Plant fiber reinforced modified soy-based resin composite material

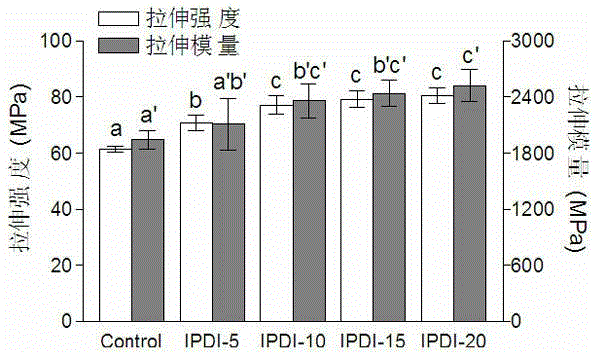

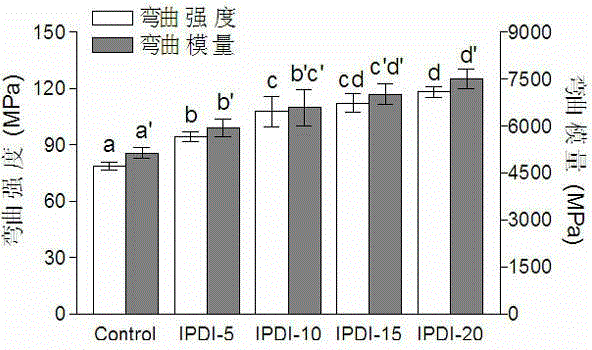

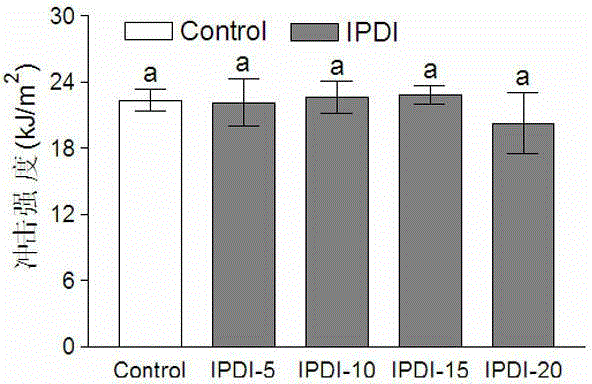

A technology of soybean oil-based resin and plant fiber, which is applied in the direction of synthetic resin layered products, wood processing equipment, lamination, etc., can solve the problems of poor interface bonding, poor mechanical properties, and shortage of petroleum-based resin raw materials, and achieve impact The effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Raw material: plant fiber is hemp fiber (hemp fiber count is 130, average length is 3cm), purchased from Anhui Tongling Sanxing Hemp Industry Co., Ltd.; soybean oil-based resin is made from N - Blending of vinylpyrrolidone (NVP) and epoxidized soybean oil acrylate (AESO): NVP was purchased from Shanghai Jingchun (Aladdin) Industrial Co., Ltd.; AESO (model: F03; viscosity (23°C): 8000–20000cps ; Acid value: ≤ 12 mgKOH / g) was purchased from Jiangsu Litian Technology Co., Ltd.; the modifier was isophorone diisocyanate (IPDI), purchased from TCI (Shanghai) Chemical Industry Development Co., Ltd.; the initiator was Tert-butyl peroxybenzoate (TBPB) was purchased from Sigma-Aldrich (Shanghai) Trading Co., Ltd.

[0016] Plant fiber / modified soybean oil-based resin composite material:

[0017] The preparation process of modified soybean oil-based resin is as follows: soybean oil-based resin (95g) and modifier (5g) are placed in a round bottom flask, and after stirring with a ma...

Embodiment 2

[0021] Raw material: plant fiber is hemp fiber (hemp fiber count is 130, average length is 3cm), purchased from Anhui Tongling Sanxing Hemp Industry Co., Ltd.; soybean oil-based resin is made from N - Blending of vinylpyrrolidone (NVP) and epoxidized soybean oil acrylate (AESO): NVP was purchased from Shanghai Jingchun (Aladdin) Industrial Co., Ltd.; AESO (model: F03; viscosity (23°C): 8000–20000cps ; Acid value: ≤ 12 mgKOH / g) was purchased from Jiangsu Litian Technology Co., Ltd.; the modifier was isophorone diisocyanate (IPDI), purchased from TCI (Shanghai) Chemical Industry Development Co., Ltd.; the initiator was Tert-butyl peroxybenzoate (TBPB) was purchased from Sigma-Aldrich (Shanghai) Trading Co., Ltd.

[0022] Plant fiber / modified soybean oil-based resin composite material:

[0023] The preparation process of modified soybean oil-based resin is as follows: put soybean oil-based resin (90g) and modifier (10g) in a round bottom flask, stir with a magnetic stirrer for 5...

Embodiment 3

[0027] Raw material: plant fiber is hemp fiber (hemp fiber count is 130, average length is 3cm), purchased from Anhui Tongling Sanxing Hemp Industry Co., Ltd.; soybean oil-based resin is made from N - Blending of vinylpyrrolidone (NVP) and epoxidized soybean oil acrylate (AESO): NVP was purchased from Shanghai Jingchun (Aladdin) Industrial Co., Ltd.; AESO (model: F03; viscosity (23°C): 8000–20000cps ; Acid value: ≤ 12 mgKOH / g) was purchased from Jiangsu Litian Technology Co., Ltd.; the modifier was isophorone diisocyanate (IPDI), purchased from TCI (Shanghai) Chemical Industry Development Co., Ltd.; the initiator was Tert-butyl peroxybenzoate (TBPB) was purchased from Sigma-Aldrich (Shanghai) Trading Co., Ltd.

[0028] Plant fiber / modified soybean oil-based resin composite material:

[0029] The preparation process of modified soybean oil-based resin is as follows: put soybean oil-based resin (85g) and modifier (15g) in a round bottom flask, stir with a magnetic stirrer for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com