Waste landfill evapotraspiration covering layer based on municipal dehydrated sludge

A landfill and dewatered sludge technology, which is applied in landfill technology, infrastructure engineering, solid waste removal, etc., can solve the problems of cumbersome construction of composite covering layers and inconvenient materials, and achieve economic benefits and environmental protection The effect of double harvest, material and structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Municipal dewatered sludge with a moisture content of 80% is selected, and it is prepared for use after being screened for impurities and heavy metals.

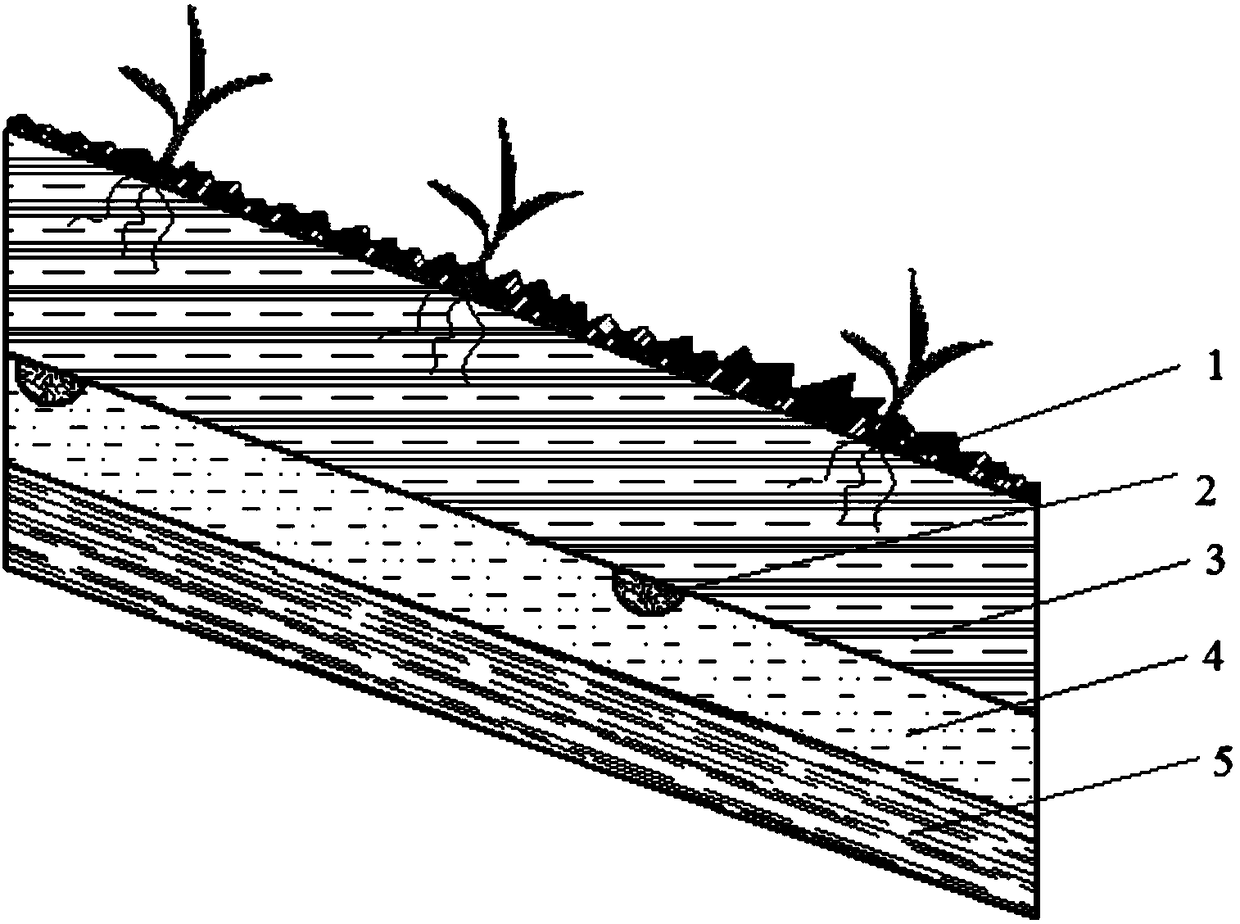

[0045] 1. Preparation of foundation cushion layer 5

[0046] The construction waste is piled on the top of the waste pile first, and mechanically crushed in situ. After crushing, the largest particle size of the block is less than 5cm, and then leveled, and the final thickness is 12cm.

[0047] 2. Preparation of adjustment layer 4

[0048] Take 1000kg of municipal dewatered sludge, add 120kg of modified agent I, mix well, and use a sludge granulator to extrude into spherical particles with a particle size range of 0.75-2mm, and place the spherical particles in a cool and ventilated environment for natural maintenance Drying, curing for 7 days, the permeability coefficient of the test sludge heap is

[0049] 2.3×10 -3 m / s, and then stack the materials on the foundation cushion layer 5, lightly compact and level it, and...

Embodiment 2

[0058] Municipal dewatered sludge with a moisture content of 83% is selected, and is ready for use after screening for impurities and heavy metals.

[0059] 1. Preparation of foundation cushion layer 5

[0060] The construction waste is piled on top of the waste pile first, and mechanically crushed in situ. After crushing, the largest particle size of the block is less than 6cm, and then leveled, and the final thickness is 15cm.

[0061] 2. Preparation of adjustment layer 4

[0062] Take 1000kg of municipal dewatered sludge, add 150kg of modified agent I, mix well, and use a sludge granulator to extrude into spherical particles with a particle size range of 0.75-2mm, and place the spherical particles in a cool and ventilated environment for natural maintenance Drying, curing for 8 days, the permeability coefficient of the test sludge heap is

[0063] 3.5×10 -3 m / s, and then stack the materials on the foundation cushion layer 5, lightly compact and level it, and finally lay ...

Embodiment 3

[0072] Municipal dewatered sludge with a moisture content of 85% is selected, and is ready for use after screening for impurities and heavy metals.

[0073] 1. Preparation of foundation cushion layer 5

[0074] The construction waste is piled on the top of the waste pile first, and mechanically crushed in situ. After crushing, the largest particle size of the block is less than 6cm, and then leveled, and the final thickness is 18cm.

[0075] 2. Preparation of adjustment layer 4

[0076] Take 1000kg of municipal dewatered sludge, add 180kg of modified agent I, stir evenly, and use a sludge granulator to extrude into spherical particles with a particle size range of 0.75-2mm, and place the spherical particles in a cool and ventilated environment for natural maintenance Drying, curing for 10 days, the permeability coefficient of the test sludge heap is

[0077] 1.7×10 -3 m / s, and then stack the materials on the foundation cushion layer 5, lightly compact and level it, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com