Toughening method of ultrahigh-performance concrete

An ultra-high-performance concrete technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems that ultra-high-performance concrete cannot bear, tensile and crack resistance limit its application, and large tensile stress, etc., to achieve tensile toughness Enhancement, high tensile toughness, good toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

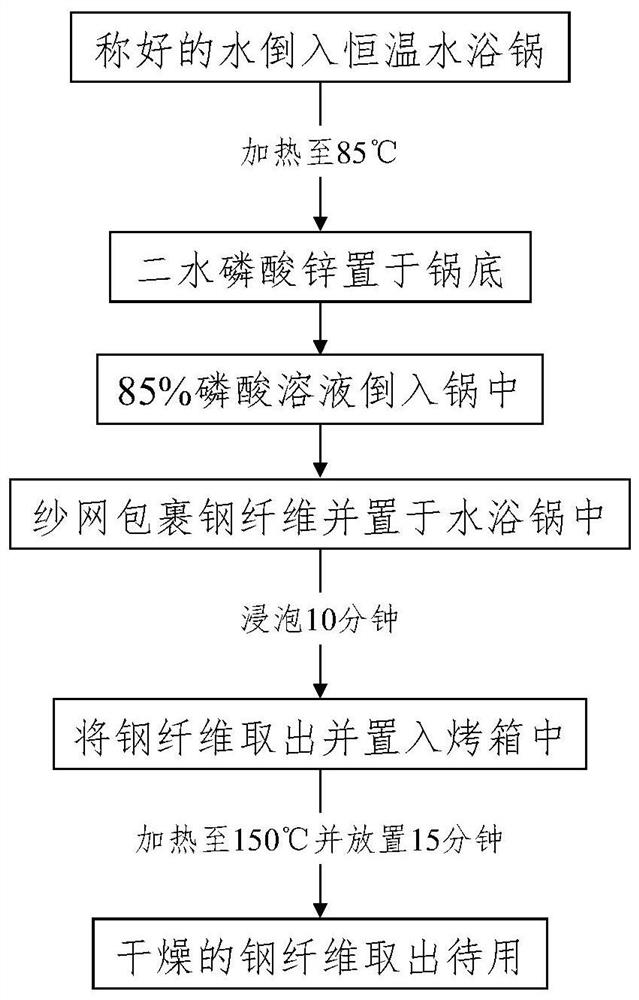

[0023] S1, such as figure 1 shown

[0024] 1. Preparation of modifying reagent: 0.46wt% zinc phosphate dihydrate, 0.91wt% 85% H 3 PO 4 Solution, and 98.63wt% water, add the required amount of water calculated according to the weight into the constant temperature water bath, then heat the water to 85°C and keep the constant temperature; under the constant temperature state, put the solid powder of zinc phosphate dihydrate in the water bath Bottom of the pot, while adding H 3 PO 4 Solution, configure the modifying reagent;

[0025] 2. Put the steel fiber to be modified in gauze to facilitate movement and prevent contamination by zinc phosphate powder. Put the steel fiber wrapped in gauze into the modification reagent and take it out after about 10 minutes; the steel fiber taken out is in a wet state and needs Place it in an electric blast drying oven at 150°C for about 15 minutes to ensure that the steel fibers become completely dry, thereby preparing steel fibers with zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com