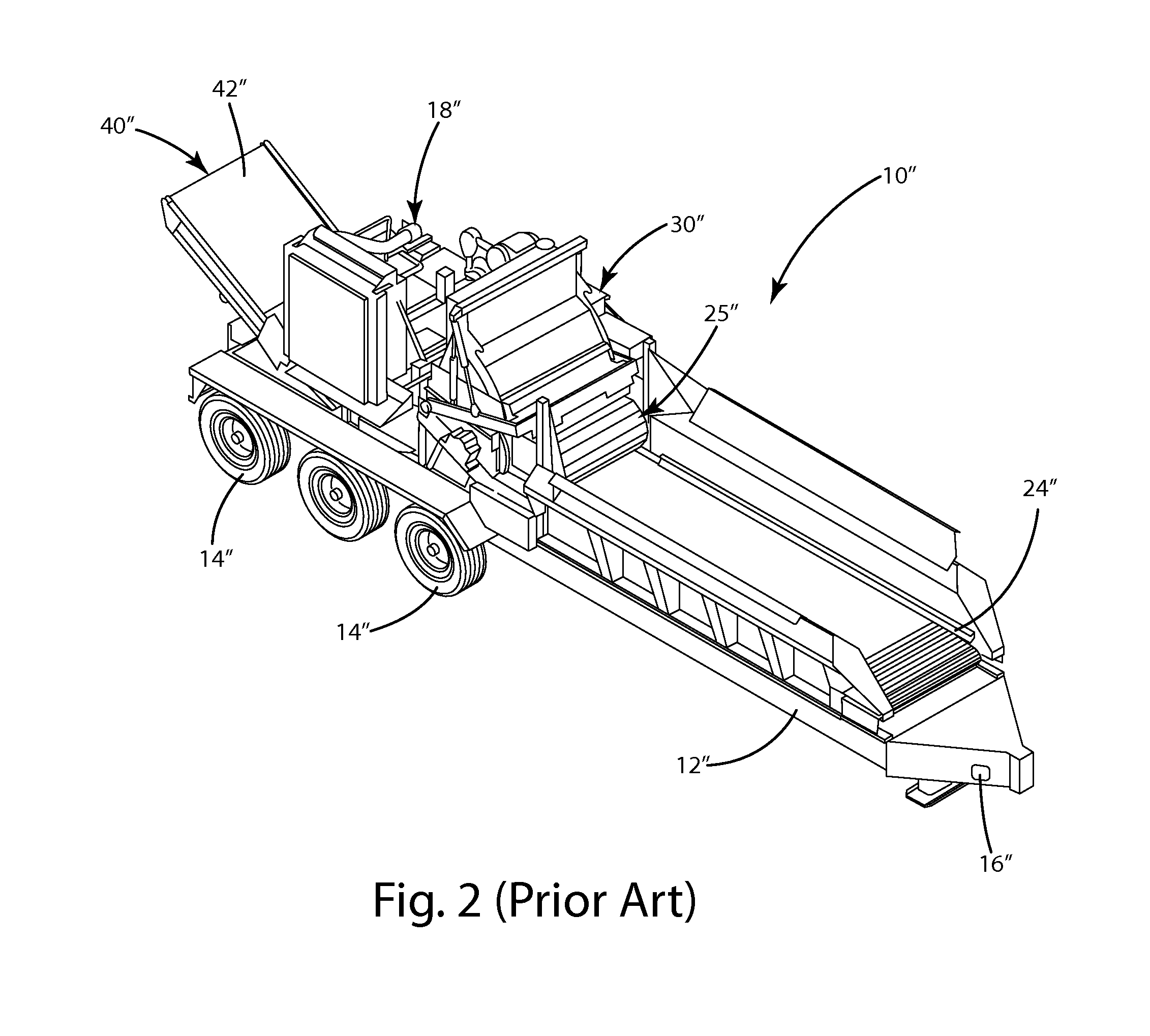

Brush chipper and methods of operating same

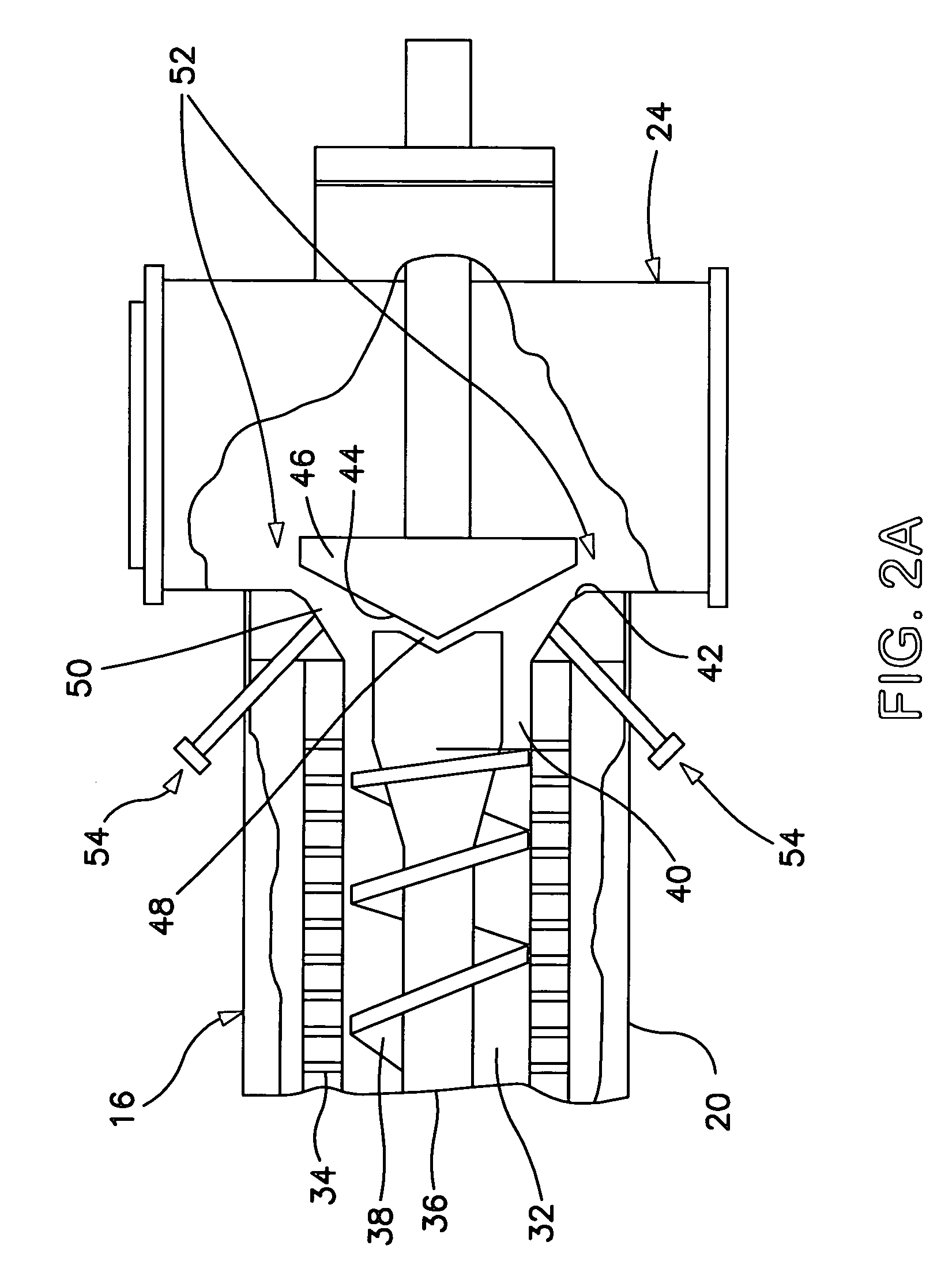

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

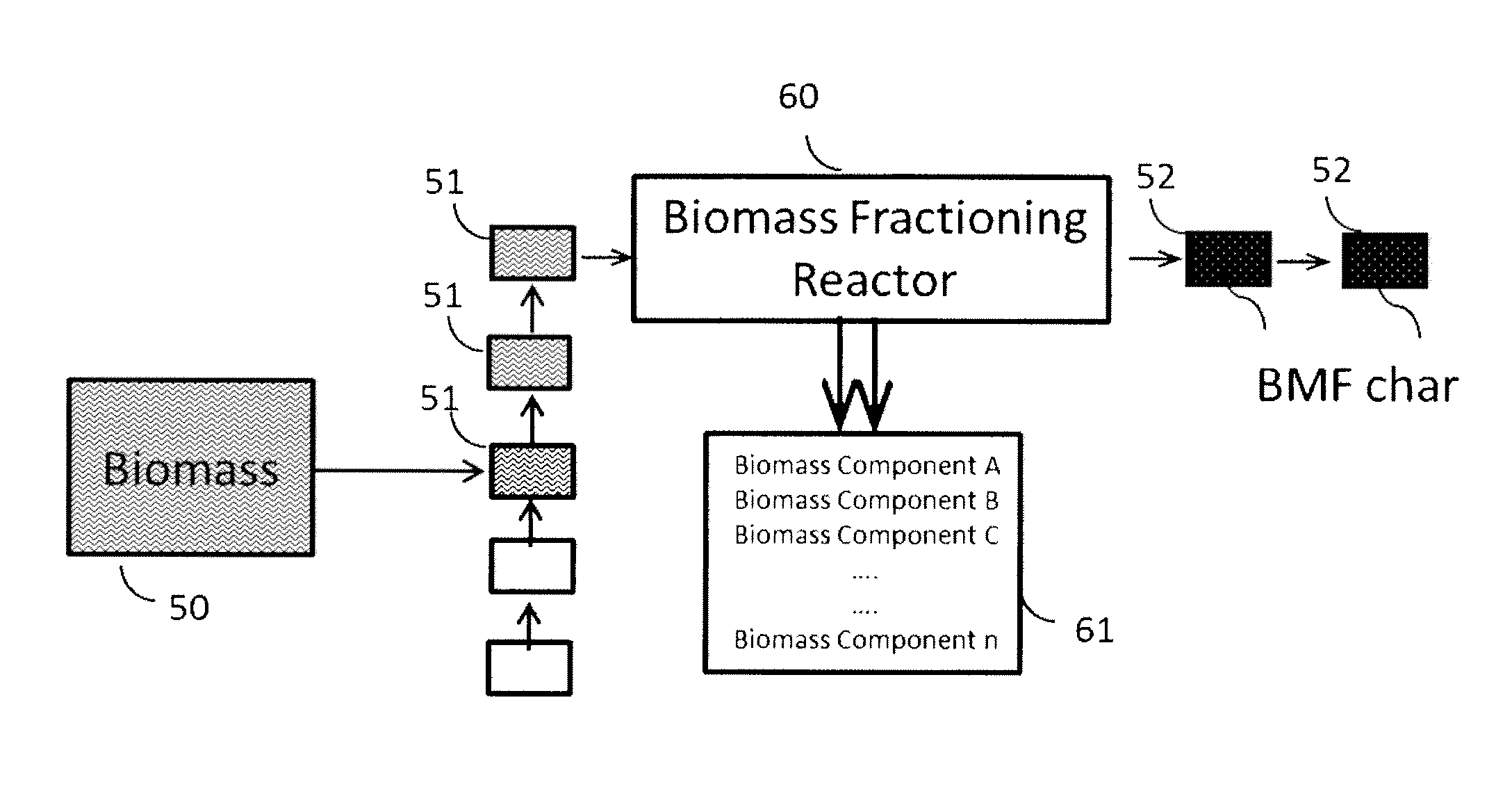

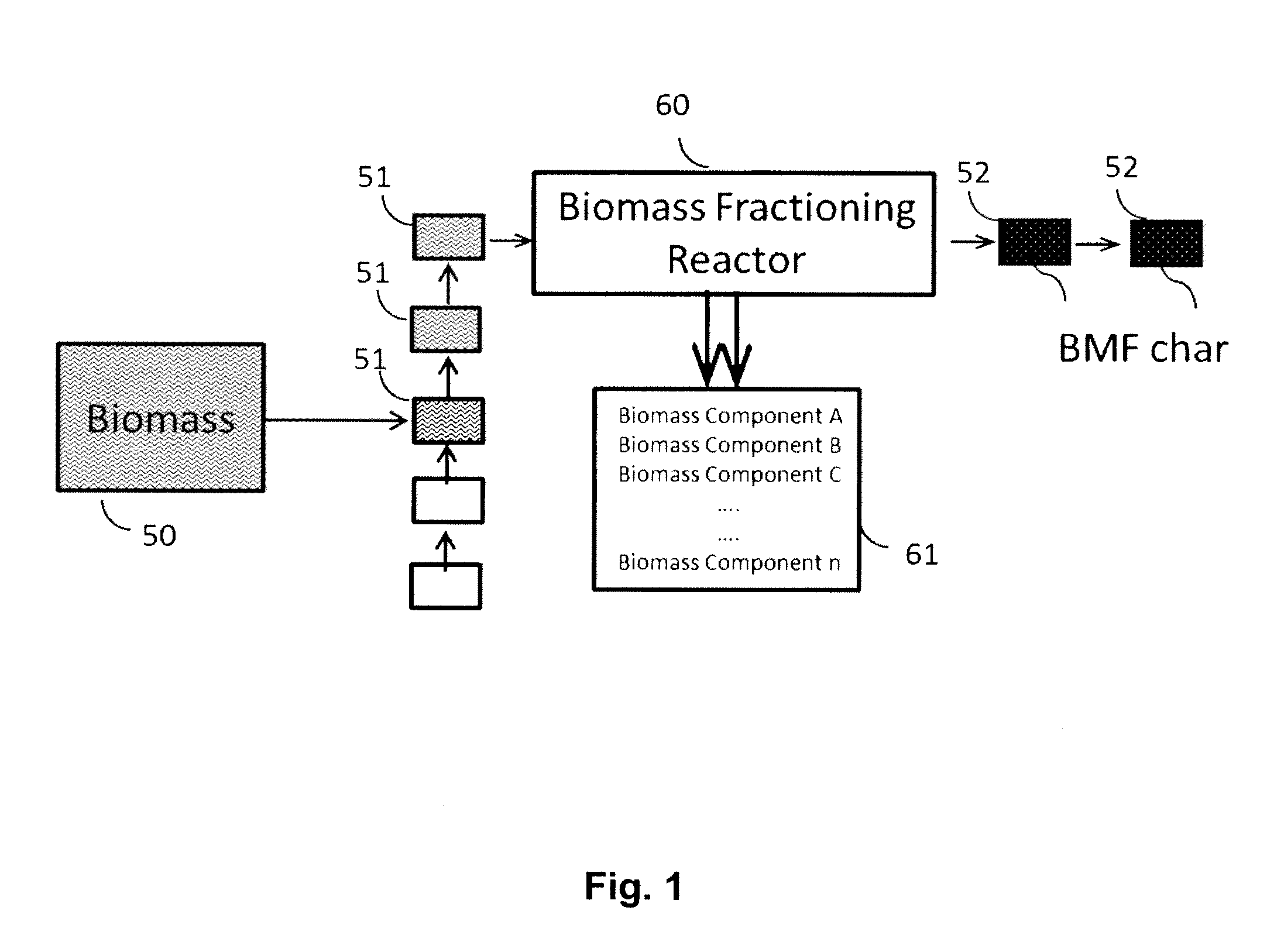

Method for biomass fractioning by enhancing biomass thermal conductivity

A method is disclosed for generating useful chemical intermediates from biomass using a novel pyrolysis reactor that utilizes the inherent thermal properties of carbon under compression as the biomass is subjected to sequential or concurrent temperature ramps. The ramps are sufficient to volatilize and selectively create different components, while the pressure application aids the selective decomposition of the biomass.

Owner:COOL PLANET ENERGY SYST

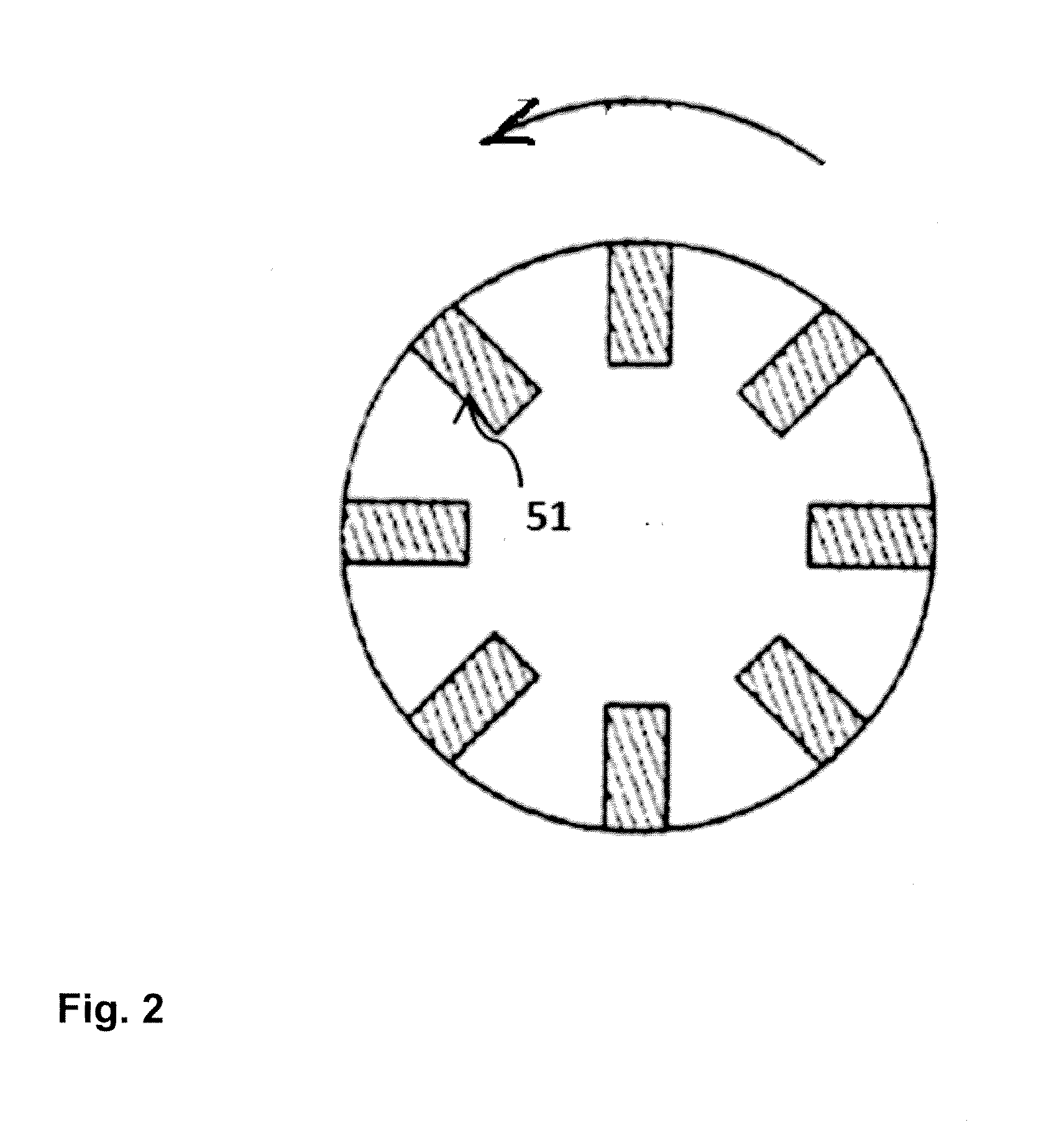

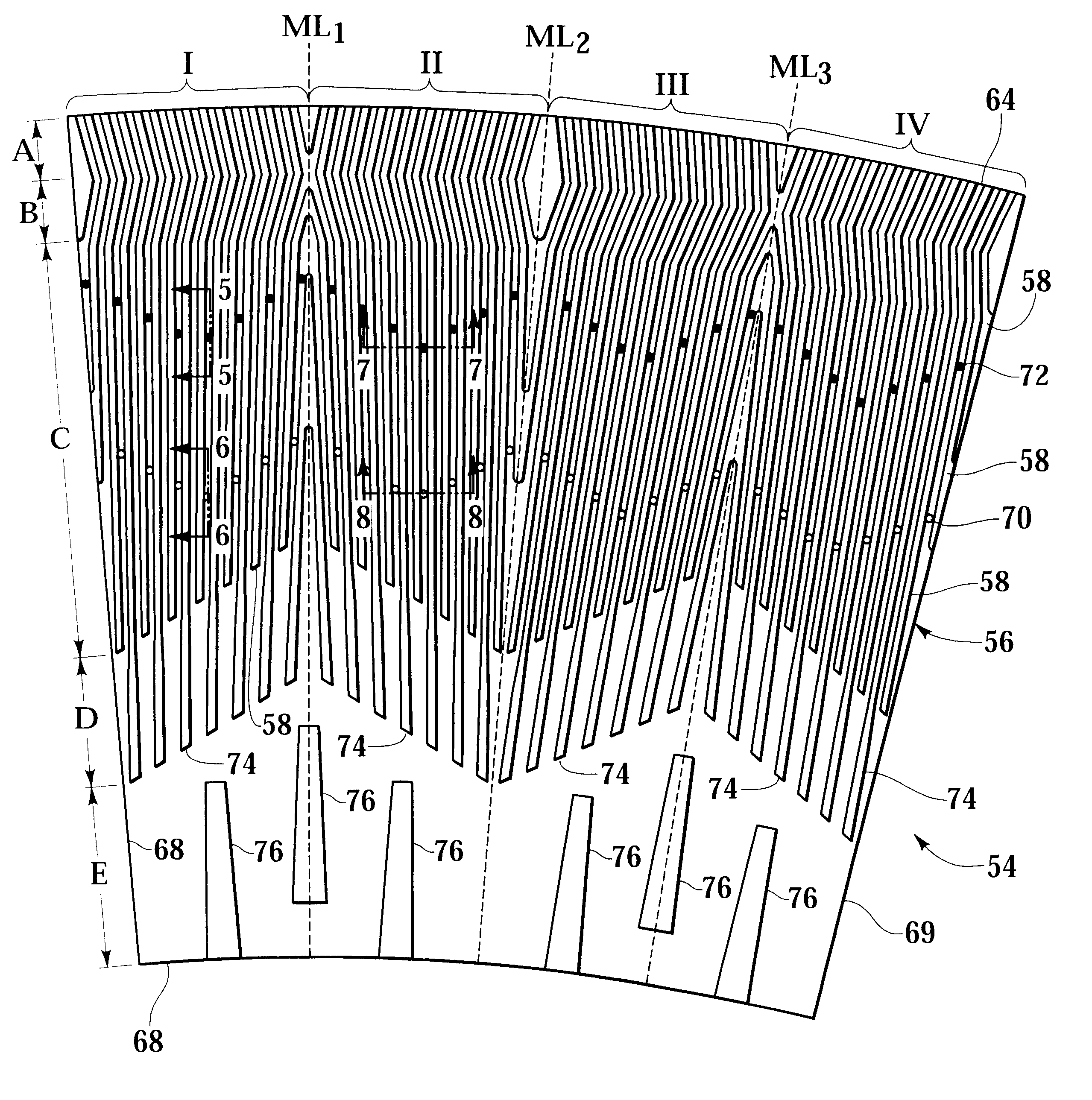

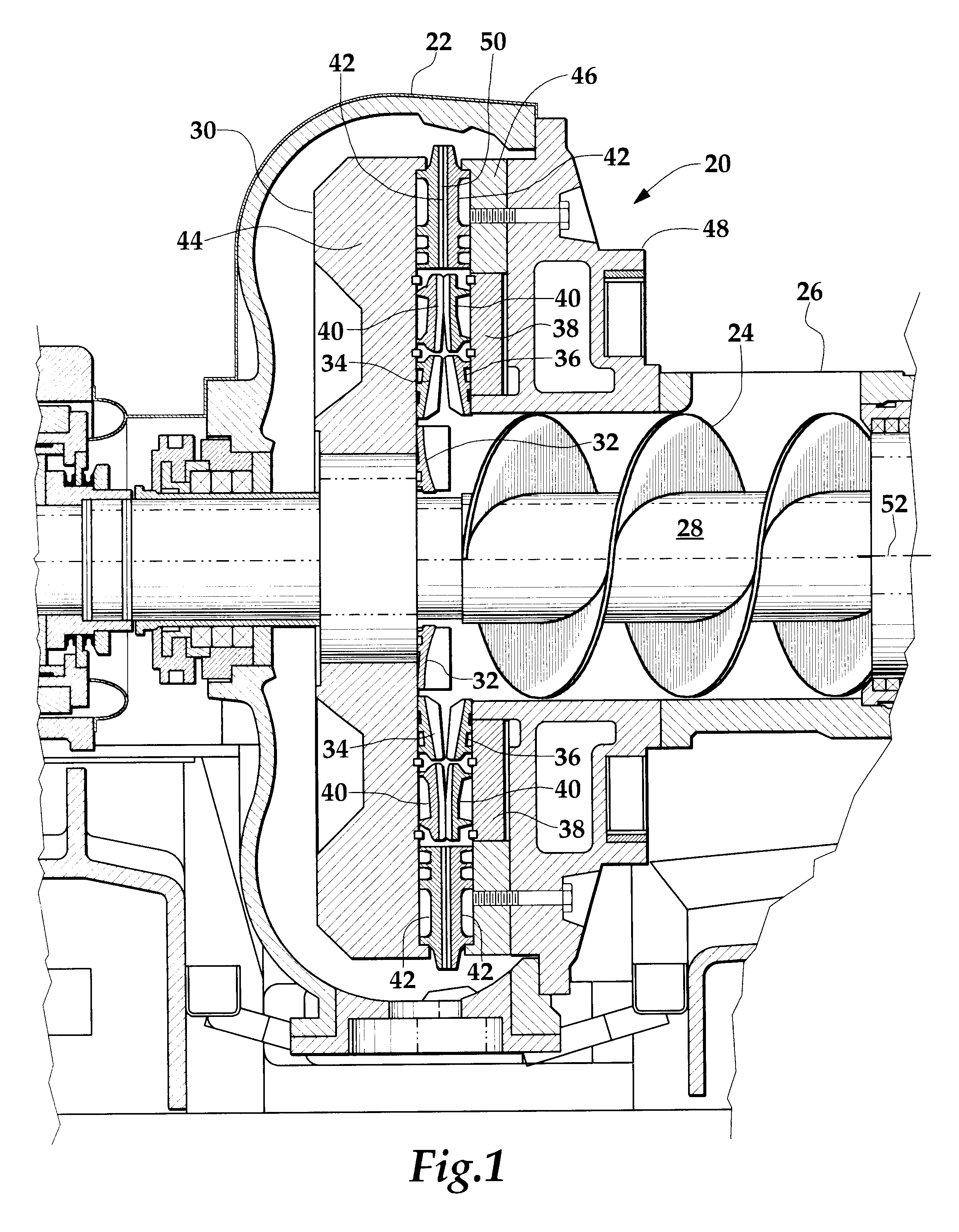

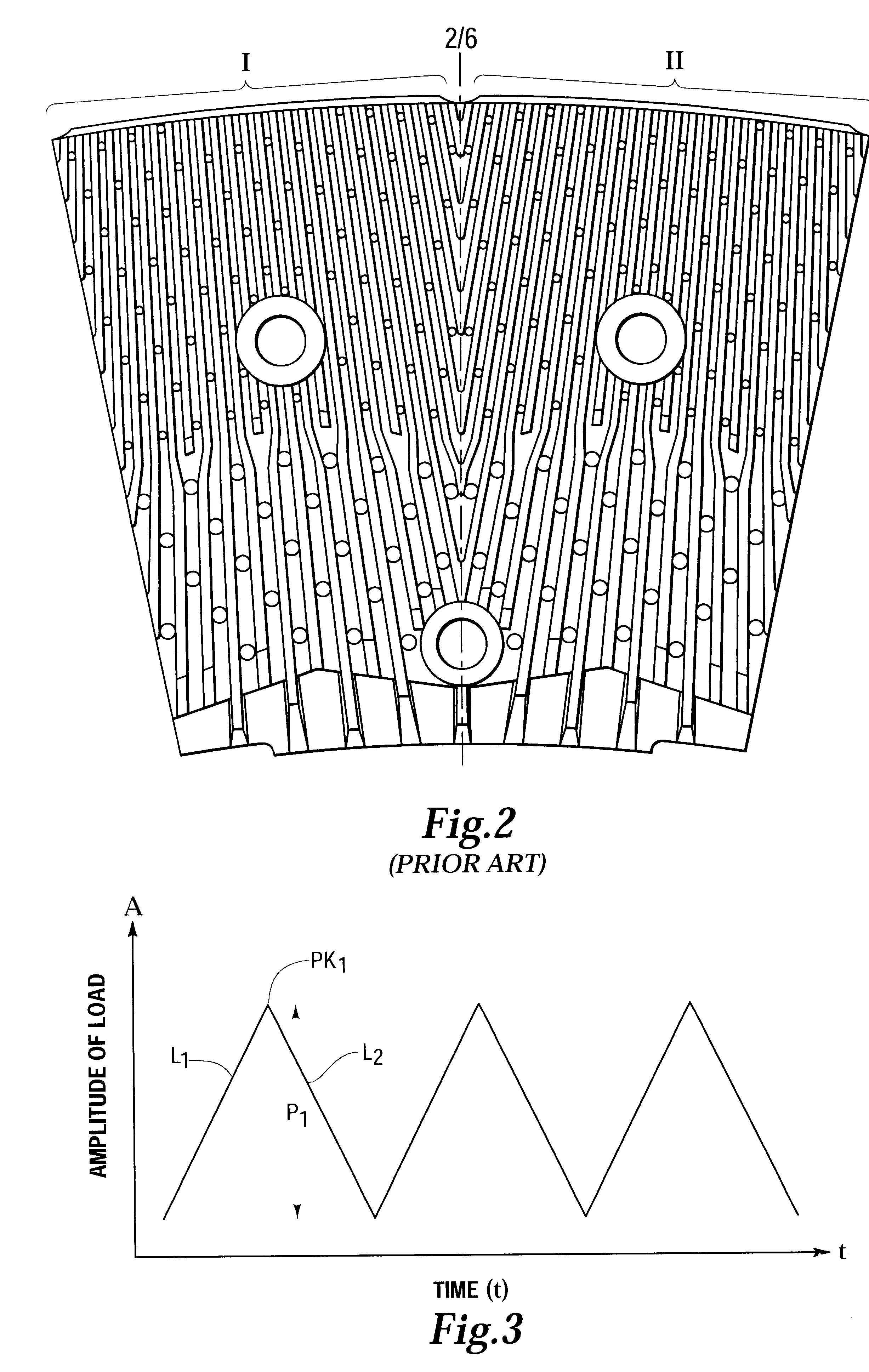

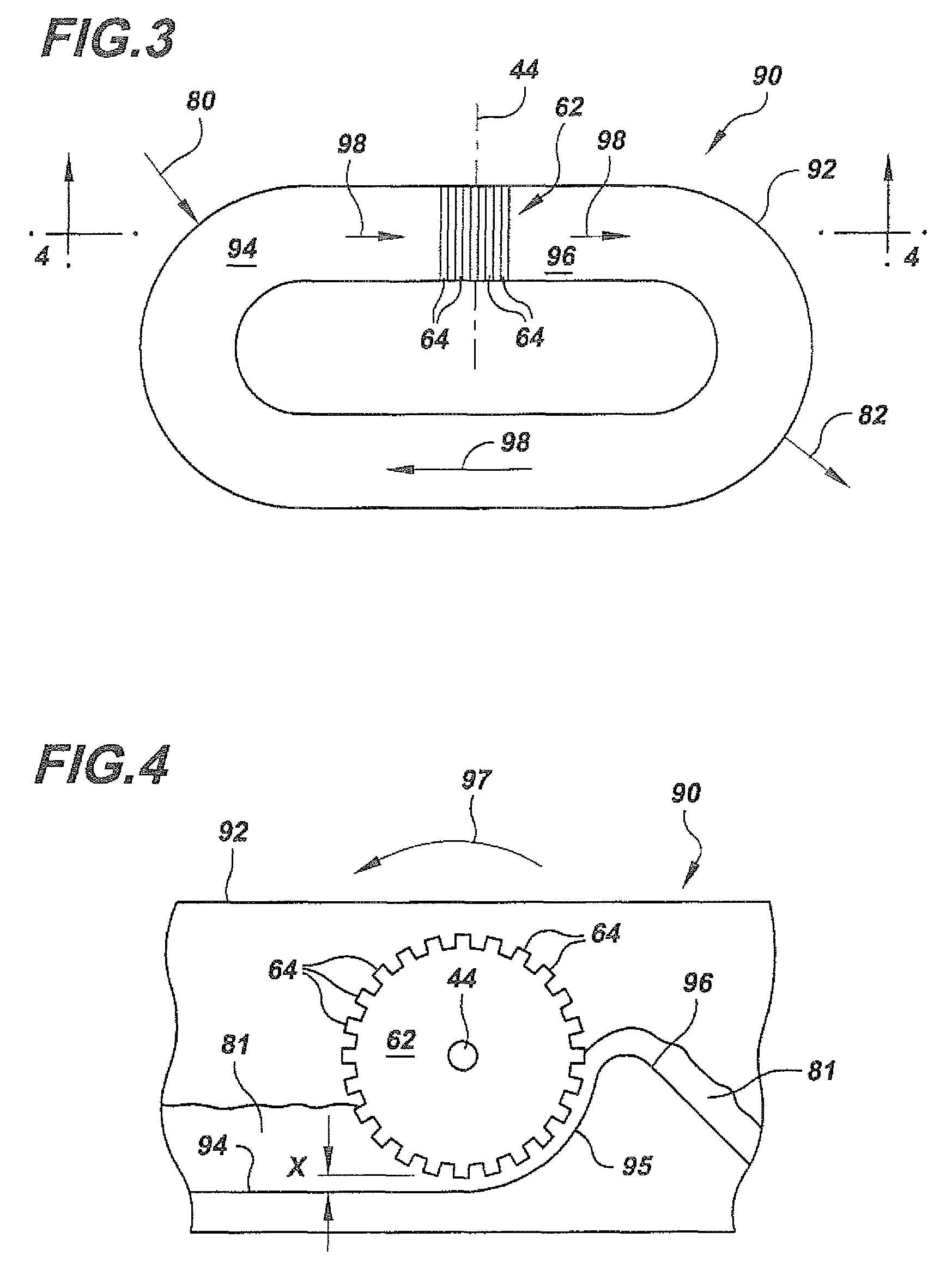

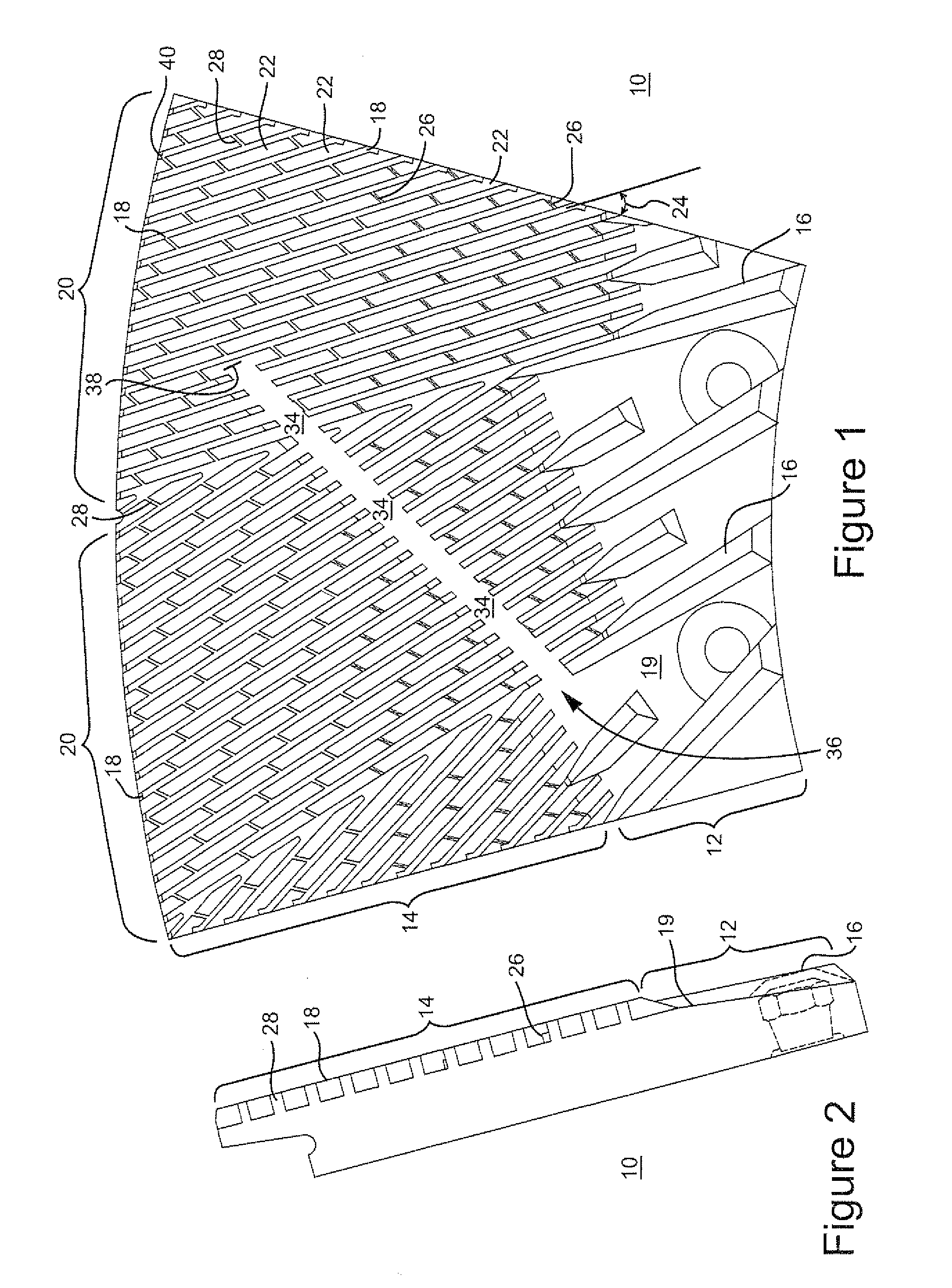

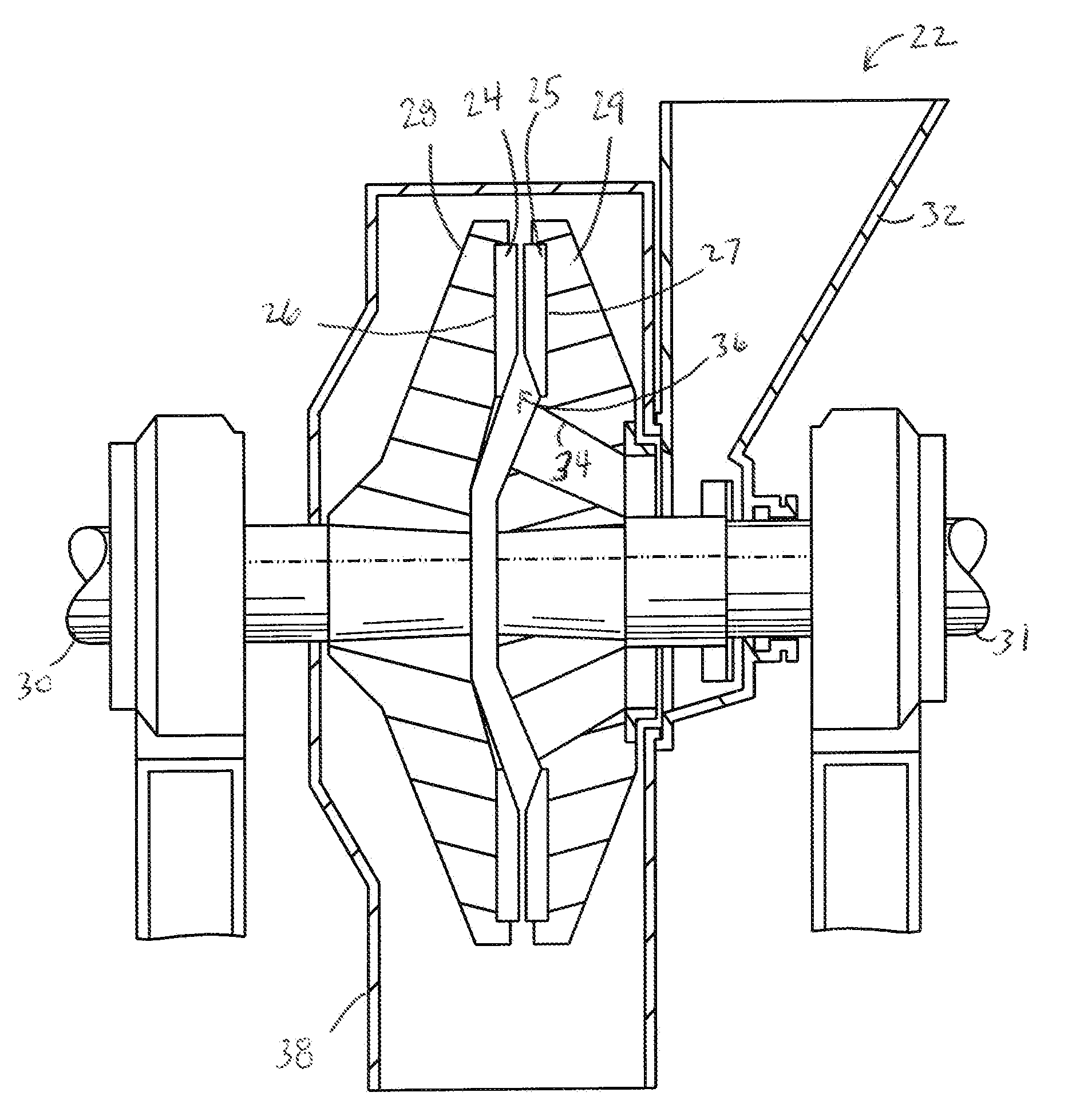

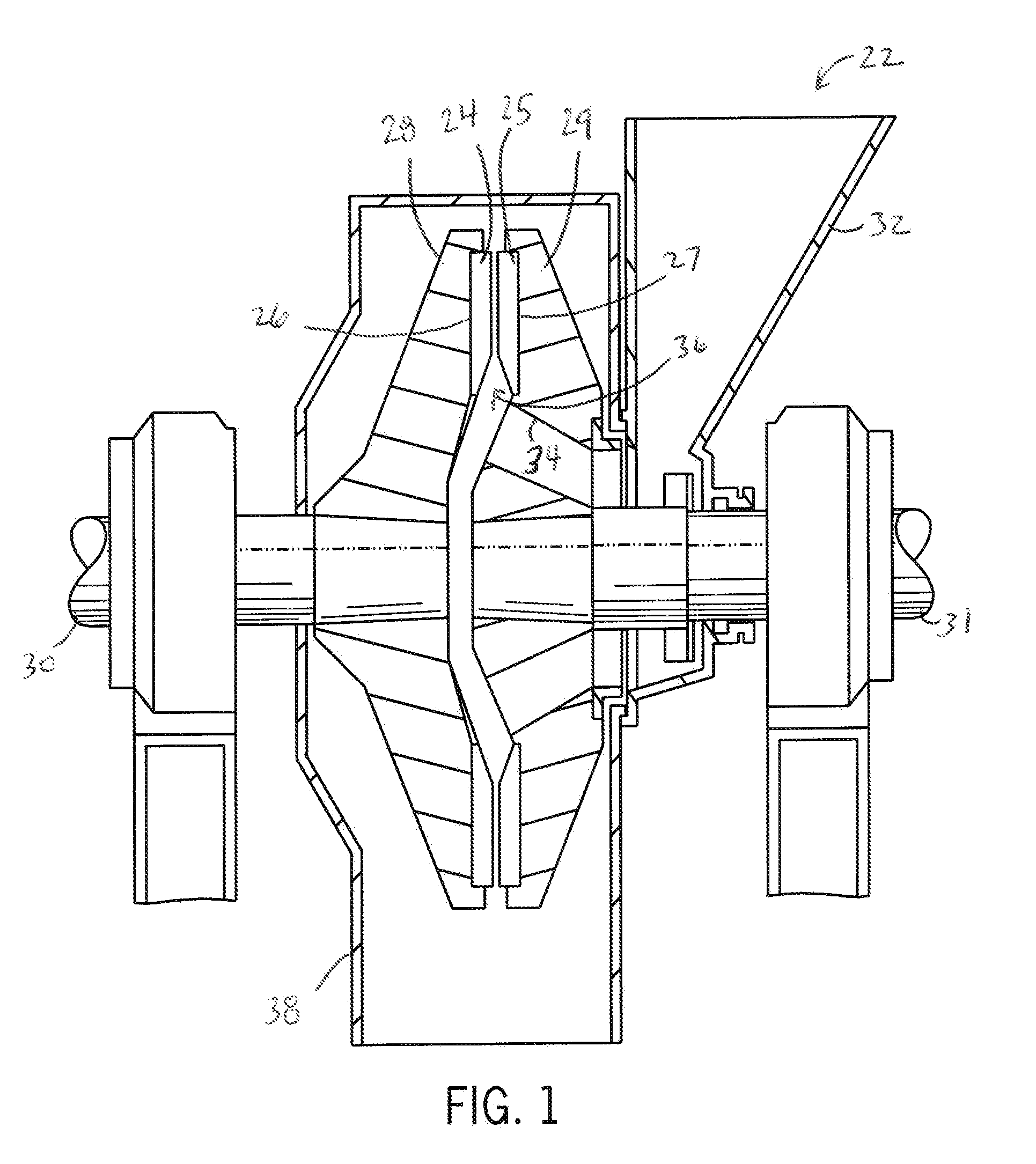

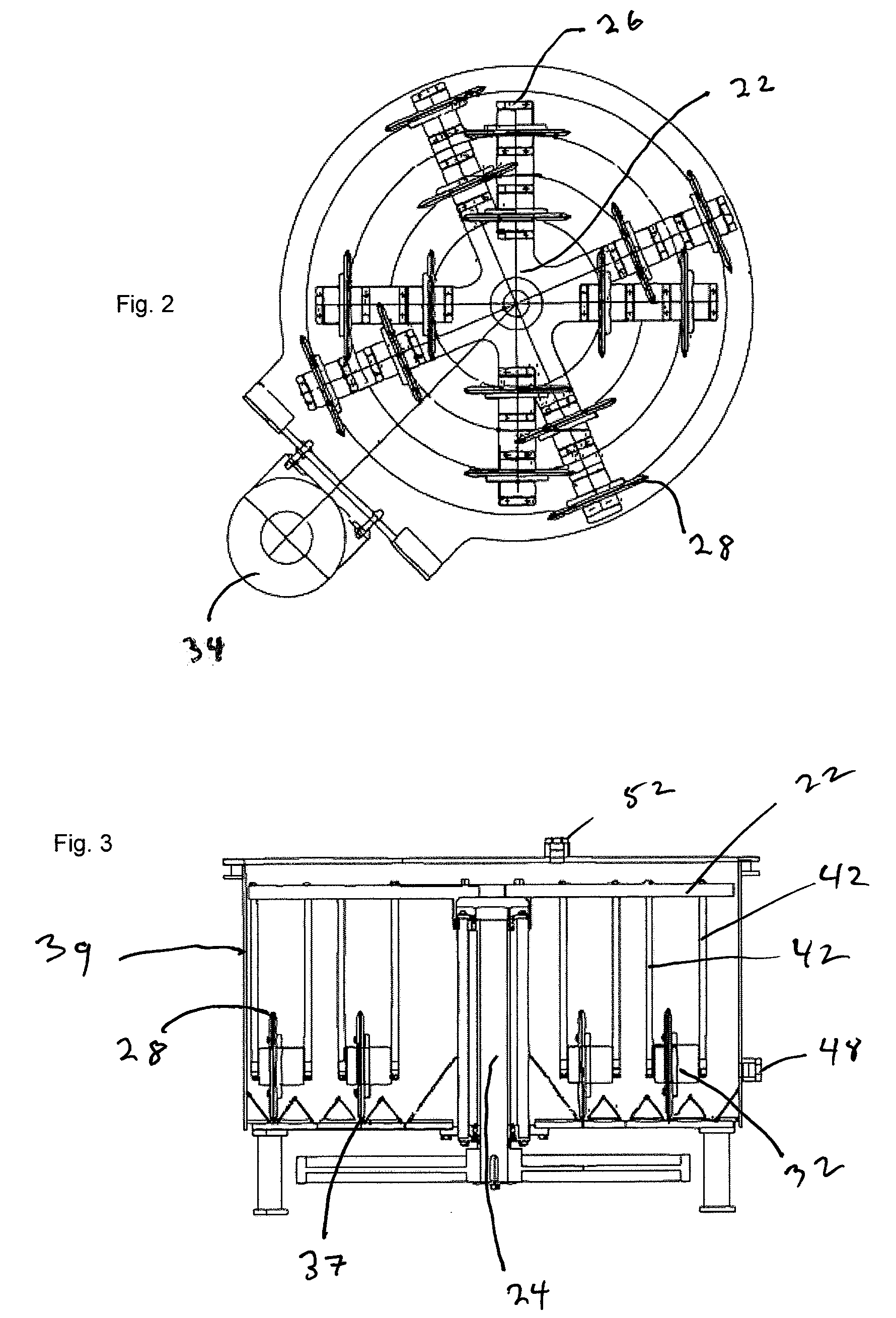

Refiner disc and method

A refiner disc and segment for a rotary disc fiber refiner which has a plurality of radial fields each having an angular extent no greater than 30° and preferably no greater than 22° for reducing the amplitude and duration of load swings that take place during pumping and holdback cycles. Each field has a refining zone with a refiner groove and a refiner bar and a second zone disposed radially outwardly of the refining zone that changes the direction of flow of stock to reduce stock flow momentum and magnitude of the load swings. Each field can have a third zone radially outward of the second zone that further changes the direction of flow of stock and an infeed zone radially inwardly of the refining zone. If desired, a zone that includes a breaker bar can be disposed radially inwardly of the infeed zone. Where the disc is segmented, the segment has at least three fields. In one preferred embodiment, the segment has at least four fields which reduces the duration and magnitude of load swings by at least 40% thereby reducing refiner vibration and wear while advantageously increasing consistency of pulp quality and throughput. The disc and segment are capable of bi-directional operation without loss of efficiency, quality, and throughput.

Owner:J & L FIBER SERVICES

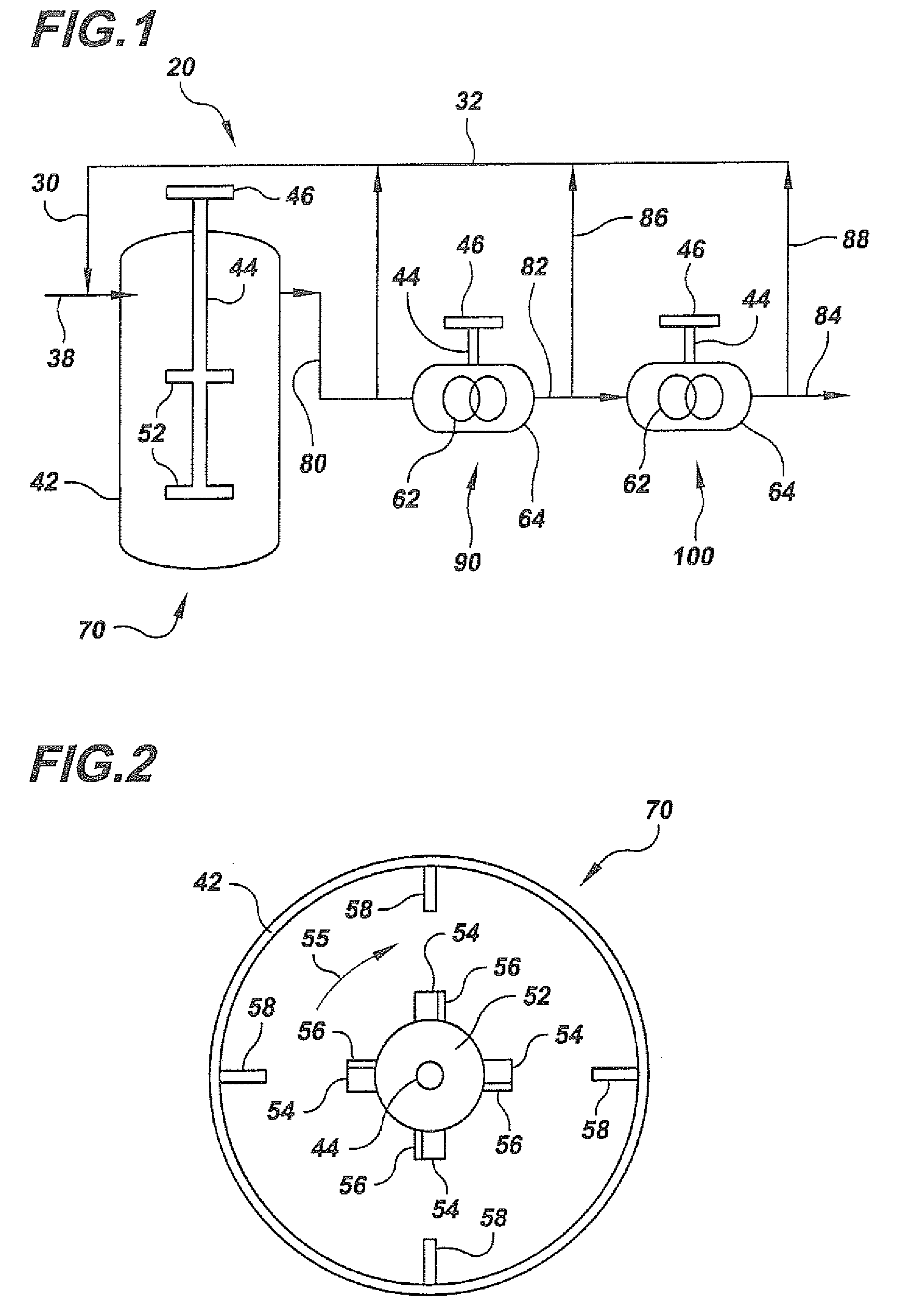

Energy efficient TMP refining of destructured chips

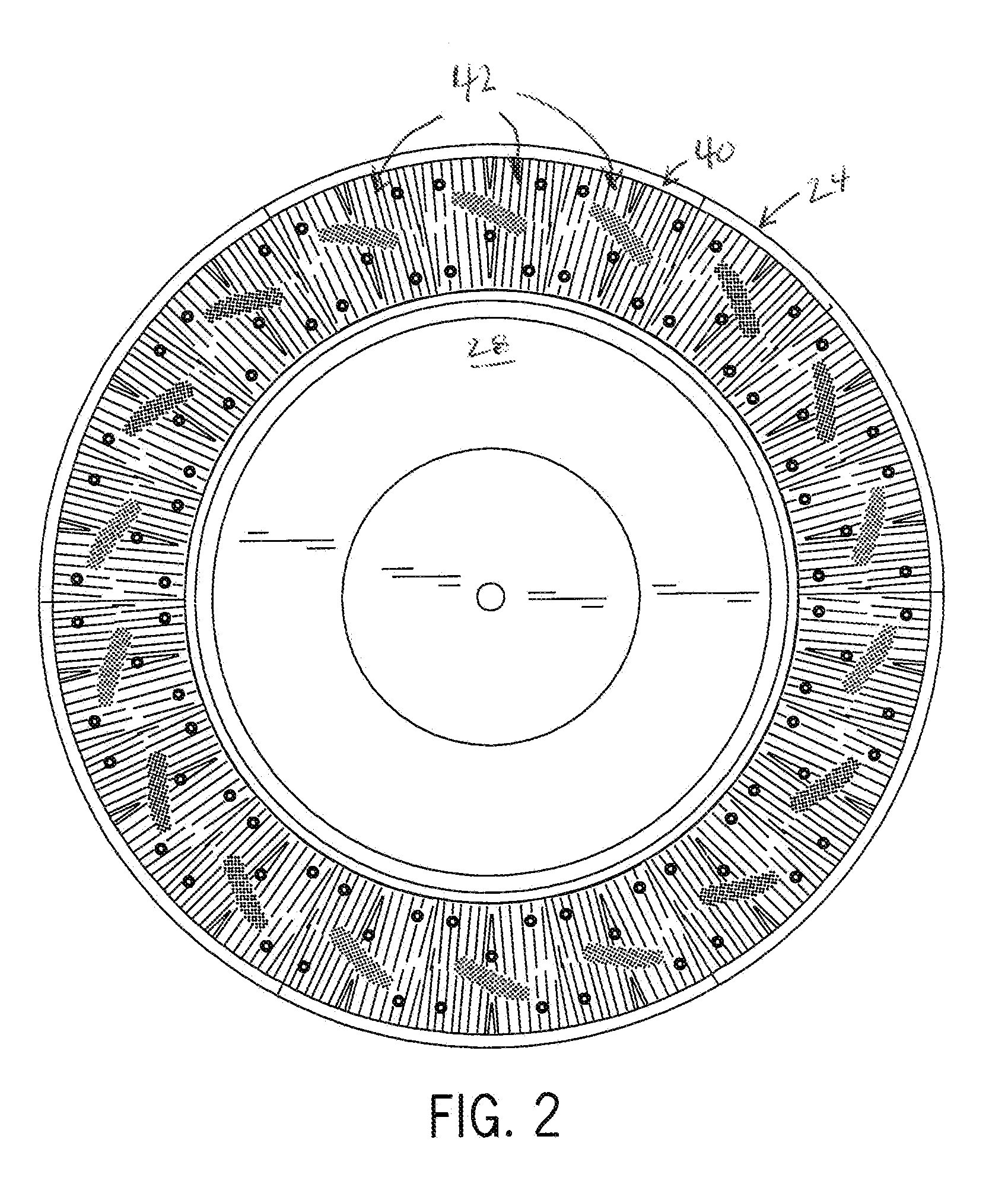

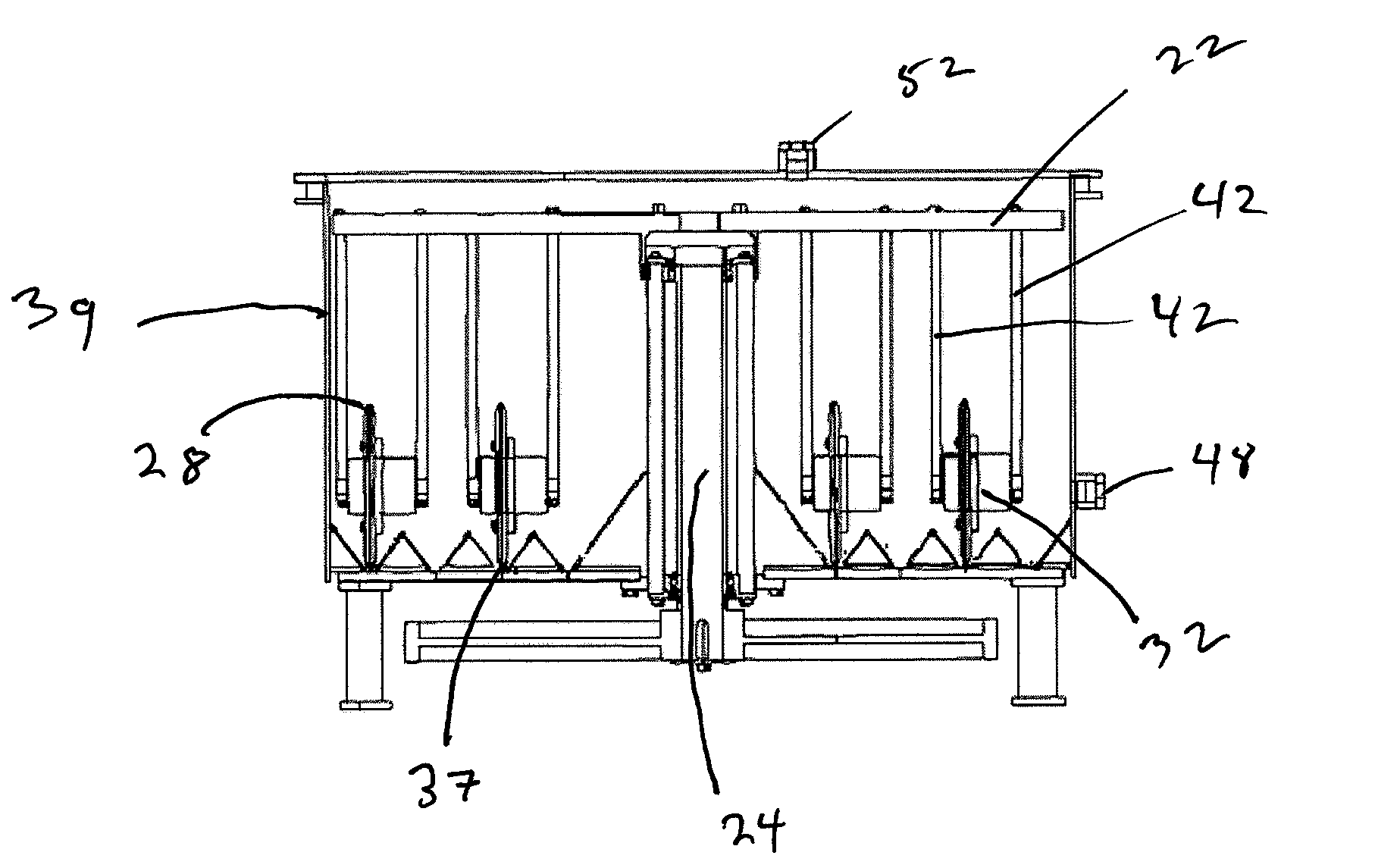

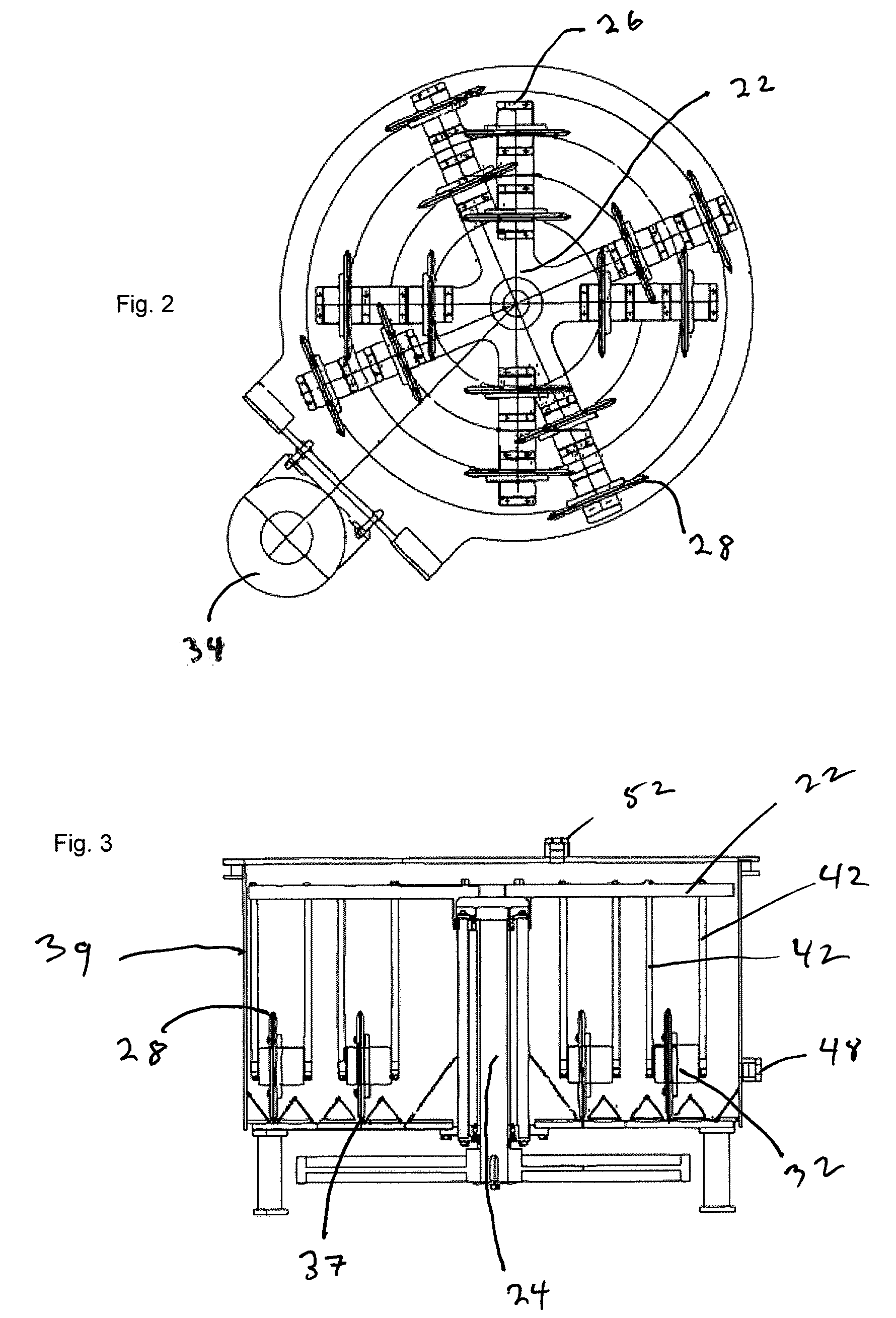

InactiveUS20060006264A1Quality improvementReduce energy consumptionCellulosic pulp after-treatmentPretreatment with water/steamFiberRing pattern

A system and method for thermomechanical refining of wood chips comprises preparing the chips for refining by exposing the chips to an environment of steam to soften the chips, compressively destructuring and dewatering the softened chips to a solids consistency above 55 percent, and diluting the destructured and dewatered chips to a consistency in the range of about 30 to 55 percent. The destructuring partially defibrates the material. This diluted material is fed to a rotating disc primary refiner wherein each of the opposed discs has an inner ring pattern of bars and grooves and an outer ring pattern of bars and grooves. The destructured and partially defibrated chips are substantially completely defibrated in the inner ring and the resulting fibers are fibrillated in the outer ring. The compressive destructuring, dewatering, and dilution can all be implemented in one integrated piece of equipment immediately upstream of the primary refiner, and the fiberizing and fibrillating are both achieved between only one set of relatively rotating discs in the primary refiner.

Owner:ANDRITZ INC

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS9051684B2Improve consistencyImprove scalabilityFinely-divided cellulose conservationReed/straw treatmentMicrometerPaperboard

Owner:FPINNOVATIONS INC

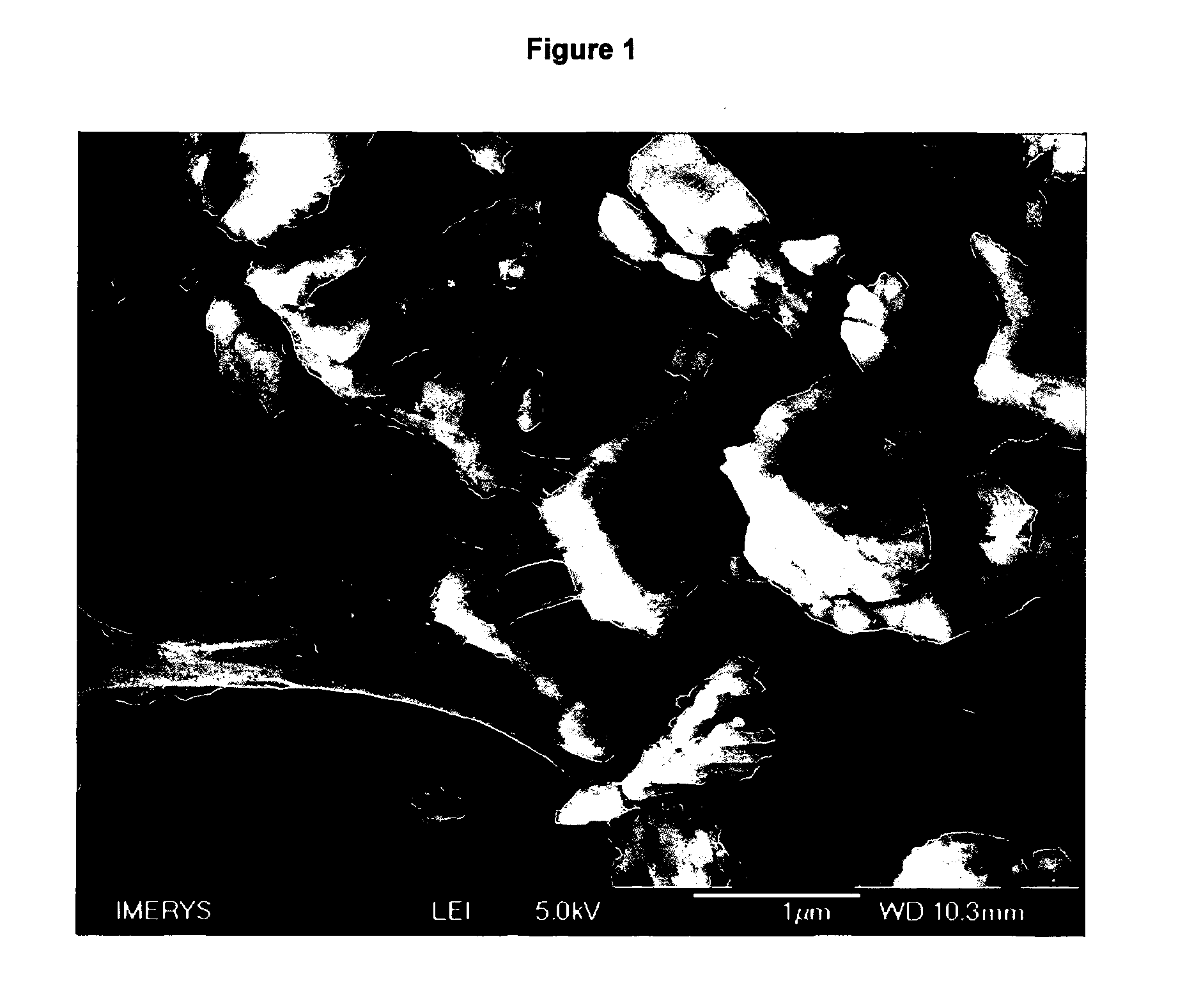

Paper filler composition

A method for preparing an aqueous suspension comprising microfibrillated cellulose and inorganic particulate material, the method comprising a step of microfibrillating a fibrous substrate comprising cellulose in an aqueous environment in the presence of an inorganic particulate material.

Owner:FIBERLEAN TECH LTD

Soft material solid-wood reinforced board and its producing method

ActiveCN101007415AImprove use valueOvercoming odd problemsCork treatment detailsVolumetric Mass DensityNormal conditions

A soft material quality wood material strengthening board is flat plate. It is characterized by: it has natural grains of raw wood, its color is the mixture color of raw wood self color, charring color and resin color, the density is 450-720kg / m<3>, surface hardness is 25-65MPa, vertical MOR is 35 - 90MPa, vertical elastic modulus is 1~10GPa, resin content (solid content) is 3% - 10%. The strengthening board can be produced floors or furniture raw materials after preliminary working, drying, rough planing, heating, resin soaking, hot pressing, placing in normal condition and fine finishing. The invention produces the strengthening board using soft material as raw material, covers the shortage of hardwood product raw materials, it increases the use-value of soft material, while meets the popular consumer demand of liking wood, and provides new materials for hardwood furniture and flooring manufacturing industry.

Owner:ZHEJIANG NENGFU TOURIST PRODS

Process for increasing the refiner production rate and/or decreasing the specific energy of pulping wood

InactiveUS20050133643A1Pose health riskIncrease ratingsPaper recyclingReed/straw treatmentProduction rateEngineering

The present invention relates to processes for enhancing a refiner's production rate and / or reducing the specific energy consumption for a freeness target through the use of lubricant(s) or carrier(s) / frictionizer(s), respectively.

Owner:SOLENIS TECH CAYMAN

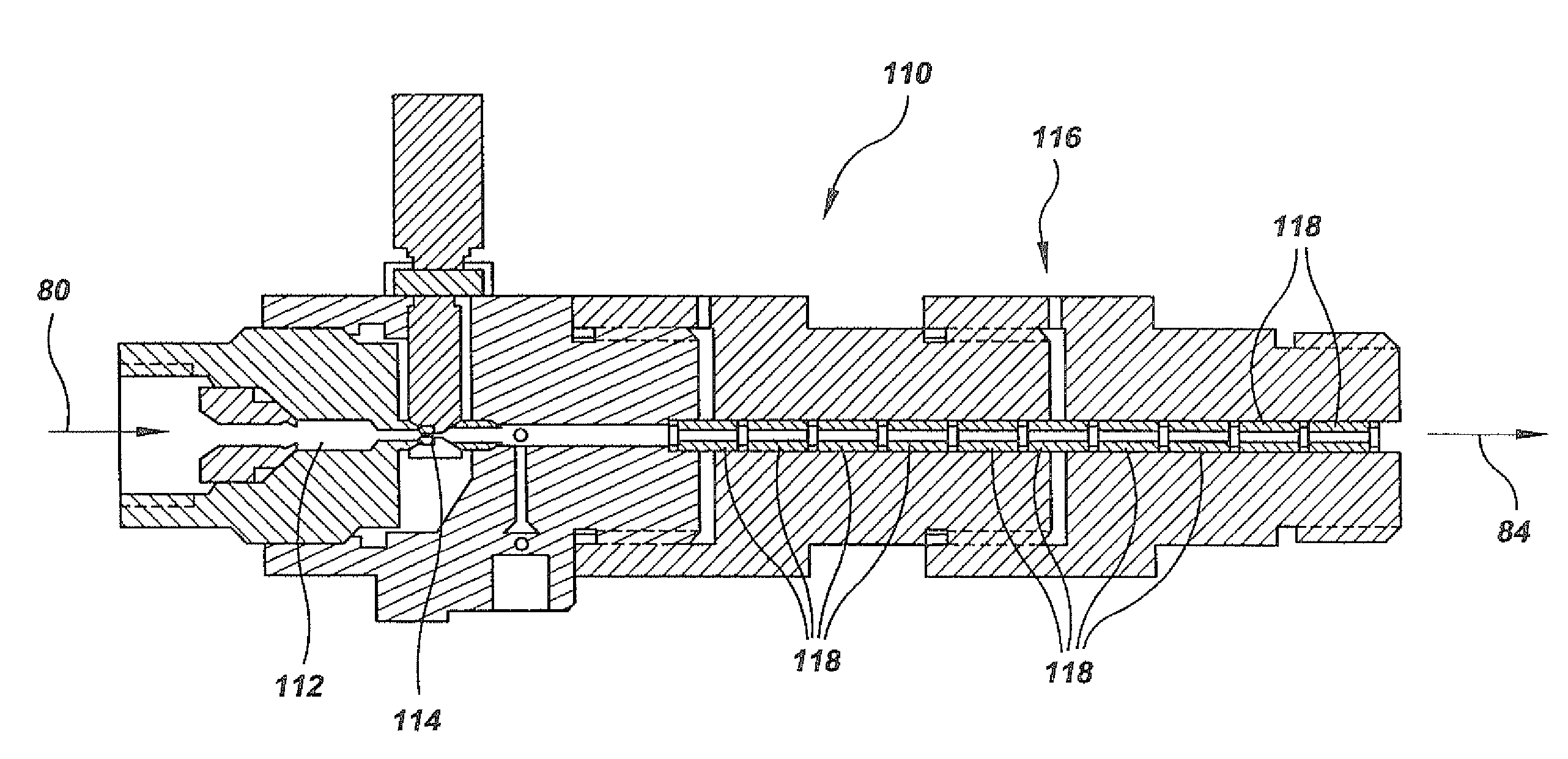

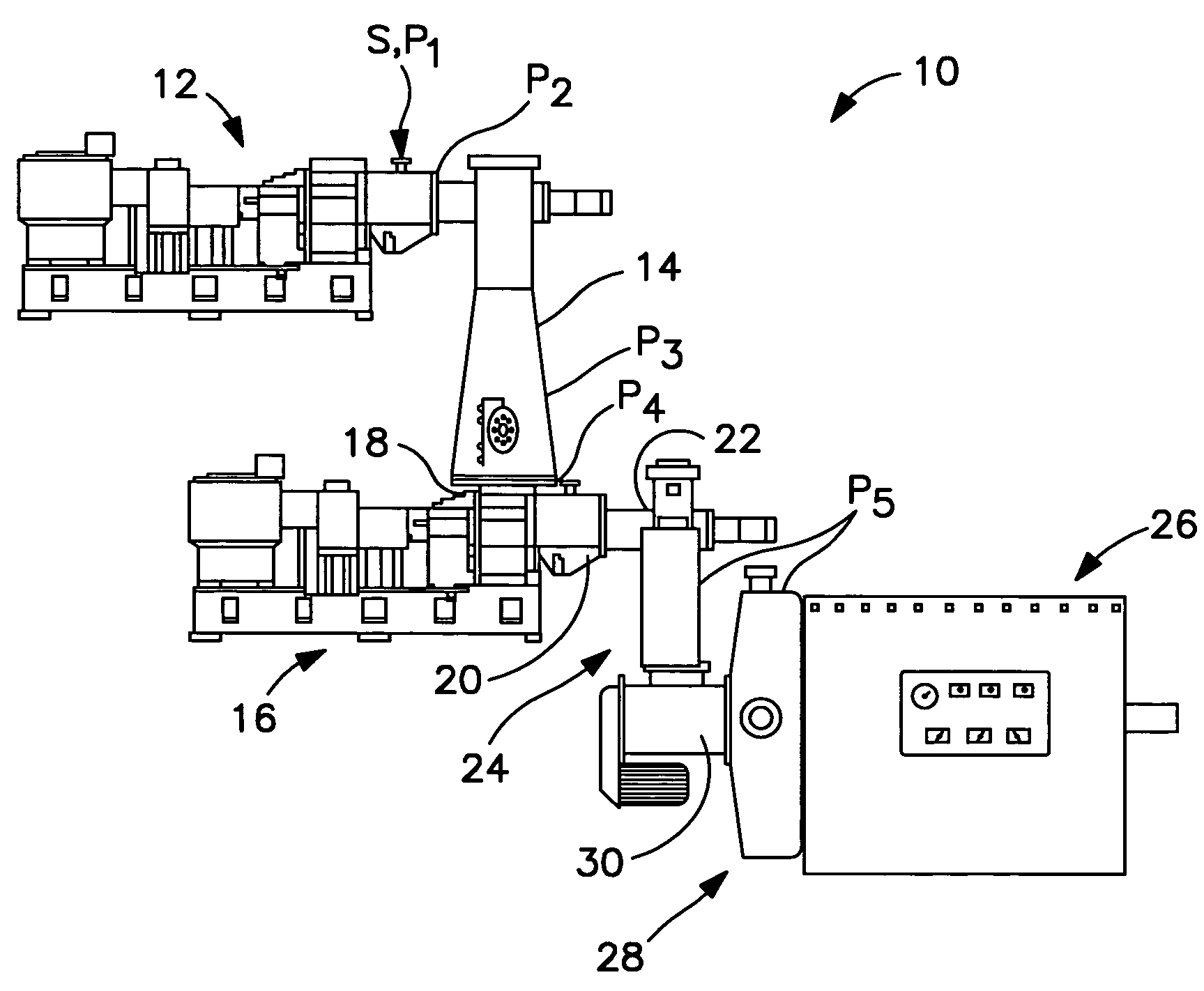

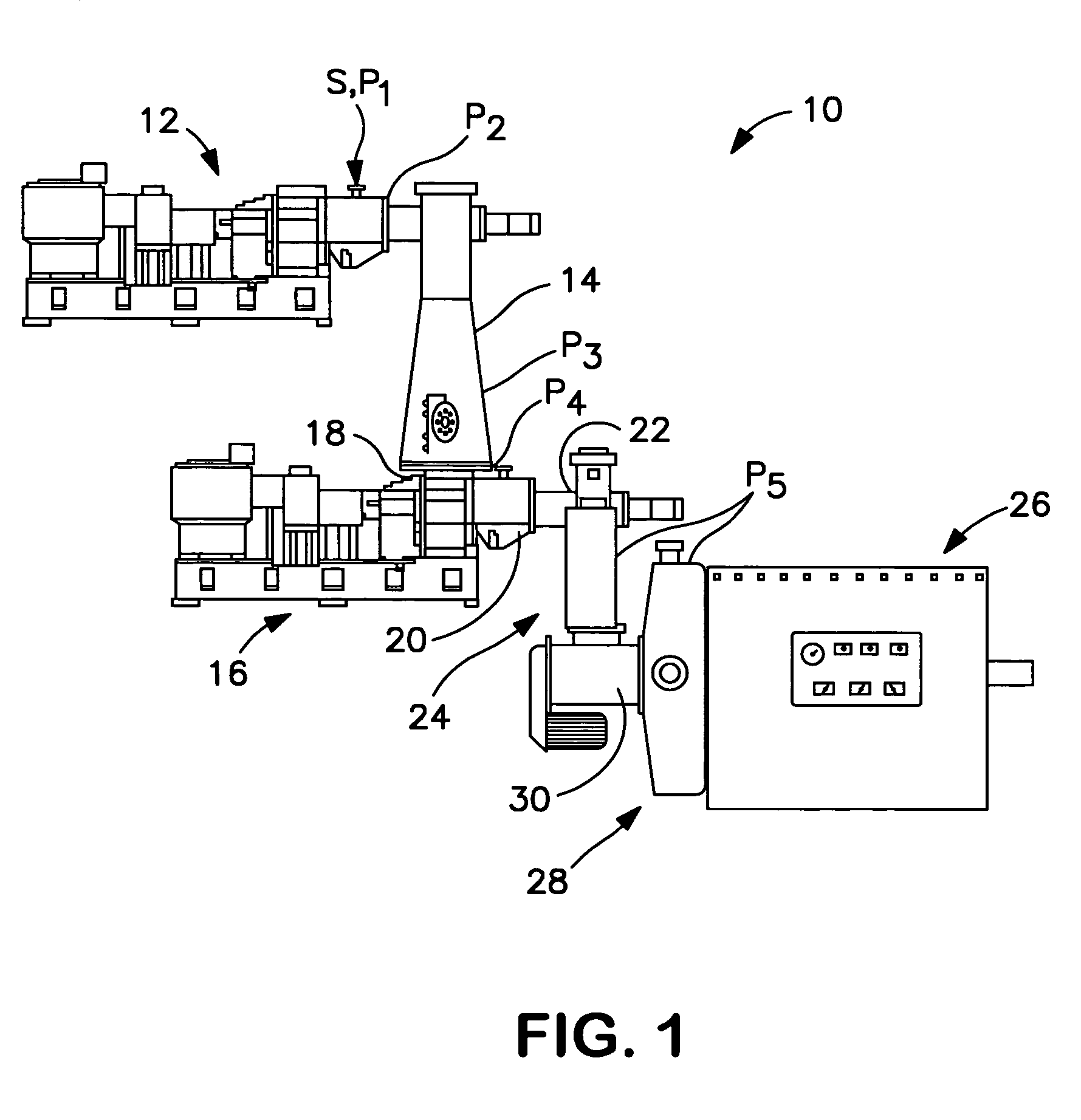

Process for producing nanofibers

ActiveUS8444808B2Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberShear rate

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

Composition and method for treating a porous article and use thereof

InactiveUS20030017565A1Facilitate ion exchangeAdditional exchangeMicrobiological testing/measurementEnzyme stabilisationCrack resistanceInorganic compound

A method for treating a porous article by efficiently performing macromolecularization in a porous article using an enzyme having a polyphenol oxidizing activity in an alkaline pH region, a phenolic compound and / or an aromatic amine compound, a composition for use in the treatment method, and treated products from the porous article obtained by the treatment method which are given or increased in strength, wear resistance, weatherability, rust-preventing properties, flame resistance, antibacterial properties, antiseptic properties, sterilizing properties, insect-repellent properties, insecticidal properties, antiviral properties, organism-repellent properties, adhesiveness, chemical agent-slow-releasing properties, coloring properties, dimension stability, crack resistance, deodorizing properties, deoxidizing properties, humidity controlling properties, moisture conditioning properties, water repellency, surface smoothness, bioaffinity, ion exchangeability, formaldehyde absorbing properties, chemical agent elution preventing properties, or properties preventing the migration of inorganic compounds onto the surface of the porous article.

Owner:SDS BIOTECH CO LTD

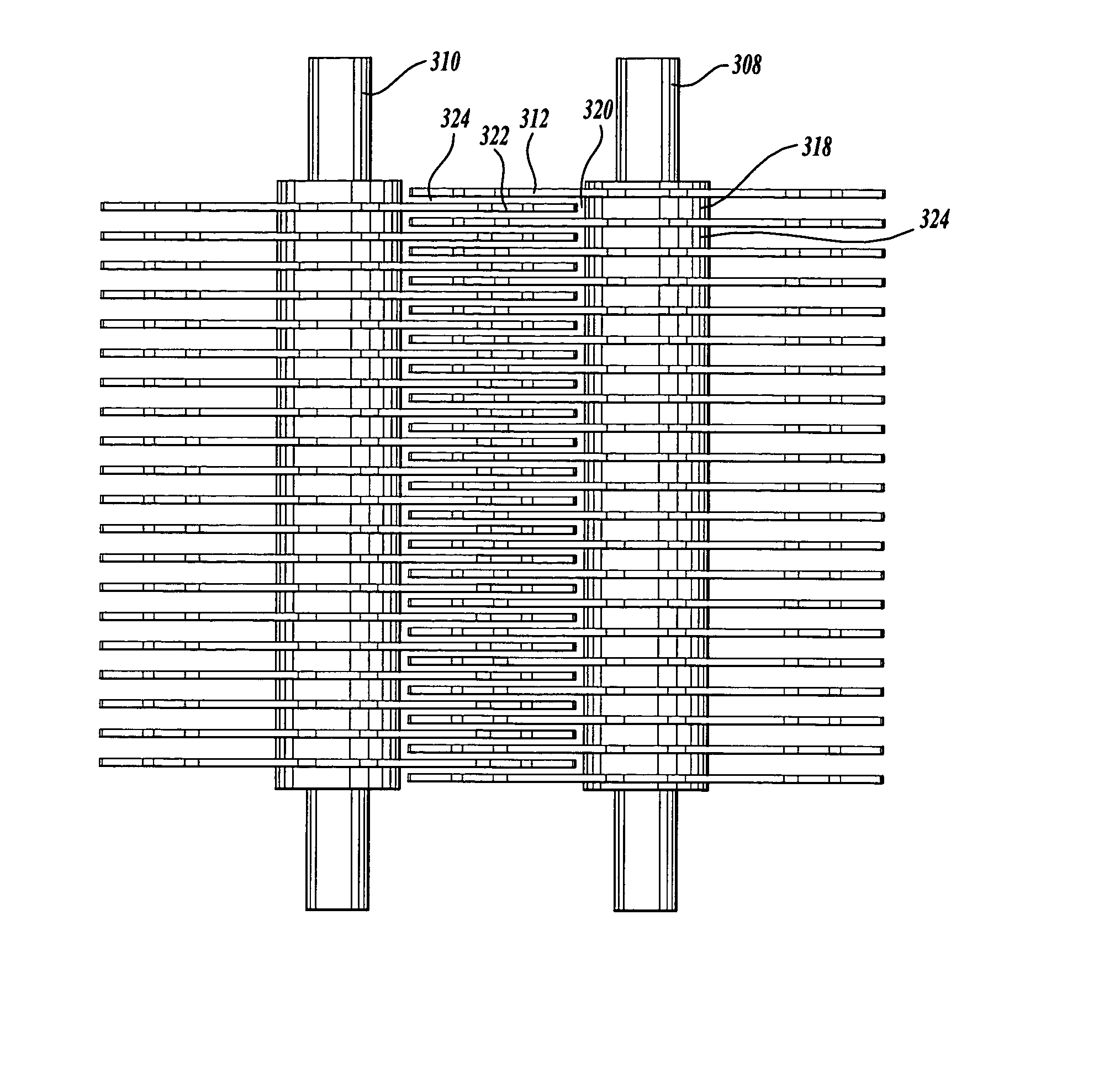

Refiner plates having steam channels and method for extracting backflow steam from a disk refiner

ActiveUS20080296419A1Reduce the amount requiredHigh energy costReed/straw treatmentCocoaGroove widthMechanical engineering

A refining plate for refining lignocellulosic material including: a radially outer peripheral edge and a substrate surface; a refining zone having a plurality of substantially radially disposed bars and grooves between the bars, wherein the bars protrude upward from the substrate surface and the grooves each have a groove width, and a steam channel traversing the bars and grooves of the refining zone, wherein the steam channel has a radially outer end radially inward of the outer peripheral edge of the plate and the steam channel has a width substantially greater than the groove width.

Owner:ANDRITZ INC

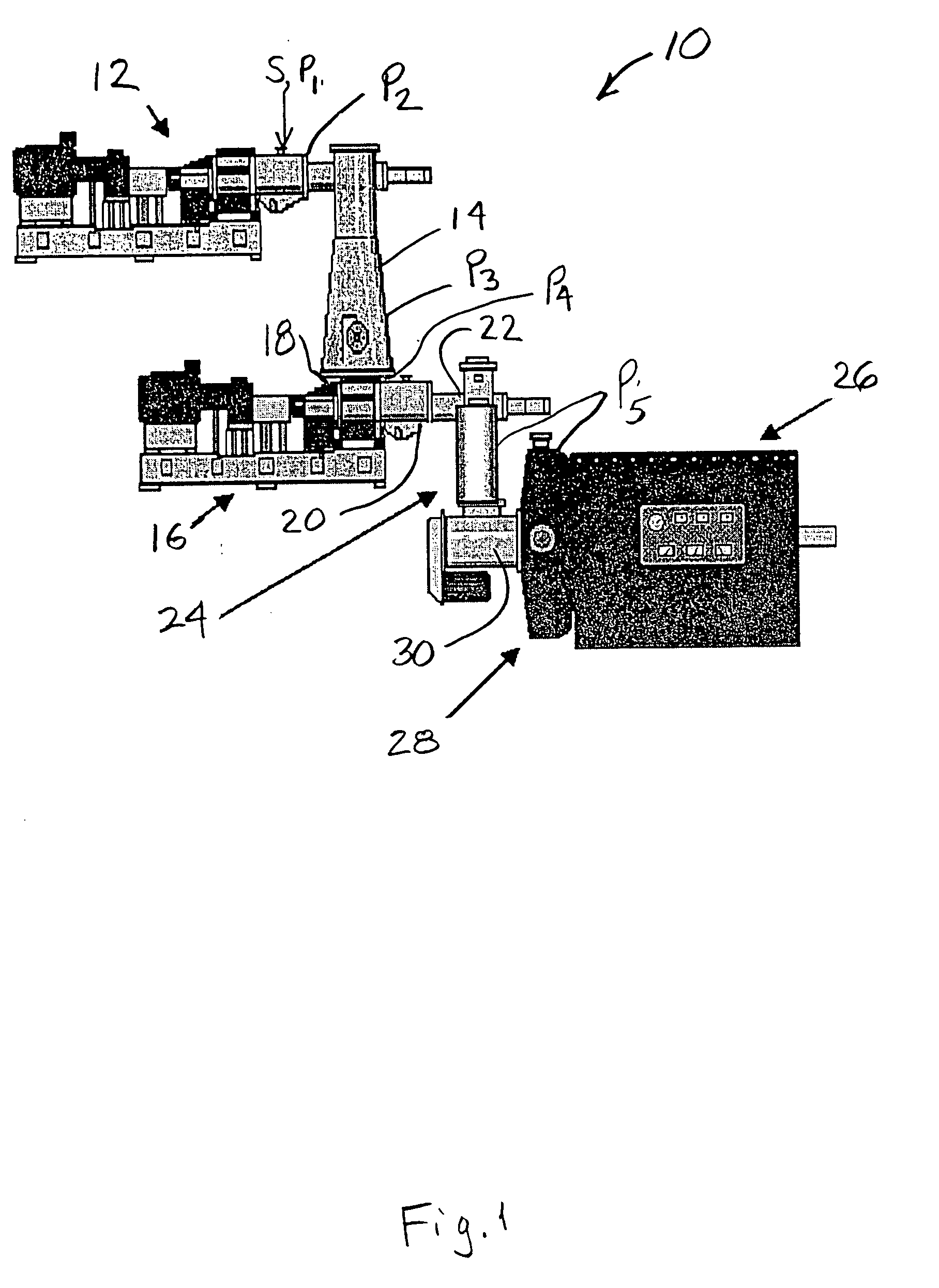

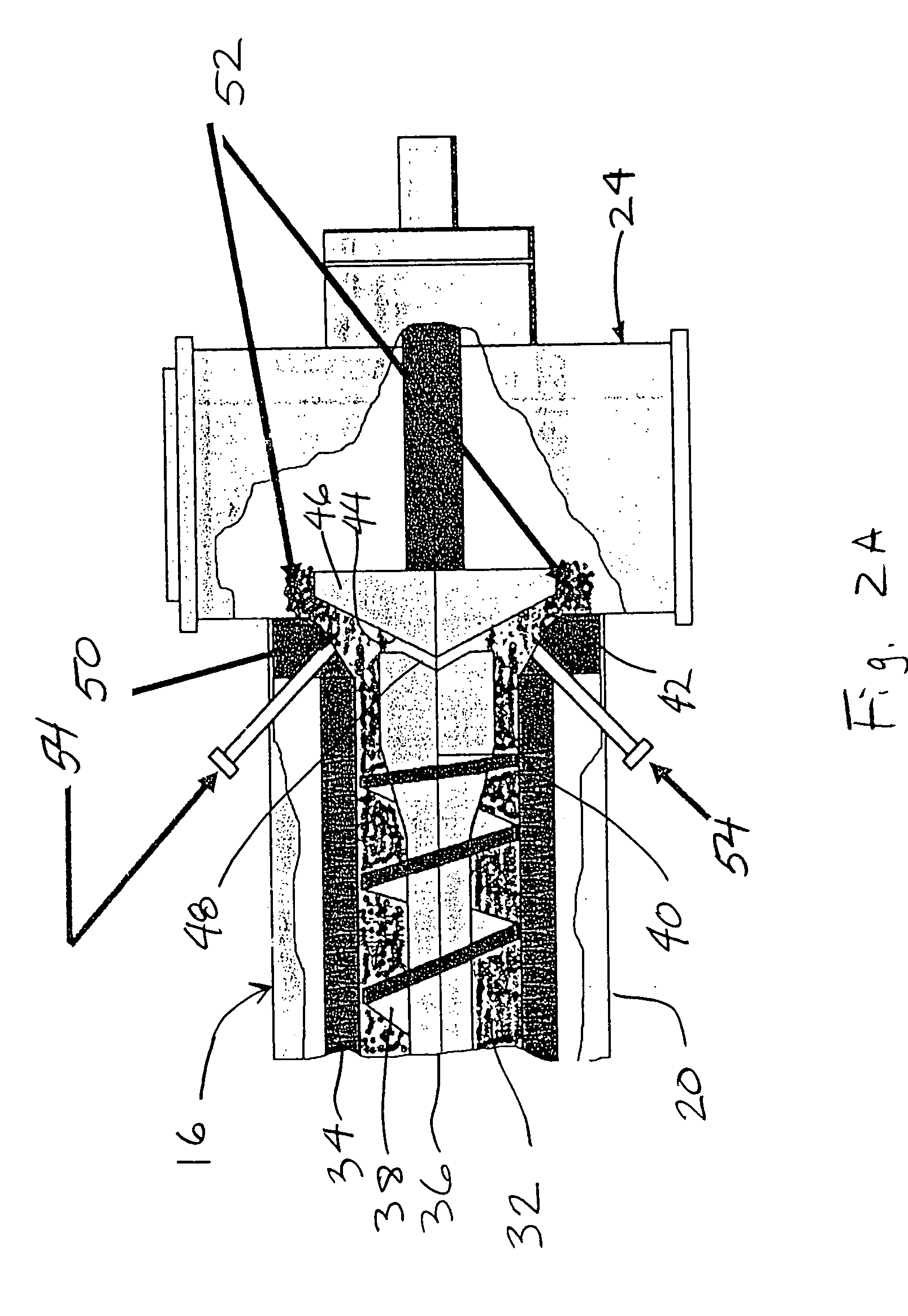

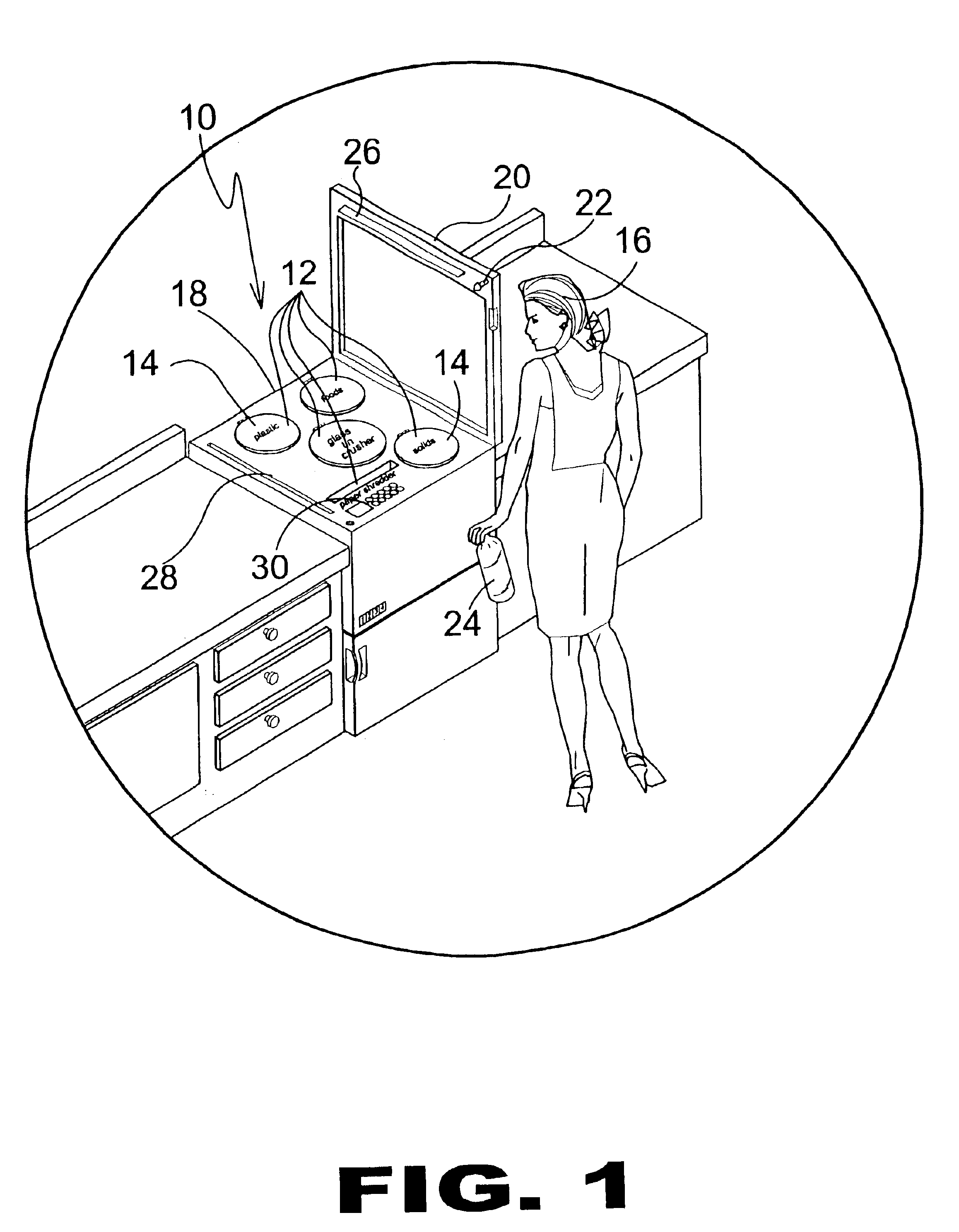

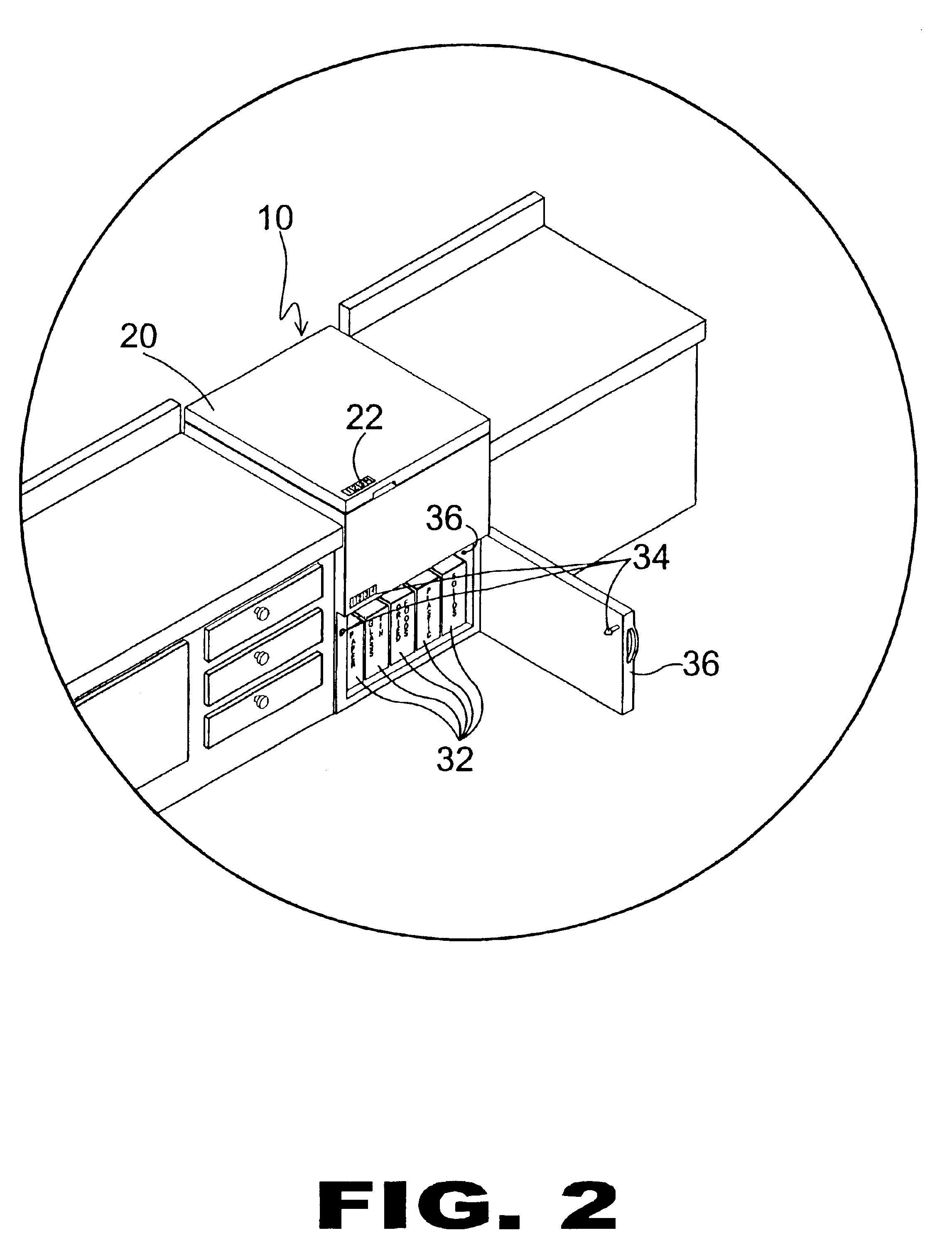

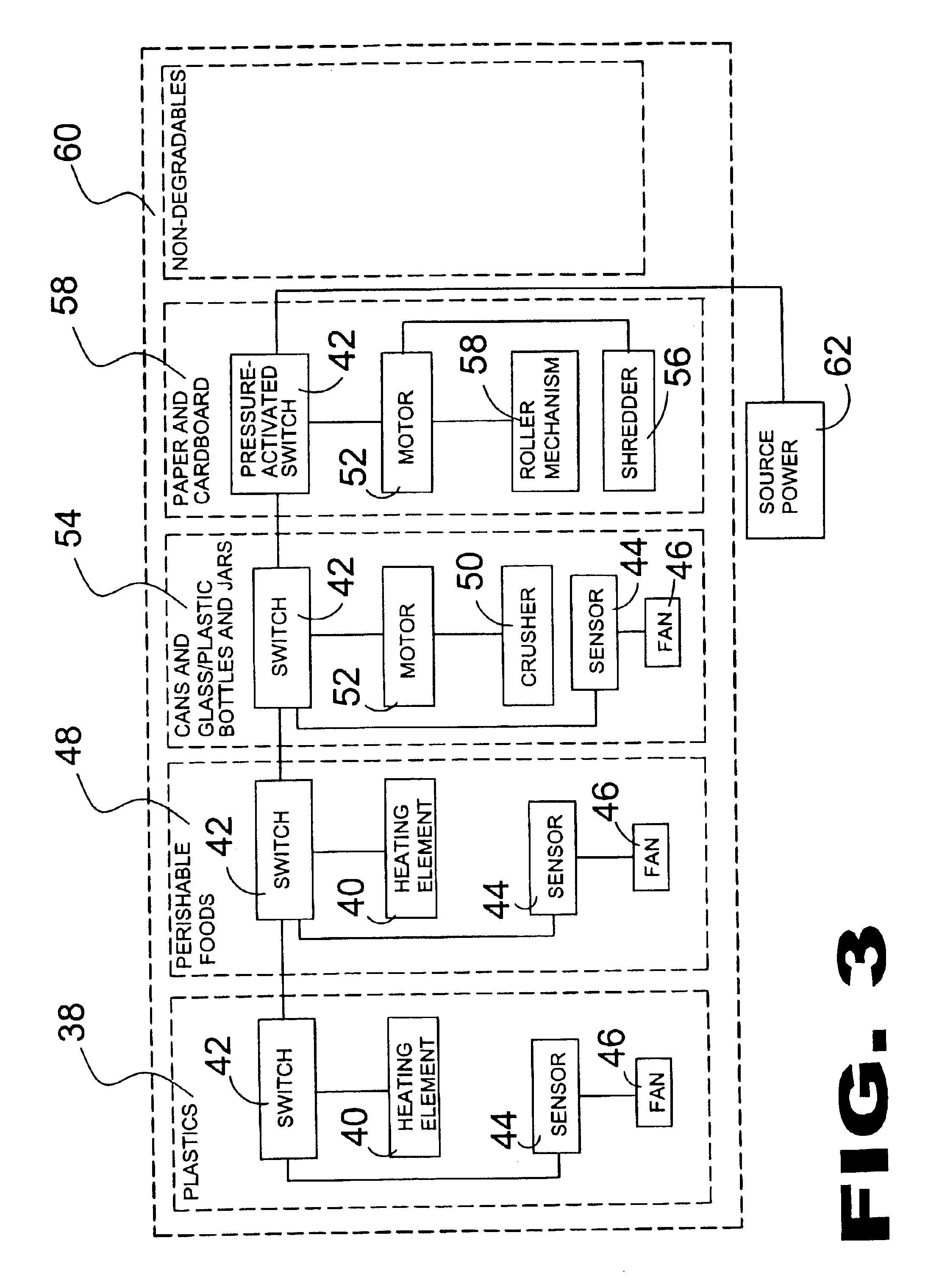

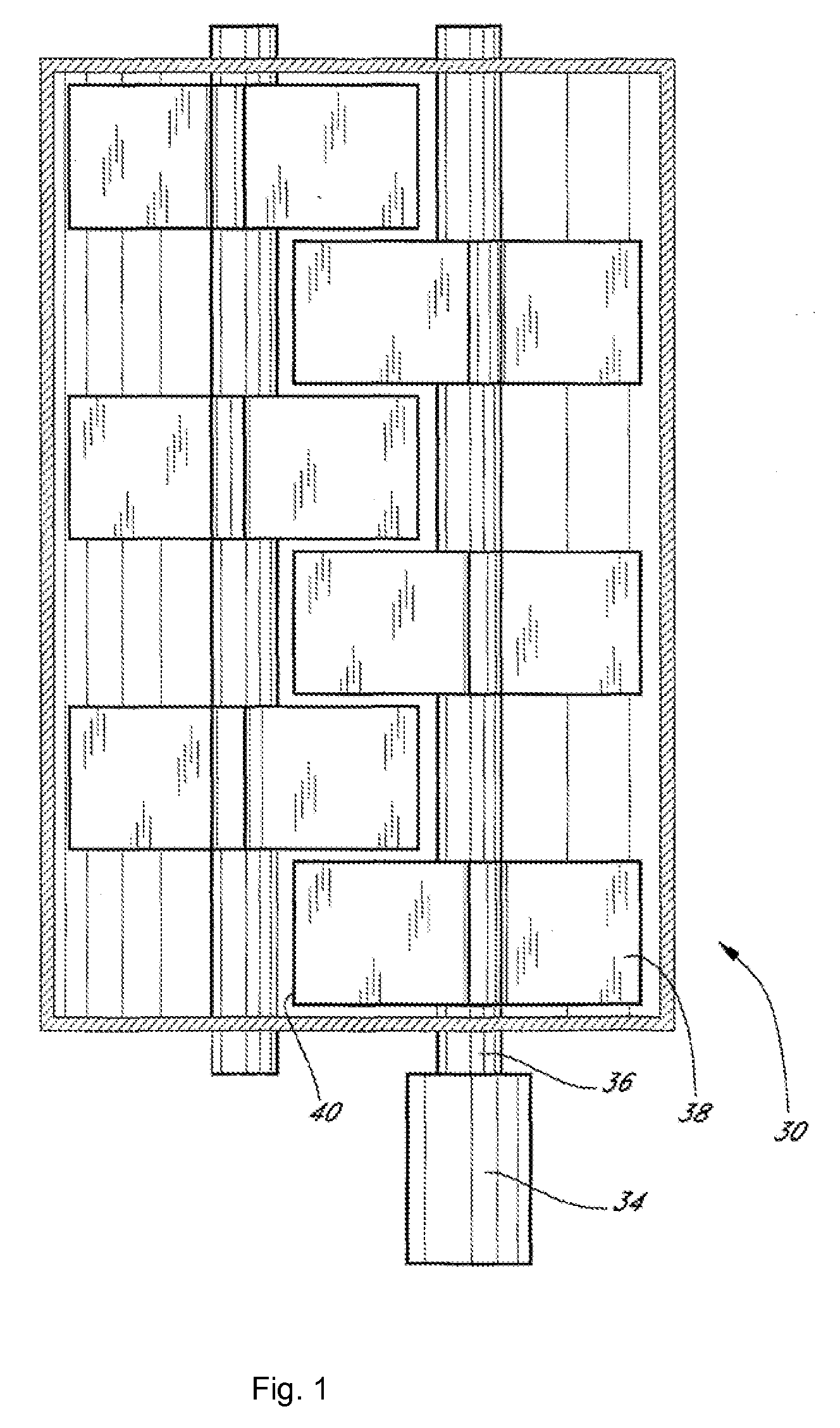

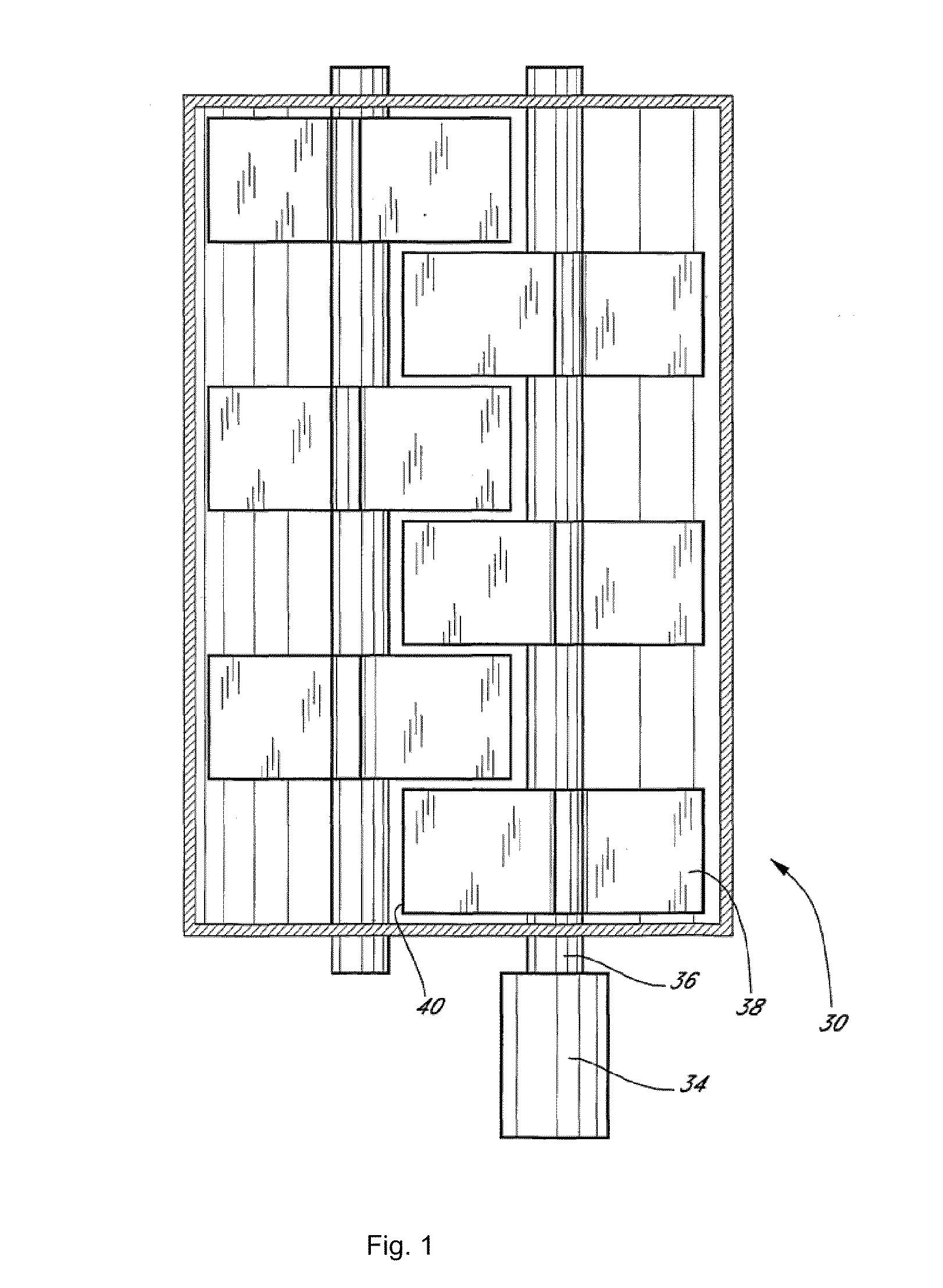

System for sorting and processing a plurality of types of solid waste products for recycling

InactiveUS6903142B1Reduce confusionLow costMechanical working/deformationSolid waste disposalCardboardWaste product

The present invention 10 discloses a trash and garbage processing device which may be sized to fit into a kitchen of a home or sized to be used in a multi-family dwelling. The present invention 10 has a plurality of sorting compartments 12 disposed on the top thereof for receiving various types of waste products. There is a compartment for shrinking and palletizing plastics, another compartment for shredding paper and cardboard 58, another compartment for perishable organic waste 48, a crushing compartment for crushing cans and glass / plastic products 54 and a disposal compartment 60 for non-degradable, solid waste such as bones and batteries. After the various types of waste materials are processed, they are transferred to a conduit to a recycling bin 32 for temporary storage and then thereafter removed from the recycling bin and transferred for final disposal. A paper cutting blade 26 is provided for cutting large pieces of cardboard or paper to proper size for placement into a paper shredding compartment 58. The individual openings 12 of the compartments have lids 14 thereon which have safety locks thereon 22 / 34 to prevent children from tampering therewith. A plastic handling compartment also may be coated with a non-stick material and the safety locks may use a touch digital keypad as commonly used. Further, the crusher unit may be equipped with a mechanism for determining the UPC codes of the materials.

Owner:STAUBER CHAIM M

Method for fiber stock preparation

InactiveUS7179347B2Negatively characteristicWeaken energyCellulosic pulp after-treatmentNatural cellulose pulp/paperFiberCardboard

A method for the preparation of fiber stock for the production of paper or cardboard, including the steps of:a) Supplying fibers in the form of a suspension that has a predetermined solids content,b) Loading of the fibers with a precipitation product, without refining the stock,c) Refining of the fibers after completion of the loading process, in order to improve the freeness value and / or to alter the fiber characteristics, andd) Transporting of the fiber stock suspension in direction of the paper machine.

Owner:VOITH PATENT GMBH

Energy efficient TMP refining of destructured chips

InactiveUS7300540B2Quality improvementReduce energy consumptionCellulosic pulp after-treatmentPretreatment with water/steamFiberRing pattern

A system and method for thermomechanical refining of wood chips comprises preparing the chips for refining by exposing the chips to an environment of steam to soften the chips, compressively destructuring and dewatering the softened chips to a solids consistency above 55 percent, and diluting the destructured and dewatered chips to a consistency in the range of about 30 to 55 percent. The destructuring partially defibrates the material. This diluted material is fed to a rotating disc primary refiner wherein each of the opposed discs has an inner ring pattern of bars and grooves and an outer ring pattern of bars and grooves. The destructured and partially defibrated chips are substantially completely defibrated in the inner ring and the resulting fibers are fibrillated in the outer ring. The compressive destructuring, dewatering, and dilution can all be implemented in one integrated piece of equipment immediately upstream of the primary refiner, and the fiberizing and fibrillating are both achieved between only one set of relatively rotating discs in the primary refiner.

Owner:ANDRITZ INC

Process for increasing the refiner production rate and/or decreasing the specific energy of pulping wood

InactiveUS7726592B2Increase ratingsReduce energy consumptionPaper recyclingReed/straw treatmentProduction rateEngineering

The present invention relates to processes for enhancing a refiner's production rate and / or reducing the specific energy consumption for a freeness target through the use of lubricant(s) or carrier(s) / frictionizer(s), respectively.

Owner:SOLENIS TECH CAYMAN

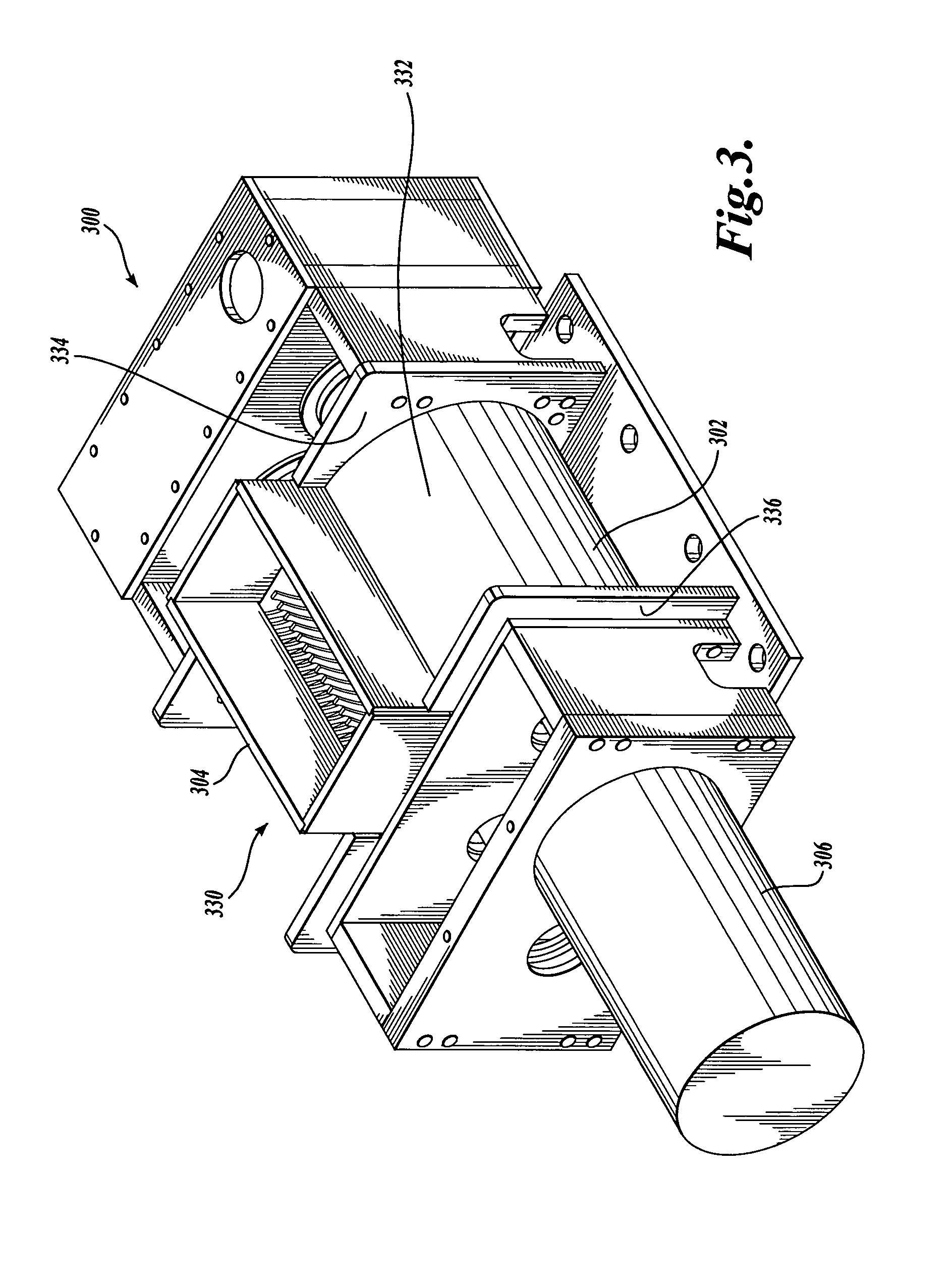

Refiner Plate Assembly and Method With Evacuation of Refining Zone

A refiner plate assembly and method includes an annular arrangement of adapter subplates that mount to a refiner disk of a disk refiner using a conventional mounting technique, such as bolted in a standard pattern associated with the particular disk refiner. The adapter subplate arrangement remains mounted to the disk and provides a universal mounting surface for an annular arrangement of individual removable refiner segments. A steam and / or accept evacuation channel is provided in this assembly via filter passages at a radially intermediate location in one or more refiner segments which communicate with a recess or channel in one or more associated adapter subplates that direct the steam and / or accepts through outlet ports in the outer rim of the adapter subplate(s). Refining efficiency is provided in a universal refiner plate assembly by eliminating steam volume and already refined pulp from outer portions of the refining zone. The filter section(s) can be placed at an optimal location of high volume fraction of pulp fibers where mounting hardware is typically located in conventional refiner segments.

Owner:VALMET TECH OY

Degreasing and desugaring method of sympodial bamboo

Owner:中宇创业联合控股有限公司

Overall-bamboo anti-cracking processing method

InactiveCN101927516AReduce the probability of crackingHigh strengthWood treatment detailsCork treatment detailsAcetic acidWeather resistance

The invention discloses an overall-bamboo anti-cracking stewing, stewing and filling, and drying method. The method comprises the following steps of: stewing a bamboo section in mixed solution of sodium chloride and acetic acid at the temperature of 100 DEG C under normal pressure, wherein bamboo green is removed from the bamboo section and a hole is punched on a bamboo joint or a bamboo wall; stewing and filling the bamboo section in the mixed solution of alum and polyethylene glycol at the temperature of 100 to 200 DEG C and under the pressure of 0.1 to 1.6 MPa; performing low-temperature drying on the bamboo section in a wood steam drying kiln; hydrofuging the drying kiln until the moisture content of the bamboo section reaches 5 to 20 percent; and unloading an overall-bamboo after slowly reducing the temperature of the kiln to indoor normal temperature. After the treatment, the overall-bamboo has the characteristics of better dryness and anti-cracking effect, improved stability, weather resistance and strength, and prolonged service life.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

Mechanical four position brush chipper feed control bar

A mechanical control mechanism for the feed of a brush chipper is disclosed. The feed control bar has four positions: (1) forward or feed, (2) neutral, (3) reverse, and (4) stop. The hydraulic control valve has the three usual positions: (1) forward or feed, (2) neutral, (3) reverse. A function of the feed control bar is to provide the three function of the hydraulic control valve, plus the fourth in a fashion amenable to emergency situations. To these ends, the control bar has an extreme rearward position wherein the feed mechanism is stopped. The only permissible change to the stopped condition of the feed mechanism is to reverse the feed. Until a reset lever is manipulated, the hydraulic control valve cannot be put into a forward feed position.

Owner:VERMEER MFG CO

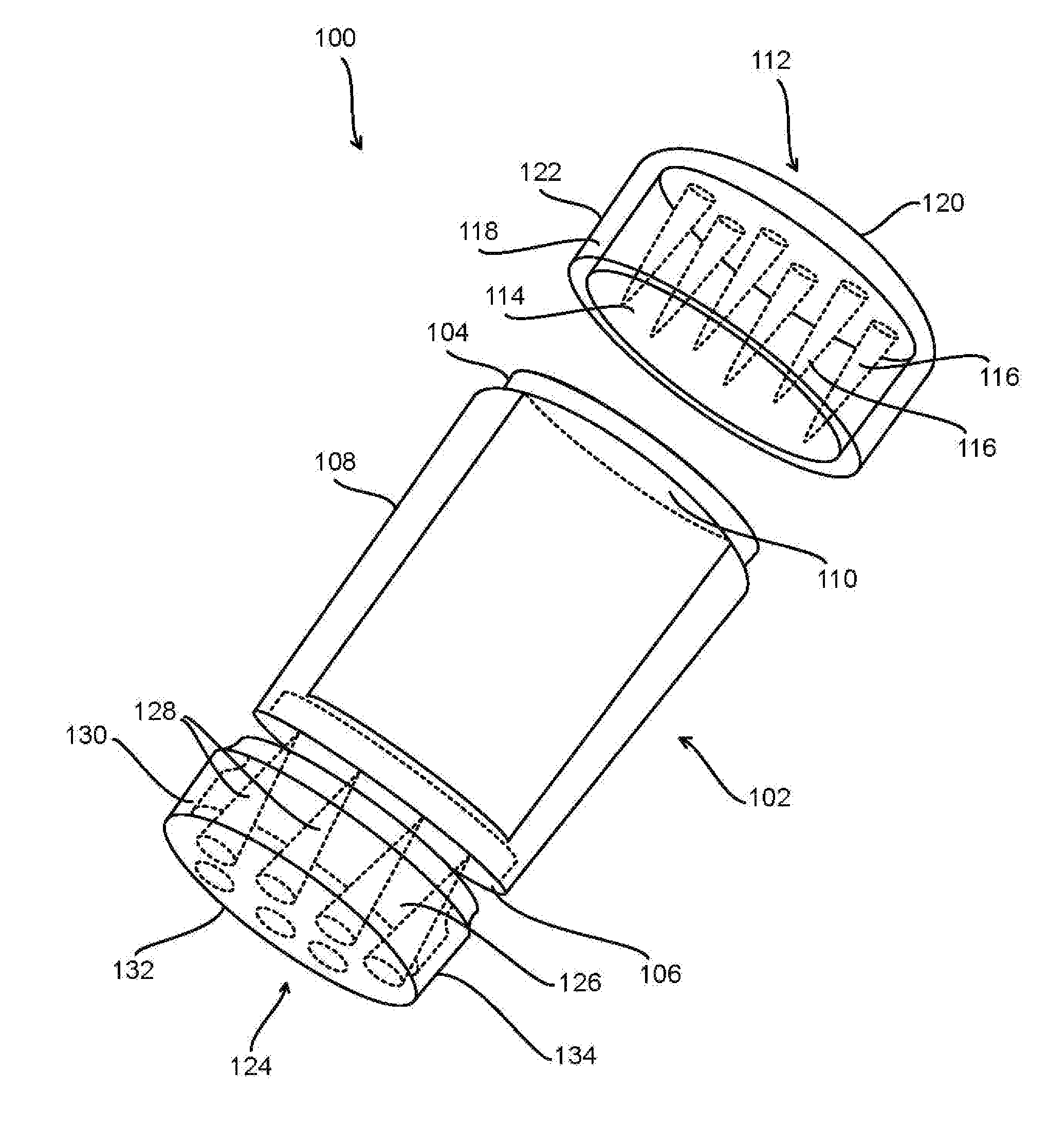

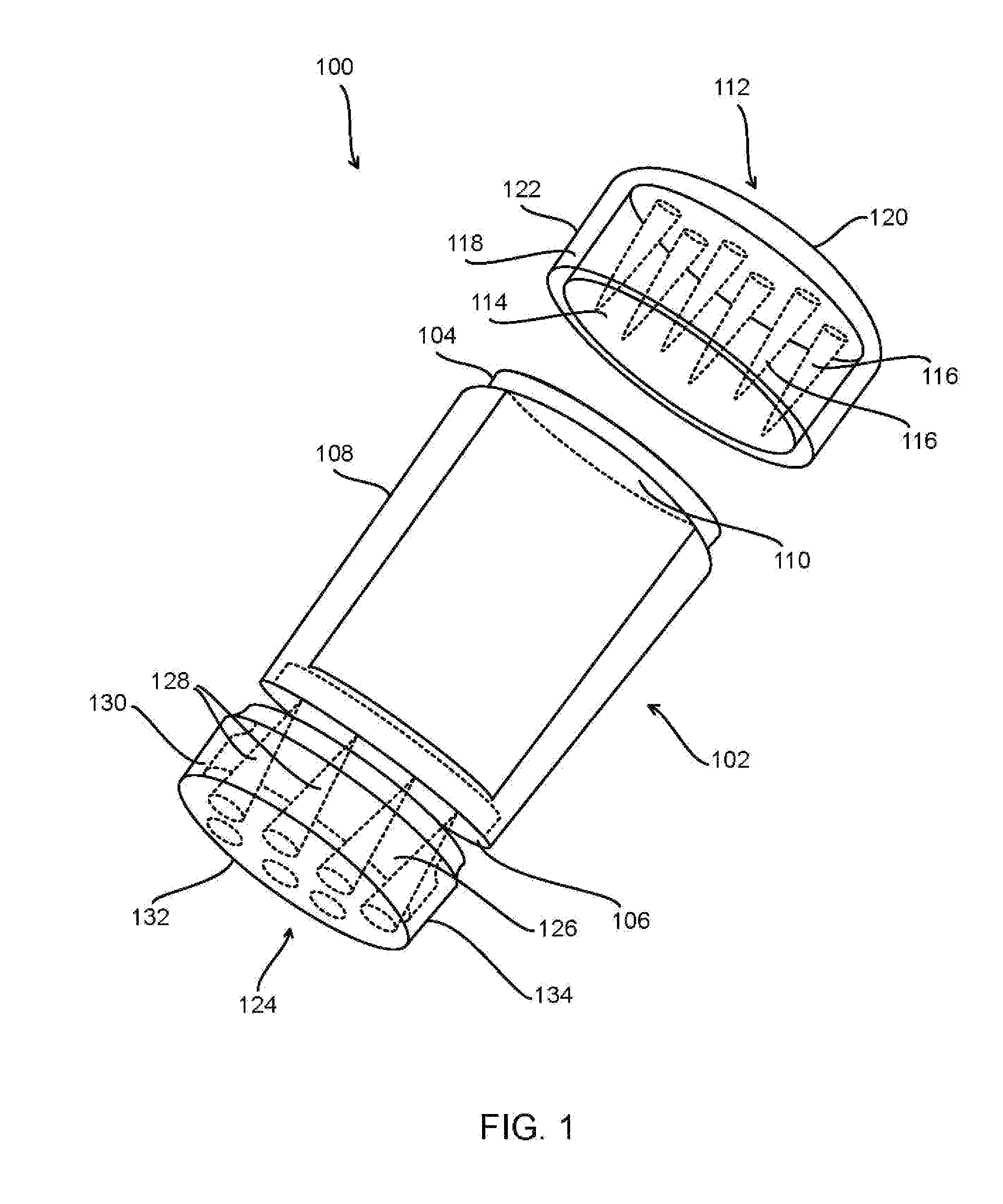

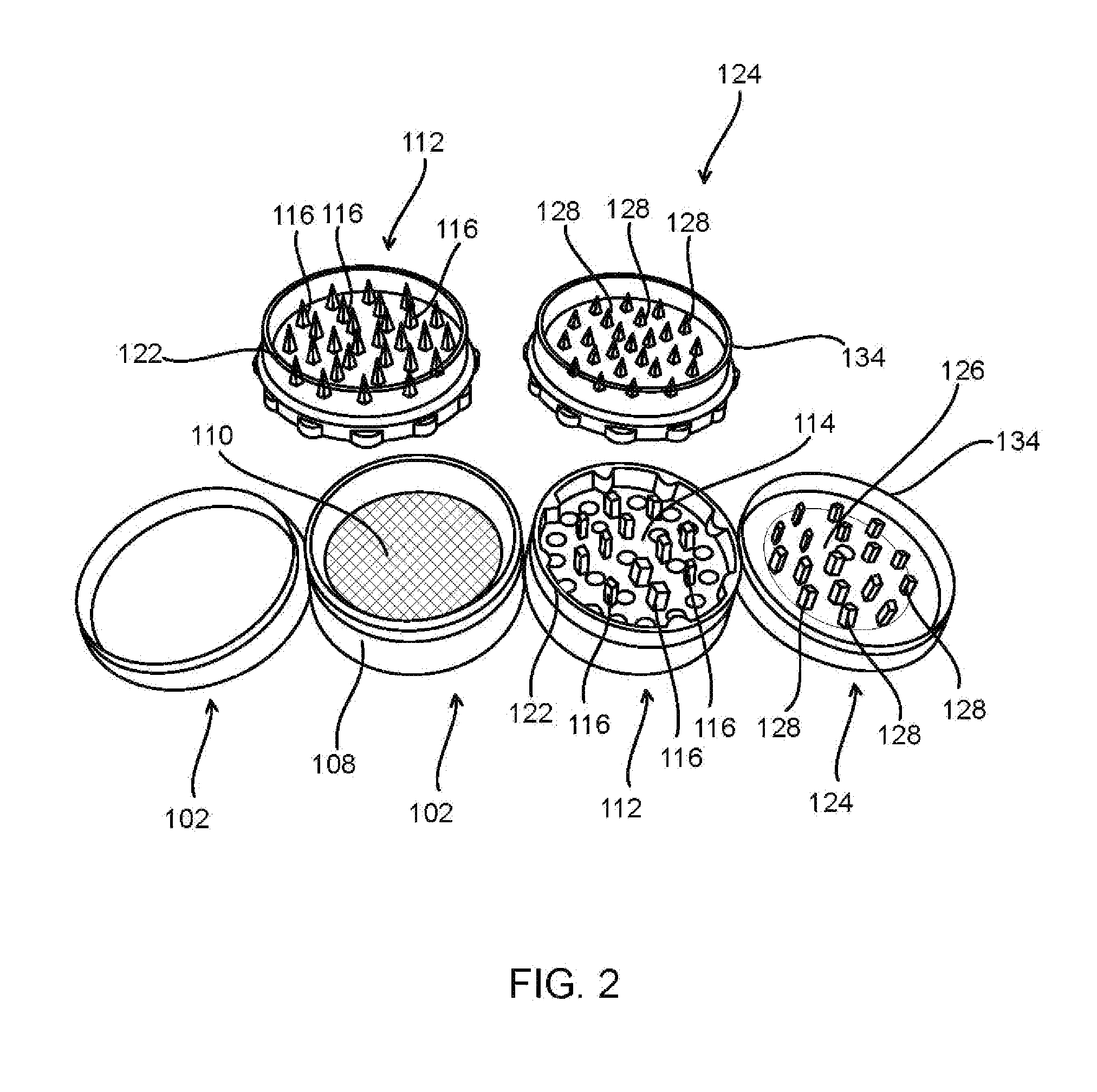

Device and Method for Airtight Storage and Grinding of Herbs

ActiveUS20160128513A1Easily and detachably convertEnhances flavor and smellMetal sawing devicesCoffee millsFlavorHermetic seal

A storage and grinding device and method provides the dual functionality of forming an airtight compartment for storing herbs to protect their flavor and essence, and disassembling into a grinder to grind, tear, and shear the herbs. The device forms an airtight compartment with detachable lids that detach from the compartment and join together to form a unitary grinder, generally for grinding the contents of the compartment. A first and second lid form an airtight seal over each end of the compartment. The airtight seal is formed when the first and second lids form a hermetic seal at each end of the compartment. The airtight seal enhances the flavor and smell of the herbs by retaining the essence within the compartment and keeping the herbs impervious to gases. The first and second lids can disengage from each end of compartment, and engage each other to form a unitary grinder.

Owner:CHAN ERIK

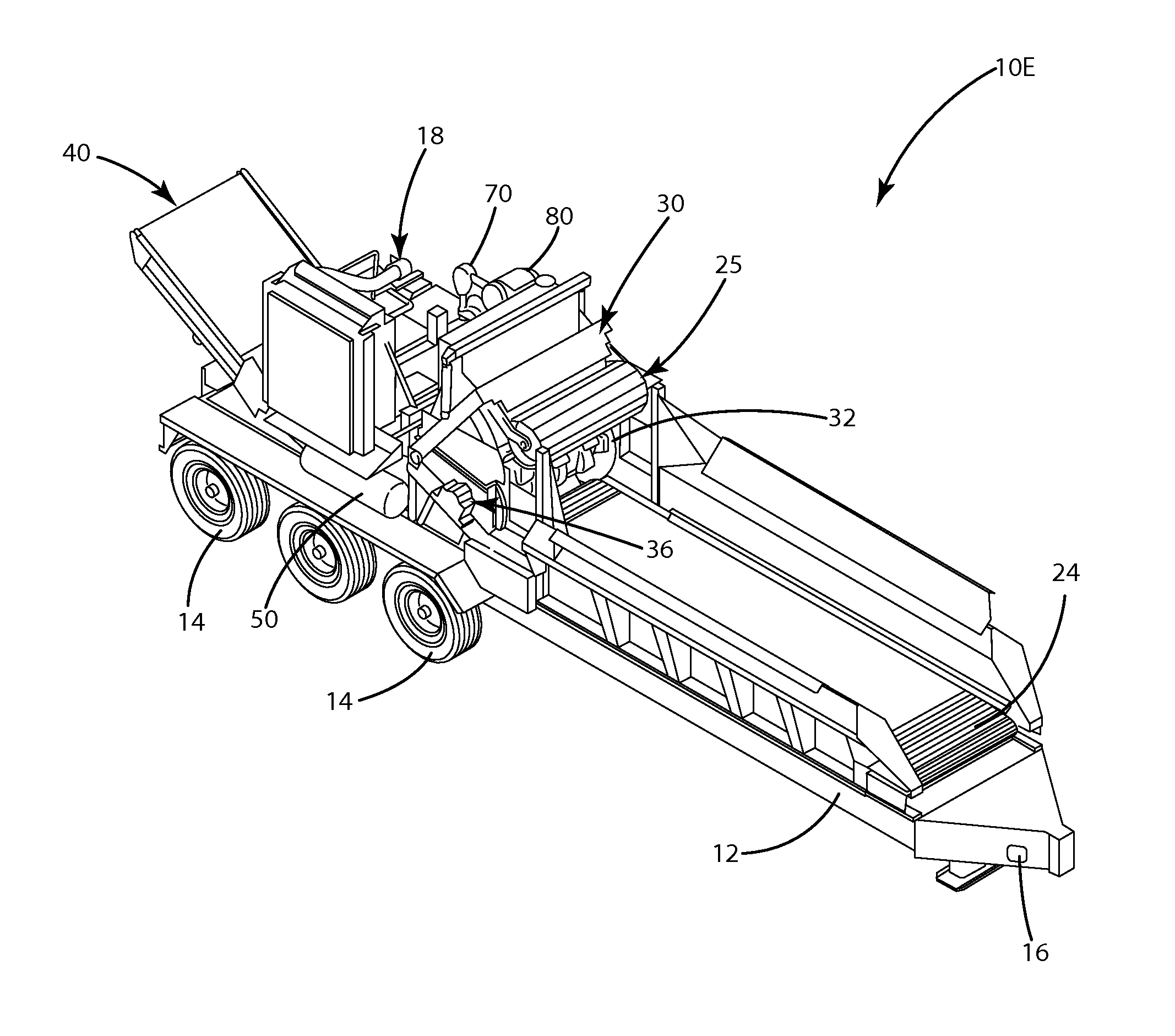

Waste processing system, machine and method thereof

ActiveUS20120234949A1Reduced material requiredMowersPlant waste comminutingWaste processingWood waste

a waste processing machine for reducing wood waste comprises an accumulator operatively connected to the cutting system so as to power the cutting system upon discharge thereof. The accumulator is adapted to receive, store, and release a charge developed from a charging device operatively connected to the accumulator and one or more systems of the waste processing machine.

Owner:BANDIT IND

Disruptor System for Dry Cellulosic Materials

ActiveUS20090224086A1Readily hydrolyzableEnhance stirringReed/straw treatmentCocoaMaximum diameterEngineering

Cellulosic biomass is reduced to a micropowder with particles having average diameters below 5-10 micrometers with a significant fraction of the particles have diameters below 1 micrometer. Biomass (e.g., wood, agricultural waste or other plant materials) is first processed into pieces having a maximum diameter of about 10 mm. This is then dried to reduce its water content to no more than about 15% by weight and introduced into a disruptor which reduces the particle size to about 1 mm. Next the biomass is processed with a disc mill where edges of rotating discs travel along a groove pressing and squeezing the biomass, thereby breaking the biomass pieces into smaller and smaller particles. The resulting micropowder is extremely susceptible to enzymatic or chemical hydrolysis into constituent sugars. In addition, the micropowder can be suspended in an air stream and burned directly to provide heat to boilers and similar devices.

Owner:BIOMASS CONVERSIONS LLC

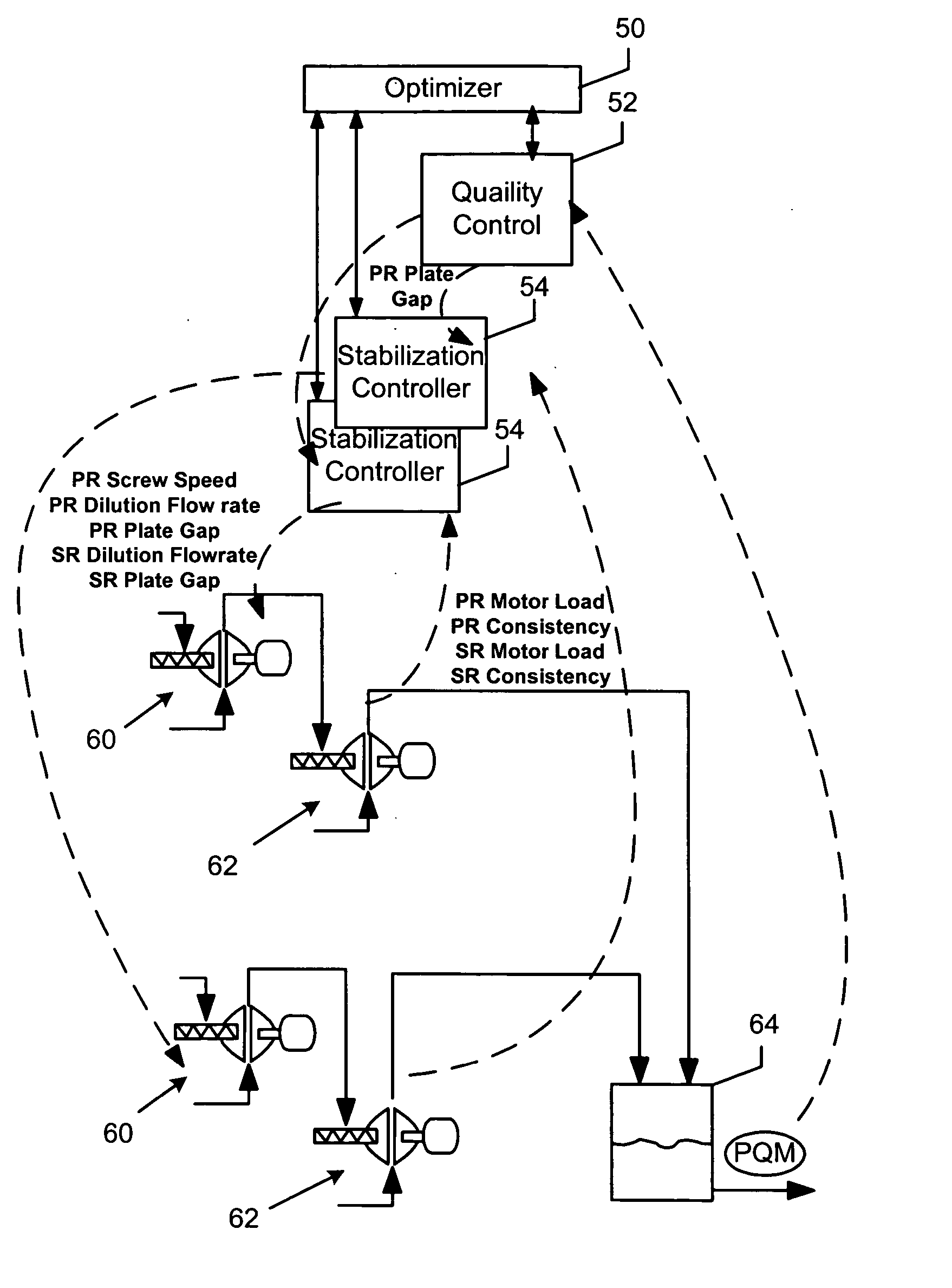

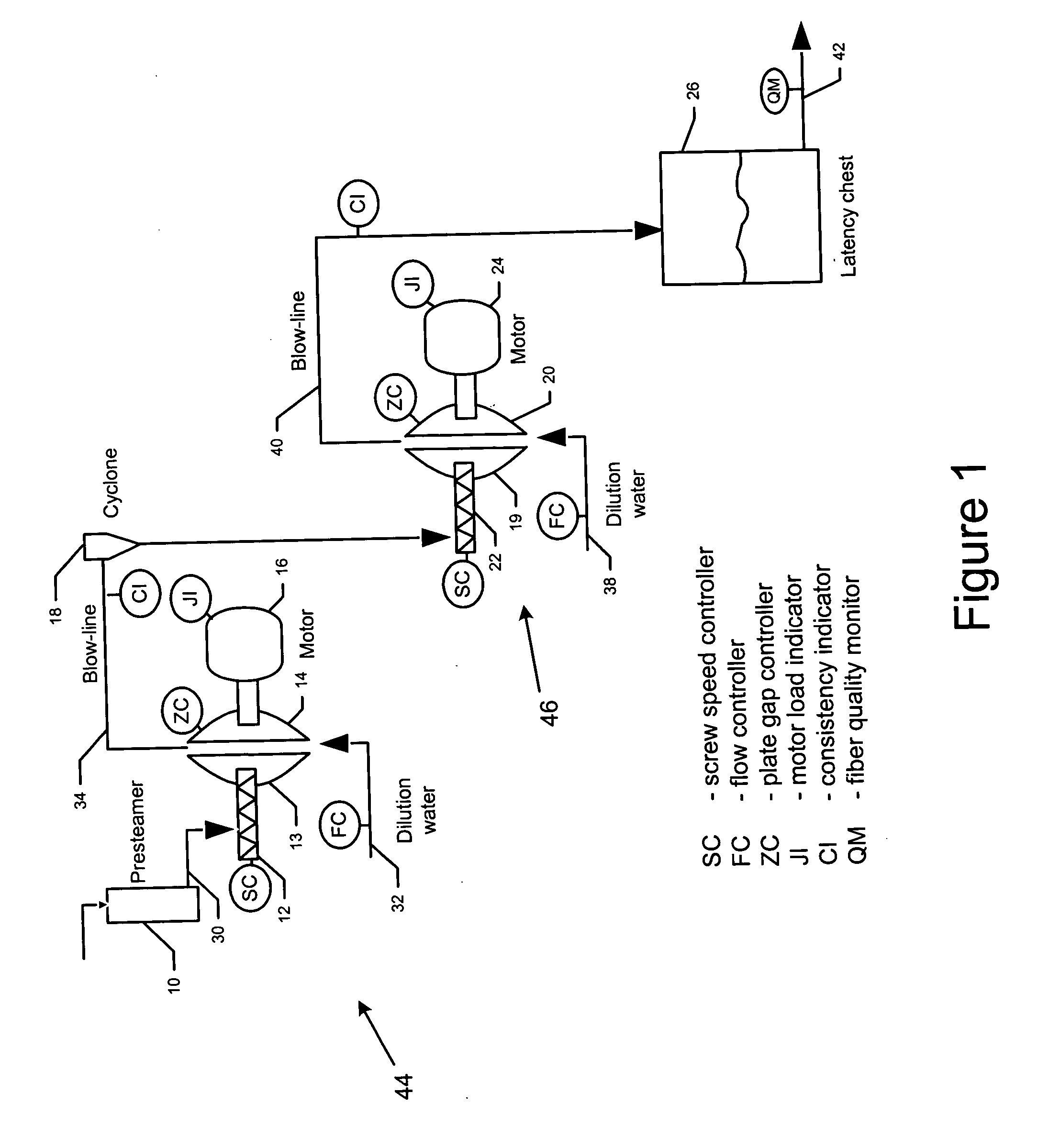

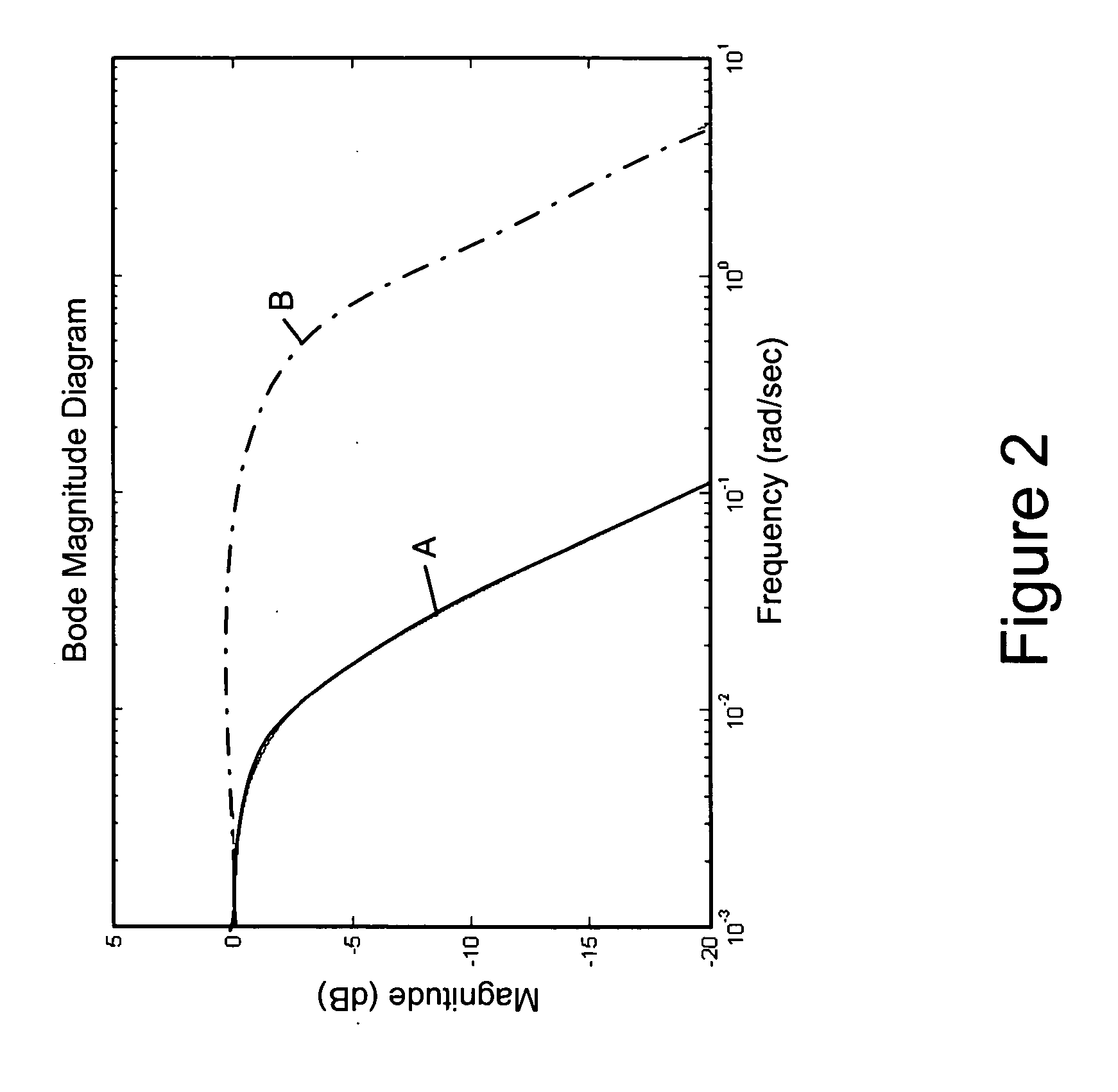

System and method for controlling a thermo-mechanical wood pulp refiner

ActiveUS20050263259A1Improve throughputReduce energy useBeating/refining control devicesComputer controlFiberQuality optimization

Thermomechanical pulp is an important process for producing fibrous mass used in papermaking. A two-level control strategy that stabilizes and optimizes the refining process has been developed. The Stabilization layer consists of a multivariable model predicative range controller that regulates the refiner line operations. The Quality Optimization layer provides the pulp quality control as measured by an online pulp quality (freeness, fibre length) sensor. This control startegy leverages the natural decoupling in the process. The modular design technique is able to handle multiple refiner lines that empty into a common latency chest. A global optimizer is also used to integrate and coordinate the two layers for enhanced constraint handling.

Owner:HONEYWELL INT INC

Processing method of Chinese redwood barks

ActiveCN104441158AFully softenedImprove wooden structureCork treatment detailsMedicineRelative humidity

The invention relates to a processing method of Chinese redwood barks. The processing method comprises the following steps: (1) cleaning the Chinese redwood barks, mixing the Chinese redwood barks with a processing agent (1) at 40 DEG C for 10-15 minutes for treating; (2) processing the Chinese redwood barks processed in the step (1) at the temperature of 85 DEG C and the relative humidity of 75% for 3 hours; (3) soaking the Chinese redwood barks processed in the step (2) at 45 DEG C for 3-5 hours by virtue of a softener; and (4) processing the Chinese redwood barks processed in the step (3) at the temperature of 60 DEG C and the relative humidity of 45% for 2 hours, and airing until the water content is 55%-65%. By specially processing the Chinese redwood barks by virtue of the processing method, the softening effect of the Chinese redwood barks can be greatly improved, and the Chinese redwood barks are uniformly softened, so that situations of breakage, cracking and the like in a weaving process are prevented, and the yield of woven products is high after processing and reaches above 96.2%.

Owner:阜南佳利工艺品股份有限公司

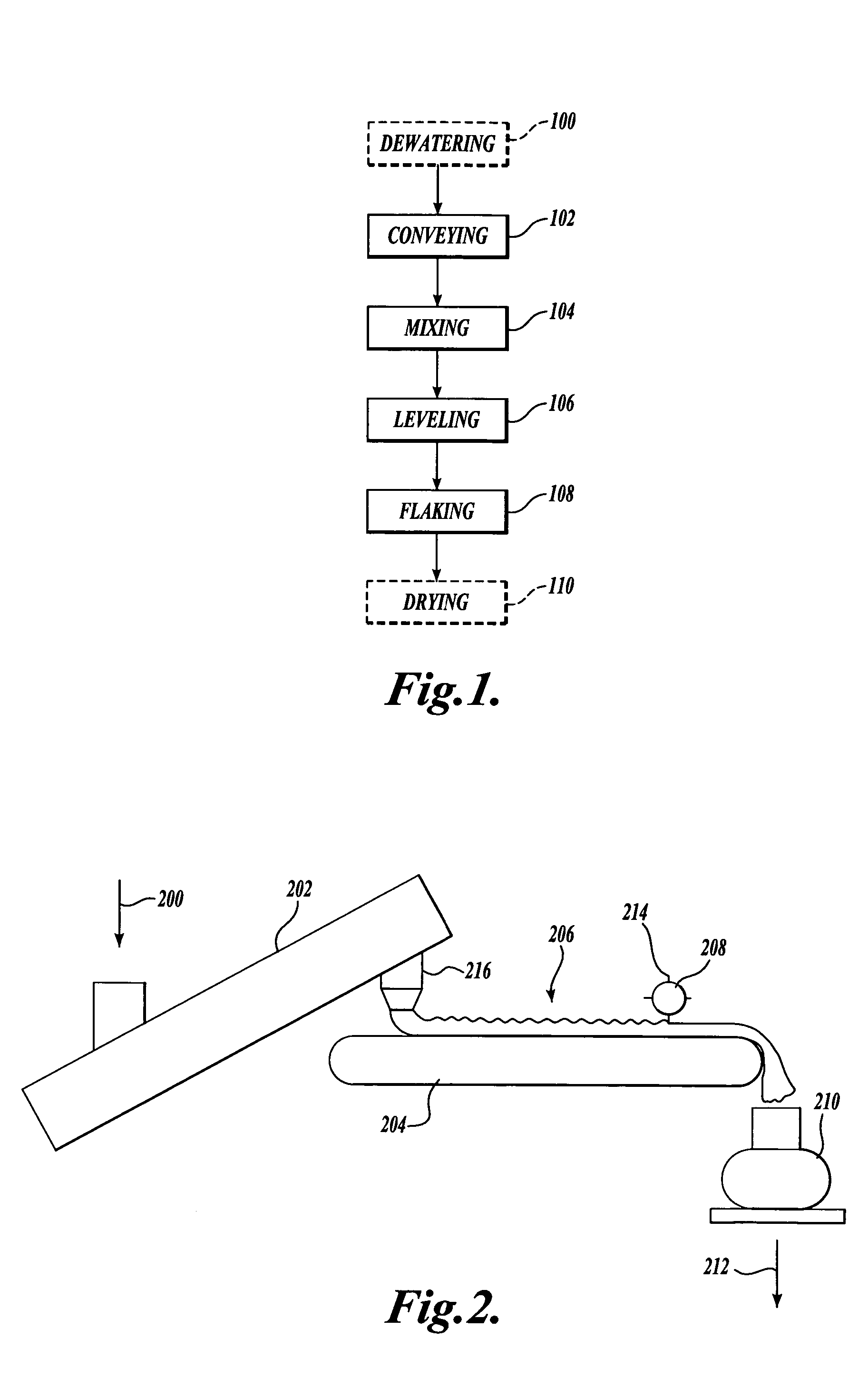

Pulp flaker

InactiveUS7291244B2Small sizePrevents scattering of the pulpDrying using combination processesDigestersPulp and paper industryMoisture

Methods for conveying, mixing, leveling, and flaking dewatered pulp to produce pulp flakes suitable to be used in a dryer. Methods for producing a consistent flow rate of pulp, and, for producing uniform pulp flakes in terms of pulp flake size and pulp flake moisture content. A method includes introducing a dewatered pulp to a rotating shaftless screw conveyor. The pulp is deposited from the screw conveyor onto a moving belt conveyor through a chute. The pulp is leveled with a rotary doctor located above the belt conveyor to produce a substantially even rate of mass flow of pulp along a length of belt conveyor. Uniform and consistent quantities of pulp per unit time can then be fed from the belt conveyor to a pulp flaker that then translates into an even rate of pulp mass flow to the dryer.

Owner:WEYERHAEUSER CO

High intensity refiner plate with inner fiberizing zone

InactiveUS20060006265A1Easy to produceReduce energy consumptionPretreatment with water/steamReed/straw treatmentFiberHigh intensity

Plate elements, a plate configuration, and associated system for thermomechanical refining of wood chips wherein destructured and partially defibrated chips are fed to a rotating disc primary refiner, where opposed discs each have an inner band pattern of bars and grooves and outer band pattern of bars and grooves, such that substantially complete fiberization (defibration) of the chips is achieved in the inner band and the resulting fibers are fibrillated in the outer band. One embodiment is directed to a pair of opposed co-operating refining plate elements for a flat disc refiner wherein the bars and grooves on each of the inner bands form an inner feed region followed by an outer working region, the bars and groove on each of the outer bands form an inner feed region followed by an outer working region, and the gap and / or material flow area formed when the plates are placed in front of each other increases between the inner working region and the outer feed region.

Owner:ANDRITZ INC

Disruptor system for dry cellulosic materials

InactiveUS7954734B2Readily hydrolyzableEnhance stirringReed/straw treatmentCocoaCelluloseMaximum diameter

Owner:BIOMASS CONVERSIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com