Method for forging sector plate by use of arc anvil

A fan-shaped plate and circular arc technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of large forging allowance and difficult operation of flat anvils, and achieve metal flow Good line, reduce forging allowance, improve the effect of workpiece hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

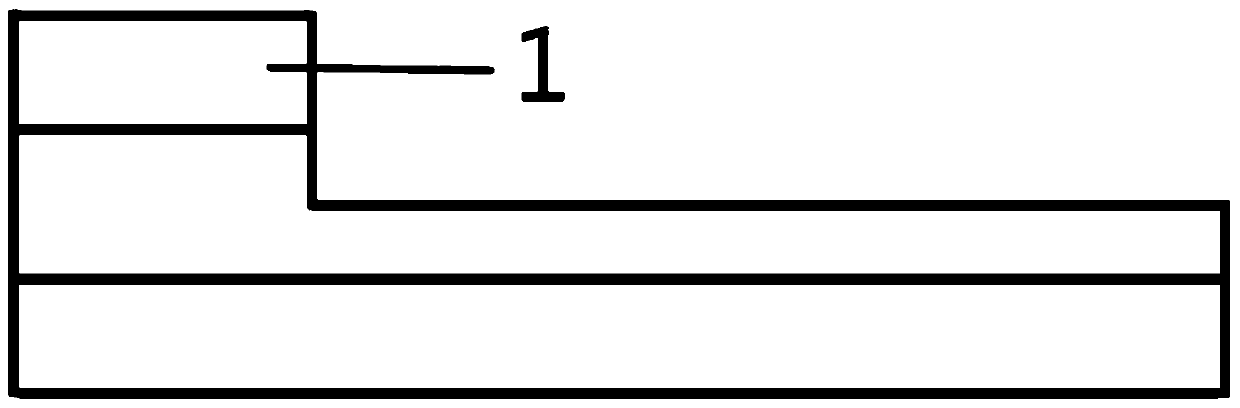

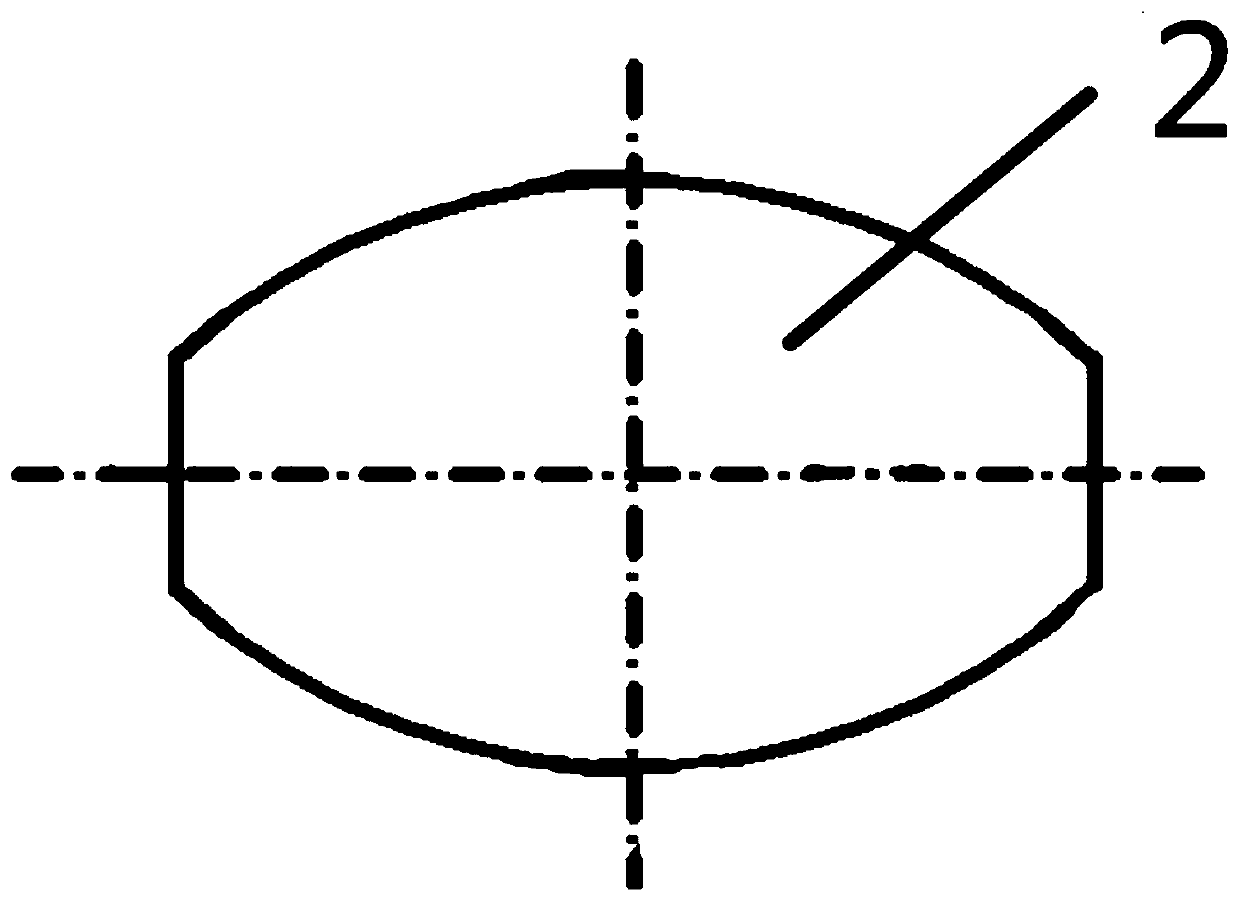

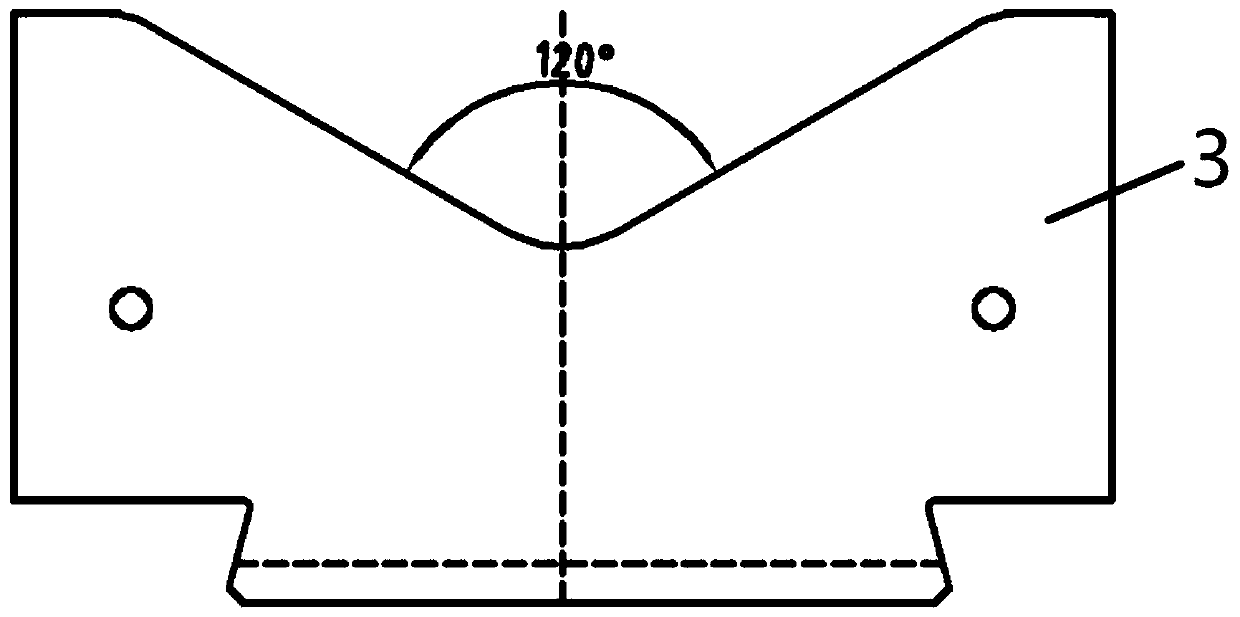

[0032] In this embodiment, the forging method of 2Cr12NiMoWVE fan-shaped plate is taken as an example. A 30MN hydraulic press is used for forging, and the weight of the steel ingot is 4.99 tons. Half-die forging of the arc anvil and anvil → finishing each part to the finished product size → flaw detection → sampling → heat treatment → inspection of performance.

[0033] Example 1

[0034] The specific forging method steps are as follows:

[0035] Step 1. Put the steel ingot into a gas heating furnace and heat it. The heating temperature is 1180°C, the holding time is 8 hours, and the temperature of the steel ingot is uniform;

[0036] Step 2: Press the steel ingot into the jaws, chamfer the edge, remove the tail of the ingot, return to the furnace for heating, and the heating temperature is 1180°C;

[0037] Step 3. Use the upsetting platform for upsetting, upsetting to φ1000mm, and the upsetting ratio is 1.5;

[0038] Step 4. Use the upper flat and lower V-shaped anvils to ...

Embodiment 2

[0043] The specific forging method steps are as follows:

[0044] Steps 1 to 3 are the same as in Example 1. Steps 4 and 5 are the same as in Example 1 except that the single reduction is 130 mm. Step 6 is the same as in Example 1.

[0045] Take 200mm samples longitudinally at both ends of the obtained fan-shaped plate, respectively, and conduct flaw detection and mechanical performance testing. The results are shown in Table 1.

Embodiment 3

[0047] Steps 1 to 3 are the same as in Example 1. Steps 4 and 5 are the same as in Example 1 except that the single reduction is 150 mm. Step 6 is the same as in Example 1.

[0048] Take 200mm samples longitudinally at both ends of the obtained fan-shaped plate, respectively, and conduct flaw detection and mechanical performance testing. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com