Preparing method for transparent temperature-sensing color-changing wood

A temperature-sensitive discoloration, wood technology, applied in wood treatment, wood heating, wood impregnation, etc., to achieve the effect of increased flexural strength, high transparency, and increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

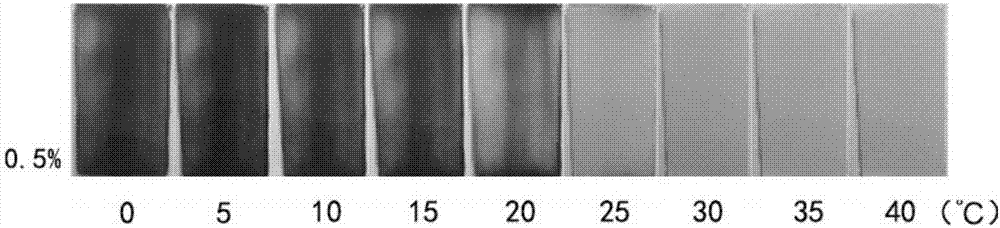

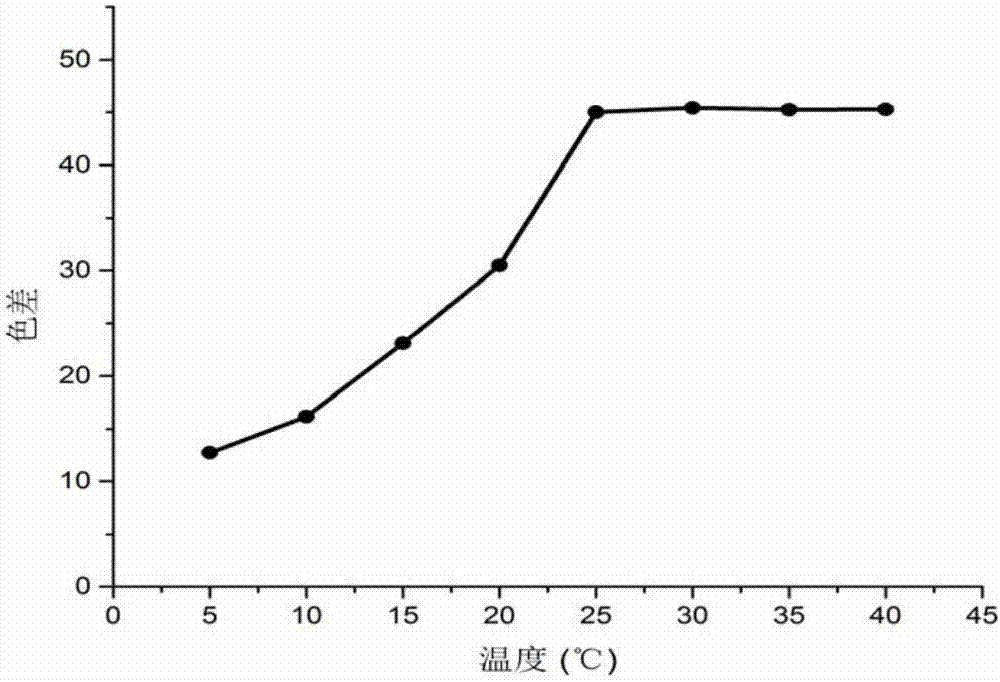

Embodiment 1

[0036] Experimental materials: 1.5mm×50mm×20mm poplar test piece, epoxy resin AB glue (Hubei Yongbang Composite Material Co., Ltd.), sodium hydroxide (analytical grade), sodium sulfite (analytical grade), sodium chlorite (analysis Pure), dark blue thermochromic powder with a color change temperature of 28°C (Shenzhen Qianse Change New Material Co., Ltd.).

[0037] Experimental steps:

[0038] 1. Put the poplar wood specimen into NaOH (2.5mol / L) and Na 2 SO 3 In the mixed solution of (0.4mol / L), change the drug solution every 4 hours, boil it for 24 hours, and then boil it with deionized water for 6 hours to remove the residual drug solution.

[0039] 2. Place the test piece in a sodium chlorite solution with a mass fraction of 1%, and adjust the pH to 4.5 with acetic acid, and then heat it in a water bath at 80°C until the test piece becomes uniform white. After washing with deionized water, store in alcohol.

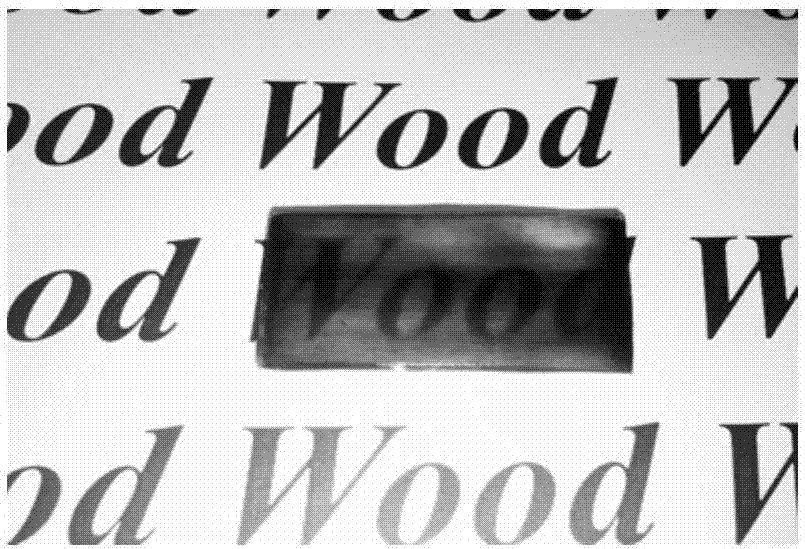

[0040] 3. Disperse 0.5% of the color-changing powder evenly into the epox...

Embodiment 2

[0049] Experimental materials: 1.5mm×50mm×30mm poplar test piece, epoxy resin AB glue (Hubei Yongbang Composite Material Co., Ltd.), sodium hydroxide (analytical grade), sodium sulfite (analytical grade), sodium chlorite (analysis Pure), dark blue thermochromic powder with a color change temperature of 28°C (Shenzhen Qianse Change New Material Co., Ltd.).

[0050] Experimental steps:

[0051] 1. Put the poplar wood specimen into NaOH (2.5mol / L) and Na 2 SO 3 In the (0.4mol / L) mixed solution, change the liquid medicine every 4 hours, boil it for 12 hours, and then boil it with deionized water for 2 hours to remove the residual liquid medicine.

[0052] 2. Place the test piece in a sodium chlorite solution with a mass fraction of 1%, and adjust the pH to 4.5 with acetic acid, and then heat it in a water bath at 80°C until the test piece becomes uniform white. After washing with deionized water, store in alcohol.

[0053] 3. Disperse 1% of the color-changing powder evenly into the epoxy...

Embodiment 3

[0061] Example 3 Comparative Example

[0062] Experimental materials: 1.5mm×50mm×20mm poplar test piece, epoxy resin AB glue (Hubei Yongbang Composite Material Co., Ltd.), sodium chlorite (analytical pure), dark blue thermochromic powder with a color change temperature of 28℃ (Shenzhen Qianse Change New Material Co., Ltd.).

[0063] Experimental steps:

[0064] 1. Put the poplar wood sample into a sodium chlorite solution with a mass fraction of 1%, and adjust the pH to 4.5 with acetic acid, and then heat it in a water bath at 80°C until the sample becomes uniform white. After washing with deionized water, store in alcohol.

[0065] 2. Disperse 0.5% discoloration powder uniformly into epoxy resin, immerse the test piece in the resin, and vacuum impregnate for about 50 minutes.

[0066] 3. Take out the test piece and place it in an oven at 40°C until fully cured.

[0067] In this example, the step of removing lignin was omitted. As a result, it was found that although the test piece cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com