Grouting slurry for reinforcing tunnel face of jacking culvert of fine-sand layer and grouting method

A technology of face and fine sand layer, which is applied in the field of grouting grout, can solve the problems of unsatisfactory grouting method, poor penetration of grouting materials, and small penetration range, so as to achieve convenient construction, easy excavation, and good effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

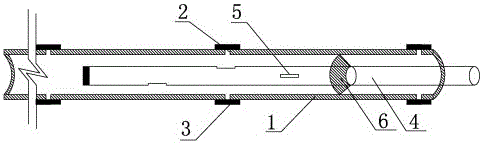

Image

Examples

Embodiment 1

[0029] This example provides a grouting slurry for reinforcing the face of a jacking culvert in a fine sand layer, including component A and component B. The component A has a modulus of 2.5 to 3.0 and a Baume degree of 20 °Bé~25°Bé, the density is 1.16g / cm 3 ~1.26g / cm 3 water glass; the B component is a calcium chloride solution formed by anhydrous calcium chloride and water with a mass concentration of 25% to 30%; the volume ratio of the A component to the B component is 1:0.8~ 1:1.2.

[0030] The modulus of component A is selected from a modulus of 2.5 to 3.0, and within this range the water glass SiO 2 The content of water glass is high, the gel time is short, and the strength of the serous stone body is high; the Baume degree is 20°Bé~25°Bé, the water glass with this concentration has good fluidity, and can reach the largest diffusion range in the dense powder and fine sand layer. And it can meet the highest calculus body strength after reacting with B component. Comp...

Embodiment 2

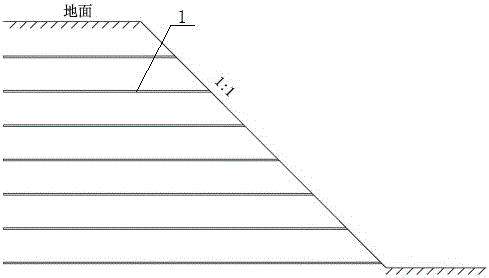

[0042] A subgrade project under the existing Beijing-Kowloon Railway in Nanchang is designed with a large-span jacking cast-in-place frame culvert. The frame culvert is located 10m below the ground. The vertical and horizontal beam lifting scheme is limited by the span here, and a new type of pipe curtain is adopted. During the frame culvert jacking process, the slope ratio of the tunnel surface should be kept at 1:0.55 according to the jacking process requirements, and the stratum here is a uniform medium-dense sand layer with a standard penetration number of 15. ~19 strokes. After calculation, without reinforcement measures, the maximum slope ratio is 1:1. To achieve a slope ratio of 1:0.55, grouting measures must be adopted to make it meet the stability requirements. In view of this, this project The grouting method of the grouting grout used for the reinforcement of the face of the culvert face of the fine sand layer jacking provided by the present invention is adopted for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com