High-toughness polypropylene and preparation method thereof

A polypropylene, high-toughness technology, applied in the field of high-toughness polypropylene and its preparation, can solve the problems of affecting optics, density, crystal form change elongation at break, modulus and tensile strength reduction, etc., and achieve high tensile strength. Toughness, improved elongation at break, effect of high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

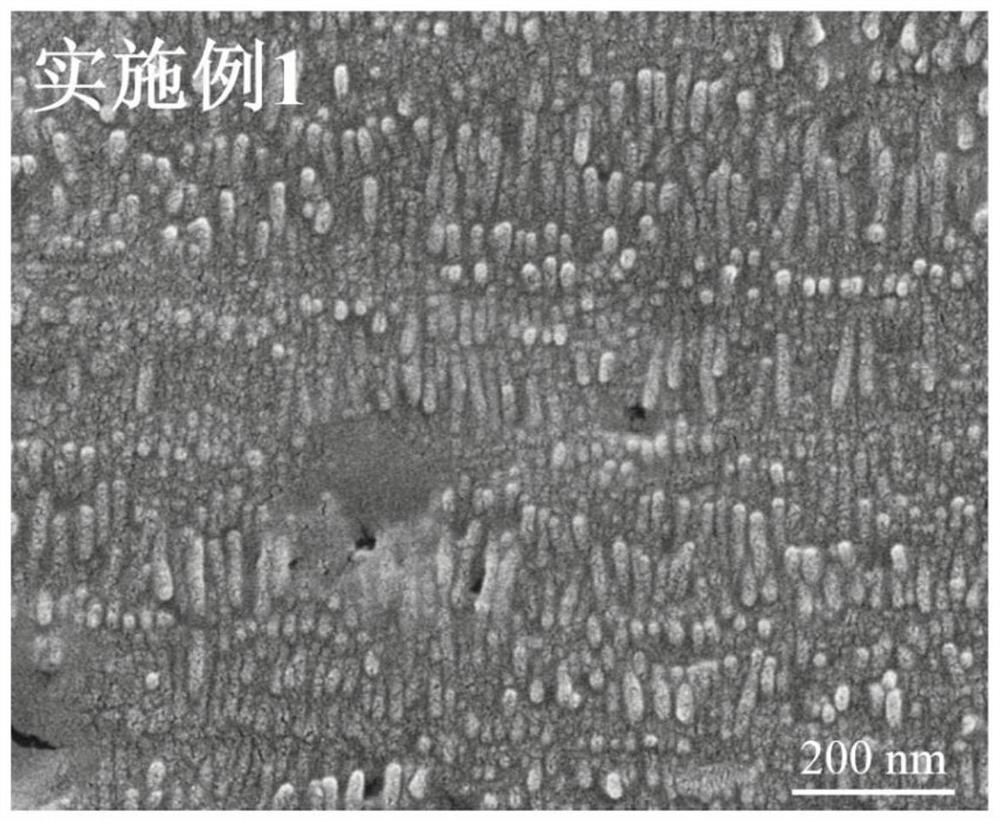

Embodiment 1

[0039] A kind of preparation of high tenacity polypropylene, operation steps are as follows:

[0040] (1) The isotactic polypropylene pellets are molded into a prefabricated film with a thickness of 1mm, and the cutting size is 45mm×20mm, and then installed and fixed on the melt stretching equipment;

[0041](2) Heat the prefabricated film from room temperature to 200°C at a heating rate of 20°C / min to completely melt and keep it warm for 10 minutes to eliminate the thermal history;

[0042] (3) Stop heating, cool at a cooling rate of 10°C / min, and when the temperature of the isotactic polypropylene melt drops to 150°C, immediately implement melt stretching at a stretching rate of 20s -1 , the stretch ratio is 20, and the molecular chain is oriented and deformed;

[0043] (4) Immediately after the stretching stops, high-speed liquid nitrogen cooling is performed at a cooling rate of about 130°C / s, and the melt solidifies to obtain high-toughness polypropylene.

[0044] SAXS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com