Carbon silicon composite material, its preparation method and use

A composite material and silicon material technology, applied in the field of carbon-silicon composite materials, can solve problems such as not meeting the needs, and achieve the effects of good dynamic performance, large porosity, and avoidance of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

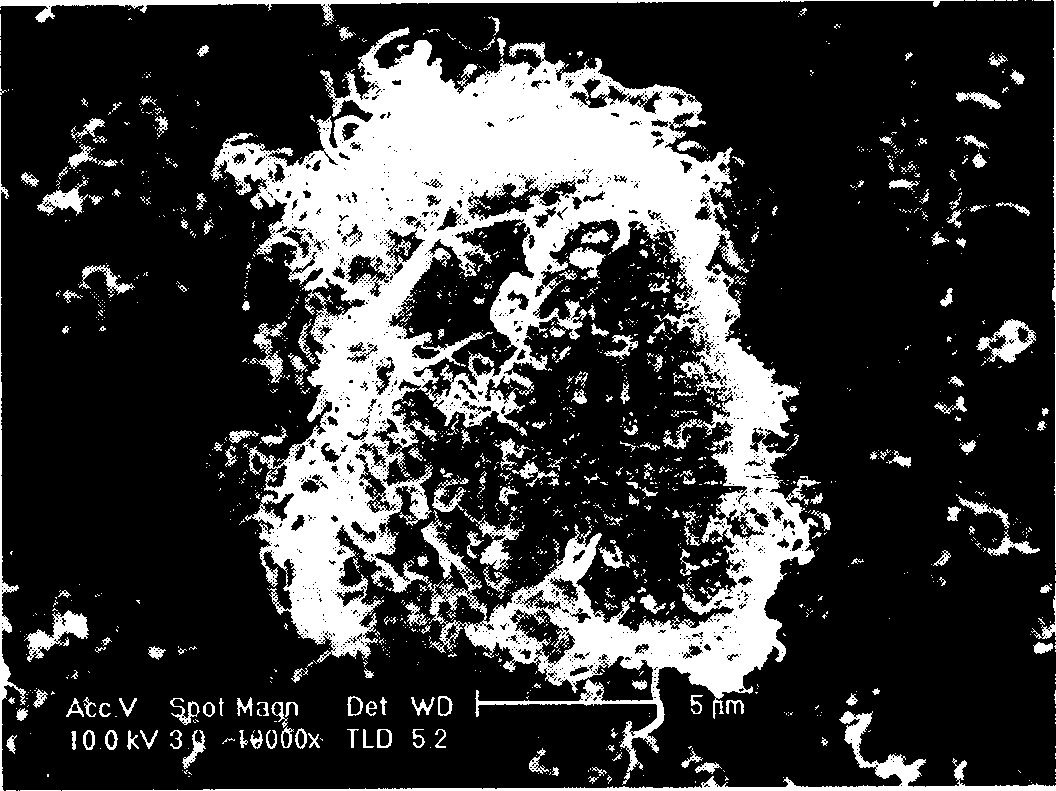

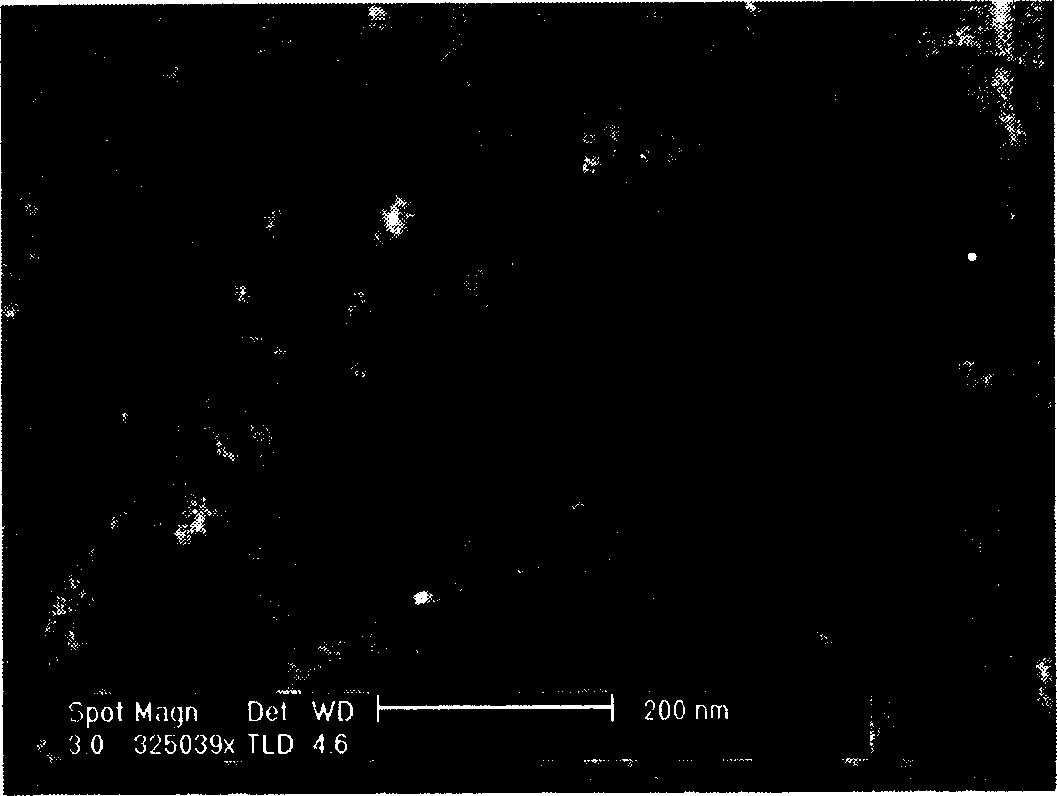

[0044] Embodiment 1: take by weighing 0.001g Fe powder and 10g silicon particle (its average particle diameter is 5 μ m), grind 5 hours, then the material of gained is placed in a graphite boat, then packs into tube furnace, fills with argon Gas, the flow rate is 20 sccm, after the temperature is programmed to 800 ° C, the gas is converted into a mixture of methane and hydrogen, the ratio is 1:20 (v / v), the total flow rate is 300 sccm, and the chemical vapor deposition is carried out at a constant temperature for 20 minutes. The gas is converted into argon, and naturally cooled to room temperature, and the obtained product is a silicon / multi-walled carbon nanotube composite material, wherein the average diameter of the multi-walled carbon nanotube is 8 nm, and the length is 60 μm. Its morphology in field emission scanning electron microscopy is as follows figure 1 As shown, the morphology in high magnification field emission scanning electron microscopy is as follows figure ...

Embodiment 2

[0048] Embodiment 2: take by weighing 0.001g Fe powder and 10g silicon particle (its average particle diameter is 10 μ m), grind 5 hours, then the material of gained is placed in the aluminum oxide boat, then packs in the tube furnace, fills Enter argon gas, the chemical vapor deposition process is the same as in Example 1, and the chemical vapor deposition time is 2 hours. Silicon / multi-walled carbon nanotube composite material, wherein the average diameter of the multi-walled carbon nanotubes is 15 nm, and the length is 160 μm.

[0049] The positive and negative electrodes were prepared as described in Example 1, and the battery was assembled for testing. The experimental battery was subjected to a charge-discharge cycle test by an automatic charge-discharge instrument controlled by a computer. The charge cut-off voltage is 4.2V, and the discharge cut-off voltage is 2.0V. Studies have proved that the silicon / multi-walled carbon nanotube composite material is used as a negati...

Embodiment 3

[0050] Embodiment 3: take by weighing 0.001g Fe powder and 10g silicon particle (its average particle diameter is 100nm), grind 5 hours, then the material of gained is placed in the aluminum oxide boat, then packs in the tube furnace, fully Enter a mixture of argon and hydrogen, the ratio of which is 85:15 (v / v). After the temperature is programmed to 700 ° C, the gas is converted to ethylene, and the flow rate is 50 sccm. After chemical vapor deposition at a constant temperature for 2 hours, the gas is converted to Nitrogen, naturally cooled to room temperature, the resulting product is silicon / multi-walled carbon nanotube composite material, wherein the average diameter of the multi-walled carbon nanotubes is 17 nm, and the length is 70 μm.

[0051] The positive and negative electrodes were prepared as described in Example 1, and the battery was assembled for testing. The experimental battery was subjected to a charge-discharge cycle test by an automatic charge-discharge inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com