Preparation method of super absorbent resin for cables or optical cables

A technology of superabsorbent resin and fiber optic cable, which is applied in the field of preparation of superabsorbent resin, can solve the problems that the liquid absorption rate and swelling height cannot meet the requirements, and achieve the effects of fast water absorption rate, high internal porosity and high swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

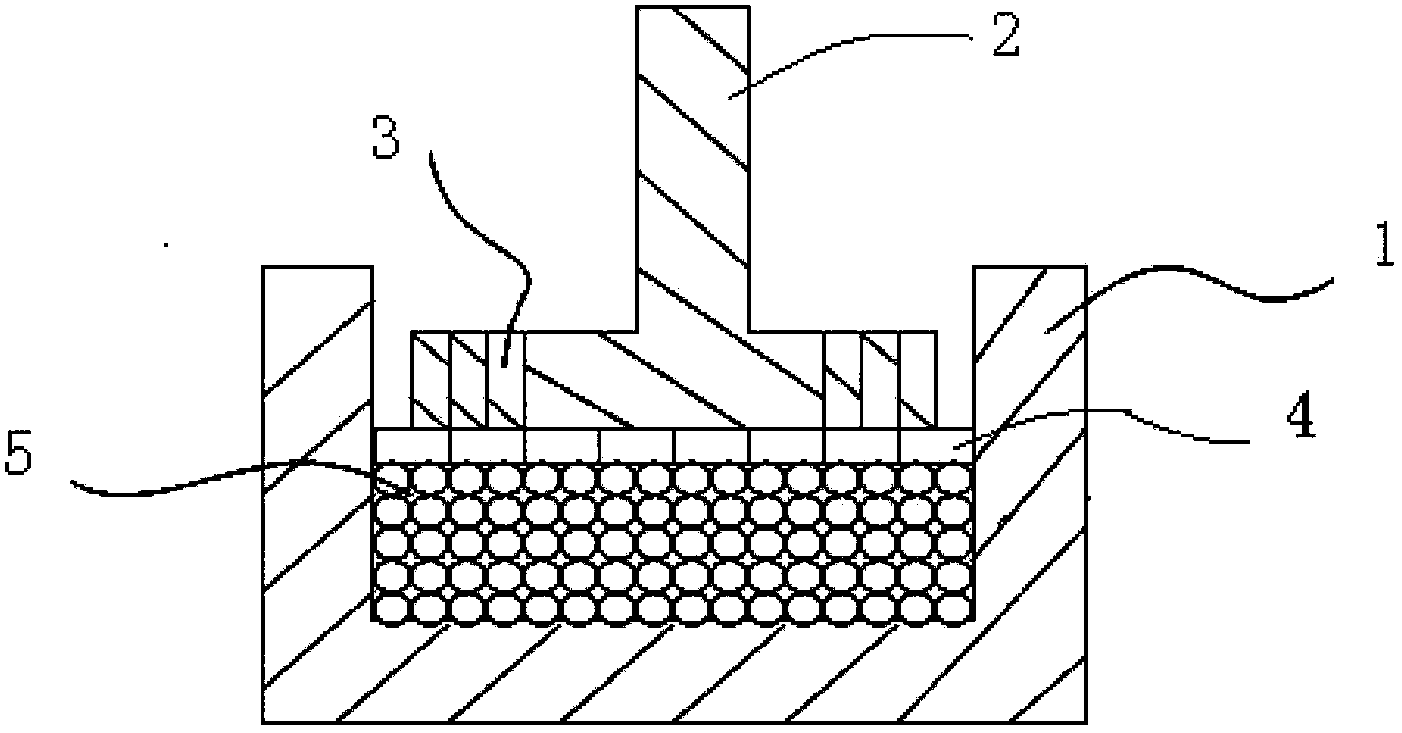

Method used

Image

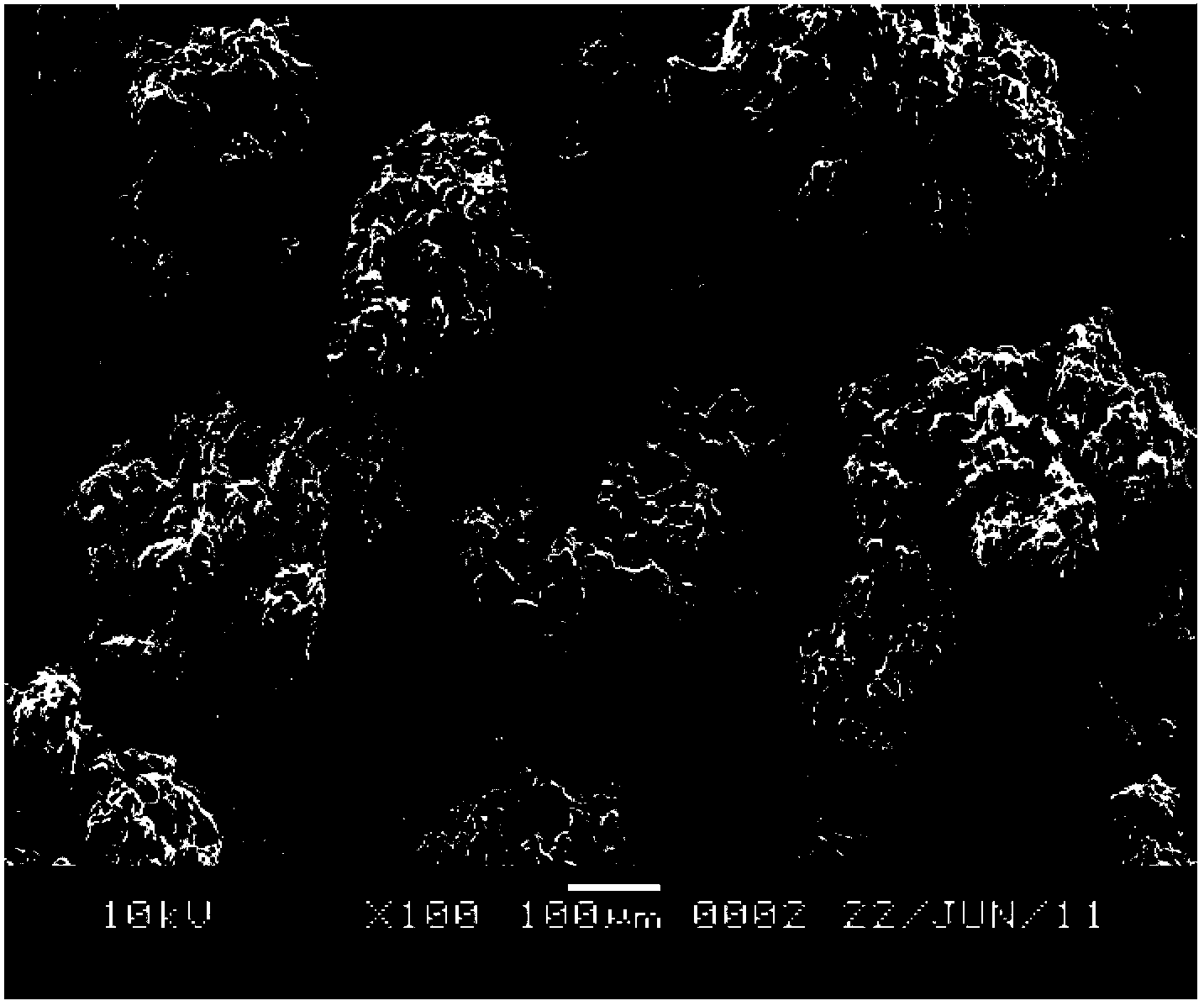

Examples

Embodiment 1

[0040] Add 380 g of cyclohexane into a 1 L five-neck round bottom flask equipped with a stirrer, reflux condenser, dropping funnel, thermometer and nitrogen inlet tube. Add 2g of 33-35wt% ethoxylated nonylphenol sulfosuccinic acid half-ester disodium salt and 0.6g of ethyl cellulose, raise the temperature to 80°C, and disperse it evenly at a stirring speed of 300rpm.

[0041] Add 100 g of an aqueous solution of acrylic acid monomer with a concentration of 75 wt % into a 500 mL beaker. 97.5 g of 32 wt % sodium hydroxide aqueous solution was added dropwise to the beaker. Then, 0.2 g of potassium persulfate and 0.1 g of propylene glycol diglycidyl ether were added thereto to obtain a partially neutralized aqueous solution of acrylic acid monomer.

[0042] Add the partially neutralized aqueous solution of acrylic acid monomer dropwise into the above-mentioned five-necked round-bottomed flask, and blow in nitrogen gas for 30-60 minutes while stirring. React for 2 hours. After th...

Embodiment 2

[0045] In addition to changing 2g 33-35wt% disodium ethoxylated nonylphenol sulfosuccinate half ester and 0.6g ethylcellulose to 2.5g 30-32wt% polyoxyethylene lauryl ether sulfate and 0.8 g hydroxymethyl cellulose, other operations are the same as in Example 1.

Embodiment 3

[0047] Add 380 g of cyclohexane into a 1 L five-neck round bottom flask equipped with a stirrer, reflux condenser, dropping funnel, thermometer and nitrogen inlet tube. Add 3.5g of 33-35wt% ethoxylated nonylphenol sulfosuccinate half ester disodium salt and 1.0g of ethyl cellulose, raise the temperature to 80°C, and disperse it evenly at a stirring speed of 300rpm.

[0048] Add 100 g of acrylic acid aqueous solution with a mass concentration of 75% (wt%) into a 500 ml beaker. 97.5 g of 32 wt % sodium hydroxide aqueous solution was added dropwise to the beaker. Then, 0.3 g of sodium persulfate and 0.06 g of glycerol glycidyl ether were added thereto to obtain a partially neutralized aqueous solution of acrylic acid monomer.

[0049] Add the partially neutralized aqueous solution of acrylic acid monomer dropwise into the above-mentioned five-necked round-bottomed flask, and blow in nitrogen gas for 30-60 minutes while stirring. React for 2 hours. After the reaction, the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com