Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Increase internal porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparing method for transparent temperature-sensing color-changing wood

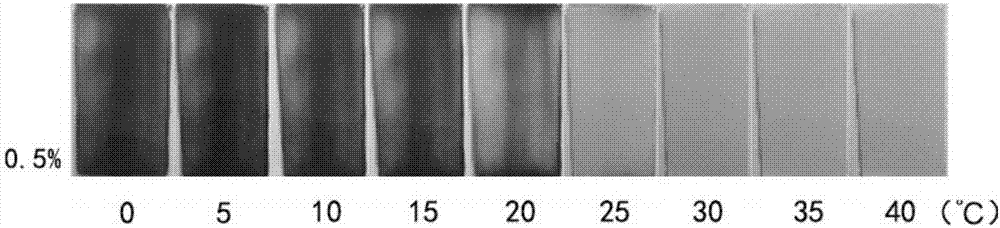

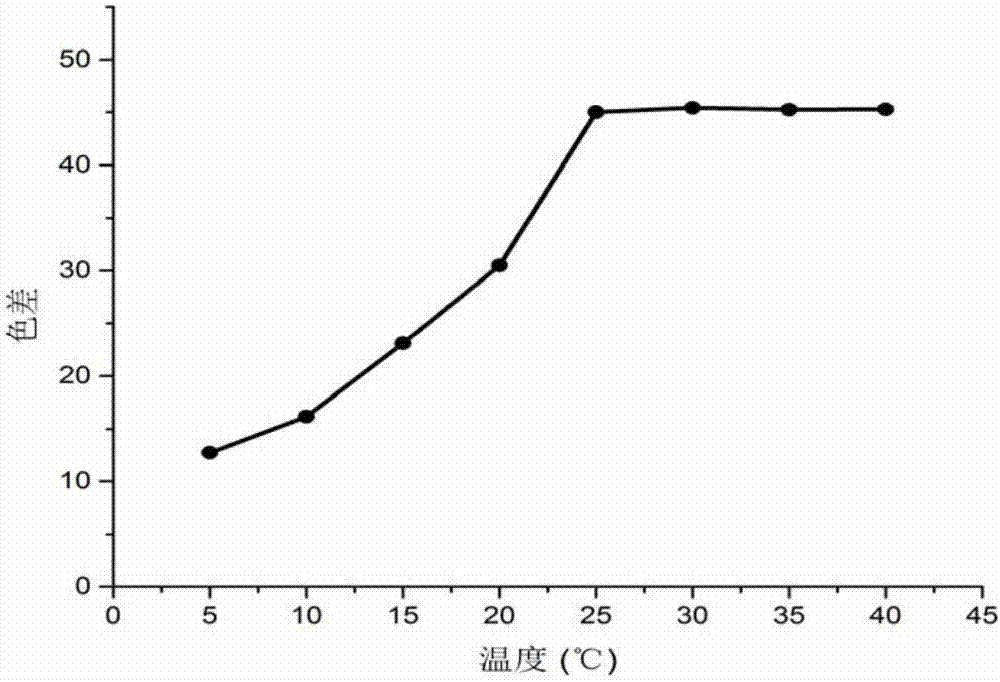

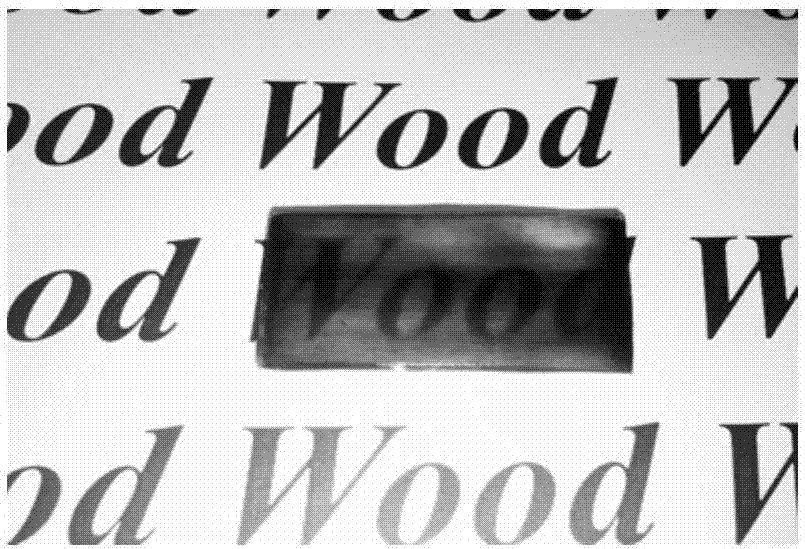

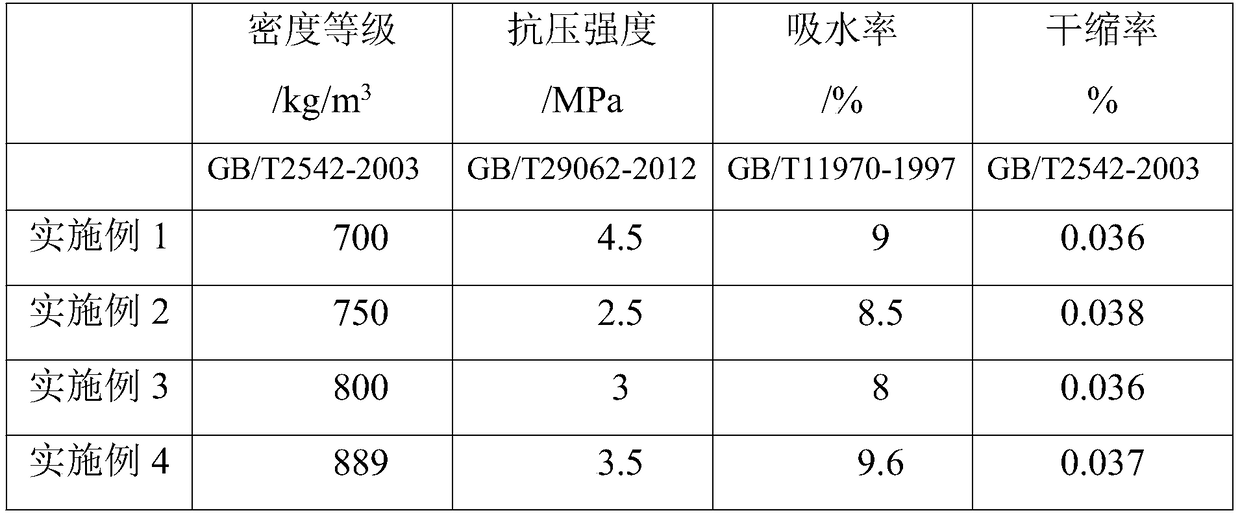

InactiveCN107379182AIncrease internal porosityGood mechanical propertiesWood treatment detailsPressure impregnationMulti fieldTemperature sense

The invention provides a preparing method for a transparent temperature-sensing color-changing wood. The preparing method comprises the following steps that the lignin is removed from the wood, the wood is bleached, and resin containing color-changing powder is immerged and injected into the wood. The particle diameter of the color-changing powder is about 1-10[mu]m, the mass percent content of the color-changing powder in the resin is 0.5-2%. The transparent temperature-sensing color-changing wood obtained through the method has good mechanical strength, further has high transparency and a color changing function, can be applied in multi-field instead of common glass, further can be used as indoor decoration or furniture materials, further can be used for preparing temperature-sensing color-changing ornaments, water cups and the like, and has broad application prospects.

Owner:BEIJING FORESTRY UNIVERSITY

Method for preparing light ceramsites by subway rail residue soil

InactiveCN106145996ASmall bulk densityHigh strengthCeramic materials productionCeramicwareFiberThermal insulation

The invention discloses a method for preparing light ceramsites by subway rail residue soil. The method includes the steps: drily grinding the subway rail residue soil by a ball grinder, then sieving the dry grinded residue soil by a sieve with100 meshes, uniformly mixing the sieved residue soil and coal ash according to a weight percentage, and preparing a mixed slurry according to water-solid ratio; performing granulation for the mixed slurry by a granulator to form balls, selecting the balls with grain diameters of 15-25mm and 10-15mm, and placing the selected balls into a constant temperature air blast drying oven with the temperature of 105 DEG C to dry by constant temperature for 4 hours or more than; tiling the dried balls on a ceramic fiber board, placing the tiled balls in a silicon-molybdenum box-type resistance furnace, increasing the temperature to 500 DEG C from the indoor temperature by the heating speed of 8-10 DEG C per minute, preheating for 20 minutes, then increasing the temperature to 1160-1250 DEG C by the heating speed of 8-10 DEG C per minute, roasting for 15 minutes, placing roasted ceramsites in a ventilated kitchen to naturally cool to the indoor temperature, and sieving the roasted ceramsites to obtain the light ceramsites. The weight percentage of the residue soil and the coal ash is 50%-85%:15%-50%, and the water-solid ratio is 15%-30%. The prepared ceramsites meet standard requirements of artificial lightweight aggregates in GB / T17431.1-2010 and GB / T17431.2-2010 and has the excellent advantages of high strength, multiple hole, high temperature resistance and the like and can serve as high-efficiency support agents for precast concrete components and thermal insulation materials of walls.

Owner:TIANJIN CHENGJIAN UNIV

Porous gelatin sponge and preparation method thereof

ActiveCN108530671AIncrease internal porosityIncrease the areaPharmaceutical delivery mechanismAbsorbent padsCross-linkPorosity

The invention discloses a preparation method of porous gelatin sponge. The preparation method comprises the following steps: S1, dissolving a crosslinking agent; adding gelatin in a stirring process and carrying out crosslinking reaction; S2, transferring a cross-linked gelatin solution into a sealed reaction container; introducing gas until the pressure in the reaction container reaches one atmospheric pressure or more, and then keeping for 10min or more; S3, carrying out programmed cooling on the gelatin solution treated by step S2 to be completely cured; S4, freezing and drying the cured gelatin; S5, immersing the freeze-dried gelatin into absolute ethyl alcohol and purified water in sequence to remove the crosslinking agent; S6, carrying out secondary freeze-drying on the immersed gelatin in step S5 and sterilizing to obtain the porous gelatin sponge. According to the preparation method of the porous gelatin sponge, disclosed by the invention, gas introduction and pressurizing, andprogrammed cooling curing treatment are carried out after the gelatin is crosslinked, and the inner porosity and specific surface area of the gelatin sponge are effectively increased; the water absorption performance of the gelatin sponge is improved so that the bleeding-stopping speed of the gelatin sponge is improved and the bleeding-stopping time is shortened.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Lightweight high-strength concrete

InactiveCN108558295AIncrease internal porosityImprove crack resistanceCeramicwareHigh strength concreteFiber

The invention relates to the technical field of concrete and preparation thereof and in particular relates to lightweight high-strength concrete. The lightweight high-strength concrete is prepared from the following raw materials in parts by weight: 25-45 parts of fly ash, 15-35 parts of cement, 15-30 parts of fine sand, 5-12 parts of diatomite, 3-15 parts of light calcium carbonate, 3-12 parts ofaluminum polychloride, 15-48 parts of lightweight aggregate, 1-5 parts of reinforced fibers, 1-3 parts of a foaming agent, 1-5 parts of graphene oxide, 0.5-1.5 parts of a water reducing agent and 0-5parts of other aids. The lightweight high-strength concrete disclosed by the invention has the characteristics of light weight, high strength and excellent weather resistance, can meet concrete performance indexes in the construction industry and has excellent application prospects.

Owner:芜湖恒固混凝土材料有限公司

Method for preparing light high-strength concrete

InactiveCN108503285AIncrease internal porosityImprove crack resistanceCeramicwareHigh strength concreteFiber

The invention relates to the technical field of concrete and preparation and particularly relates to a method for preparing light high-strength concrete. The method for preparing the light high-strength concrete comprises the following steps: uniformly mixing the following components in parts by weight: 25-45 parts of coal ash, 15-35 parts of cement, 15-30 parts of fine sand, 5-12 parts of kieselguhr, 3-15 parts of light calcium carbonate, 3-12 parts of polymeric aluminum, 15-48 parts of lightweight aggregate, 1-5 parts of a reinforced fiber and 1-5 parts of graphene oxide under a mechanical stirring condition so as to obtain a mixture; further uniformly mixing with a water reduction agent, aids and a foaming agent, and performing pressing molding, so as to obtain a concrete test sample. The light high-strength concrete prepared by using the method provided by the invention has the characteristics of being light in weight, high in strength and good in weather resistance, index requirements on properties of concrete of the building industry can be met, and a relatively good application prospect can be achieved.

Owner:芜湖恒固混凝土材料有限公司

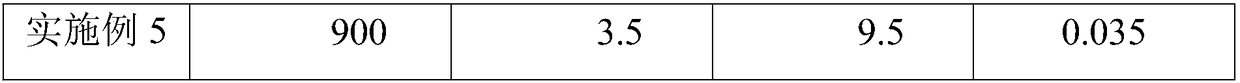

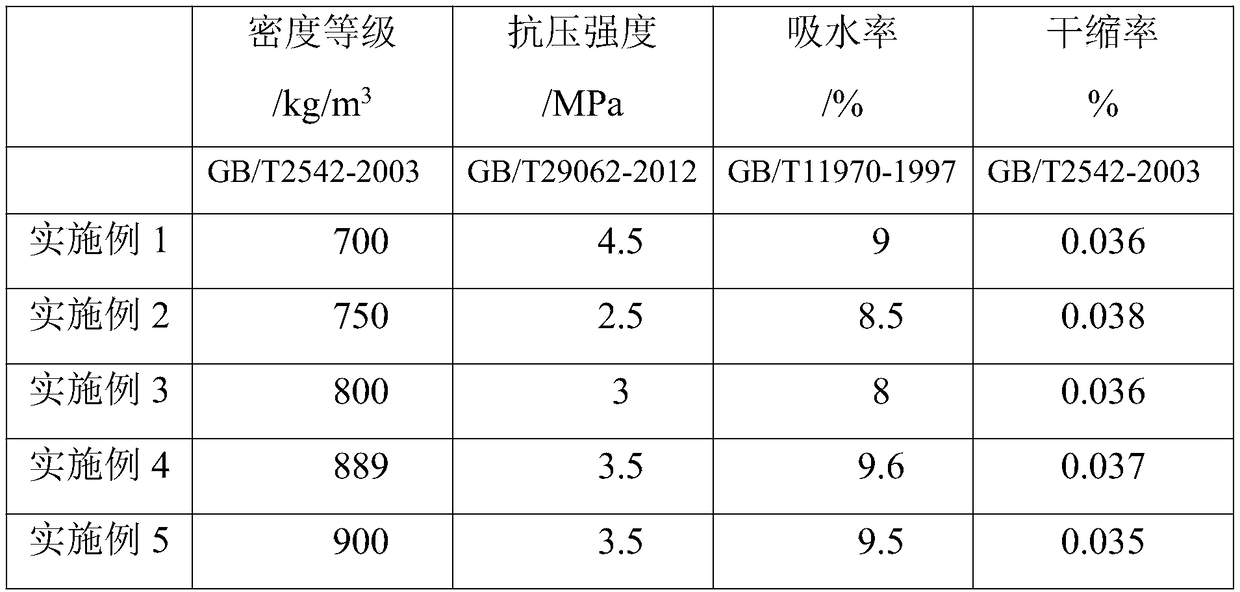

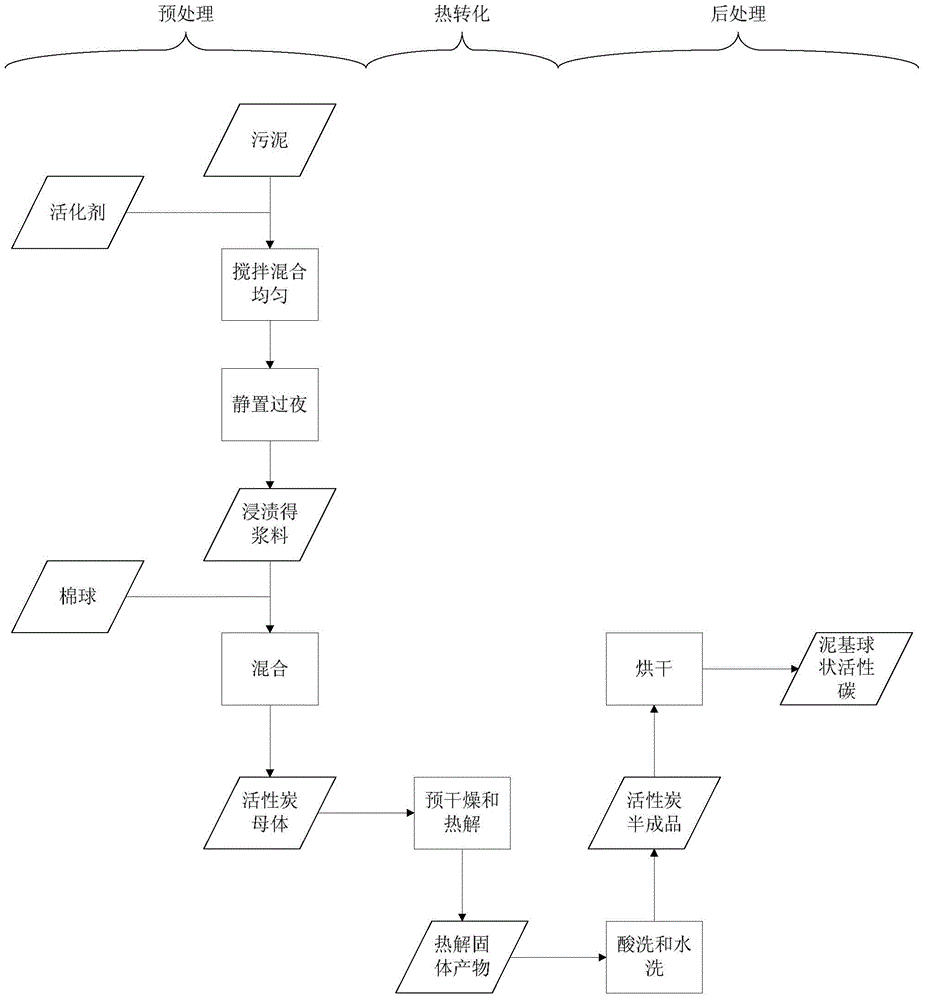

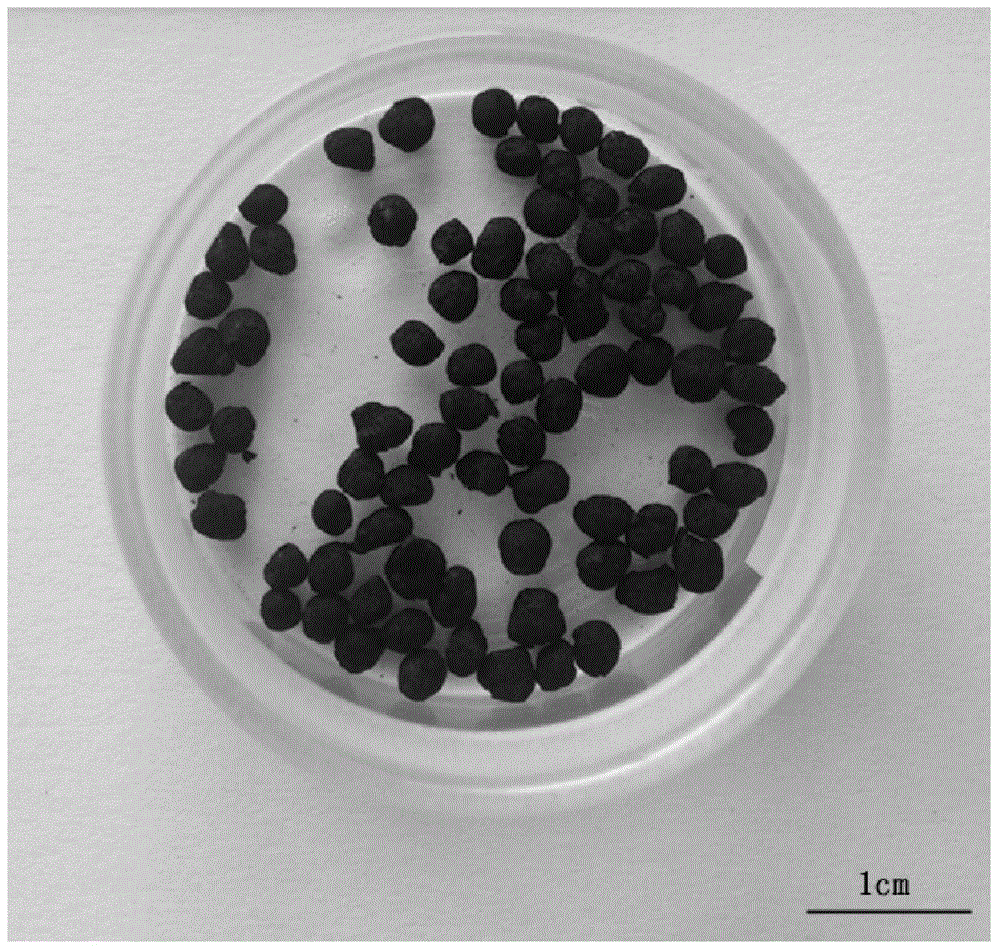

Mud-based spherical active carbon as well as preparation method and application thereof

ActiveCN104556031AHighly porousLarge specific surface areaCatalyst carriersOther chemical processesFiberChemical reaction

The invention belongs to the field of preparation of active carbon, and discloses a mud-based spherical active carbon as well as a preparation method and an application thereof. The method comprises the following steps: mixing and impregnating mud and an activator to make slurry, mixing the slurry with cotton balls to wrap the cotton balls with the slurry to obtain active carbon matrixes, then pyrolyzing the obtained active carbon matrixes, acid washing, water washing and finally drying pyrolysis products to obtain the mud-based spherical active carbon. The inner layer of the mud-based spherical active carbon obtained according to the preparation method is loose fiber substances, and the outer layer is compact porous medium; and the mud-based spherical active carbon has higher specific surface area, lower apparent density and excellent properties, and can be used as an adsorption filler for water treatment or a catalyst carrier for chemical reaction, thus achieving resource utilization of solid wastes.

Owner:SOUTH CHINA UNIV OF TECH

Plastic mould steel and production technology thereof

InactiveCN108085601AReduce P contentImprove internal porosityFurnace typesProcess efficiency improvementChemical compositionUltimate tensile strength

The invention belongs to plastic mould steel and a production technology thereof. The plastic mould steel comprises the chemical compositions of, by mass, 0.37-0.40% of C, 0.4-0.5% of Si, 1.4-1.5% ofMn, 1.8-2.0% of Cr, 0.4-0.5% of Mo, 1.0-1.1% of Ni, no more than 0.008% of P, no more than 0.003% of S, 0.018-0.030% of Als, and the balance Fe and remaining elements. The thickness of the plastic mould steel is 150 mm, the carbon equivalent in the chemical compositions of the plastic mould steel is 1.1-1.3, and the plastic mould steel has the advantages of being high in strength, high in hardnessand excellent in performance.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Preparation method for biochemical compound phosphor-removing agent

InactiveCN107459148AIncrease internal porosityImprove adsorption capacityWater contaminantsTreatment with anaerobic digestion processesSludgeSlag

The invention relates to the technical field of wastewater treating agent and specifically relates to a preparation method for a biochemical compound phosphor-removing agent. The phosphor-removing agent provided by the invention firstly utilizes the fixed phosphor-removing microorganism to perform nitrating decomposition on the organic phosphorus or metaphophate in wastewater; a part of phosphor is absorbed by the microorganism so as to change into microorganism sludge; the rest phosphor is decomposed to be converted into ortho-phosphate micromolecules; under the effect of the fixed microorganism, the chelated iron ions and magnesium ions are released again; these released iron ions and magnesium ions and the metallic oxide under free state cooperate with each other for replacing the medium / low-valence phosphate positive ions in the wastewater; most phosphate anions are captured into alumen ustum sediment of alkali phosphate compound clathrate through a bridging absorbing net; the introduced building steel slag can be hydrolyzed into the hydroxy polynuclear complex high in positive charge in water; various phosphate anions are subjected to complexing adsorption phosphorous removal; finally, the formed precipitate is removed, so that the phosphor-removing purpose can be achieved; the phosphor-removing agent has wide application prospect.

Owner:郭迎庆

Preparation method of lightweight foamed composite concrete wallboard

InactiveCN108424167AIncrease internal porosityImprove impact resistanceCeramicwareFiberPerformance index

The invention relates to the technical field of concrete and preparation thereof and particularly relates to a preparation method of a lightweight foamed composite concrete wallboard. The preparationmethod of the lightweight foamed composite concrete wallboard comprises the following steps: uniformly mixing 30-50 weight parts of fly ash, 15-35 weight parts of cement, 15-30 weight parts of fine sand, 5-12 weight parts of diatomite, 3-15 weight parts of amino modified silicon dioxide, 3-12 weight parts of aluminum polychloride, 15-48 weight parts of lightweight aggregate, 1-5 weight parts of reinforced fibers and modified rubber under mechanical stirring conditions to obtain a mixture; adding a water reducing agent, an assistant and a foaming agent to be uniformly mixed, and performing compression molding, so as to obtain the concrete wallboard. The lightweight foamed composite concrete wallboard prepared by the method disclosed by the invention has the characteristics of light weight,high strength and excellent impact resistance, can meet the concrete performance index requirement in the construction industry and has excellent application prospects.

Owner:芜湖恒固混凝土材料有限公司

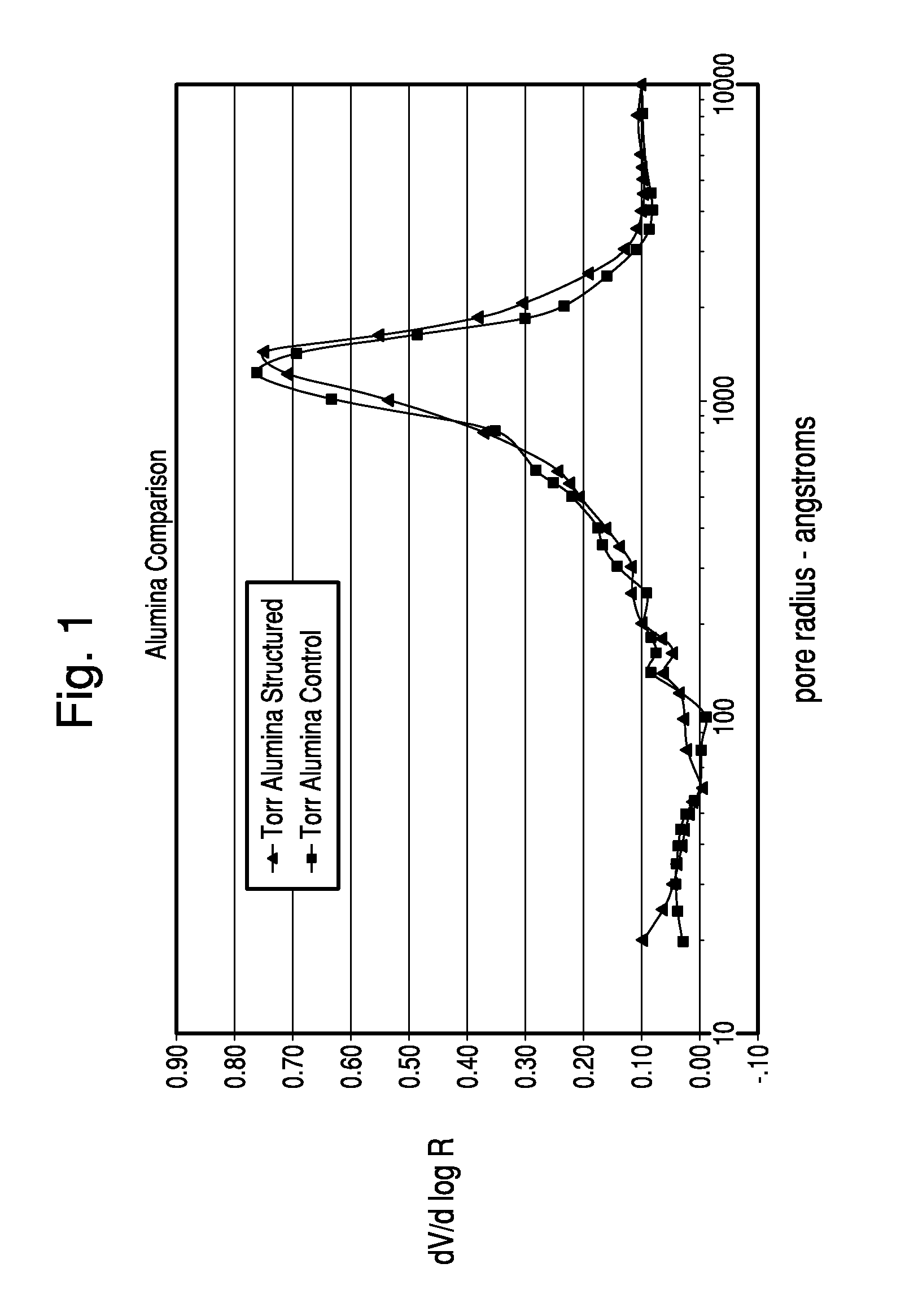

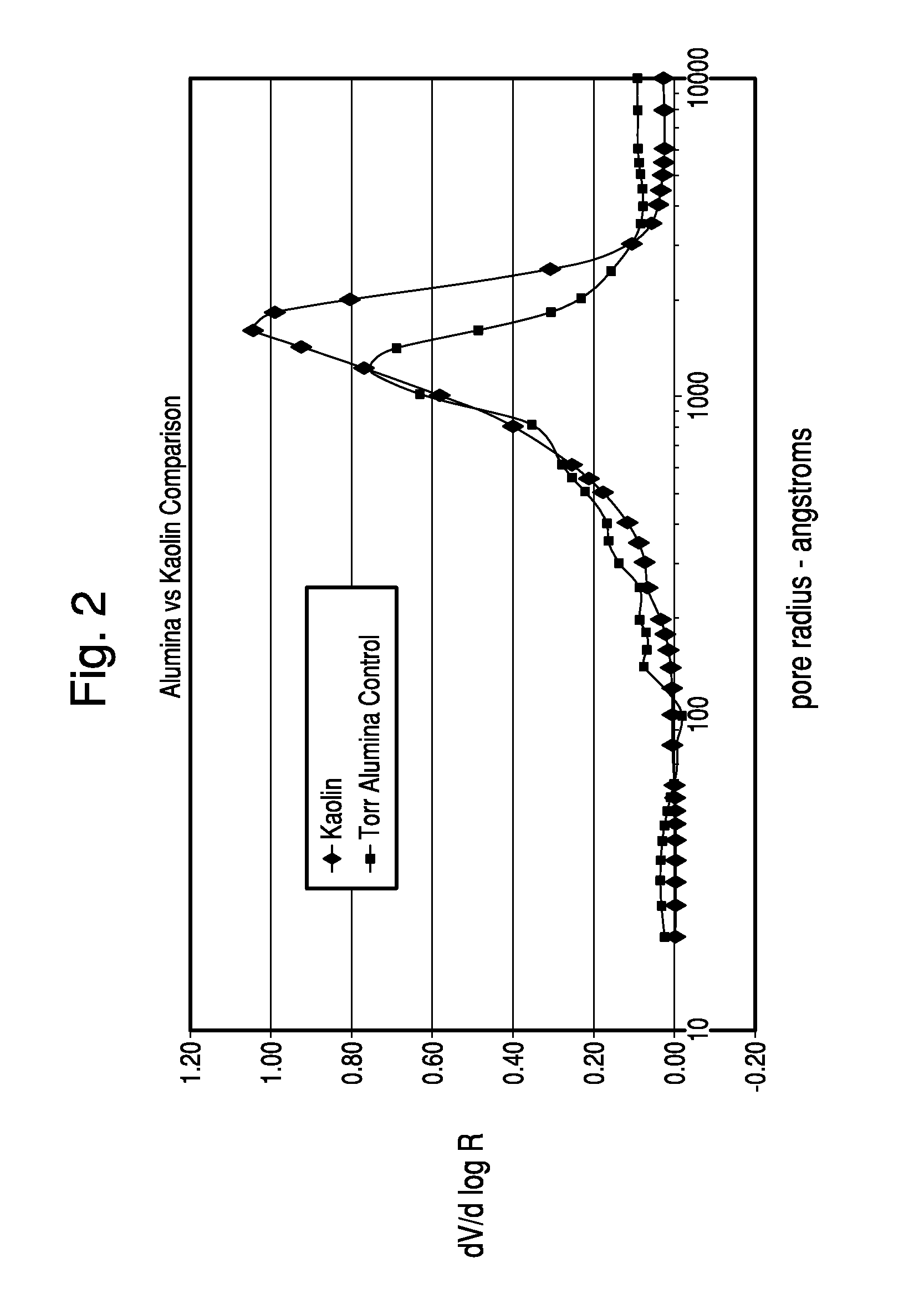

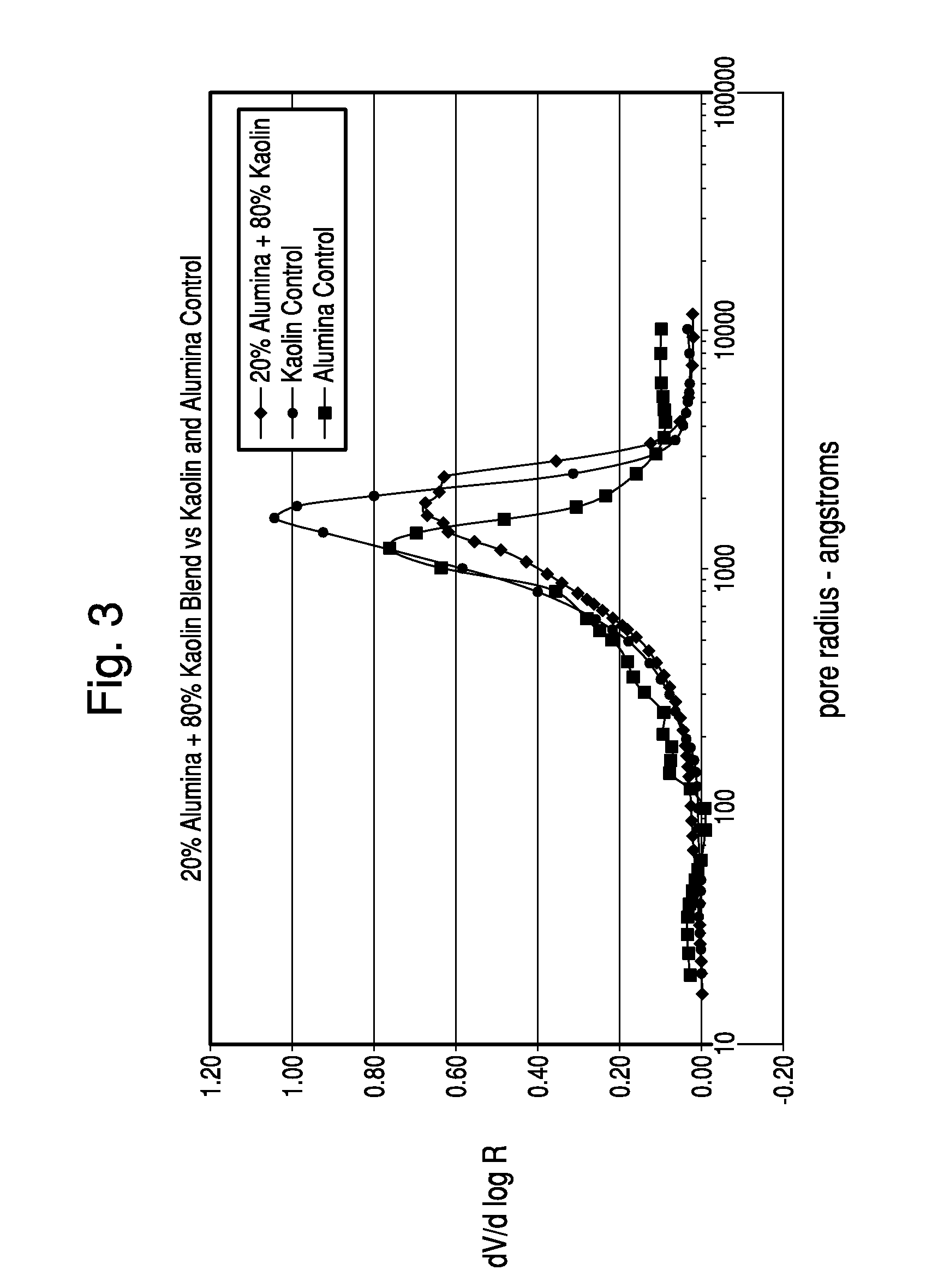

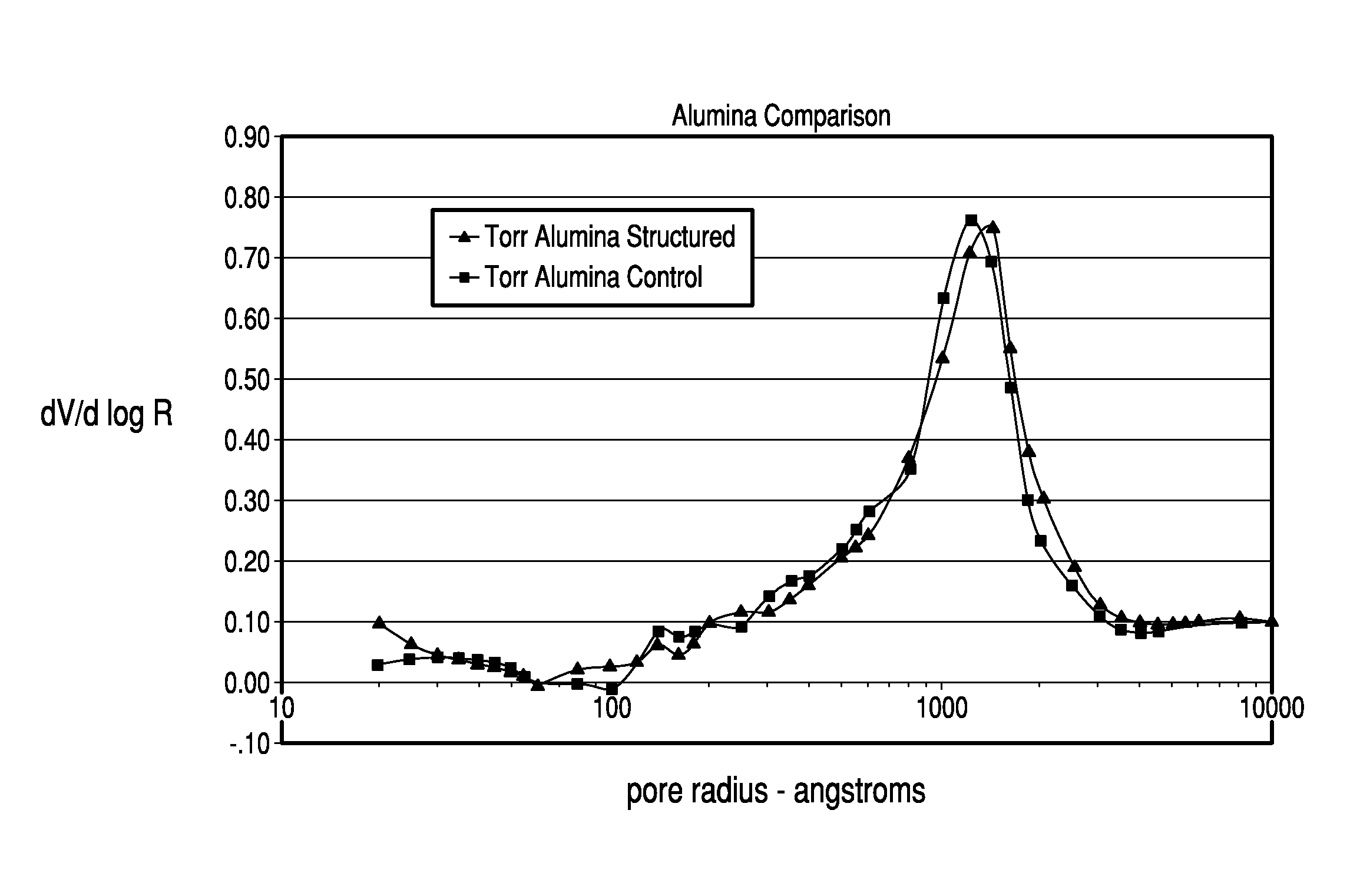

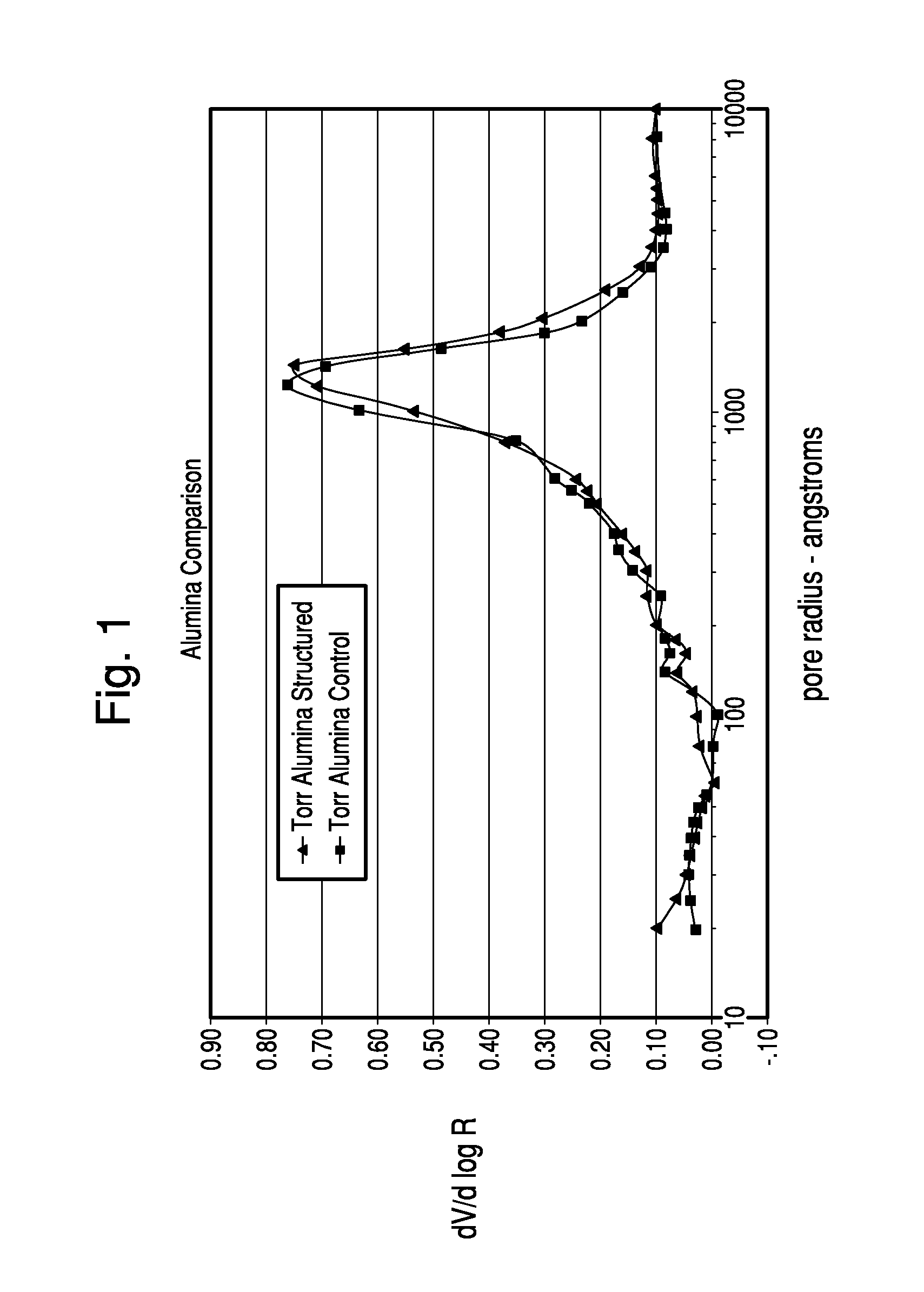

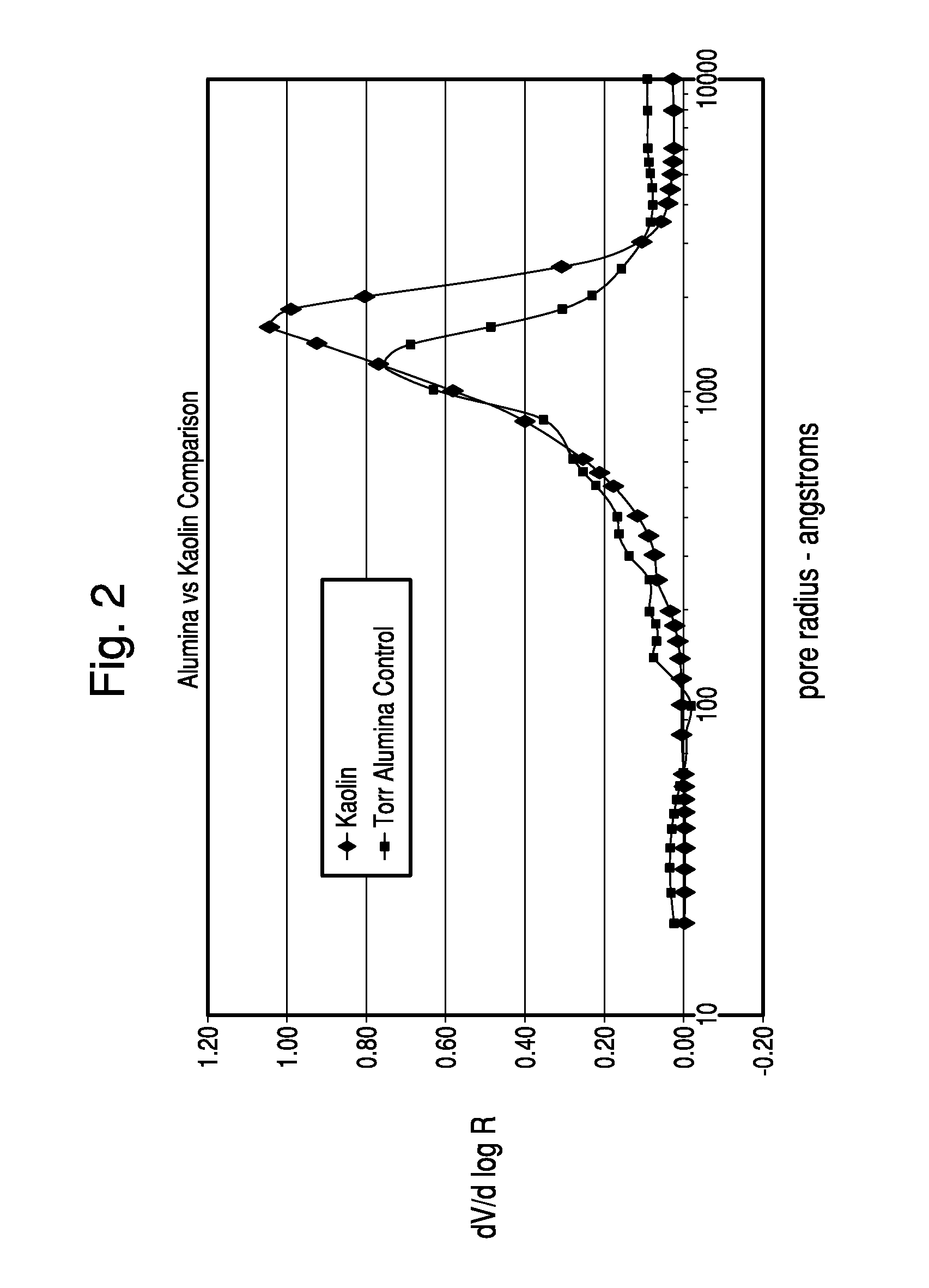

Beneficial Thermo-Chemical Treatment of Kaolin with Ammonium Polyphosphate

InactiveUS20120227629A1Increase internal porosityMaintain internal pore volumePigmenting treatmentNatural cellulose pulp/paperAmmonium polyphosphateThermo chemical

Minerals which can be anionically dispersed in water such as kaolin are provided with unique structure by adding small amounts of a polyphosphate structuring agent and heating the mixture to allow reaction of the structuring agent with the mineral.

Owner:BASF CORP

Coal ash heat preservation brick

The invention discloses a coal ash heat preservation brick and belongs to the technical field of building materials. The coal ash heat preservation brick is prepared by sequentially weighing the following components in parts by weight: coal ash, quartz mine tailings, modified soft wood granules, pretreated paulownia wood, additives, Portland cement, urea, water, gypsum and quick lime; mixing the Portland cement with the water in a stirring machine, and sequentially adding the additives, the modified soft wood granules, the urea, the coal ash, the quartz mine tailings, the quick lime, the gypsum and the pretreated paulownia wood into the stirring machine, and performing stirring and mixing for 45-100 minutes under conditions that the temperature is 50-60 DEG C and the rotation speed is 200-300r / min so as to obtain a pretreatment blank; performing pressing molding on the pretreatment blank under a condition that the pressure is 25-30MPa so as to obtain a blank material, maintaining the blank material for 10-20 hours under conditions that the temperature is 180-200 DEG C and the vapor pressure is 1.2-1.5MPa, performing cooling to the room temperature, and performing material discharge, so as to obtain the coal ash heat preservation brick. The coal ash heat preservation brick disclosed by the invention has excellent mechanical properties and heat preservation properties.

Owner:杨帮燕

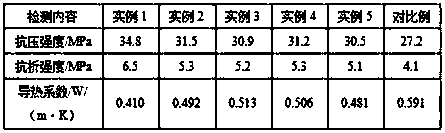

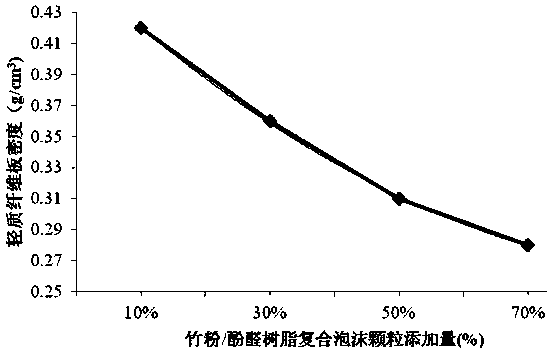

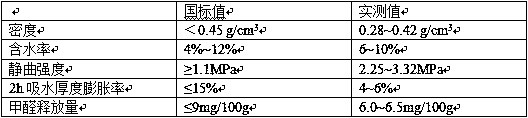

Preparation method for density-controllable light bamboo-wood-based fiber plate

ActiveCN107813397AIncrease moisture contentLow densityRadiation/waves wood treatmentWood treatment detailsFiberPorosity

The invention relates to a preparation method for a density-controllable light bamboo-wood-based fiber plate. The method comprises the steps that firstly, thermosetting phenolic resin is prepared; secondly, bamboo powder phenolic resin composite foam particles are prepared, then, fir wood fiber, paraffin and the bamboo powder phenolic resin composite foam particles are placed into a mixer, next, amodified urea-formaldehyde resin adhesive is sprayed, and paving is performed after the mixture is uniformly stirred; thirdly, the mixture is placed into a pre-presser for prepressing, and then the product is moved into a hot press to be subjected to hot-pressing treatment; and finally, the product is subjected to pressure relief, cooling, plate cutting and maintenance, and the density-controllable light bamboo-wood-based fiber plate is obtained. According to the method, bamboo powder and the phenolic resin are processed into a foam particle composite system by means of the special treatmenttechnology, and the foam particle composite system is used for replacing a part of layer structures of the fiber plate material; and the purpose of weight reduction is achieved by enhancing the porosity of the original material system, the complexity of the processing technique is effectively lowered, and the controllability of the processing technique and the regulation of the product density areimproved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Corrosion resistant epoxy resin paint

ActiveCN106752721AStrong adhesionImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsSodium antimonateMechanical property

The invention discloses a corrosion resistant epoxy resin paint. The corrosion resistant epoxy resin paint comprises a component A and a component B; the component A contains the following raw materials according to weight ratio: 40-60 parts of bisphenol A epoxy resin, 15-35 parts of polyamide resin, 10-18 parts of E-44 epoxy resin, 2-4 parts of a silane coupling agent, 2-8 parts of a zeolite powder, 1-5 parts of sodium antimonate, 5-15 parts of a modified bamboo powder, 0.5-1.5 parts of epoxidized soybean oil, 2-4 parts of dibutyl ester, 1-2 parts of an anti-settling agent, 1-2 parts of a leveling agent, 1-2 parts of a dispersant and 1-2 parts of a defoaming agent; the component B contains the raw materials in parts by weight: 15-25 parts of di-hexyl triamine, 15-25 parts of hexamethylene diamine, 15-20 parts of butanol and 2-10 parts of dimethylbenzene; the weight ratio of the component A to the component B is 10: 2-4. The corrosion resistant epoxy resin paint disclosed by the invention has the advantages of strong adhesive force, good corrosion resistance and excellent mechanical property.

Owner:安徽浩丰特种电子材料有限公司

High-concentration wastewater resource utilization method

InactiveCN109126701AHigh decolorization rateReduce pollution loadOther chemical processesWater contaminantsHigh concentrationSorbent

The invention discloses a high-concentration wastewater resource utilization method. The high-concentration wastewater resource utilization method comprises the following steps: adding a cation exchanger in wastewater, and carrying out stirring reaction to enable extractable substances in the wastewater to be exactly condensed into insoluble fine and small solid particles; separating out the cation exchanger, slowly adding a proper amount of chemical agent in the wastewater to generate small air bubbles, and enabling the air bubbles to adhere to the fine and small solid particles in the wastewater so as to reduce viscosity of the wastewater; heating to the temperature which is higher than a connecting material softening point by 0-30 DEG C, and enabling the fine and small solid particles to adhere to one another so as to form large-particle solids; carrying out insulation treatment for a certain time so that a blocky extract is formed; cooling the extract with a saturated potassium hydroxide solution; and carbonizing and activating the pulverized and dried blocky extract at one step for 1-4 h at the temperature of 700 DEG C under the protection of nitrogen, and breaking the blockyextract to obtain an adsorbent. The adsorption capacity of the adsorbent prepared by the method to cationic dyestuff can reach 450 mg / g or above.

Owner:QINGDAO UNIV

High-concentration wastewater pollutant extracting and utilizing method

InactiveCN109126705AHigh decolorization rateReduce pollution loadSludge treatment by de-watering/drying/thickeningOther chemical processesHigh concentrationSorbent

The invention discloses a high-concentration wastewater pollutant extracting and utilizing method. The high-concentration wastewater pollutant extracting and utilizing method comprises the following steps: adding a proper amount of cation exchange material in wastewater, and carrying out stirring reaction to enable an extractable substance in the wastewater to be exactly condensed into insoluble fine and small solid particles; separating out the cation exchange material, adding a proper amount of chemical agent in the wastewater while stirring to generate small air bubbles, and enabling the air bubbles to adhere to the fine and small solid particles in the wastewater so as to reduce viscosity of the wastewater; carrying out ultrasonic treatment, heating to the temperature which is higher than a connecting material softening point by 0-20 DEG C, and enabling the fine and small solid particles to adhere to one another so as to form large-particle solids; carrying out ultrasonic insulation treatment for a certain time so that a blocky extract is formed; cooling the extract with a saturated potassium hydroxide solution; and carbonizing and activating the dried blocky extract at one step for 1-4 h at the temperature of 700 DEG C under the protection of nitrogen, and breaking the dried blocky extract to obtain an adsorbent. The adsorption capacity of the adsorbent prepared by the method to cationic dyestuff can reach 450 mg / g or above.

Owner:QINGDAO UNIV

Light foamed composite concrete wallboard

The invention relates to the technical fields of concrete and preparation thereof, in particular to a light foamed composite concrete wallboard. The light foamed composite concrete wallboard is prepared from the following raw materials in parts by weight: 25 to 45 parts of fly ash, 15 to 35 parts of cement, 15 to 30 parts of fine sand, 5 to 12 parts of diatomite, 3 to 15 parts of amino-modified silicon dioxide, 3 to 12 parts of poly aluminum chloride, 15 to 48 parts of lightweight aggregate, 3 to 8 parts of waste rubber particles, 1 to 5 parts of reinforced fiber, 1 to 3 parts of a foaming agent, 0.5 to 1.5 parts of a water reducer, and 0 to 5 parts of other additives. The light foamed composite concrete wallboard has the characteristics of low weight, high strength and good shock resistance, can meet the requirement on concrete performance indexes by the construction industry, and has a good application prospect.

Owner:芜湖恒固混凝土材料有限公司

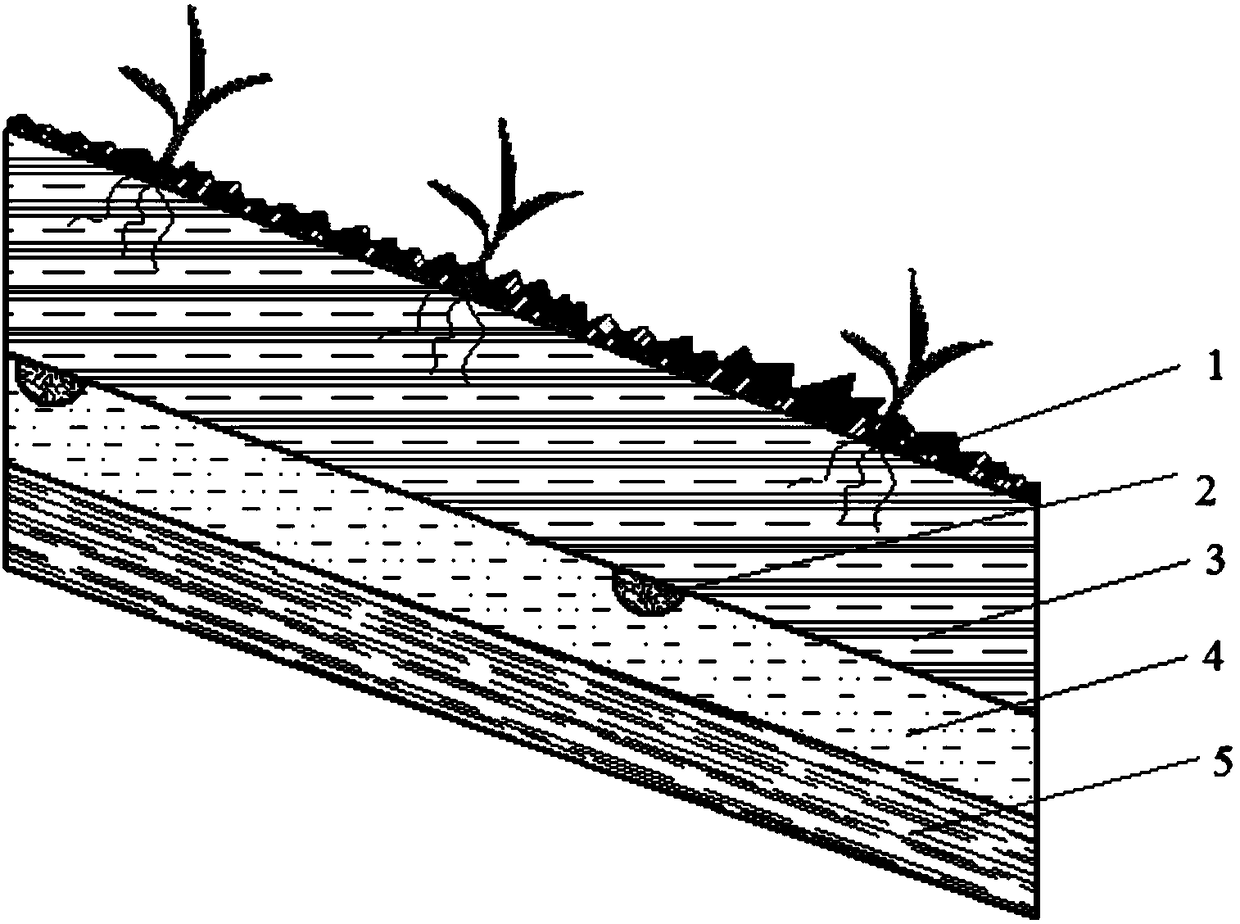

Waste landfill evapotraspiration covering layer based on municipal dehydrated sludge

ActiveCN108273821ASimple materialSimple structureLandfill technologiesSolid waste disposalWater storageWoody plant

The invention relates to a waste landfill evapotraspiration covering layer based on municipal dehydrated sludge. The waste landfill evapotraspiration covering layer comprises a foundation bed, an adjusting layer, a water storage layer and a vegetation layer. The foundation bed is obtained through the method that building waste is crushed mechanically in situ and flattened; the adjusting layer is obtained through the method that after first modified agents are added in the municipal dehydrated sludge after dehydrating, the municipal dehydrated sludge and the first modified agents are stirred evenly and then extruded into spherical particles, and the spherical particles are placed in a cool ventilating environment to be naturally cured and dried; the water storage layer is obtained through the method that after second modified agents and synthetic fibers are added in the municipal dehydrated sludge, the municipal dehydrated sludge, the second modified agents and the synthetic fibers arestirred evenly; and the vegetation layer is formed through the method that evergreen herbaceous plant seeds are sewed on the surface of the water storage layer, and shrubs or shrub woody plants are planted. According to the waste landfill evapotraspiration covering layer based on municipal dehydrated sludge, materials and the structure of the evapotraspiration covering layer are optimized, resource utilization of the sludge is achieved, and double harvesting of economic benefits and environment benefits is achieved.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Preparation method of super absorbent resin for cables or optical cables

The invention discloses a preparation method of super absorbent resin for cables or optical cables. The preparation method comprises: adding a partially neutralized acrylic acid solution containing an initiator and a cross-linking agent into petroleum hydrocarbon containing an anionic-nonionic surfactant and a polymeric protective colloid for anti-phase suspension polymerization, to prepare the super absorbent resin which has high porosity and large specific surface area in the interior, has rapid water absorption rate and high swelling capacity, and is applied to the cables or the optical cables.

Owner:浙江卫星新材料科技有限公司

High-dyeing rate nylon 6 fishing net

InactiveCN107099871ASimple internal structureReduce crystallinityFilament forming substance formingArtificial filament heat treatmentPolyesterPlasticizer

The invention discloses a high-dyeing rate nylon 6 fishing net. The high-dyeing rate nylon 6 fishing net is obtained by uniformly mixing modified nylon 6, polyester, a plasticizer and nano-sized bentonite, then performing melt extrusion by using an extruder, cooling and pre-drafting, drafting and shaping, winding, making wires and netting. Through modification of the nylon 6, the internal structure of the nylon 6 can be greatly improved, the crystallinity of the nylon 6 is reduced, and the internal molecular structure of the nylon 6 is loosened to a certain extent to increase internal pores of the nylon 6 and reduce the hydrophobicity, so that in the dying process after the nylon 6 is produced into the fishing net, dye molecules can continue to quickly diffuse or penetrate into crystal areas after the dye molecules diffuse or penetrate into molecular amorphous areas, and the dyeing rate and the dyeing fastness of the nylon 6 fishing net can be greatly improved; through modification of the nylon 6, the monofilament tensile strength of the nylon 6 fishing net can be significantly improved, so that the using performance of the nylon 6 fishing net is improved.

Owner:CHAOHU XIANGYU FISHING GEAR

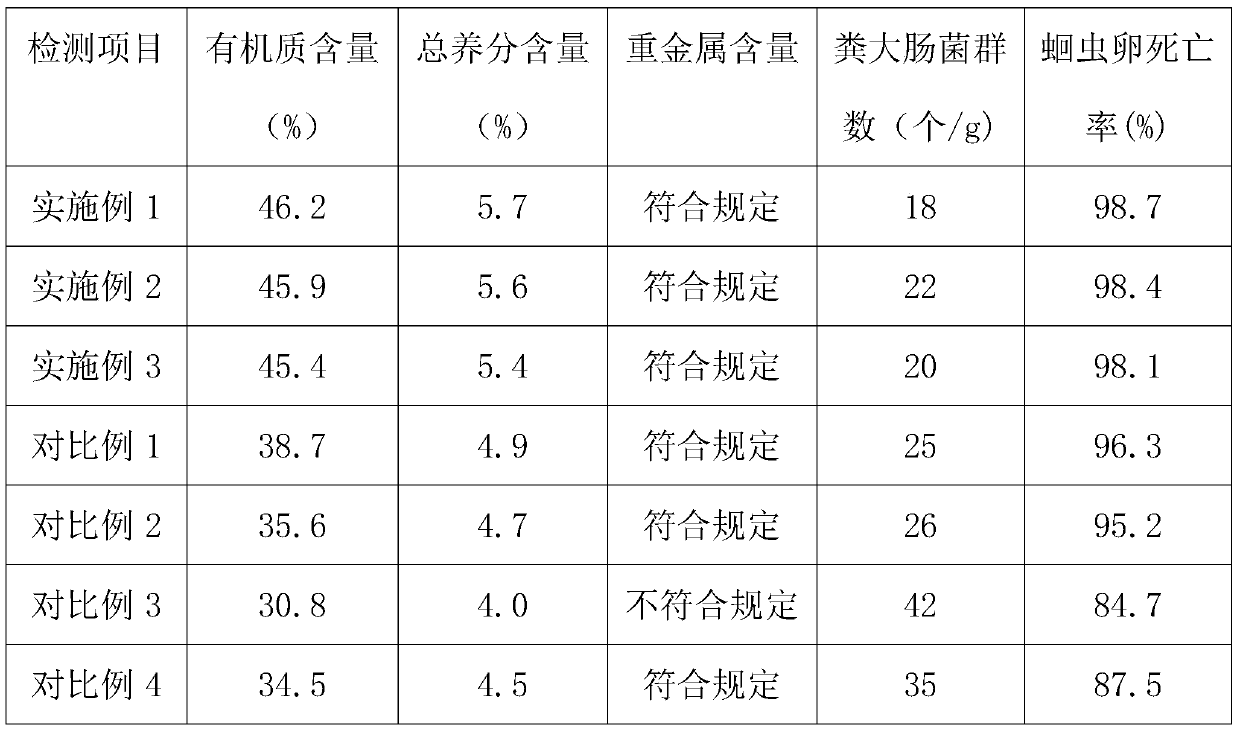

Biomass-based organic fertilizer preparation technology and application method

InactiveCN110143837AIncrease internal porosityLarge specific surface areaClimate change adaptationExcrement fertilisersPeatCarbon chain

The invention discloses a biomass-based organic fertilizer preparation technology and an application method. The preparation technology comprises the following steps: mixing, expansion and activation,hydrothermal carbonization, fermentation and granulation. Technological parameters such as moisture, temperature, etc. are strictly controlled such that the wrapping effect of peat moss and straw onwalnut kernel shell and grape skin substances is strengthened, and macromolecular carbon chains in the molecules are also cracked into small-molecular carbon under the impact of high-pressure nitrogen. The product of the invention has fertilizer impartiality, contains rich elements, is long-acting and efficient, and has a good synergistic effect with soil. According to the application method, fourfertilization methods including seedling transplantation, hole fertilization of a base fertilizer, spraying of leaf surface and seedbed fertilization are selected. Organic content of the organic fertilizer of the invention reaches 46.2%, total nutrient content reaches 5.7%, number of fecal coliforms is 18 / g, and mortality of ascarid eggs is 98.7%. By applying the organic fertilizer to fertilization of fruit trees, fruiting season is advanced for 15 days, the maturation period is advanced for 17 days, and the yield growth rate reaches 8.4%.

Owner:舒艳婷

Preparation method of heavy metal ion adsorbent

InactiveCN109289766AHigh decolorization rateReduce pollution loadOther chemical processesWater contaminantsHigh concentrationWater based

The invention discloses a preparation method of a heavy metal ion adsorbent. The heavy metal ion adsorbent is mainly prepared by the following steps: in-situ aqueous phase heating and bonding of an extract in water-based ink printing wastewater, thermal insulation and pore-forming, dehydration, drying, and one-step carbonization activation. The preparation method specifically comprises the following steps: adding a cation exchange material into the high-concentration water-based ink printing wastewater, stirring and reacting, and controlling the reaction until pH of the wastewater is 3-6; heating and stirring to make the fine particles and the cation exchange material adhere to each other to form an internally porous large granular extract; carrying out thermal insulation for full bondingand deformation of the extract and shrinkage of volume and dehydration, and forming pores by a water phase; discharging water when the volume of the extract is fully shrunk, adding a saturated potassium hydroxide solution and cooling; taking out the extract, and drying at low temperature; crushing the dried extract and carrying out one-step carbonization activation under the protection of nitrogenat 600-800 DEG C for 1-4 h so as to prepare the heavy metal ion adsorbent.

Owner:QINGDAO UNIV

Durable foam concrete and preparation method thereof

ActiveCN110668841AAvoid erosionAvoid collapse failureSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a durable foam concrete and a preparation method thereof, and belongs to the technical field of building materials. The preparation method comprises the following steps: weighing raw materials, and equally dividing water in the raw materials into three parts; mixing cement, carbonized rice hull fibers, microcrystalline cellulose, mirabilite and 2 / 3 of water, and carrying out high-viscosity kneading for 45-60 min to obtain a kneaded material; heating the kneaded material to 55-75 DEG C, adding a foaming agent, a foam stabilizer and the remaining 1 / 3 of water, performingstirring and mixing, injecting the obtained mixture into a mold, standing the mixture for foaming, and performing curing and demolding to obtain a green body; and adding the green body and silicate ester into a reaction kettle, sealing the reaction kettle, pressurizing the reaction kettle to 0.3-0.5 MPa, heating the reaction kettle to 85-95 DEG C, carrying out a heat preservation reaction, and discharging the obtained reaction product to obtain the durable foam concrete. The product obtained in the invention has good mechanical properties, and the foam strength of the product also has good tolerance to water and temperature.

Owner:江苏鸿宇天盛新材料科技有限公司

Reinforced concrete internal curing high-water-absorption microsphere material and preparation method thereof

The invention provides an enhanced concrete internal curing high-water-absorption microsphere material and a preparation method thereof. The enhanced concrete internal curing high-water-absorption microsphere material is prepared from the following raw materials: nano silicon dioxide, chitosan, glutaraldehyde, Arabic gum, methacrylic acid, glacial acetic acid, cumene hydroperoxide, ferrous chloride and sodium ethoxide. By improving the transition area of the cement paste and the aggregate and modifying the microstructure in the cement-based material, the porosity is reduced, and the mechanicalproperty is improved. The whole preparation process flow is relatively simple, professional technicians do not need to operate and guide, and only the operation is carried out according to the description of the invention. The strength, durability, service life and the like of cement concrete are obviously improved by the reinforced concrete internal curing high-water-absorption microsphere prepared by the method disclosed by the invention.

Owner:CHANGAN UNIV

Thermochemical structuring of matrix components for FCC catalysts

InactiveUS8940156B2Increase internal porosityCatalytic crackingMolecular sieve catalystsPolyphosphateMetal

A catalyst particle which comprises a metallic oxide such as kaolin is provided with the unique structure by mixing small amounts of a polyphosphate structuring agent with the metallic oxide and heating the mixture of metallic oxide and polyphosphate to allow reaction of the structuring agent with the metallic oxide.

Owner:BASF CORP

Method for preparing inorganic wall body insulating material

The invention relates to a method for preparing an inorganic wall body insulating material, and belongs to the technical field of construction material preparation. According to the method, perlite isexpanded by high-temperature calcination, so that pores inside the perlite can be increased; sodium hydroxide is utilized to react with the main ingredient silicon dioxide in the expanded perlite under a high-temperature high-pressure condition; the perlite and vegetable oil are mixed and subjected to rancidifying treatment, so that organic acid generated in rancidification is used for dissolvingand removing acid-soluble ingredients in the perlite, the modified perlite, filtrate containing sodium silicate and a gelatin solution are mixed to perform hydrolysis and condensation polymerizationunder the effect of acid by utilizing the sodium silicate, and silicon hydroxyl generated in hydrolysis reacts with amino and carboxyl in gelatin and the hydrogen bond generated in hydroxy active siteon the surface of the modified perlite besides self condensation, and the three-dimensional network structure achieves an effect of dispersive stress when the inorganic wall body insulating materialis subjected to external stress effect. The inorganic wall body insulating material has excellent cracking resistance, and has a wide application prospect.

Owner:常州蓝森环保设备有限公司

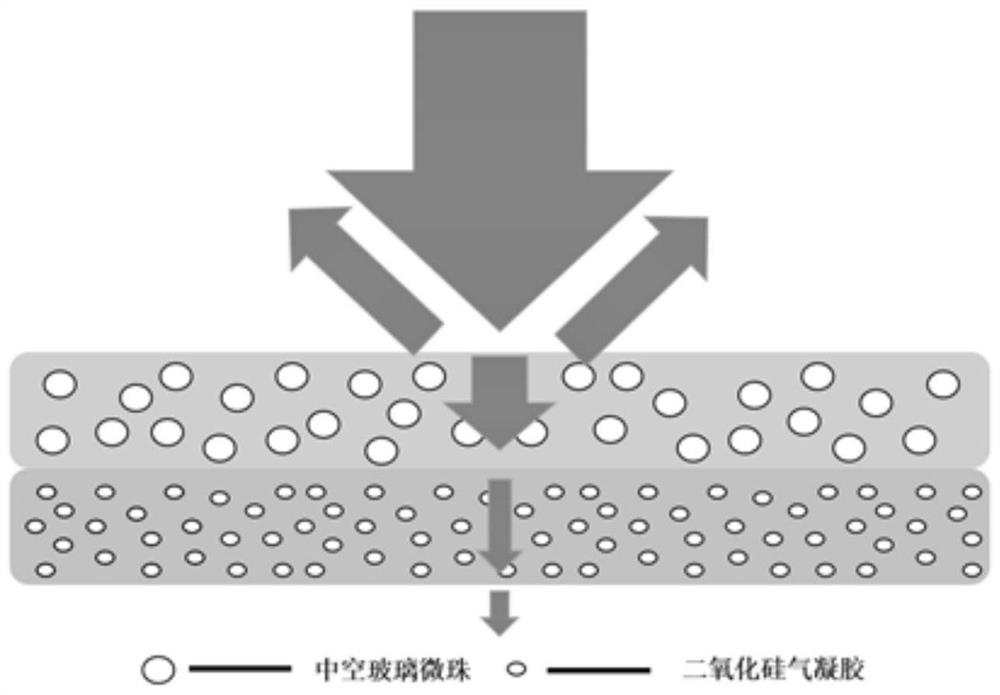

Preparation method of modified silicon dioxide emulsion and reflective insulation coating

PendingCN112592442AAvoid reunionImprove insulation performancePolyurea/polyurethane coatingsReflecting/signal paintsEmulsionThermal break

The invention discloses a preparation method of a modified silicon dioxide emulsion, which comprises the following steps: adding 5-8 parts by weight of modified silicon dioxide aerogel, 15-20 parts byweight of butyl acrylate, 12-18 parts by weight of styrene, 8-15 parts by weight of methacrylic acid, 5-10 parts by weight of emulsifier, 0.2-0.5 part by weight of initiator and 45-65 parts by weightof solvent, and stirring to react at 70-90 DEG C to obtain the modified silicon dioxide emulsion; and the invention also discloses a reflective insulation coating. The coating disclosed by the invention is composed of a double-layer structure, wherein an outer reflecting layer is mainly composed of fluorocarbon resin, hollow glass beads and a reflecting filler; an inner thermal insulation layer is mainly composed of polyurethane resin and silica aerogel, according to the invention, the solar reflectivity is as high as 90% or above, the heat conductivity coefficient is low, and external heat is effectively prevented from diffusing into the coating.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

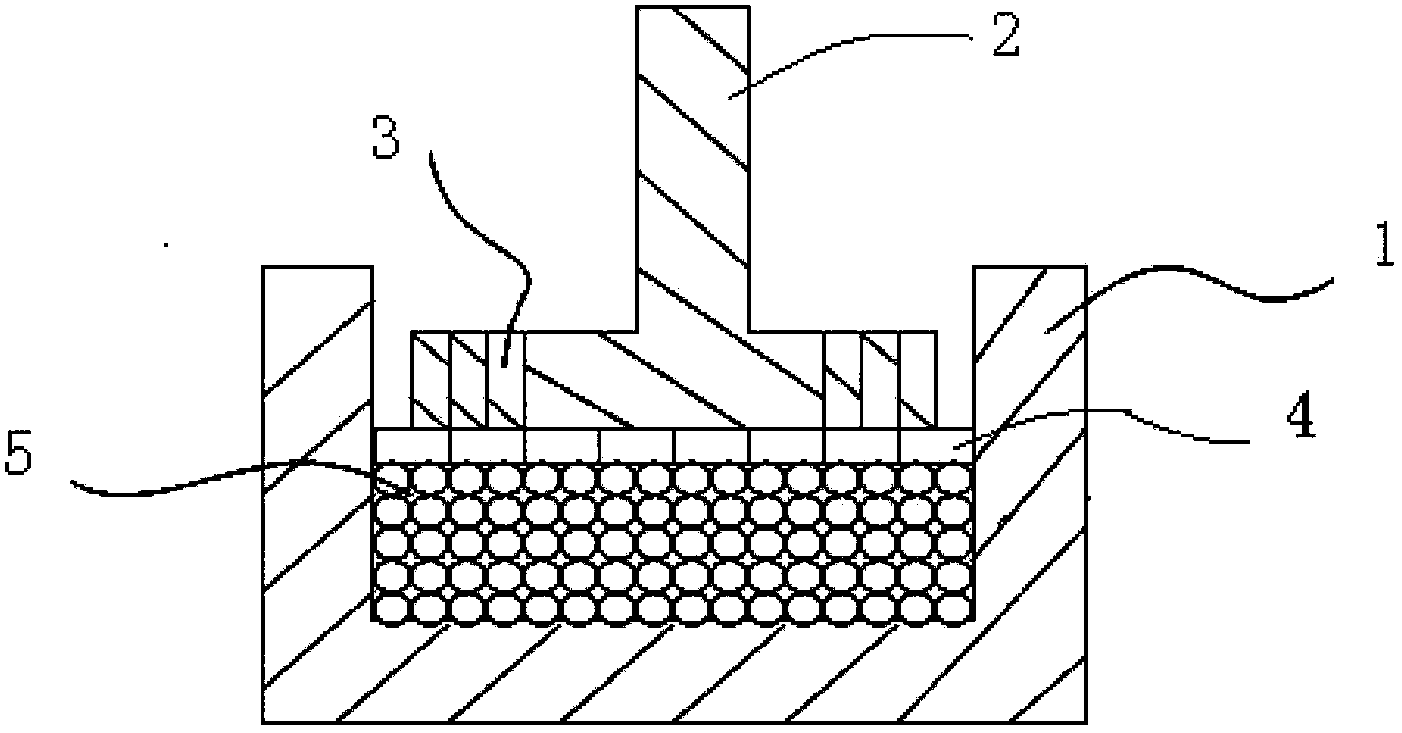

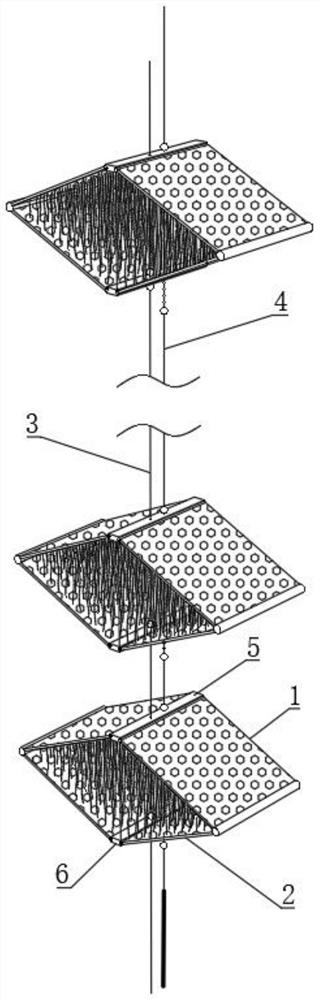

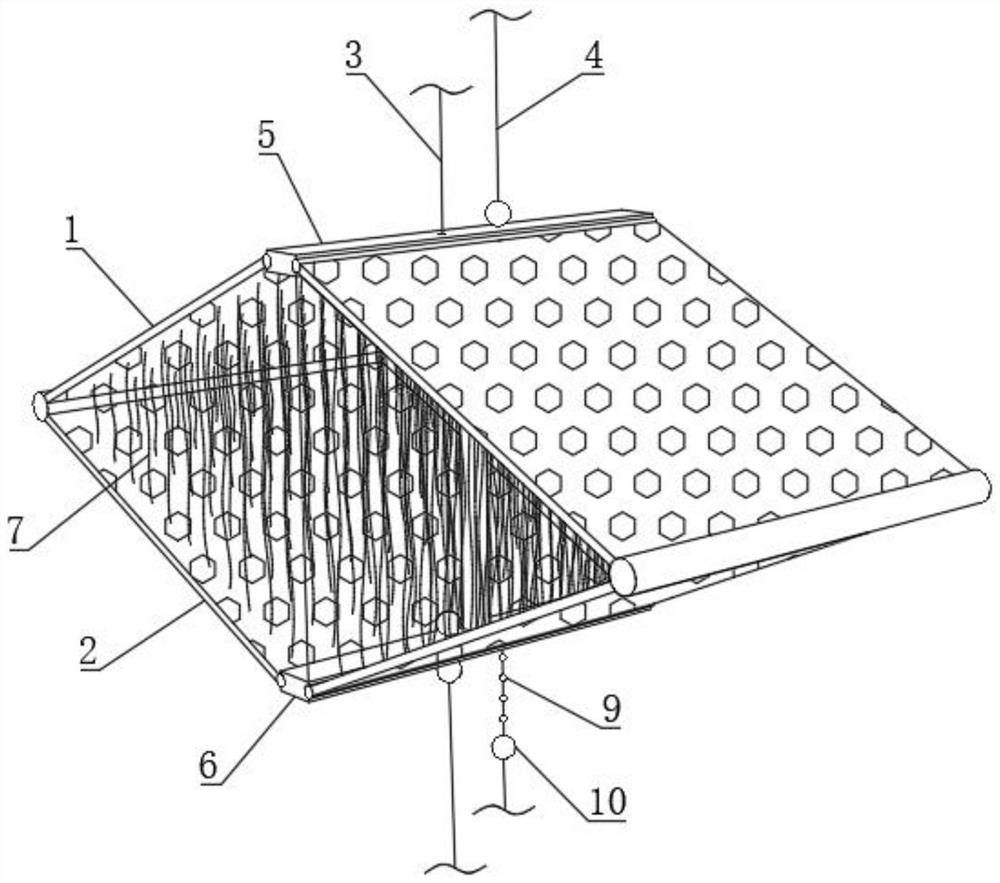

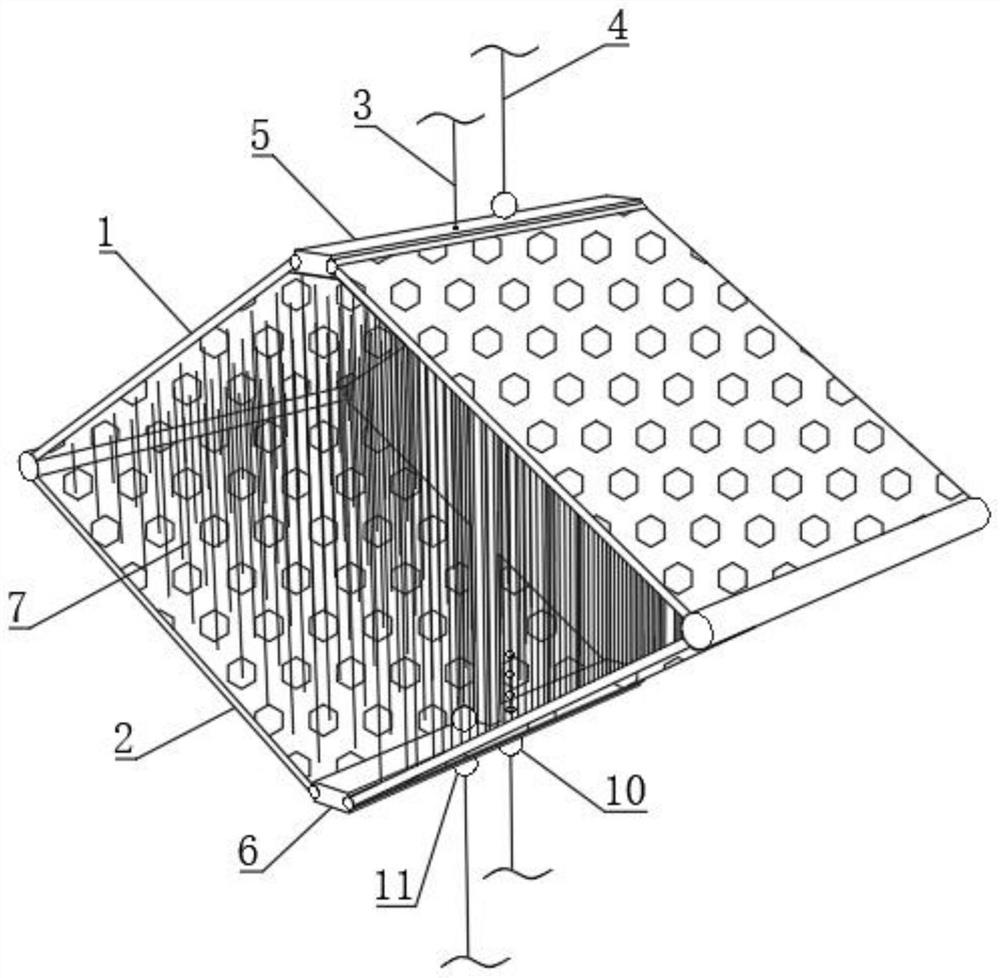

Wire-drawing gathering-scattering type combined filler for sewage treatment

InactiveCN113072194AChange densityIncrease internal porosityBiological treatment apparatusChemistryComposite material

The invention discloses a wire-drawing gathering-scattering type combined filler for sewage treatment, and belongs to the field of combined fillers. The wire-drawing gathering-scattering type combined filler for sewage treatment comprises a fixed rope, a semi-elastic movable rope and a plurality of uniformly distributed rhombic filler bodies, wherein the fixed rope and the semi-elastic movable rope sequentially penetrate through the rhombic filler bodies and are connected with the rhombic filler bodies, and the rhombic filler body comprises a pair of upper net plates and a pair of lower net plates. According to the invention, the shape change of the rhombic filler body is controlled, so that the loose state and the dense degree of the biofilm hanging silk are changed, the integrity of a biofilm is damaged, the internal pores of the biofilm are enlarged, the dense degree of the biofilm can be quantitatively and uniformly adjusted according to the actual situation, on the basis of not influencing the normal use of the biofilm, the internal porosity of the biofilm is improved, the adhesion capacity of the biofilm is reduced, and the separation of the aged biofilm is promoted so as to provide the combined filler which is easy to adjust, promotes demolding and has efficient degradation capacity for sewage treatment.

Owner:刘日山

Anti-crack mortar and preparation method thereof

ActiveCN114804786AImprove mechanical propertiesImprove crack resistanceSolid waste managementCelluloseFiber

The invention relates to the field of building materials, in particular to anti-crack mortar and a preparation method thereof.The anti-crack mortar is prepared from cement, PTB emulsion, VAE emulsion, light coarse sand, light fine sand, hydroxypropyl methyl cellulose, toughening fibers, alkali lignin, a polycarboxylate superplasticizer, fly ash, a calcium sulphoaluminate expanding agent, an organic silicon water repellent and water. The anti-crack mortar provided by the invention has good mechanical properties and anti-crack performance.

Owner:新化县天马建筑新材料科技有限公司

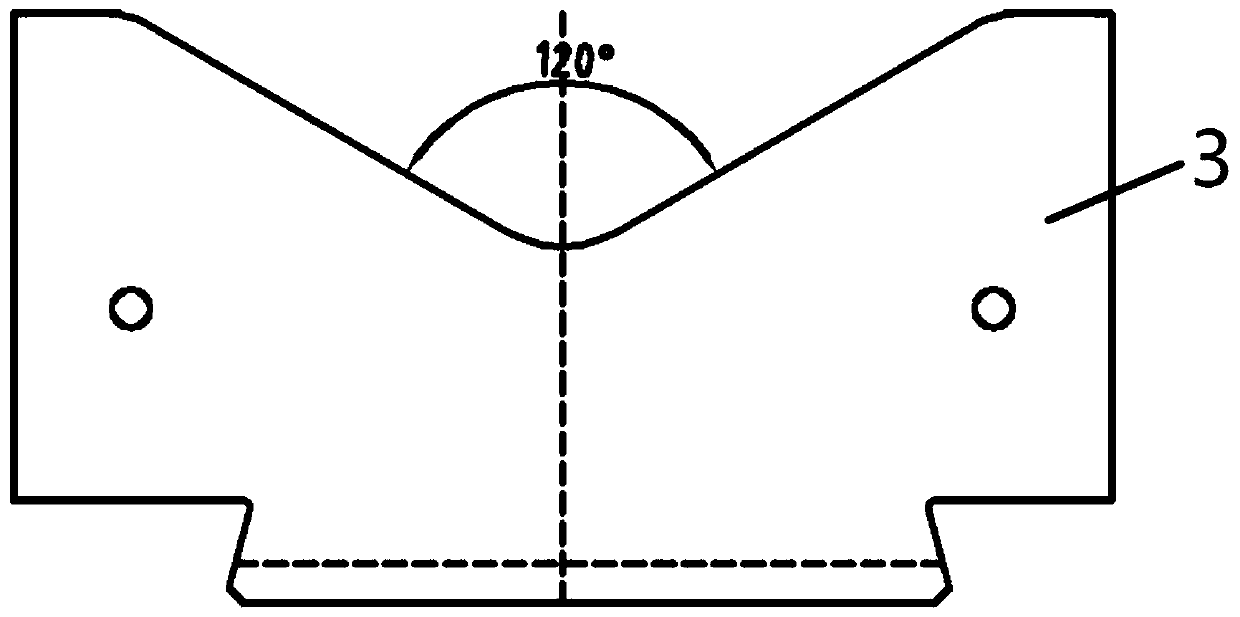

Method for forging sector plate by use of arc anvil

ActiveCN111167984ADestruction of positive and negative segregationIncrease internal porosityForging/hammering/pressing machinesManufacturing cost reductionIngot

The invention relates to a method for forging a sector plate by use of an arc anvil, belongs to the field of material machining and aims to solve the problems that existing flat anvil forging methodsare difficult to operate and forging allowance of a flat anvil is large. The method for forging the sector plate by use of the arc anvil comprises steps as follows: a steel ingot is put into a gas heating furnace to be heated to certain temperature and kept at the temperature for a period of time, so that the temperature of the steel ingot is uniform; the steel ingot is subjected to jaw pressing,chamfering and ingot tail removal and returned to the furnace to be heated, and upsetting is performed by an upsetting platform; the upset steel ingot is elongated by the anvil with an upper flat partand a lower V-shaped part; the steel ingot is forged by an arc anvil bed and the arc anvil according to technological requirements, and a finished product is finally forged; and the forged finished product is machined, and a finished product, namely, the vector plate, is obtained. The method is applied to production of the vector plate, the inherent quality of the product can be improved, the hardness of a workpiece is improved, operation is simple, equipment is protected, process weight of a blank of a forge is reduced, the manufacturing cost is reduced, and the batch production effect is realized.

Owner:建龙北满特殊钢有限责任公司

Preparation method of light composite concrete panel

The invention relates to the technical field of concrete and preparation thereof, specifically to a preparation method of a light composite concrete panel. The preparation method of the light composite concrete panel comprises the following steps: uniformly mixing 25-45 parts by weight of slag powder, 15-35 parts by weight of cement, 15-30 parts by weight of fine sand, 5-12 parts by weight of diatomite, 3-15 parts by weight of light calcium carbonate, 3-12 parts by weight of polyaluminum chloride, 15-48 parts of lightweight aggregate, 1-5 parts of reinforced fibers and modified rubber under the condition of mechanical agitation so as to obtain a mixture; then adding a water reducer, an auxiliary agent and a foaming agent and uniformly mixing, and carrying out compression moulding to obtaina concrete panel sample. The light composite concrete panel prepared by the above method has characteristics of light weight, high strength and good weatherability, can meet performance index requirements of concrete panels in the building industry, and has a good application prospect.

Owner:芜湖恒固混凝土材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com