Low-temperature curing cyanate ester adhesive and preparation method thereof

A cyanate ester and adhesive technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc. The effect of low, high bond strength, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment 1: In this embodiment, the low-temperature curing cyanate ester adhesive consists of 70-100 parts by weight of cyanate resin, 2-20 parts of catalyst, 5-40 parts of modified resin, 3-15 parts of organic nanoparticles, 0.5-5 parts of inorganic nanoparticles, 1-5 parts of diluent and 5-15 parts of toughening agent;

[0025] The cyanate resin is bisphenol A cyanate, bisphenol B cyanate, bisphenol E cyanate, bisphenol M cyanate, phenolic cyanate, dicyclopentadiene type cyanate and cashew One or a combination of several phenol cyanate resins;

[0026] The modified resin is bisphenol A type epoxy resin E-54, bisphenol A type epoxy resin E-51, bisphenol A type epoxy resin E-44, bisphenol A type epoxy resin E-42, Bisphenol A type epoxy resin E-35, bisphenol A type epoxy resin E-31, bisphenol A type epoxy resin E-20, bisphenol A type epoxy resin E-14, bisphenol A type epoxy resin Resin E-12, bisphenol A type epoxy resin E-06, bisphenol A type epoxy resin E-0...

specific Embodiment approach 2

[0043] Specific embodiment two: the preparation method of this embodiment low-temperature curing cyanate ester adhesive is carried out according to the following steps:

[0044] 1. Weigh 70-100 parts of cyanate resin, 2-20 parts of catalyst, 5-40 parts of modified resin, 3-15 parts of organic nanoparticles, 0.5-5 parts of inorganic nanoparticles, 1-5 parts 1 part diluent and 5-15 parts toughening agent;

[0045] 2. Under the condition of 40℃~100℃, mix the cyanate ester resin, inorganic nanoparticles and organic nanoparticles and stir at a speed of 60~300r / min for 20~50min, and then in a high-speed mixer at a speed of 700~1500r / min Disperse at a speed of 20-60 minutes to obtain mixture A;

[0046] 3. Add the toughening agent weighed in step 1 to the mixture A, and stir at a speed of 60-300 r / min under the condition of 100°C-150°C until completely dissolved to obtain the mixture B;

[0047] 4. Add modified resin and diluent to mixture B under the condition of 100°C-150°C, stir...

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the cyanate resin described in step one is bisphenol A cyanate, bisphenol B cyanate, bisphenol E cyanate, bisphenol M One or a combination of cyanate esters, phenolic cyanate esters, dicyclopentadiene type cyanate esters and cardanol cyanate resins. Others are the same as in the second embodiment.

[0049] In the present embodiment, when the cyanate resin is a composition, the ratio of each component is arbitrary.

PUM

| Property | Measurement | Unit |

|---|---|---|

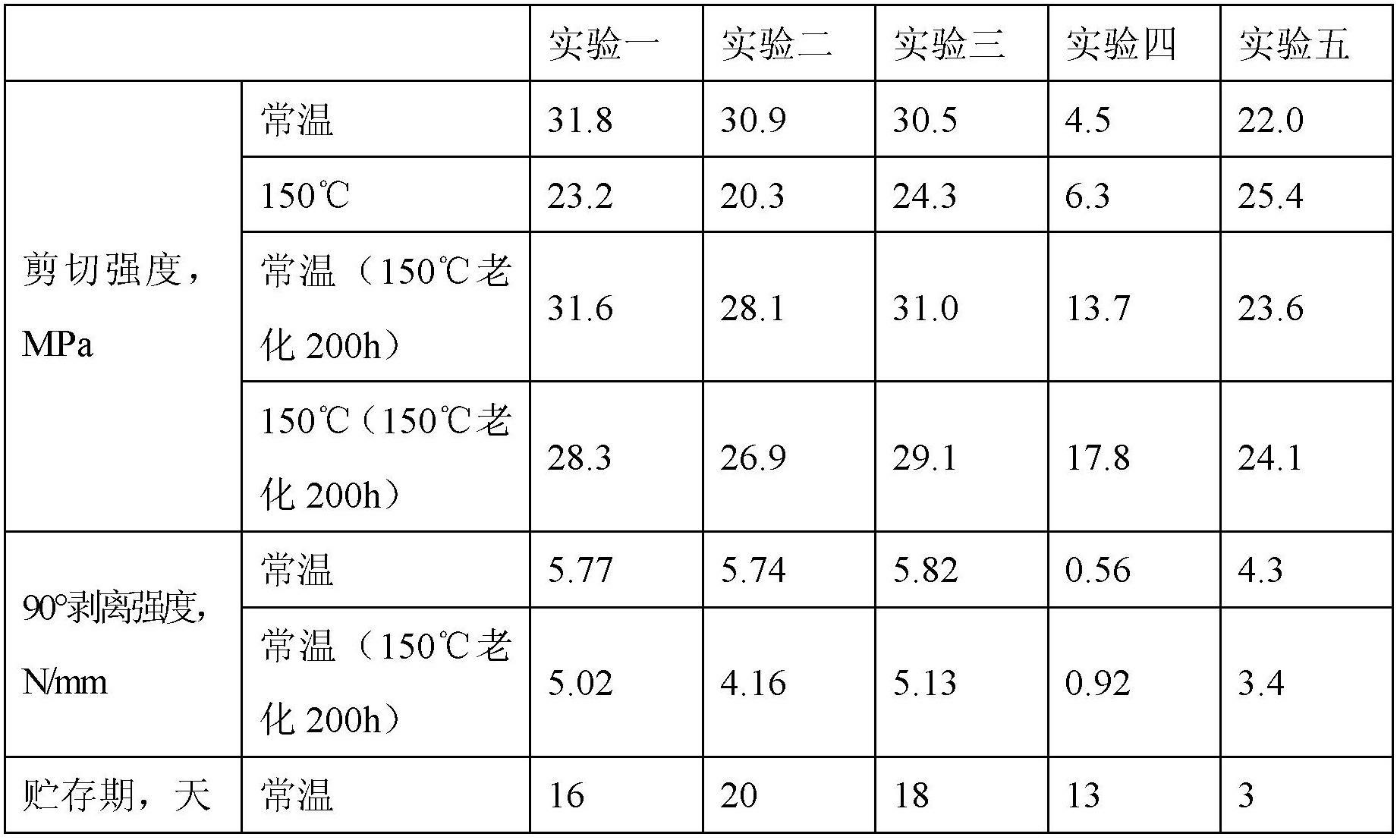

| Shear strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com