Wavelength conversion device, relevant fluorescent color wheel and relevant projection device

A technology of wavelength conversion device and fluorescent color wheel, which is applied in the direction of lighting devices, projection devices, lighting device components, etc., can solve the problems of low outgoing light efficiency and large optical expansion, and achieve high outgoing light efficiency and not easy to crack Effect of deformation, surface flatness and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a wavelength conversion device according to Embodiment 1 of the present invention. The wavelength conversion device includes a light-emitting layer 101, a sapphire layer 102, and a specular reflection film 103, wherein between the light-emitting layer 101 and the sapphire layer 102, the sapphire layer 102 and the specular reflection film 103 close connection between them.

[0034] In the working state, the light emitted by the luminescent layer 101 passes through the sapphire layer 102 , reaches the specular reflection film 103 , is reflected by the specular reflection film 103 , passes through the sapphire layer 102 and the luminescent layer 101 in sequence, and then exits. The heat generated by the light-emitting layer 101 is conducted to the specular reflection film 103 through the sapphire layer 102 and dissipated from the sapphire layer 102 and the specular reflection film 103 .

[0035] ...

Embodiment 2

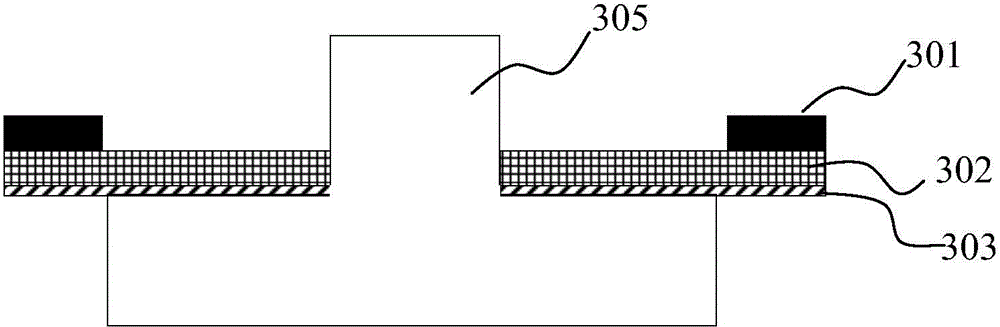

[0044] See image 3 , image 3It is a structural schematic diagram of the fluorescent color wheel of the second embodiment of the present invention. Compared with Embodiment 1, the fluorescent color wheel of this embodiment has an additional driving device 305, which is used to drive the wavelength conversion device to rotate.

[0045] Compared with the fixed wavelength conversion device without the driving device 305, the fluorescent color wheel of this embodiment dissipates heat faster through rotation, so that it can work at higher optical power.

[0046] Figure 4 It is a structural schematic diagram of a modified embodiment of the second embodiment. Compared with the second embodiment, the sapphire layer 402 is fixedly connected with the driving device 405, the driving device 405 drives the sapphire layer 402 to rotate, and the sapphire layer 402 drives the light emitting layer 401 and the mirror reflection film 403 to rotate. Since the sapphire layer 402 has a crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com