Combined-edge center drill or combined-edge countersink

A countersink drilling and compound cutting technology, which is applied in the direction of center drilling, drilling/drilling equipment, drilling repair, etc., can solve the problems of prone to waste products, poor centering structure, and unqualified precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

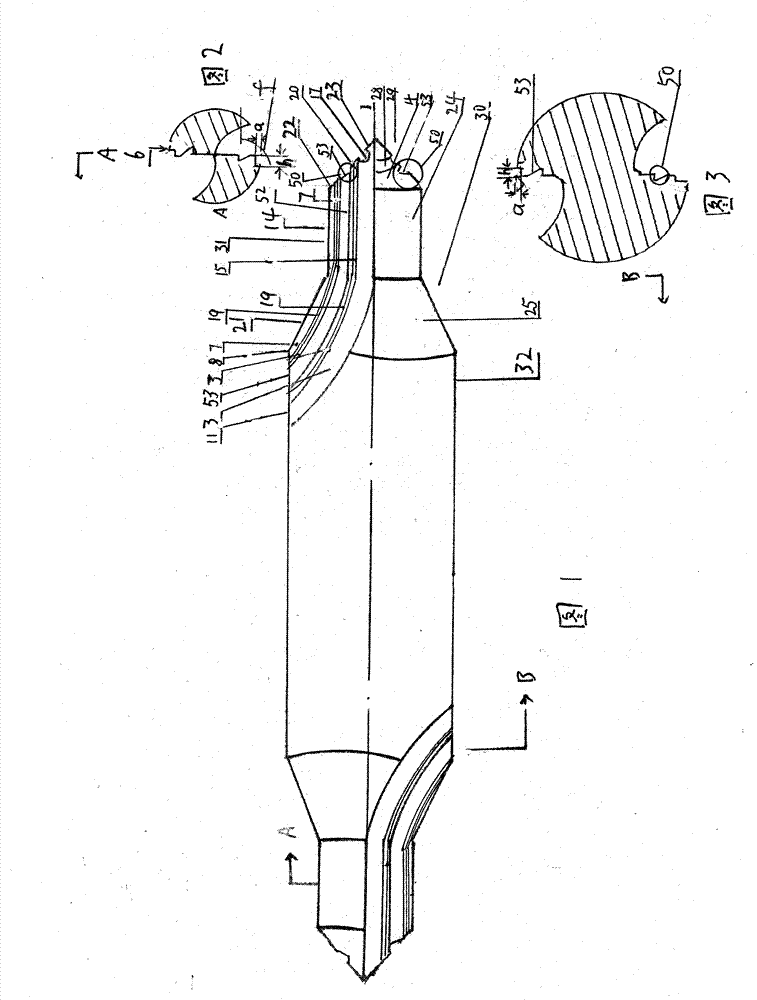

Embodiment approach 1

[0040] Such as figure 1 , figure 2 , image 3 , Figure 22-Figure 29As shown, the embodiment of the compound edge center drill or the compound edge countersink drill on the center drill without the protective cone of the first embodiment of the present invention mainly relates to the center drill or countersink for machining, including the tool head, The tool head is integrally provided with a front cutting cone 29 and a rear cutting cone 30, and a front cutter body 31 is integrally arranged between the front cutting cone 29 and the rear cutting cone 30, and the rear portion of the rear cutting cone 30 is a rear cutter body 32, and the front The cutting cone 29, the front cutter body and the rear cutting cone 30 are respectively composed of a plurality of integral cutting blades or cutting blade bodies 2, and the edge facing the outer side of the cutting direction of each cutting blade or cutting blade body 2 is formed as a secondary cutting blade. Edge 14, the surface fac...

Embodiment approach 2

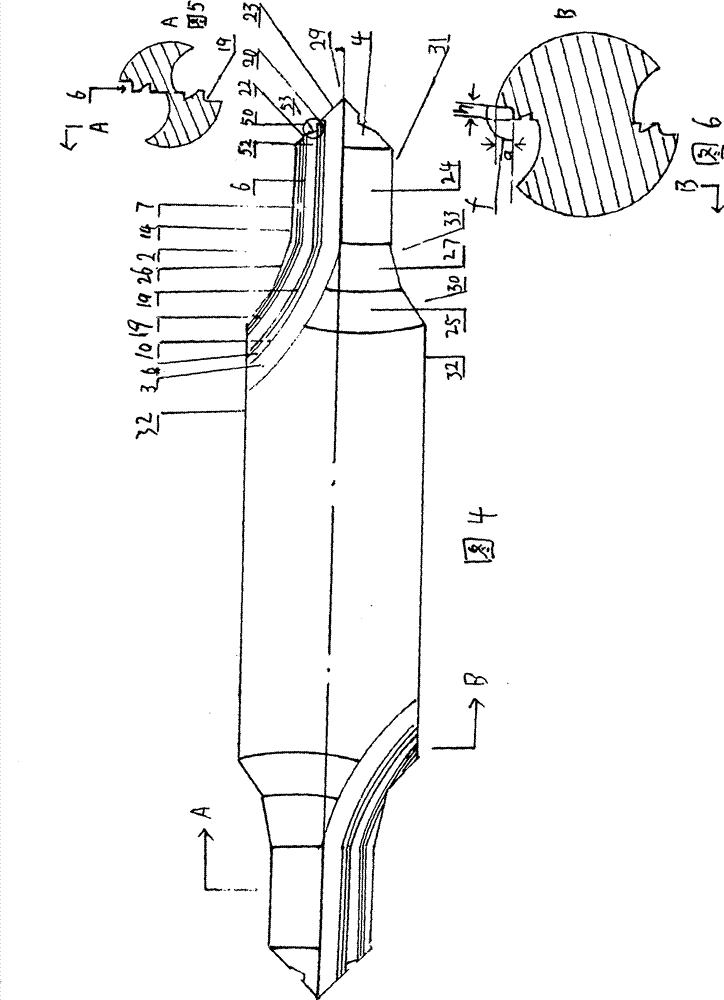

[0044] Such as Figure 4 , Figure 5 , Image 6 , Figure 22-Figure 29 As shown, the compound edge center drill or the compound edge countersink drill of the second embodiment of the present invention is on the embodiment of the center drill with a protective cone. On the basis of the first embodiment, this embodiment includes a cutter head, a cutter head A front cutting cone 29 and a rear cutting cone 30 are integrally provided with, and a front cutter body 31 is integrally arranged between the front cutting cone 29 and the rear cutting cone 30, and the rear portion of the rear cutting cone 30 is a rear cutter body 32, and the front cutting cone 29. The front cutter body and the rear cutting cone 30 are respectively composed of a plurality of integral cutting blades or cutting cutter bodies 2, and a protective cone 33 is integrally arranged between the front cutter body 31 and the rear cutting cone 30, and the protective cone 33 The surface on the outer side is the rear co...

Embodiment approach 3

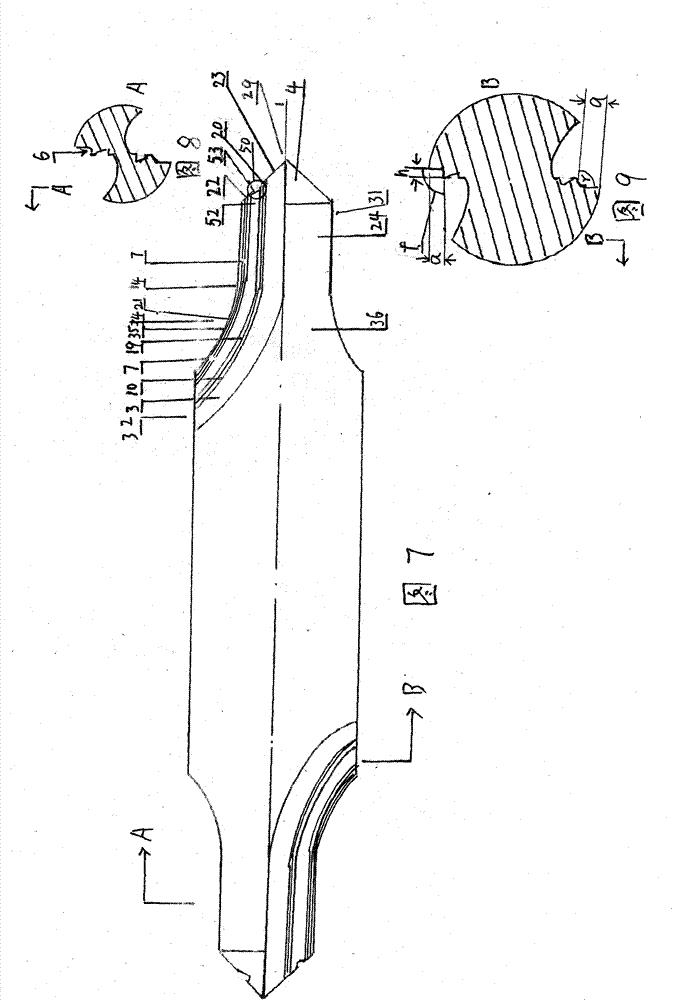

[0047] Such as Figure 7 , Figure 8 , Figure 9 , Figure 22-Figure 29As shown, the embodiment of the compound edge center drill or the compound edge countersink drill on the arc-shaped center drill of the third embodiment of the present invention, on the basis of the first - second embodiment, this embodiment includes a tool head, a tool The head is integrally provided with a front cutting cone 29 and an arc-shaped cutting cone 34, and a front cutter body 31 is integrally arranged between the front cutting cone 29 and the arc-shaped cutting cone 34, and the rear portion of the arc-shaped cutting cone 34 is a rear cutter body 32 , the front cutting cone 29, the front cutter body 31 and the arc cutting cone 34 are respectively composed of a plurality of cutting blades or cutting blade bodies 2 integrally, and the surface on the outer side of the arc cutting cone 34 is an arc rear cone surface 36. The face in the cutting direction is the cutting face 7, which intersects with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com