Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Improve cracking strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

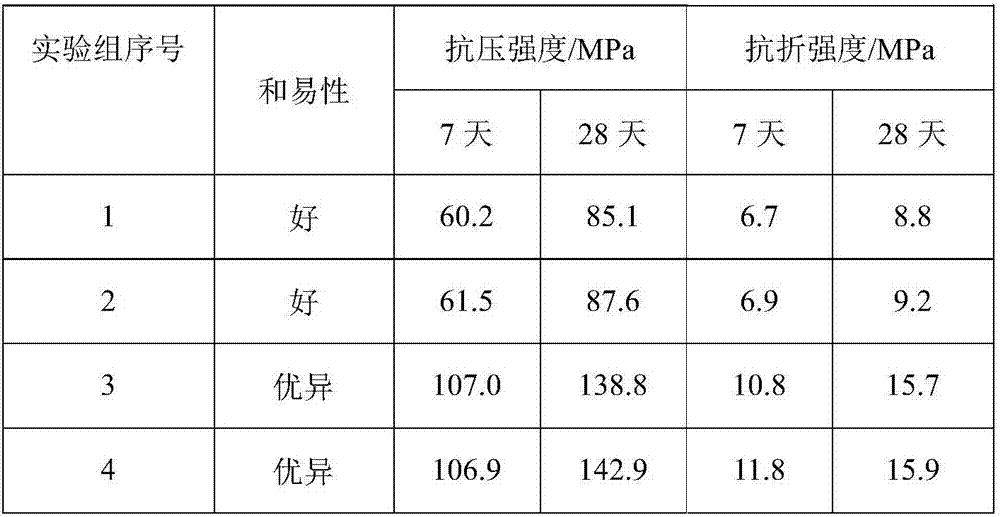

Lightweight high-strength ceramsite concrete and concrete pole

The invention relates to the technical field of concrete and more concretely relates to lightweight high-strength ceramsite concrete and a concrete pole. The lightweight high-strength ceramsite concrete is prepared from raw materials including the following ingredients in parts by mass: 380-420 parts of silicate cement, 45-53 parts of silica fume, 75-85 parts of slag powder, 560-620 parts of stone powder sand with the grain diameter of 0.16-4.75mm, 650-715 parts of shale ceramsite with the grain diameter of 5-20mm, 2.8-3.4 parts of efficient water reducing agent with the water reducing ratio higher than 30%, 115-126 parts of water and 0.4-0.6 part of polypropylene fiber. The concrete pole is formed through uniformly distributing the lightweight high-strength ceramsite concrete on a reinforcing steel bar net. According to the lightweight high-strength annular ceramsite concrete pole, the material source is wide, and a large amount of mineral waste is doped; and the weight is light, the carbonization resistance is good, the freeze-thaw resistance is good, the compressive strength is high, and the crack resistant strength is good.

Owner:佛冈龙清电力器材有限公司

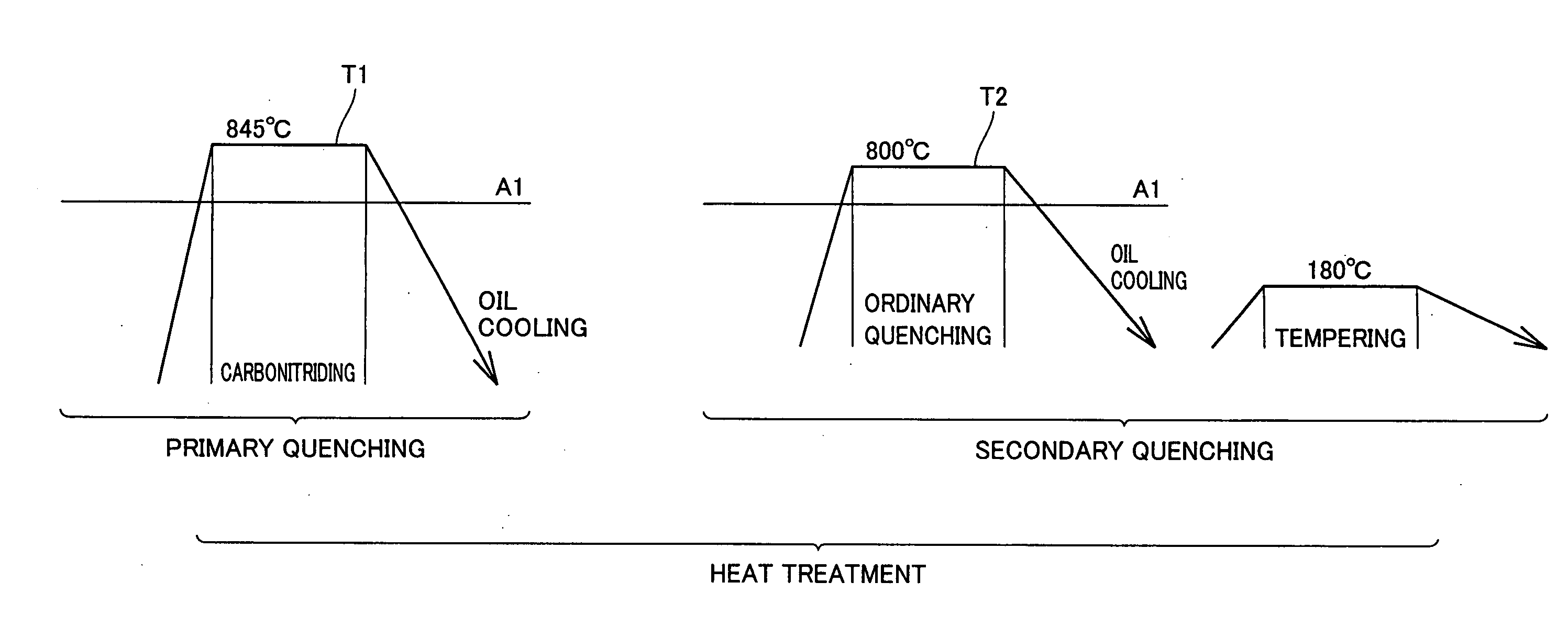

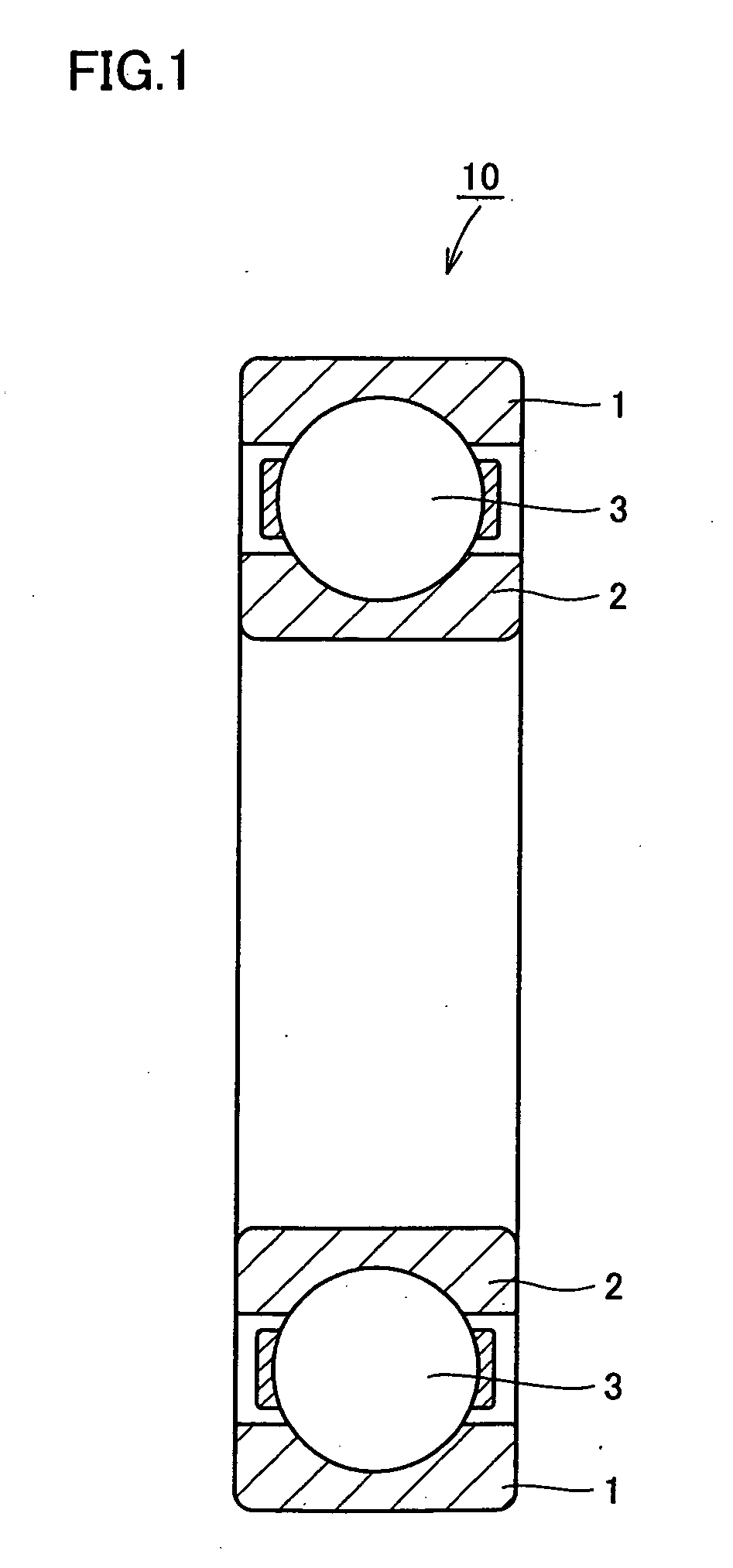

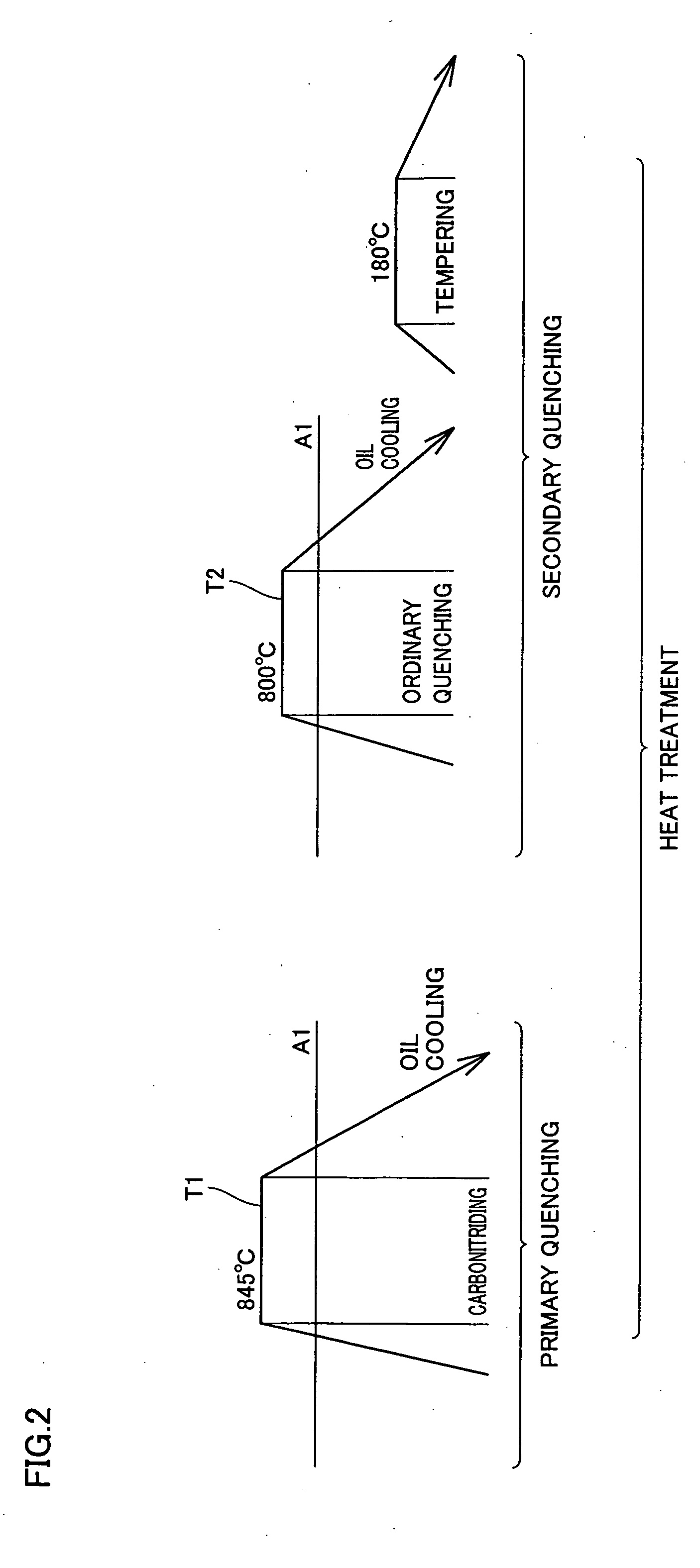

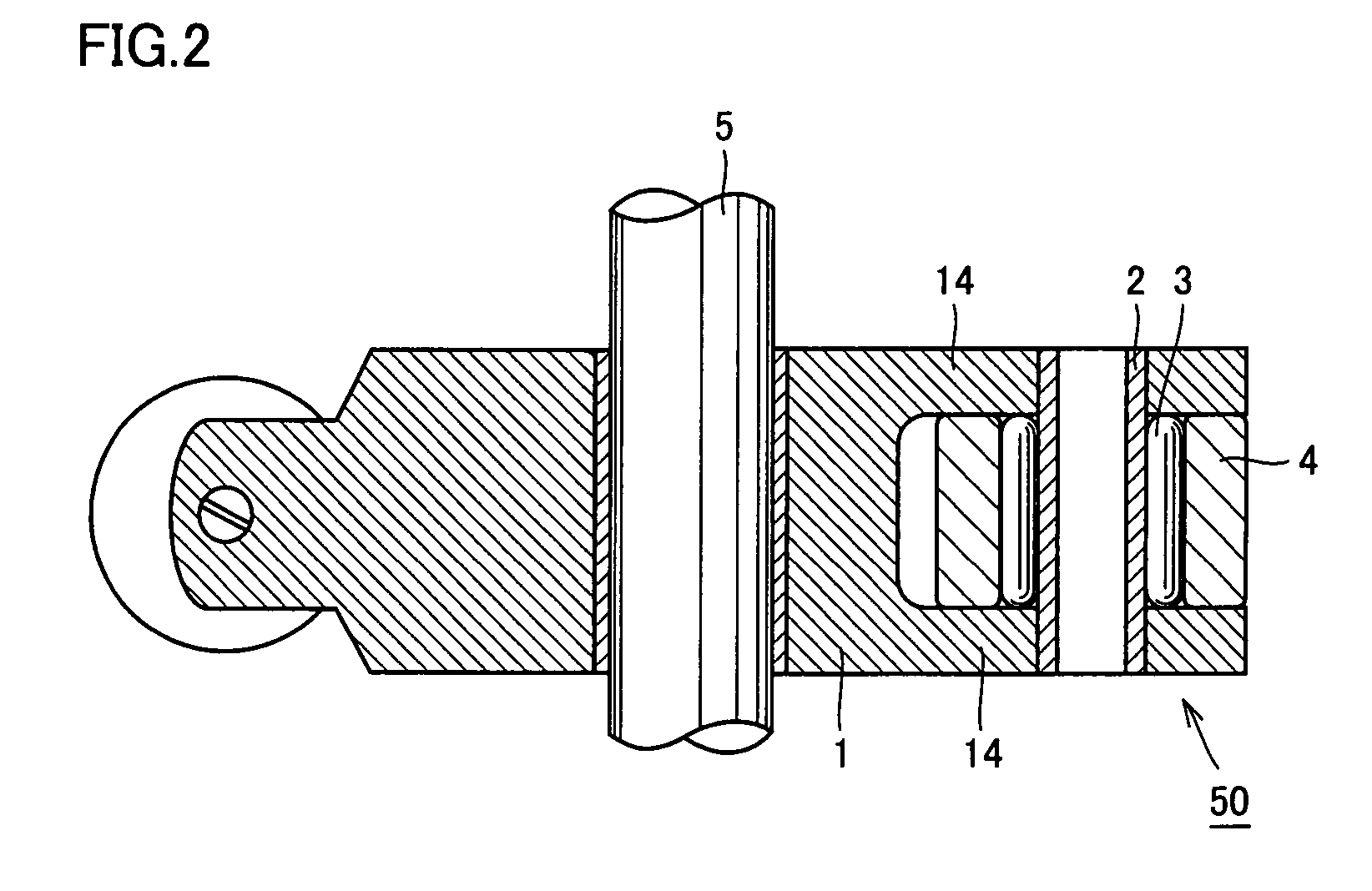

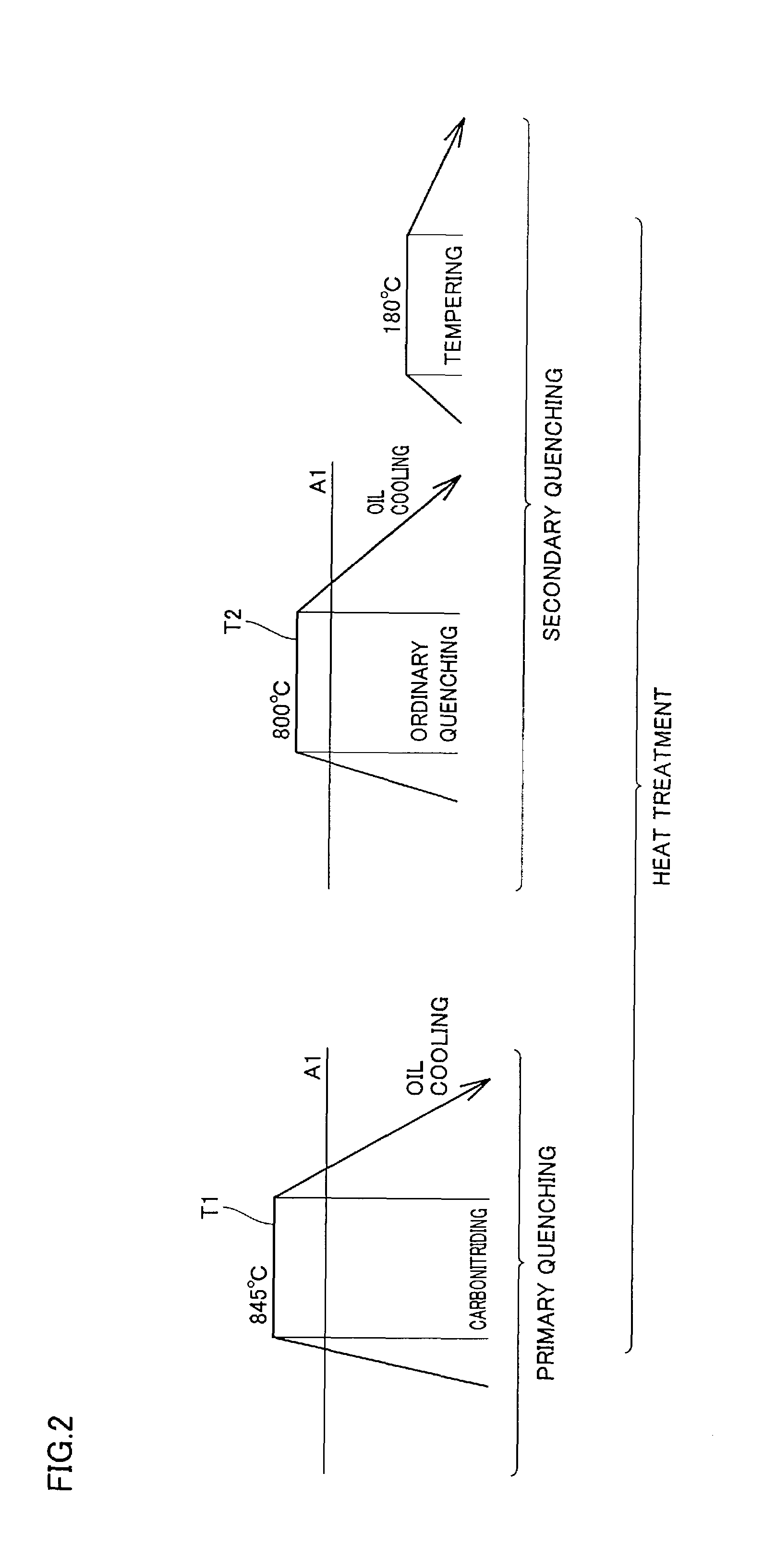

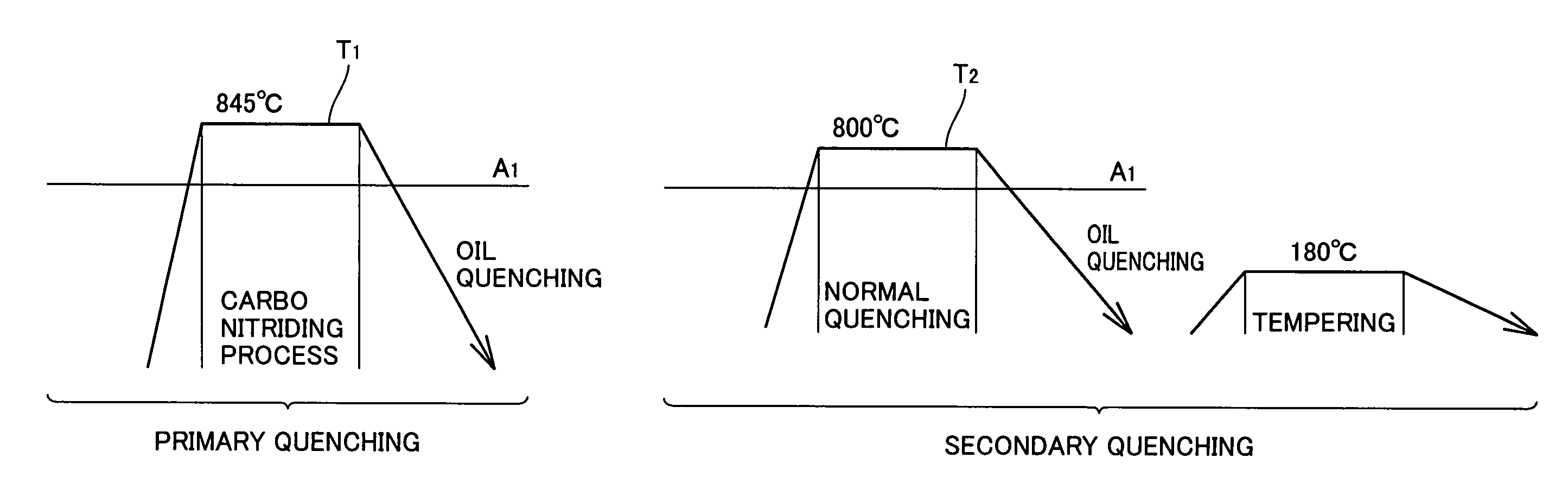

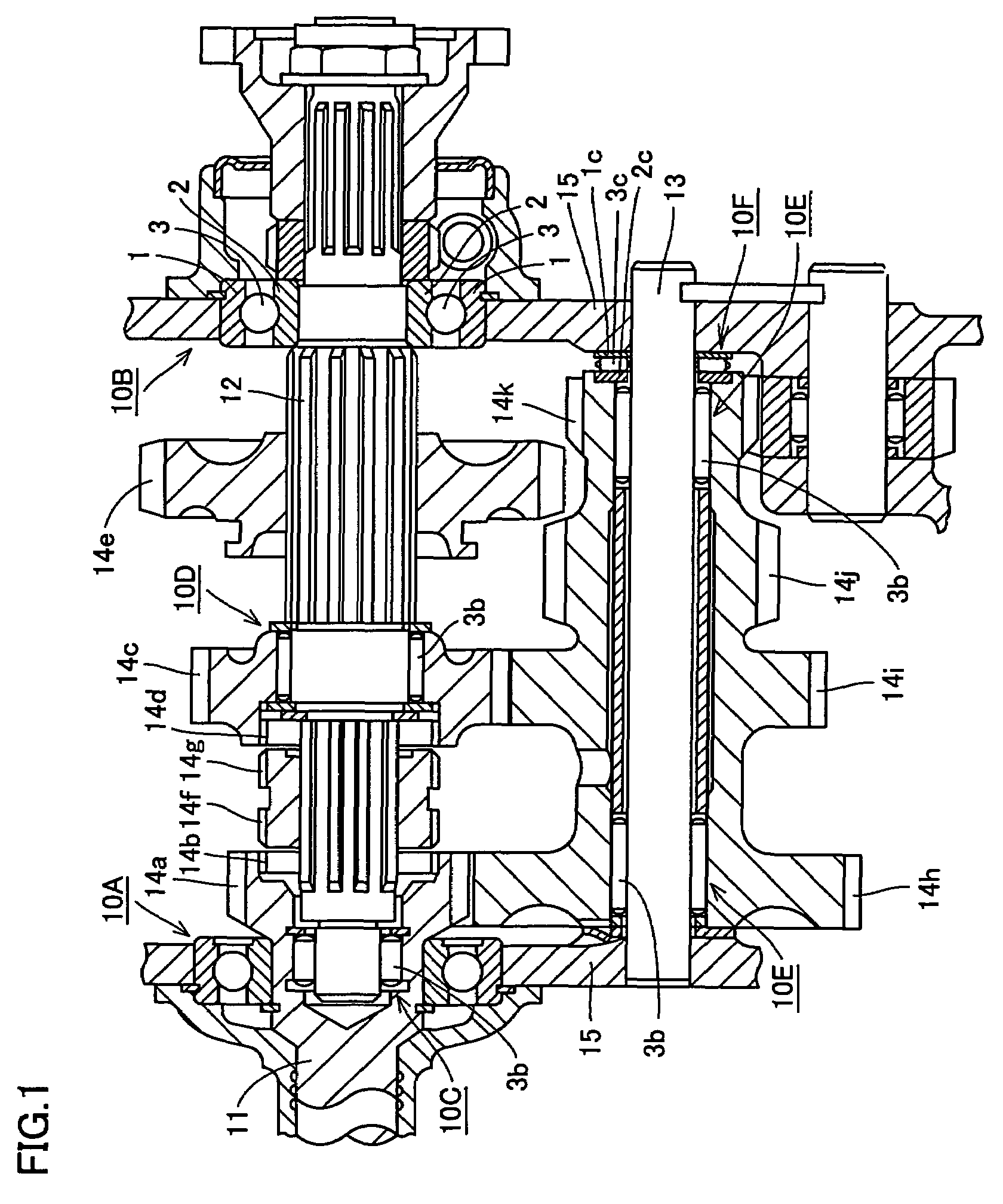

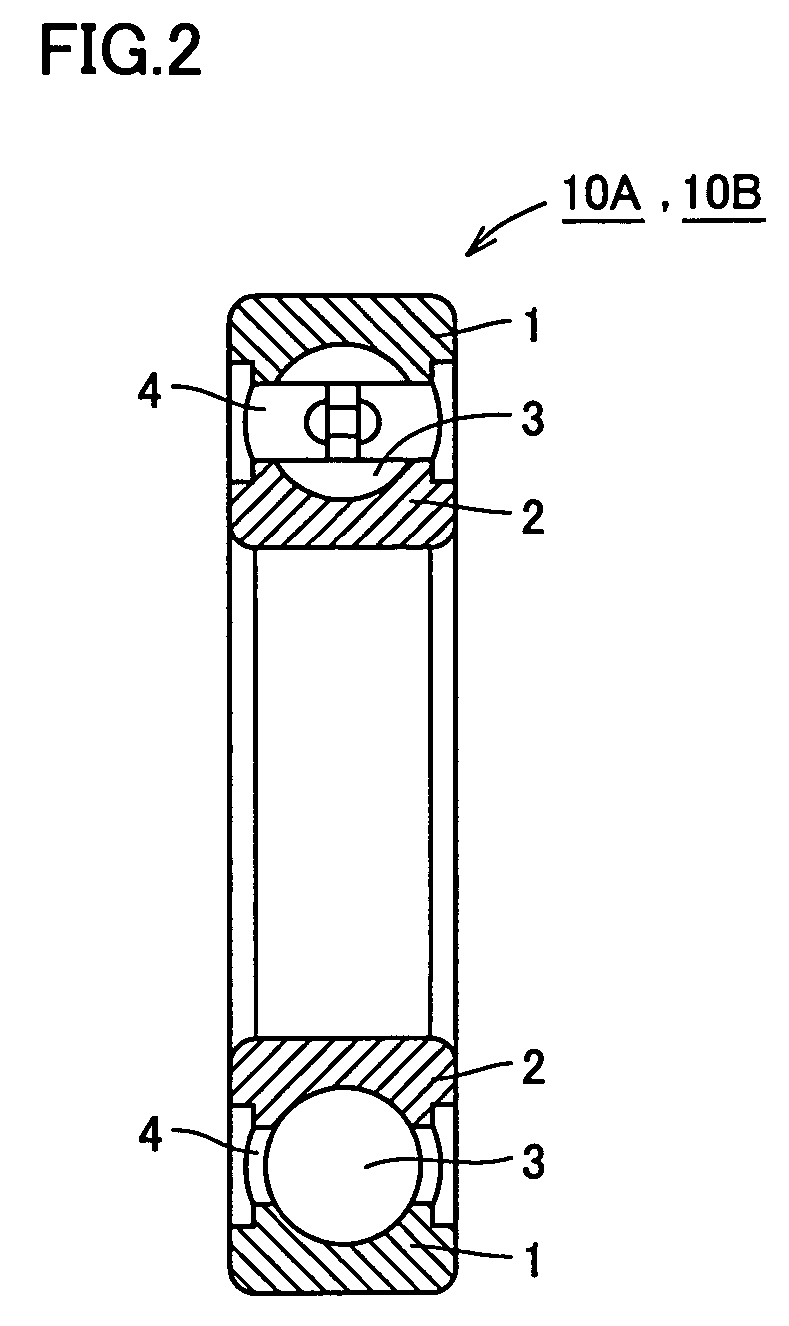

Bearing part, heat treatment method thereof, and rolling bearing

ActiveUS20050205163A1Solution to short lifeImprove cracking strengthShaftsBall bearingsQuenchingTransition temperature

A bearing part comprising steel subjected to carbonitriding at a carbonitriding temperature exceeding the A1 transformation temperature, and cooled to a temperature lower than the A1 transformation temperature. The steel is reheated to a temperature for quenching that is not lower than the A1 transformation temperature but lower than the carbonitriding temperature, and then quenched.

Owner:NTN CORP

Inorganic composite insulation board and preparation method thereof

InactiveCN103265262AImprove heat resistanceLow temperature shrinkageFiberBuilding insulation materials

The invention provides an inorganic composite insulation board and a preparation method thereof, belonging to the technical field of novel building insulation materials. The inorganic composite insulation board is characterized by comprising the following components by weight parts: 40-48 parts of expanded perlite, 5-15 parts of phenolic foam particles, 32-36 parts of an inorganic binder, 2-6 parts of an organic reinforcing agent, 2-3 parts of a waterproof agent, 2-3 parts of inorganic enhance fibers, 1-2 parts of a hardening agent, and 1-2 parts of a fire retardant. The above raw materials are fully stirred, compressed, molded, and dried under a constant temperature to prepare the inorganic composite insulation board, and the board has advantages of good thermal insulation performance, light weight, small thermal conductivity coefficient, good stability, high intensity, convenient construction, etc., and can be widely applied in roofs and walls of various industrial and civil buildings, waterproofing and insulation of cold storages, barns and basements, as well as various cold insulation engineering.

Owner:安徽百穗供应链有限公司

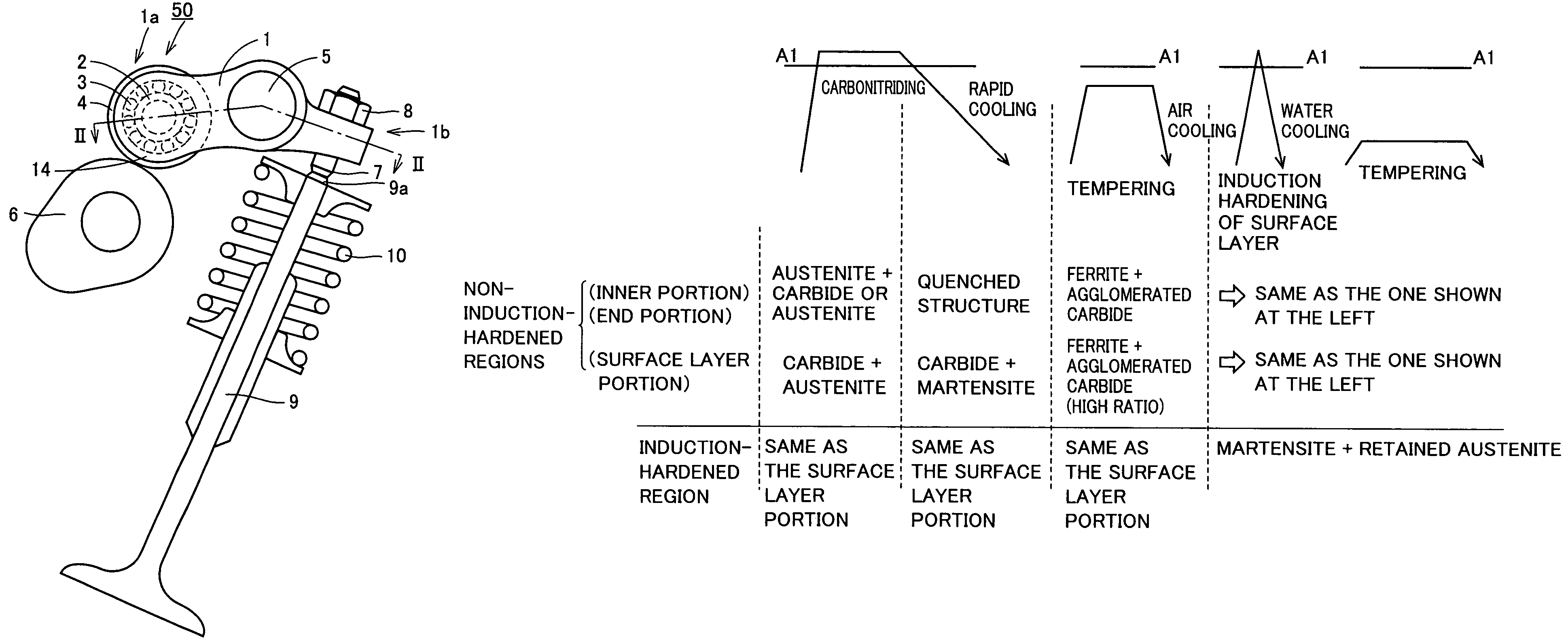

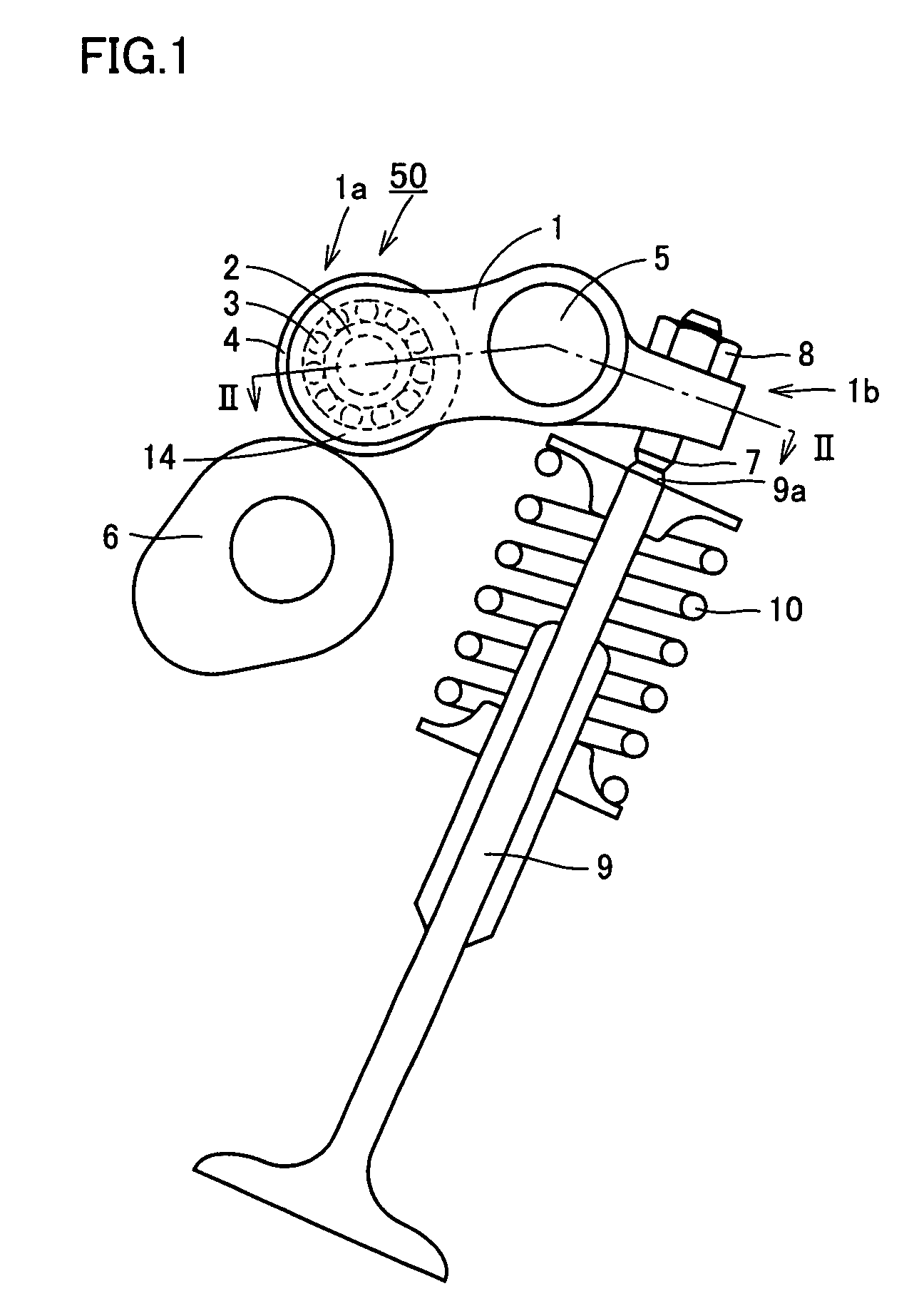

Rolling bearing for rocker arm

ActiveUS7614374B2Improve fatigue lifeImprove cracking strengthControlling membersValve arrangementsAustenite grainRolling-element bearing

A rolling bearing for a rocker arm includes an outer ring in rolling contact with a cam of an engine, an outer-ring shaft placed inside the outer ring and fixed to the rocker arm, and a plurality of rollers provided between the outer ring and the outer-ring shaft. At least one of the outer ring, the outer-ring shaft and the rolling elements has a nitrogen-rich layer, an austenite crystal grain size number in a range exceeding 10, and a surface hardness Hv of at least 653. Thus, the life can be extended.

Owner:NTN CORP

Bicomponent gypsum base polystyrene foamed particle heat insulation paint

The present invention relates to a double-component gypsum base polystyrene foam particle heat-insulating coating for thermal insulation of building internal wall, external wall and roof. Its composition includes (by weight portion) 2-6 portions of polystyrene foam particle, 4-10 portions of modified calcium oxide, 4-10 portions of synthetic resin emulsion, 35-45 portions of water, 0.1-1.5 portions of thickening agent, 0.1-1.5 portions of modifying agent, 0.1-2 portions of reinforcing fibre, 0.5-1.5 portions of delayed coagulant, 30-50 portions of calcined gypsum powder and 0.1-0.3 portion of foaming agent. Besides, said invention also provides its preparation method.

Owner:常熟市蓝都弹性涂料有限公司

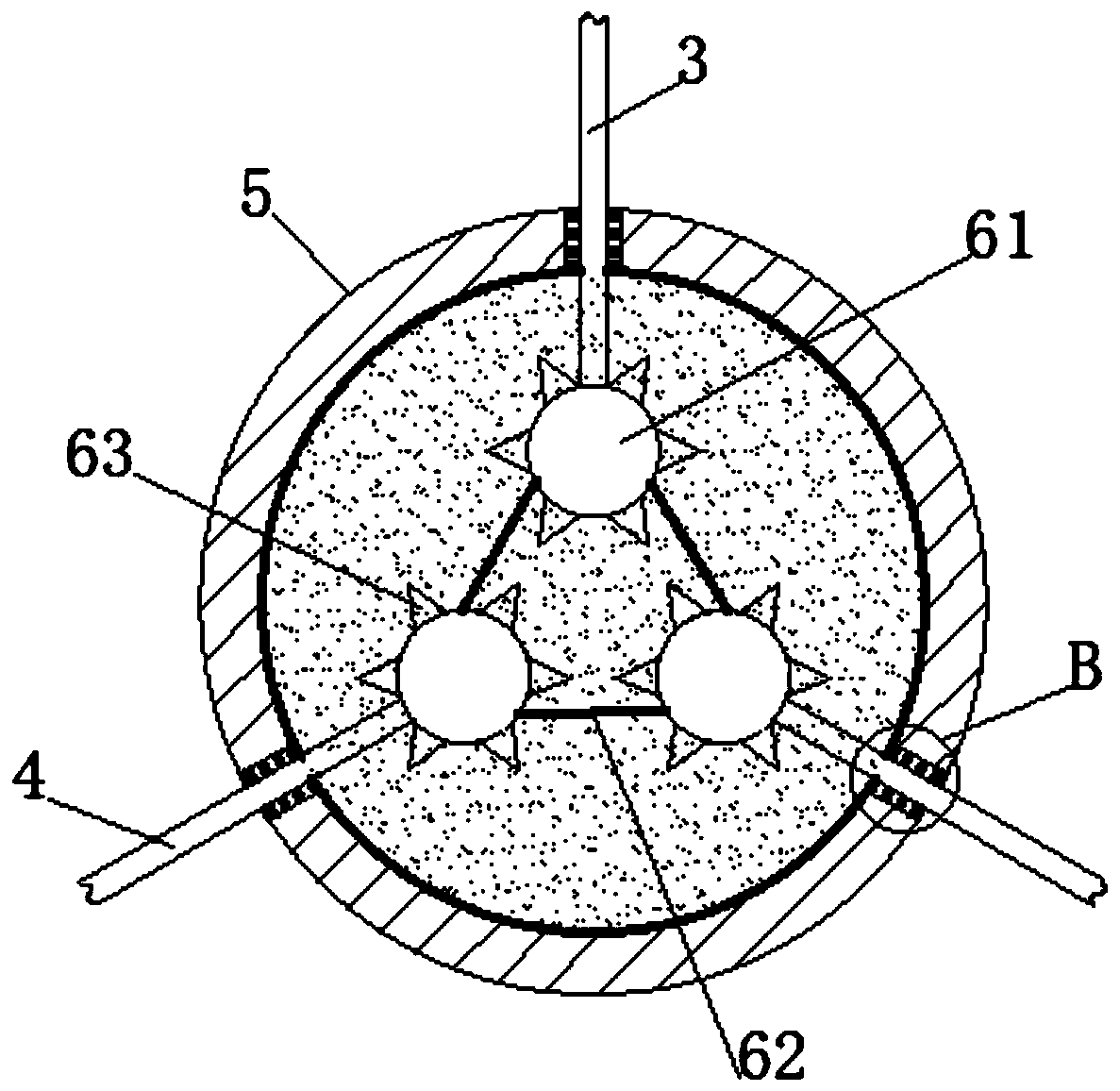

Novel compound electric pole

InactiveCN105503065AHigh compressive strengthImproves carbonation resistanceSolid waste managementTowersCentrifugationEngineering

The invention belongs to the field of electric power materials and discloses a novel compound electric pole. The novel compound electric pole is prepared from concrete and a reinforcing mesh through compounding. The novel compound electric pole is prepared through uniformly distributing concrete in an electric pole mold with the reinforcing mesh through a material distribution machine, carrying out tensioning, carrying out centrifugation molding, carrying out standing for 4-5h and carrying out demolding. The novel compound electric pole has good performances and a wide application scope.

Owner:徐筱瑜

Bearing part, heat treatment method thereof, and rolling bearing

InactiveUS7438477B2Improve cracking strengthAdd dimensionShaftsBall bearingsRolling-element bearingQuenching

A bearing part comprising steel subjected to carbonitriding at a carbonitriding temperature exceeding the A1 transformation temperature, and cooled to a temperature lower than the A1 transformation temperature. The steel is reheated to a temperature for quenching that is not lower than the A1 transformation temperature but lower than the carbonitriding temperature, and then quenched.

Owner:NTN CORP

Rubber-asphalt concrete and preparation method thereof

The invention belongs to the field of building materials and particularly relates to rubber-asphalt concrete and a preparation method thereof. The rubber-asphalt concrete comprises, by weight, 50-60 parts of mineral powder fly ash, 20-30 parts of stone chips, 6-8 parts of limestone, 10-15 parts of cement, 5-10 parts of supermolecule rubber composite material, 6-10 parts of asphalt, 2-4 parts of glass fibers, 2-3 parts of sucrose diacetate hexaisobutyrate and 80-120 parts of water. The preparation method includes: using a method combining microwave and mechanical gridnign to regenerate waste rubber powder, performing grafting modification on the regenerated rubber powder, subjecting the limestone to high-temperature calcining, adding the supermolecule rubber composite material and the restof raw materials into the limestone, adding water, and evenly mixing to obtain the rubber-asphalt concrete. The rubber-asphalt concrete is good in performance such as high-temperature stability, low-temperature toughness, aging resistance, fatigue resistance and water damage resistance and capable of satisfying use requirements.

Owner:罗永山

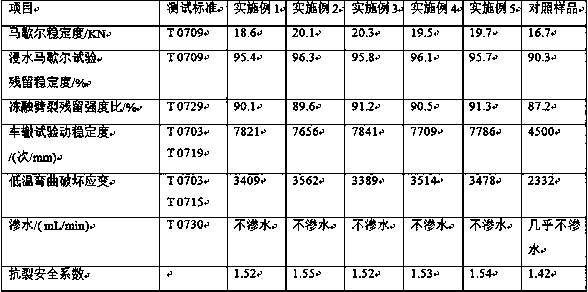

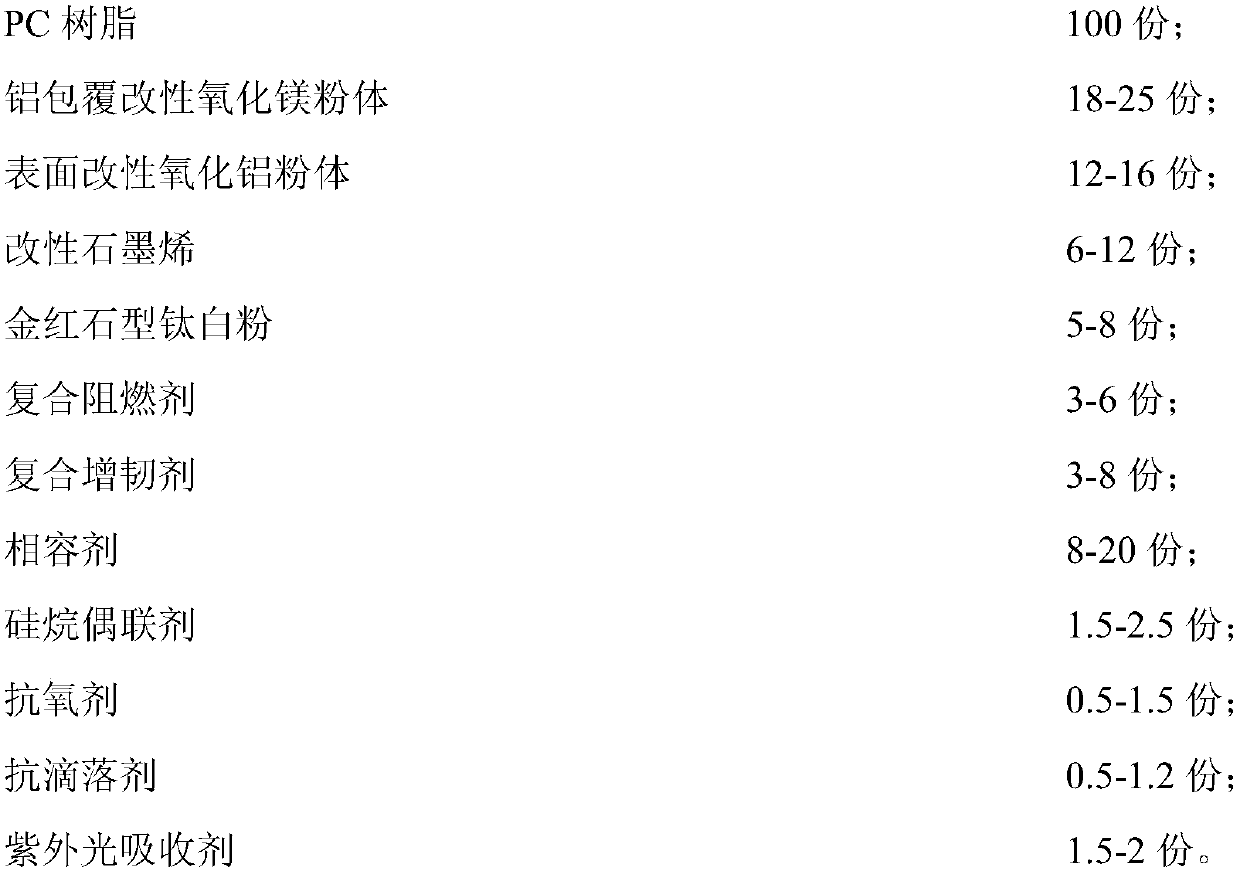

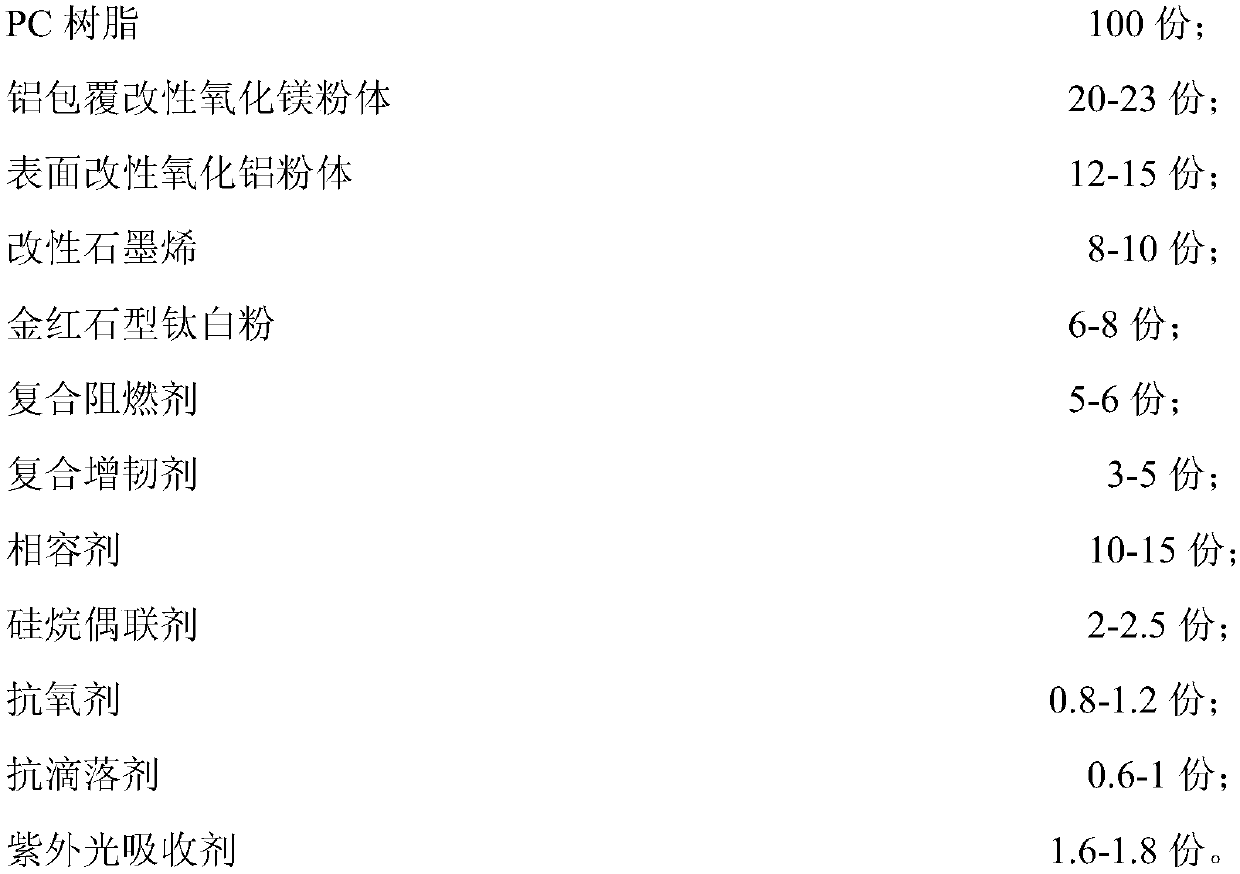

PC alloy material and preparation method thereof

The invention provides a PC alloy material and a preparation method thereof. The PC alloy material is prepared by mixing the following components in parts by weight: 100 parts of PC resin, 18-25 parts of aluminium coated modified magnesium oxide powder, 12-16 parts of surface modified aluminum oxide powder, 5-8 parts of rutile type titanium dioxide, 6-12 parts of modified graphene, 3-8 parts of a composite toughing agent, 3-6 parts of a composite flame-retardant agent, 8-20 parts of a compatilizer, 1.5-2.5 parts of a silane coupling agent, 0.5-1.5 parts of an oxidation inhibitor, 0.5-1.2 parts of an anti-dripping agent and 1.5-2 parts of an ultraviolet absorber. According to the PC alloy material, the PC resin and the various kinds of powder are fused; the powder is modified so that the powder can be fused in the PC resin fused body well; and the composite flame-retardant agent and the composite toughing agent are innovated, so that the prepared PC alloy material has good mechanical property, thermal property, optical property and electrical property, belongs to a brand-new PC alloy material, and has wide market popularization and application prospects.

Owner:东莞市亚仑塑料原料有限公司

Construction method for sticking SBC water-proof coiled material by JS composite water-proof paint

InactiveCN101250904AImprove cracking strengthImprove waterproof performanceAntifouling/underwater paintsRoof covering using flexible materialsCrack resistanceSlurry

The invention relates to a construction method for JS composite underwater paint to stick SBC waterproof coiled material, the construction steps are as follows: (1) construction surface is treated; (2) liquid material and powder material of the JS composite underwater paint are mixed and stirred evenly, then are painted on the construction surface and stuck with the SBC waterproof coiled material, so that the SBC waterproof coiled material forms a layer of waterproof additional layer through sticking; (3) the liquid material and the powder material of the JS composite underwater paint and water are mixed and stirred to serosity, then painted on the waterproof additional layer; (4) the liquid material and the powder material of the JS composite underwater paint and water are stirred to the serosity and stuck on a bond coat and then stuck with a layer of waterproof coiled material; (5) positions where leakage is easy to happen such as wall angles, drain gullies, pipe orifices, dilatation joints and so on are covered with a layer of waterproof additional layer according to the step (2); (6) finally the liquid material and the powder material of the JS composite underwater paint and water are mixed and stirred evenly to serosity, then painted a layer of protective layer on the upper surface of the coiled material. The construction method of the invention can effectively make up for defects caused by crackles or holes of a foundation course, strengthen cracking resistance, improve waterproof effect and reduce the cost.

Owner:河南省第二建筑工程有限责任公司

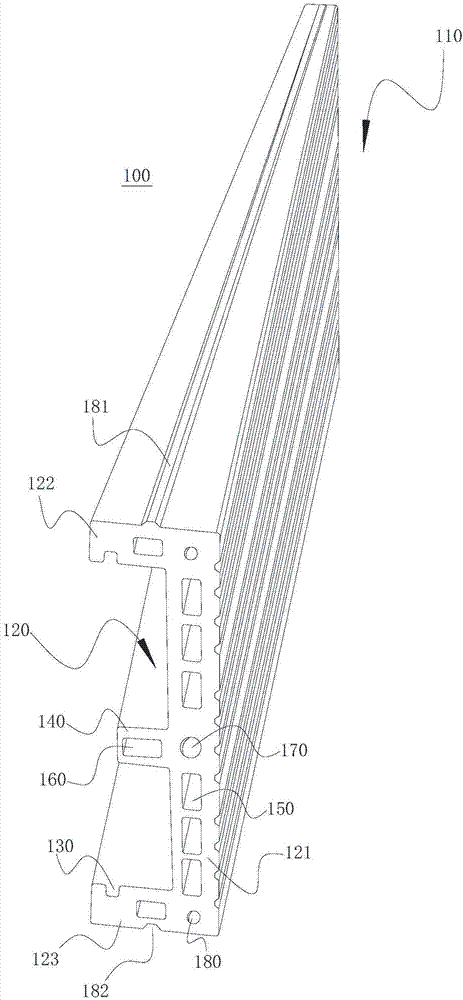

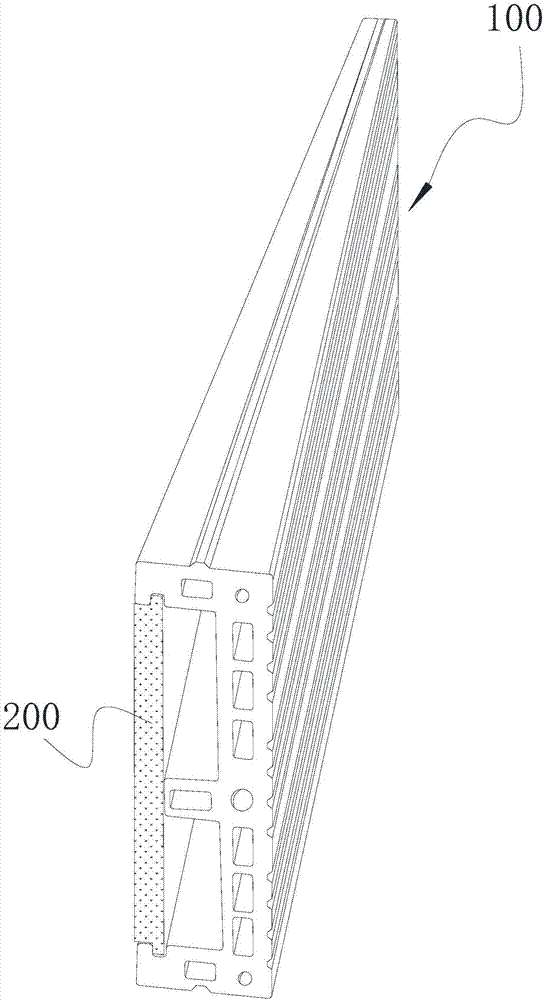

Acoustic shielding backing plate and concrete thereof

PendingCN107445553AImprove securityImprove support stabilityNoise reduction constructionFiberEngineering

The invention relates to the technical field of construction materials, and provides an acoustic shielding backing plate and concrete thereof. The concrete is prepared from the following raw materials: a gelling material, aggregate, admixture, fibers and an additive, and has excellent durable mechanical performance. The acoustic shielding backing plate comprises a backing plate body, wherein an acoustic shielding slot is formed in the backing plate body along the length direction of the backing plate body, and first lightening holes are respectively formed in the bottom wall, first side wall and second side wall of the acoustic shielding slot along the length direction of the backing plate body; a male groove and a female groove are respectively formed in the side, far from the acoustic shielding slot, of the first side wall and the second side wall along the length direction of the backing plate body, and are matched in shapes; reinforcing holes are formed in the first side wall, the second side wall and a stiffener; and the impact resistance and bending strength of the backing plate can be remarkably reinforced by implanting reinforcing ribs, injecting a grouting material and plugging a grouting socket with concrete, and the durability and the stability can be greatly improved, and the absolute safety of the backing plate can be guaranteed. The acoustic shielding backing plate has an excellent supporting effect and an acoustic shielding effect.

Owner:SICHUAN SHUANGTIE TECH CO LTD

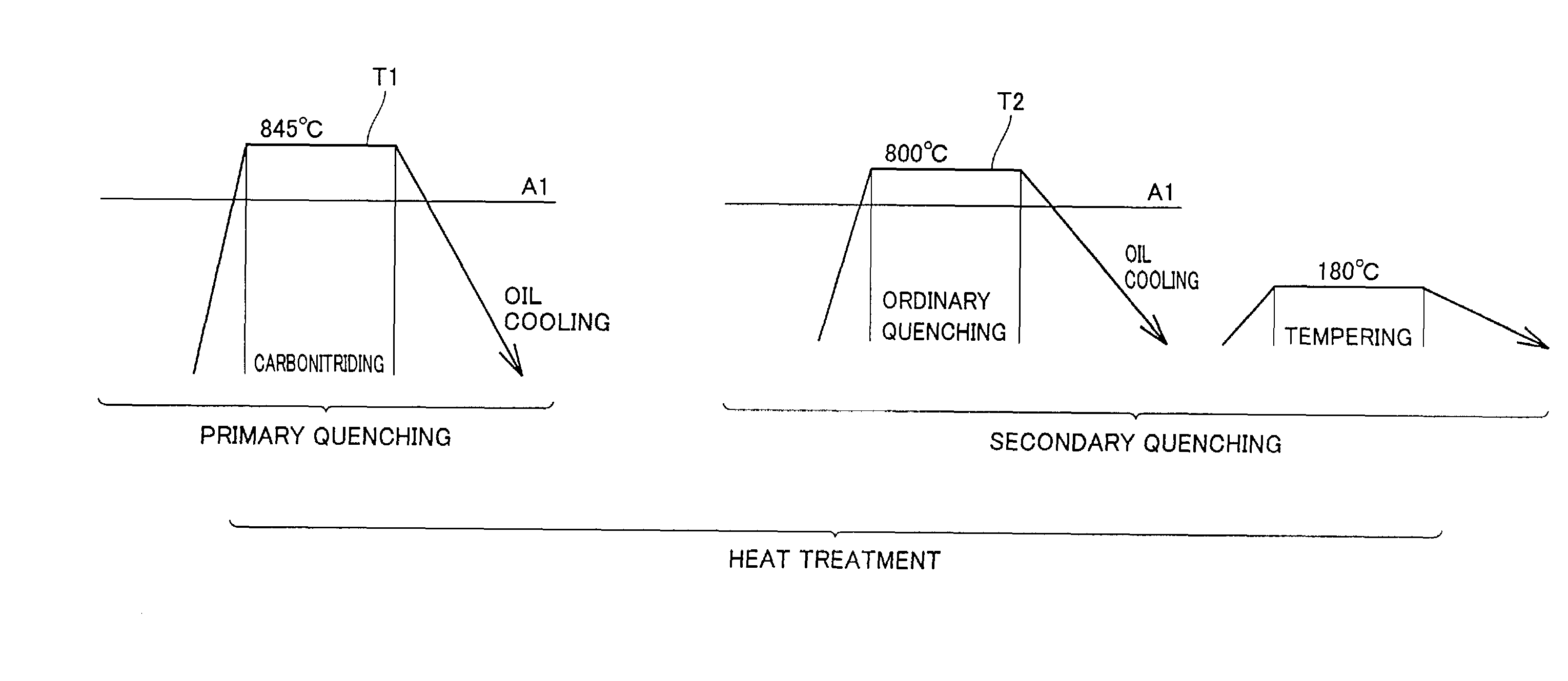

Rolling bearing heat treatment process method

InactiveCN101994120ALong life against rolling contact fatigueGood cracking strengthSolid state diffusion coatingFurnace typesQuenchingSize change

The invention relates to a rolling bearing heat treatment process method for rolling bearing steel. The invention provides a rolling bearing heat treatment process method, which makes the rolling bearing steel have longer rolling contact-resistant fatigue life, high cracking resistance and limited aging size change. The rolling bearing steel heat treatment process method comprises the following steps of: performing carbonitriding on the steel for a bearing component at the carbonitriding temperature higher than a phase-transition temperature A; cooling the steel to the temperature lower than the phase-transition temperature; heating the rolling bearing steel to the quenching temperature, wherein the temperature is not lower than the phase-transition temperature and is lower than the carbonitriding temperature; and performing quenching process on the steel.

Owner:杨辰薇

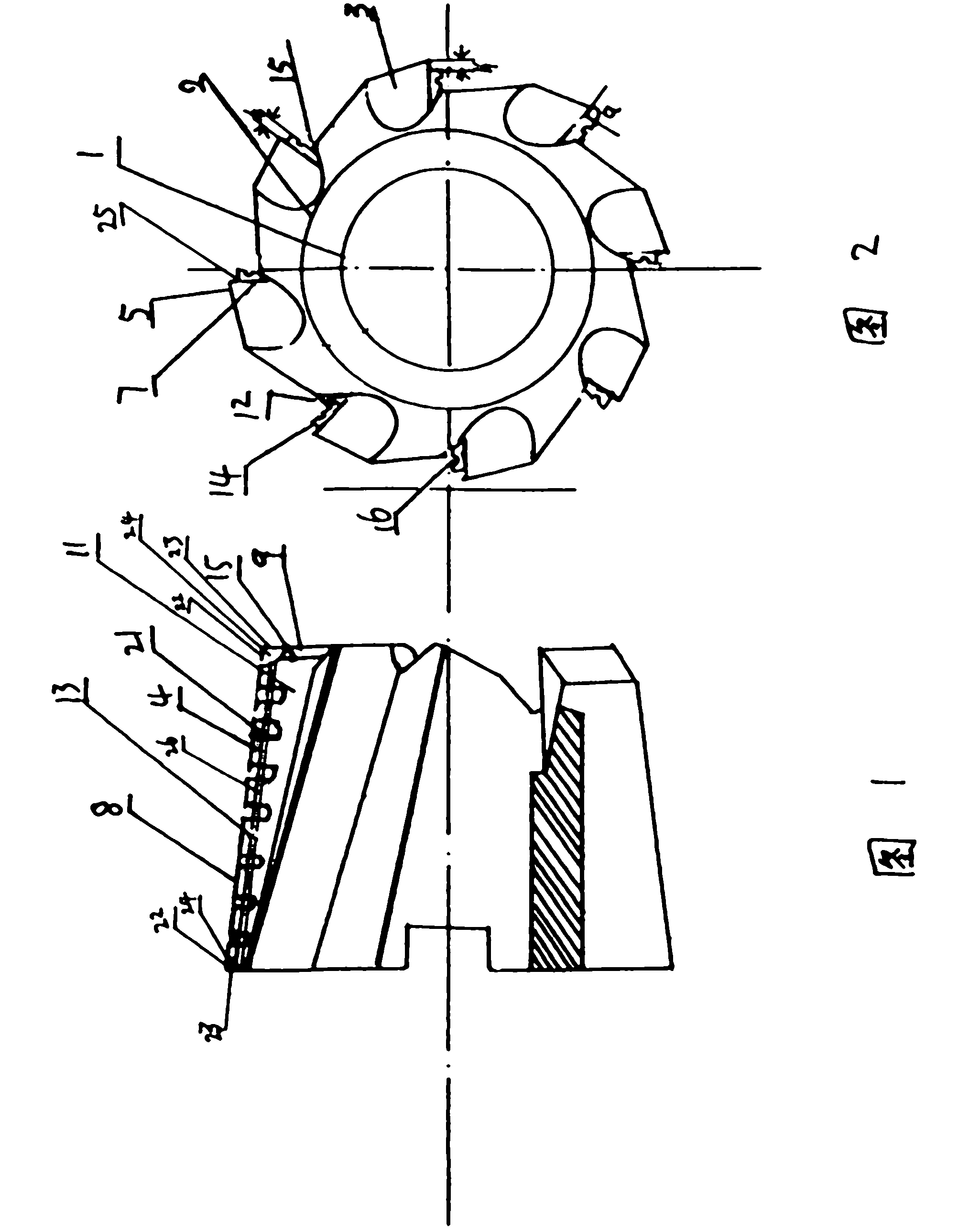

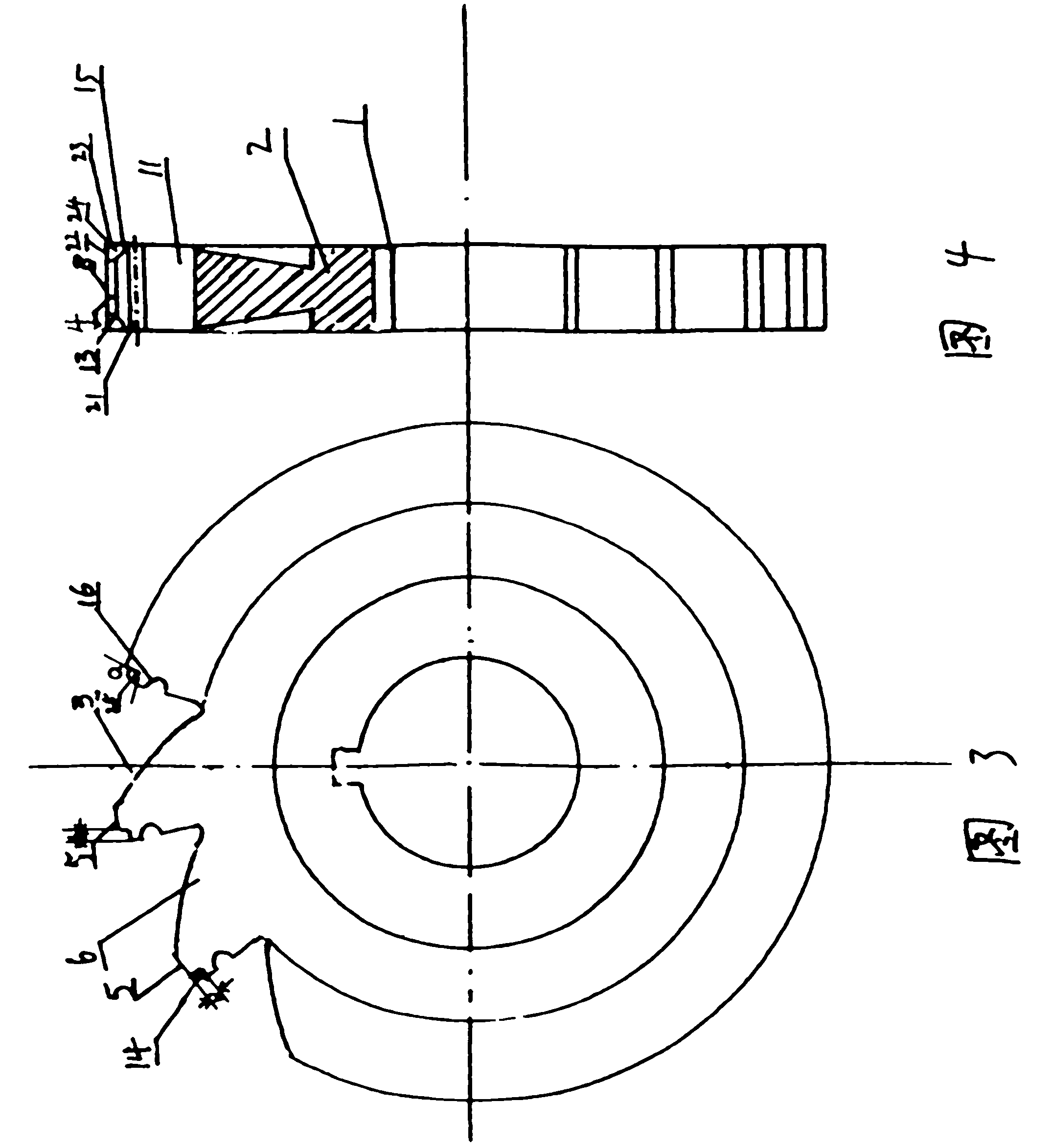

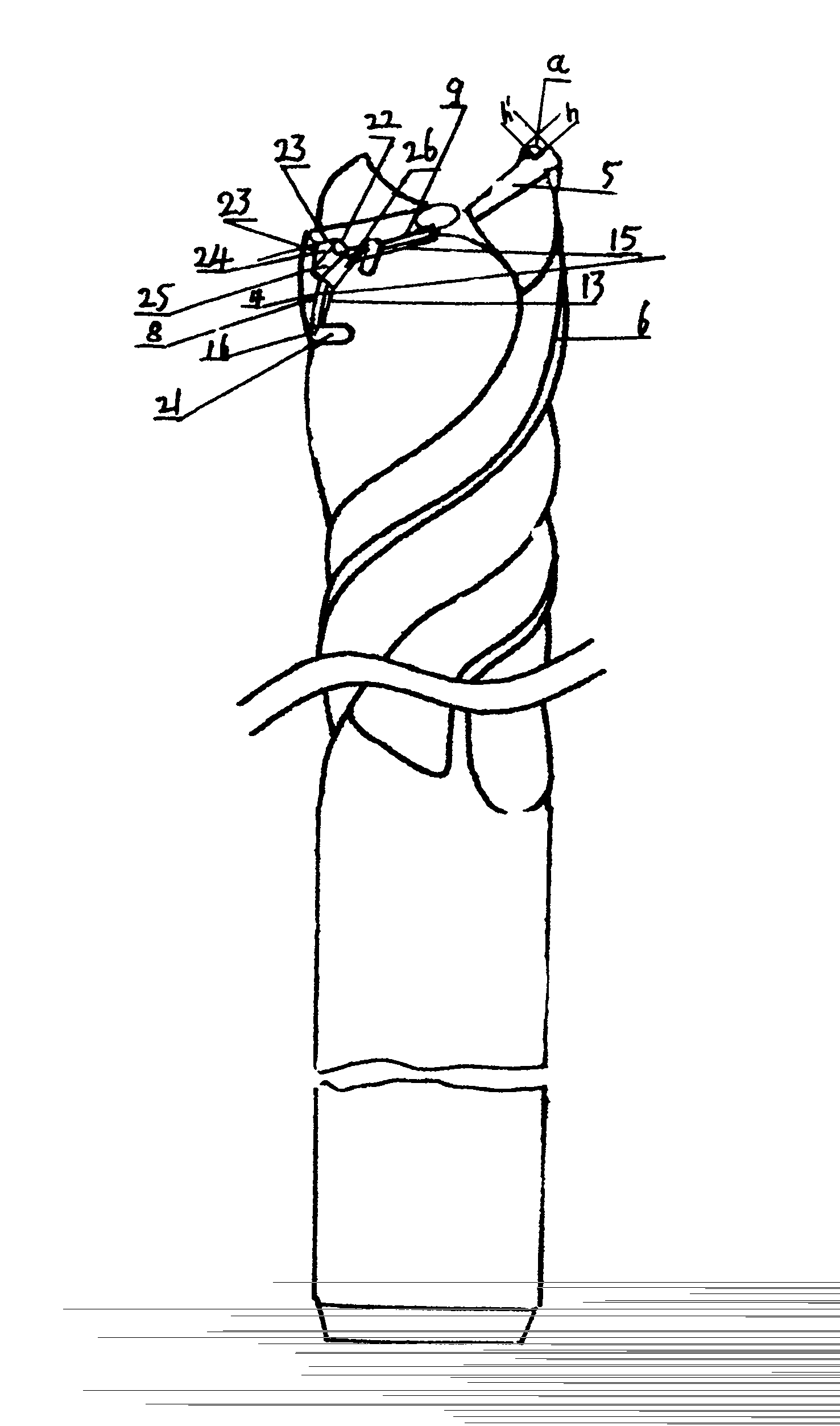

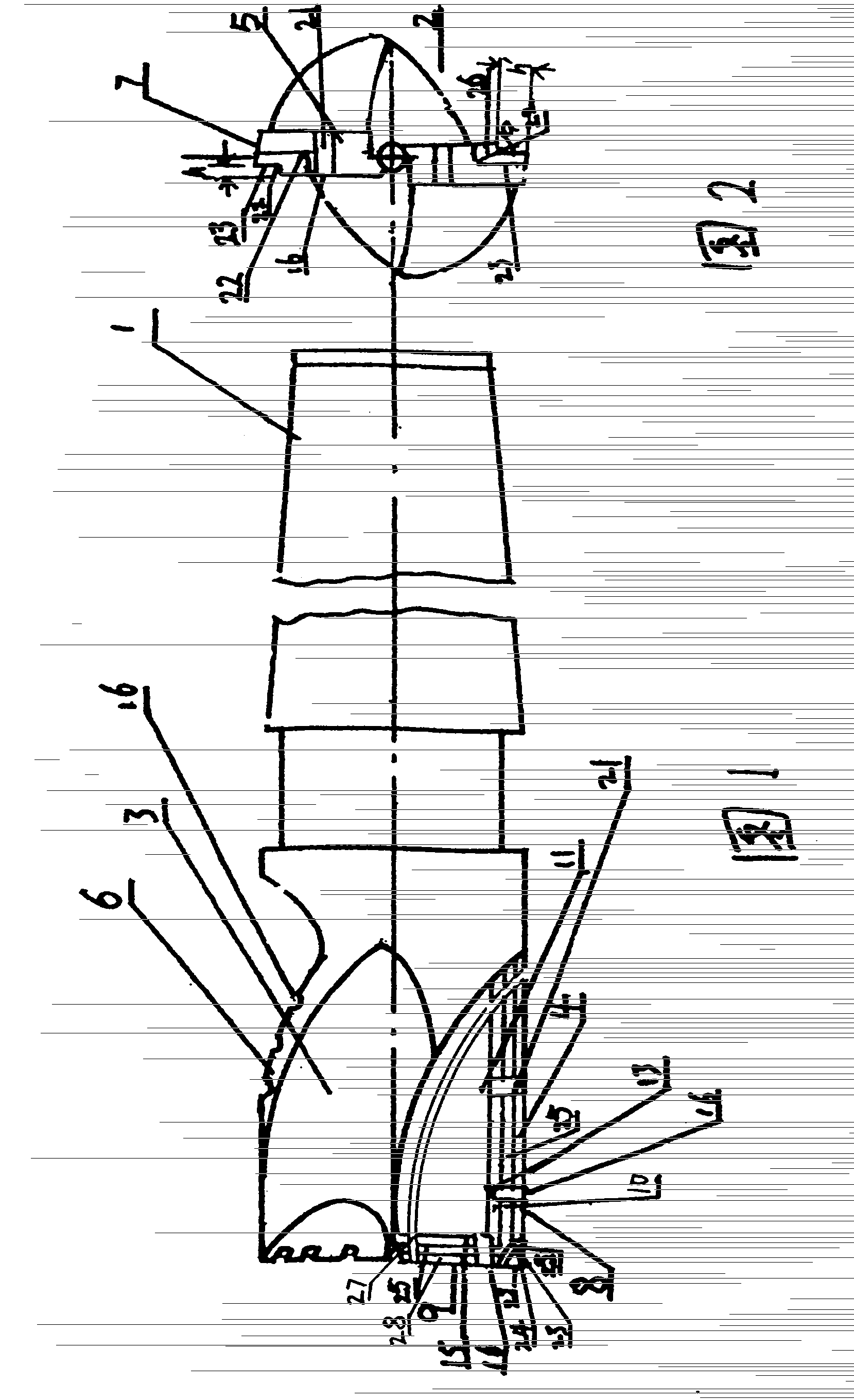

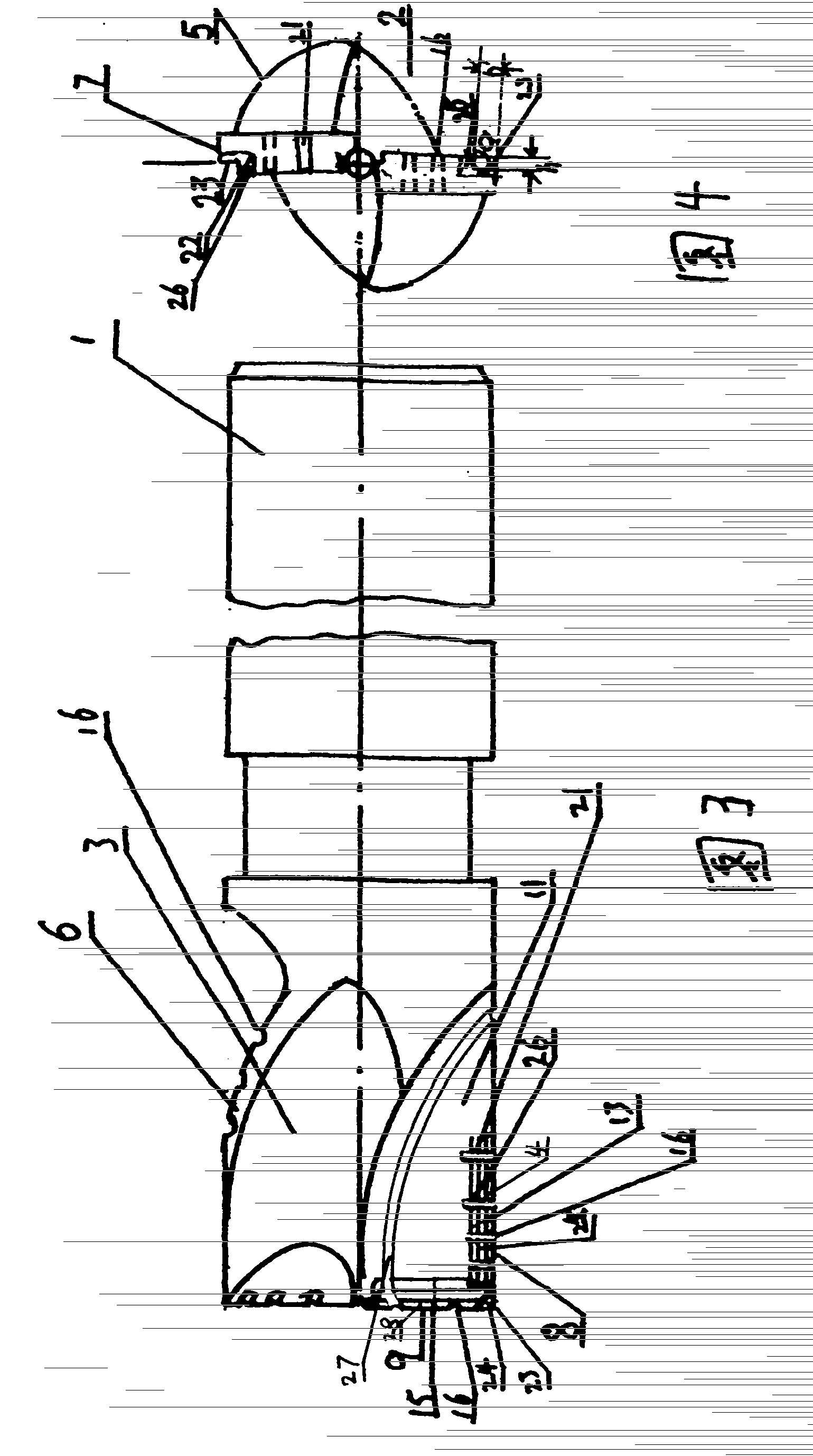

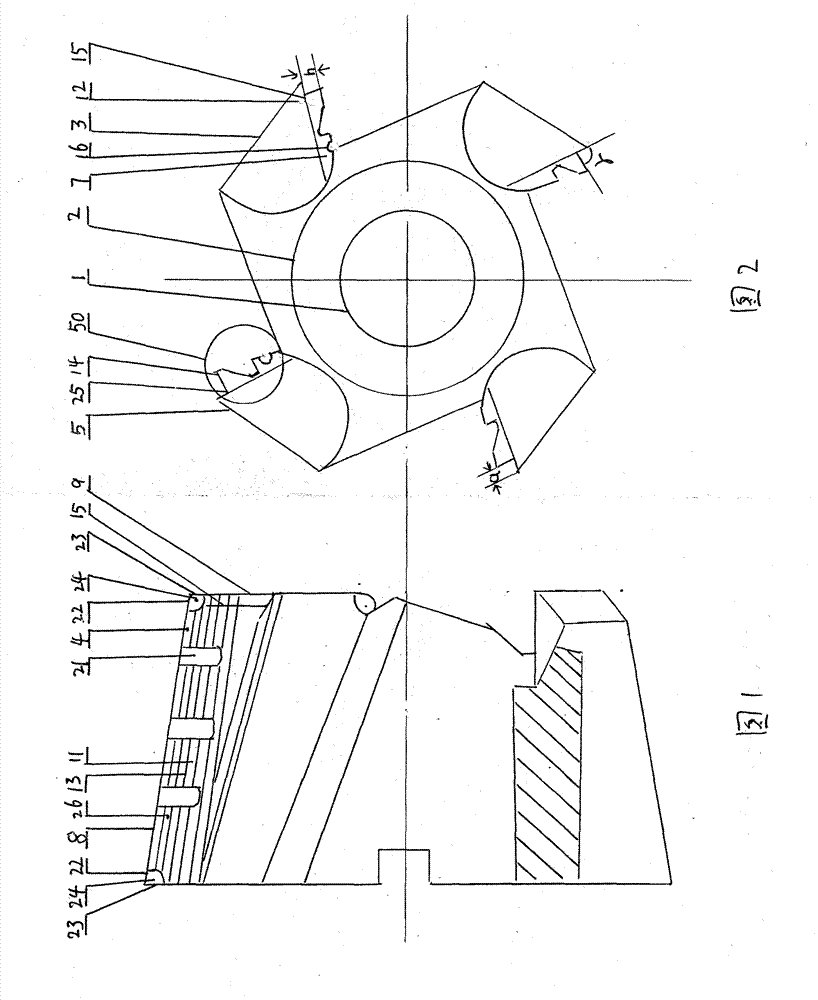

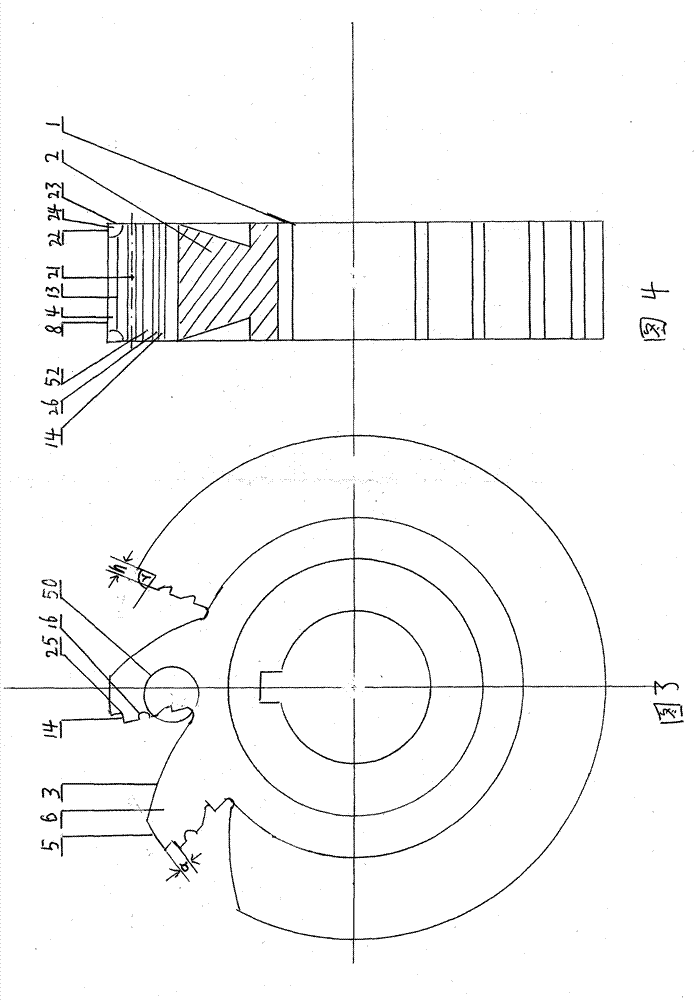

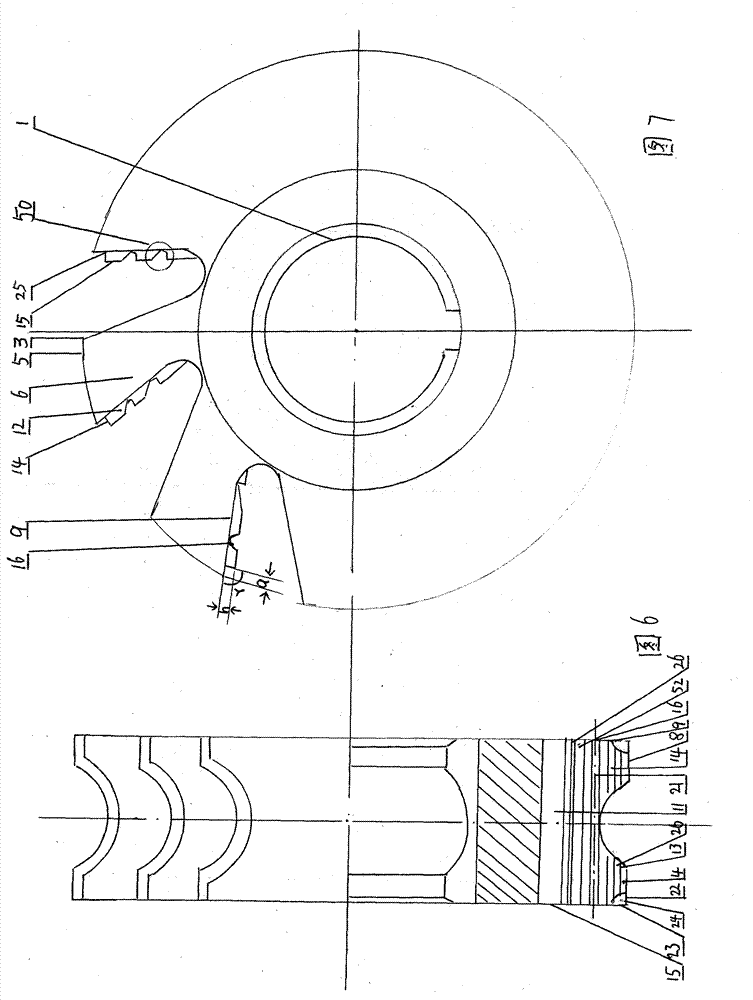

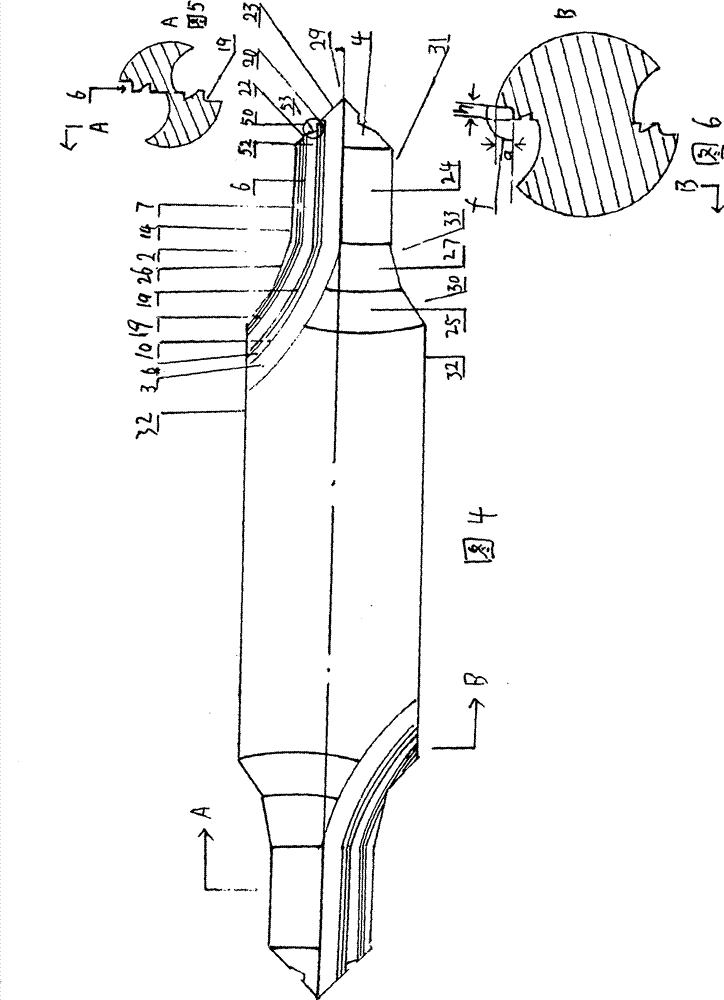

Composite milling cutter

InactiveCN103381499ATroubleshoot data issues for production implementationSolve data problemsMilling cuttersMilling cutterHeight difference

The invention provides a composite milling cutter. The cutter has high efficiency, high strength, and a long service life and comprises a cutter handle or a locating hole and a cutter head. The cutter is characterized in that a definition is formed about the height relationship between a crack-resisting slitting platform or a high-efficiency slitting platform and an inside adjacent high-efficiency slitting platform; the included angle between a composite helix cutting face and an adjacent composite locating disintegrating platform is more than or equal to 90 DEG; or the height difference of two adjacent composite helix cutting faces is more than or equal to 0.01 mm, or less than four fifths of the thickness of an discharged chip, or less than or equal to a height accounting for 9 times of the cutting feeding amount; or the thickness of the crack-resisting slitting platform is more than 0.6 mm, or less than or equal to one third of the diameter of the milling cutter; or a helix groove is disposed at the composite helix cutting face.

Owner:河北雄安赛立康机械科技有限公司

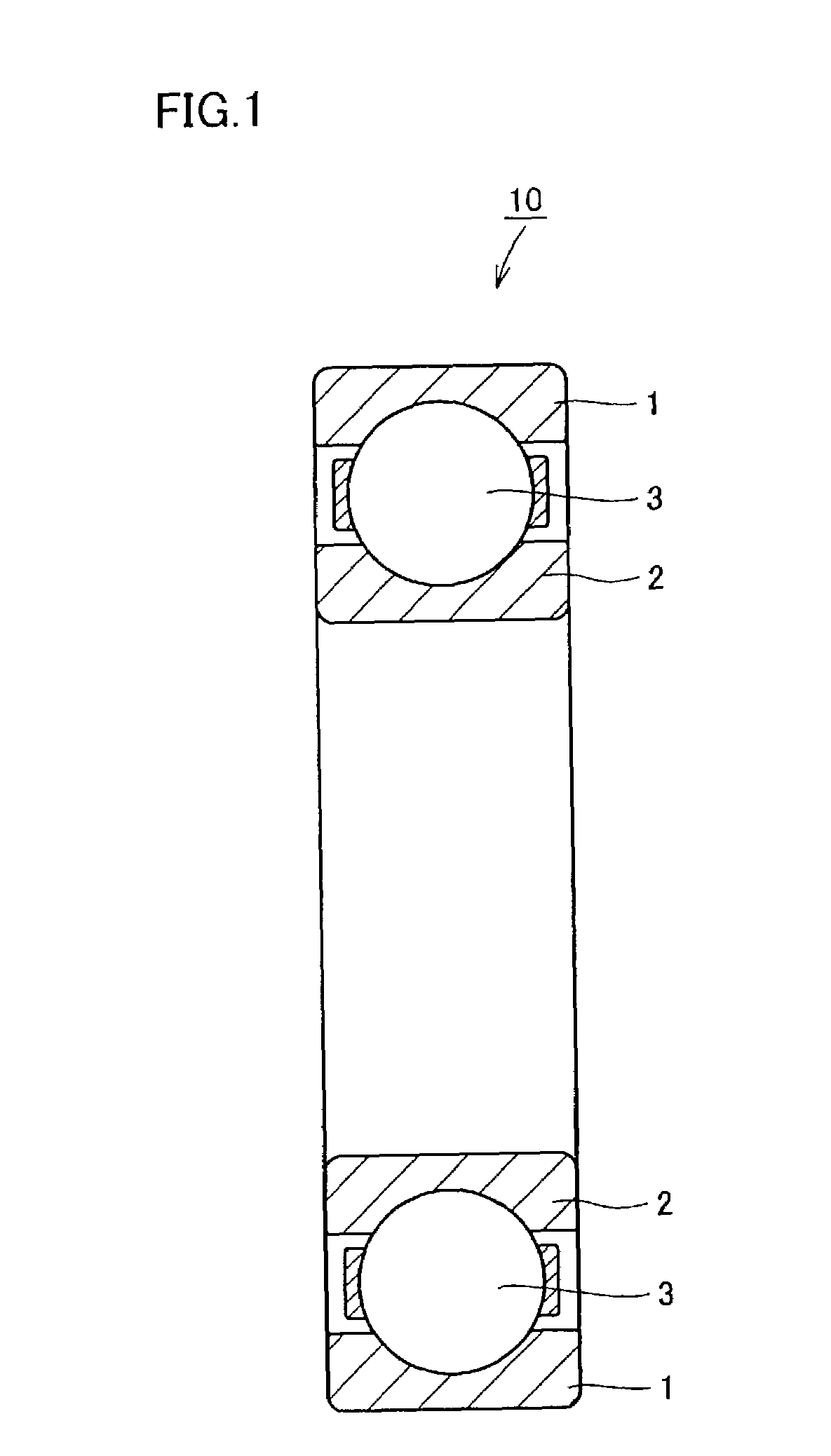

Transmission component, method of manufacturing the same, and tapered roller bearing

ActiveUS7682087B2Improve cracking strengthGood dimensional stabilityGearboxesPortable liftingAustenite grainSurface layer

A transmission component is incorporated into a transmission in which an input shaft, an output shaft, or a gear is rotatably supported by a rolling bearing. The component has a nitriding layer at a surface layer and an austenite grain with a grain size number falling within a range exceeding 10. This provides a transmission component having an increased anti-crack strength, enhanced dimensional stability, and a long fatigue life. A method of manufacturing such a transmission component and a tapered roller bearing are also provided.

Owner:NTN CORP

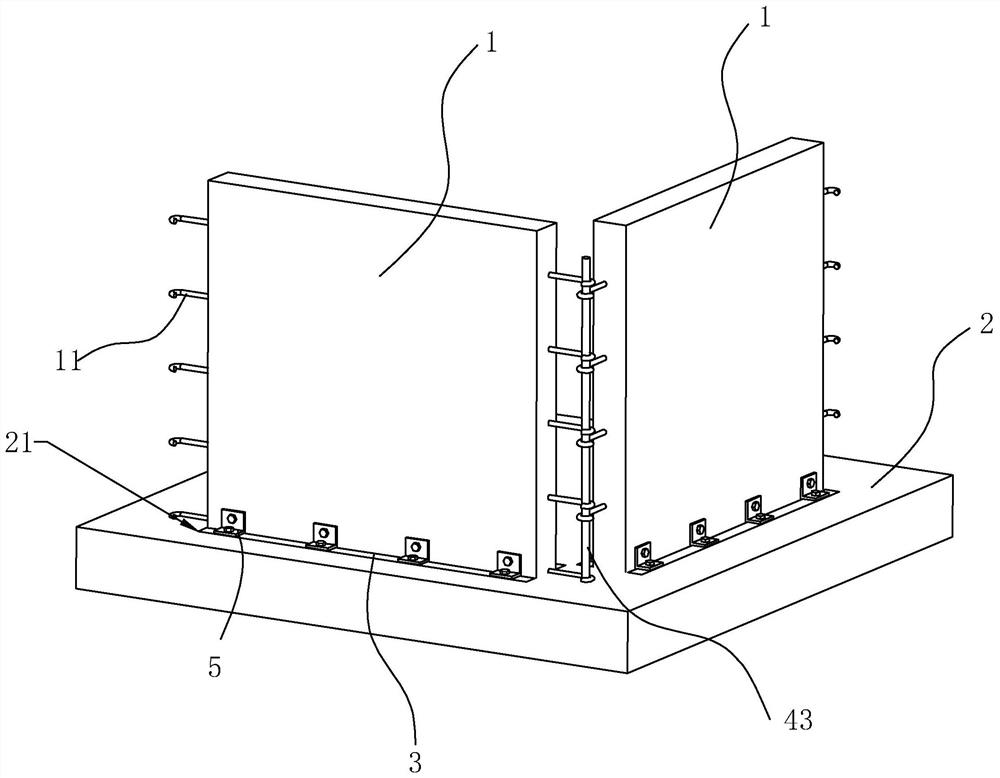

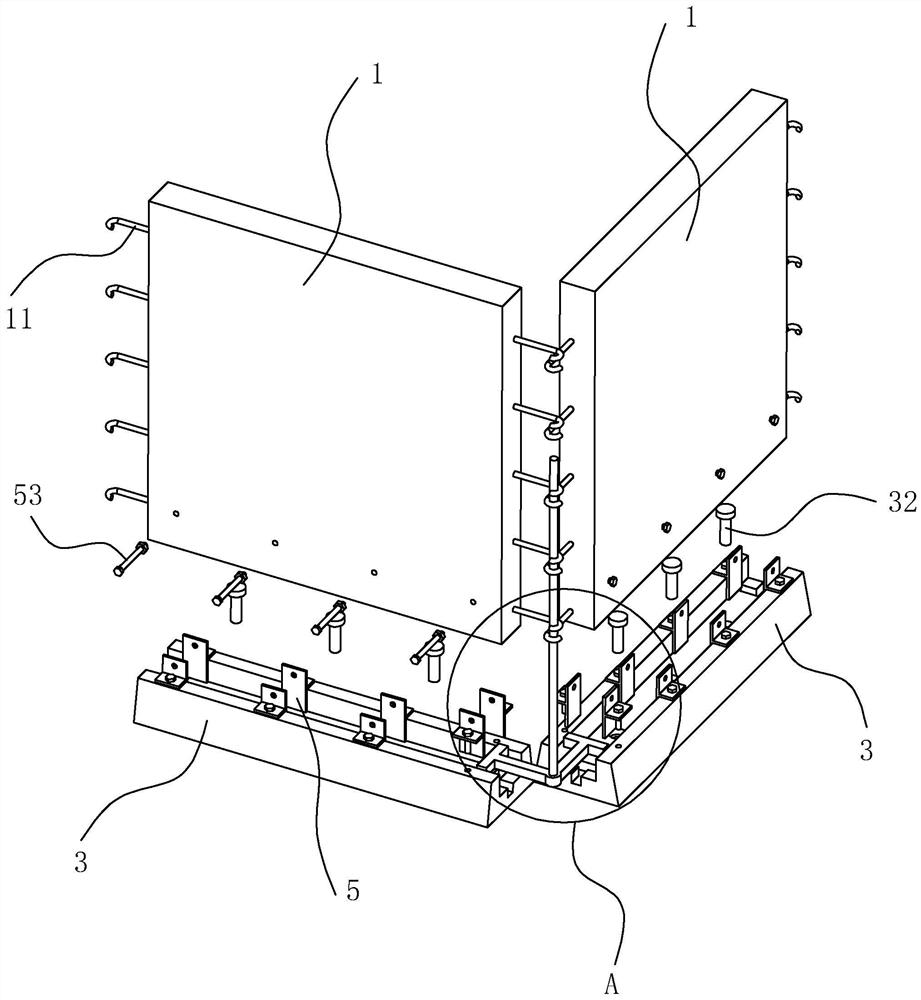

Fabricated concrete wall structure

ActiveCN112922170ANot easy to shiftAchieve adhesive fixationConstruction materialProtective buildings/sheltersIsosceles trapezoidChisel

The invention relates to a fabricated concrete wall structure. The fabricated concrete wall structure comprises a plurality of sets of prefabricated wallboards, the ground is horizontally arranged, a plurality of sets of bases with the same length as the wallboards are horizontally hoisted on the ground, sinking grooves are vertically and concavely formed in the upper end faces of the bases, the wallboards are matched with the sinking grooves in an inserted connection mode, a plurality of sets of inserting holes are vertically formed in the groove bottoms of the sinking grooves, steel chisels with the lower ends penetrating into the ground are inserted into all the sets of inserting holes, the upper end faces of all the sets of steel chisels and the groove bottoms of the sinking grooves are horizontally coplanar, the outer contours of the vertical sections of the bases are in an isosceles trapezoid shape, and the lower end faces of the bases abut against the ground. Settlement of the wallboards on the ground is remarkably reduced, the stability of the wallboards on the soft foundation ground is improved, and the structural stability of the fabricated building is improved.

Owner:广东世纪建设工程有限公司

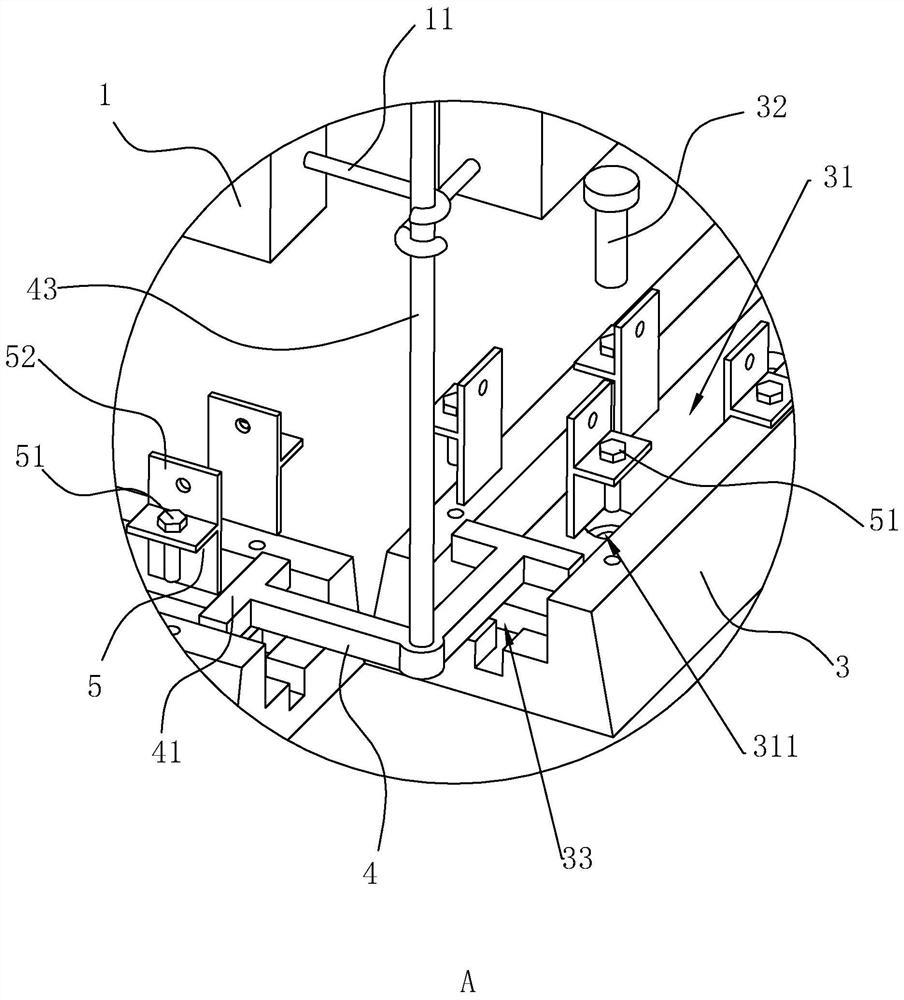

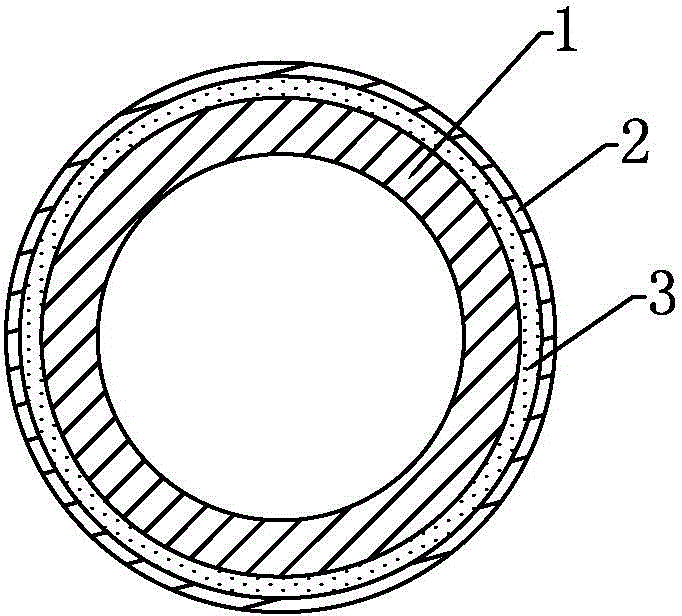

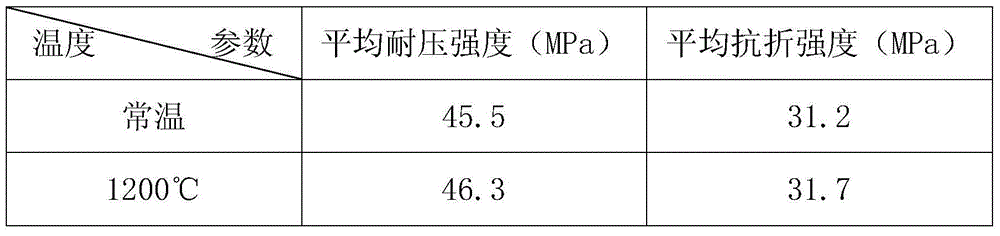

Thermal shock resistant ceramic tube mold and preparation method thereof

The invention belongs to the field of metallurgy casting and smelting, and particularly discloses a thermal shock resistant ceramic tube mold and a preparation method thereof. The thermal shock resistant ceramic tube mold comprises an inner ceramic tube mold, wherein an outer steel-made tube mold layer sleeves the outer side of the inner ceramic tube mold; a self-flowing thermal-resistant casting material is filled between the inner ceramic tube mold and the inner ceramic tube mold; the inner ceramic tube mold is made of the following raw materials in percentage by weight: 40-50% of carbon silicon micro powder, 20-25% of silicon powder, 20-25% of primary aluminum nitride powder, 2-5% of graphite micro powder, 2-3% of zirconium oxide micro powder, 0.5-1% of yttrium oxide micro powder, 0.2-0.5% of absolute ethyl alcohol and 3-4% of an adhesive. The thermal shock resistant ceramic tube mold is high in pressure resistance, good in breaking strength, good in high temperature corrosion resistance and long in service life; when nodular cast iron tubes are produced by using the thermal shock resistant ceramic tube mold, the production procedures can be reduced, the energy is saved, the equipment maintenance expense is reduced, and the production cost is lowered, so that the nodular cast iron pipe thermal shock resistant ceramic tube mold has great significance for the metallurgy tube industry and has wide application prospect and popularization values.

Owner:山东坤能环保科技有限公司

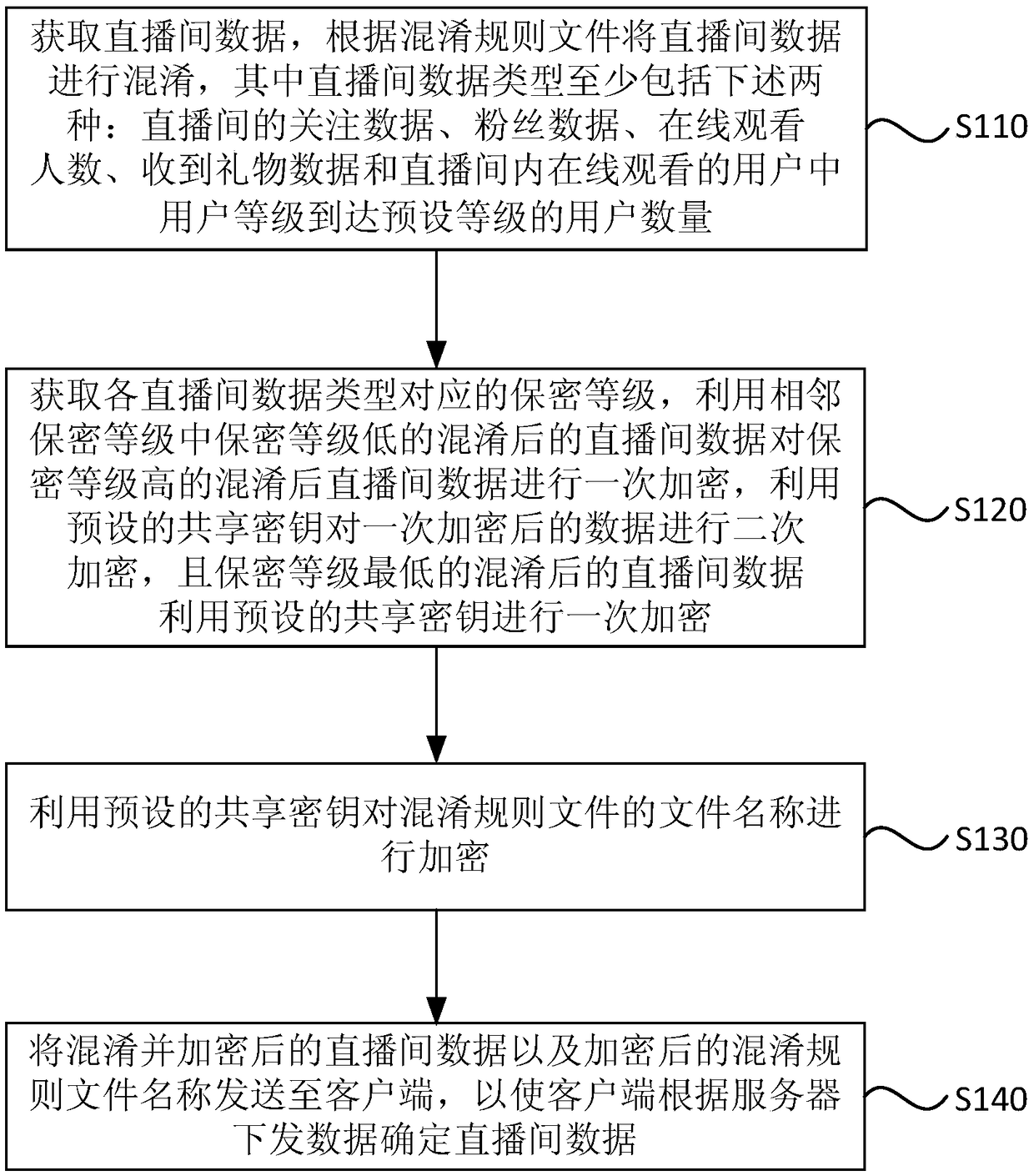

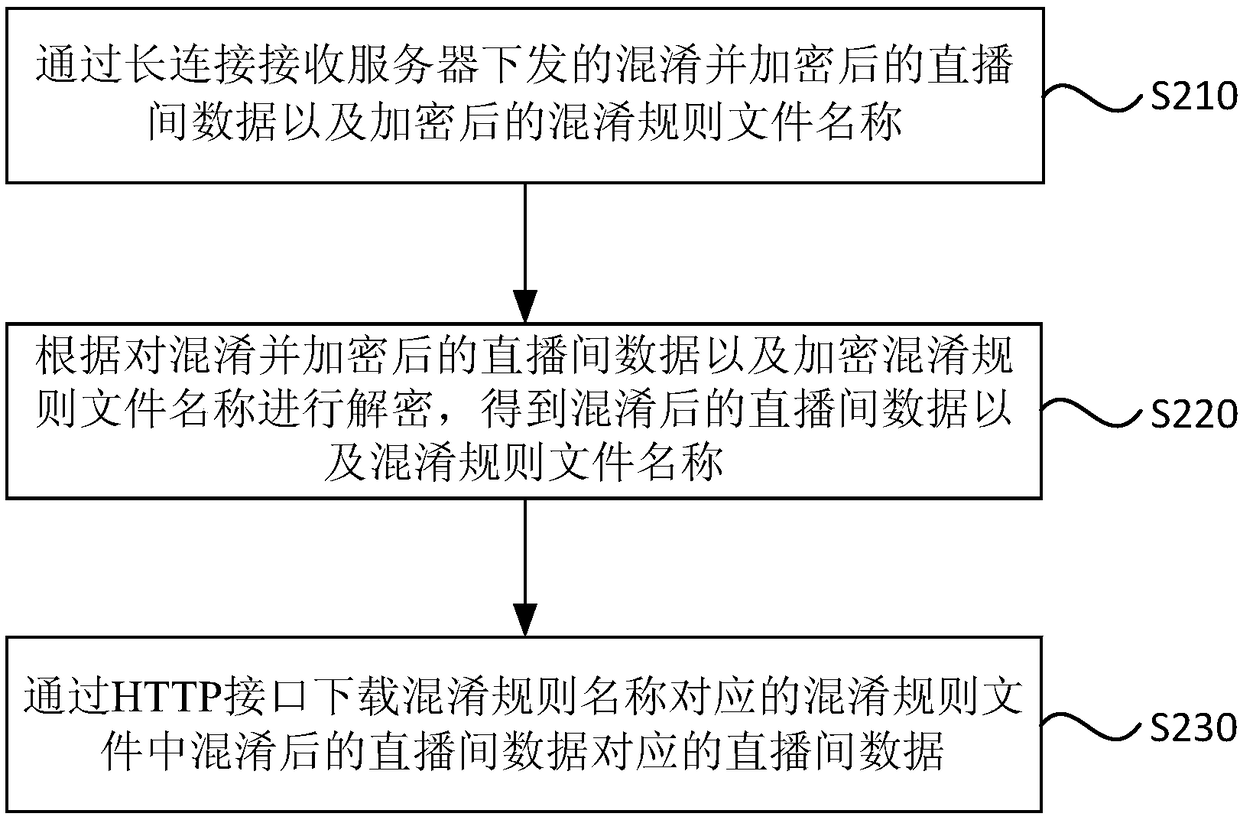

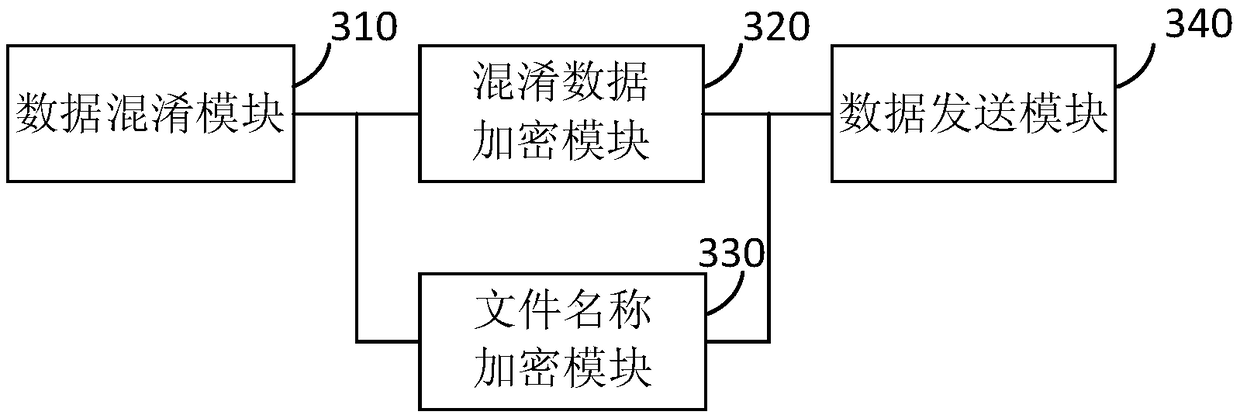

Anti-crawling method, device, terminal and readable medium for live broadcast room data

ActiveCN109067805AImprove cracking strengthEnsure safetyKey distribution for secure communicationObfuscationLow confidentiality

The embodiment of the invention discloses an anti-crawler method, a device, a terminal and a readable medium for the data between live broadcasts. The method comprises the following steps: obtaining the data between live broadcasts; obtaining the data between live broadcasts; obtaining the data between live broadcasts according to the obfuscation rule file; obfuscating the data between live broadcasts. The confusion data with low confidentiality level in the adjacent confidentiality level is used to encrypt the confusion data with high confidentiality level once, the data encrypted once is used to encrypt twice by using the shared key, and the confusion data with the lowest confidentiality level is used to encrypt once by using the preset shared key. Encrypting the file name of the obfuscation rule file by using a shared key. The encrypted confused data and the file name are distributed to the client, so that the client can determine the live broadcast data according to the data distributed by the server. The anti-crawling method, the device, the terminal and the readable medium of the live broadcasting room data provided by the embodiment of the invention improve the data breakingstrength of the live broadcasting room, prevent the crawler from climbing to obtain the correct live broadcasting room data, and ensure the safety of the data of the live broadcasting room.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

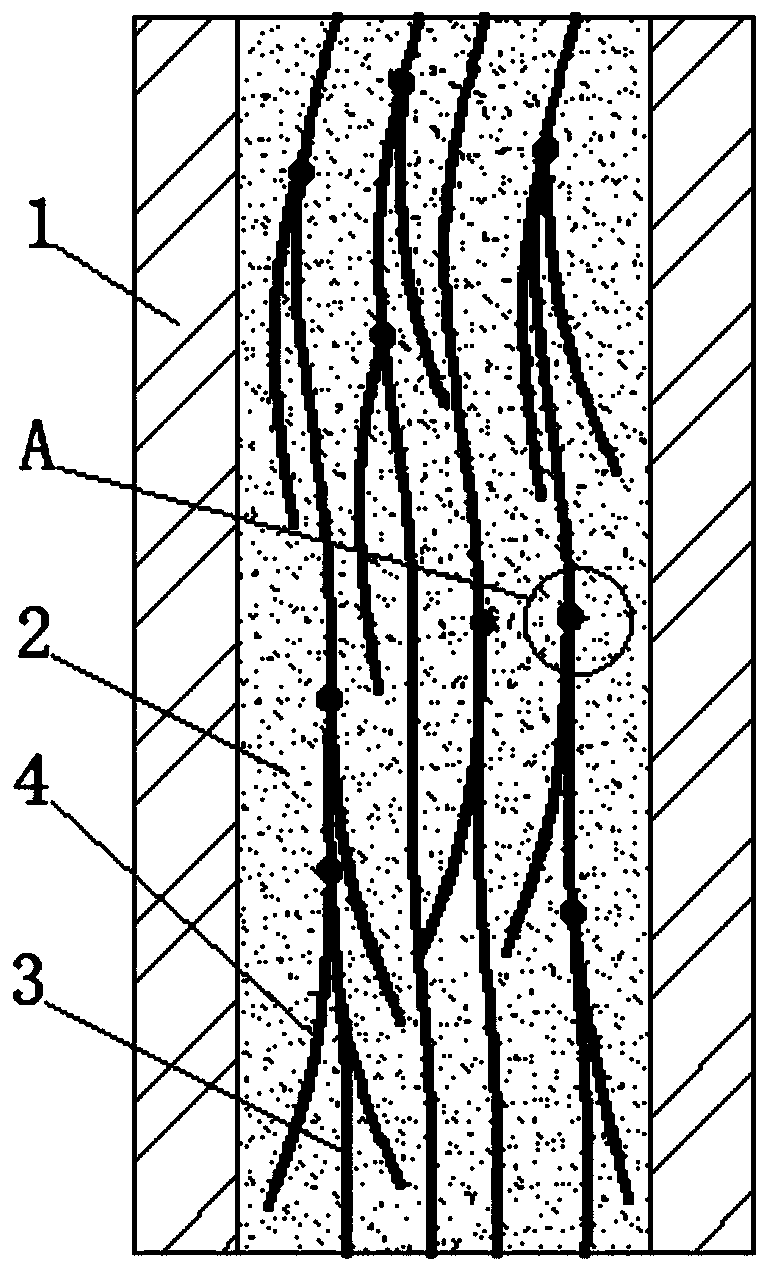

Crack-resistant concrete structure and construction method thereof

ActiveCN110512801AGrowth inhibitionEasy outflowUnderground chambersFoundation engineeringEngineeringStructural engineering

The invention discloses a crack-resistant concrete structure and a construction method thereof, and belongs to the field of concrete structures. According to the crack-resistant concrete structure andthe construction method thereof, the situation that when concrete has signs of cracking, the parts, near cracks, of pre-fracture points can be subjected to relatively large force, and the adjacent pre-rupture points are broken can be realized, internal repair fluid conveniently flows out, then the cracks are repaired and bonded, and the further enlargement of the cracks is effectively suppressed;meanwhile, under the action of multi-branch drawing wires, concrete exhibits tensile properties in the longitudinal direction, after cracking, the concrete can show mutual drag in the longitudinal direction, and the role of enlarging the cracks is further played; and meanwhile, even if the concrete cracks are large, concrete fragments are generated, and under the action of the multi-branch drawing wires, the concrete fragments are difficult to fall and can still be connected to the crack-resistant concrete structure, so that the possibility of injuring workers due to fallen concrete blocks due to cracking is effectively reduced, the safety is improved, and the potential safety hazards are effectively reduced.

Owner:乐清市五星混凝土有限公司

Asphalt mixture additive and preparation method thereof

ActiveCN104559258APerformance is easy to controlImprove road performanceBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt mixture additive and a preparation method thereof. The asphalt mixture additive comprises the following components in parts by mass: 10-20 parts of a polymer, 5-10 parts of a cross linker, 10-20 parts of padding, 0.5-2 parts of a smog inhibitor, 1-2 parts of a plasticizer, 0.1-1 part of an antioxidant and 50-70 parts of matrix asphalt, wherein the matrix asphalt is one of Shell 70#, Shell 90#, SK70# or SK90#. Compared with the prior art, the asphalt mixture additive has the advantages that the anti-rutting performance and water damage resistance of an asphalt mixture can be significantly improved, the low-temperature cracking resistance and ageing resistance of asphalt concrete can be effectively improved, and the service life of asphalt roads is prolonged; meanwhile, the asphalt mixture additive can substitute about 15-25% of asphalt raw materials in the asphalt mixture, so that the production temperature is reduced to 140 DEG C, then the smoking phenomenon in the production and spreading processes is effectively reduced, and the asphalt mixture additive is energy-saving and environment-friendly; and the production method is simple, low in cost and suitable for industrialized production.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

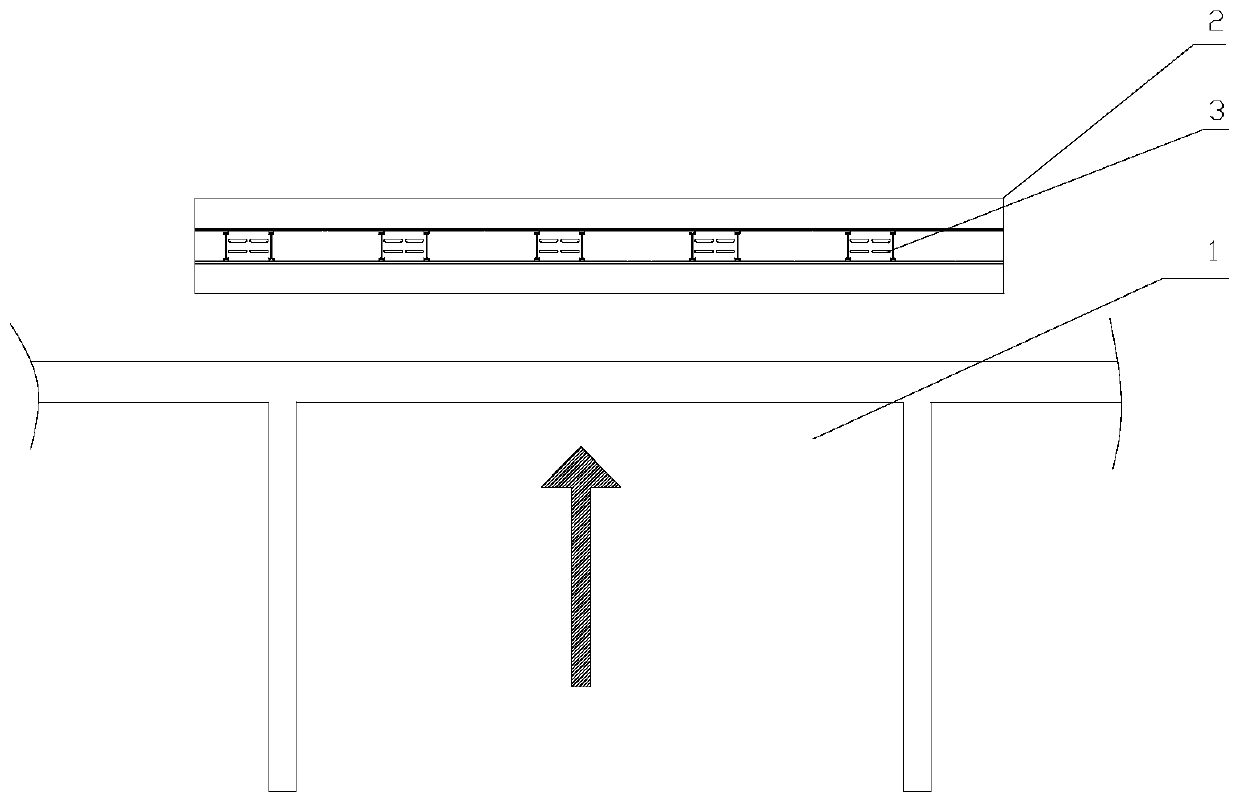

Embedding structure and method for improving pavement cracking around luminous floor tile

ActiveCN111254779ASolve the problem of stagnant waterAchieve horizontal scalingSingle unit pavingsPaving gutters/kerbsPondingCarriageway

The invention discloses an embedding structure and method for improving pavement cracking around a luminous floor tile. A pavement groove is embedded above a pavement, the luminous floor tile is arranged above the pavement groove, the pavement groove is dug between a zebra crossing and a carriageway, a base concrete layer is arranged at the upper part in the pavement groove, angle steel is arranged in an angle steel mounting groove through an angle steel bolt, reinforcing steel bars are arranged on one side above the base concrete layer, a drainage groove is formed at the middle above the baseconcrete layer, an anchoring plate and deformed steel are vertically arranged above the angle steel, an expansion joint rubber strip is arranged between the anchoring plate and the deformed steel, ananchoring rib is connected to the reinforcing steel bars in a welded mode, a bottom plate is arranged at the bottom of the deformed steel, both ends of partition plates are arranged in partition plate installation grooves through installation groove rubber strips, the luminous floor tile is arranged on a floor tile supporting plate, a second concrete layer is arranged on the base concrete layer,and an asphalt surface layer is arranged on the second concrete layer. The problem of water accumulation at the bottom of a cast iron box of an existing pavement light-emitting device can be solved, the pavement telescopic effect is solved, and damage of brake starting to the pavement is reduced.

Owner:NANTONG UNIVERSITY

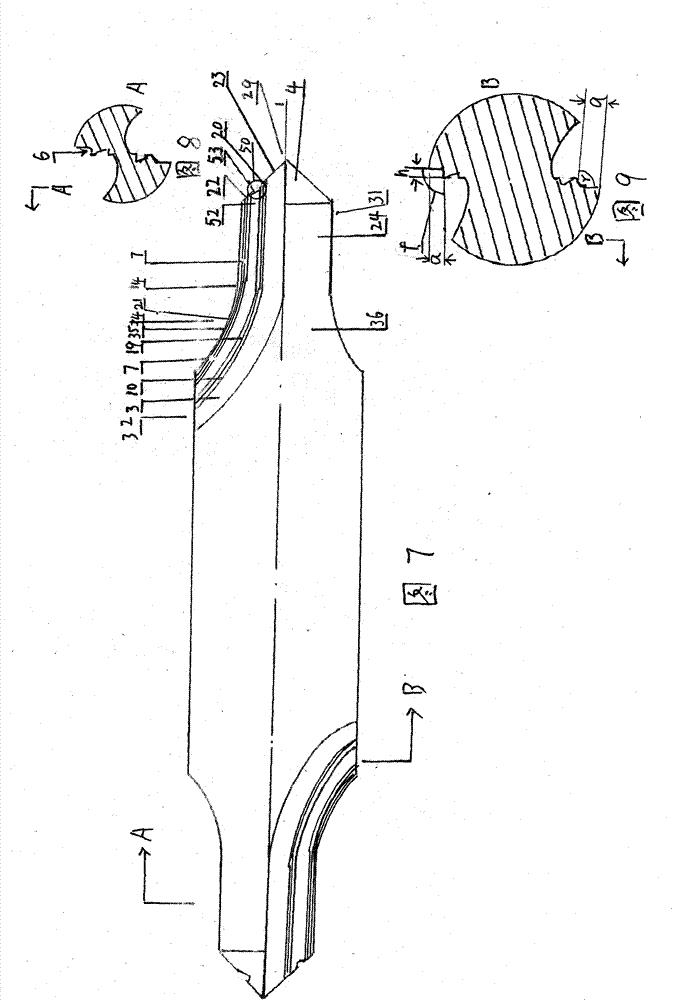

Helix milling cutter with compound blade

InactiveCN103381501AImprove cutting efficiencyExtended service lifeMilling cuttersMilling cutterEngineering

The invention provides a helix milling cutter with a compound blade, and the helix milling cutter has high efficiency, high strength and a long service life. The helix milling cutter is provided with a cutter handle or a locating hole and a cutter head which are connected with each other or integrated together, and the cutter head is integrally provided with a plurality of cutter stripes or cutter bodies or helix cutting stripes. The helix milling cutter with the compound blade is characterized in that: a definition is formed about the height relationship between a crack-resisting slitting platform or a high-efficiency slitting platform and an inside adjacent high-efficiency slitting platform; the included angle between a composite helix cutting face and an adjacent composite locating disintegrating platform is more than or equal to 90 DEG; or the height difference of two adjacent composite helix cutting faces is more than or equal to 0.01 mm, or less than four fifths of the thickness of an discharged chip, or less than or equal to a height accounting for 9 times of the cutting feeding amount; or the thickness of the crack-resisting slitting platform is more than 0.6 mm, or less than or equal to one third of the diameter of the milling cutter; or a helix groove is disposed at the composite helix cutting face.

Owner:李仕清

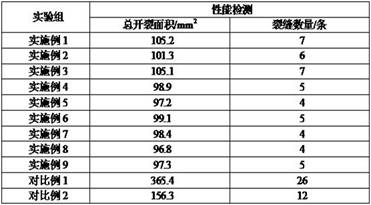

Anti-cracking recycled concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses anti-cracking recycled concrete and a preparation method thereof. A waterproof and corrosion-resistant wood board for a laboratory fume hood is prepared from 55-60 parts of cement, 20-30 parts of water, 25-30 parts of fly ash, 0.2-0.4 parts of cellulose ether, 6-8 parts of entangled fibers, 3-5 parts of SiO2 aerogel particles and 80-100 parts of recycled aggregate; The entangled fibers are prepared by mixing wollastonite fibers and polypropylene fibers according to a mass ratio of 1: (6-8). The preparation method comprises the following preparation steps of: S1, coating modification of recycled aggregate; S2, premixing treatment; and S3, mixing again. According to the recycled concrete, wollastonite fibers and polypropylene fibers are entangled and compounded and are mutually lapped to form a three-dimensional network, the three-dimensional network and a concrete aggregate structure jointly resist the action of shear force, and the anti-cracking strength of the recycled concrete material is improved.

Owner:叶智勇

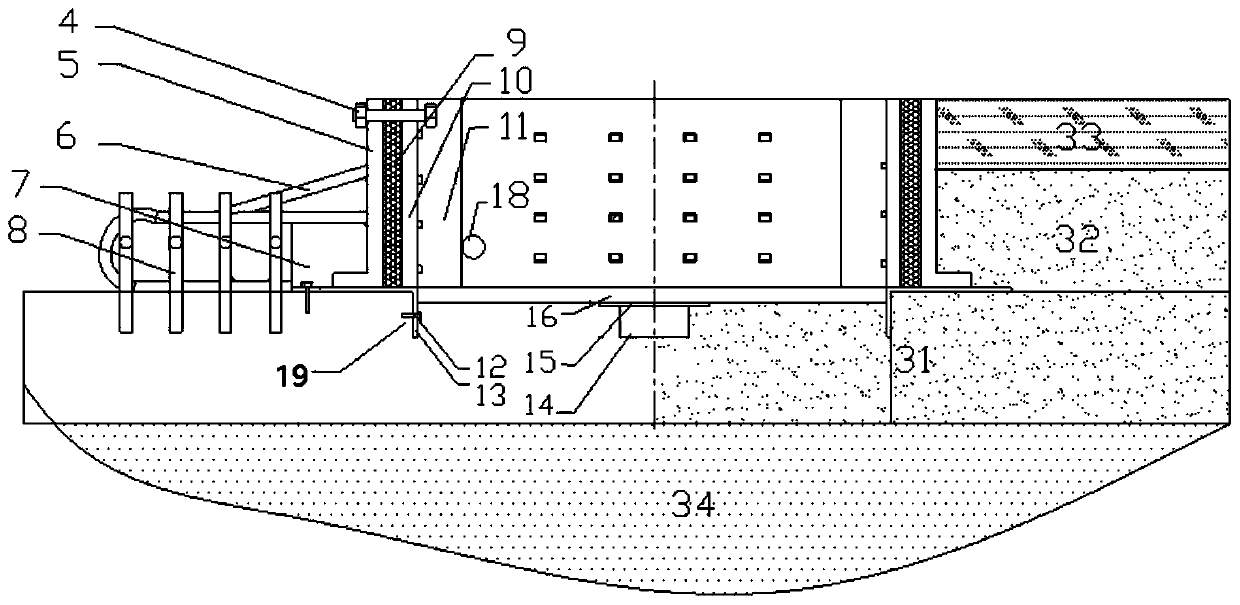

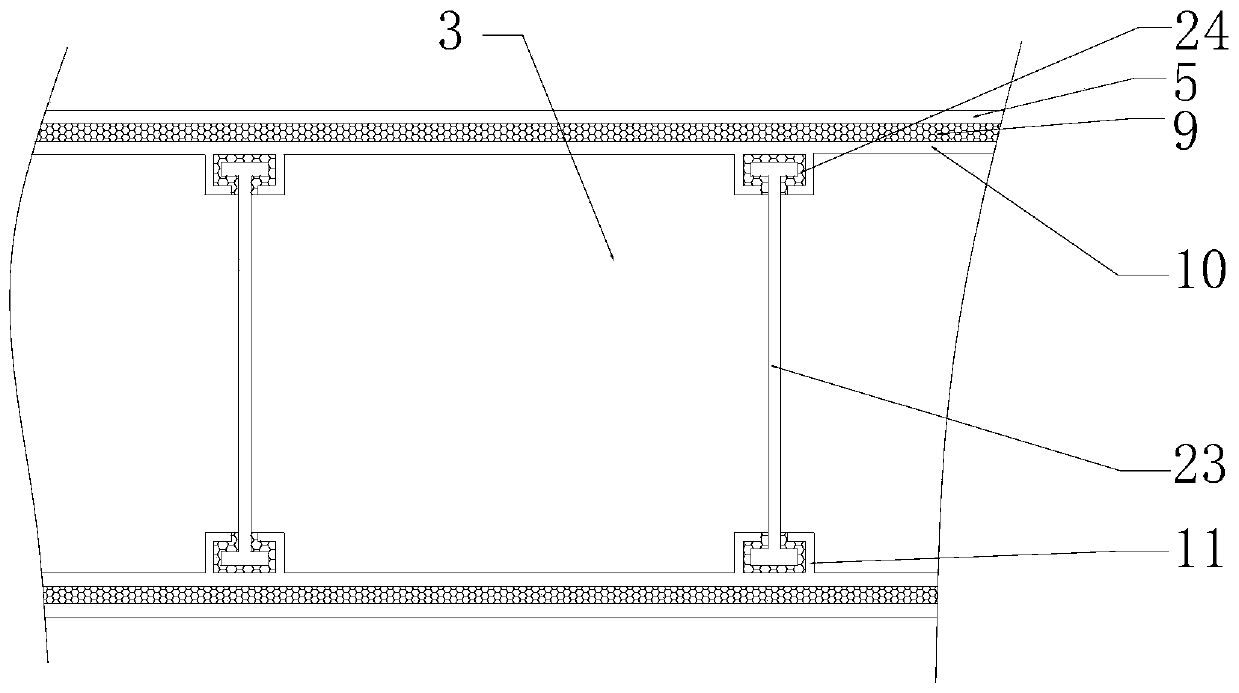

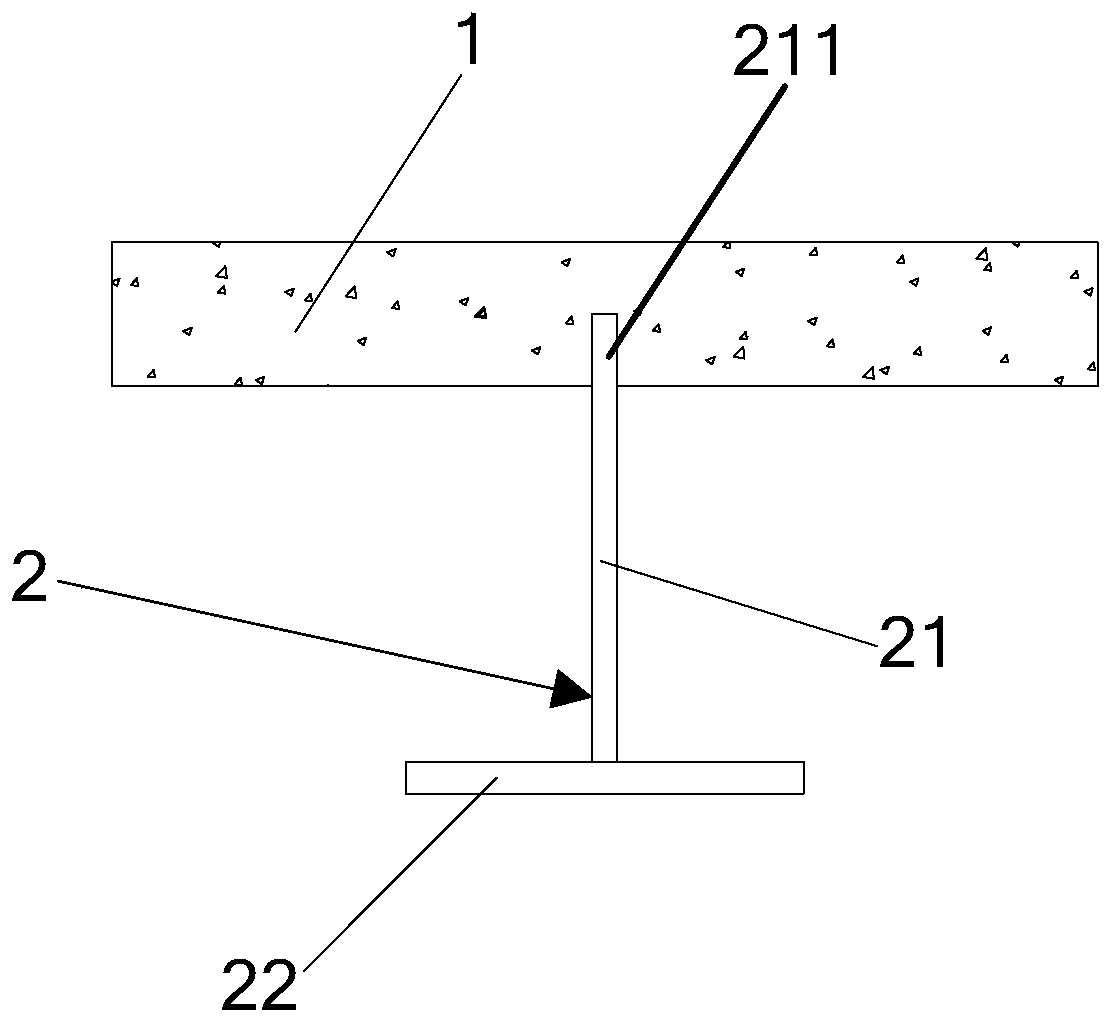

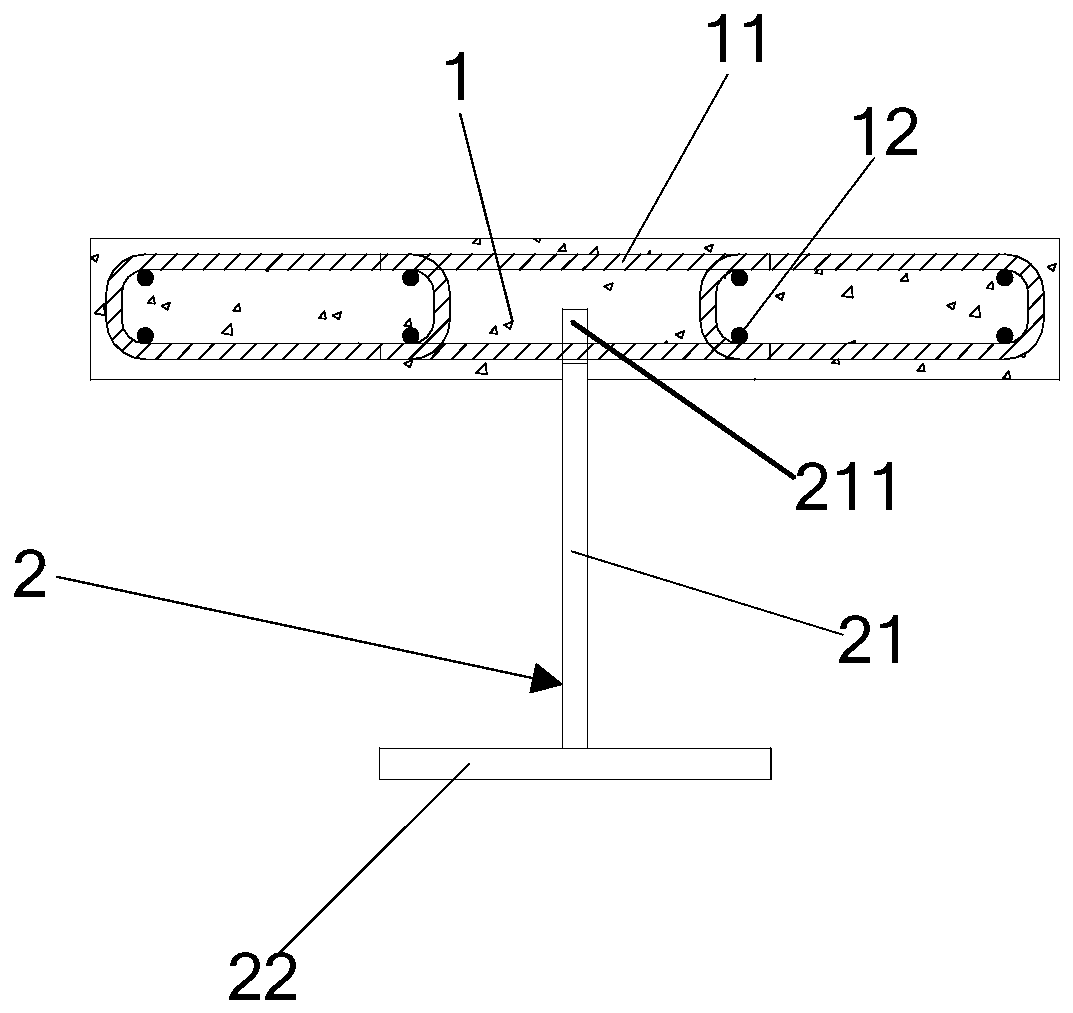

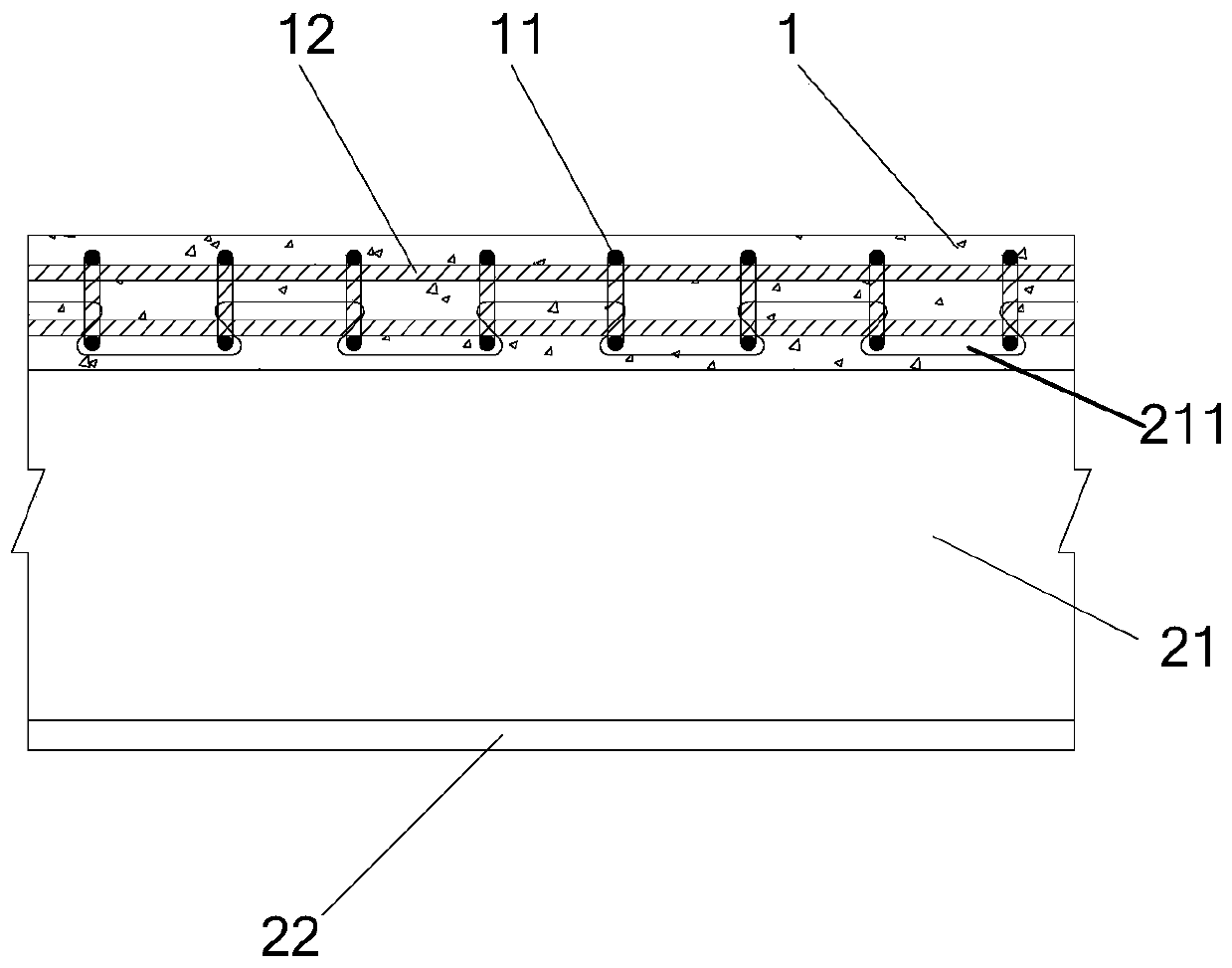

Combined beam and manufacturing method thereof

PendingCN110158447AImprove cracking strengthIncreased durabilityBridge structural detailsBridge erection/assemblyShear stiffnessEngineering

The invention relates to the field of bridge construction, and discloses a combined beam. The combined beam comprises a concrete plate, wherein transverse steel bars are arranged in the concrete plateat intervals. The combined beam further comprises an inverted T-shaped steel beam, the inverted T-shaped steel beam comprises a web plate and further comprises a wing plate, wherein a connecting partis arranged on one side of the web plate, the connecting part is arranged in the concrete plate, the web plate is connected with the transverse steel bars through the connecting part, and the wing plate is connected with the web plate in a perpendicular mode. The invention further discloses a manufacturing method of the combined beam. The mode that the connecting part is connected with the transverse steel bars in the concrete plate is adopted in the combined beam and is compared with the mode that shearing force nails are adopted to achieve the connection between a steel plate and a concreteplate, the advantages of being high in shear stiffness, high in bearing capacity, good in ductility and the like; and in addition, the combined beam is simple in structure, convenient and fast to construct, high in cracking strength and good in durability. According to the combined beam and the manufacturing method thereof, the defects that when the mode that the shearing force nails are adoptedto achieve the connection between the steel plate and the concrete plate is adopted, the shear resistance and the bearing capacity of a connecting piece are low, the shear stiffness is low, and the ductility is poor are overcome, and the problems that the concrete plate is prone to cracking, and the durability is poor are solved.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Bicomponent cement base polystyrene foamed particle heat insulation paint

The present invention relates to a double-component cement base polystyrene foam particle heat-insulating coating. Its composition includes (by weight portion) 2-6 portions of polystyrene foam particles, 1-15 portions of fly-ash, 40-45 portions of water, 0.1-0.3 portion of thickening powder, 3-5 portions of modifying agent, 0.1-2 portions of reinforcing fibre, 30-50 portion of Portland cement, 0.05-1 portion of excitation agent and 0.1-0.3 portion of foaming agent. Said invention also provides its preparation method and application.

Owner:常熟市蓝都弹性涂料有限公司

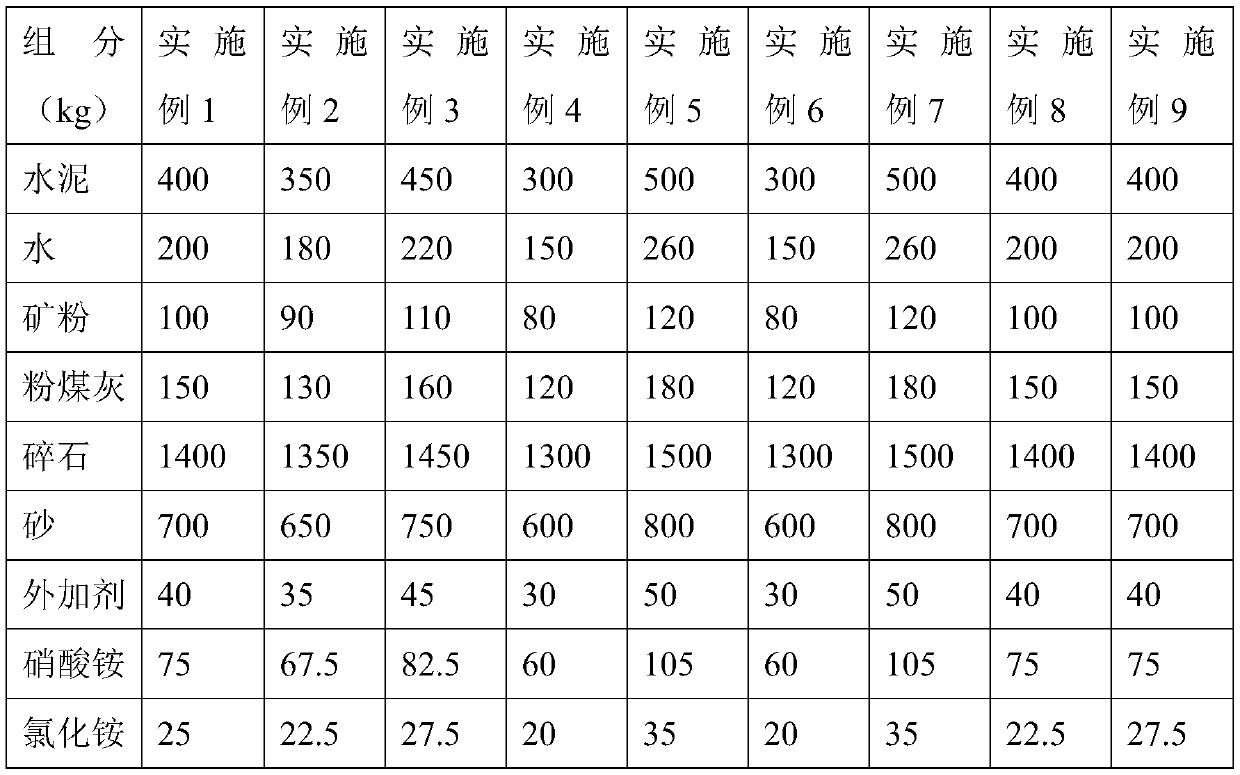

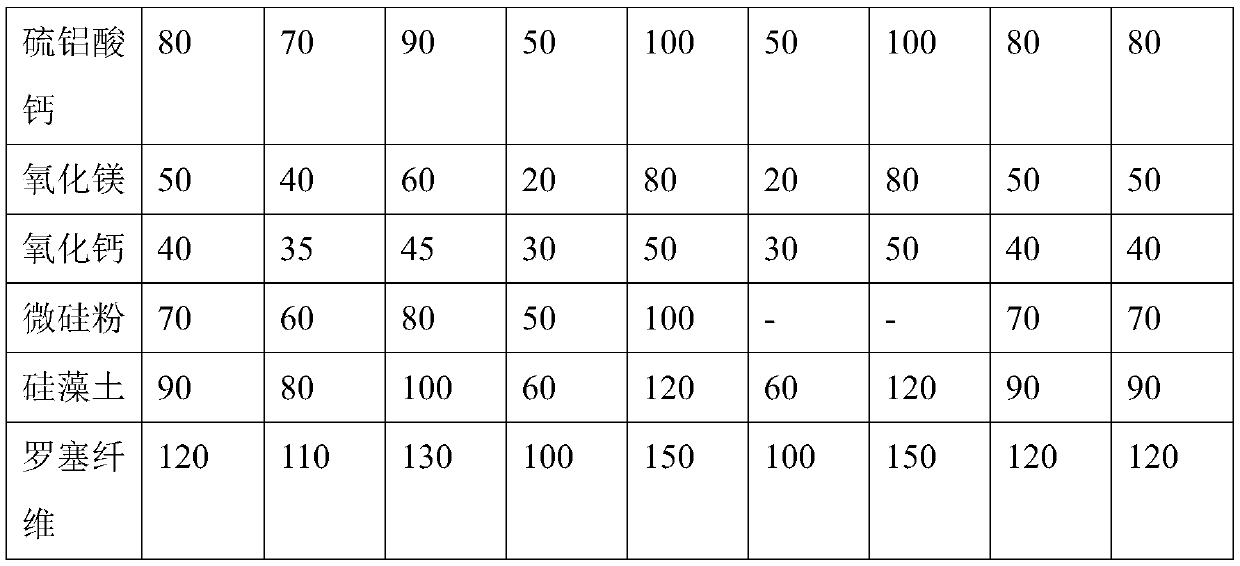

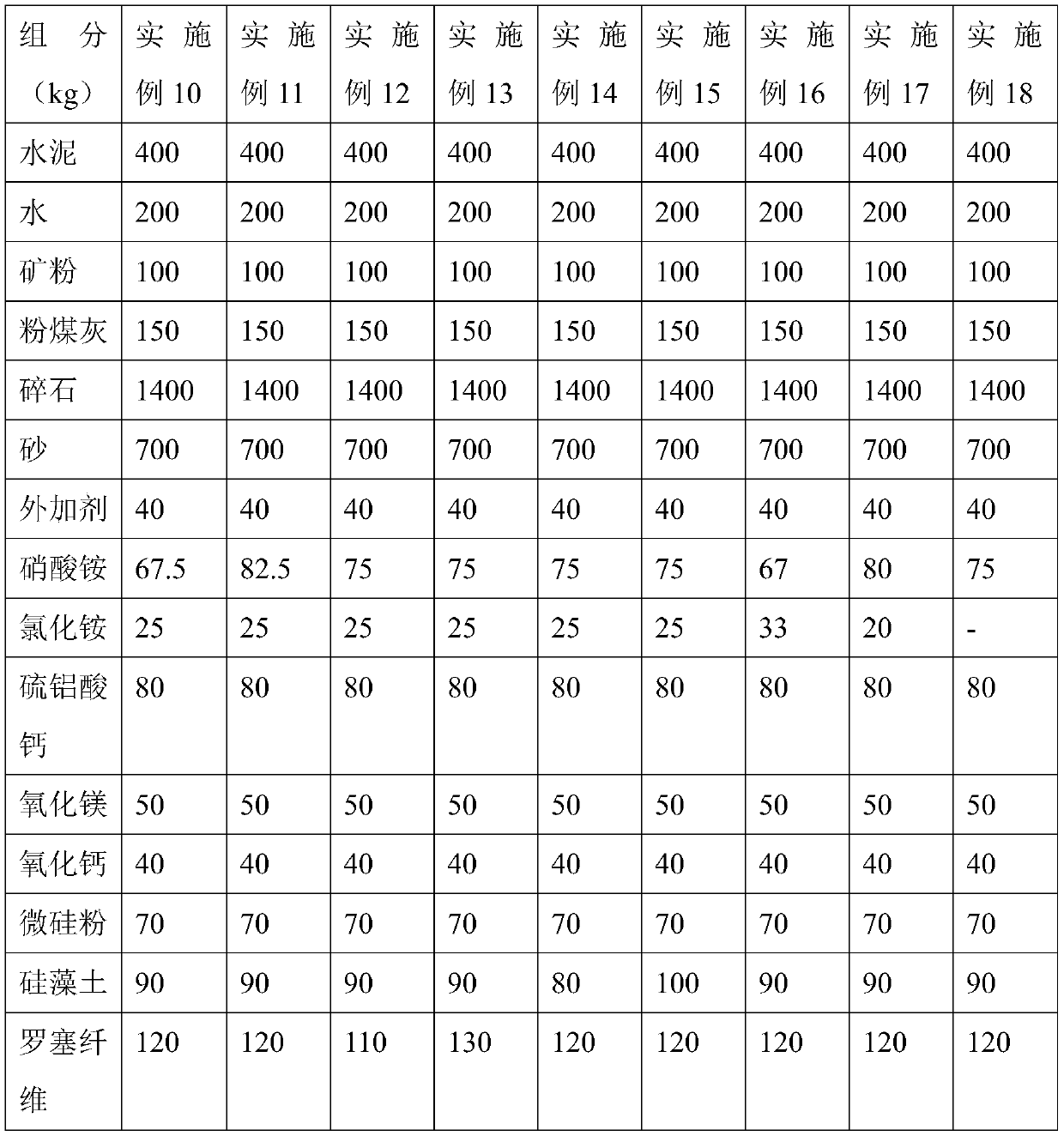

Crack-resistant mass concrete and preparation method thereof

InactiveCN110467413AImprove cracking strengthReduce the temperature difference between inside and outsideFiberCrack resistance

The invention discloses crack-resistant mass concrete and a preparation method thereof, wherein the crack-resistant mass concrete is prepared from the following raw materials by weight: 300-500 partsof cement, 150-260 parts of water, 80-120 parts of mineral powder, 120-180 parts of fly ash, 1300-1500 parts of crushed stone, 600-800 parts of sand, 30-50 parts of an admixture, 80-140 parts of an ammonium salt, 100-230 parts of an expansion agent, 60-120 parts of diatomite, and 100-150 parts of Roycele fiber, wherein the ammonium salt comprises one or two selected from ammonium nitrate and ammonium chloride. The preparation method comprises: pouring crushed stone, pouring Roycele fiber, pouring sand and diatomite, stirring for 5-10 min, pouring cement, fly ash, mineral powder and an expansion agent, stirring for 10-15 min, dissolving an admixture in water, adding the dissolved admixture, stirring for 5 min, adding an ammonium salt, and stirring for 20-30 min to obtain the product. According to the present invention, the prepared concrete has advantages of low hydration heat, high strength and excellent crack resistance.

Owner:北京城建九秋实混凝土有限公司

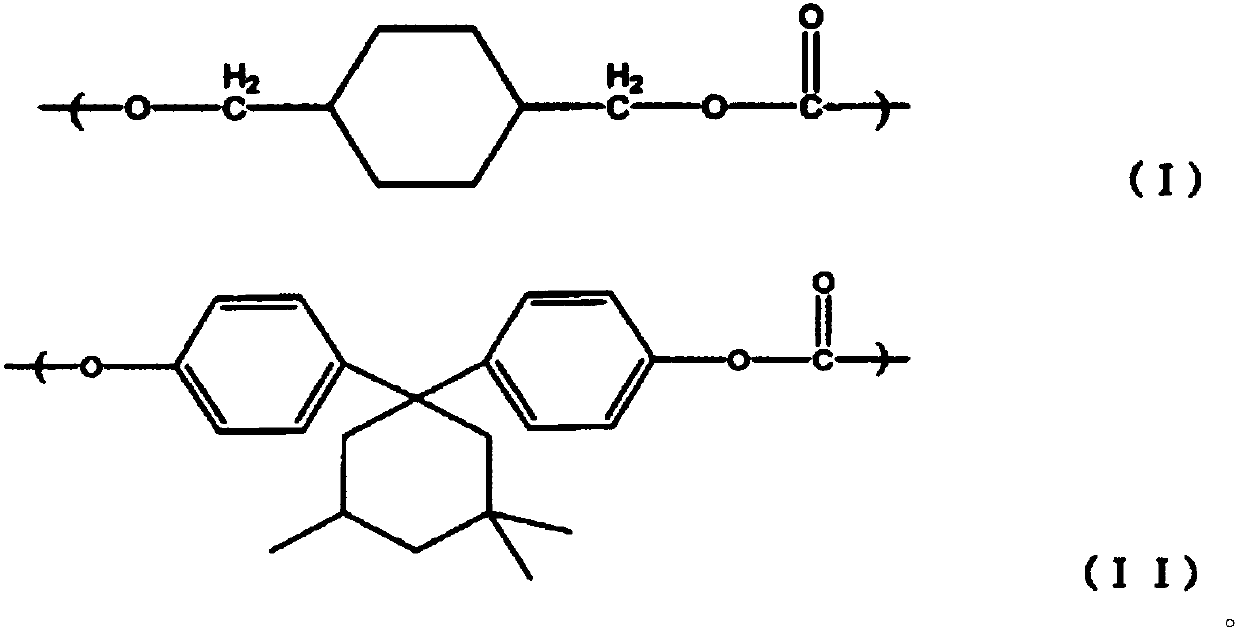

Environment-friendly and flame-retardant PET-PC (polyethylene terephthalate - polycarbonate) alloy material and preparation method thereof

InactiveCN105295313AImprove cracking strengthStrong stretch resistanceCorrosion resistantAntioxidant

The invention discloses an environment-friendly and flame-retardant PET-PC (polyethylene terephthalate - polycarbonate) alloy material and a preparation method thereof. The environment-friendly and flame-retardant PET-PC alloy material comprises the following components in percentage by weight: 55% to 70% of PET slices, 15% to 25% of PC particles, 5% to 8% of phosphate ester type flame retardant, 3% to 4% of thermoplastic elastomer, 0.6% to 1% of antioxidant, 0.1% to 0.2% of lubricant, and 2% to 4% of compatilizer. The environment-friendly and flame-retardant PET-PC alloy material has the advantages that by selecting the components and reasonably proportioning, the advantages of PET material and PC material are simultaneously realized; the cracking-resistant strength is high, the tensile-resistant property is high, the heat-resistant, abrasion-resistant and corrosion-resistant properties are realized, the processing fluidity is good, and the mechanical and chemical comprehensive properties are better; the processing technology is improved, and is more reasonable and scientific, so that the cost is reduced, the energy consumption is decreased, and the environment-friendly and energy-saving effects are realized.

Owner:符瞰

Composite milling cutter

InactiveCN103706854AImprove cracking strengthReduce and break down cutting resistanceMilling cuttersEngineeringMilling cutter

The invention provides a composite milling cutter. The composite milling cutter is high in efficiency and strength, and long in service life, and is provided with a cutter handle or a locating hole and a cutter head. The composite milling cutter is characterized in that: on a cutting face arrange toward the helix direction, a triangle groove or a trapezoid-shaped groove, or an arc triangle groove or an arc trapezoid-shaped groove is arranged, or an arc-shaped convex, or an inclined convex and concave is arranged, and at least one grade bottom or side part is provided, a plurality of internal inclined cutting faces arranged with an angle more than 90 DEG and less than 180 DEG with the helix cutting face are provided, or a plurality of composite helix cutting faces; or extending of the arc-shaped convex or the inclined convex forms a compound locating resolution platform which is connected with an internal composite helix cutting face, forms a plurality of internal inclined blades or side concave blades, or side inclined blades, so that cutting stress is inclined toward inside, force arm is reduced, outside cutting resistance is resolved, cutting efficiency and service life of the composite milling cutter are increased and prolonged to a largest value respectively, cost is reduced, and resources are saved.

Owner:李仕清

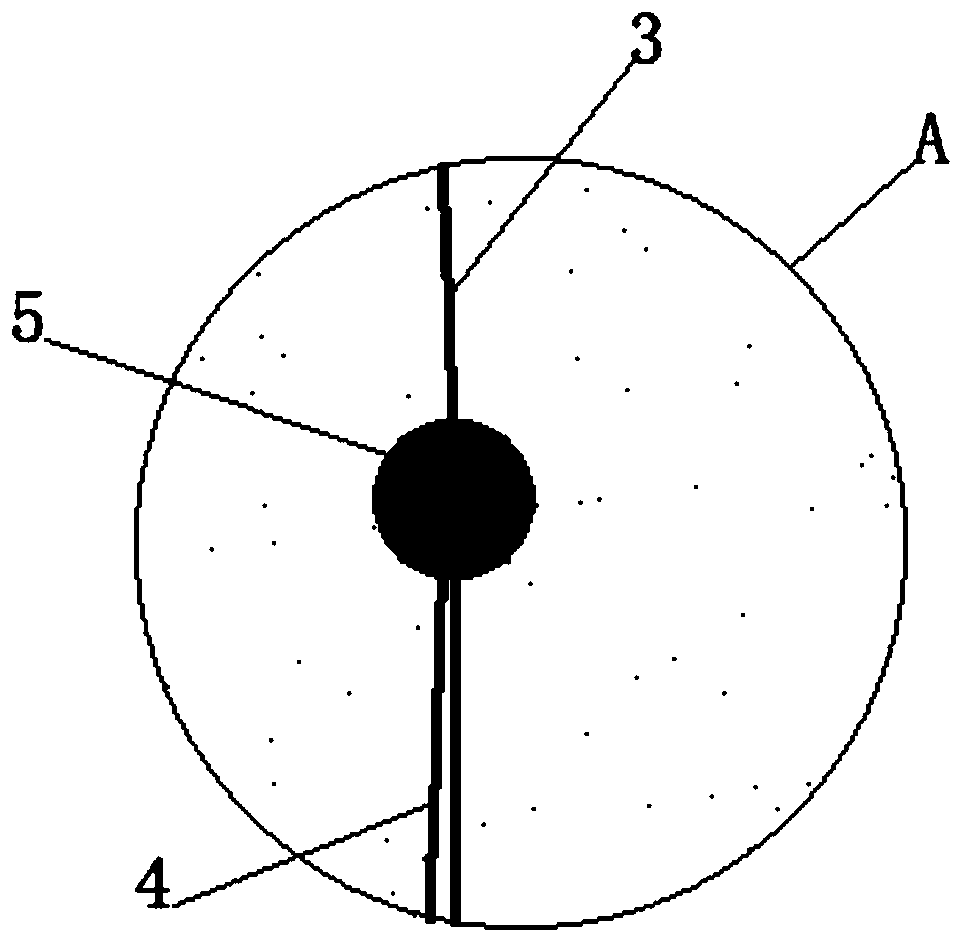

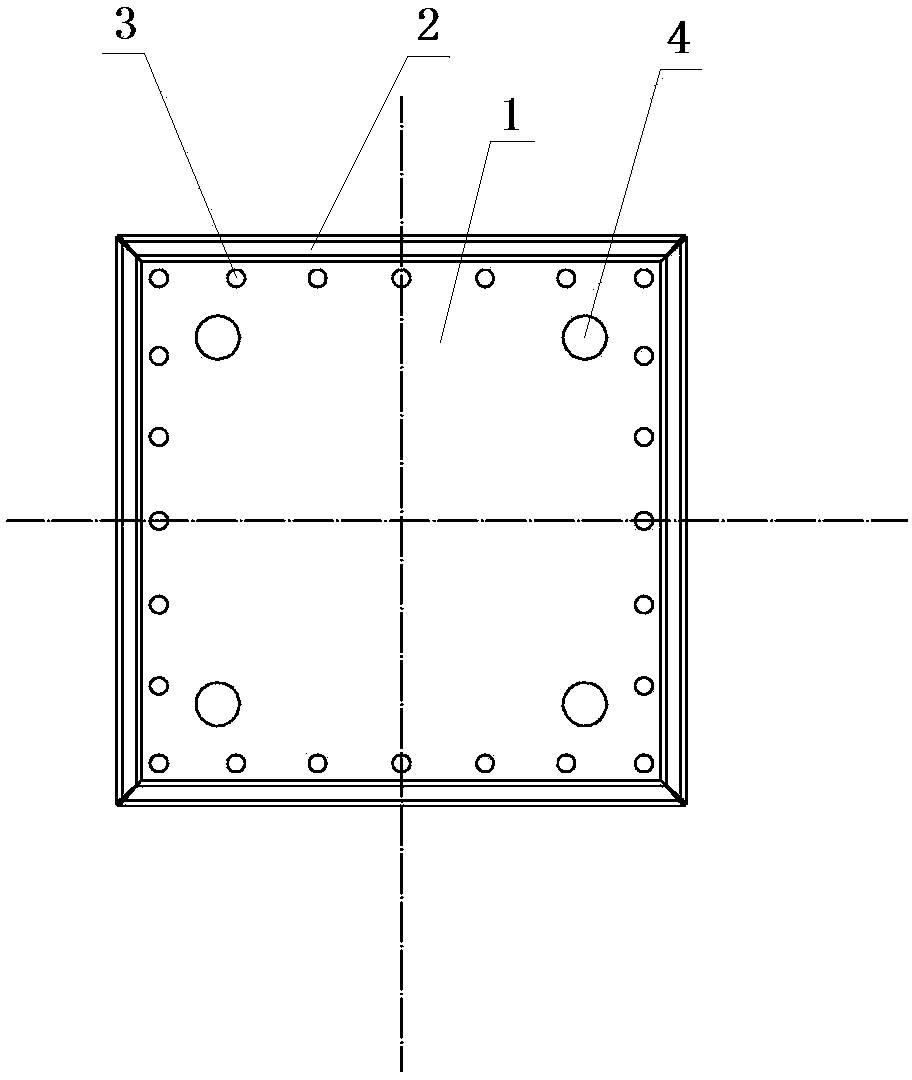

Full pre-stressing solid square pile end board

The invention discloses a full pre-stressing solid square pile end board which comprises a square bottom board (1). A plurality of threading holes (3) enabling reinforcing steel bars to penetrate are formed in the periphery of the bottom board (1), a pile splicing anchoring hole (4) is formed in the inner side of each threading hole (3), and an outer edge (2) of the bottom board (1) is folded upwards. The full pre-stressing solid square pile end board is arranged on the end portion of a square pile, a main reinforcing bar is located through the end board, and after the stretch-draw stress is exerted on the end board, the phenomenon that the accuracy of a stretch-draw stress value is influenced due to natural deflection caused by the length of the pre-stressing main reinforcing bar is avoided. The section face, generated by the end board, of the pre-stressing square pile is not flat and the cracking resistance when piling is conducted is improved. The end board is used for producing the pre-stressing square pile, so that labor and time are saved, quality is guaranteed, the production efficiency is improved, the job progress is guaranteed, the economic benefit of an enterprise is improved, and high praise of a user can be obtained.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Environmentally-friendly power transmission rack

ActiveCN105330227AImprove freeze-thaw resistanceHigh freeze-thaw resistanceSolid waste managementTowersEnvironmental resistanceEggshell

The invention belongs to the field of electric power materials, and discloses an environmentally-friendly power transmission rack. The environmentally-friendly power transmission rack is made from, by weight, 1-2 parts of corn straws, 1-2 parts of peanut shells, 2-3 parts of polyurethane foam, 2-3 parts of eggshells, 2-3 parts of fish bone wastes, 2-3 parts of sodium dodecyl benzene sulfonate, 3-4 parts of a sodium hydroxide solution, 20-30 parts of phosphogypsum, 25-35 parts of fly ash, 30-40 parts of carbide slag, 35-45 parts of blast furnace slag, 40-60 parts of water, 60-80 parts of crushed stones and 100-120 parts of No. 42.5 ordinary Portland cement. The power transmission rack has the advantages of wide material sources, massive use of wastes, saving and environmental protection.

Owner:南通旭德科技有限公司

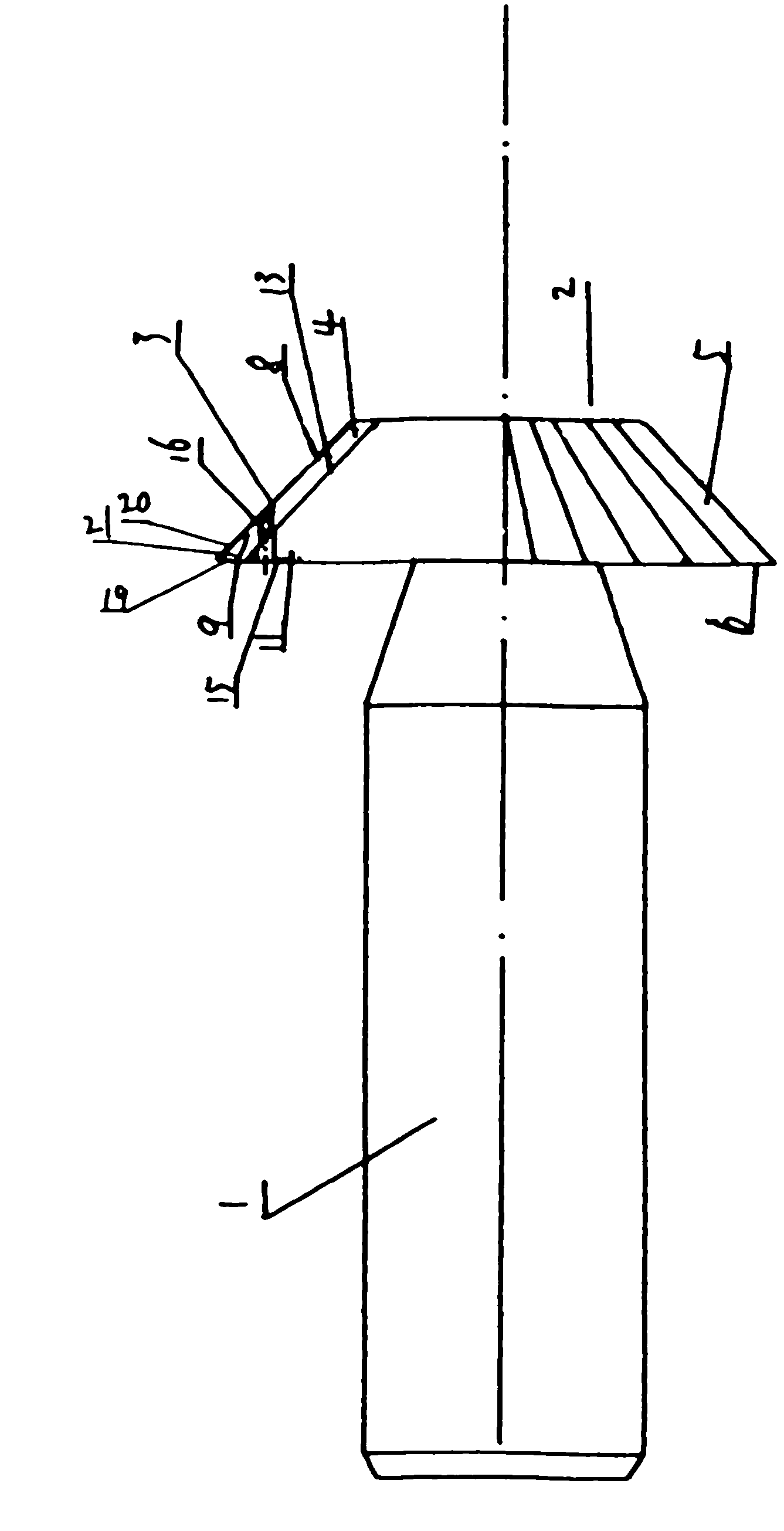

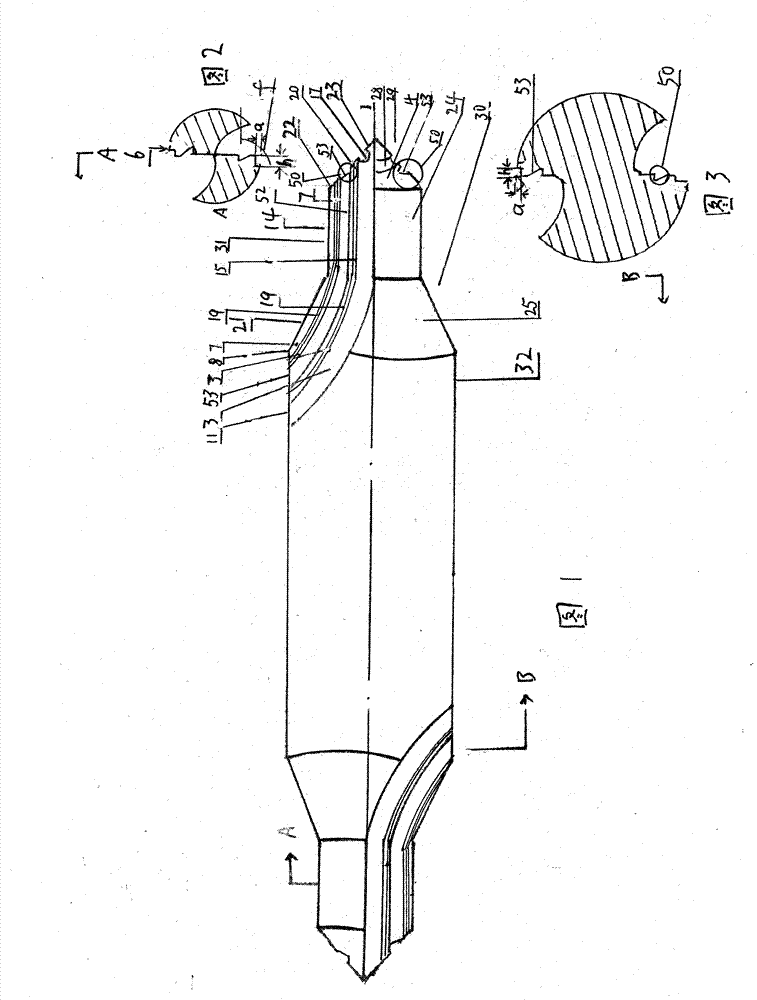

Combined-edge center drill or combined-edge countersink

InactiveCN103706844AImprove cracking strengthReduce and break down cutting resistanceTransportation and packagingCenter drillsMachiningTwist drill

The invention provides a combined-edge center drill or combined-edge countersink and mainly relates to a machining twist drill for machining. The combined-edge center drill or combined-edge countersink is high in stability, high in radiating efficiency, long in service life and easy to position for drilling. The combined-edge center drill or combined-edge countersink is characterized in that cutting faces in the rotation direction are provided with at least one level of bottom or lateral various inner bevel cutting faces or various combined cutting faces in the manners of triangular grooves, or trapezoidal grooves, or arc triangular grooved indentations, or arc triangular grooved indentations, or arc projections or bevel projecting indentations; the inner bevel cutting faces or combined cutting faces have included angles of larger than 90 degrees and smaller than 180 degrees with the cutting faces or combined cutting faces; or by means of arc projections or bevel projecting upright extensions, the cutting faces are provide with combined positioning decomposition steps, intersecting with the inner combined cutting faces, and various inner bevel edges, or lateral indented edges or lateral bevel edges. Therefore, cutting stress inclines inwards, arms of force are reduced, outer cutting resistance is decomposed, cutting efficiency of the combined-edge center drill or combined-edge countersink is maximized, the service life of the combined-edge center drill or combined-edge countersink is maximally prolonged, the cost is reduced, and resources are saved.

Owner:李仕清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com