Preparation method of modified silicon dioxide emulsion and reflective insulation coating

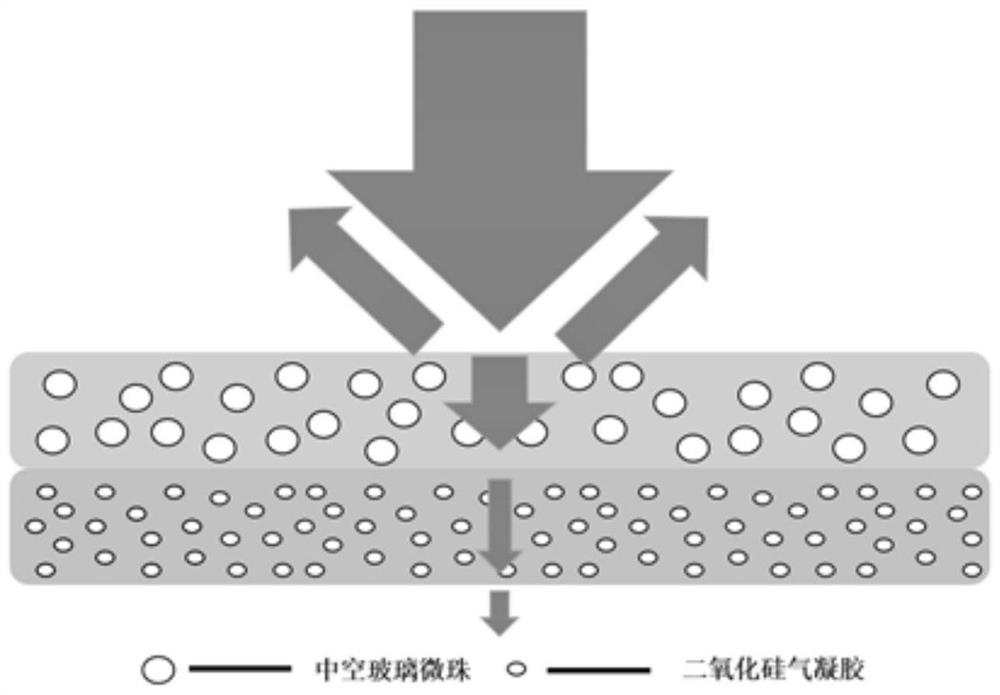

A reflective heat-insulating coating, silica technology, applied in the direction of reflection/signal coatings, polyurea/polyurethane coatings, coatings, etc. Problems such as the inability of the gel to disperse evenly, to avoid the effect of heat accumulation, avoid agglomeration, and prevent excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

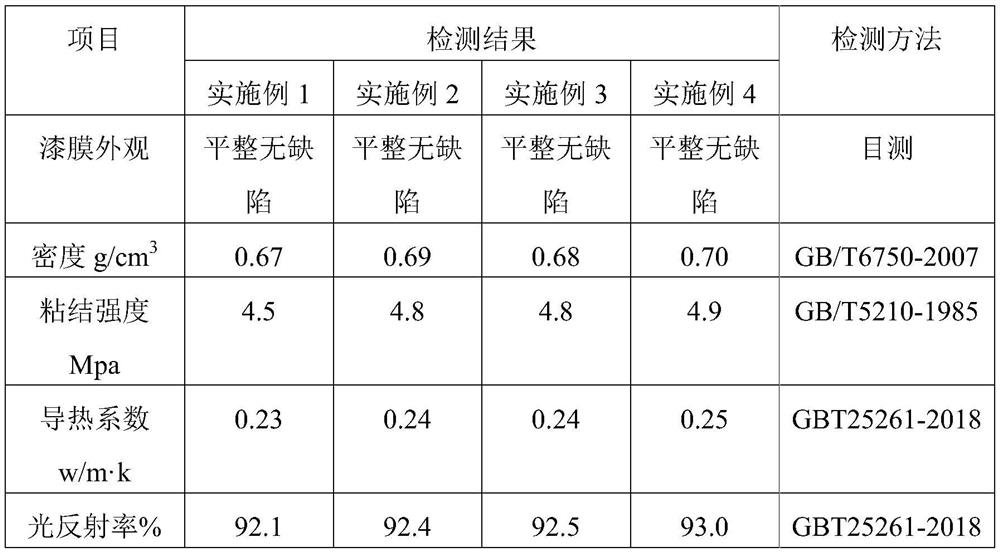

Embodiment 1

[0044]Put the silica airgel in a constant temperature drying oven at 100°C for 1 hour, take 5 parts by weight of dry silica airgel, 5 parts by weight of KH-550, 5 parts by weight of OP-10, and 70 parts by weight to remove Ionized water, ultrasonically dispersed for 15 minutes, stirred at 80°C for 4 hours, and finally centrifuged, washed and dried to prepare the modified silica airgel. With 5 parts by weight of modified silica airgel, 15 parts by weight of butyl acrylate, 12 parts by weight of styrene, 8 parts by weight of methacrylic acid, 5 parts by weight of OP-10, 0.2 parts by weight of azobisisobutyronitrile ( AIBN), 45 parts by weight of ethylene glycol butyl ether (BG) solvent, stirred and reacted at 80° C. for 2 hours to prepare a modified silica emulsion.

[0045] Get 45 parts by weight of polyurethane emulsion, 10 parts by weight of modified silica emulsion, 1 part by weight of 4100, 1 part by weight of 024, 1 part by weight of 381, 0.5 parts by weight of R299, 4 part...

Embodiment 2

[0048] Put the silica airgel in a constant temperature drying oven at 100°C for 1 hour, take 6 parts by weight of dry silica airgel, 7 parts by weight of KH-560, 7 parts by weight of SDS, and 73 parts by weight of deionized water , ultrasonically dispersed for 15 minutes, stirred at 80°C for 4 hours, and finally centrifuged, washed and dried to prepare the modified silica airgel. 6 parts by weight of modified silica airgel, 17 parts by weight of butyl acrylate, 14 parts by weight of styrene, 10 parts by weight of methacrylic acid, 7 parts by weight of sodium dodecyl sulfate (SDS), 0.3 parts by weight of AIBN , 50 parts by weight of diethylene glycol butyl ether (DBG), stirred and reacted at 80° C. for 2 hours to prepare a modified silica emulsion.

[0049] Get 50 parts by weight of polyurethane emulsion, 12 parts by weight of modified silica emulsion, 0.5 parts by weight of 4100, 0.5 parts by weight of 902W, 0.5 parts by weight of 381, 0.5 parts by weight of R299, 5 parts by w...

Embodiment 3

[0052] Put the silica airgel in a constant temperature drying oven and dry it at 100°C for 2 hours, take 7 parts by weight of dry silica airgel, 9 parts by weight of KH-570, and 9 parts by weight of sodium dodecylbenzenesulfonate (DBS), 77 parts by weight of deionized water, ultrasonically dispersed for 15 minutes, stirred at 80°C for 4 hours, and finally centrifuged, washed and dried to prepare the modified silica airgel. With 7 parts by weight of modified silica airgel, 19 parts by weight of butyl acrylate, 16 parts by weight of styrene, 13 parts by weight of methacrylic acid, 9 parts by weight of DBS, 0.4 parts by weight of dibenzoyl peroxide (BPO) , 60 parts by weight of dipropylene glycol butyl ether (DPNB), stirred and reacted at 80° C. for 2 hours to prepare a modified silica emulsion.

[0053] Get 55 parts by weight of polyurethane emulsion, 14 parts by weight of modified silica emulsion, 0.5 parts by weight of 270, 0.5 parts by weight of 902W, 1 part by weight of 450,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com