High glass fiber content enhanced high-temperature nylon composite material and preparation method thereof

A nylon composite material and glass fiber technology, which is applied in the field of high glass fiber content reinforced high temperature nylon composite material and its preparation to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

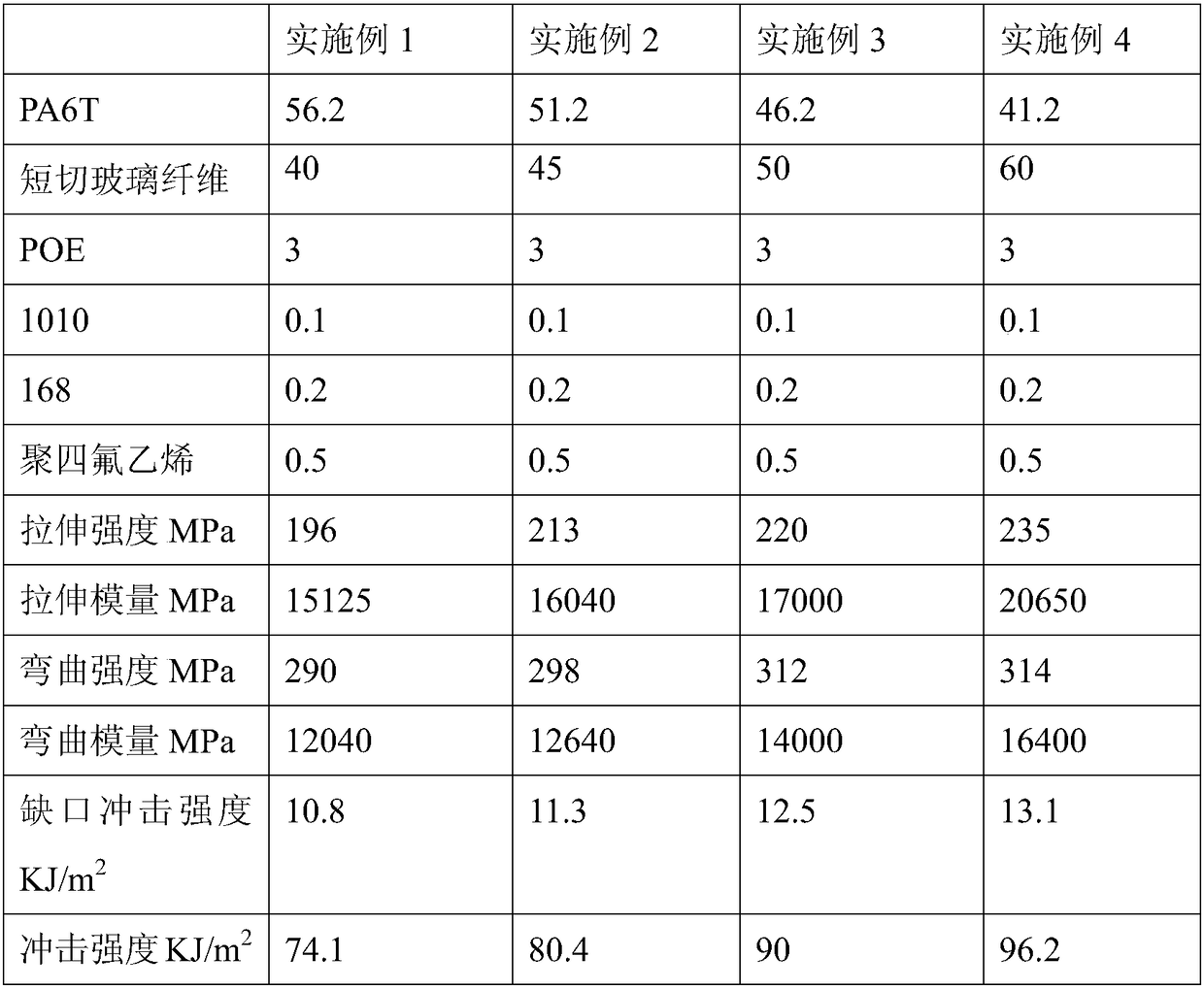

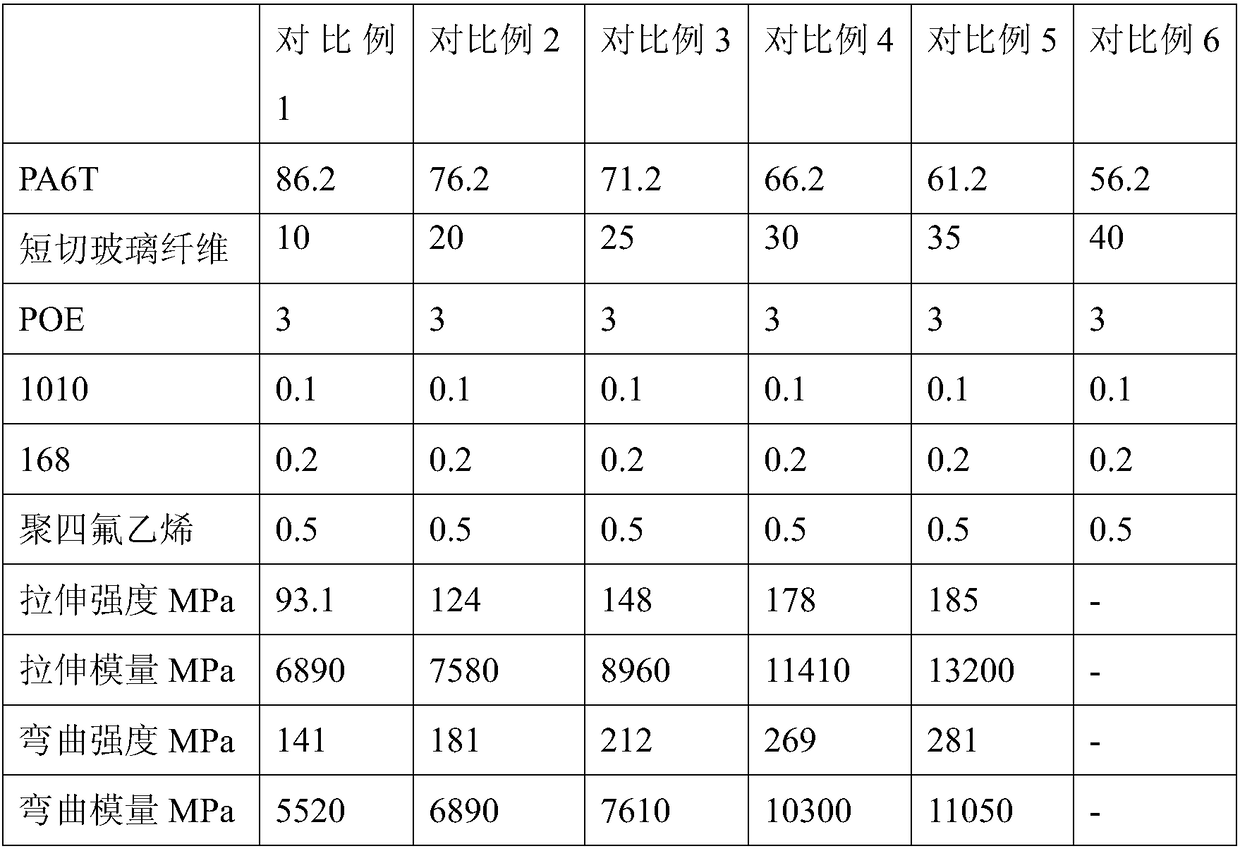

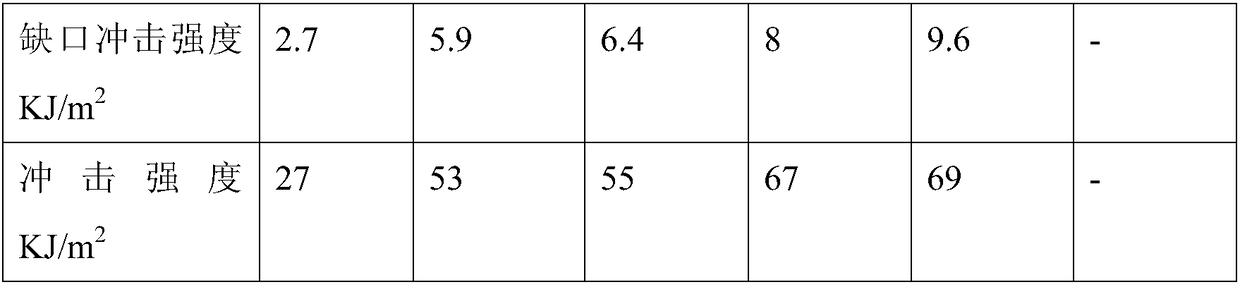

Examples

Embodiment 1

[0027] 1): Glass fiber surface treatment: mix 20wt% silane coupling agent, 72wt% absolute ethanol, and 8wt% water to form a solution, add glass fiber into the solution for soaking treatment, soak for 3 to 5 minutes, and then put The glass fibers are taken out and dried to obtain surface-treated glass fibers;

[0028] 2): Take 56.2 parts of nylon 6T resin according to the weight ratio, and dry it in an oven; add 3 parts of toughening agent, 0.3 part of antioxidant, and 0.5 part of lubricant and stir and mix in a high-speed machine for 3 to 5 minutes;

[0029] 3): the material obtained in step (2) is sent into the twin-screw extruder through the main feeder, and in the side feeding port of the twin-screw extruder, adding parts by weight is 40 parts of glass fiber; Twin-screw extruder melt extrusion, the extrusion process is: Twin-screw extruder temperature zone: the temperature of the first zone is 310℃~320℃, the temperature of the second zone is 310℃~320℃, the temperature of th...

Embodiment 2

[0032] 1): Glass fiber surface treatment: mix 20wt% silane coupling agent, 72wt% absolute ethanol, and 8wt% water to form a solution, add glass fiber into the solution for soaking treatment, soak for 3 to 5 minutes, and then put The glass fibers are taken out and dried to obtain surface-treated glass fibers;

[0033] 2): Take 51.2 parts of nylon 6T resin according to the weight ratio, and dry it in an oven; add 3 parts of toughening agent, 0.3 part of antioxidant, and 0.5 part of lubricant and stir and mix in a high-speed machine for 3 to 5 minutes;

[0034] 3): The material obtained in step (2) is sent into the twin-screw extruder through the main feeder, the rotating speed of the main feeder is 30r.p.m, and the Add 45 parts by weight of glass fiber into the feed port; melt and extrude through a twin-screw extruder, the extrusion process is: temperature zone of the twin-screw extruder: the temperature of the first zone is 310°C to 320°C, and the temperature of the second zone...

Embodiment 3

[0037] 1): Glass fiber surface treatment: mix 20wt% silane coupling agent, 72wt% absolute ethanol, and 8wt% water to form a solution, add glass fiber into the solution for soaking treatment, soak for 3 to 5 minutes, and then put The glass fibers are taken out and dried to obtain surface-treated glass fibers;

[0038] 2): Weigh 46.2 parts of raw nylon 6T resin according to the weight ratio, and dry it in an oven; add 3 parts of toughening agent, 0.3 part of antioxidant, and 0.5 part of lubricant and stir and mix in a high-speed machine for 3 to 5 minutes;

[0039]3): The material obtained in step (2) is sent into the twin-screw extruder through the main feeder, the rotating speed of the main feeder is 30r.p.m, and the Add 50 parts by weight of glass fiber into the feed port; melt and extrude through a twin-screw extruder, the extrusion process is: temperature zone of the twin-screw extruder: the temperature of the first zone is 310°C to 320°C, and the temperature of the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com