Polylactic acid and polystyrene compatibilization blending material and preparation method thereof

A technology of polystyrene and polylactic acid, which is applied in the field of polylactic acid/polystyrene compatibilized blend materials and its preparation, can solve the problems of compatibility and mechanical properties of polylactic acid/polystyrene blends, Problems such as the decrease of tensile strength, modulus and impact strength of the blend, and weak interfacial interaction force have achieved the effects of easy processing, reduced material and process costs, and high compatibilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

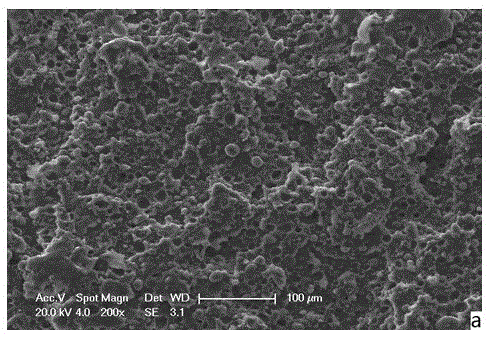

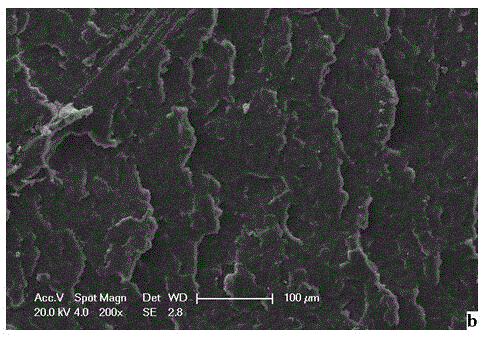

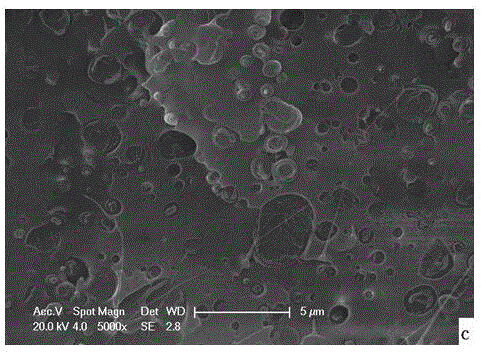

Image

Examples

Example Embodiment

[0024] Example 1

[0025] The compatibilizer provided by the invention prepares raw materials by the following weight proportions, and the polymerization method is soap-free emulsion polymerization:

[0026] Styrene 100

[0027] Methyl Acrylate 20

[0028] Potassium persulfate 0.7

[0029] Add 250ml of water to a 500ml flask, heat up to 40°C, add monomer and emulsifier in proportion, start stirring, heat up to 75°C, add potassium persulfate aqueous solution, and stop the reaction after 8 hours of reaction. After demulsification, filtration, washing and drying, it is ready for use.

[0030] The material provided by the present invention is configured by the following raw materials in proportion by weight:

[0031] PLA 100

[0032] polystyrene 20

[0033] Compatibilizer 0.5

[0034] First, the polylactic acid and polystyrene in the above-mentioned raw materials were dried in a vacuum drying oven at 90°C for 8 hours, the compatibilizer was dried in a vacuum drying oven at ...

Example Embodiment

[0035] Example 2

[0036] The compatibilizer provided by the invention prepares raw materials by the following weight proportions, and the polymerization method is emulsion polymerization:

[0037] Methyl Styrene 100

[0038] n-Butyl Acrylate 40

[0039] Potassium persulfate 0.7

[0040] Add 250ml of water to a 500ml flask, heat up to 40°C, add monomer and emulsifier in proportion, start stirring, heat up to 75°C, add potassium persulfate aqueous solution, and stop the reaction after 8 hours of reaction. After demulsification, filtration, washing and drying, it is ready for use.

[0041] The material provided by the present invention is configured by the following raw materials in proportion by weight:

[0042] PLA 100

[0043] High impact polystyrene 40

[0044] Compatibilizer 1

[0045] First, the polylactic acid and polystyrene in the above-mentioned raw materials were dried in a vacuum drying oven at 90°C for 8 hours, the compatibilizer was dried in a vacuum drying ...

Example Embodiment

[0046] Example 3

[0047] The compatibilizer provided by the invention prepares raw materials by the following proportions, and the polymerization method is emulsion polymerization:

[0048] Styrene 100

[0049] Methyl Acrylate 40

[0050] Potassium persulfate 0.7

[0051] Add 250ml of water to a 500ml flask, heat up to 40°C, add monomer and emulsifier in proportion, start stirring, heat up to 75°C, add potassium persulfate aqueous solution, and stop the reaction after 8 hours of reaction. After demulsification, filtration, washing and drying, it is ready for use.

[0052] The material provided by the present invention is configured by the following raw materials in proportion by weight:

[0053] PLA 100

[0054] Styrene-butadiene-styrene triblock copolymer 5

[0055] Compatibilizer 0.1

[0056] First, the polylactic acid and styrene-butadiene-styrene triblock copolymer in the above raw materials were dried in a vacuum drying oven at 90°C for 8 hours, and the compatibil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com