Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Slow curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

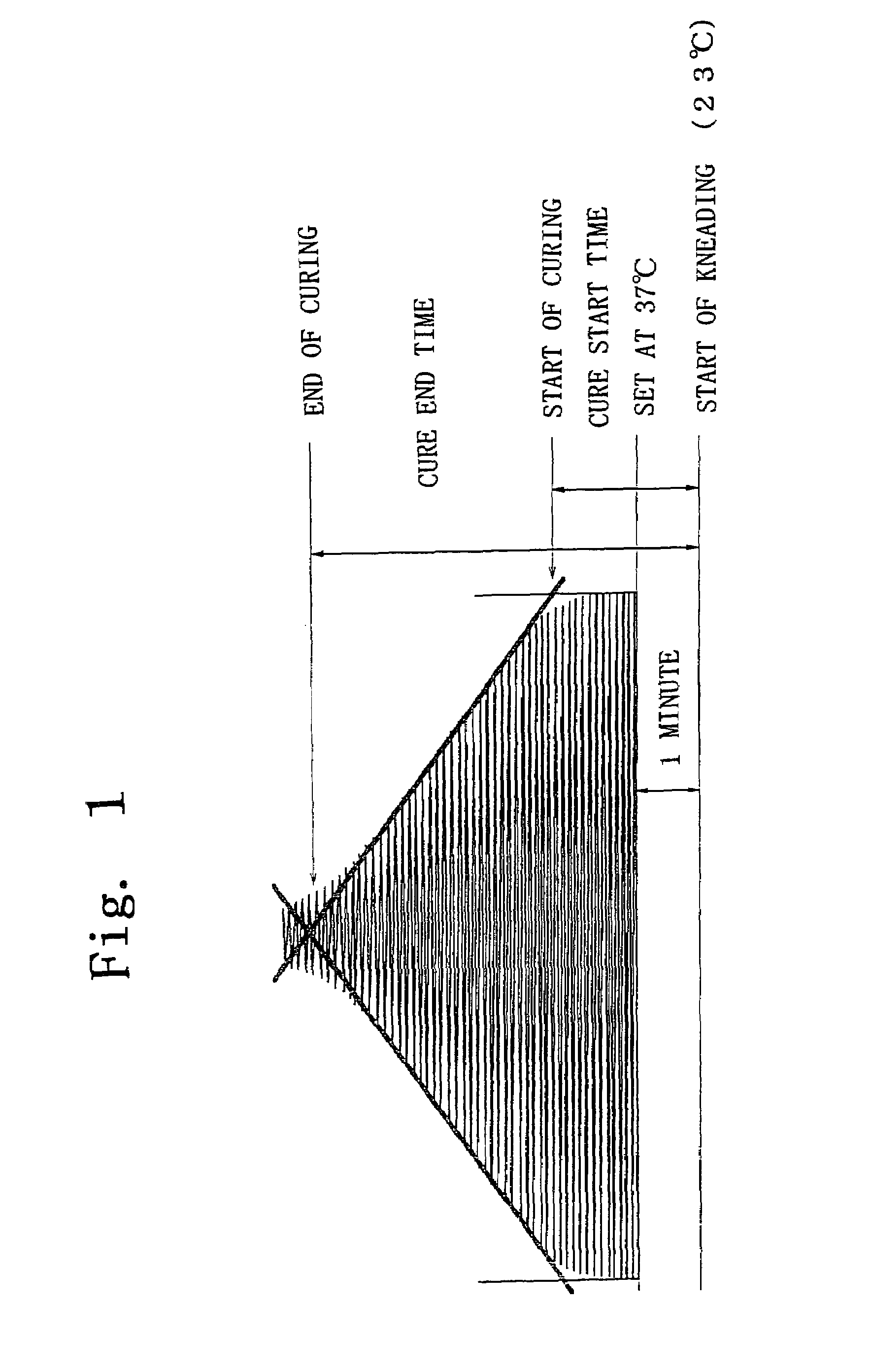

Biodegradable polyurethane/urea compositions

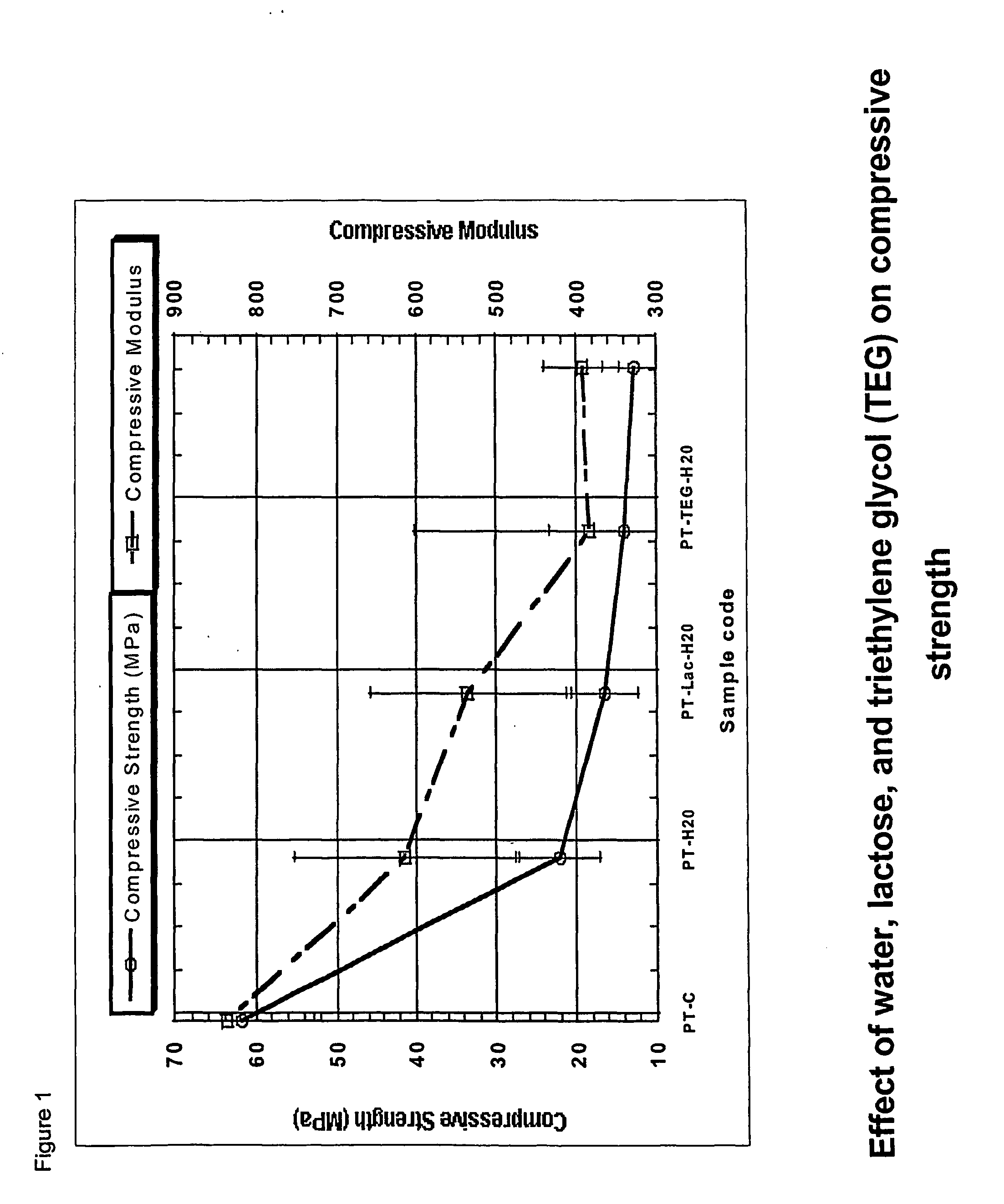

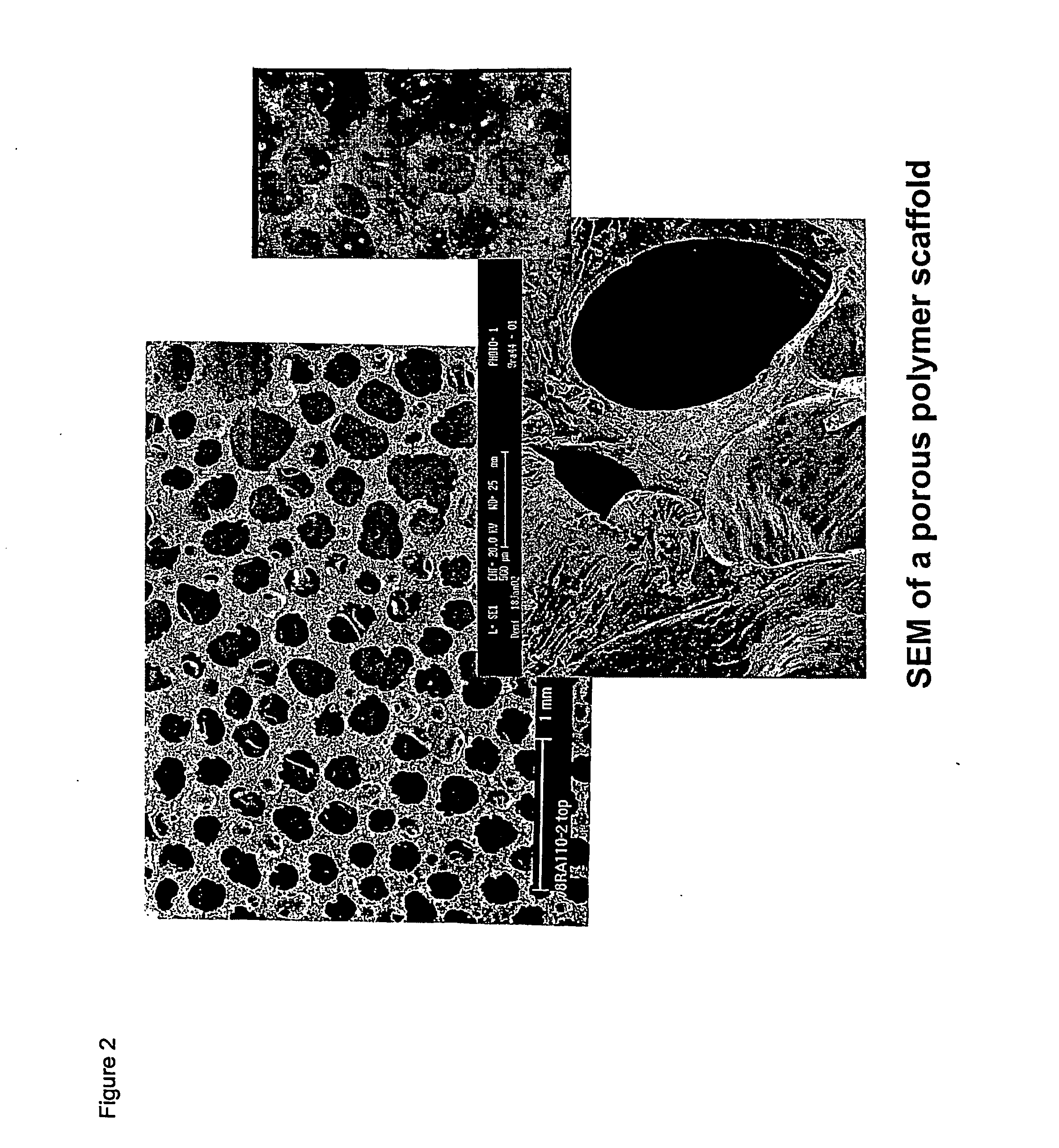

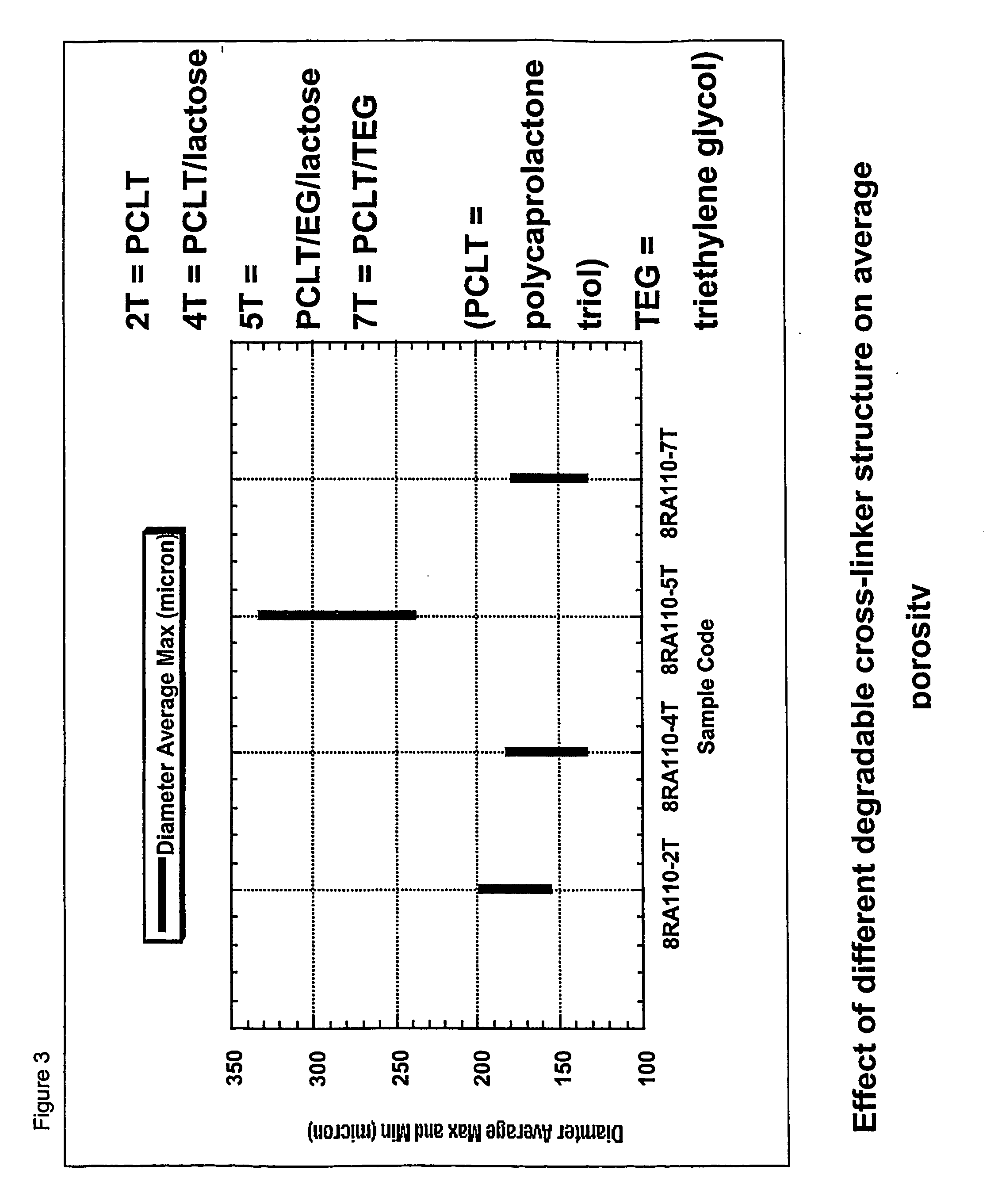

The present invention relates to biocompatible, biodegradable polyurethane / urea polymeric compositions that are capable of in-vivo curing with low heat generation to form materials suitable for use in scaffolds in tissue engineering applications such as bone and cartilage repair. The polymers are desirably flowable and injectable and can support living biological components to aid in the healing process. They may be cured ex-vivo for invasive surgical repair methods, or alternatively utilized for relatively non-invasive surgical repair methods such as by arthroscope. The invention also relates to prepolymers useful in the preparation of the polymeric compositions, and to methods of treatment of damaged tissue using the polymers of the invention.

Owner:POLYNOVO BIOMATERIALS PTY LTD

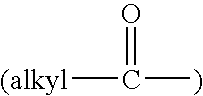

Method of preparing an aliphatic polyurea spray elastomer system

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is less than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention also concerns a a polyurea elastomer, comprising the reaction product of (a) a resin blend containing one or more polyoxyalkyleneamine and an aspartic ester and (b) an isocyanate, wherein the aspartic ester in the resin blend comprises a reaction product of an amine chain extender and a dialkyl maleate, wherein the mole ratio of amine functionality in the amine chain extender to dialkyl maleate or fumarate is greater than 1:1.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

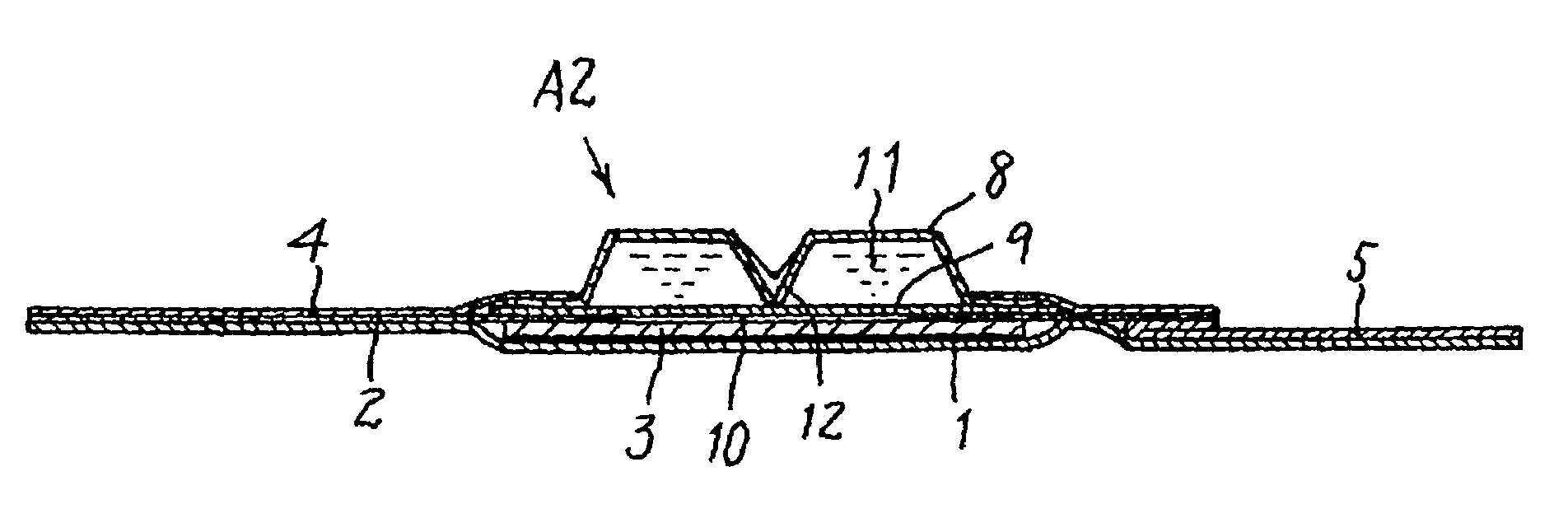

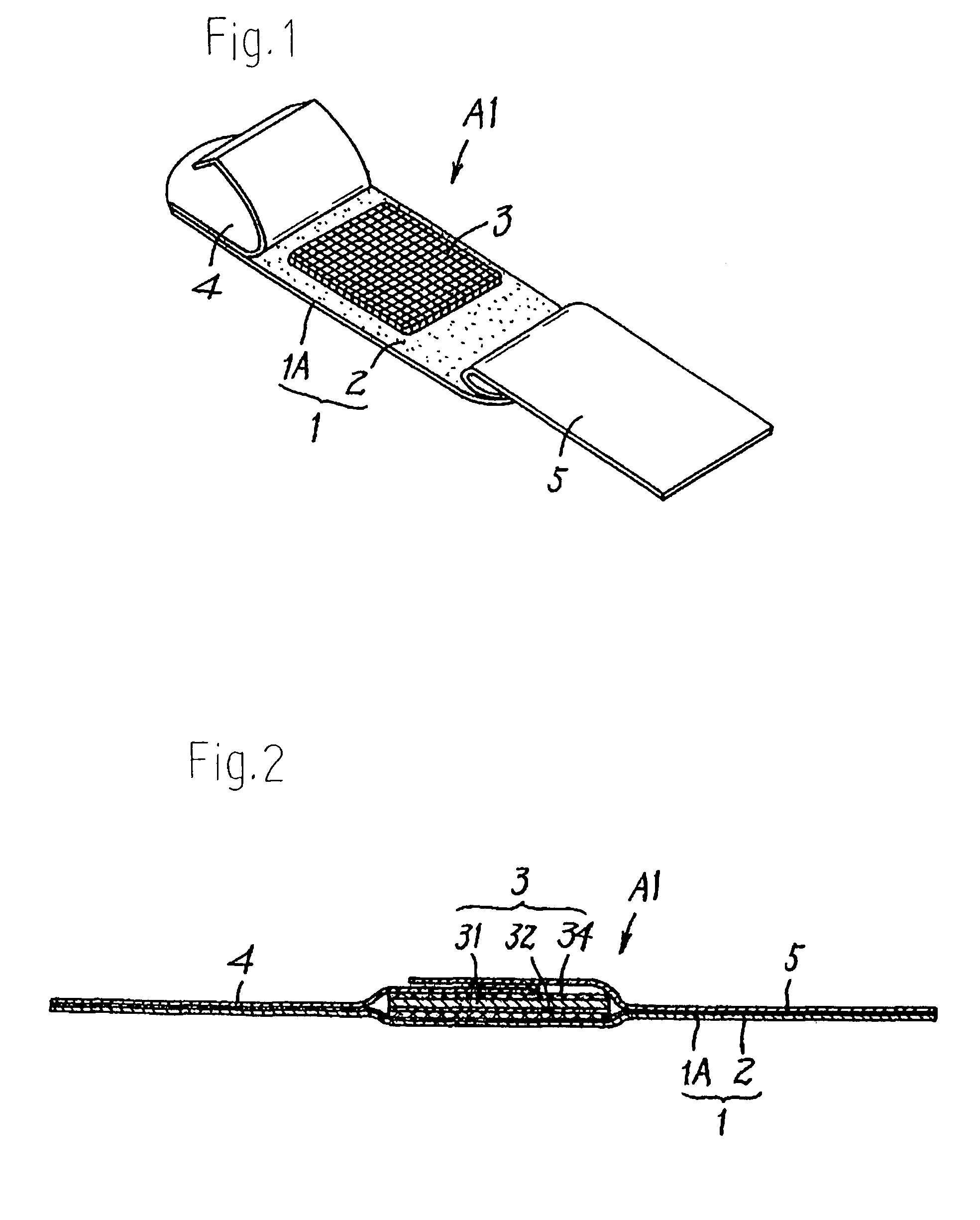

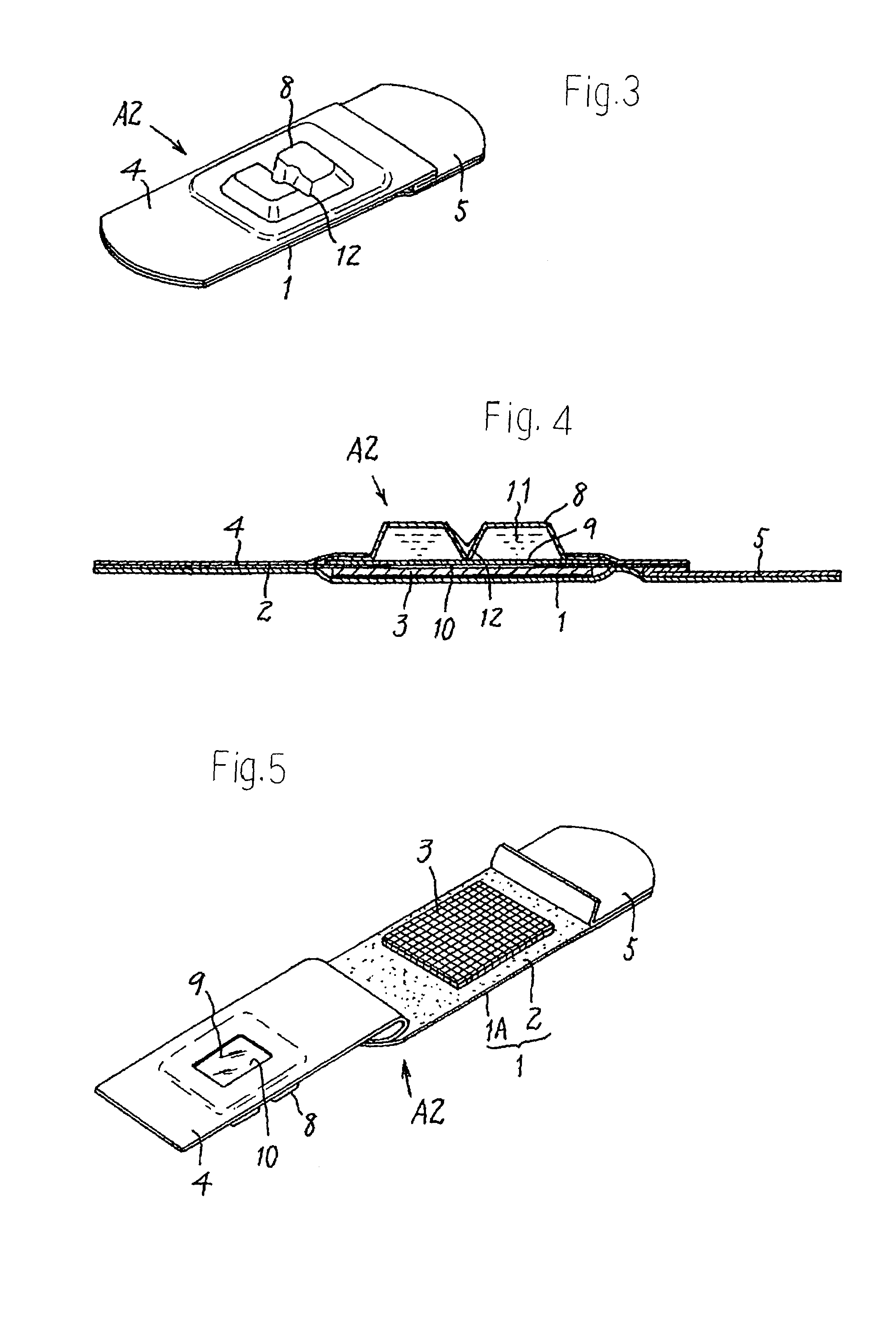

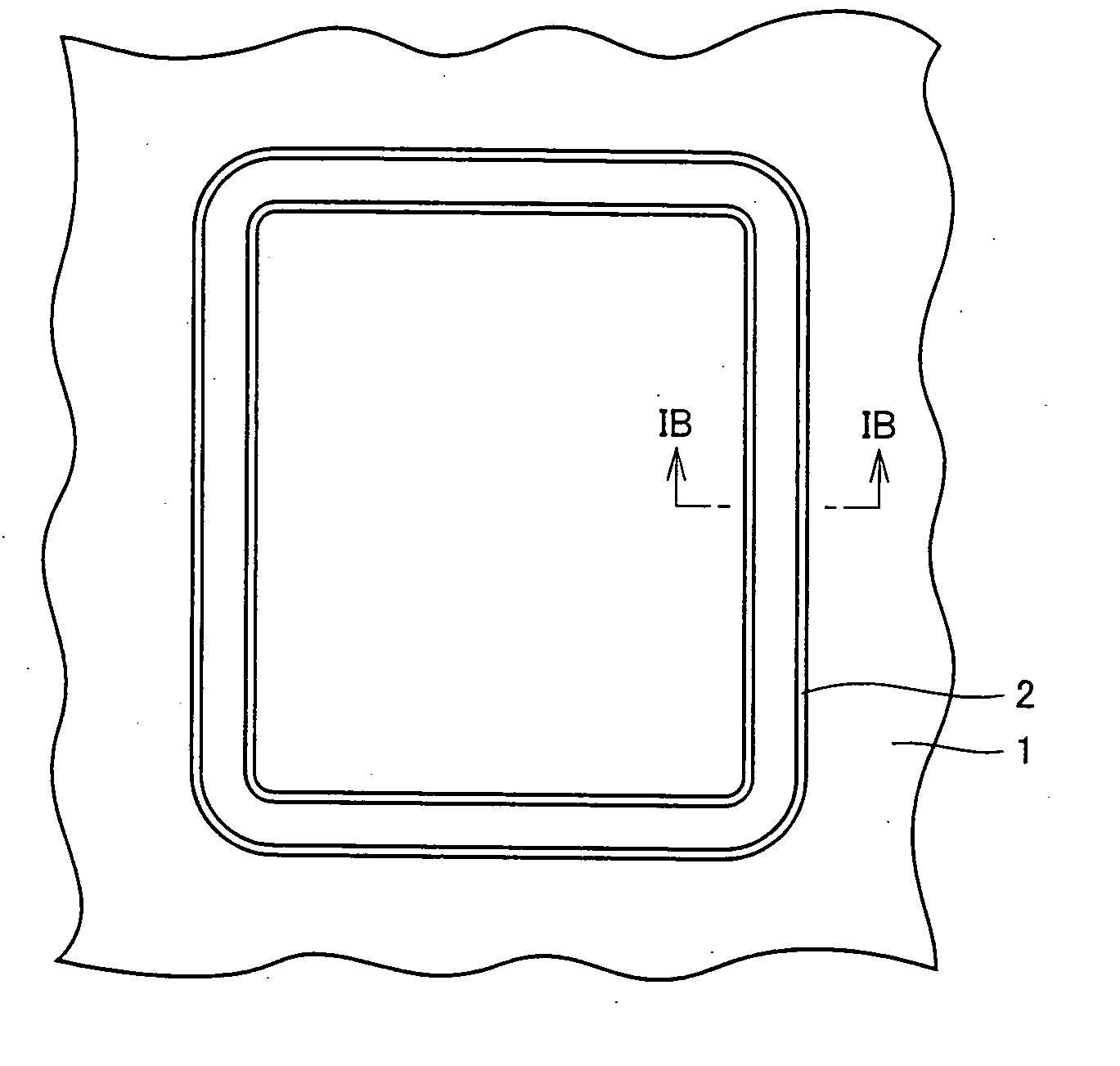

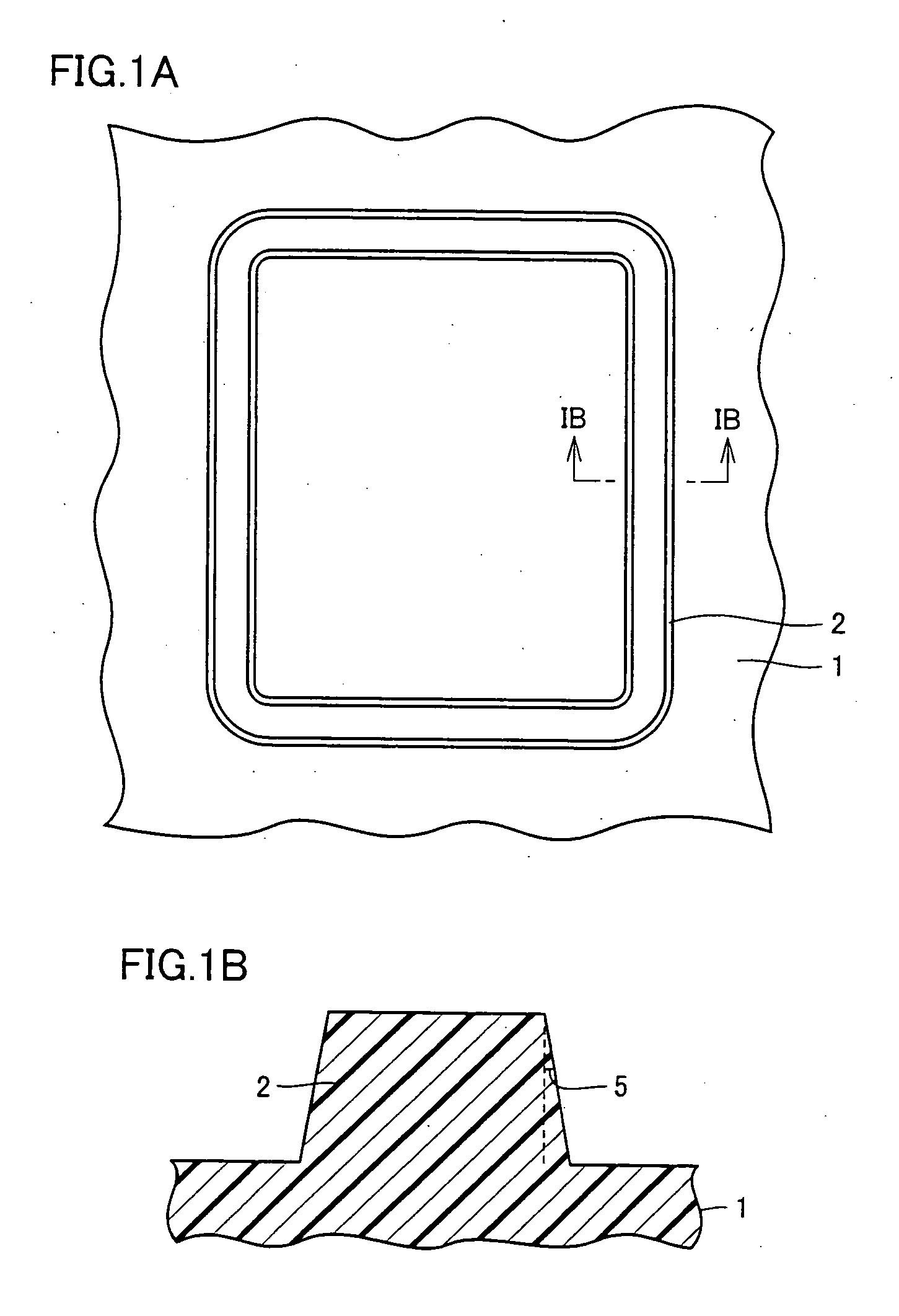

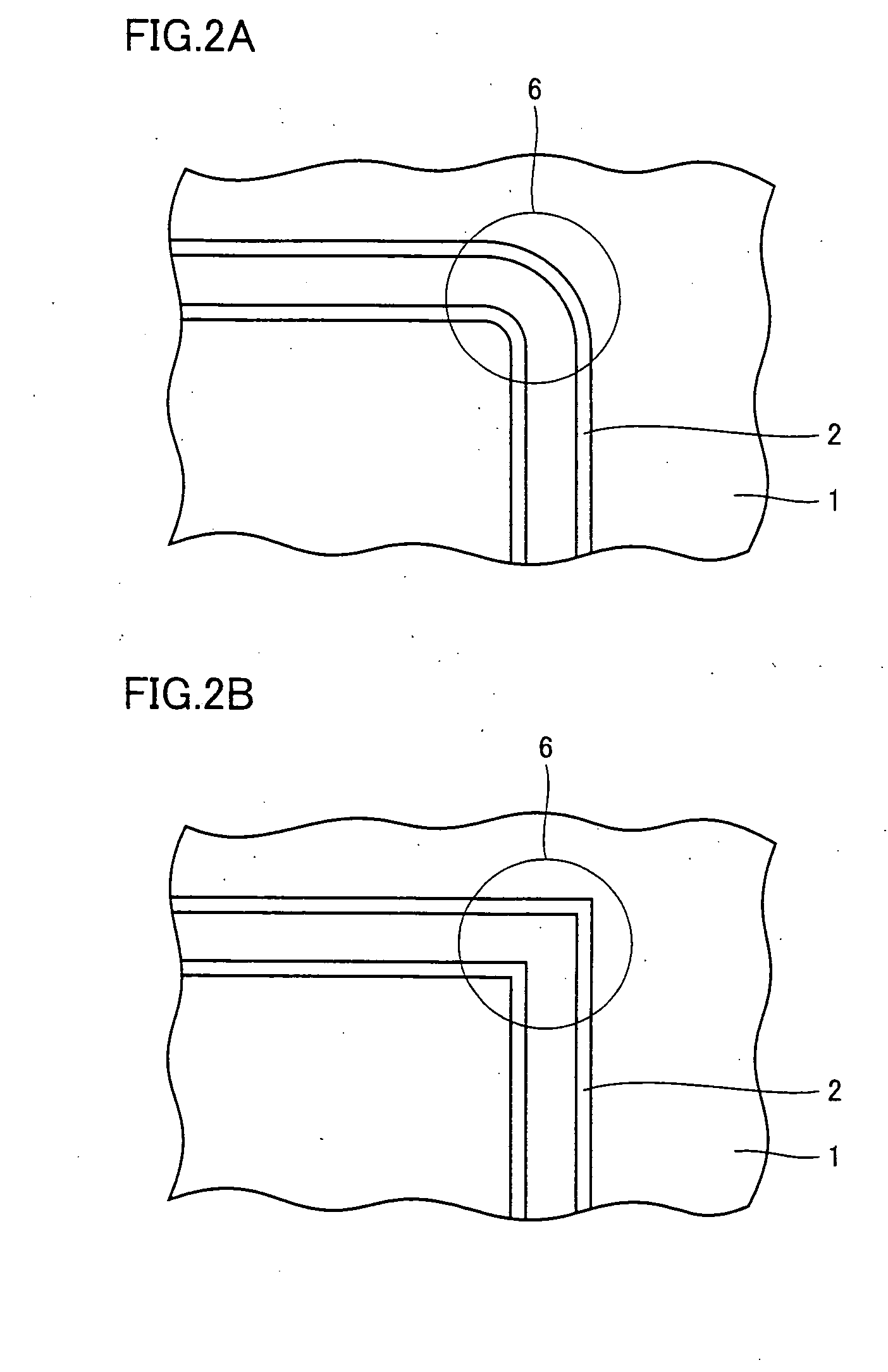

First aid adhesive plaster

ActiveUS7067709B2Accurate placementImprove production efficiencyAdhesive dressingsNon-surgical orthopedic devicesAdhesiveEngineering

A first aid adhesive plaster includes an adhesive sheet, a pad member stuck onto the center of the adhesive sheet, and release papers, which are releasably stuck to the adhesive sheet and cover the pad member. The pad member comprises a pad made of a gauze, an unwoven fabric, a woven fabric or the like, and a ultraviolet blocking film disposed inside the pad or on the lower surface thereof. The pad member may be wrapped with a net.

Owner:ASO PHARMA CO LTD

Method of preparing spray elastomer systems

InactiveUS6399736B1Improved physical propertyExcellent impact resistancePolyurea/polyurethane coatingsDiaminePolyurea

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is greater than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention concerns a method for the preparation of polyurethane elastomers, comprising: (a) reacting an diamine chain extender with dialkyl maleate or fumarate, wherein the mole ratio of primary amine functionality in the diamine chain extender to dialkyl maleate or fumarate is more than 1:1; (b) coating a substrate with effective film forming amounts of the product of step (a), an isocyanate, and a polyhydroxyl compound under conditions effective to form a the polyurethane elastomer.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Antimicrobial radiation curable coating

InactiveUS7098256B2The environment is moreOptimal for incorporationBiocideAntifouling/underwater paintsCross-linkCarbamate

Owner:MICROBAN PROD CO INC

Antimicrobial radiation curable coating

InactiveUS20050080158A1Activity depletedInferior antimicrobial efficacyBiocideAntifouling/underwater paintsCross-linkOligomer

The invention is a radiation curable coating containing an antimicrobial agent, where upon irradiation with UV light, the radiation curable coating rapidly cures to a polymeric coating. The polymeric coating has durable antimicrobial properties, being especially effective at preventing the growth of Staphylococcus aureaus and Kleibsella pneunoniae on wood flooring and furniture. The major components in the radiation curable coating are a urethane acrylic oligomer, a radiation cure package, an antimicrobial agent, a cross-linking agent, and optionally, an additive package. The radiation curable urethane oligomer is a relatively short chain backbone urethane polymer that is end capped with a radiation curable moiety, where the moiety is an acrylic. The cross-linking agent is one or more monomers used to lower the viscosity and promote cross-linking, and include acrylate esters of mono-, di-, tri-, or tetrafunctional alcohols. The radiation cure package contains at least one photoinitiator.

Owner:MICROBAN PROD CO INC

Method of making lightweight structures

InactiveUS20100051183A1Eliminate pollutionSlow curingLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:BENTELER SGL

Method of preparing spray elastomer systems

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is greater than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention concerns a method for the preparation of polyurethane elastomers, comprising: (a) reacting an diamine chain extender with dialkyl maleate or fumarate, wherein the mole ratio of primary amine functionality in the diamine chain extender to dialkyl maleate or fumarate is more than 1:1; (b) coating a substrate with effective film forming amounts of the product of step (a), an isocyanate, and a polyhydroxyl compound under conditions effective to form a the polyurethane elastomer.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

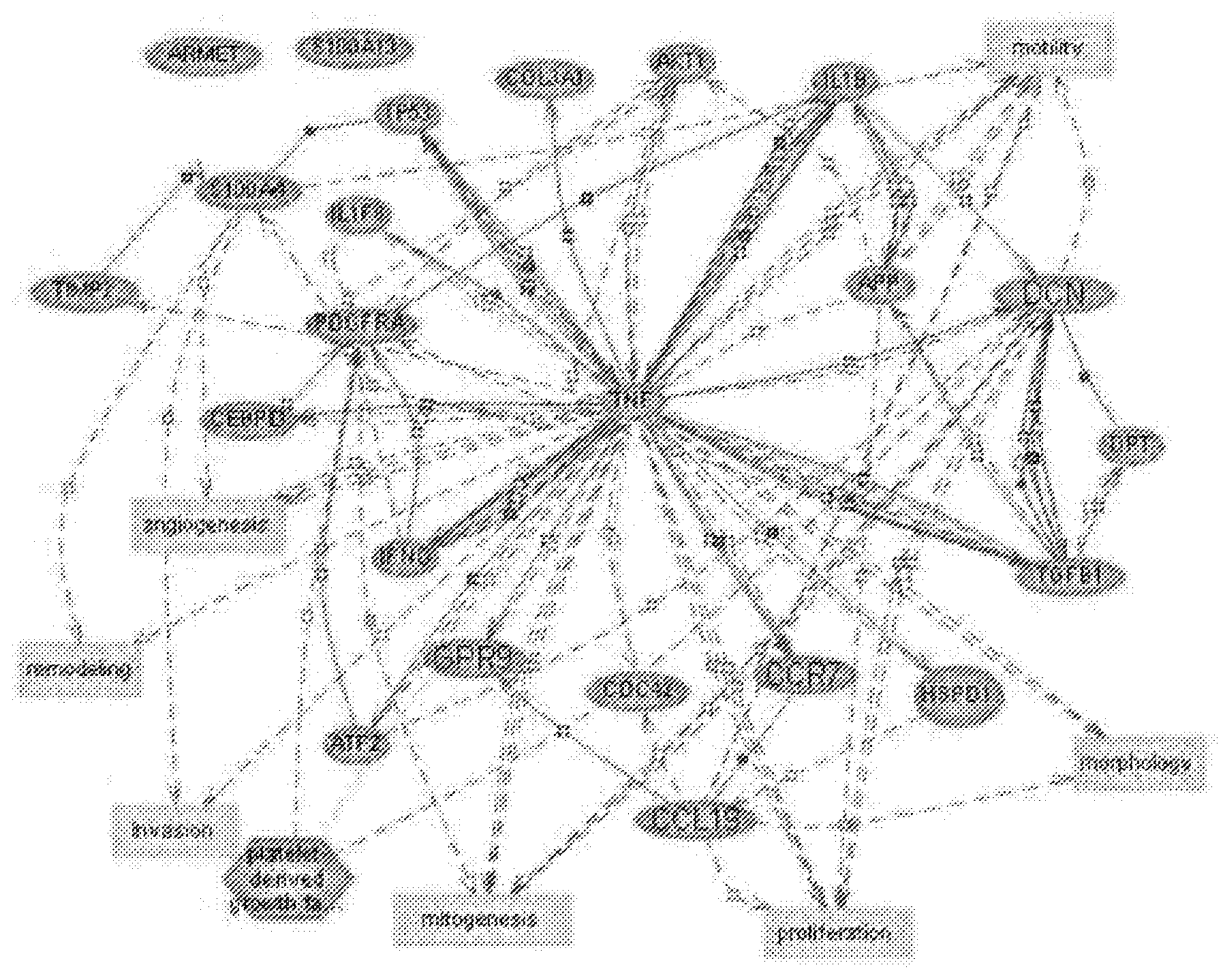

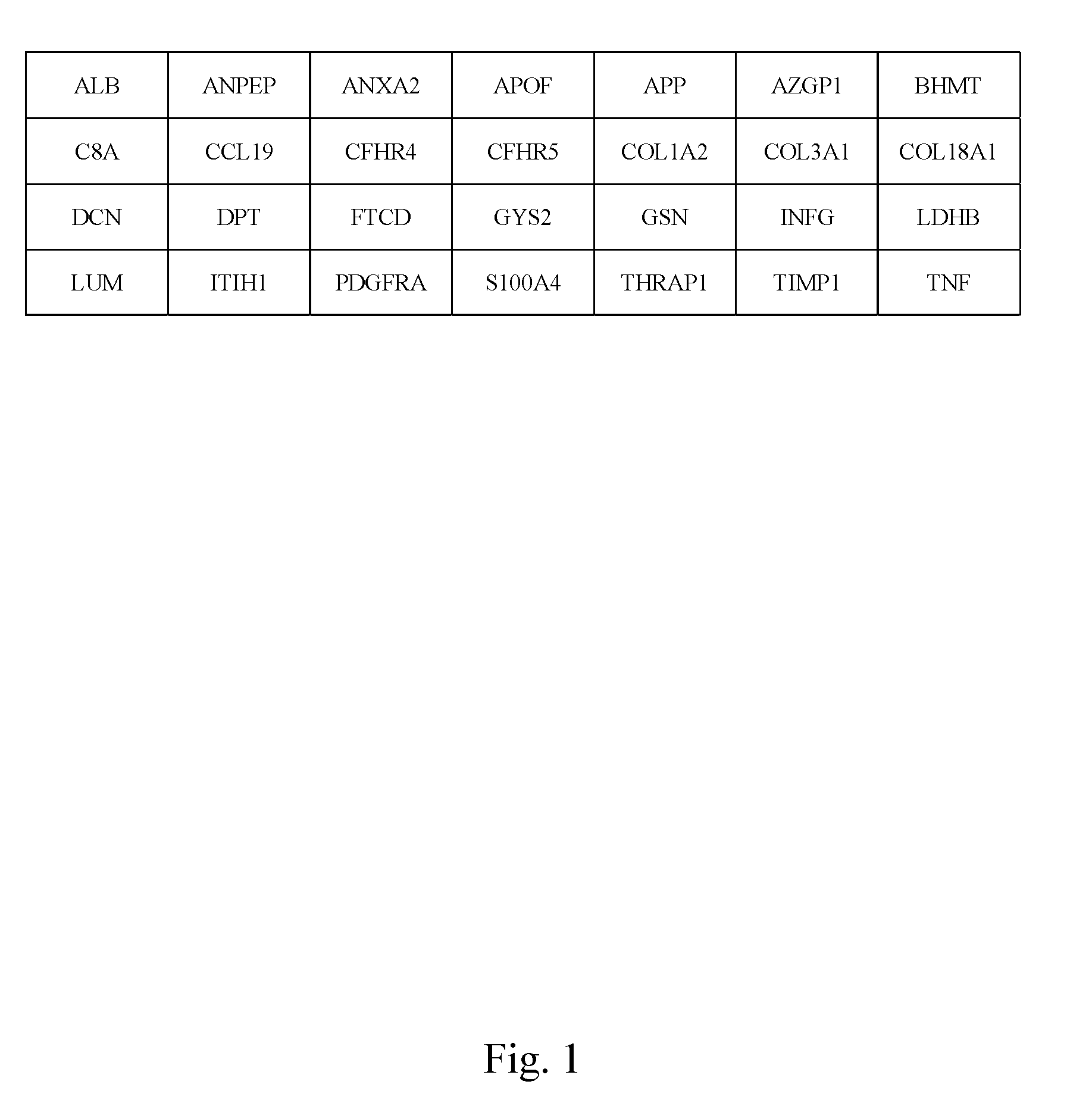

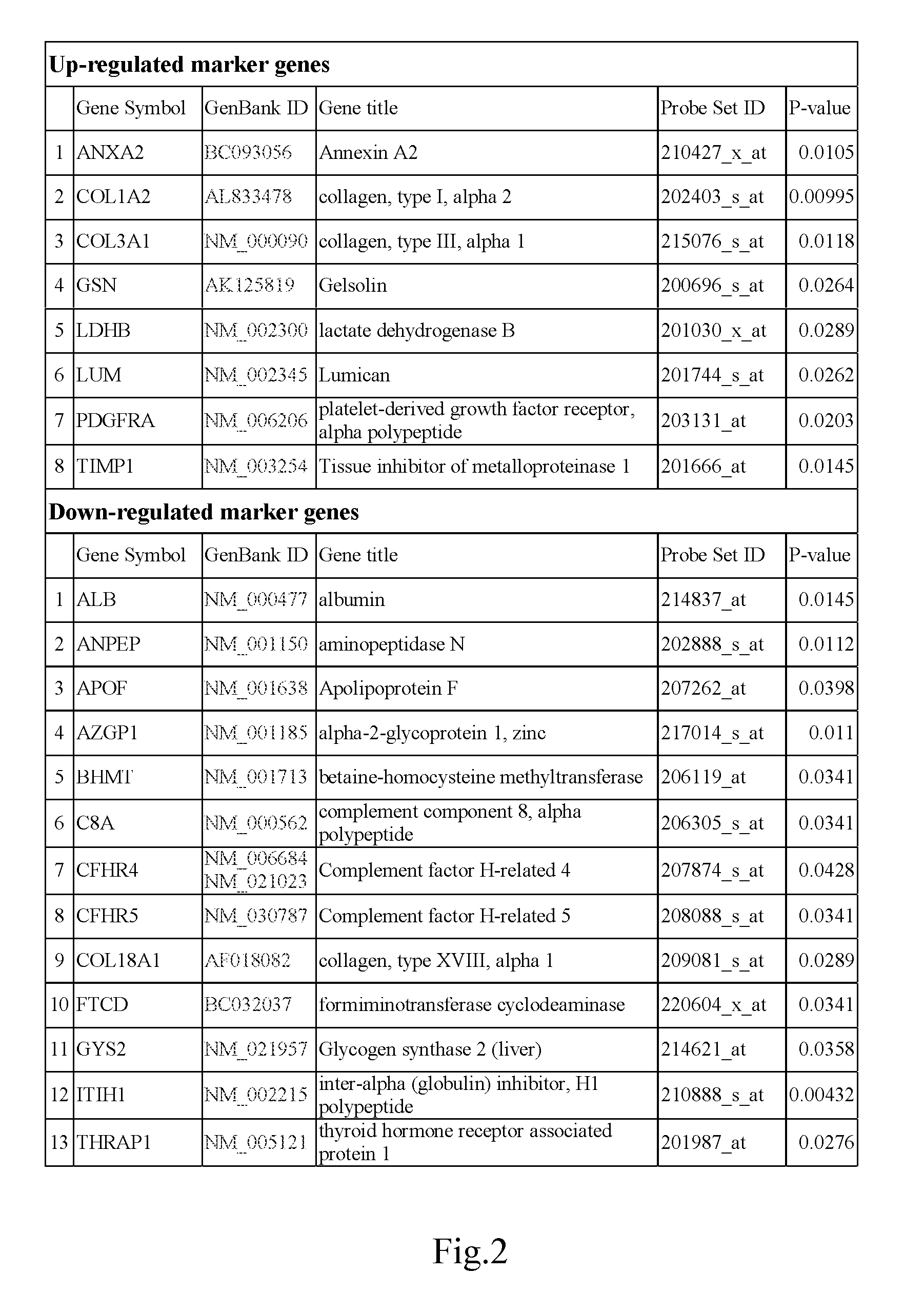

Markers identified for liver fibrosis and cirrhosis and the microarray panel thereof

InactiveUS20080161203A1Cure and slow down liver fibrosis progressionSlow curingPeptide librariesHydrolasesCFHR5Biology

In the present invention, the markers identified for liver fibrosis and cirrhosis and the microarray panel thereof comprise at least one of the following proteins / genes:8 up-regulated genes such asANXA2; COL1A2; COL3A1; GSN; LDHB; LUM; PDGFRA and TIMP1.13 down-regulated genes such asALB; ANPEP; APOF; AZGP1; BHMT C8A; CFHR4; CFHR5; COL18A1; FTCD; GYS2; ITIH1, and THRAP1.9 therapeutic targets such as PDGFRA; S100A4; COL3A1; CCL19; DCN; DPT; APP; TNF; and INFG.The present invention is capable of screening markers for the early warning of the occurrence for severe fibrosis or cirrhosis and potentially targets for drug design.

Owner:VITA GENOMICS

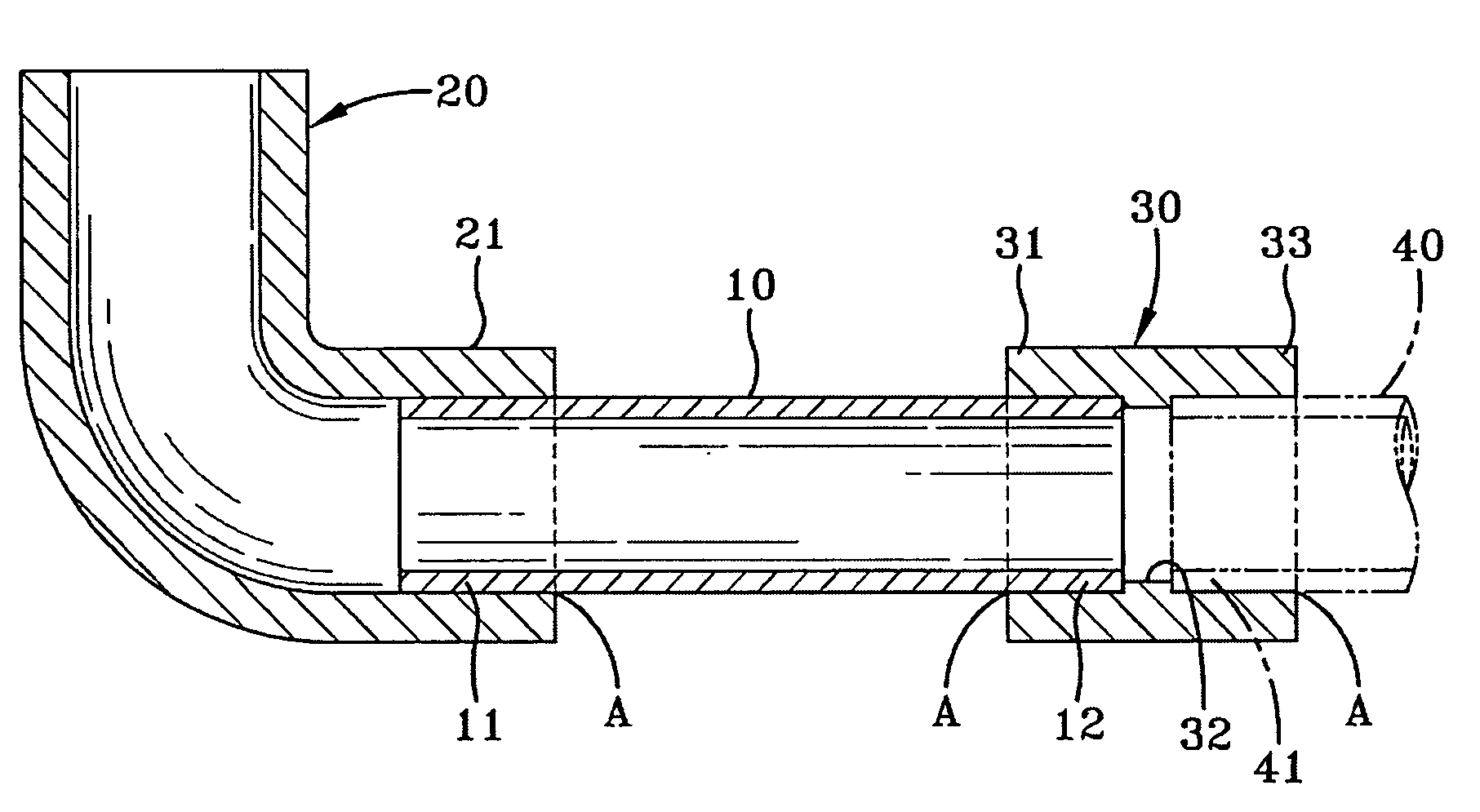

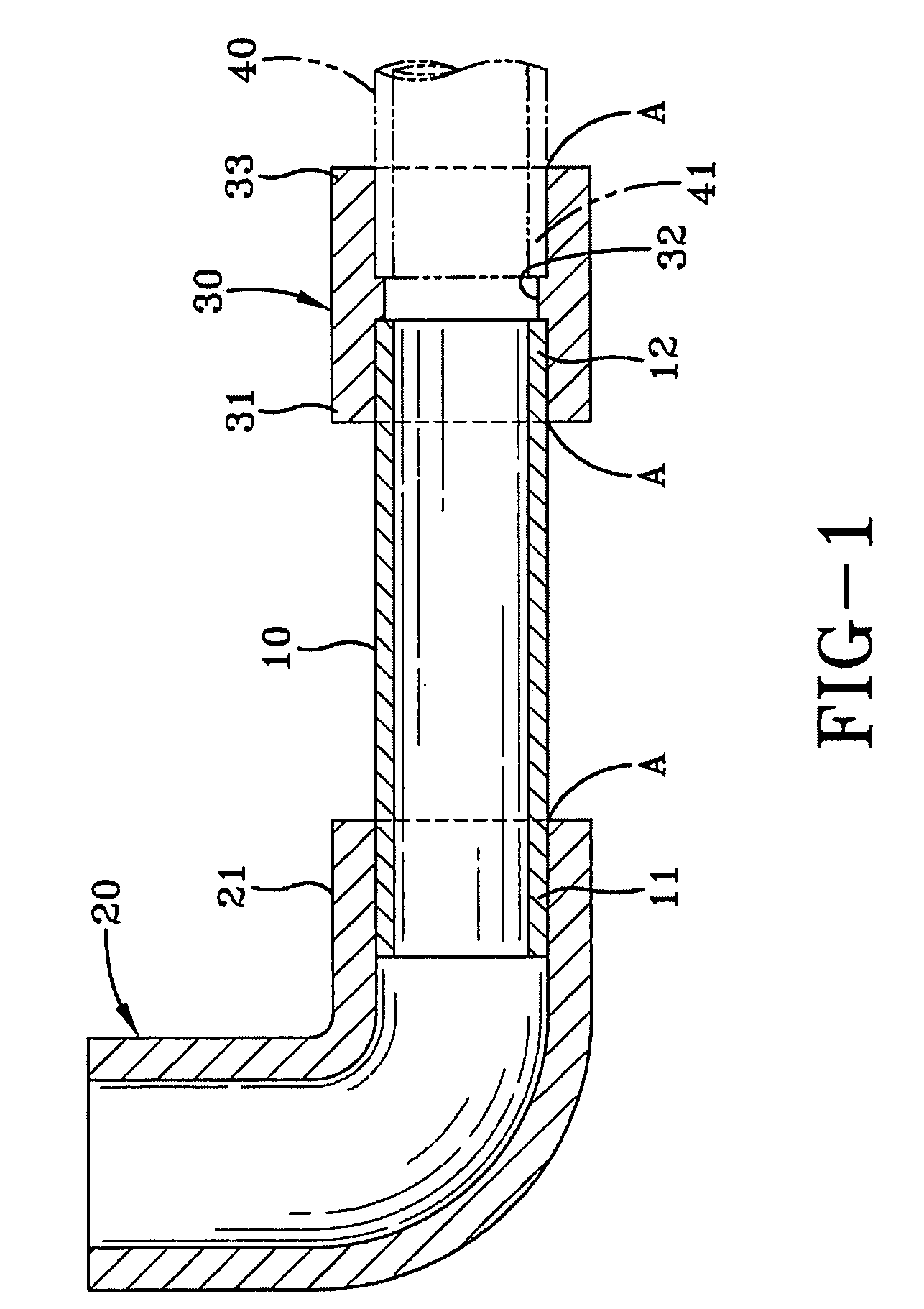

Adhesively Secured, Fluid-Tight Pipe Joint Of PVC/CPVC Pipe And Fitting

PVC and / or CPVC tubing and / or pipe is adhesively-secured at one end with a pipe fitting telescopably mated with each other with a uniquely effective epoxy adhesive. The resulting pipe joint is fluid-tight. PVC pipe joints meet the requirements of ASTM F1970; CPVC pipe joints meet the requirements of ASTM D2864. Such PVC and CPVC piping systems are chosen to carry cold and hot aqueous streams respectively, under pressure and elevated temperature in continuous service, both, in industrial and domestic piping systems. Such piping systems also carry more corrosive fluids for specified duration, less than 50 years.

Owner:LUBRIZOL ADVANCED MATERIALS INC

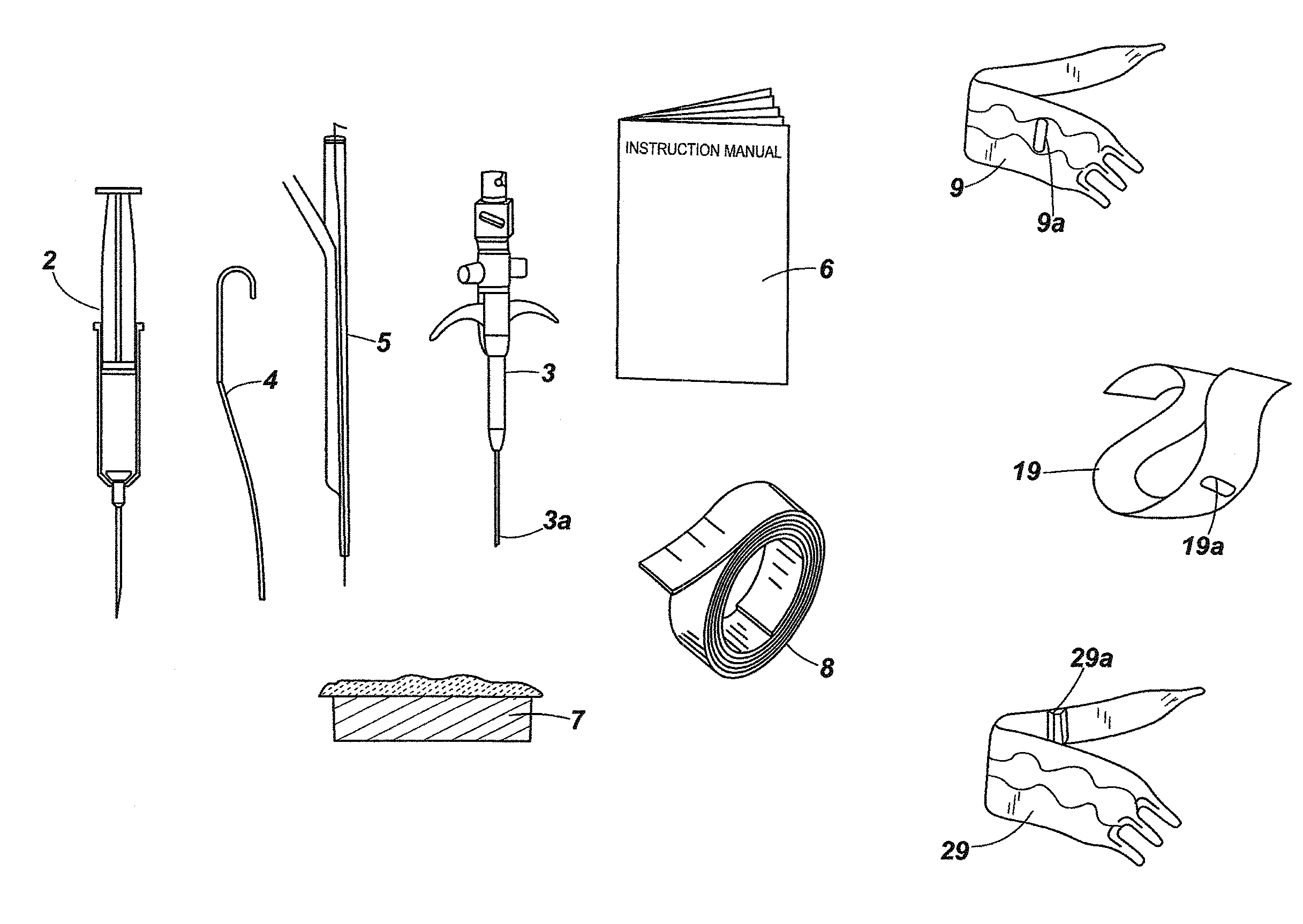

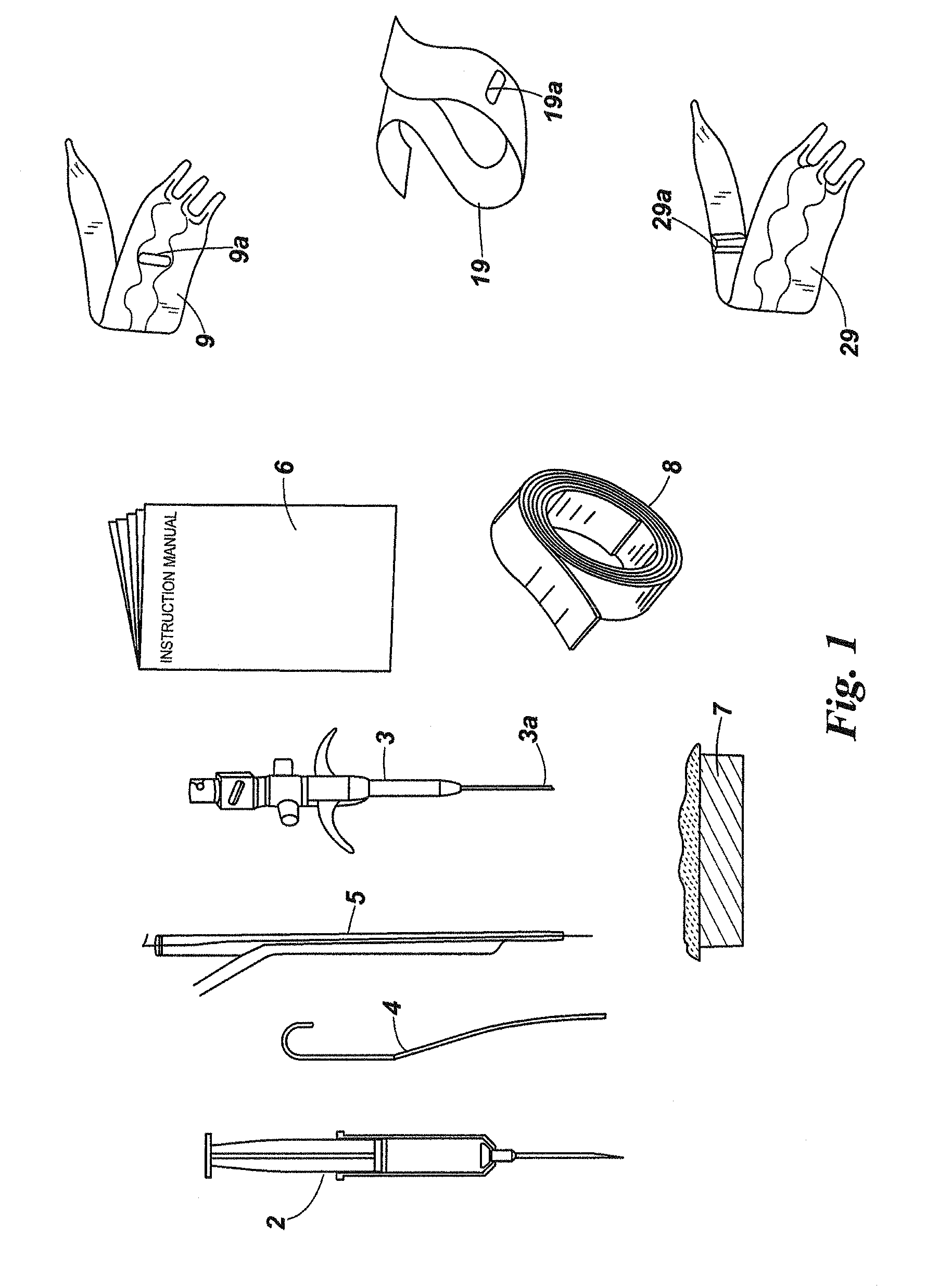

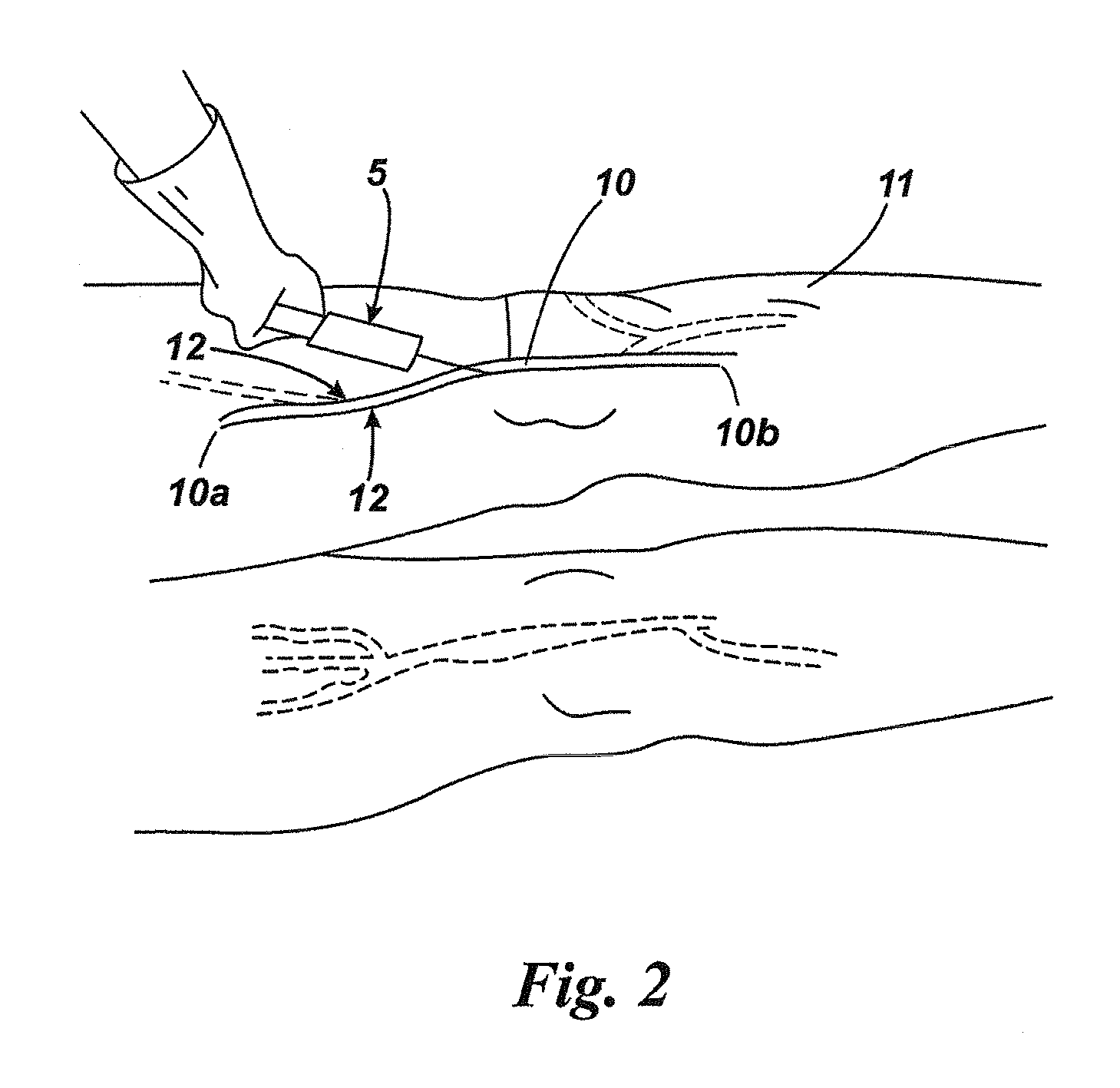

Varicose vein treatment

ActiveUS20110060277A1Fast recovery timePromote resultsSurgical furnitureDiagnosticsAdhesiveGuide wires

Methods for treating an undesired varicose or spider vein in a venous system of a patient generally includes substantially emptying the vein of blood between its proximal end and distal end; introducing a medically acceptable adhesive into the substantially emptied vein; and applying pressure to the vein to cause the opposing side walls of the vein to be adhered together in a collapsed configuration by the adhesive. Also disclosed are kits for the treatment of undesired varicose or spider vein in a venous system of a patient. The kits include a medically acceptable adhesive; a cannula; a guide wire; and a catheter.

Owner:JEAN PIERRE LILLEY

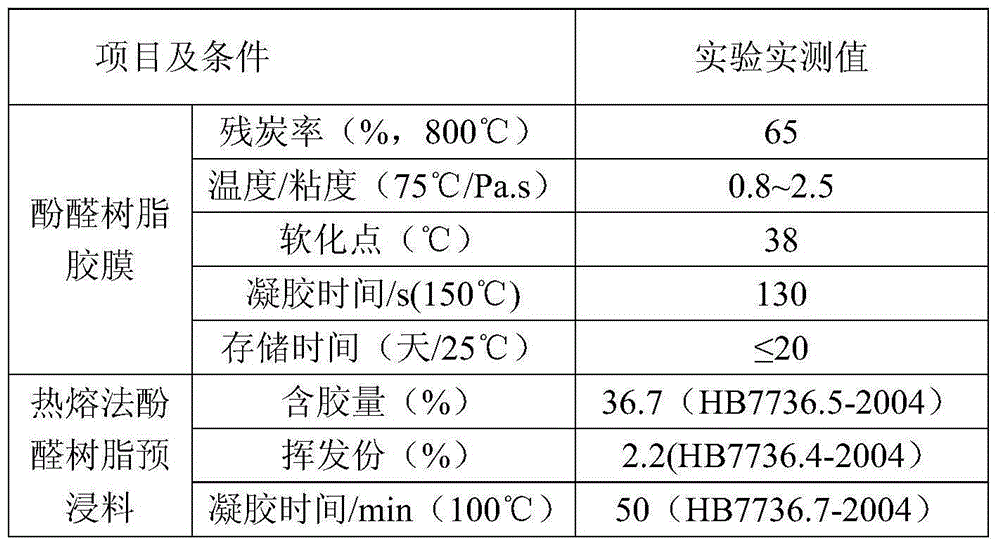

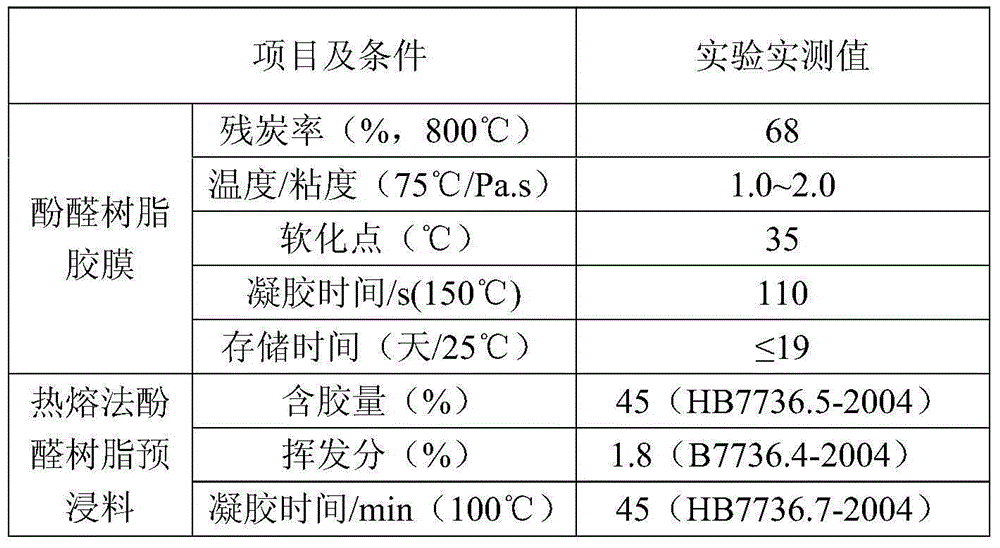

Hot-melting phenolic resin prepreg and preparation method thereof

The invention discloses a hot-melting phenolic resin prepreg and a preparation method thereof. The hot-melting phenolic resin prepreg comprises a fiber-reinforced material and the following materials by mass: 50 to 100 parts of thermoset phenolic resin, 1 to 10 parts of a film forming agent, and 1 to 10 parts of a boron-containing additive, wherein the mass ratio of the fiber-reinforced material to the thermoset phenolic resin is (1-3):1. The hot-melting phenolic resin prepreg is slow in curing rate, and relatively high in heat resistance; the preparation method is simple.

Owner:XI AN JIAOTONG UNIV

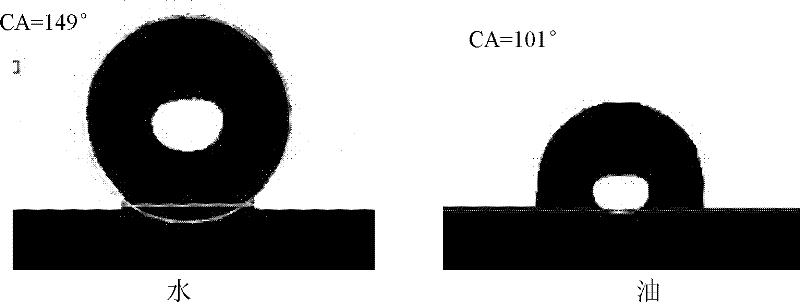

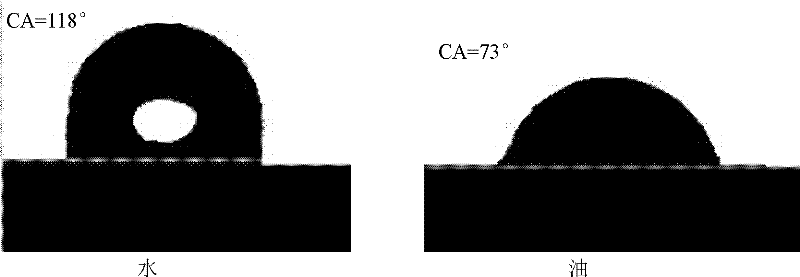

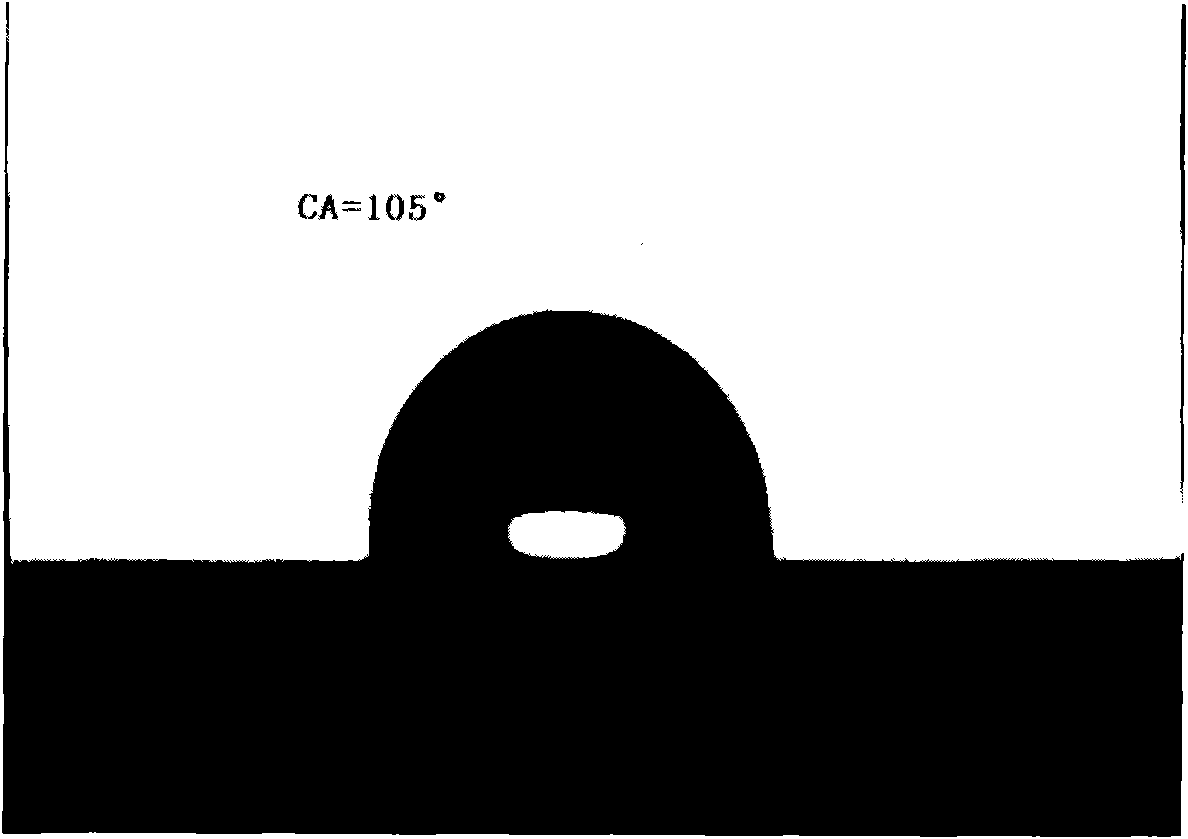

Hydrophobic olephobic epoxy paint and its preparation and application method

InactiveCN102229777ALow costFix compatibility issuesPretreated surfacesEpoxy resin coatingsEpoxyMass ratio

The invention provides a hydrophobic olephobic epoxy paint and its preparation and application method. The paint is prepared by mixing the following raw materials according to the mass ratio of epoxy paint for color coding: fluorine-silicon copolymer: a mixed solvent: nanometer silica: a curing agent = 1.0 : 0.005-0.12 : 0.5-3.0 : 0-0.30 : 0.01-0.25. An epoxy coating formed by the paint has a microscopic rough structure, overcomes the disadvantage of poor compatibility of an epoxy paint modified by a fluorine-silicon material, and has a water contact angle of 149 degrees and an oil contact angle of 101 degrees, being an epoxy coating with strong hydrophobicity and olephobicity.

Owner:HEBEI UNIV OF TECH

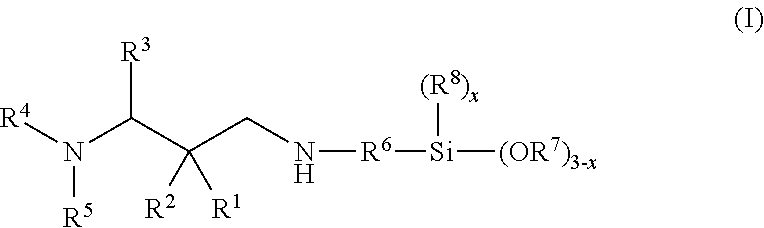

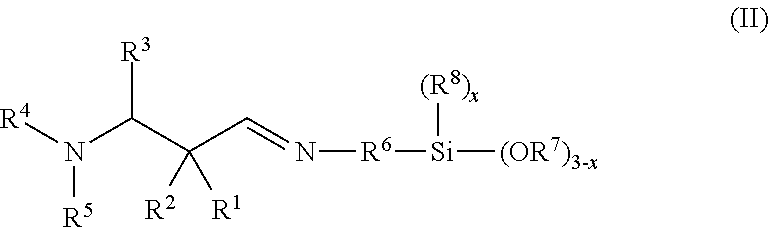

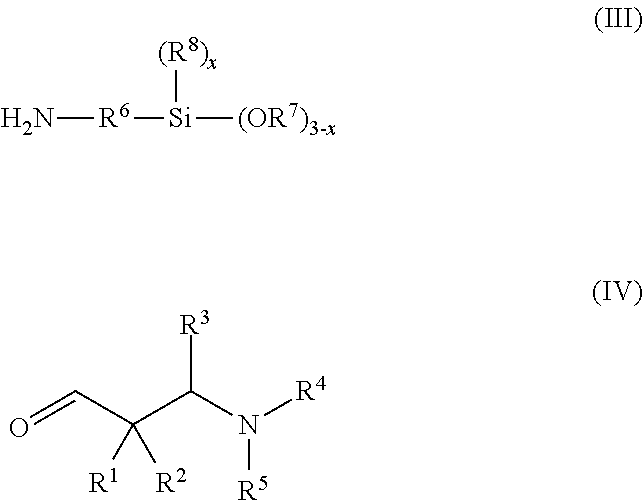

Secondary aminosilanes

InactiveUS20130281562A1Difference in surface tackinessSlow curingSilicon organic compoundsPolyureas/polyurethane adhesivesThermal stabilityViscosity

The present disclosure invention relates to novel secondary aminosilanes, a method for producing same, and the use thereof. The secondary aminosilanes can be produced from readily available reactants in a simple manner. The secondary aminosilanes are characterized for example by a low viscosity and are well suited for producing silane-functional polymers that have a low viscosity, fast curing, and good thermal stability.

Owner:SIKA TECH AG

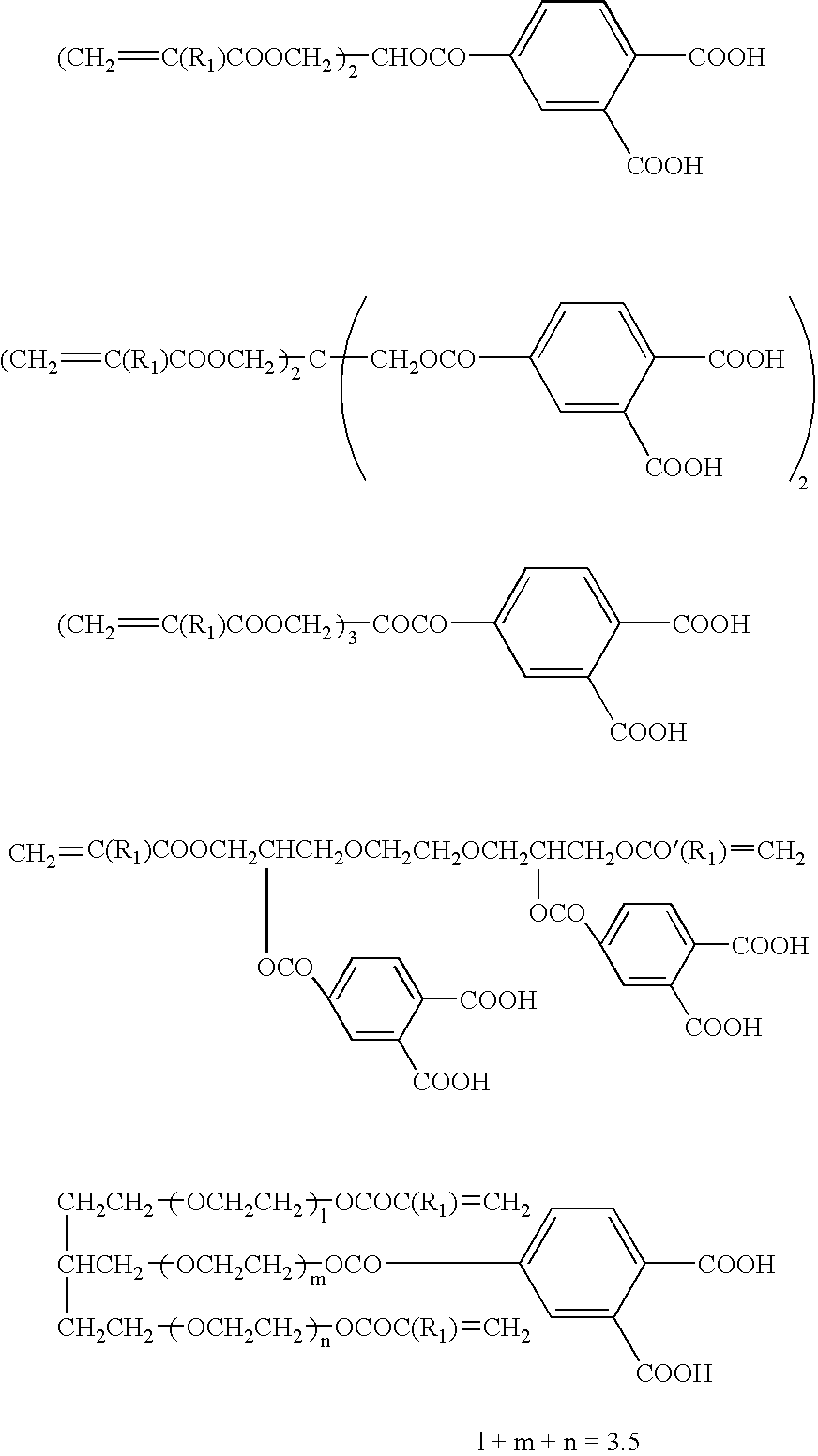

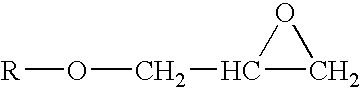

Ormocers, method for their production, and their use

InactiveUS20010056197A1Improve polishing effectIncrease chanceGroup 4/14 element organic compoundsGroup 1/11 element organic compoundsVinyl etherHydrogen

Ormocers, which can be obtained by the hydrolytic condensation of one or more silicon compounds, and the subsequent polymerization of organic monomers, wherein at least one silicon compound comprises vinyl ether radicals of formula (I): wherein R represents hydrogen, methyl, or ethyl. The new ormocers are used in dental materials.

Owner:DEGUDENT

Novel copolymerized white latex

InactiveCN101130586AImprove stabilityImprove performanceMonocarboxylic acid ester polymer adhesivesSodium bicarbonateOrganic film

The invention discloses a new typed white copolymerization emulsion in the binding technical domain, which comprises the following steps: dispensing raw materials with polyvinyl alcohol, deionized water, sodium bicarbonate, vinyl acetate, butyl acrylate, tertiary carbonate vinyl ester, dispersant, defoamer, ammonium persulphate, plasticizer and pH value adjuster; doing the polymerizing reaction in the glass lining autoclave; putting the polyvinyl alcohol and deionized water in the autoclave; heating to dissolve the materials; cooling to adding the dispersant and defoamer; adding the reacting monomer to polymerize under normal pressure at 72-80 deg. c in the stirring condition; adding fitful quantity of pH adjuster to control the pH value between 6. 0 and 7. 0; adding plasticizer DBP; forming the product with good binding property and transparent organic film, safety and environment protection to save resource.

Owner:林玉珠

Synergistic amine chain-extenders in polyurea spray elastomers

Disclosed are derivatives of isophorone diamine exhibiting a synergistic relationship with other commonly employed chain extenders offering enhanced efficacy with regard to slowing of the polyurea elastomer cure profile, and processes employing their use. According to the invention, extensions of the gel-free and tack-free times are more readily achieved at lower loading levels for these chain extender blends than are afforded through the sole use of the individual molecules.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

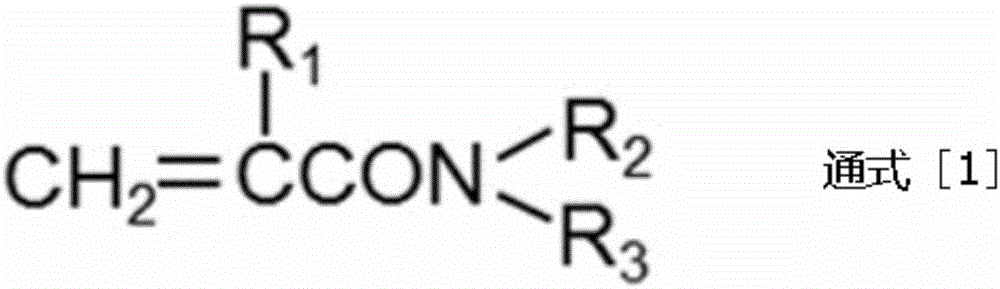

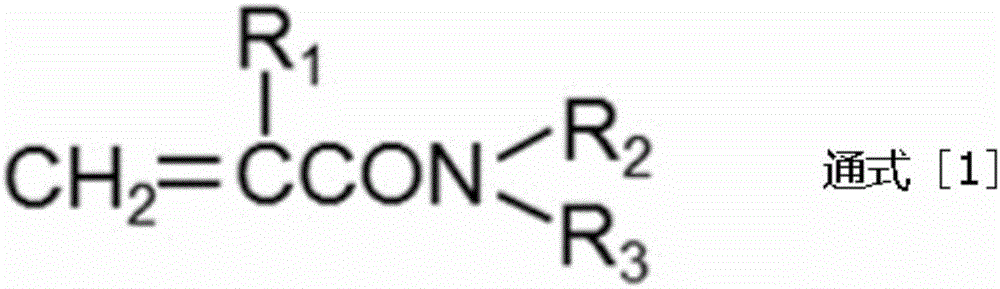

Urethane oligomer and active energy ray curable resin composition containing same

ActiveCN106029727AGood compatibilityExcellent chemical resistancePolyureas/polyurethane adhesivesInksChemistryOligomer

The purpose of the present invention is to provide a (meth)acrylamide-based urethane oligomer which has excellent compatibility with organic solvents and general purpose acrylic monomers and oligomers and a high curing speed when irradiated with active energy rays; and to provide an active energy ray curable resin composition, and a formed product thereof, which contains said urethane oligomers, has excellent adhesion, moisture resistance and surface curability and has low curing shrinkage. By using a (meth)acrylamide-based urethane oligomer having a carbonate skeleton, a diene skeleton or a hydrogenated diene skeleton in the molecule and containing 5 wt% or less of a component having one or more (meth)acrylamide groups and a molecular weight of less than 1000 (excluding (meth)acrylamide compounds (A) having a hydroxyl group), it is possible to obtain an oligomer which has excellent compatibility with organic solvents and general purpose acrylic monomers and oligomers and high curability, and to obtain an active energy ray curable resin composition which contains said oligomer and has excellent adhesion, tack resistance, moisture resistance and shrinkage resistance.

Owner:科捷化成品公司

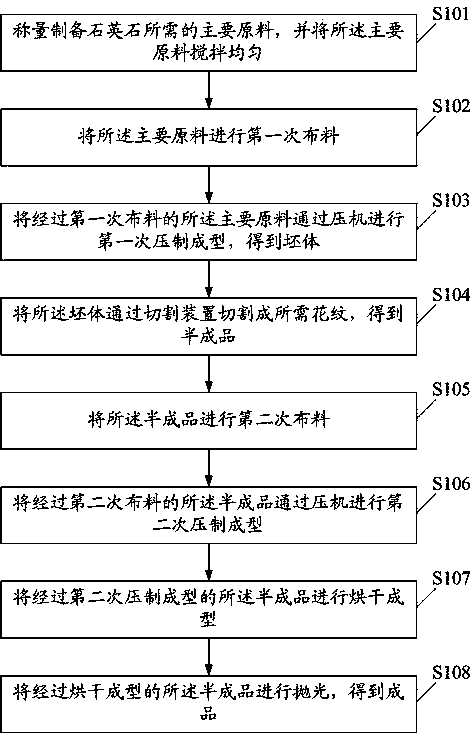

Quartz stone and preparation method thereof

The invention discloses a preparation method of quartz stone. The method comprises the following steps of: A, weighing and uniformly stirring main raw materials required for preparing the quartz stone; B, primarily distributing the main raw materials; C, performing first compression moulding on the primarily distributed main raw materials through a press to obtain a blank; D, cutting the blank to required figures through a cutting device to obtain a semi-product; E, secondarily distributing the semi-product; F, performing second compression moulding on the secondarily distributed semi-product through the press; G, drying and moulding the secondarily pressed semi-product; and H, polishing the dried and moulded semi-product to obtain a finished product. Correspondingly, the invention further discloses the quartz stone prepared by the preparation method. Due to the adoption of the preparation method disclosed by the invention, under the premise of no dies, figures of various types, especially linear figure patterns can be formed on the surface of the quartz stone, so that the competitiveness of the product is improved.

Owner:FOSHAN BLUE SEA QUARTZ STONE

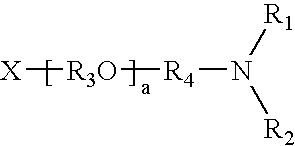

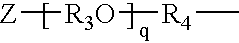

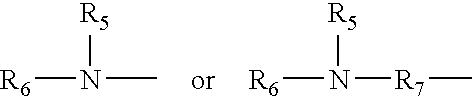

Binding agents having barrier properties

InactiveUS20060162860A1High cure rateFurther processing of bondedLamination ancillary operationsPolyureas/polyurethane adhesivesAdhesiveOrganic compound

Binding agents having barrier properties are provided which contain: a) a compound having at least one NCO group and at least one reactive functional group, which can be cured by radiation and which serves as component (A), and; b) a silicon-organic compound serving as component (B) with at least one NCO group and at least one functional group of formula (I): —Si(X)3-n, in which X represents —NH2; —NH—CO—R; —OOC—R; —O—N═C(R)2 or OR′; R represents a linear or branched, saturated or unsaturated C1-C18 alkyl radical; R′ represents R, an oxyalkylene radical having up to 4 carbon atoms, a C5-C8 cycloalkyl radical; a C6-C10 aryl radical or a C7-C12 aralkyl radical; and n equals 0, 1 or 2. The binding agent can be used as a radiation curable binding agent in coating agents, fillers, sealants or adhesives, for example in the preparation of laminated films having barrier properties.

Owner:HENKEL KGAA

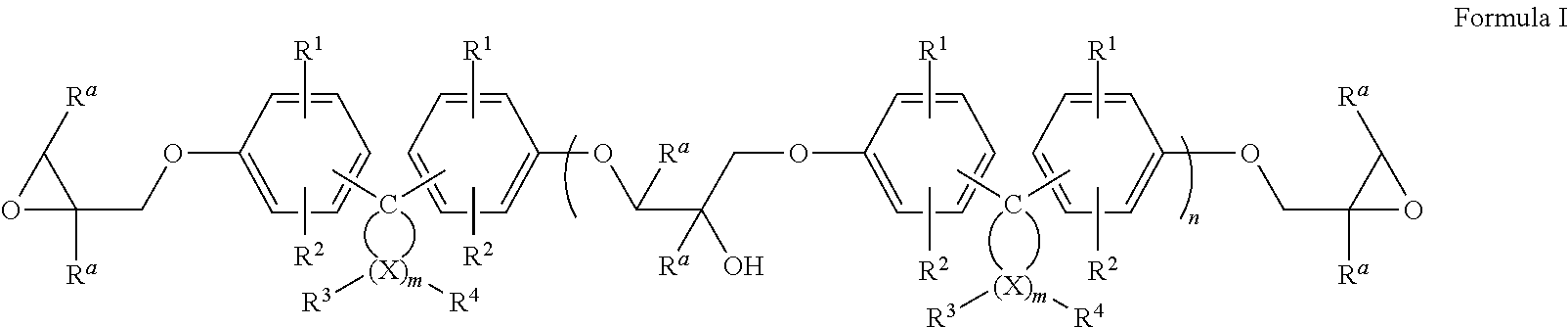

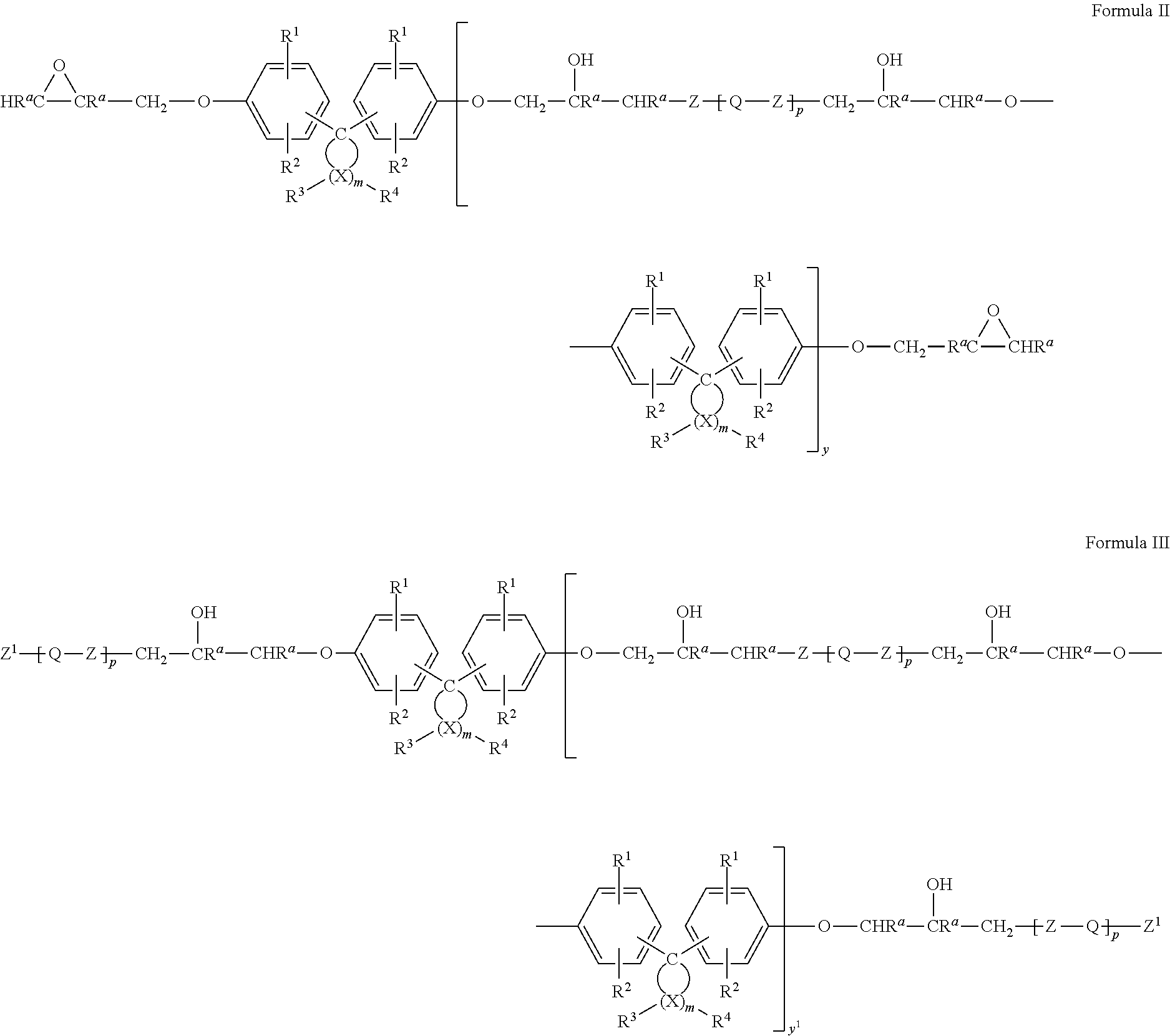

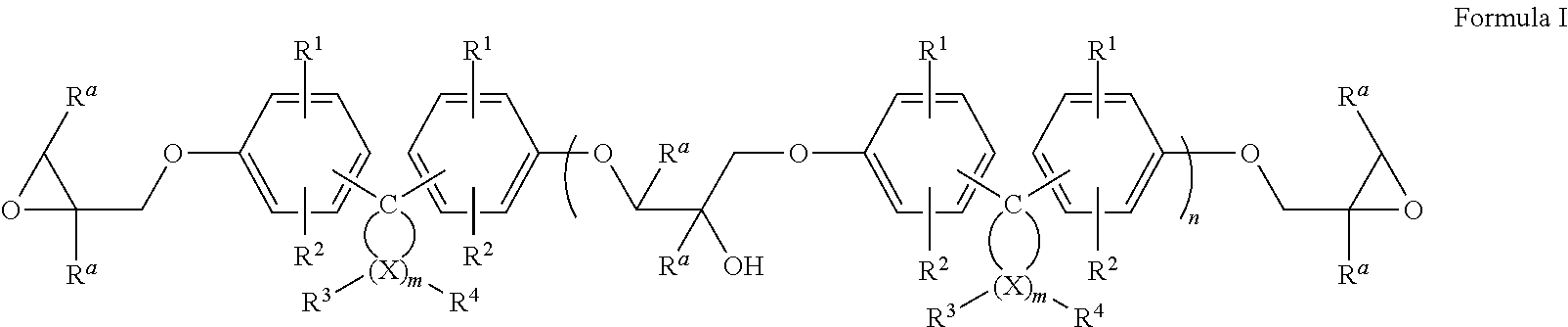

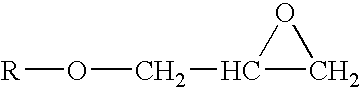

Epoxy resin compositions

An epoxy resin composition prepared from a dihydroxydiphenyl-cycloalkane compound to form a diglycidyl ether of dihydroxydiphenyl cycloalkane compound which may be useful for making various products including, for example, powder coatings, composites and electrical laminates.

Owner:BLUE CUBE IP

Polarizing plate manufacturing method

InactiveUS20120057230A1Improve throughputGood lookingLamination ancillary operationsAdhesive processes with surface pretreatmentPolarizerComposite material

Owner:NITTO DENKO CORP

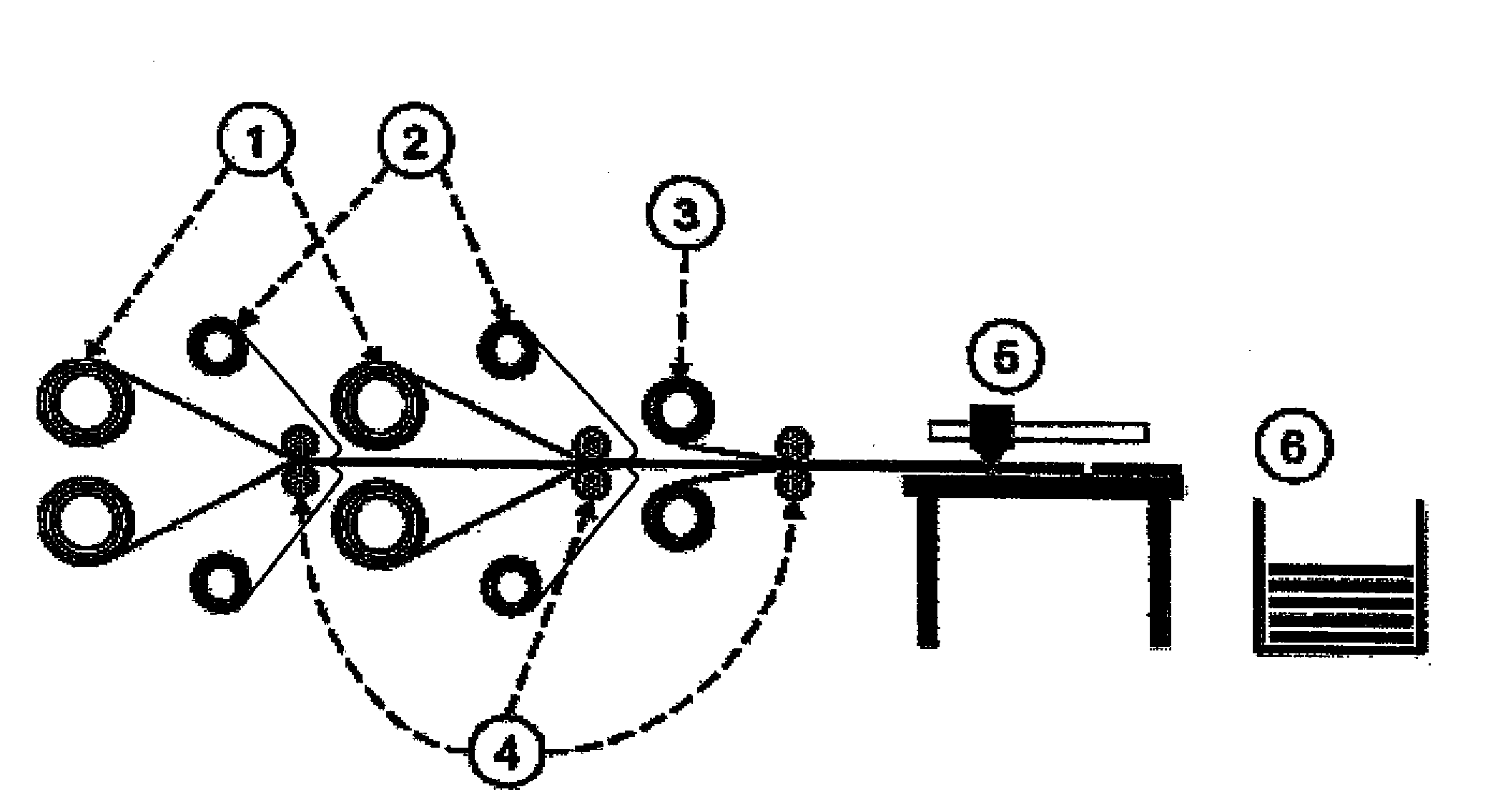

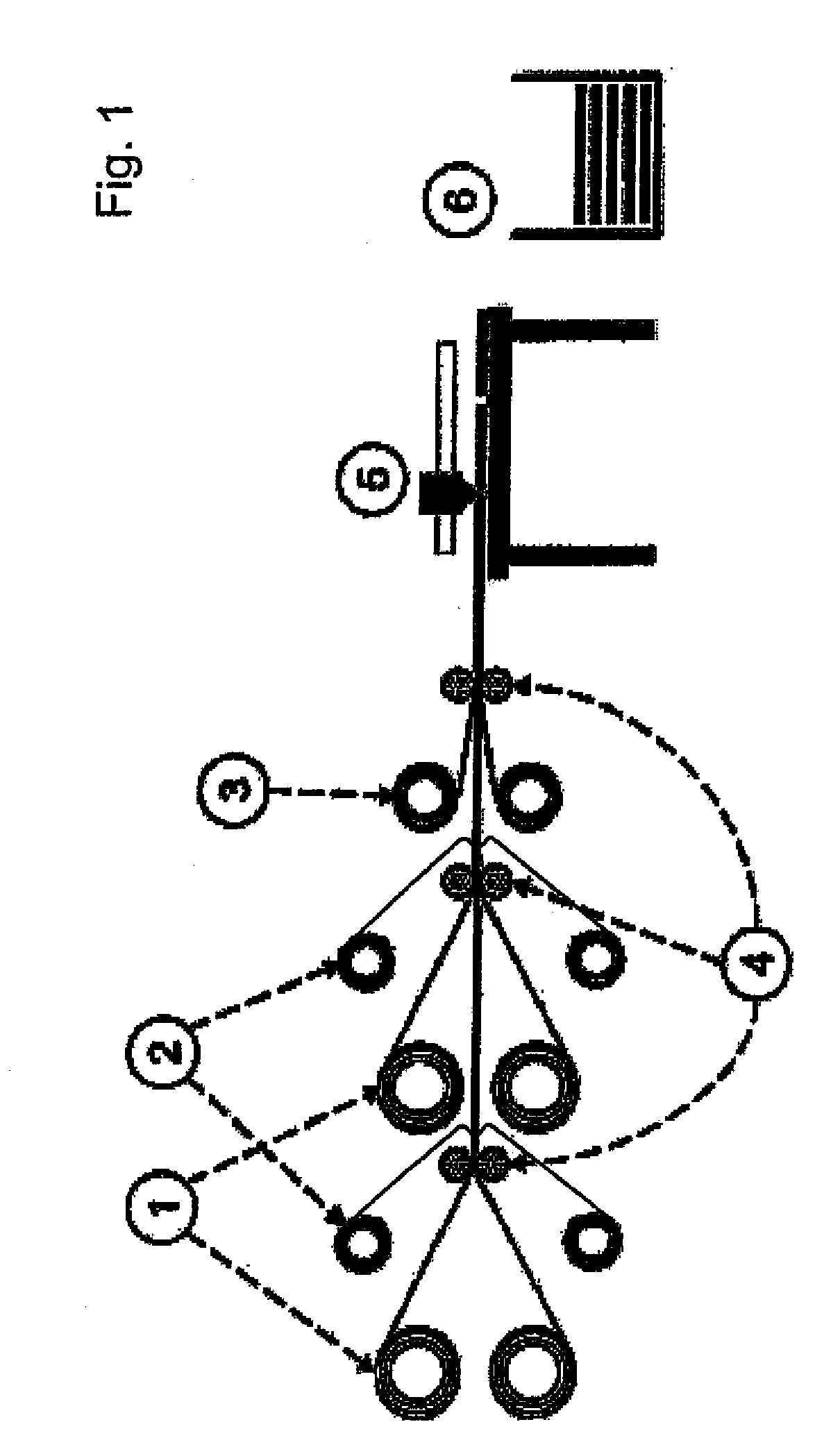

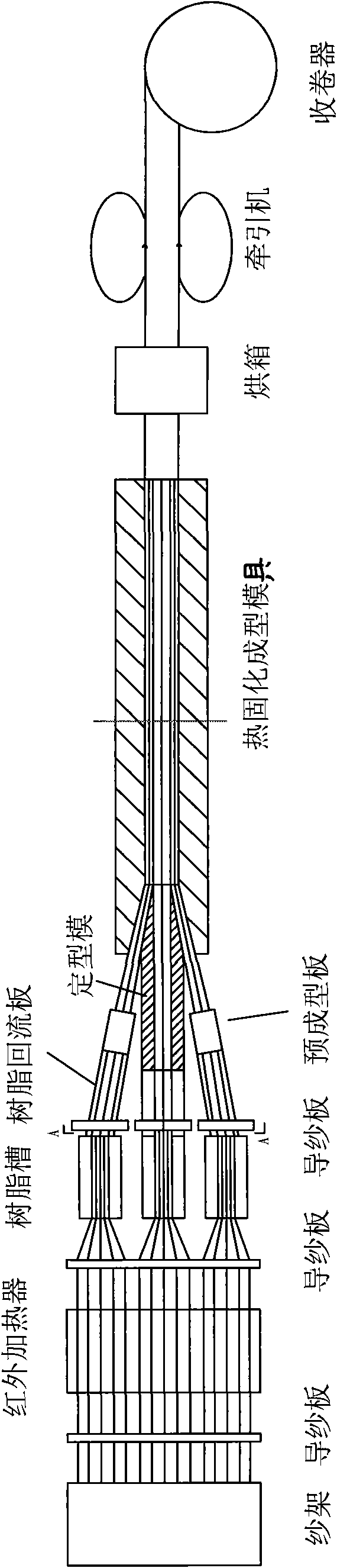

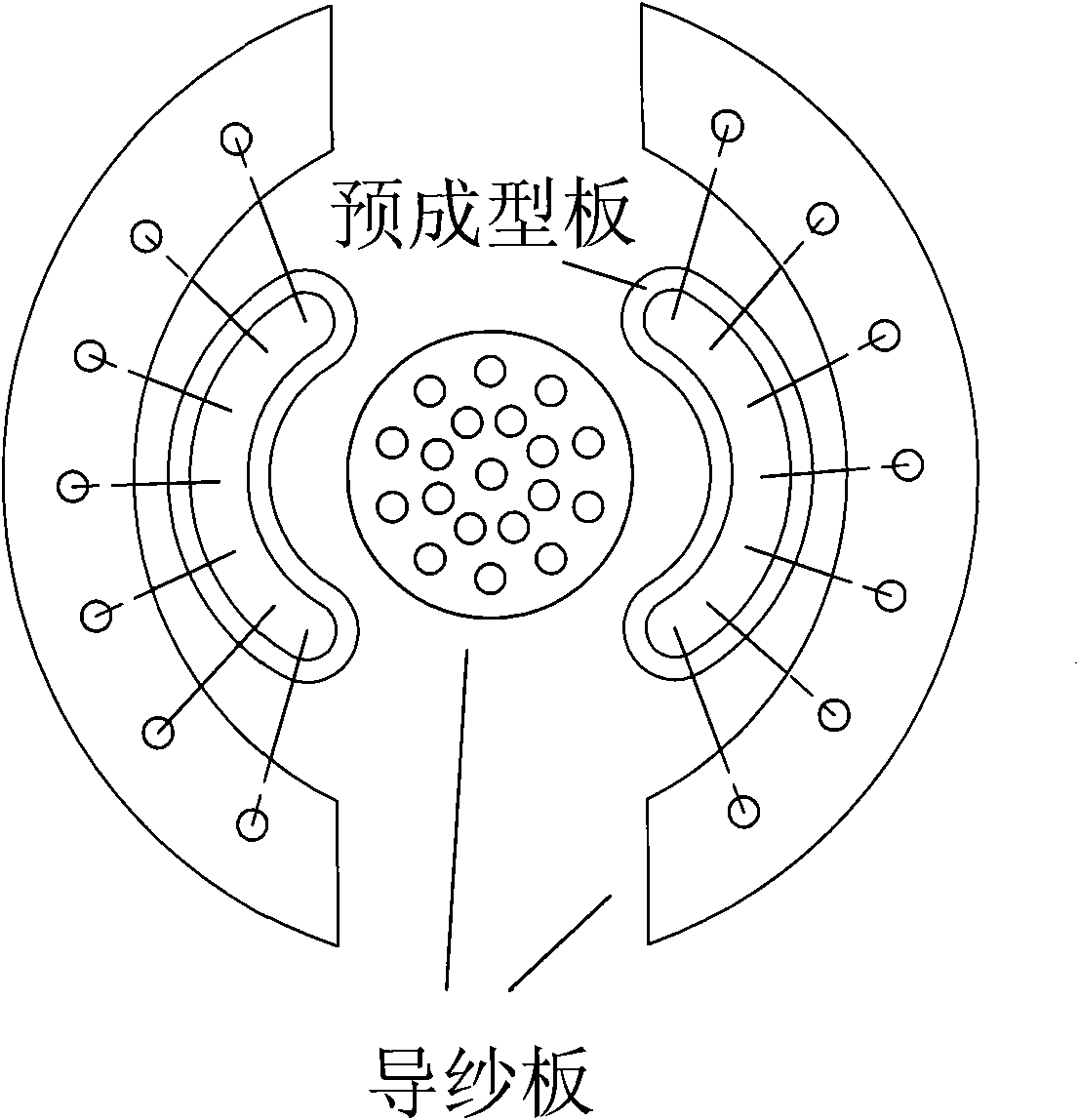

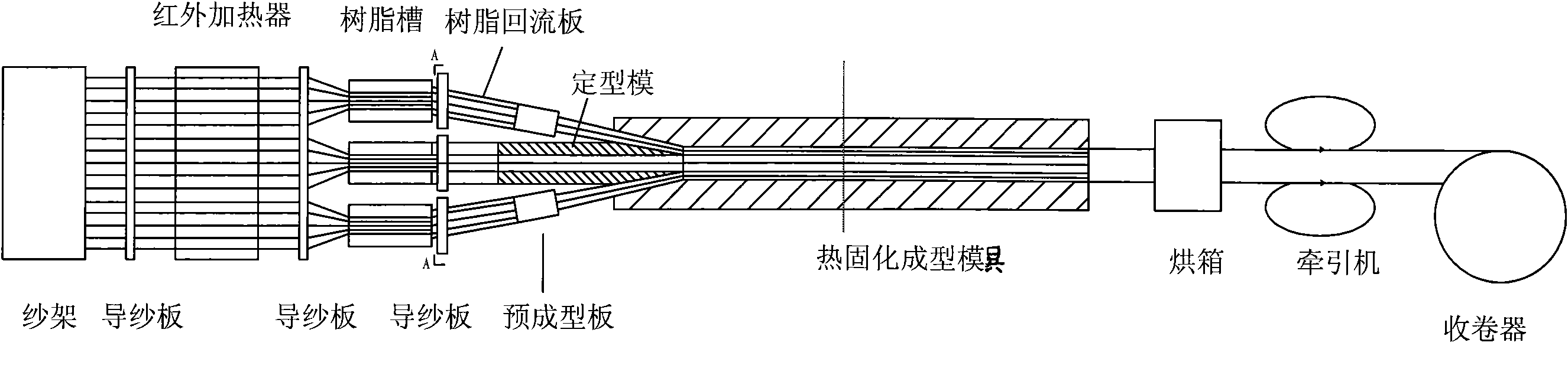

Cable composite core and manufacturing method thereof

InactiveCN101807446AImprove toughnessClimate change performanceNon-insulated conductorsCable/conductor manufactureFiberWinding machine

The invention provides a cable composite core with high temperature resistance, ageing resistance, high tensile strength, extremely high toughness, simple process and small equipment investment and a manufacturing method thereof. The cable composite core is formed by inner layer carbon fiber, outer layer glass fiber and mixed resin matrix adhered on the inner layer carbon fiber and the outer layer glass fiber in longitudinal directional distribution. The manufacturing method is implemented as follows: 1, preparing mixed resin and respectively pouring the mixed resin into three resin grooves; 2, placing the carbon fiber and the glass fiber on creels respectively, leading out by a yarn guide plate in a multi-beam manner, and drying by an infrared heater; 3, performing size soaking on the carbon fiber by an intermediate resin groove, performing size soaking on the glass fiber via the other two resin grooves at the two sides, and premolding; and 4, finishing moulding by a stock mould, entering in a thermocuring moulding mould for curing and moulding, drying, performing secondary curing, hauling by a hauling machine and rolling by a winding machine.

Owner:张国志

Method for curing a binder on insulation fibers

Owner:CERTAINTEED CORP

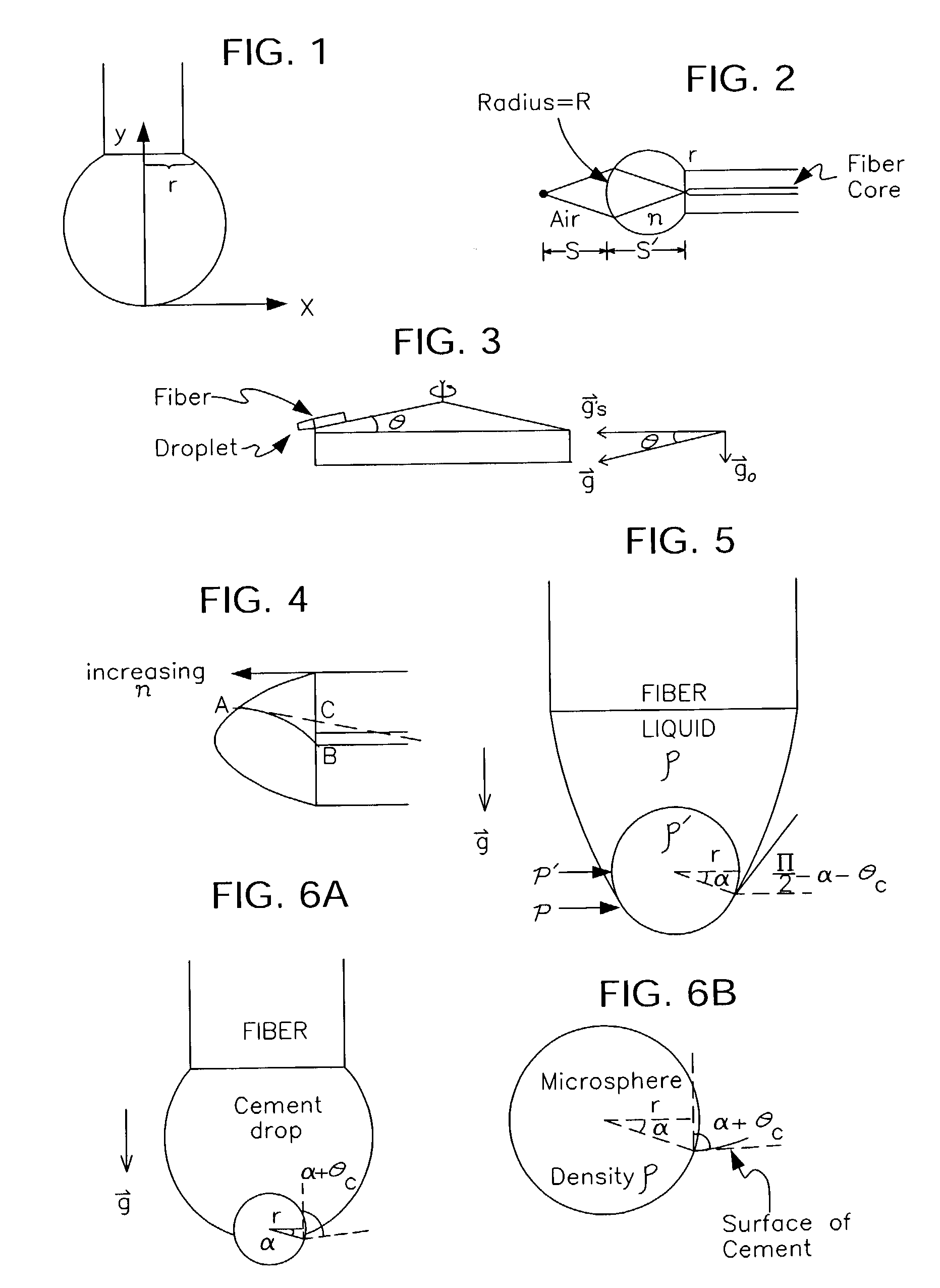

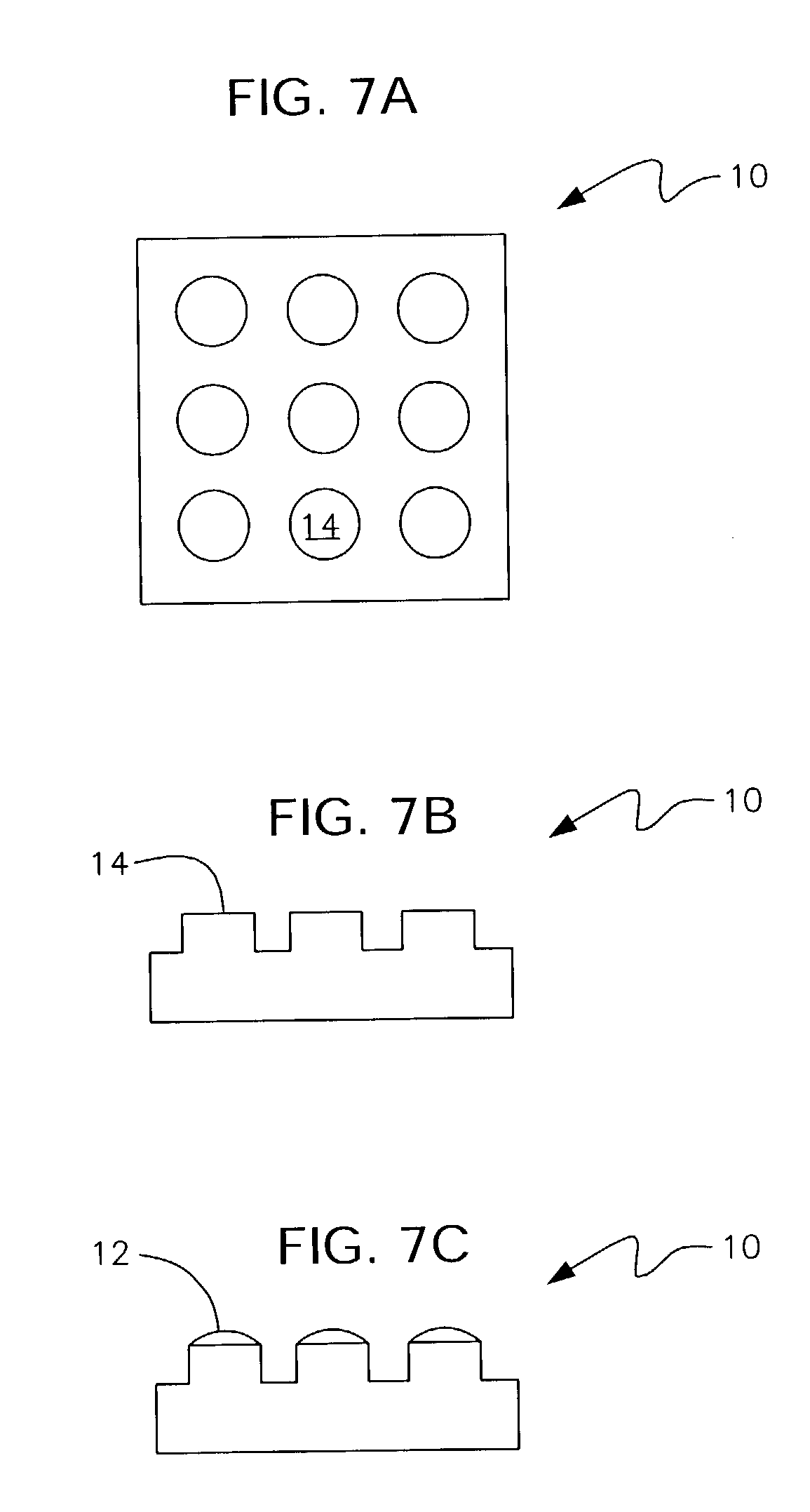

Methods for fabricating lenses at the end of optical fibers in the far field of the fiber aperture

InactiveUS7128943B1High transparencyLow shrinkageCladded optical fibrePretreated surfacesChemical treatmentMicrosphere

A microlens is affixed in the far field of an optical fiber to spatially transform a beam either entering or exiting the fiber. In a first embodiment, a droplet of photo polymer is placed on the end of an optical fiber and the fiber is spun to create an artificial gravity. The droplet is cured by UV radiation during the spinning. In a second embodiment, nanoparticles are mixed into the droplet to increase the refractive index of the photo polymer. A third embodiment employs artificial gravity to attach a microsphere to the end of the optical fiber. A fourth embodiment chemically treats the surface of the microsphere so that the requirement of artificial gravity is either reduced or eliminated. In a fifth embodiment the droplet is cured under equlibrium or nonequilibrium conditions to obtain different final shapes for the lenslet. A sixth embodiment discloses fabrication of microlens arrays.

Owner:UNIV OF SOUTH FLORIDA

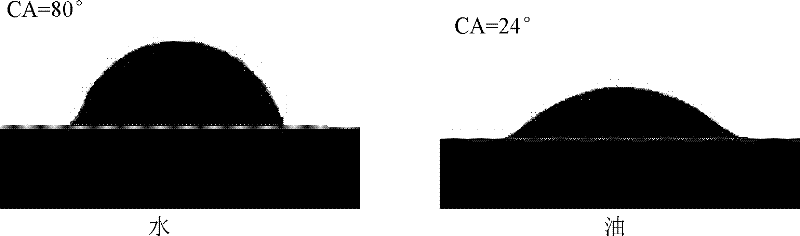

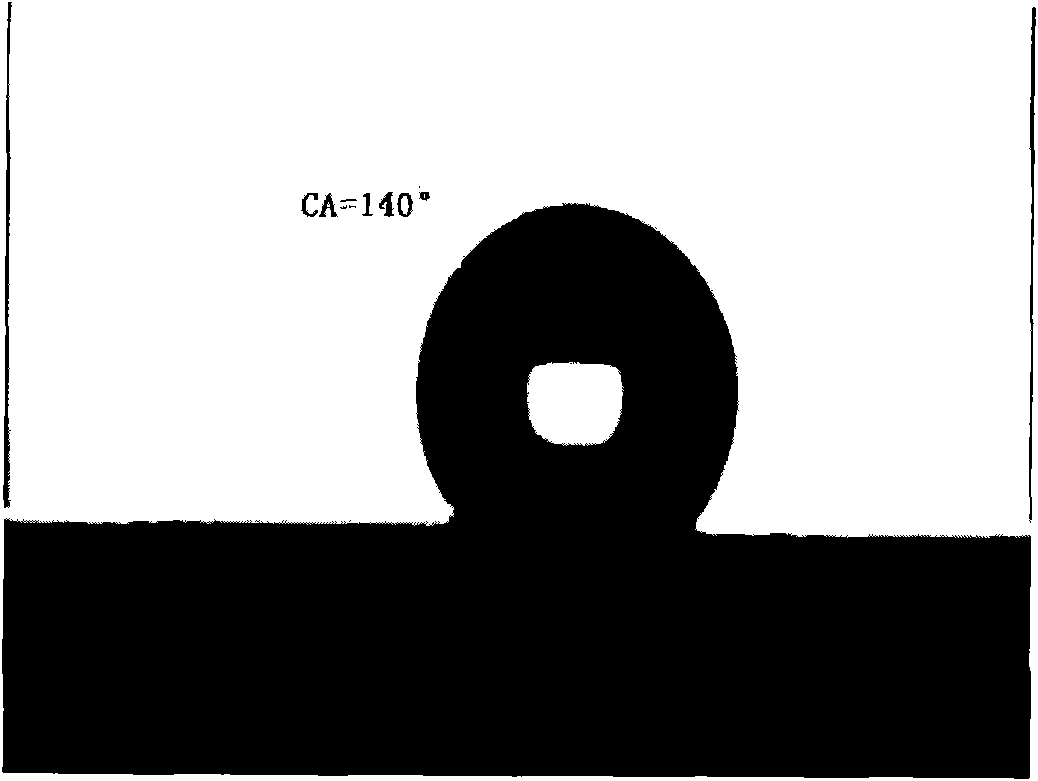

Epoxy coating and preparation method and using method thereof

InactiveCN101591497ASimple methodLow costPretreated surfacesAnti-corrosive paintsFirming agentSolvent

The invention provides an epoxy coating and a preparation method and a using method thereof. The coating is formed by mixing a component A and a component B according to the proportion, wherein the component A comprises a fluoroacrylate copolymer, epoxy color paint and a mixed solvent 1; and the component B comprises a curing agent and a mixed solvent 2. The epoxy coating is prepared by the following steps: (1) adding the fluoroacrylate copolymer and the epoxy color paint into a reactor 1 according to the proportion, and adding the mixed solvent into the reactor 1 to obtain the component A; (2) adding the curing agent into a reactor 2 according to the proportion, and adding the mixed solvent into the reactor 2 to obtain the component B; and (3) mixing the component A and the component B evenly to finally obtain the modified epoxy coating. The epoxy coating ensures good compatibility of fluorine-containing copolymer and the epoxy coating and endows an epoxy coating with extremely low surface energy, thereby ensuring that an contact angle of the modified epoxy coating with water reaches around 140 degrees; and the application fields of the epoxy coating are greatly enlarged, the service life of the epoxy coating is prolonged, and the epoxy coating has quite good industrial application value.

Owner:HEBEI UNIV OF TECH

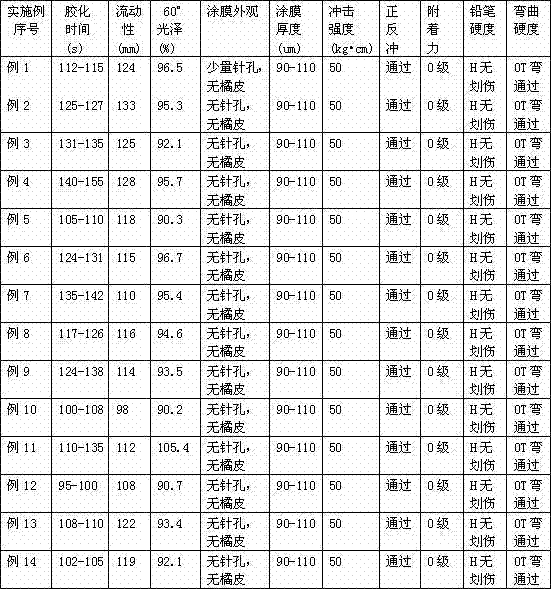

Method for improving pinholes and levelling property of hydroxyalkylamide/polyester powder paint

ActiveCN102212305AHelps thick coatingImprove pinholePolyurea/polyurethane coatingsPowdery paintsPolyesterSynthesis methods

The invention relates to a method for improving the pinholes and levelling property of hydroxyalkylamide / polyester powder paint. After the existing hydroxyalkylamide / polyester powder paint is cured, pinholes are generated on the surface of the paint. The method comprises the following steps: firstly, adopting the highly branched polymer synthesis method and using isocyanate monomer and polyfunctional monomer to synthesize highly branched polyurethane solution; secondly, using water to precipitate the solution, performing suction filtering, drying to obtain highly branched polyurethane powder,mixing the highly branched polyurethane powder with hydroxyalkylamide / polyester powder paint according to a ratio, using a double-screw extruder to melt, extrude and tablet the mixture and obtain sheet, grinding the sheet to fine powder, and sieving to obtain the modified hydroxyalkylamide / polyester powder paint. By adopting the method, the problem that as the viscosity of the powder paint is increased too fast in the curing process, pinholes are generated, can be obviously improved, the curing speed can be reduced, the effect of high levelling can be realized and high thickness coating of the powder paint is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

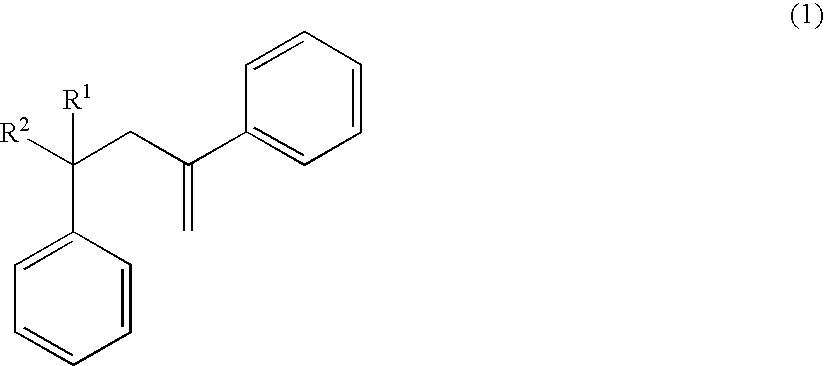

Dental adhesive

A dental adhesive containing an acidic group-containing radically polymerizable monomer, a non-acidic radically polymerizable monomer, a chemical polymerization initiator and a filler, as well as a 2,4-diphenyl-4-methyl-1-pentene. When the dental adhesive is used for adhering a crown restorative to the tooth, an excess of cement swelling from the surface of adhesion can be favorably removed, the curing time can be suitably adjusted without decreasing the strength of adhesion to the tooth, and a change in the color tone of the cured body can be effectively suppressed.

Owner:TOKUYAMA CORP +1

Flexographic pringting plate, flexographic printing device, production method for flexographic printing plate and production method for printing matter

InactiveUS20060016355A1Minimize substance residueDecrease the inclinationPlate printingPhotomechanical exposure apparatusPrinting pressComputer engineering

Owner:HITACHI PLANT TECH LTD +2

Phenolic resin compositions containing etherified hardeners

ActiveUS20060020102A1Long application periodMinimizing and eliminating void and pinholePolymer sciencePolyol

This invention relates to a resin composition capable of being thermally cured while minimizing or eliminating voids in the resulting composite, the composition having both a long pot life at low temperatures and a fast curing rate at higher temperatures containing a mixture of (a) a phenol-formaldehyde resole resin, and (b) an etherified hardener, the etherified hardener being prepared from an alkoxylated polyol or a mono epoxy functional diluent.

Owner:GEORGIA PACIFIC CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com