Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Improve tensile toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene oxide-based curing agent as well as preparation and use thereof

InactiveCN104262588AImprove thermal stabilityLow resistivityNon-macromolecular adhesive additivesEpoxy resin adhesivesArray data structureGlycidyl ethers

The invention discloses a preparation method of a graphene oxide-based curing agent and application of the graphene oxide-based curing agent in epoxy resin conductive glue. The conductive glue consists of the following components in parts by weight: 1-2 parts of a graphene oxide-based curing agent, 3-10 parts of a conventional curing agent, 10-20 parts of E-51 epoxy resin, 10-20 parts of AG-80 epoxy resin, 15-25 parts of carbon black, 15-25 parts of silver precipitate powder, 1-8 parts of amine accelerants, 1-5 parts of a liquid imidazole defoaming agent and 1-20 parts of glycidyl ether diluents. The preparation method of the graphene oxide-based curing agent comprises the following steps: firstly, preparing graphene oxide and then modifying the graphene oxide to obtain a graphene oxide-based curing agent capable of conducting and toughening; and then, blending according to a formula of the conductive glue and curing to obtain a graphene oxide-based epoxy resin composite material. The graphene oxide-based curing agent with capacity of conducting and toughening is obtained by the preparation method; and an epoxy-based composite adhesive material prepared by taking the graphene oxide as the curing agent has good conducting capacity, acid and alkaline resistance, thermal stability and mechanical performance; and the adhesive is suitable for adhering electronic elements.

Owner:HUNAN UNIV

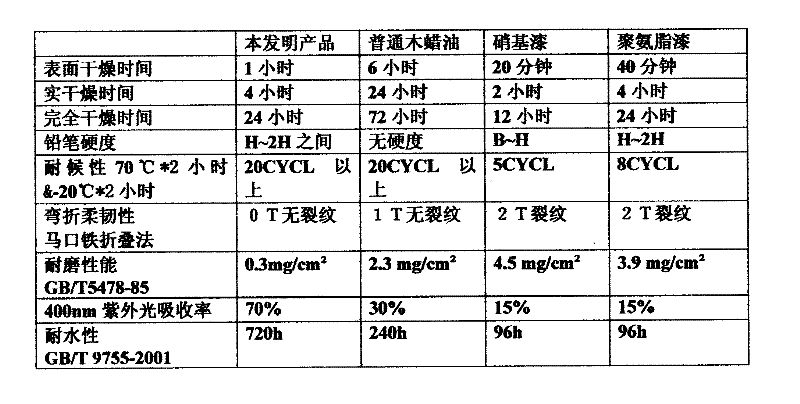

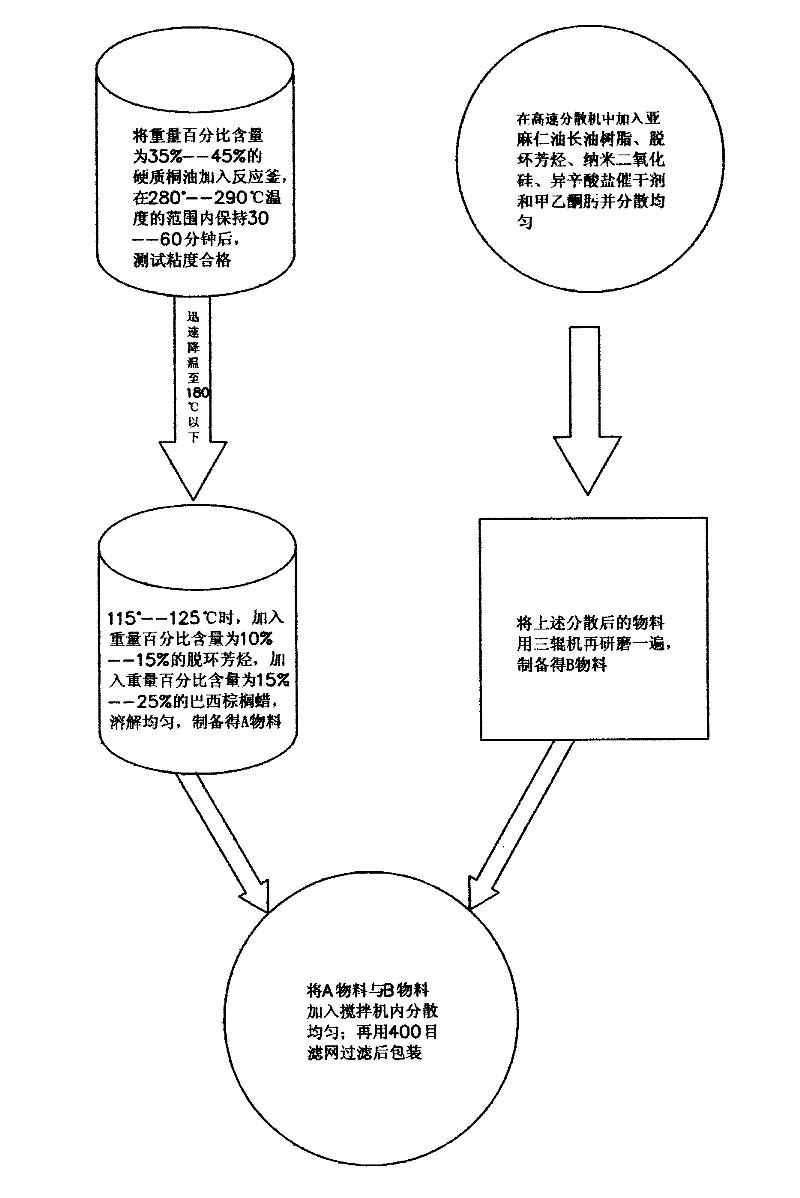

Nano silicon dioxide modified hard wood wax oil and preparation method thereof

InactiveCN102408828AMaintain wood grain penetration protectionAchieve waterproof, mildew, crack and other three protection effectsWax coatingsPolyester coatingsDistillationLinseed oil

The invention discloses a nano silicon dioxide modified hard wood wax oil and a preparation method thereof. The invention aims to overcome the defects of low drying speed and low hardness in the existing wood wax oil, and to be applied to furniture application instead of common wood wax oil or nitrocellulose paint / polyurethane paint. The product comprises the following raw materials in percentage by weight: 35-45% of modified hard tung oil or linseed oil, 15-25% of carnauba wax of which the softening point is 85-95 DEG C, 15-25% of linseed oil long oil alkyd of which the oil length is 78-80% and the solid content is higher than 98%, 3-5% of nano silicon dioxide of which the particle size is 60-80 nm, 20-30% of decyclized aromatic hydrocarbon of which the distillation range is 160-200 degrees, 1-2% of isooctoate compound drying agent and 0.3-0.5% of methylethylketoxime. The preparation method comprises the following steps: preparing a material A, preparing a material B, and mixing the material A and the material B.

Owner:深圳市圣马斯科技有限公司

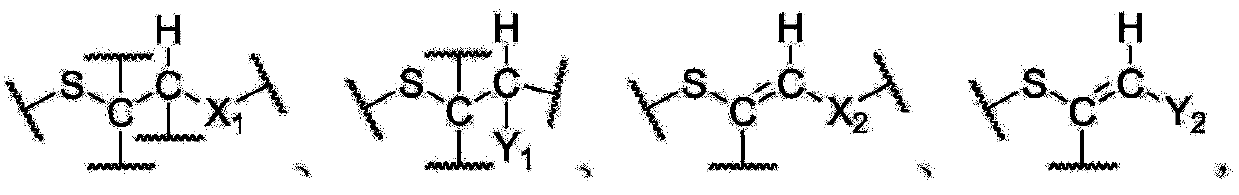

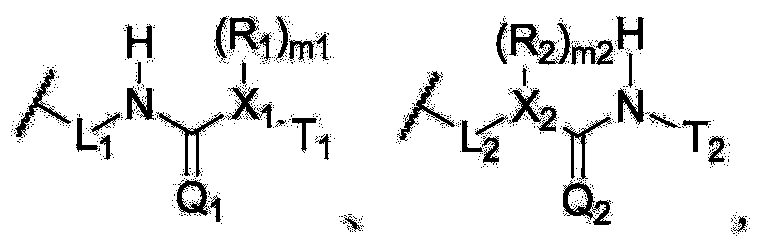

Self-repairing solid-state hybrid dynamic polymer and application thereof

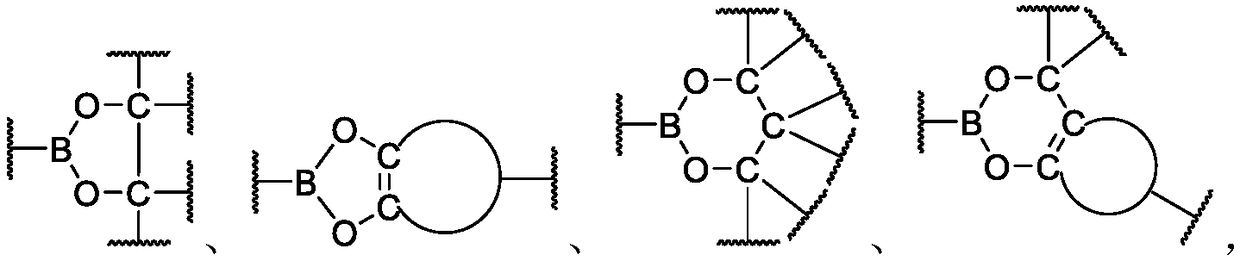

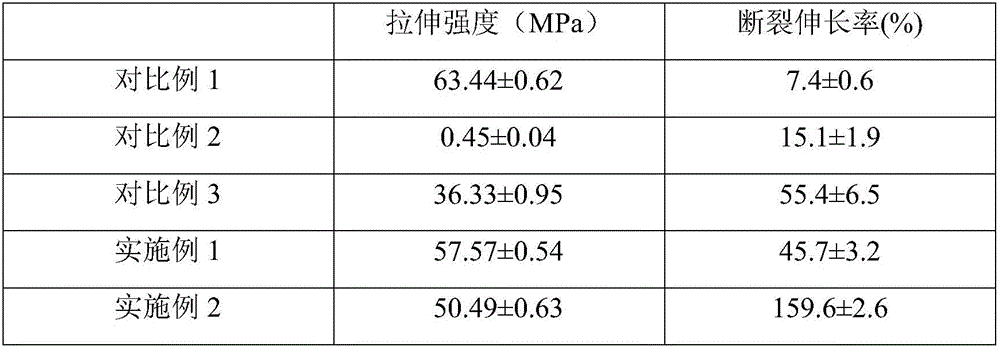

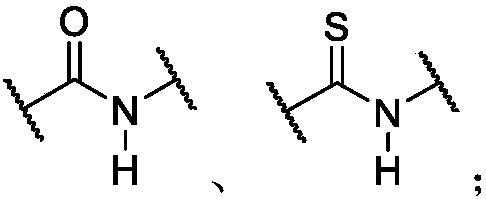

PendingCN109666168ARich dynamic reversible characteristicsVarious forms of activationDevice materialBackbone chain

The invention discloses a self-repairing solid-state hybrid dynamic polymer. The self-repairing solid-state hybrid dynamic polymer contains sulfydryl-Michael addition bond dynamic covalent crosslinking and supermolecular hydrogen bond interaction, wherein the sulfydryl-Michael addition bond dynamic covalent crosslinking reaches above a gel point in at least one crosslinking network; sulfydryl-Michael addition bonds are obtained through sulfydryl-Michael addition reaction between sulfydryl groups and electron-deficient conjugate alkenes / enynes; the supermolecular hydrogen bond interaction contains hydrogen bond interaction involving at least one from side hydrogen bond groups, backbone hydrogen bond groups and other end hydrogen bond groups; with dynamic reversibility, the sulfydryl-Michaeladdition bonds and the supermolecular hydrogen bonds endow the self-repairing solid-state hybrid dynamic polymer with good plasticity, self-repairability, repeatability, reusability and recoverability and ensure that the self-repairing solid-state hybrid dynamic polymer can be widely applied to self-repairing materials, flexible materials, shape memory materials, energy storage device materials and the like.

Owner:厦门天策材料科技有限公司

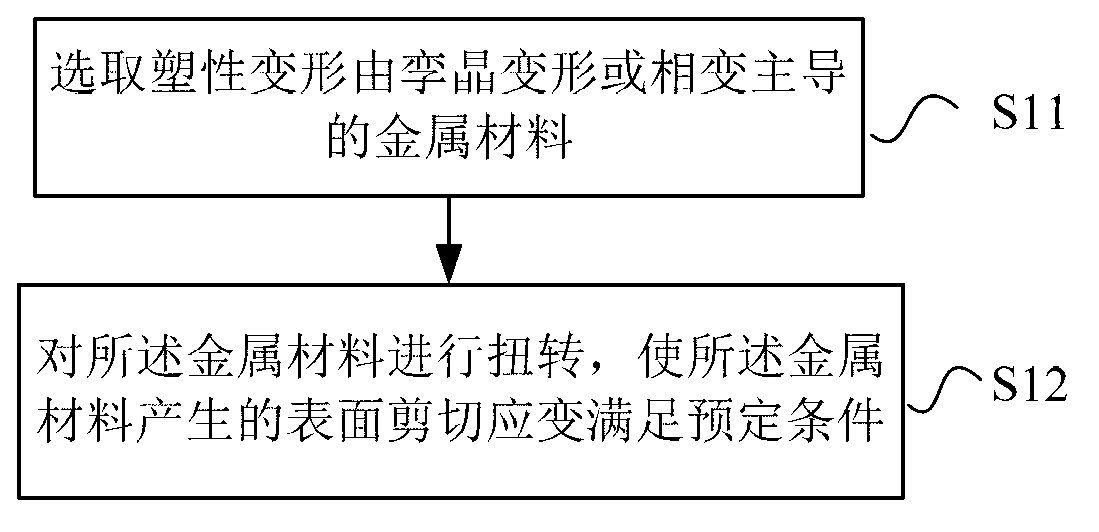

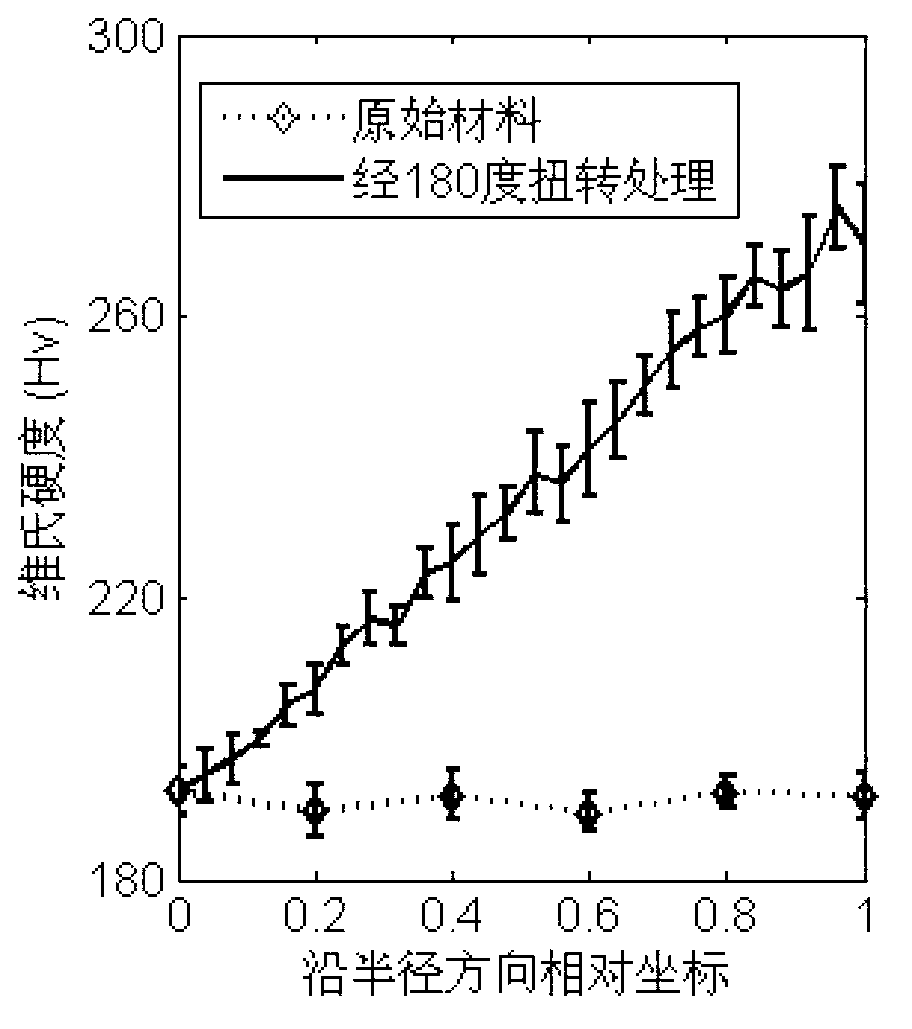

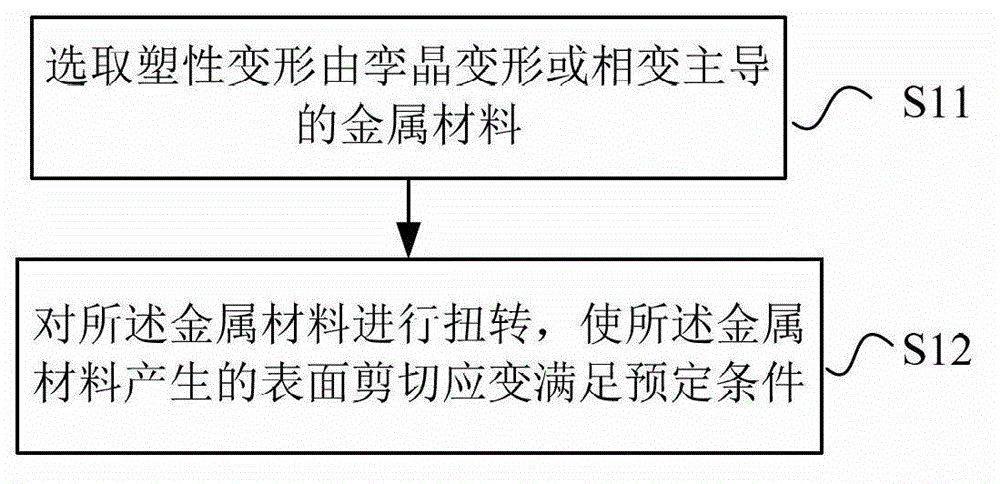

Method for improving intensity of metal material

The invention provides a method for improving the intensity of a metal material. The method comprises the following steps of: selecting the metal material, of which the plastic deformation is guided by twin crystal deformation or phase change; twisting the metal material, so that surface strain generated by the metal material meets predetermined conditions. According to the method provided by the invention, the intensity of the metal material can be improved observably without influences on the tension toughness of the metal material.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

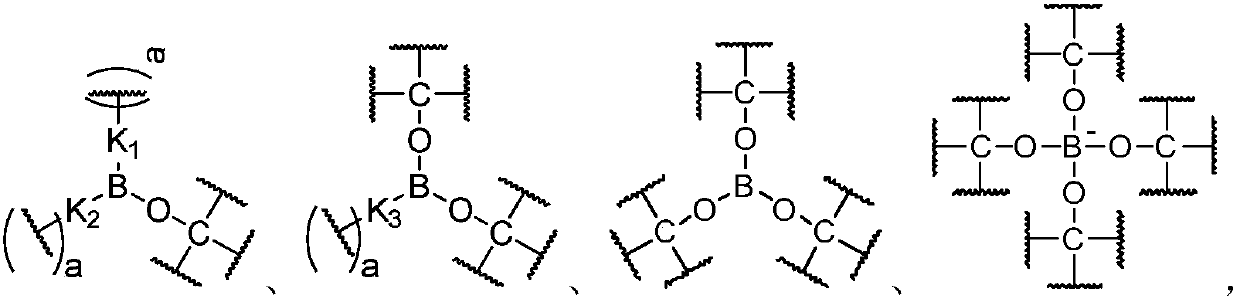

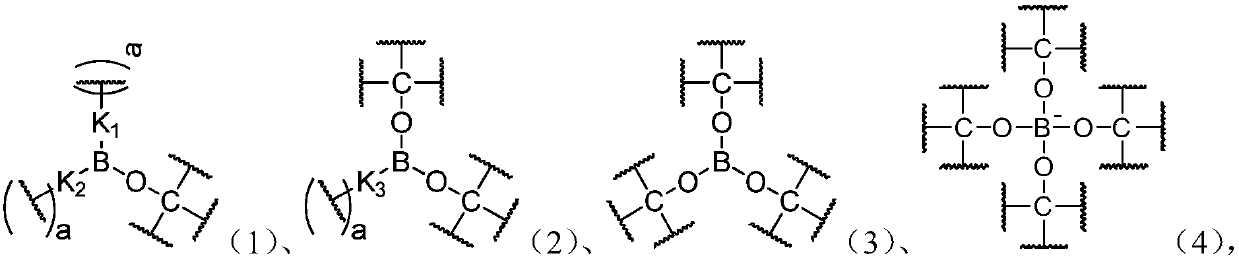

Energy-absorbing method based on dynamic polymer

InactiveCN108341944ADynamicImprove energy absorptionFibre treatmentPolyether coatingsCross-linkHydrogen

The invention discloses an energy-absorbing method based on a dynamic polymer. The method employs a dynamic polymer containing a cyclic organic borate bond and an optional supramolecular hydrogen bondfor energy-absorption, wherein the cyclic organic borate bond exists as a polymeric chain joint and / or cross-linked chain joint for the dynamic polymer and is a necessary condition for the formationor maintenance of the structure of the dynamic polymer. Due to dynamic reversibility of the cyclic organic borate bond, the dynamic polymer has an energy dissipation characteristic; as an energy-absorbing material, the dynamic polymer can provide the good functions of damping, shock absorption, sound insulation, noise abatement, impact resistance and the like; and the dynamic polymer is especiallyapplicable to the body protection of people during exercises, daily life and working, the body protection of the military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

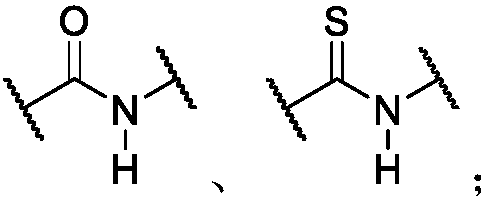

Preparation method of polylactic acid/epoxy soybean oil resin alloy and product

The invention relates to a preparation method and a product of polylactic acid / epoxy soybean oil resin alloy and belongs to the field of biological macromolecular materials. According to the method, epoxy soybean oil, aliphatic dibasic acid and polylactic acid react and are blended, cross-linked epoxy soybean oil resin is introduced to a polylactic acid substrate to prepare the high-performance polylactic acid / epoxy soybean oil resin alloy, the elongation at break of the alloy during tensile failure is 50-350%, and the tensile strength is 3-58 MPa. When the content of polylactic acid serves as a main body, the low-modulus epoxy soybean oil resin remarkably improves the tensile toughness of the polylactic acid. When the content of the epoxy soybean oil resin serves as a main body, the high-strength thermoplastic polylactic acid can endow thermoplasticity for the epoxy soybean oil resin, and the mechanical properties of the epoxy soybean oil resin can be also improved.

Owner:SOUTHWEST UNIVERSITY

Electronic donor type biological carrier and preparation method thereof

InactiveCN108178338APromote growthPromote enrichmentBiological treatment apparatusTreatment with anaerobic digestion processesElectrode potentialStandard electrode potential

The invention discloses an electronic donor type biological carrier and a preparation method thereof. The biological carrier is mainly applied to a low-oxygen suspended carrier biomembrane process. Anelectronic donor with standard electrode potential being less than 100 mV is used as a feature modified functional material and the traditional carrier is modified in a blending modification manner,so that the electronic donor type biological carrier is prepared. The biological carrier provided by the invention is favorable for enrichment of a membrane biological functional flora and improvementon the treatment property of a low-oxygen suspended carrier biomembrane reactor.

Owner:DALIAN UNIV OF TECH

Energy absorption method based on dynamic polymer

InactiveCN109423148ASimple mode of actionImprove energy absorptionCoatingsGraft polymer adhesivesHydrogenEnergy absorption

The invention discloses an energy absorption method based on a dynamic polymer. The energy absorption method employs the dynamic polymer containing at least one second set supramolecular interaction and comprising an optionally first set supramolecular interaction for performing energy absorption, wherein the second set supramolecular interaction includes an ion interaction, an ion-dipole interaction, a subject-object interaction, an ion hydrogen bond interaction, a metallophilic interaction, a dipole-dipole interaction, a halogen bond interaction, a cation-[pi] interaction, an anion-[pi] interaction, a benzene-fluorobenzene interaction, a [pi]-[pi] stacking interaction and a free radical cation dimerization interaction, and the first set supramolecular interaction includes a hydrogen bondinteraction, and a metal-ligand interaction. The dynamic polymer can exhibit energy dissipation characteristics by virtue of the dynamic reversibility of the supramolecular interaction, and can be used as an energy absorbing material to provide functions of good damping, shock absorption, sound insulation, noise reduction, impact resistance, and the like.

Owner:翁秋梅

Long-chain branching polymer-type processing aid and preparation method and application thereof

The invention discloses a long-chain branching polymer-type processing aid. The long-chain branching polymer-type processing aid I is obtained by ring-opening polymerization and polycondensation reaction of the double-hydroxy acid and the lactone sequentially, or the obtained long-chain branching polymer-type processing aid I is further subjected to ring-opening polymerization with the propyl acetate to obtain the long-chain branching polymer-type processing aid II. Because the long-chain branching polymer-type processing aid has the characteristics of long chain branching on the self-structure, the structure of physical cross-linked network similar to rubber can be formed, which can be applied to polyester toughening, in particular, when the long-chain branching polymer-type processing aid is mixed with the PLA, the elongation at break of the PLA matrix can be greatly increased, the cross-linking can be avoided in the preparation process, the transparency and the biodegradability of the PLA can be maintained, and the crystallization rate of the PLA can be effectively improved.

Owner:SICHUAN UNIV

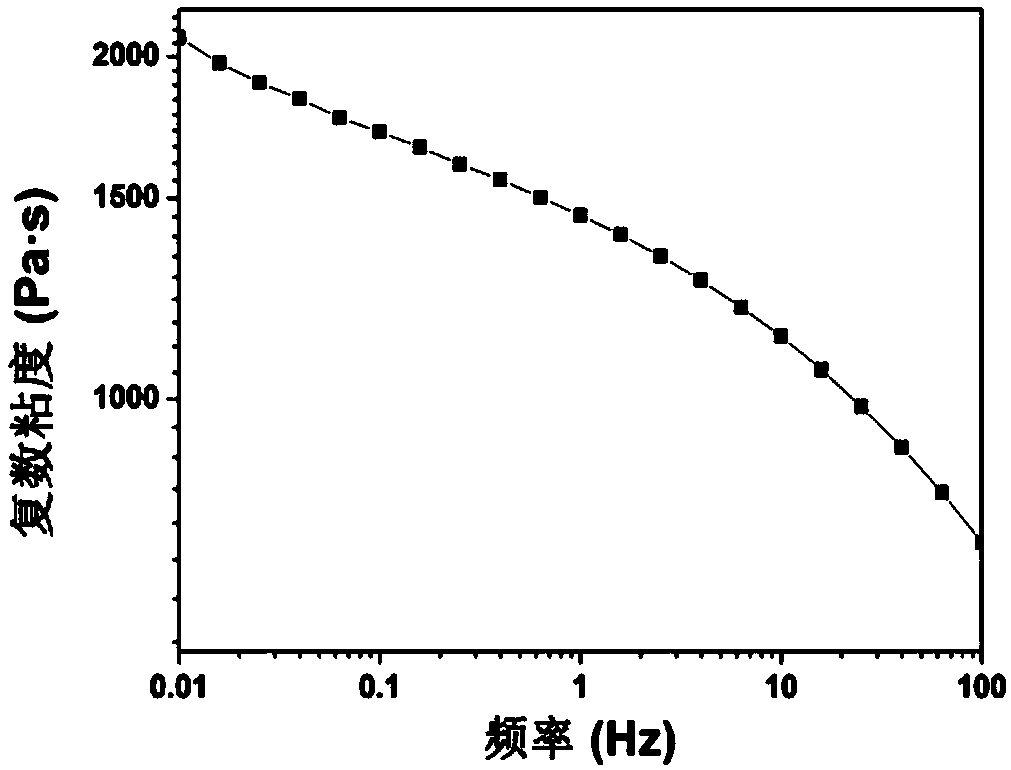

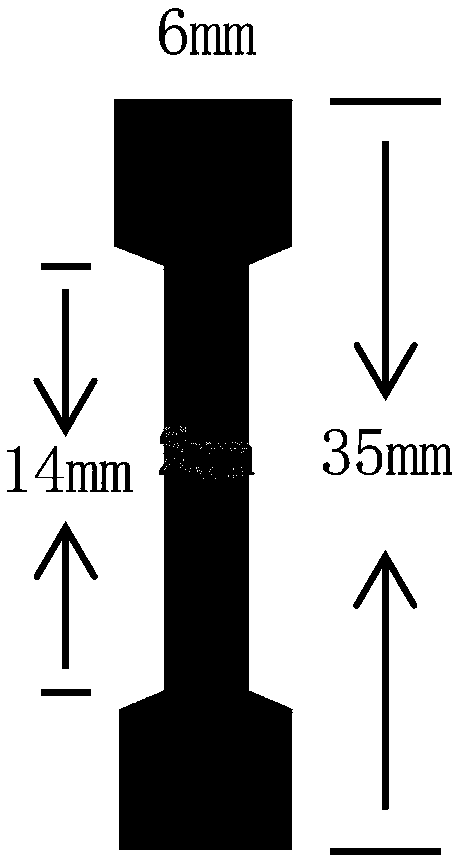

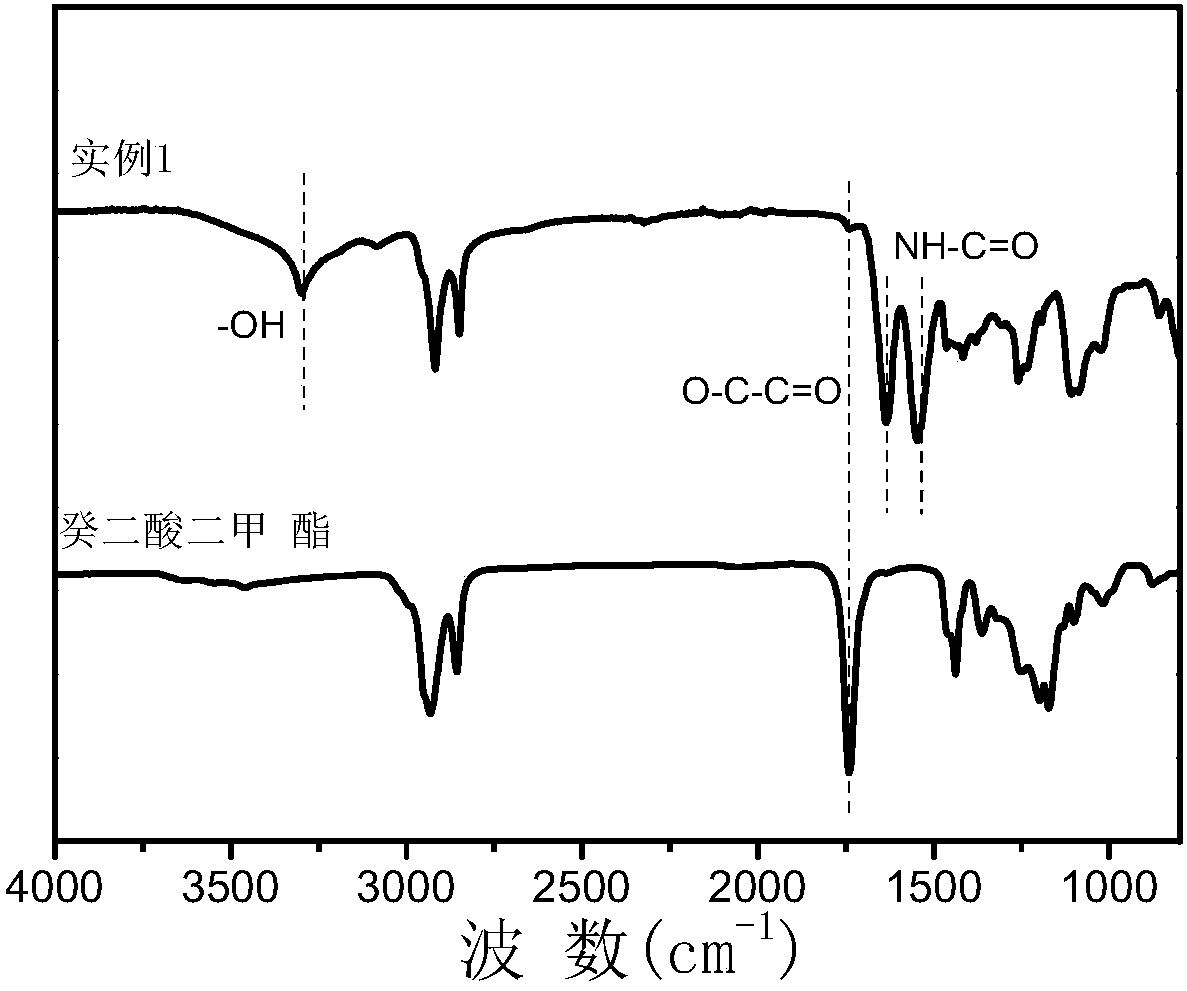

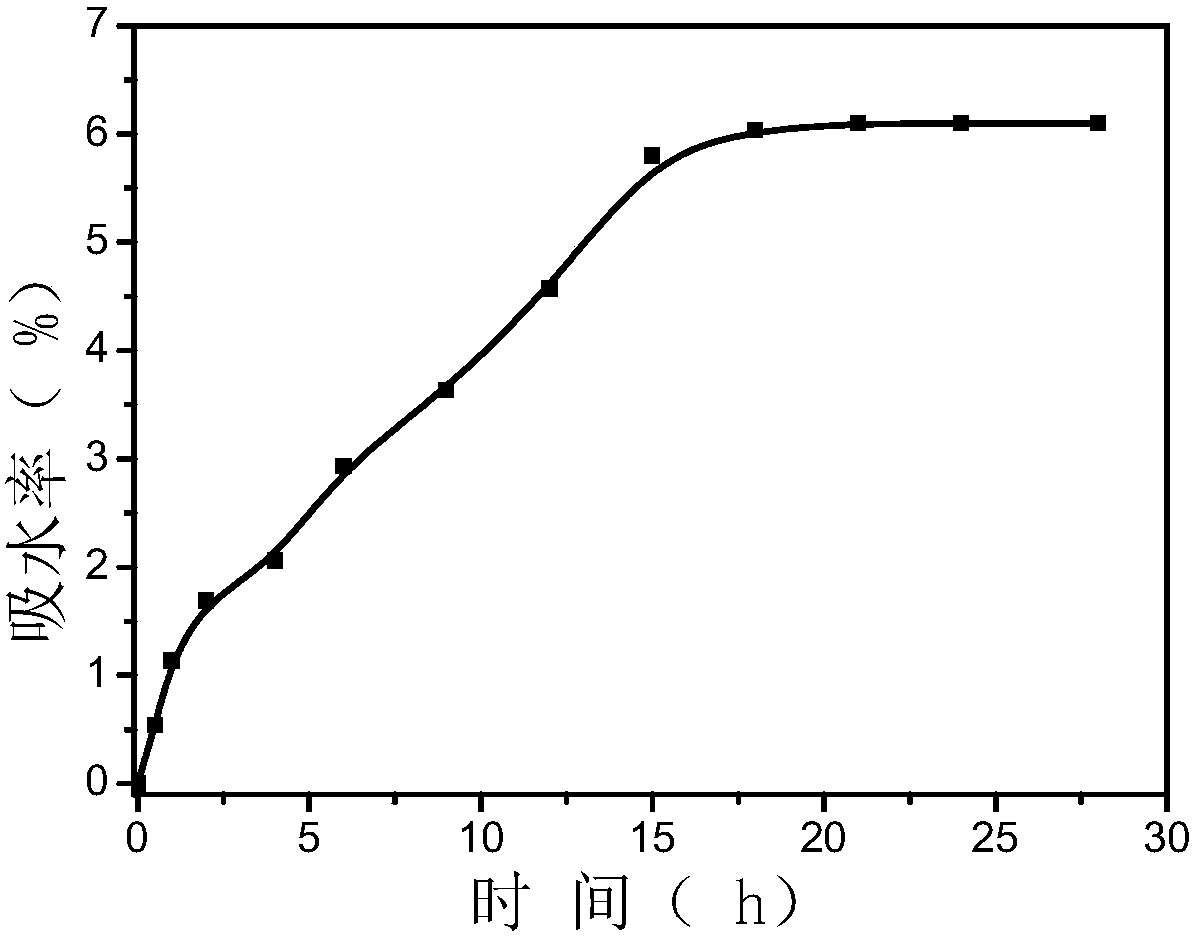

High-strength and high-humidity-response poly-oxyamide and preparation method thereof

The invention relates to high-strength and high-humidity-response poly-oxyamide and a preparation method thereof. The preparation method of poly-oxyamide comprises the steps that a dimethyl compound and an alcohol amine compound are heated, dissolved and evenly stirred to form a reaction solution; a basic catalyst is added to the reaction solution, sealed and heated at 68-72 DEG C, and a reactionis conducted for 2-24 h; then a reaction system is heated to 95-105 DEG C, and a vacuum pumping reaction is conducted through a water pump for 1-3 hours; then the reaction system is heated to 145-155DEG C, and a vacuum pumping reaction is conducted through an oil pump for 0.5-1.5 hours; finally, the reaction system is heated to 210-230 DEG C, a vacuum pumping reaction is conducted through the oilpump for 0.5-1.5 hours, and poly-oxyamide is obtained. The prepared poly-oxyamide has high strength of polyamide and the humidity response at the same time, the toughness after water absorption is greatly improved, and accordingly poly-oxyamide has wider application prospects on functional materials.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of polypropylene composite material with high strength and high toughness

ActiveCN102532706AImprove tensile toughnessImprove impact toughnessFine chemicalPolypropylene composites

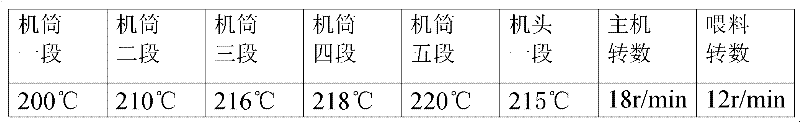

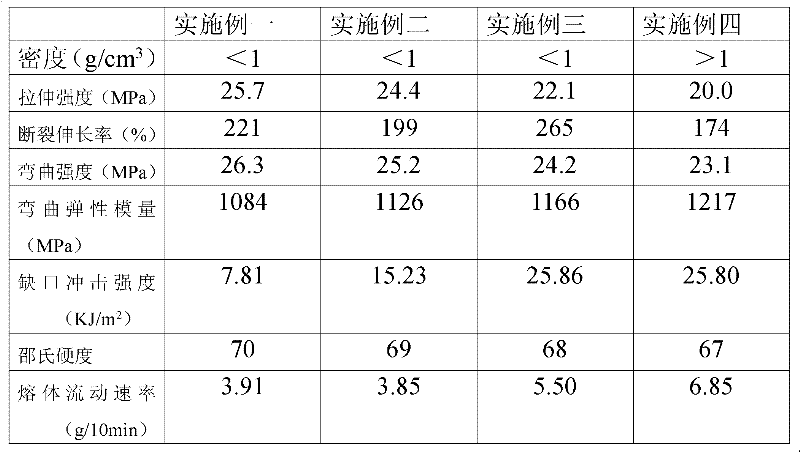

A preparation method of a polypropylene composite material with high strength and high toughness belongs to the fields of chemical engineering and fine chemical industry. The preparation method comprises the following steps: weighing components according to the following mass percents: 10-45% of homopolymerized polypropylene, 10-25% of copolymerized polypropylene, 15-40% of copolymerized polypropylene, 9-16% of POE, 5-35% of polypropylene reinforcing toughening modifiers, 0.15-0.4% of nucleating agents, 0.25-0.55% of anti-oxidants, and 0.2-0.5% of lubricants; adding the weighed materials into a high-speed mixer, fully mixing at a speed of 1000 r / min for two minutes, releasing the materials; adding the mixed materials into a hopper of a double screw extruder, extruding the materials according to technological parameters to obtain the composite material particles. According to the polypropylene composite material of the invention, the crystallization state of polypropylene is changed by components of the polypropylene reinforcing toughening modifier, the ethane-octylene copolymer, the nucleating agent and the like, and thus mechanical properties such as strength and toughness of the composite material are changed.

Owner:CHANGCHUN DALI NANO TECH DEV

Modified bamboo fiber enhanced PBT (polybutylene terephthalate) resin based cabinet board and preparation method thereof

InactiveCN106084841AHigh strengthGood compatibilityConjugated synthetic polymer artificial filamentsNon-woven fabricsMethacrylateFiber

The invention discloses a modified bamboo fiber enhanced PBT (polybutylene terephthalate) resin based cabinet board. The bamboo-plastic board is prepared from the following raw materials in parts by weight: 50 to 60 parts of modified bamboo fiber, 20 to 25 parts of PBT resin, 1 to 2 parts of hydroxyl silicone oil, 3 to 5 parts of maleic anhydride grafted polyester, 2 to 3 parts of asphalt-based mesocarbon microbeads, 0.1 to 0.2 part of antioxidants, 5 to 8 parts of ionic liquid and 1 to 2 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

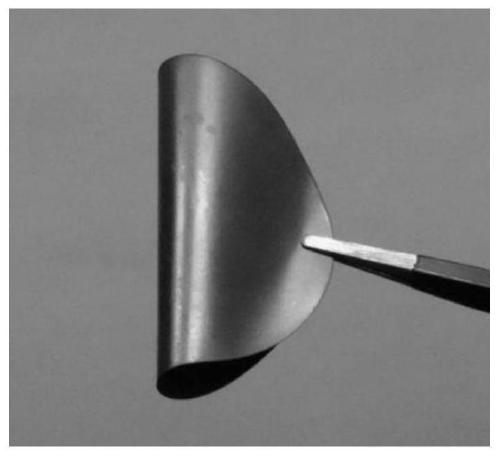

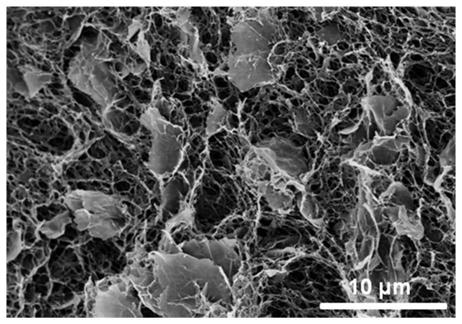

High-toughness high-thermal-conductivity PBONF-based composite film and preparation method thereof

The invention provides a high-toughness high-thermal-conductivity PBONF-based composite film and a preparation method thereof, and belongs to the technical field of heat-conducting composite materials. The high-toughness high-thermal-conductivity PBONF-based composite film comprises PBONF and a heat-conducting nano material; the PBONF forms a three-dimensional net structure, and the heat-conducting nano material is located in the three-dimensional net structure; the PBONF is in a forked geometrical shape. The high-toughness high-thermal-conductivity PBONF-based composite film has the advantages of low density, high toughness, high thermal conductivity and the like, can replace existing aviation aluminum alloy, reduces the weight of aerospace vehicles, and meanwhile, has higher heat dissipation efficiency and excellent structural reliability.

Owner:HUNAN UNIV

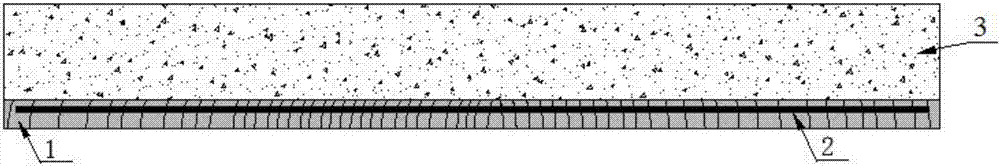

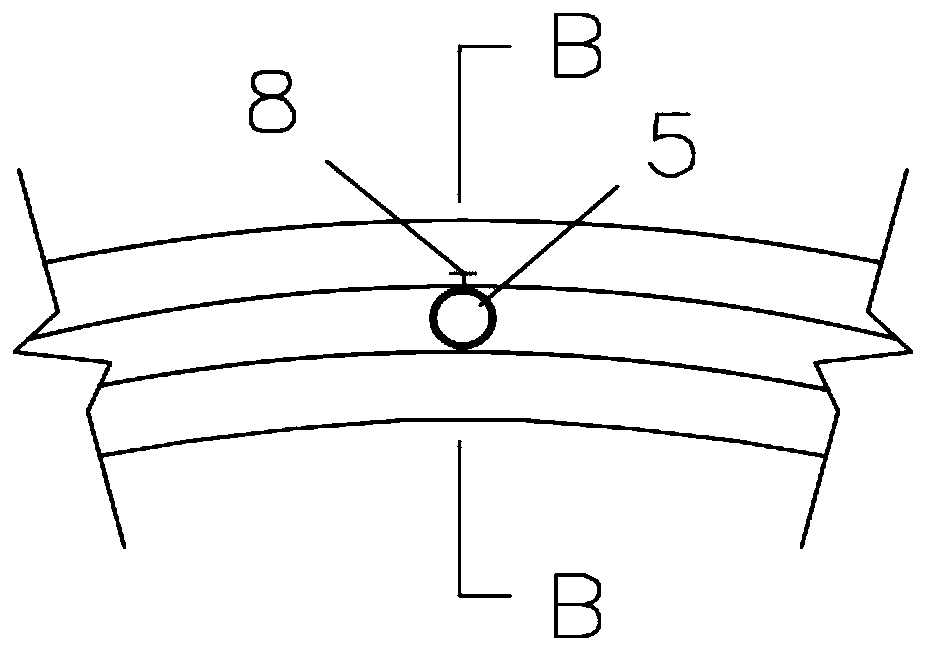

Reinforcing structure and reinforcing method of sea sand steel bar concrete beam

PendingCN106968455ASolve the carrying capacitySolve Excessive CracksClimate change adaptationBuilding repairsConcrete beamsRebar

The invention relates to the technical field of building engineering and discloses a reinforcing structure of a sea sand steel bar concrete beam. The reinforcing structure comprises a sea sand concrete layer and a reinforcing layer which are sequentially arranged in an adjoining mode from top to bottom. The reinforcing layer comprises a tensile steel bar and an ultrahigh toughness cement-based composite material layer covering the tensile steel bar. The invention further discloses a reinforcing method of the sea sand steel bar concrete beam. The reinforcing method comprises the steps that sea sand concrete on the periphery of the steel bars on the tensile side is cleaned up, the ultrahigh toughness cement-based composite material layer is poured outside the exposed tensile steel bar, and the poured ultrahigh toughness cement-based composite material layer is made to cover the tensile steel bar. According to the reinforcing structure and reinforcing method of the sea sand steel bar concrete beam, ECC (Engineered Cementitious Composites) are utilized to separately reinforce the sea sand steel bar concrete beam, or FRP (Fiber Reinforce Polymer)-ECC is utilized to reinforce the sea sand steel bar concrete beam in a combined mode, so that the bearing capacity of the sea sand steel bar concrete beam is effectively repaired, the ductility of the structure is improved, the situation that chloride ions and harmful media in the external environment corrodes the tensile steel bar is resisted, and the steel bar is prevented from being rusted for the second time, so that the durability of the structure is improved.

Owner:SHENZHEN UNIV

Garbage bag and preparation technology thereof

The invention discloses a garbage bag and a preparation technology thereof. According to the technical scheme, the garbage bag is characterized by being prepared from components in parts by weight as follows: 50-90 parts of polyethylene, 5-10 parts of metallocene, 5-10 parts of thermoplastic resin, 3-5 parts of a pigment and 3-5 parts of perfume, wherein polyethylene comprises 40-60 parts of low-pressure polyethylene and 10-30 parts of linear polyethylene, and thermoplastic resin is EVA. Produced films are uniform in quality and excellent in tensile toughness through cooperation of the components.

Owner:台州市瑞康日用品科技有限公司

Combined energy absorption method and application thereof

The invention discloses a combined energy absorption method and application thereof. According to the combined energy absorption method, a combined hybrid dynamic polymer containing at least two typesof dynamic covalent bonds and optional hydrogen bonds is adopted for energy absorption. According to the combined hybrid dynamic polymer, dynamic covalent bonds with different dynamic properties andoptional hydrogen bonds are introduced, so that a dynamic polymer material with a wide controllable range, rich structures and various properties can be prepared. When the polymer material is physically impacted, the polymer material has the effects of absorbing, dissipating, dispersing and the like on impact energy. The dynamic polymer is used as an energy absorption material for energy absorption, and has the effects of damping, buffering, impact resistance protection, noise elimination, sound insulation, shock absorption and the like.

Owner:翁秋梅

Durable concrete and preparation method

The invention belongs to the technical field of building materials and provides durable concrete and a preparation method. The preparation method comprises the following steps: preparing polypropylene / polyvinyl alcohol compound porous fibers where nano silicon dioxide is dispersed uniformly; then adsorbing sodium alginate; and uniformly mixing the mixture with cement, sand, macadam, a water reducer, an air entraining agent, calcium carbonate, glucolactone and water to prepare durable concrete. Compared with a conventional method, as the prepared durable concrete, polypropylene and polyvinyl alcohol organic fibers have tensile ductility and calcium alginate is formed, so that the interfacial bonding of organic fibers and inorganic concrete is good, the stress transfer speed is high, the shrinkage stress of the concrete which is hardened can be transferred, and the concrete is prevented from cracking, so that the concrete has good durability.

Owner:张玉英

Method for improving intensity of metal material

The invention provides a method for improving the intensity of a metal material. The method comprises the following steps of: selecting the metal material, of which the plastic deformation is guided by twin crystal deformation or phase change; twisting the metal material, so that surface strain generated by the metal material meets predetermined conditions. According to the method provided by the invention, the intensity of the metal material can be improved observably without influences on the tension toughness of the metal material.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

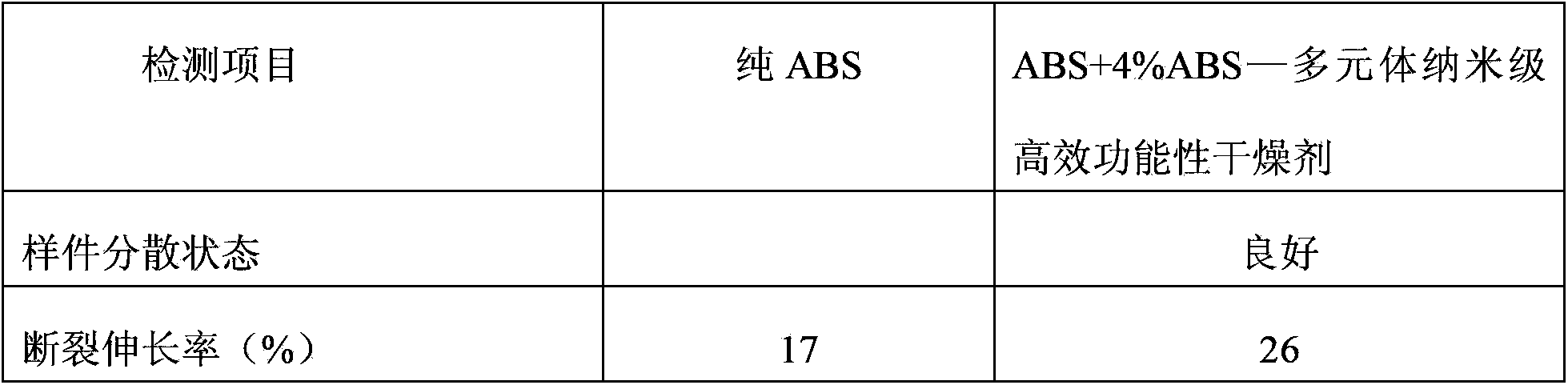

Preparation method of acrylonitrile-butadiene-styrene (ABS) resin multi-component nano functional drying agent

The invention relates to a preparation method of an acrylonitrile-butadiene-styrene (ABS) resin multi-component nano functional drying agent, belonging to the field of preparation of nano environment-friendly functional materials. The preparation method comprises the following steps: after preparing materials according to a certain weight ratio, 1, putting nano calcium carbonate into a mixing machine, and performing low-speed mixing; 2, putting an antistatic agent into the mixing machine, performing low-speed mixing for 3 minutes, and performing antistatic treatment on the nano calcium carbonate; 3, putting a coupling agent into the nano calcium carbonate subjected to antistatic treatment, performing low-speed mixing for 10 minutes, and performing primary calcium carbonate coating treatment; 4, putting ABS and remaining assistant into the nano calcium carbonate subjected to primary coating treatment, performing high-speed mixing for 5 minutes, and performing secondary calcium carbonate coating treatment; and 5, transferring the mixed materials into a double screw extruder, extruding, and cutting into uniform particles. According to the invention, the production procedures are simplified, the energy consumption is lowered, the production efficiency is enhanced, and the tensile toughness, processing flowability and aging resistance of the product are improved; and the addition of the drying agent within a certain proportional range can not increase the weight of the product.

Owner:天成高新纳米复合材料有限公司

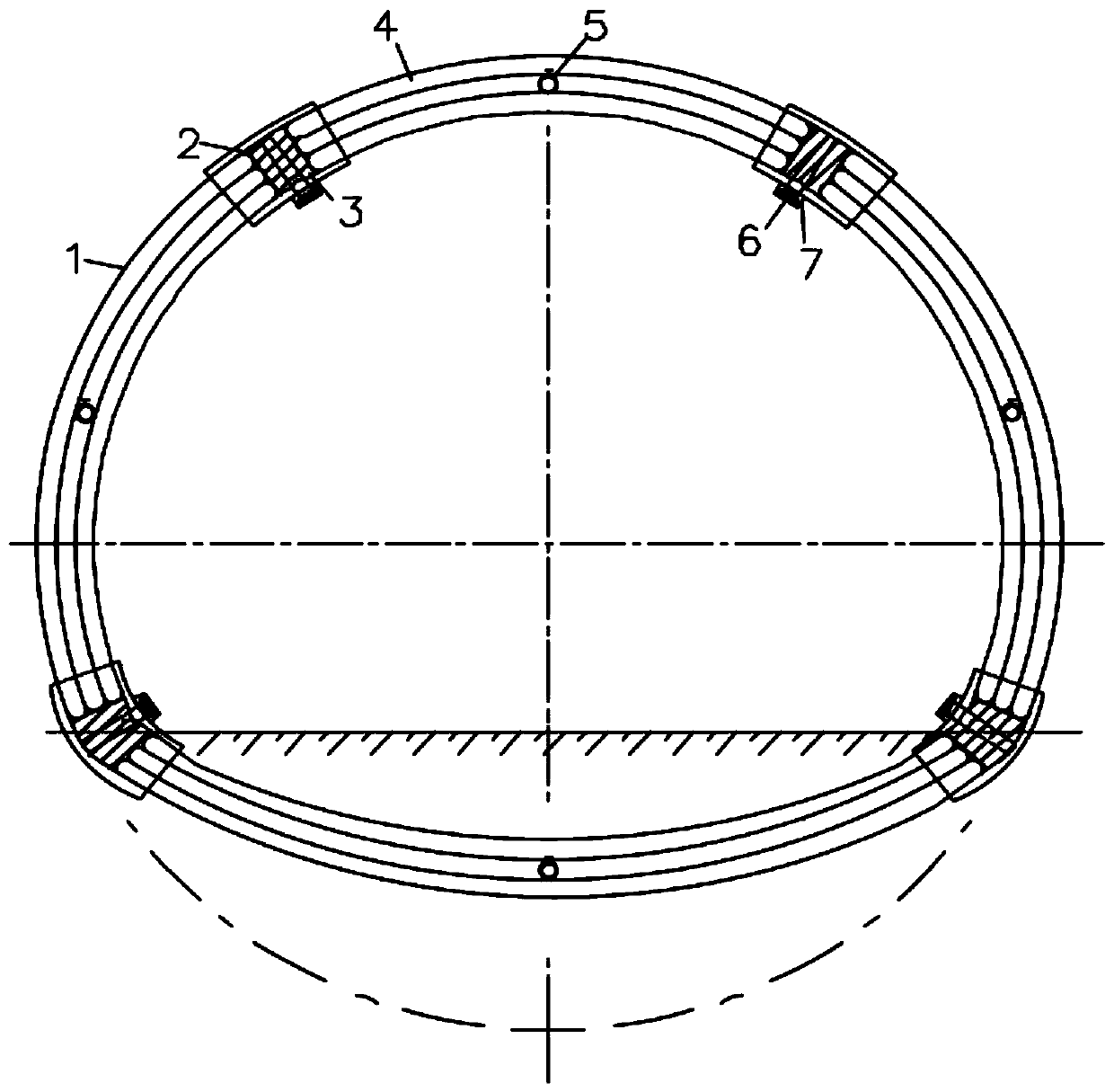

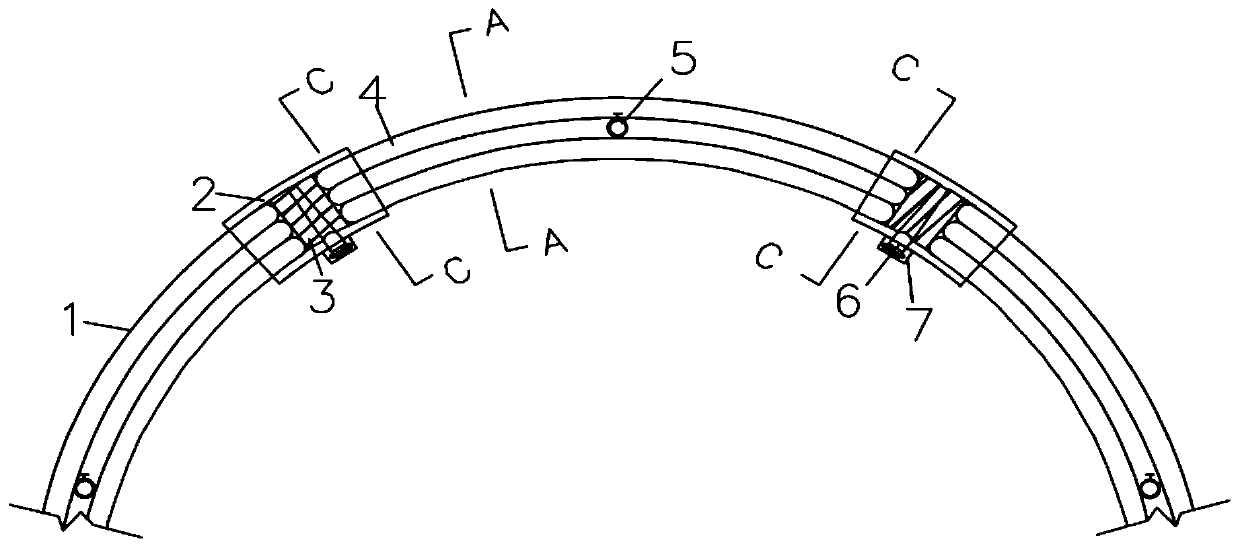

Water bag filling pipe type combined arch frame and construction process thereof

ActiveCN110700863AWith micro-expansionImprove tensile toughnessUnderground chambersTunnel liningFiberWhole body

The invention discloses a water bag filling pipe type combined arch frame and a construction process thereof. The water bag filling pipe type combined arch frame comprises multiple sections of steel pipes; the multiple sections of steel pipes are connected through connecting sleeves to form an arched-shaped cross section; multiple high-performance fiber bag bodies are pasted in each section of steel pipe and are opened in advance at the position of a water injection hole and the two ends of each section of steel pipe to play a role of fixing the bag bodies; liquid is injected into the high-performance fiber bag bodies; and meanwhile, an anti-bending reinforcing steel bar is arranged on the inner arc side of the steel pipe arch frame so as to improve the bending bearing capacity of the archframe. By adopting the water bag filling pipe type combined arch frame, high-concentration fiber cement slurry is injected into gaps of the connecting sleeves, so that the whole device forms the combined arch frame; and the inner bag bodies of the water bag filling pipe type combined arch frame have the micro-expansion property, and the multiple bag bodies are mutually extruded, fill an inner cavity of each section of steel pipe and are in wet connection with the cement at a connector to form a whole body so as to fully fill the whole arch frame.

Owner:SHANDONG JIANZHU UNIV

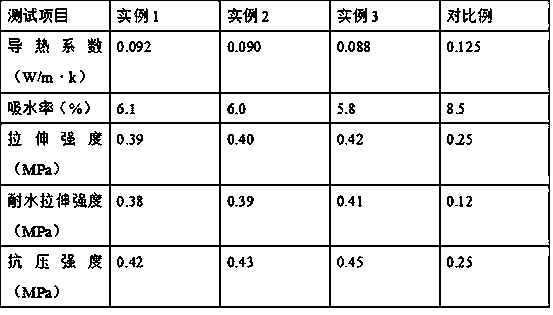

Method for preparing inorganic wall body insulating material

The invention relates to a method for preparing an inorganic wall body insulating material, and belongs to the technical field of construction material preparation. According to the method, perlite isexpanded by high-temperature calcination, so that pores inside the perlite can be increased; sodium hydroxide is utilized to react with the main ingredient silicon dioxide in the expanded perlite under a high-temperature high-pressure condition; the perlite and vegetable oil are mixed and subjected to rancidifying treatment, so that organic acid generated in rancidification is used for dissolvingand removing acid-soluble ingredients in the perlite, the modified perlite, filtrate containing sodium silicate and a gelatin solution are mixed to perform hydrolysis and condensation polymerizationunder the effect of acid by utilizing the sodium silicate, and silicon hydroxyl generated in hydrolysis reacts with amino and carboxyl in gelatin and the hydrogen bond generated in hydroxy active siteon the surface of the modified perlite besides self condensation, and the three-dimensional network structure achieves an effect of dispersive stress when the inorganic wall body insulating materialis subjected to external stress effect. The inorganic wall body insulating material has excellent cracking resistance, and has a wide application prospect.

Owner:常州蓝森环保设备有限公司

Energy-absorbing method based on dynamic polymer

InactiveCN108341945ADynamicImprove energy absorptionPolyurea/polyurethane coatingsCross-linkEnergy absorption

The invention discloses an energy-absorbing method based on a dynamic polymer. The method is characterized in that the dynamic polymer containing an inorganic borate bond produced by a reaction of aninorganic boric acid element with a monohydroxy element and an optional supramolecular hydrogen bond is used as an energy-absorbing material for energy-absorbing protection, wherein the inorganic borate bond exists as a polymeric chain joint and / or cross-linked chain joint for the dynamic polymer and is a necessary condition for the formation or maintenance of the structure of the dynamic polymer.Due to dynamic reversibility of the dynamic inorganic borate bond, the dynamic polymer has the characteristics of energy dissipation and energy absorption; as an energy-absorbing material, the dynamic polymer can provide the good functions of damping, shock absorption, sound insulation, noise abatement, impact resistance, high toughness and the like; and the dynamic polymer is especially applicable to the body protection of people during exercises, daily life and working, the body protection of the military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

Functional master batch for improving polyethylene packaging film toughness

The invention relates to the field of functional master batches, and discloses a functional master batch for improving polyethylene packaging film toughness. The functional master batch is prepared from the following components in parts by weight: 80-100 parts of carrier resin, 20-25 parts of toughener, 10-15 parts of low-density polypropylene resin, 1-2 parts of curing agent, 0.6-1.0 part of oxidized polyethylene wax, 0.6-0.8 part of white carbon black, 0.5-0.8 part of antioxidant 1076 and 0.5-1.0 part of coupling agent. The carrier resin is a polyethylene resin; and the toughener is composed of milk fibers, corn fibers and graphene. Under the synergic actions of the characteristics of stretching resistance, high strength and scratch resistance of the milk fibers, corn fibers, low-density polypropylene and the like, the functional master batch improves the stretching toughness and puncture resistance of the polyethylene packaging film product, enhances the aging resistance and mold resistance of the polyethylene packaging film product and prolongs the service life of the polyethylene packaging film.

Owner:长兴天晟能源科技有限公司

Preparation method of polylactic acid/polycaprolactone/polyformaldehyde blend

The invention relates to a preparation method of a polylactic acid / polycaprolactone / polyformaldehyde blend and belongs to the field of high polymer materials. The blend is prepared by mixing polylactic acid, polycaprolactone and polyformaldehyde. The polylactic acid used in the invention is bio-based polymer resin taking renewable biological resources as raw materials and has abundant raw materialsources, good biocompatibility and biodegradability and no pollution to the environment. The polycaprolactone is also biodegradable synthetic polymer resin, has good processing properties, and biocompatibility similar to that of the polylactic acid, and is widely applied to the aspects of medical fields, biodegradable packaging plastics and the like. Therefore, the prepared blending material belongs to an environment-friendly material. Meanwhile, according to the preparation method disclosed by the invention, by adding a small amount of polyformaldehyde, the tensile toughness of the polylactic acid / polycaprolactone blending material can be greatly improved.

Owner:HAINAN UNIVERSITY +1

Modified bamboo fiber reinforced high density polyethylene-based kitchen cabinet board containing soybean protein fibers and production method of modified bamboo fiber reinforced high density polyethylene-based kitchen cabinet board

InactiveCN106189311AHigh strengthEasily damagedConjugated synthetic polymer artificial filamentsNon-woven fabricsLow-density polyethyleneMethacrylate

The invention discloses a modified bamboo fiber reinforced high density polyethylene-based kitchen cabinet board containing soybean protein fibers. A bamboo-plastic board is produced by using the following raw materials in parts by weight: 50 to 60 parts of modified bamboo fibers, 2 to 3 parts of polyacrylonitrile based carbon fiber, 10 to 12 parts of soybean protein fiber, 30 to 40 parts of high density polyethylene, 4 to 5 parts of maleic anhydride grafted polyethylene, 1 to 2 parts of hydrogenated castor oil, 0.1 to 0.2 part of antioxidant, 5 to 8 parts of ionic liquid and 1 to 2 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

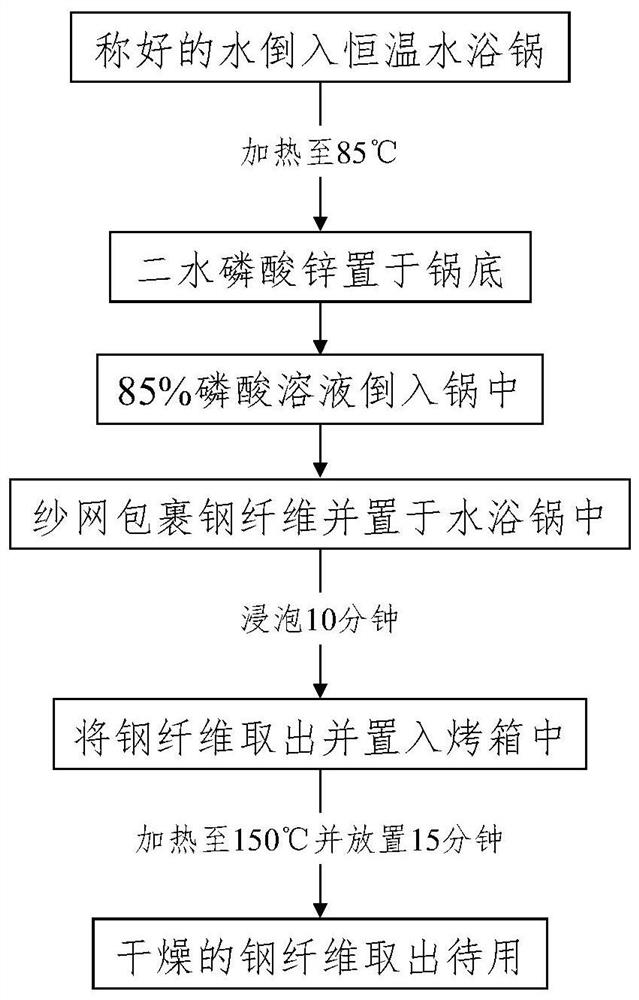

Carbide slag fly ash stabilized soil material for roads and preparation method thereof

InactiveCN112897982ASustainable development and utilizationImprove tensile toughnessSolid waste managementCalcium silicateAluminite

The invention discloses a carbide slag fly ash stabilized soil material for roads and a preparation method thereof, the carbide slag fly ash stabilized soil material comprises the following components by mass percentage: 4%-12% of carbide slag, 8%-17% of fly ash, 77%-85% of dry soil, 0.1% of polypropylene fiber and 0.004% of an active activator. Crystalline crystals such as hydrated calcium silicate, hydrated calcium aluminate, ettringite and the like are generated through a pozzolanic reaction of the carbide slag and the fly ash cementing material, and meanwhile, the tensile strength of the stabilized soil is improved by doping the polypropylene fibers. A filling material is provided for a road base and a subbase, the problems of accumulation and storage of the carbide slag and the fly ash, insufficient utilization rate, soil and environment pollution and the like can be effectively solved, the industrial waste residues are reasonably recycled and secondarily developed, and the material is very beneficial to the development of the country, society and enterprises no matter from the perspective of social benefit, environmental benefit and economic benefit, and is also beneficial to the sustainable development and utilization of natural resources.

Owner:CHANGAN UNIV +1

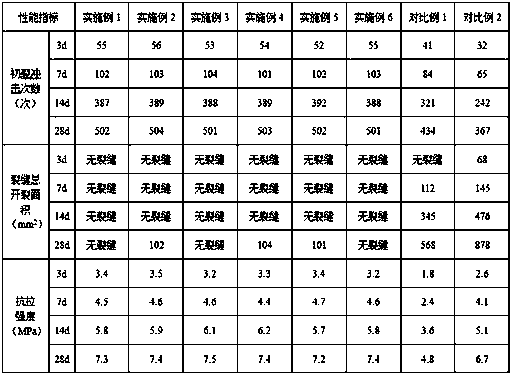

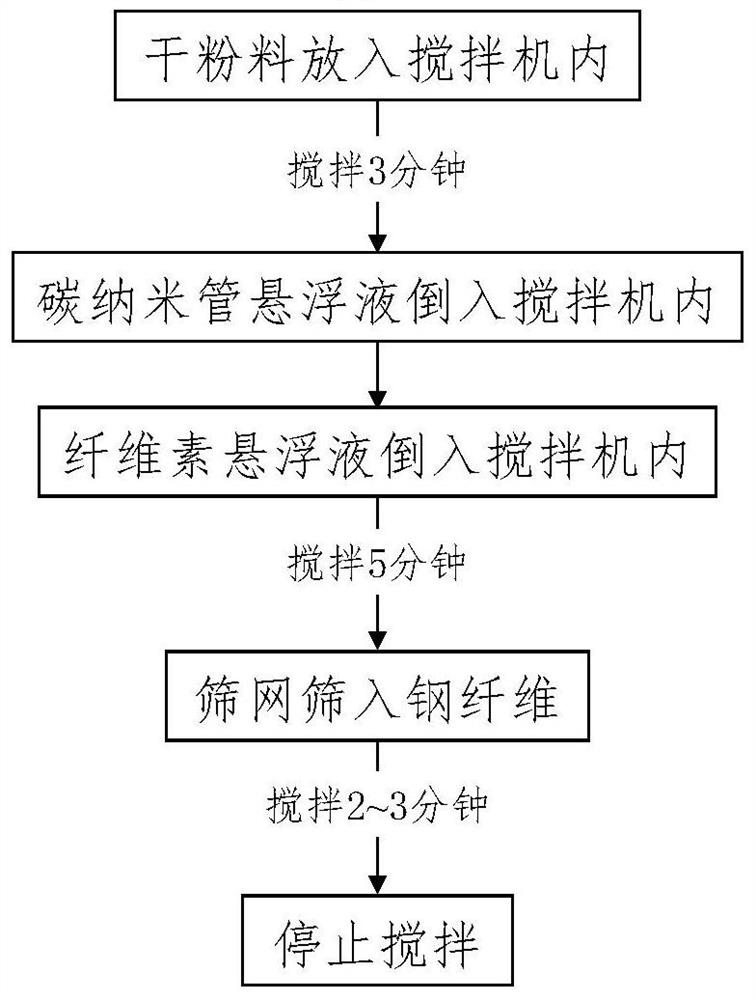

Toughening method of ultrahigh-performance concrete

ActiveCN112028514AHigh tensile toughnessGood toughening effectCeramic shaping apparatusSurface modificationCarbon nanotube

The invention discloses a toughening method of ultrahigh-performance concrete. According to the invention, carbon nanotubes, cellulose and zinc phosphate surface-modified steel fibers are added into raw materials of the ultrahigh-performance concrete and are uniformly mixed to obtain a mixture, and the mixture is poured along the main stress direction of a component, so fiber orientation in the ultrahigh-performance concrete component tends to the main stress direction. The carbon nanotubes and the cellulose are added, so higher tensile strength and toughness are obtained compared with concrete obtained by independently adding the carbon nanotubes or the cellulose; and a better toughening effect is obtained by adopting two fiber toughening technologies, namely steel fiber orientation and steel fiber surface modification, compared with concrete obtained by independently using one fiber toughening technology. By integrating four measures, the cracking strength of the ultrahigh-performance concrete is improved by 77.4%, the tensile strength of the ultrahigh-performance concrete is improved by 129.5%, and the peak deflection of the ultrahigh-performance concrete is improved by 113.6%,so it is indicated that the scheme obviously enhances the cracking resistance and tensile toughness of the ultrahigh-performance concrete.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

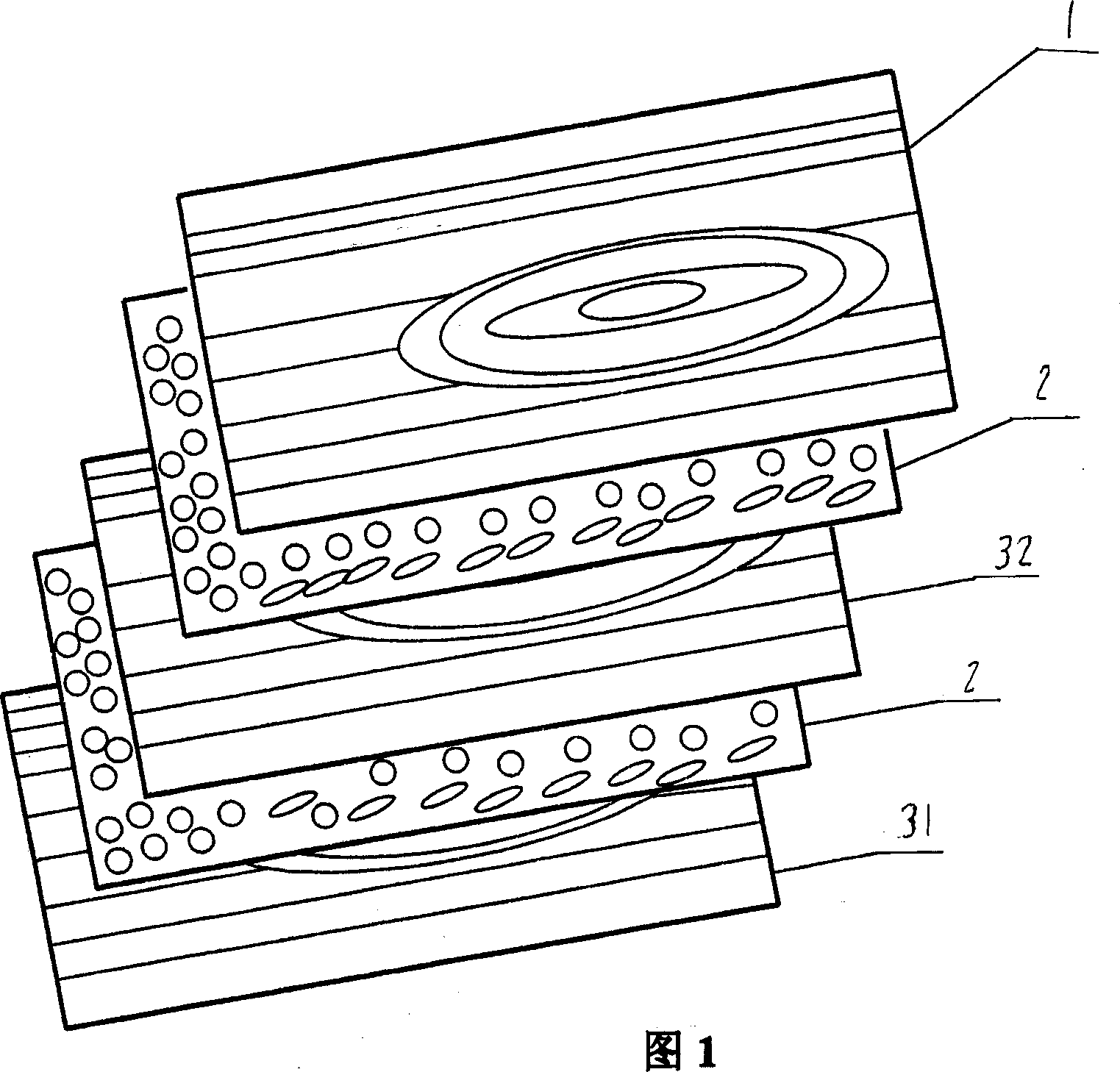

Bamboo-wood structure floor

The invention relates to a novel bamboo and wooden structure floor. A core layer made of non-wooden material is arranged between a bamboo surface layer and a solid wood layer, and a solid wood middle layer is arranged in the middle of the core layer made of non-wooden material. The core layer is made of artificial fibre or artificial fibre fabric, natural fiber or natural fiber fabric, synthetic fiber fabric, etc. The loading is 10-440g / m2 and the thickness is 0.1-2mm. With the non-wooden material filled between the bamboo layer and the solid wood layer, the invention improves the strength and the deformation resistance of the floor, and is provided with funny and beautiful texture, natural and true elasticity.

Owner:杨大伟

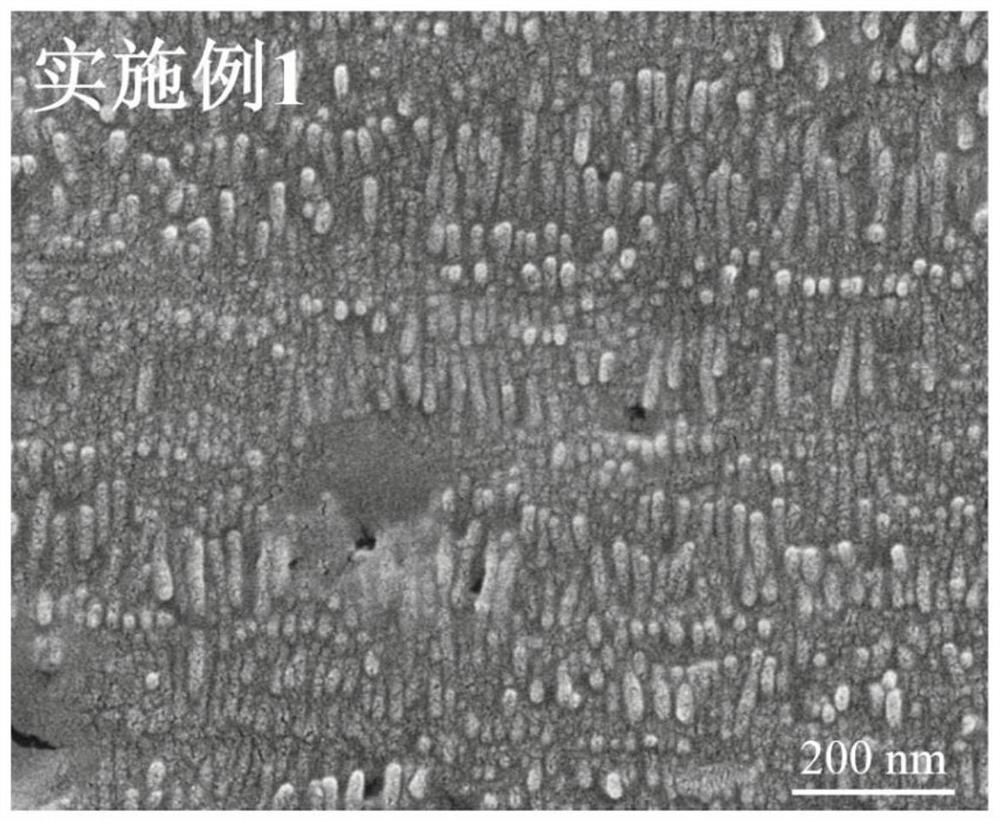

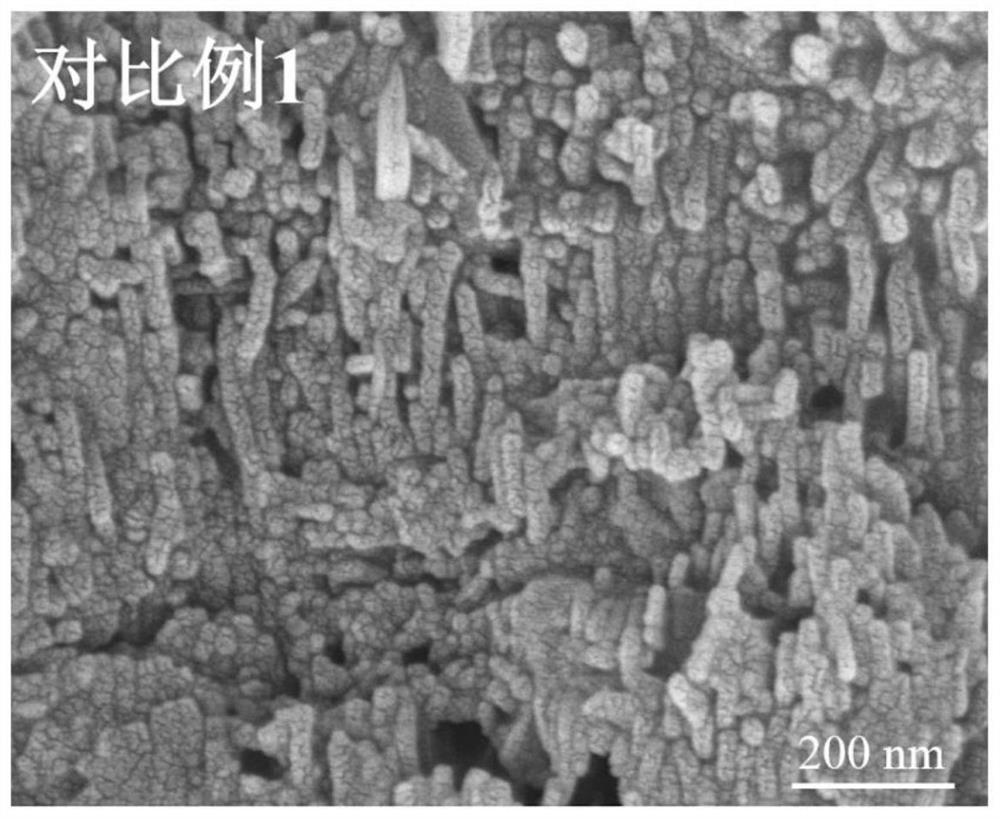

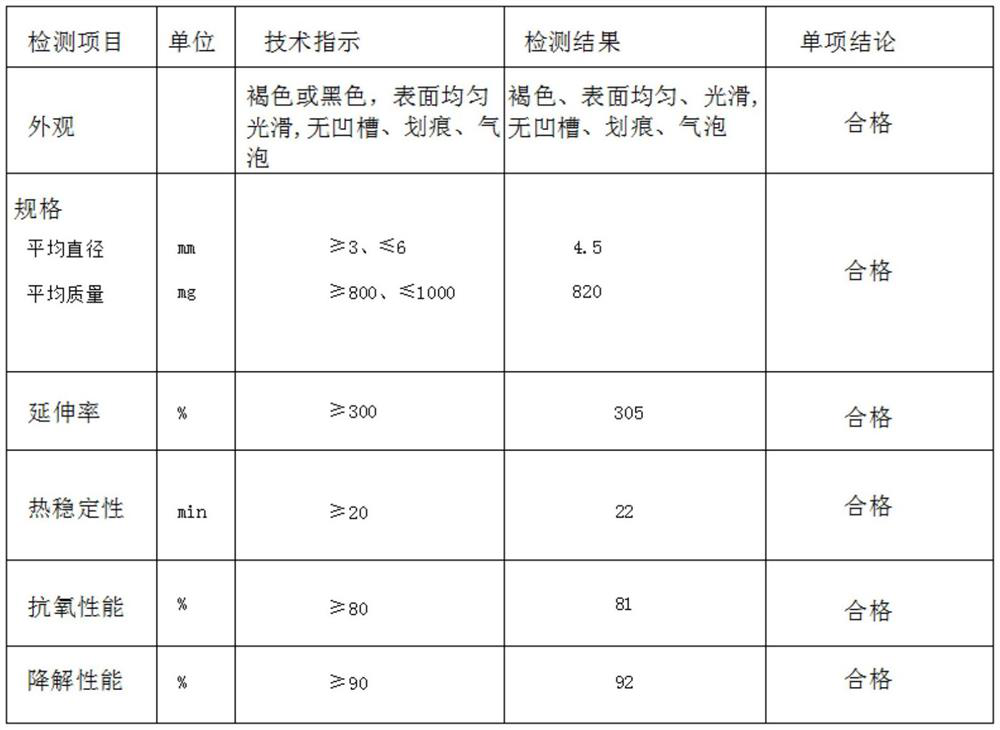

High-toughness polypropylene and preparation method thereof

The invention belongs to the technical field of polymer processing, and particularly relates to high-toughness polypropylene and a preparation method thereof. The polypropylene is only composed of pure isotactic polypropylene, the axial tensile strength of the polypropylene is 50-60MPa, and the elongation at break of the polypropylene is 700-800%. According to the high-toughness polypropylene andthe preparation method thereof, the concept of grain refinement in metal materials is applied to isotactic polypropylene material processing for the first time, and meanwhile the influence of grain orientation is considered. The preparation method of the high-toughness polypropylene comprises the steps that polypropylene melt is stretched at a high speed at a certain temperature, molecular chain orientation is promoted, then high-speed cooling is conducted immediately, the melt is solidified, and a polypropylene product with a high-density and strong-orientation microcrystalline structure is prepared. Meanwhile, the obtained polypropylene has the large elongation at break and shows ultrahigh toughness under the condition that the high tensile strength is guaranteed.

Owner:ZHENGZHOU UNIV

Preparation process of recyclable coffee residue plant fiber polypropylene particles

InactiveCN113388200AImprove performanceImprove the mixing effectExpanded polystyreneChlorinated polyethylene

The invention belongs to the technical field of polypropylene particle preparation, particularly relates to a preparation process of recyclable coffee residue plant fiber polypropylene particles, and provides the following scheme aiming at the problems that an existing polypropylene particle preparation mode is complex, plant fiber preparation is not adopted, and the environmental protection performance is poor. The preparation method comprises the following preparation steps: S1, preparing raw materials, wherein the raw materials comprise 35-40 parts of coffee residue powder, 60-80 parts of a polypropylene resin, 2-5 parts of a compatilizer, 4-8 parts of a toughening agent component, 1-3 parts of a diffusant, 1-3 parts of maleic anhydride, 0.7-1.6 parts of an anti-uv agent, 3-6 parts of an antioxidant component, 1-2 parts of white oil and 0.1-0.5 part of a lubricant, and the toughening agent component comprises polypropylene, expanded polystyrene and chlorinated polyethylene. According to the invention, coffee residue is mixed for preparation so as to reuse the waste coffee residue, the prepared polypropylene particles contain fiber components, and the performance of the material is improved.

Owner:深圳市科思飞科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com