Hydrophobic olephobic epoxy paint and its preparation and application method

An epoxy coating and oleophobic technology, which is applied to epoxy coatings, coatings, devices for coating liquids on surfaces, etc., can solve the problem of less amphiphobic materials, and achieve the effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation and characterization of fluorine-containing acrylate-vinyltriethoxysilane-styrene copolymer:

[0030] Add 0.04 g of sodium dodecyl sulfate (SDS), 0.08 g of nonylphenol polyoxyethylene ether (OP-10), 1.5 ml of tetrafluoropropanol, 1.5 ml of n-butanol, 3.0 gram of perfluoroalkyl ethyl acrylate (FA), 0.6 gram of vinyltriethoxysilane (VTES), 2.4 gram of styrene (St), 35 gram of distilled water, pre-emulsified at 45°C for 30 minutes to obtain a pre-emulsion . The temperature of the system was raised to 75° C., and 0.06 g of azobisisobutyronitrile (AIBN) was added to react for 4 hours. After the reaction, use ethanol or saline to break the emulsification; the product is suction filtered, washed with water, and dried under vacuum at 50°C to obtain a perfluoroalkylethylacrylate-vinyltriethoxysilane-styrene copolymer.

[0031] Characterization of Copolymers:

[0032] 3400cm -1 It is the Si-OH peak produced by the hydrolysis of vinyltriethoxysilane; 3062cm -1 ...

Embodiment 2

[0049] Except that the nano silicon dioxide consumption is 0.12 gram, other are all the same as embodiment 1.

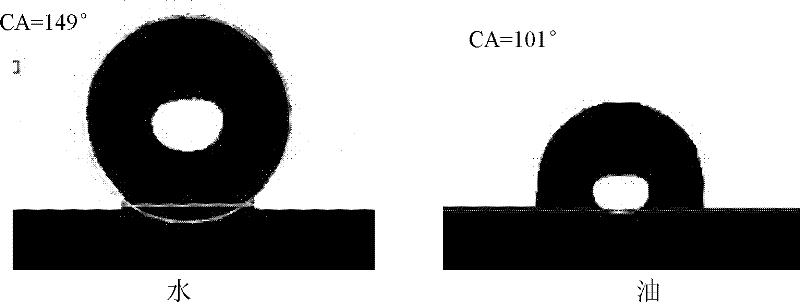

[0050] The contact angle of the obtained modified epoxy coating to water is 142°, and the contact angle to oil is 95°, indicating that the hydrophobic and oleophobic properties of the epoxy coating have been greatly improved.

Embodiment 3

[0052] Except that the nano silicon dioxide consumption is 0.10 gram, other are all the same as embodiment 1.

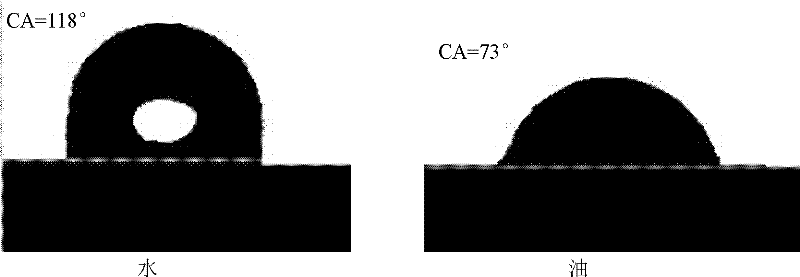

[0053] The contact angle of the obtained modified epoxy coating to water is 127°, and the contact angle to oil is 80°, indicating that the hydrophobic and oleophobic properties of the epoxy coating have been improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com