Coal ash heat preservation brick

A technology for fly ash and thermal insulation bricks, which is applied in the field of fly ash thermal insulation bricks, can solve the problems of poor mechanical properties and thermal insulation properties of fly ash bricks, and achieves the improvement of mechanical properties, compressive strength and thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

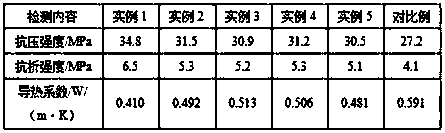

Examples

example 1

[0038] Mix Paulownia wood particles with a particle size of 1.5mm and water at a mass ratio of 1:10, and add dopamine 0.3 times the water quality to the mixture of Paulownia wood particles and water, and set the temperature at 40°C and rotate at 300r / min. Stir and mix for 30 minutes under the same conditions, filter to obtain pretreated paulownia wood; add water to a beaker and heat to 60°C, add ammonium nitrate to the beaker until crystals are precipitated, filter to obtain the filtrate, and obtain a saturated aqueous solution of ammonium nitrate ; Mix cork particles and ammonium nitrate saturated aqueous solution at a mass ratio of 1:10, stir and mix for 30 minutes at a temperature of 60°C and a rotational speed of 300r / min, then cool the mixture of cork particles and ammonium nitrate aqueous solution to 20°C , filtered to obtain a filter cake, and dried the filter cake at a temperature of 70°C for 40 minutes to obtain pretreated cork particles, which were mixed with pretreat...

example 2

[0040] Mix Paulownia wood particles with a particle size of 1.5mm and water at a mass ratio of 1:10, and add dopamine 0.3 times the water quality to the mixture of Paulownia wood particles and water, and set the temperature at 40°C and rotate at 300r / min. Stir and mix for 30 minutes under the same conditions, filter to obtain pretreated paulownia wood; add water to a beaker and heat to 60°C, add ammonium nitrate to the beaker until crystals are precipitated, filter to obtain the filtrate, and obtain a saturated aqueous solution of ammonium nitrate Add diisocyanate into the reactor, drip diethylamine solution with 3 times the quality of diisocyanate into the reactor at a rate of 10mL / min, and feed nitrogen into the reactor at a rate of 20mL / min, at a temperature of 55 ℃, the rotation speed is 300r / min under the condition of heating and stirring for 3 hours, the pretreated isocyanate is obtained, and the pretreated isocyanate is vacuum-dried for 5 days at a temperature of 50℃, an...

example 3

[0042] Mix Paulownia wood particles with a particle size of 1.5mm and water at a mass ratio of 1:10, and add dopamine 0.3 times the water quality to the mixture of Paulownia wood particles and water, and set the temperature at 40°C and rotate at 300r / min. Stir and mix for 30 minutes under the same conditions, filter to obtain pretreated paulownia wood; add water to a beaker and heat to 60°C, add ammonium nitrate to the beaker until crystals are precipitated, filter to obtain the filtrate, and obtain a saturated aqueous solution of ammonium nitrate ; Mix agar and water at a mass ratio of 1:15, and add beef extract 0.3 times the mass of agar and peptone 0.2 times the mass of agar to the mixture of agar and water, at a temperature of 65°C and a rotation speed of 300r / min After stirring and mixing for 50 minutes, the agar mixture was obtained. The cork particle agar mixture was mixed at a mass ratio of 1:5, soaked at a temperature of 55°C for 90 minutes, and then filtered to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com