Magnesium acrylate-superfine cement compounded grouting material and preparation method thereof

A technology of ultra-fine cement and magnesium acrylate, which is applied in the field of building materials, can solve the problems of limited groutability and applicability, and achieve the effects of good groutability, good durability, and high stone strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

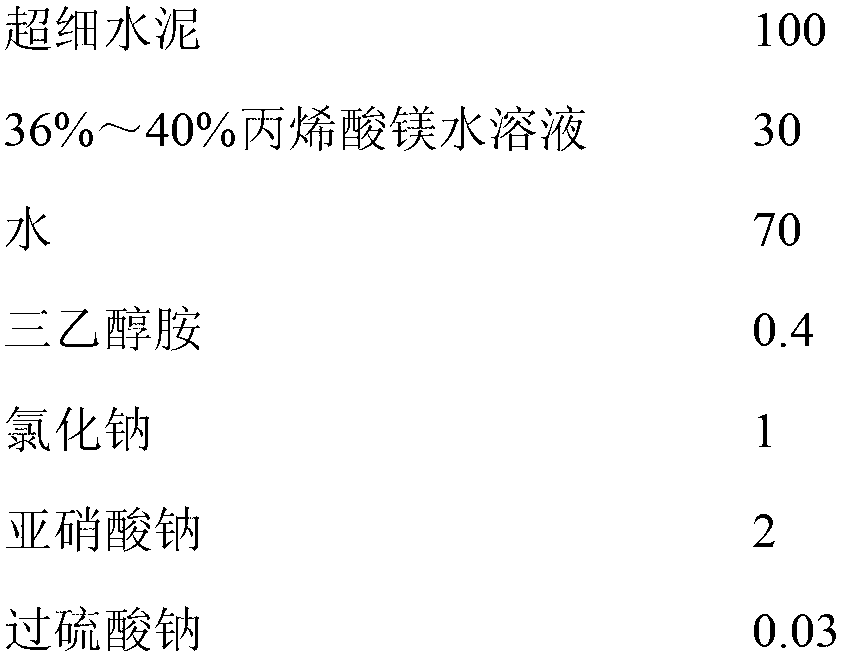

Embodiment 1

[0012] The weight proportion of each component of embodiment 1 is:

[0013]

[0014] After the materials are mixed and stirred evenly, the obtained grouting material has good fluidity, high permeability, good slurry stability, and large grouting range. The initial setting time is about 14 minutes, the final setting time is about 45 minutes, and the grouting material after 60 minutes The compressive strength of serous stones is about 4MPa.

[0015] After changing the ratio test, the main ingredients are superfine cement: 36% ~ 40% magnesium acrylate aqueous solution: water: triethanolamine: sodium chloride: sodium nitrite: sodium persulfate = 100: 10 ~ 30: 30 ~ 70: In the range of 0.1-0.5: 0.5-1: 1-3: 0.01-0.05, all have the basic effects of good groutability and high strength of serous stones.

[0016] In a further preferred experiment, the weight ratio of each component is controlled at: superfine cement: 36%~40% magnesium acrylate aqueous solution: water: triethanolamine...

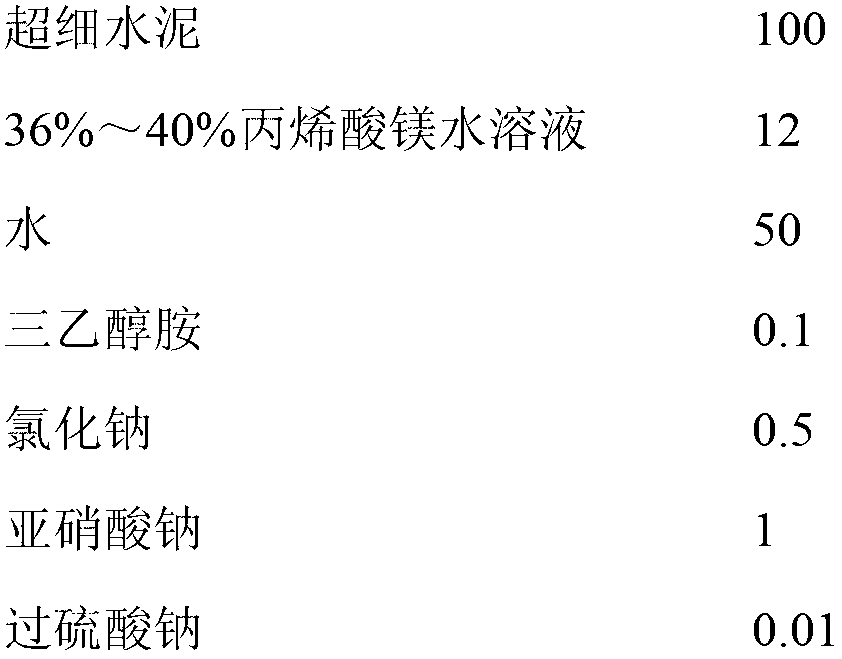

Embodiment 2

[0017] The weight proportion of each component of embodiment 2 is:

[0018]

[0019] After the materials are mixed and stirred evenly, the obtained grouting material has the properties of high fluidity, high permeability, good slurry stability, and high grout stone strength. The initial setting time is about 4 minutes, the final setting time is about 35 minutes, and the final setting time after 60 minutes. The compressive strength of slurry stones is about 12MPa.

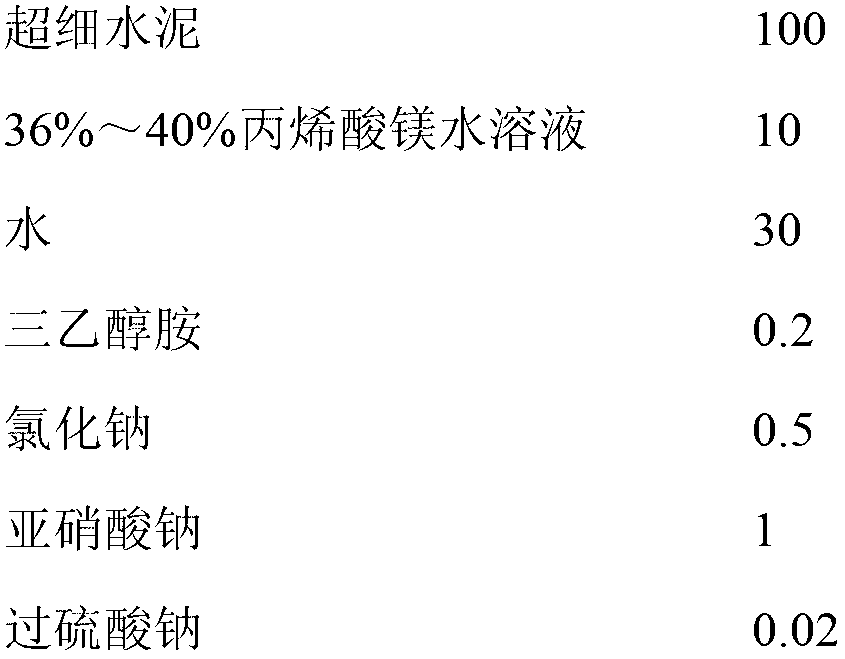

Embodiment 3

[0020] The weight proportion of each component of embodiment 3 is:

[0021]

[0022] After the above raw materials are mixed and stirred evenly, the obtained grouting material has the characteristics of good slurry stability, fast setting time, and high strength of slurry stones. The initial setting time is about 2 minutes, and the final setting time is about 25 minutes. The compressive strength is about 16MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com