Mud-based spherical active carbon as well as preparation method and application thereof

An activated carbon and spherical technology, which is applied in the field of mud-based spherical activated carbon and its preparation, high-performance mud-based spherical activated carbon and its preparation field, can solve the problems of increasing the preparation cost, high apparent density of mud-based activated carbon, etc., and achieves low apparent density. , good sphericity, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

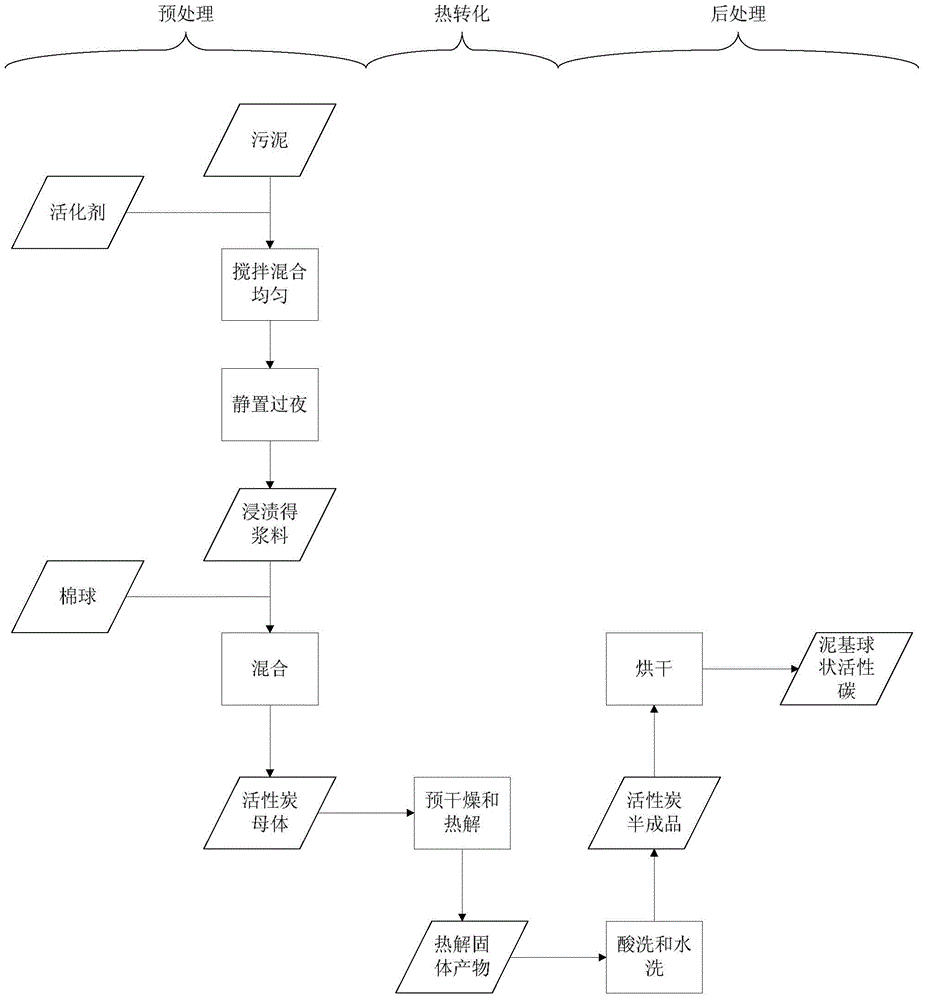

[0039] The preparation method of mud-based spherical activated carbon of the present invention, process flow chart is as follows figure 1 As shown, the method can be divided into three stages of pretreatment-thermal conversion-posttreatment, specifically including the following steps:

[0040] (preprocessing stage):

[0041] (1) Mix the sludge and the activator evenly in proportion, leave it to stand overnight and impregnate to obtain a slurry;

[0042] (2) mixing the slurry obtained in step (1) with cotton balls, so that the slurry is wrapped on the surface of the cotton balls to obtain the active carbon matrix;

[0043] (thermal conversion stage):

[0044] (3) Place the obtained activated carbon precursor in an oxygen-free heating furnace for pre-drying, then program the temperature to the pyrolysis temperature and maintain the pyrolysis time, so that the activated carbon precursor completes the carbonization and activation process, and naturally cools to room temperature ...

Embodiment 1

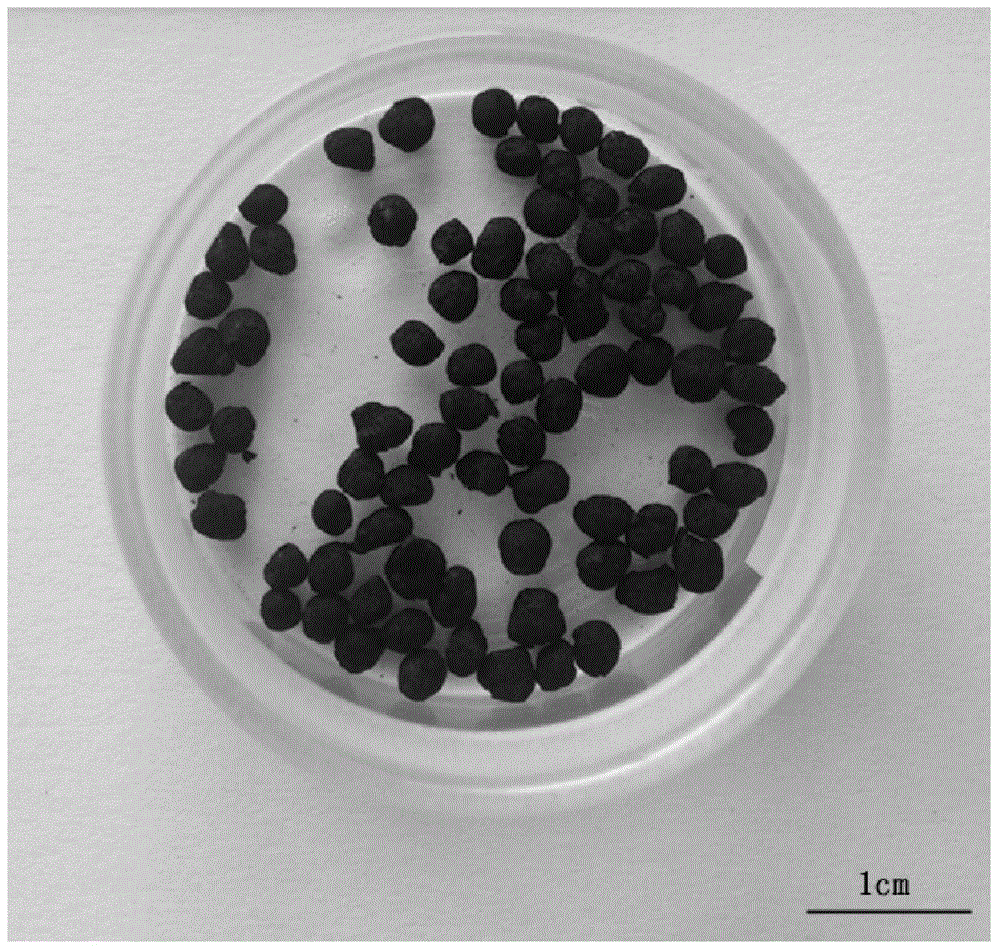

[0048] Example 1: High-performance mud-based spherical activated carbon was prepared using municipal sludge from Liede Sewage Treatment Plant in Guangzhou.

[0049]The sludge was taken from the dehydration centrifuge of Guangzhou Liede Sewage Treatment Plant. The industrial analysis results of the sludge were expressed in mass fractions: water content was 78.4%, ash content was 55.9%, volatile content was 38.2%, and fixed carbon content was 5.9%. Sludge is directly used as raw material for the preparation of mud-based spherical activated carbon.

[0050] The preparation method of mud-based spherical activated carbon is as described above, and the specific operations are:

[0051] Take a portion of sludge with a 500mL beaker, put it in a balance and weigh 21.1g, then add ZnCl 2 Mix 13.7g powder with sludge evenly, impregnate ZnCl 2 The sludge was left to stand overnight to obtain a slurry; in the obtained slurry, about 150 cotton balls with an average particle diameter of 3mm...

Embodiment 2

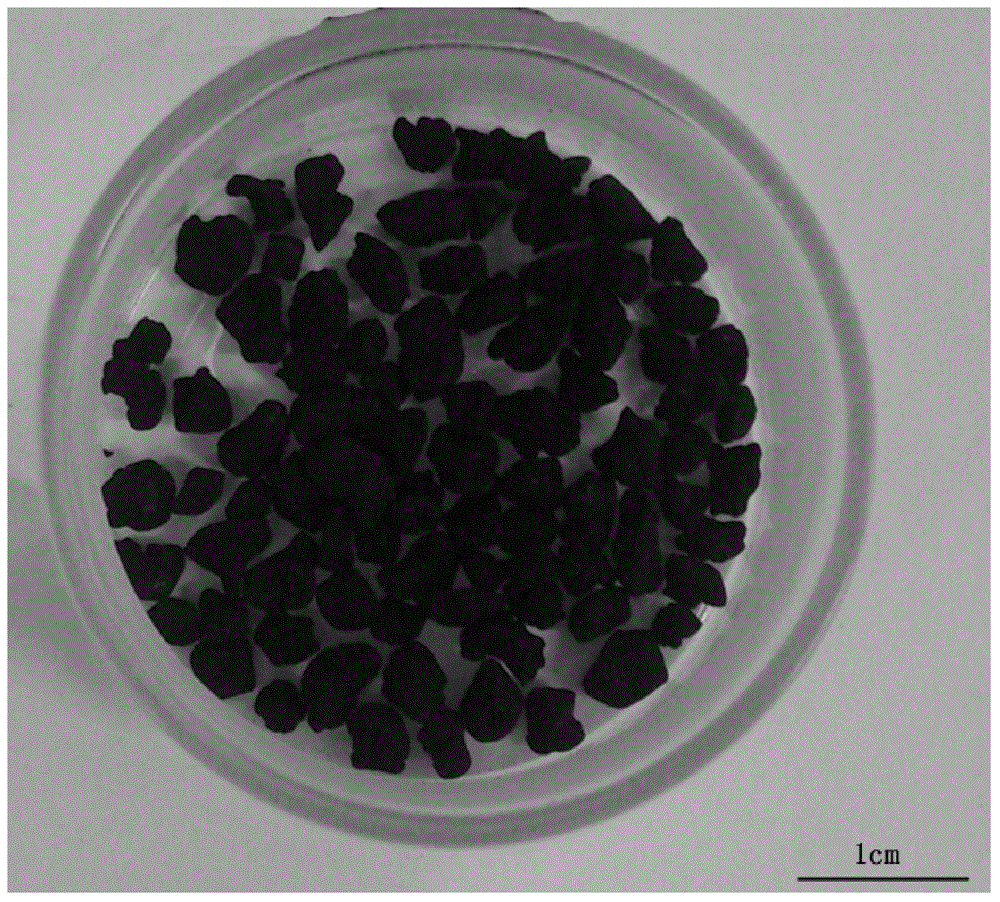

[0056] Example 2: High-performance mud-based spherical activated carbon was prepared from municipal sludge of Datansha Sewage Treatment Plant in Guangzhou.

[0057] The sludge sample was changed to the sludge in the centrifugal filter press of Guangzhou Datansha Sewage Treatment Plant. The industrial analysis results of the sludge were expressed in terms of mass fraction: water content was 88.6%, ash content was 36.3%, volatile content was 54.8%, fixed Carbon 8.9%.

[0058] The specific operation of the preparation method of the mud-based spherical activated carbon is as follows: keep the ratio of the dry weight in the sludge to the mass of the activator at 1:3, take 24.8g of sludge in this embodiment, mix and add 8.48g of ZnCl 2 powder. The same steps and reaction conditions as in Example 1 were used to prepare high-performance mud-based spherical activated carbon.

[0059] The obtained product adopts the method identical with embodiment 1 to carry out specific surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com