Mechanical four position brush chipper feed control bar

a technology of feed control and brush chipper, which is applied in the field of mechanical four-position brush chipper feed control, can solve the problem of less versatility of electrical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

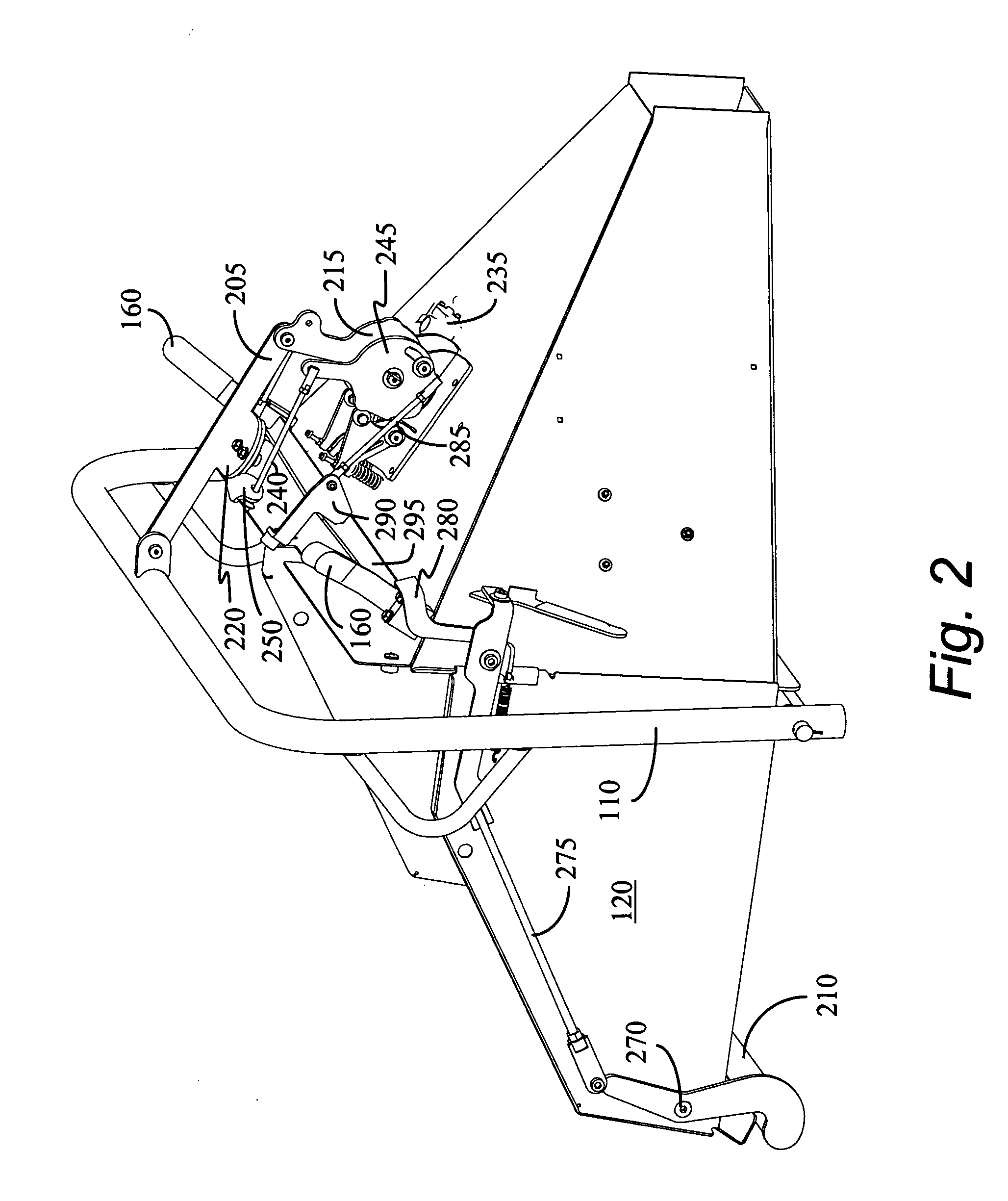

[0042] For the purposes of this document, the term mechanical control is defined as a control system wherein actuation is due to a mechanical linkage from the control bar to the hydraulic control valve. No electrical actuation is incorporated. Of course merely adding electrical components to the mechanical system of the present invention can be done and still be within the scope and spirit of the present invention.

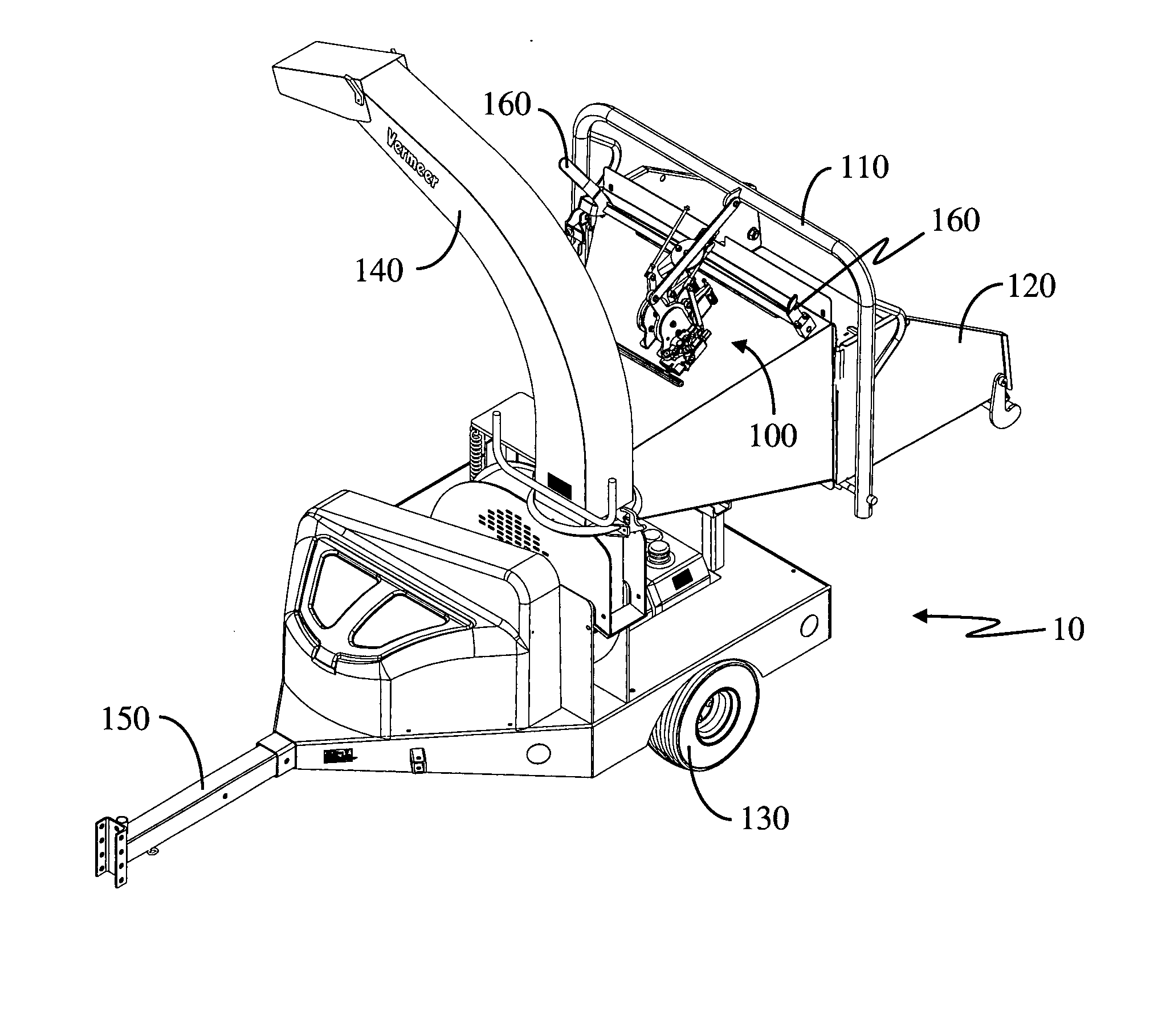

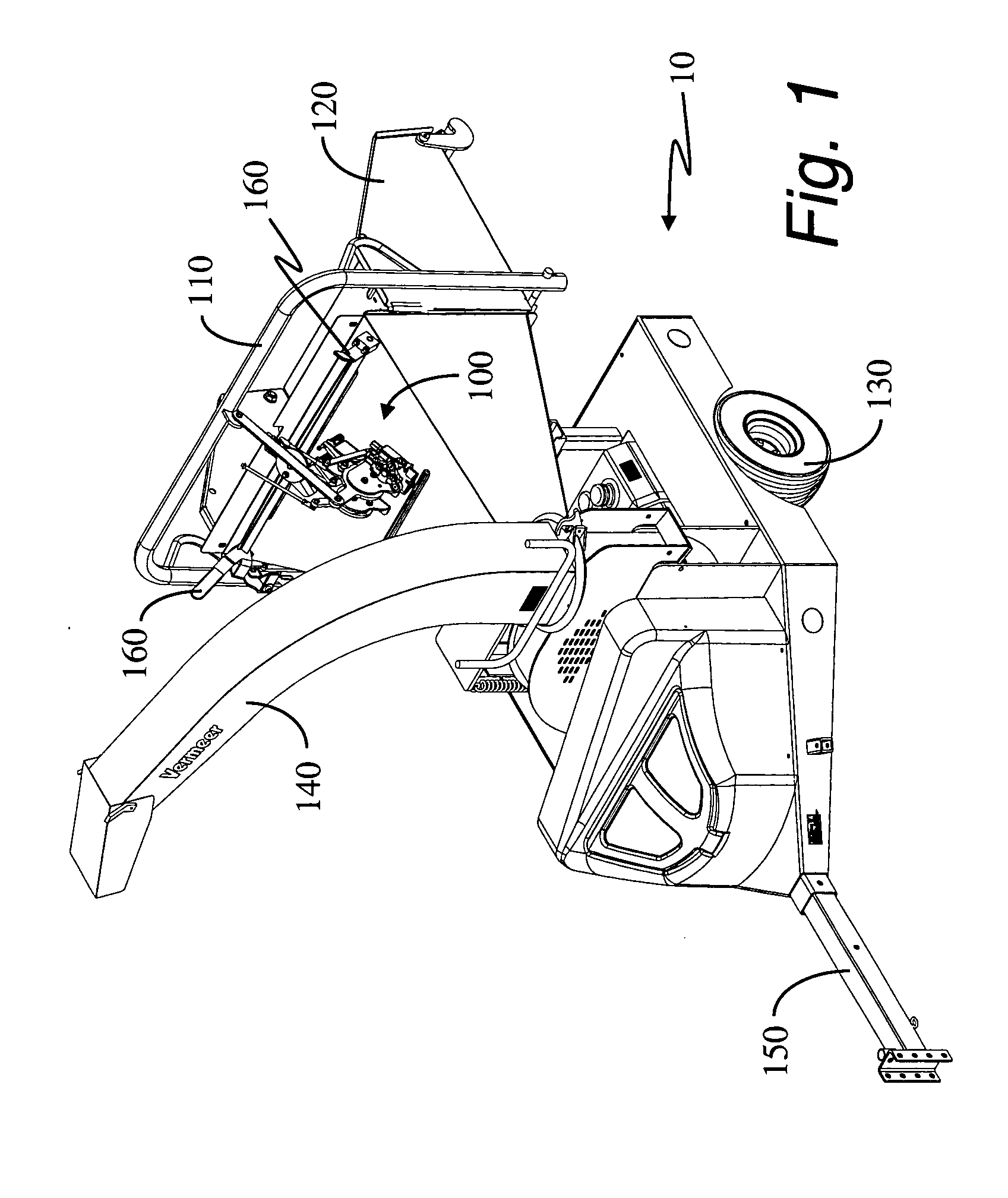

[0043] A brush chipper 10 is shown in FIG. 1. The direction of brush feeding is generally controlled through the manipulation of the feed control assembly 100 via the upper feed control bar 110. Generally, the brush chipper comprises a feed table assembly 120, ground engaging wheels 130 (only one seen in FIG. 1), and a conveyance for chipped matter, in this case a chute 140. Not seen in FIG. 1 are a plurality of feed rollers driven by hydraulic motors, and at least one cutter drum or cutter disk.

[0044] The brush chipper 10 of FIG. 1 has a front, generally toward the tong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension force | aaaaa | aaaaa |

| compressive force | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com