Self-repairing solid-state hybrid dynamic polymer and application thereof

A self-healing, polymer technology, applied in the field of smart polymers, can solve problems such as non-recyclability, lack of structural dynamic reversibility in common covalent structures, poor plasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

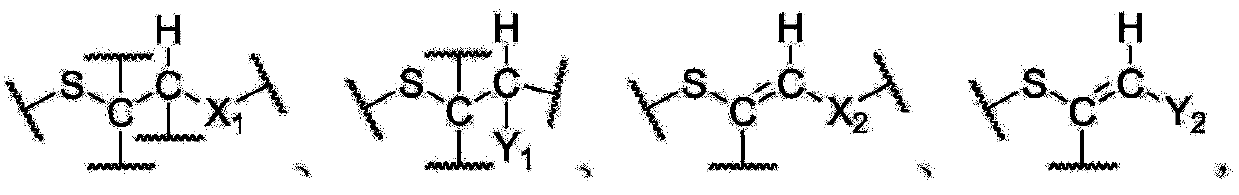

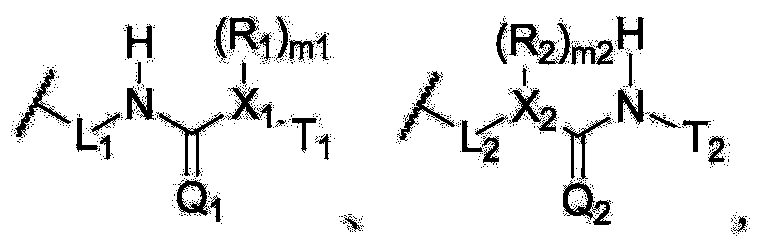

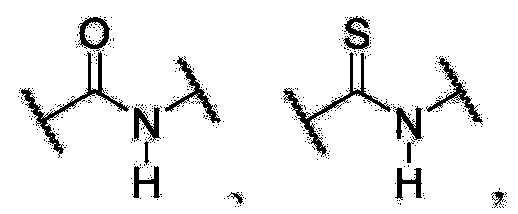

[0252] In the preparation process of the hybrid dynamic polymer, for the hybrid dynamic polymer with the first network structure, it can utilize at least one compound (I) and at least one compound (II) to participate in the formation of mercapto-Michaelga Forming a bond to obtain a hybrid crosslinked network; or utilizing at least one compound (III), or participating in at least one compound (I) and / or at least one compound (II) to generate a mercapto-Michael addition bond to obtain Hybrid crosslinked network; either utilizing at least one compound (IV), or its combination with compound (II) and / or compound (V). In any combination of the above compounds, one or more compounds (V) can be optionally added to jointly participate in the formation of a cross-linked network. Any one of the compound combinations includes at least one compound containing a hydrogen bond group and / or a compound capable of forming a hydrogen bond group through a reactive group in the compound.

[0253]...

Embodiment 1

[0327] With tetrahydrofuran as solvent and 1,8-diazabicycloundec-7-ene as catalyst, 1,4-benzenedithiol and allyl methacrylate with a molar ratio of 1:2 are passed through Mercapto-Michael addition reaction to obtain diolefin-containing monomer 1. Under the catalysis of triethylamine, the reaction of isobutanol and 3-isothiocyanate group-1-propene in equimolar ratio produces the olefin monomer 2 containing thiocarbamate group.

[0328] Add 50ml of methyl hydrogen-containing silicone oil (molecular weight: 20000) into the three-necked flask, the molar equivalent of 10mol% of the above-mentioned diolefin monomer 1 and 40mol% of the diolefin monomer 2 relative to the side group silicon hydrogen content of the methyl hydrogen-containing silicone oil, and then add 2.0 mL of 1% Pt(dvs)-xylene solution was used as a hydrosilylation catalyst, and the temperature was raised and maintained at 80° C., and reacted for 24 hours under the protection of nitrogen, and a dynamic polymer was obt...

Embodiment 2

[0330] Using tetrahydrofuran as a solvent and hexylamine as a catalyst, diols are prepared by mercapto-Michael addition reaction of equimolar ratio of hydroxyl acrylate and 2-mercaptoethanol; using aqueous sodium hydroxide as a solvent and tetrabutylsulfuric acid Ammonium hydrogen is used as a catalyst, and the epoxy monomer containing a dynamic covalent structure is prepared by stirring and reacting epichlorohydrin with the above diol at 30°C for 3 hours; using hexylamine as a catalyst, the aminoethyl methyl Diamines were prepared by mercapto-Michael addition reaction between acrylate and 2-aminoethanethiol.

[0331] Weigh 4 parts by mass of foaming agent Celogen-OT, 0.5 parts by mass of surfactant Pluronic L-64, and 5 parts by mass of toluene, stir and mix evenly, then add it to 80 parts by mass of the above-mentioned epoxy monomer at a temperature of 65°C With 20 parts by mass of tert-butyl (oxirane-2-ylmethyl) carbamate, after mixing evenly at high speed, add 12 parts by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com