Epoxy coating and preparation method and using method thereof

An epoxy coating and coating technology, which is applied to epoxy coatings, anti-corrosion coatings, coatings, etc., can solve the problems of low surface energy, inability to prepare strong hydrophobic coatings, etc., and achieves low cost, simple method and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation and characterization of fluorine-containing acrylate-methyl methacrylate-styrene copolymer:

[0032] Add 0.25 grams of sodium dodecyl sulfate (SDS), 0.25 grams of nonylphenol polyoxyethylene ether (OP-10), 0.8 grams of tetrafluoropropanol, 0.4 grams of n-butanol, 4.0 gram of perfluoroalkyl ethyl acrylate (FA), 2.4 grams of methyl methacrylate (MMA), 2.4 grams of styrene (St), 43 grams of distilled water, pre-emulsified at 40°C at a stirring speed of 2500 rpm After 30 minutes, the pre-emulsion was obtained, and then 2 / 3 of the pre-emulsion was poured into the constant pressure dropping funnel. Fill the system with nitrogen and deoxygenate for 30 minutes (the following reaction process is kept under nitrogen atmosphere), the temperature of the system is raised to 80 ° C, and 0.06 grams of potassium persulfate (KPS) and 0.03 grams of sodium bisulfite (NaHSO 3 ), reacted for 1.5 hours, then added dropwise the mixed solution in the constant pressure dropping ...

Embodiment 2

[0058] (1) Weigh 0.04 grams of perfluoroalkyl ethyl acrylate-methyl methacrylate-styrene copolymer (same as Example 1), and 1.0 grams of epoxy paint (same as Example 1) to reactor 1 , add mixed solvent (with embodiment 1) 0.9 gram in reactor 1, stir, make mixture dissolve completely, obtain first component;

[0059] (2) Weigh 0.3 grams of curing agent TMEG in reactor 2, add 0.8 grams of mixed solvent (same as Example 1) to reactor 2, and stir with a glass rod until the curing agent TMEG is completely dissolved to obtain component B;

[0060] (3) Application method: Mix components A and B evenly, brush the board, put the sample board at 90°C for 3 hours, and then cure at 120°C for 2 hours;

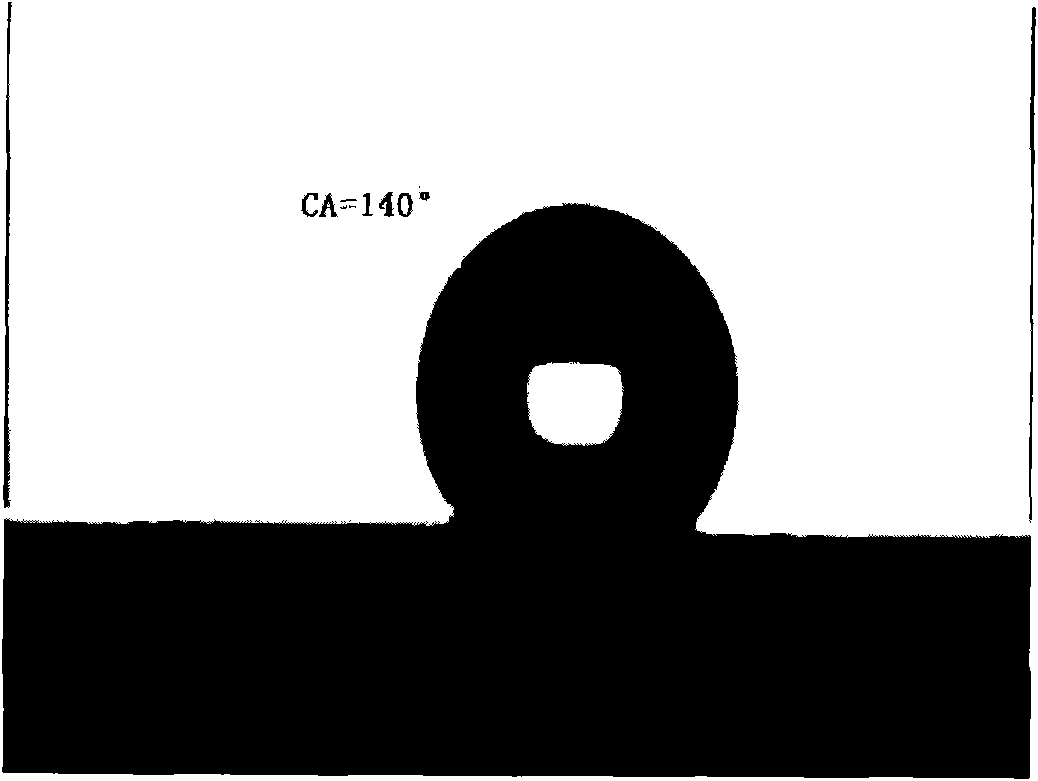

[0061] The contact angle of the obtained modified epoxy coating to water is 140 °, and the water absorption rate is 0.15%, indicating that the hydrophobicity of the epoxy coating has been greatly improved; the adhesion of the modified epoxy coating is grade 1, the pencil hardness is 3H, and...

Embodiment 3

[0063] (1) Weigh 0.03 grams of perfluoroalkyl ethyl acrylate-methyl methacrylate-styrene copolymer (same as Example 1), and 1.0 grams of epoxy paint (same as Example 1) to reactor 1 , add mixed solvent (with embodiment 1) 0.9 gram in reactor 1, stir, make mixture dissolve completely, obtain first component;

[0064] (2) Weigh 0.3 grams of curing agent TMEG in reactor 2, add 1.0 grams of mixed solvent (same as in Example 1) to reactor 2, and stir with a glass rod until the curing agent TMEG is completely dissolved to obtain component B;

[0065] (3) Application method: Mix components A and B evenly, brush the board, put the sample board at 90°C to cure for 3 hours, and then cure at 125°C for 2 hours;

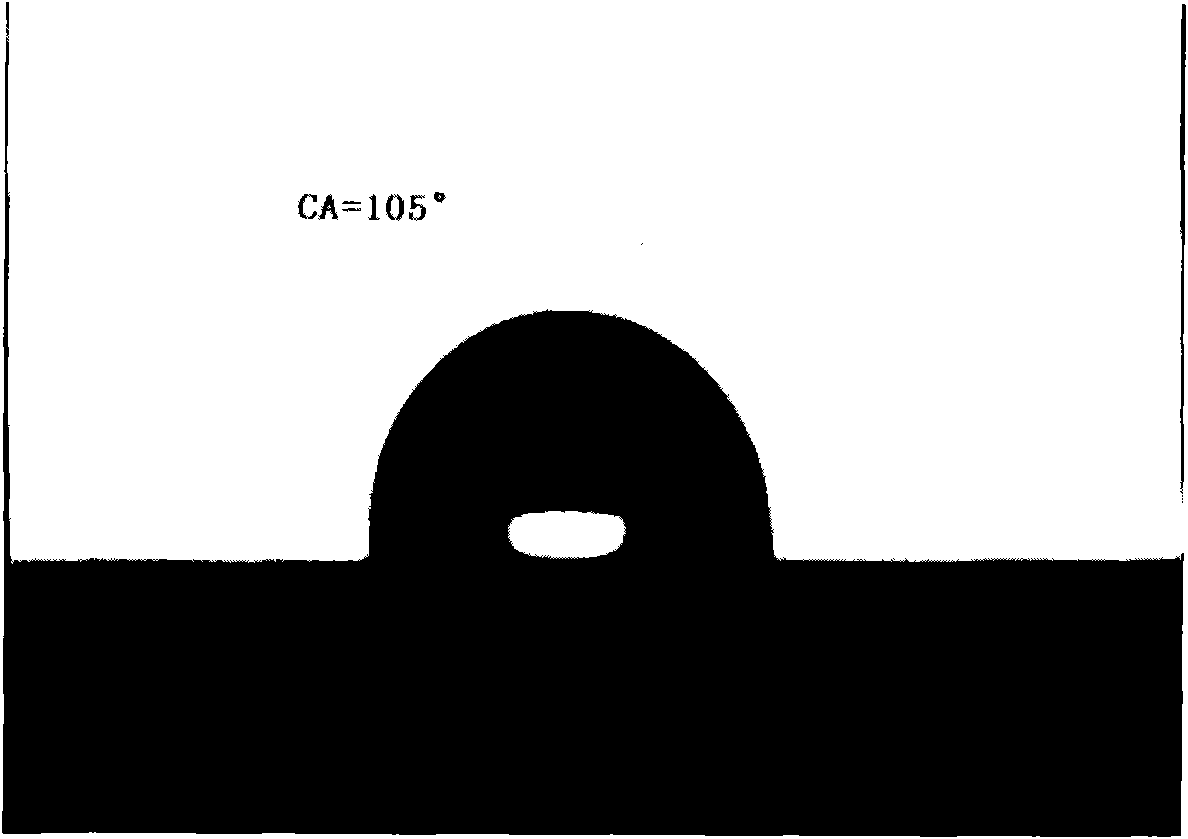

[0066] The contact angle of the obtained modified epoxy coating to water is 136 °, and the water absorption rate is 0.16%, indicating that the hydrophobicity of the epoxy coating has been greatly improved; the adhesion of the modified epoxy coating is grade 1, the pencil hardness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com