Biomass-based organic fertilizer preparation technology and application method

A preparation process and organic fertilizer technology, applied in the field of biomass-based organic fertilizer preparation process and application, can solve the problems of large fluctuation range of biomass organic fertilizer content, failure to consider soil fertility and function, increase soil heavy metal content, etc. , to achieve good synergy with the soil, rich elements, and the effect of expanding internal pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

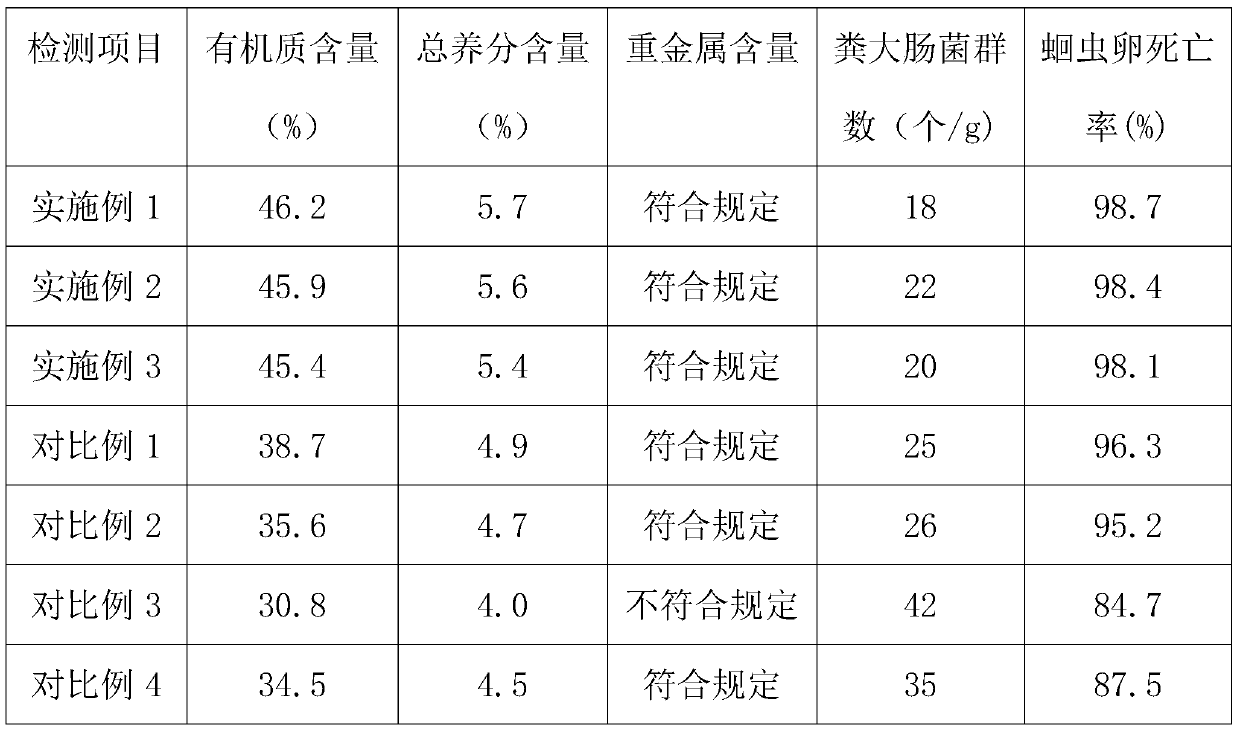

Examples

Embodiment 1

[0035] The present embodiment provides a kind of biomass-based organic fertilizer preparation process, comprising the following steps:

[0036] S1. Mixing: In parts by weight, take 16 parts of walnut kernel skin, 29 parts of grape skin, 7 parts of peat moss, and 46 parts of straw, and mix and stir evenly to obtain the mixture a; the straw is made of corn stalk and wheat straw according to the mass ratio of 1 :2 mixed. The walnut kernel skin needs to be pretreated. The specific process is: soak the walnut kernel skin in clean water, air-dry and crush it into powder, put it into a vacuum dryer, heat it up to 115°C under a negative pressure of -10KPa, and dry it for 1.2 Hours; when the temperature is lowered to 46°C, the material is discharged, and sieved to obtain particles with a particle size of 60-80 mesh.

[0037] S2. Expansion activation: Mixture a is put into the vacuum reaction furnace, and under the vacuum conditions of 110°C and -15KPa, it is filled with water vapor fo...

Embodiment 2

[0042] The present embodiment provides a kind of biomass-based organic fertilizer preparation process, comprising the following steps:

[0043] S1. Mixing: In parts by weight, take 15 parts of walnut kernel skin, 30 parts of grape skin, 8 parts of peat moss, and 45 parts of straw, and mix and stir evenly to obtain the mixture a; The mass ratio is 1:1:1 mixed. The walnut kernel skin needs to be pretreated. The specific process is as follows: soak the walnut kernel skin in clean water, air-dry and crush it into powder, put it into a vacuum dryer, heat it up to 108°C under a negative pressure of -10KPa, and dry it for 1.8 Hours; when the temperature is lowered to 48°C, the material is discharged, and sieved to obtain particles with a particle size of 60-80 mesh.

[0044] S2. Expansion activation: the mixture a is put into the vacuum reaction furnace, and under the vacuum conditions of 115°C and -16KPa, it is filled with water vapor for expansion activation, and the 3m 3 water v...

Embodiment 3

[0049] The present embodiment provides a kind of biomass-based organic fertilizer preparation process, comprising the following steps:

[0050] S1. Mixing: In parts by weight, take 18 parts of walnut kernel skin, 31 parts of grape skin, 9 parts of peat moss, and 48 parts of straw, and mix and stir evenly to obtain a mixture a; the straw is composed of wheat straw, sorghum straw, peanut straw, Rice straw is mixed according to the mass ratio of 1:1:1:1. The walnut kernel skin needs to be pretreated. The specific process is: soak the walnut kernel skin in clean water, air-dry and crush it into powder, put it into a vacuum dryer, heat it up to 115°C under a negative pressure of -10KPa, and dry it for 1.8 Hours; when the temperature is lowered to 48°C, the material is discharged, and sieved to obtain particles with a particle size of 60-80 mesh.

[0051] S2. Expansion activation: the mixture a is put into the vacuum reaction furnace, and under the vacuum conditions of 120°C and -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com